Page 1

1 pA Monolithic Electrometer

a

FEATURES

DC PERFORMANCE

1 mV max Input Offset Voltage

Low Offset Drift: 20 mV/8C

1 pA max Input Bias Current

Input Bias Current Guaranteed Over Full

Common-Mode Voltage Range

AC PERFORMANCE

3 V/ms Slew Rate

1 MHz Unity Gain Bandwidth

Low Input Voltage Noise: 4 mV p-p, 0.1 Hz to 10 Hz

Available in a Low Cost, 8-Pin Plastic Mini-DIP

Standard Op Amp Pinout

APPLICATIONS

Electrometer Amplifiers

Photodiode Preamps

pH Electrode Buffers

Log Ratio Amplifiers

Operational Amplifier

AD546*

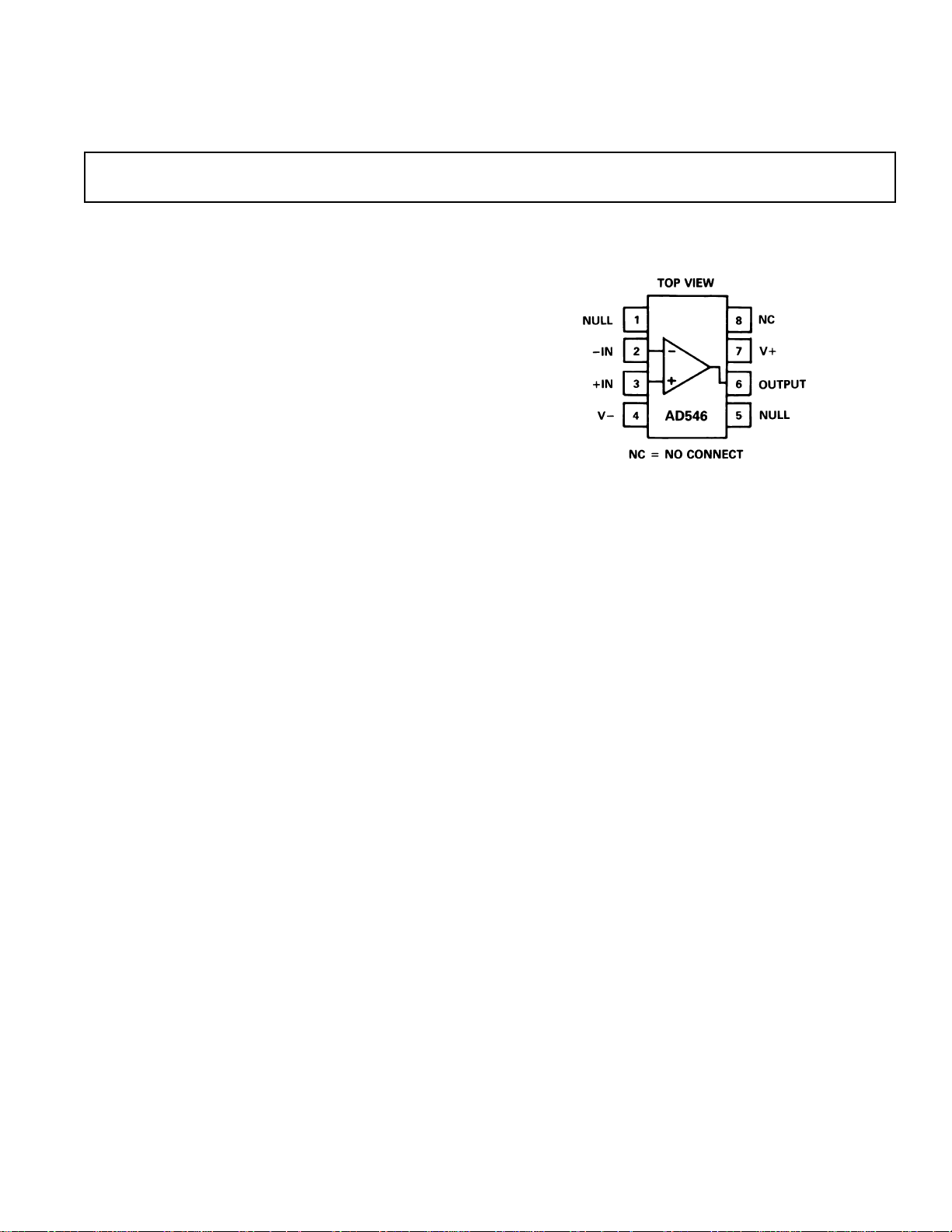

CONNECTION DIAGRAM

8-Pin Plastic

Mini-DIP Package

PRODUCT DESCRIPTION

The AD546 is a monolithic electrometer combining the virtues

of low (1 pA) input bias current with the cost effectiveness of a

plastic mini-DIP package. Both input offset voltage and input

offset voltage drift are laser trimmed, providing very high performance for such a low cost amplifier.

Input bias currents are reduced significantly by using “topgate”

JFET technology. The 10

resulting from a bootstrapped input stage, insures that input

bias current is essentially independent of common-mode voltage

variations.

The AD546 is suitable for applications requiring both minimal

levels of input bias current and low input offset voltage. Applications for the AD546 include use as a buffer amplifier for current output transducers such as photodiodes and pH probes. It

may also be used as a precision integrator or as a low droop rate

sample and hold amplifier. The AD546 is pin compatible with

standard op amps; its plastic mini-DIP package is ideal for use

with automatic insertion equipment.

The AD546 is available in two performance grades, all rated

over the 0°C to +70°C commercial temperature range, and

packaged in an 8-pin plastic mini-DIP.

*Covered by Patent No. 4,639,683.

15

Ω common-mode impedance,

PRODUCT HIGHLIGHTS

1. The input bias current of the AD546 is specified, 100%

tested and guaranteed with the device in the fully warmed-up

condition.

2. The input offset voltage of the AD546 is laser trimmed to

less than 1 mV (AD546K).

3. The AD546 is packaged in a standard, low cost, 8-pin

mini-DIP.

4. A low quiescent supply current of 700 µA minimizes any

thermal effects which might degrade input bias current and

input offset voltage specifications.

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

Page 2

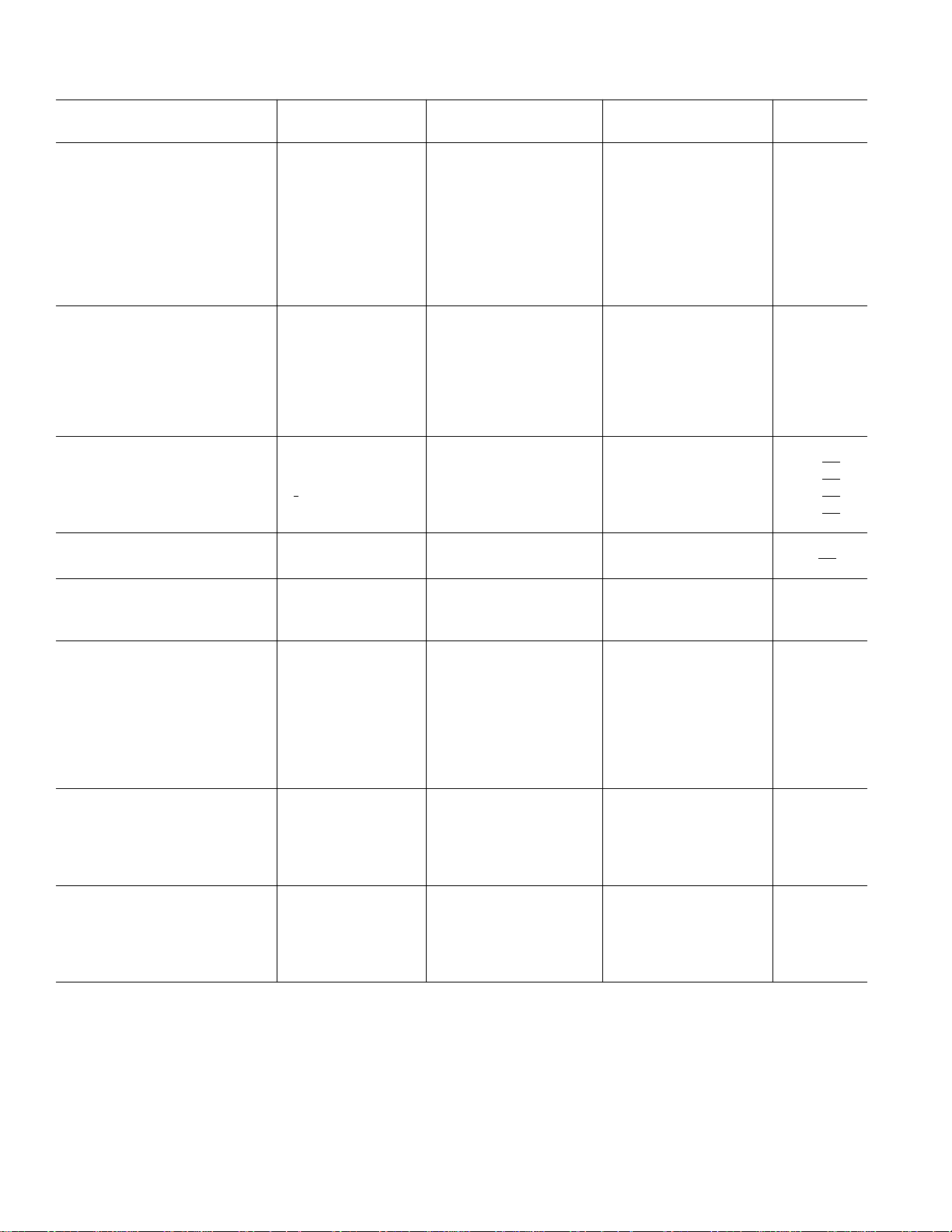

AD546–SPECIFICATIONS

(@ +258C and 615 V dc, unless otherwise noted)

AD546J AD546K

Model Conditions Min Typ Max Min Typ Max Units

INPUT BIAS CURRENT

1

Either Input VCM = 0 V 0.2 1 0.2 0.5 pA

Either Input V

= ±10 V 0.1 1 0.2 0.5 pA

CM

Either Input

@ T

MAX

Either Input V

Offset Current V

VCM = 0 V 40 20 pA

= ±10 V 40 20 pA

CM

= 0 V 0.17 0.09 pA

CM

Offset Current

@ T

MAX

VCM = 0 V 13 7 pA

INPUT OFFSET

Initial Offset 21pA

Offset @ T

MAX

32mV

vs. Temperature 20 20 µV/°C

vs. Supply 100 100 µV/V

vs. Supply T

MIN–TMAX

100 100 µV/V

Long-Term Stability 20 20 µV/Month

INPUT VOLTAGE NOISE f = 0.1 Hz to 10 Hz 4 4 µV p-p

f = 10 Hz 90 90 nV/√

f = 100 Hz 60 60 nV/√

Hz

Hz

f = 1 kHz 35 35 nV/√Hz

f = 10 kHz 35 35 nV/√Hz

INPUT CURRENT NOISE f = 0.1 Hz to 10 Hz 1.3 1.3 fA rms

f = 1 kHz 0.4 0.4 fA/√Hz

INPUT IMPEDANCE

Differential V

Common Mode V

OPEN LOOP GAIN V

T

MIN–TMAX

T

MIN–TMAX

INPUT VOLTAGE RANGE

Differential

3

= ±1 V 10

DIFF

= ±10 V 10

CM

= ±10 V

O

R

= 10 kΩ 300 1000 300 1000 V/mV

LOAD

V

= ±10 V

O

R

= 10 kΩ 300 800 300 800 V/mV

LOAD

V

= ±10 V

O

R

= 2 kΩ 100 250 100 250 V/mV

LOAD

V

= ±10 V

O

R

= 2 kΩ 80 200 80 200 V/mV

LOAD

13

i110

15

i0.8 10

13

i1 ΩipF

15

i0.8 ΩipF

±20 ± 20 V

Common-Mode Voltage –10 +10 –10 +10 V

Common-Mode Rejection Ratio V

= ±10 V 80 90 84 100 dB

CM

T

MIN

to T

MAX

76 80 76 80 dB

OUTPUT CHARACTERISTICS

Voltage R

= 10 kΩ –12 +12 –12 +12 V

LOAD

R

= 2 kΩ –10 +10 –10 +10 V

LOAD

Current Short Circuit 15 20 35 15 20 35 mA

Load Capacitance Stability Gain = +1 4000 4000 pF

–2–

REV. A

Page 3

AD546

WARNING!

ESD SENSITIVE DEVICE

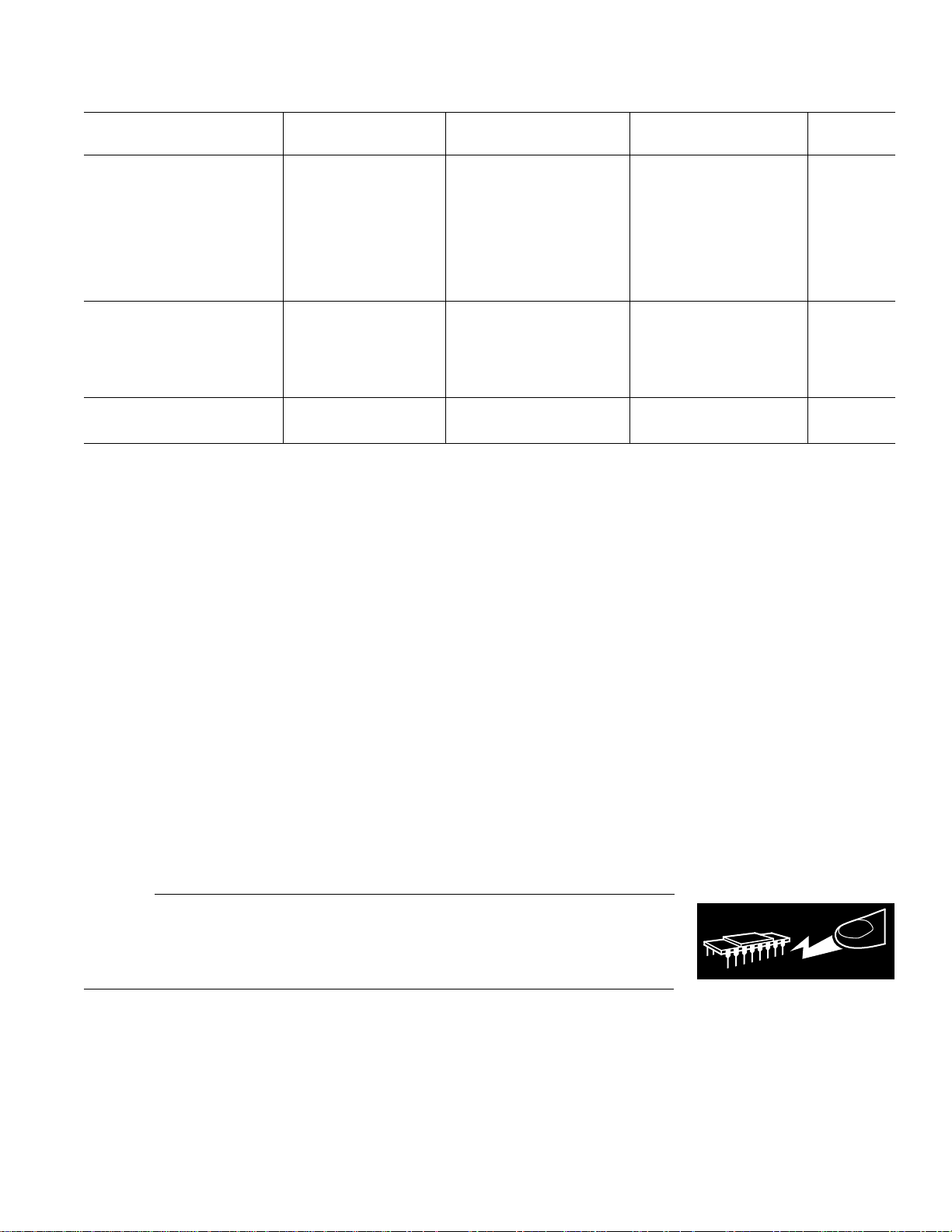

AD546J AD546K

Model Conditions Min Typ Max Min Typ Max Units

FREQUENCY RESPONSE

Gain BW, Small Signal G = –1 0.7 1.0 0.7 1.0 MHz

Full Power Response V

Slew Rate, Unity Gain G = –1 2 3 2 3 V/µs

Settling Time to 0.1% 4.5 4.5 µs

Overload Recovery 50% Overdrive

POWER SUPPLY

Rated Performance ±15 ± 15 V

Operating Range 65 618 65 618 V

Quiescent Current 0.60 0.7 0.60 0.7 mA

Transistor Count # of Transistors 50 50

PACKAGE OPTIONS

Plastic Mini-DIP (N-8) AD546JN AD546KN

NOTES

1

Bias current specifications are guaranteed maximum, at either input, after 5 minutes of operation at T

every 10°C rise in temperature.

2

Input offset voltage specifications are guaranteed after 5 minutes of operation at TA = +25°C.

3

Defined as max continuous voltage between inputs, such that neither exceeds ± 10 V from ground.

Specifications subject to change without notice.

Specifications in boldface are tested on all production units at final electrical test. Results from those tests are used to calculate outgoing quality levels. All min and

max specifications are guaranteed, although only those shown in boldface are tested on all production units.

= 20 V p-p 50 50 kHz

O

to 0.01% 5 5 µs

Gain = –1 2 2 µs

= +25°C. Bias current increases by a factor of 2.3 for

A

ABSOLUTE MAXIMUM RATINGS

1

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Internal Power Dissipation . . . . . . . . . . . . . . . . . . . . . .500 mW

Input Voltage

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±18 V

Output Short Circuit Duration . . . . . . . . . . . . . . . . . Indefinite

Differential Input Voltage . . . . . . . . . . . . . . . . . . +V

and –V

S

S

Storage Temperature Range . . . . . . . . . . . . . –65°C to +125°C

Operating Temperature Range . . . . . . . . . . . . . . 0°C to +70°C

Lead Temperature Range (Soldering 60 sec) . . . . . . . . +300°C

NOTES

1

Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those indicated in the

operational section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

2

For supply voltages less than ±18 V, the absolute maximum input voltage is equal

to the supply voltage.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD546 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. A

–3–

Page 4

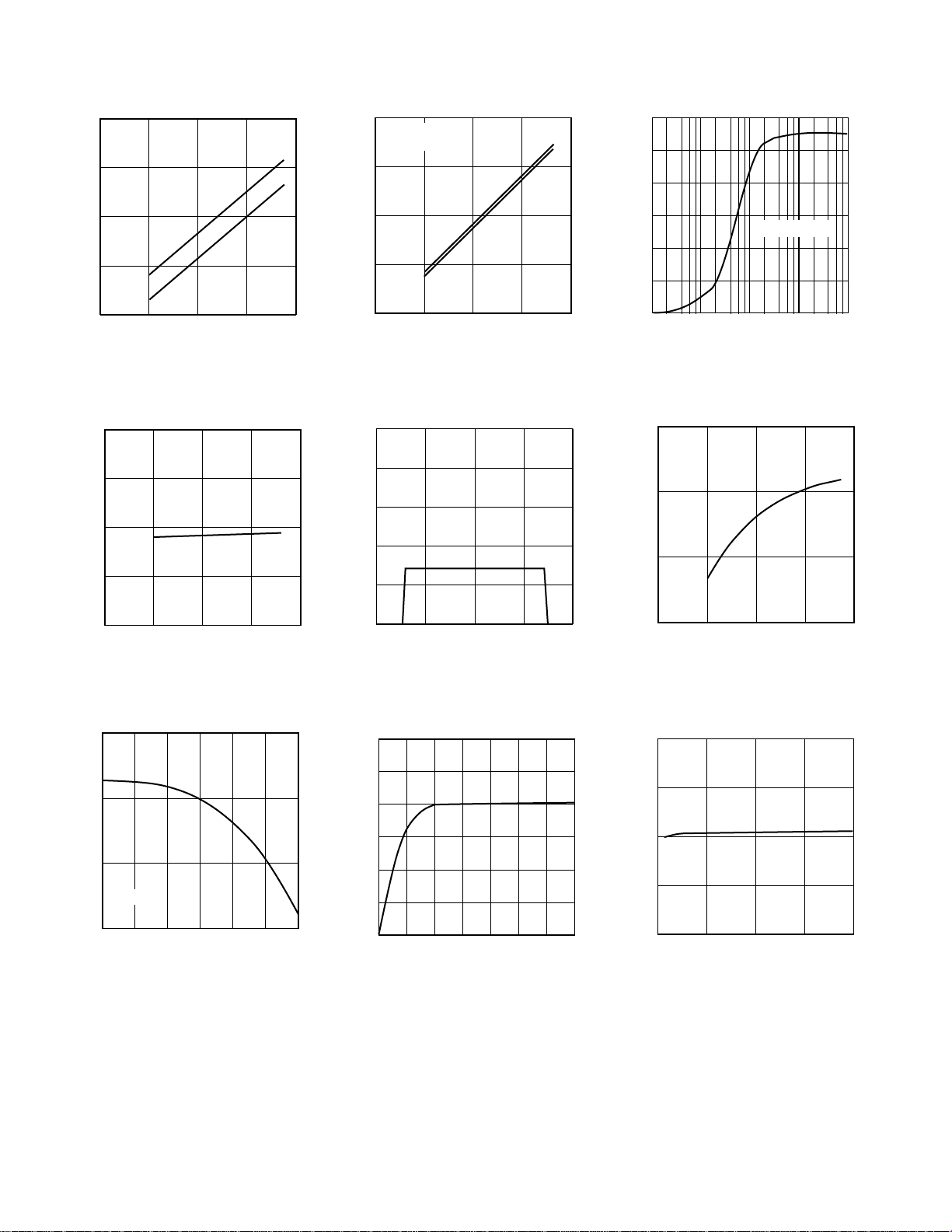

AD546–Typical Characteristics

RL = 10kΩ

SUPPLY VOLTAGE ± V

OPEN LOOP GAIN – V/mV

3000

1000

100

05 20

10 15

300

(VS = 615 V, unless otherwise noted)

20

15

+V

IN

10

–V

5

INPUT VOLTAGE RANGE ± V

0

05 20

SUPPLY VOLTAGE ± V

IN

10 15

Figure 1. Input Voltage Range

vs. Supply Voltage

800

700

600

20

+25oC

= 10kΩ

R

L

15

10

5

OUTPUT VOLTAGE RANGE ± V

0

05 20

SUPPLY VOLTAGE ± V

+V

OUT

–V

OUT

10 15

Figure 2. Output Voltage Range

vs. Supply Voltage

120

110

100

90

30

25

20

15

10

5

OUTPUT VOLTAGE SWING – Volts p-p

0

100

LOAD RESISTANCE – Ω

VS = ± 15 VOLTS

Figure 3. Output Voltage Swing

vs. Resistive Load

100k10k1k10

500

QUIESCENT CURRENT – µA

400

05 20

10 15

SUPPLY VOLTAGE ± V

Figure 4. Quiescent Current vs.

Supply Voltage

3000

1000

300

OPEN LOOP GAIN – V/mV

RL = 10kΩ

100

–25 125

–55

5356595

TEMPERATURE – oC

Figure 7. Open Loop Gain vs.

Temperature

80

COMMON MODE REJECTION RATIO – dB

70

–15

INPUT COMMON MODE VOLTAGE – V

Figure 5. CMRR vs. Input

Common-Mode Voltage

30

25

20

15

∆ |VOS| –µV

10

5

0

01 7

23456

WARM-UP TIME – Minutes

Figure 8. Change in Offset

Voltage vs. Warm-Up Time

+15–10 0 +10

Figure 6. Open Loop Gain vs.

Supply Voltage

300

250

200

150

INPUT BIAS CURRENT – fA

100

–10 –5 10

COMMON-MODE VOLTAGE – Volts

05

+25oC

Figure 9. Input Bias Current vs.

Common-Mode Voltage

–4–

REV. A

Page 5

AD546

SOURCE RESISTANCE – Ohms

100k

0.1

100k 1M 100G10M 100M 1G 10G

10k

1k

100

10

INPUT NOISE VOLTAGE – µV p-p

1

WHENEVER JOHNSON NOISE IS GREATER THAN

AMPLIFIER NOISE, AMPLIFIER NOISE CAN BE

CONSIDERED NEGLIGIBLE FOR THE APPLICATION.

RESISTOR JOHNSON NOISE

1 kHz BANDWIDTH

AMPLIFIER GENERATED NOISE

10 Hz

BANDWIDTH

300

250

200

150

INPUT BIAS CURRENT – fA

100

05 20

SUPPLY VOLTAGE ± VOLTS

10 15

+25oC

Figure 10. Input Bias Current

vs. Supply Voltage

100

80

60

40

20

0

OPEN LOOP GAIN – dB

–20

–40

10 100 10M1k 10k 100k 1M

FREQUENCY – Hz

Figure 13. Open Loop Frequency

Response

160

140

120

100

80

60

40

NOISE SPECTRAL DENSITY – nV/√Hz

20

10

Figure 11. Input Voltage Noise

Spectral Density vs. Frequency

100

80

60

40

20

0

–20

–40

40

35

30

25

20

15

10

PHASE MARGIN – Degrees

OUTPUT VOLTAGE SWING – V

5

0

10

Figure 14. Large Signal Frequency

Response

100

FREQUENCY – Hz

100

FREQUENCY – Hz

10k1k

Figure 12. Noise vs. Source

Resistance

1M

100k10k1k

Figure 15. CMRR vs. Frequency

REV. A

Figure 16. PSRR vs. Frequency

Figure 17. Output Settling Time vs.

Output Swing and Error Voltage

–5–

Page 6

AD546

Figure 18. Unity Gain Follower

Figure 21. Unity Gain Inverter

MINIMIZING INPUT CURRENT

The AD546 is guaranteed to have less than 1 pA max input bias

current at room temperature. Careful attention to how the amplifier is used will reduce input currents in actual applications.

The amplifier operating temperature should be kept as low as

possible to minimize input current. Like other JFET input amplifiers, the AD546’s input current is sensitive to chip temperature, rising by a factor of 2.3 for every 10°C rise. This is

illustrated in Figure 24, a plot of AD546 input current versus

ambient temperature.

Figure 19. Unity Gain Follower

Large Signal Pulse Response

Figure 22. Unity Gain Inverter

Large Signal Pulse Response

Figure 20. Unity Gain Follower

Small Signal Pulse Response

Figure 23. Unity Gain Inverter

Small Signal Pulse Response

On-chip power dissipation will raise chip operating temperature

causing an increase in input bias current. Due to the AD546’s

low quiescent supply current, chip temperature when the

(unloaded) amplifier is operated with 15 V supplies, is less than

3°C higher than ambient. The difference in input current is

negligible.

However, heavy output loads can cause a significant increase in

chip temperature and a corresponding increase in input current.

Maintaining a minimum load resistance of 10 kΩ is recommended. Input current versus additional power dissipation due

to output drive current is plotted in Figure 25.

Figure 24. AD546 Input Bias Current vs

Ambient Temperature

–6–

Figure 25. AD546 Input Bias Current vs.

Additional Power Dissipation

REV. A

Page 7

Circuit Board Notes

The AD546 is designed for through hole mount into PC boards.

Maintaining picoampere level resolution in that environment requires a lot of care. Since both the printed circuit board and the

amplifier’s package have a finite resistance, the voltage difference between the amplifier’s input pin and other pins (or traces

on the PC board) will cause parasitic currents to flow into (or

out of) the signal path (see Figure 26). These currents can easily

exceed the 1 pA input current level of the AD546 unless special

precautions are taken. Two successful methods for minimizing

leakage are guarding the AD546’s input lines and maintaining

adequate insulation resistance.

The AD546’s positive input (Pin 3) is located next to the negative supply voltage pin (Pin 4). The negative input (Pin 2) is

next to the balance adjust pin (Pin 1) which is biased at a potential close to the negative supply voltage. The layouts shown in

Figures 27a and 27b for the inverter and follower connections

will guard against the effects of low surface resistance of the

board. Note that the guard traces should be placed on both sides

of the board. In addition the input trace should be guarded on

both of its edges along its entire length.

AD546

Figure 26. Sources of Parasitic Leakage Currents

REV. A

Figure 27a. Guarding Scheme—Inverter

Figure 27b. Guarding Scheme—Follower

–7–

Page 8

AD546

Figure 28. Input Pin to Insulating Standoff

Leakage through the bulk of the circuit board will still occur

with the guarding schemes shown in Figures 27a and 27b. Standard “G10” type printed circuit board material may not have

high enough volume resistivity to hold leakages at the subpicoampere level particularly under high humidity conditions.

One option that eliminates all effects of board resistance

is shown in Figure 28. The AD546’s sensitive input pin (either

Pin 2 when connected as an inverter, or Pin 3 when connected

as a follower) is bent up and soldered directly to a Teflon* insulated standoff. Both the signal input and feedback component

leads must also be insulated from the circuit board by Teflon

standoffs or low-leakage shielded cable.

Contaminants such as solder flux on the board’s surface and on

the amplifier’s package can greatly reduce the insulation resistance between the input pin and those traces with supply or signal voltages. Both the package and the board must be kept clean

and dry. An effective cleaning procedure is to first swab the surface with high grade isopropyl alcohol, then rinse it with deionized water and, finally, bake it at 80°C for 1 hour. Note that if

either polystyrene or polypropylene capacitors are used on the

printed circuit board, a baking temperature of 70°C is safer,

since both of these plastic compounds begin to melt at approximately +85°C.

Other guidelines include making the circuit layout as compact

as possible and reducing the length of input lines. Keeping circuit board components rigid and minimizing vibration will reduce triboelectric and piezoelectric effects. All precision high

impedance circuitry requires shielding from electrical noise and

interference. For example, a ground plane should be used under

all high value (i.e., greater than 1 MΩ) feedback resistors. In

some cases, a shield placed over the resistors, or even the entire

amplifier, may be needed to minimize electrical interference

originating from other circuits. Referring to the equation in Figure 26, this coupling can take place in either, or both, of two

different forms—coupling via time varying fields:

Table I. Insulating Materials and Characteristics

Volume Minimal Minimal Resistance

Resistivity Triboelectric Piezoelectric to Water

Material1(V–CM) Effects Effects Absorption

Teflon* 1017–10

Kel-F** 1017–10

Sapphire 1016–10

Polyethylene 1014–10

Polystyrene 1012–10

Ceramic 1012–10

Glass Epoxy 1010–10

PVC 1010–10

Phenolic 105–10

G–Good with Regard to Property.

M–Moderate with Regard to Property.

W–Weak with Regard to Property.

1

Electronic Measurements, pp.15-17, Keithley Instruments, Inc., Cleveland,

Ohio, 1977.

*Teflon is a registered trademark of E.I. du Pont Co.

**Kel-F is a registered trademark of 3M Company.

18

WWG

18

WMG

18

MGG

18

MGM

18

WMM

14

WMW

17

WMW

15

GMG

12

WGW

OFFSET NULLING

The AD546’s input offset voltage can be nulled by using balance

Pins 1 and 5, as shown in Figure 29. Nulling the input offset

voltage in this fashion will introduce an added input offset voltage drift component of 2.4 µV/°C per millivolt of nulled offset.

dV

C

P

dT

or by injection of parasitic currents by changes in capacitance

due to mechanical vibration:

dCp

V

dT

Both proper shielding and rigid mechanical mounting of components help minimize error currents from both of these sources.

Table I lists various insulators and their properties.

–8–

Figure 29. Standard Offset Null Circuit

The circuit in Figure 30 can be used when the amplifier is used

as an inverter. This method introduces a small voltage in series

with the amplifier’s positive input terminal. The amplifier’s

REV. A

Page 9

input offset voltage drift with temperature is not affected. However, variation of the power supply voltages will cause offset

shifts.

Figure 30. Alternate Offset Null Circuit for Inverter

AC RESPONSE WITH HIGH VALUE SOURCE AND

FEEDBACK RESISTANCE

Source and feedback resistances greater than 100 kΩ will

magnify the effect of input capacitances (stray and inherent to

the AD546) on the ac behavior of the circuit. The effects of

common-mode and differential-input capacitances should be

taken into account since the circuit’s bandwidth and stability

can be adversely affected.

In a follower, the source resistance, R

mode capacitance, C

(including capacitance due to board and

S

, and input common-

S

capacitance inherent to the AD546), form a pole that limits circuit bandwidth to 1/2 π R

. Figure 31 shows the follower

SCS

pulse response from a 1 MΩ source resistance with the

amplifier’s input pin isolated from the board, only the effect of

the AD546’s input common-mode capacitance is seen.

AD546

Figure 32. Inverter Pulse Response with 1 MΩ Source and

Feedback Resistance

Figure 33. Inverter Pulse Response with 1 MΩ Source and

Feedback Resistance, 1 pF Feedback Capacitance

COMMON-MODE INPUT VOLTAGE OVERLOAD

The rated common-mode input voltage range of the AD546 is

from 3 V less than the positive supply voltage to 5 V greater

than the negative supply voltage. Exceeding this range will degrade the amplifier’s CMRR. Driving the common-mode voltage above the positive supply will cause the amplifier’s output to

saturate at the upper limit of output voltage. Recovery time is

typically 2 µs after the input has been returned to within the

normal operating range. Driving the input common mode voltage within 1 V of the negative supply causes phase reversal of

the output signal. In this case, normal operation is typically

resumed within 0.5 ms of the input voltage returning within

range.

Figure 31. Follower Pulse Response from 1 MΩ Source

Resistance

In an inverting configuration, the differential input capacitance

forms a pole in the circuit’s loop transmission. This can create

peaking in the ac response and possible instability. A feedback

capacitance can be used to stabilize the circuit. The inverter

pulse response with R

and R

F

equal to 1 MΩ, and the input pin

S

isolated from the board appears in Figure 32. Figure 33 shows

the response of the same circuit with a 1 pF feedback capacitance. Typical differential input capacitance for the AD546

is 1 pF.

REV. A

–9–

DIFFERENTIAL INPUT VOLTAGE OVERLOAD

A plot of the AD546’s input current versus differential input

voltage (defined as V

Figure 34. Input Current vs. Differential Input Voltage

+ –VIN–) appears in Figure 34. The

IN

Page 10

AD546

input current at either terminal stays below a few hundred

femtoamps until one input terminal is forced higher than 1 V to

1.5 V above the other terminal. Under these conditions, the

input current limits at 30 µA.

INPUT PROTECTION

The AD546 safely handles any input voltage within the supply

voltage range. Subjecting the input terminals to voltages beyond

the power supply can destroy the device or cause shifts in input

current or offset voltage if the amplifier is not protected.

A protection scheme for the amplifier as an inverter is shown in

Figure 35. The protection resistor, R

, is chosen to limit the

P

current through the inverting input to 1 mA for expected transient (less than 1 second) overvoltage conditions, or to 100 µA

for a continuous overload. Since R

is inside the feedback loop,

P

and is much lower in value than the amplifier’s input resistance,

it does not affect the inverter’s dc gain. However, the Johnson

noise of the resistor will add root sum of squares to the

amplifier’s input noise.

than 1 pA), such as the FD333’s should be used, and should be

shielded from light to keep photocurrents from being generated.

Even with these precautions, the diodes will measurably increase

the input current and capacitance.

In order to achieve the low input bias currents of the AD546, it

is not possible to use the same on-chip protection as used in

other Analog Devices op amps. This makes the AD546 sensitive

to handling and precautions should be taken to minimize ESD

exposure whenever possible.

Figure 35. Inverter with Input Current Limit

In the corresponding version of this scheme for a follower,

shown in Figure 36, R

and the capacitance at the positive input

P

terminal will produce a pole in the signal frequency response at

a f = 1/2 π RC. Again, the Johnson noise of R

will add to the

P

amplifier’s input voltage noise.

Figure 37 is a schematic of the AD546 as an inverter with an in-

put voltage clamp. Bootstrapping the clamp diodes at the inverting input minimizes the voltage across the clamps and keeps the

leakage due to the diodes low. Low leakage diodes (less

Figure 36. Follower with Input Current Limit

Figure 37. Input Voltage Clamp with Diodes

Figure 38. Sample and Difference Circuit for Measuring

Electrometer Leakage Currents

MEASURING ELECTROMETER LEAKAGE CURRENTS

There are a number of methods used to test electrometer leakage currents, including current integration and direct current to

voltage conversion. Regardless of the method used, board and

interconnect cleanliness, proper choice of insulating materials

(such as Teflon or Kel-F), correct guarding and shielding techniques and care in physical layout are essential for making accurate leakage measurements.

Figure 38 is a schematic of the sample and difference circuit

which is useful for measuring the leakage currents of the AD546

and other electrometer amplifiers. The circuit uses two AD549

electrometer amplifiers (A and B) as current to voltage converters with high value (10

10

Ω) sense resistors (RSa and RSb). R1

and R2 provide for an overall circuit sensitivity of 10 fA/mV

(10 pA full scale). C

loop compensation. C

and CF provide noise suppression and

C

should be a low leakage polystyrene ca-

C

pacitor. An ultralow-leakage Kel-F test socket is used for con-

–10–

REV. A

Page 11

AD546

tacting the device under test. Rigid Teflon coaxial cable is used

to make connections to all high impedance nodes. The use of

rigid coax affords immunity to error induced by mechanical vibration and provides an outer conductor for shielding. The entire circuit is enclosed in a grounded metal box.

The test apparatus is calibrated without a device under test

present. A five minute stabilization period after the power is

turned on is required. First, V

ERR1

and V

are measured.

ERR2

These voltages are the errors caused by offset voltages and leakage currents of the current to voltage converters.

V

= 10 (VOSA – IBA × RSa)

ERR1

V

= 10 (VOSB – IBB × RSb)

ERR2

Once measured, these errors are subtracted from the readings

taken with a device under test present. Amplifier B closes the

feedback loop to the device under test, in addition to providing

current to voltage conversion. The offset error of the device under test appears as a common-mode signal and does not affect

the test measurement. As a result, only the leakage current of

the device under test is measured.

V

– V

A

– V

V

X

= 10[RSa × I

ERR1

= 10[RSb × I

ERR2

(+)]

B

(–)]

B

Although a series of devices can be tested after only one calibration measurement, calibration should be updated periodically to

compensate for any thermal drift of the current-to-voltage converters or changes in the ambient environment. Laboratory results have shown that repeatable measurements within 10 fA can

be realized when this apparatus is properly implemented. These

results are achieved in part by the design of the circuit, which

eliminates relays and other parasitic leakage paths in the high

impedance signal lines, and in part by the inherent cancellation

of errors through the calibration and measurement procedure.

PHOTODIODE INTERFACE

The AD546’s 1 pA current and low input offset voltage make it

a good choice for very sensitive photodiode preamps (Figure

39). The photodiode develops a signal current, I

= R × P

I

S

, equal to:

S

where P is light power incident on the diode’s surface in watts

and R is the photodiode responsivity in amps/watt. R

converts

F

the signal current to an output voltage:

V

= RF × I

OUT

S

Input current, I

, will contribute an output voltage error, VE1,

B

proportional to the feedback resistance:

V

= IB × R

E1

F

The op amp’s input voltage offset will cause an error current

through the photodiode’s shunt resistance, R

I = V

OS/RS

:

S

The error current will result in an error voltage (VE2) at the

amplifier’s output equal to:

V

= (1 +RF/RS) V

E2

Given typical values of photodiode shunt resistance (on the order of 10

9

Ω), R

can be greater than one, especially if a large

F/RS

feedback resistance is used. Also, R

OS

will increase with tem-

F/RS

perature, as photodiode shunt resistance typically drops by a

factor of two for every 10°C rise in temperature. An op amp

with low offset voltage and low drift helps maintain accuracy.

Figure 40. Photodiode Preamp DC Error Sources

Photodiode Preamp Noise

Noise limits the signal resolution obtainable with the preamp.

The output voltage noise divided by the feedback resistance is

the minimum current signal that can be detected. This minimum detectable current divided by the responsivity of the photodiode represents the lowest light power that can be detected

by the preamp.

Noise sources associated with the photodiode, amplifier, and

feedback resistance are shown in Figure 41; Figure 42 is the

voltage spectral density versus frequency plot of each of the

noise source’s contribution to the output voltage noise (circuit

parameters in Figure 40 are assumed). Each noise source’s rms

contribution to the total output voltage noise is obtained by integrating the square of its spectral density function over frequency. The rms value of the output voltage noise is the square

root of the sum of all contributions. Minimizing the total area

under these curves will optimize the preamplifier’s resolution for

a given bandwidth.

Figure 39. Photodiode Preamp

DC error sources and an equivalent circuit for a small area

(0.2 mm square) photodiode are indicated in Figure 40.

REV. A

Figure 41. Photodiode Preamp Noise Sources

–11–

Page 12

AD546

Figure 42. Photodiode Preamp Noise Sources’ Spectral

Density vs. Frequency

The photodiode preamp in Figure 39 can detect a signal current

of 26 fA rms at a bandwidth of 16 Hz, which assuming a photodiode responsivity of 0.5 A/W, translates to a 52 fW rms minimum detectable power. The photodiode used has a high source

resistance and low junction capacitance. C

width with R

and also limits the “peak” in the noise gain that

F

multiplies the op amp’s input voltage noise contribution. A

single pole filter at the amplifier’s output limits the op amp’s

output voltage noise bandwidth to 26 Hz, a frequency comparable to the signal bandwidth. This greatly improves the

preamplifier’s signal to noise ratio (in this case, by a factor of

three).

Photodiode Array Processor

The AD546 is a cost effective preamp for multichannel applications, such as amplifying signals from photo diode arrays, as illustrated in Figure 43. An AD546 preamp converts each of the

diodes’ output currents to a voltage. An 8 to 1 multiplexer

switches a particular preamp output to the input of an AD1380

16-bit sampling ADC. The output of the ADC can be displayed

or put onto a databus. Additional preamps and muxes can be

added to handle larger arrays. Layout of multichannel circuits is

critical. Refer to “PC board notes” for guidance.

pH PROBE AMPLIFIER

A pH probe can be modeled as a mV-level voltage source with a

series source resistance dependent upon the electrode’s composition and configuration. The glass bulb resistance of a typical

pH electrode pair falls between 10

6

Ω and 109 Ω. It is, therefore,

important to select an amplifier with low enough input currents

such that the voltage drop produced by the amplifier’s input

bias current and the electrode resistance does not become an

appreciable percentage of a pH unit.

The circuit in Figure 44 illustrates the use of the AD546 as a

pH probe amplifier. As with other electrometer applications, the

use of guarding, shielding, Teflon standoffs, etc., is a must in

order to capitalize on the AD546’s low input current. If an

AD546J (1 pA max input current) is used, the error contributed

by input current will be held below 10 mV for pH electrode

source impedances up to 10

9

Ω. Input offset voltage (which can

be trimmed) will be below 2 mV. Refer to AD549 data sheet for

temperature compensated pH probe amplifier circuit.

sets the signal band-

F

C1291–10–7/89

Figure 43. Photodiode Array Processor

Figure 44. pH Probe Amplifier

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

Mini-DIP (N) Package

PRINTED IN U.S.A.

–12–

REV. A

Loading...

Loading...