Page 1

PRELIMINARY TECHNICAL DA T A

12/14-Bit High Bandwidth

a

Preliminary Technical Data

FEATURES

+2.5 V to +5.5 V Supply Operation

50MHz Serial Interface

10MHz Multiplying Bandwidth

±10V Reference Input

10-Lead MSOP Packages

Pin Compatible 12 and 14 Bit Current Output DACs

Extended Temperature range –40°C to +125°C

Guaranteed Monotonic

Four Quadrant Multiplication

Power On Reset with brownout detection

µµ

<0.5

µA typical Current Consumption

µµ

APPLICATIONS

Portable Battery Powered Applications

Waveform Generators

Analog Processing

Instrumentation Applications

Programmable Amplifiers and Attenuators

Digitally-Controlled Calibration

Programmable Filters and Oscillators

Composite Video

Ultrasound

Gain, offset and Voltage Trimming

Multiplying DACs with Serial Interface

AD5444/AD5446*

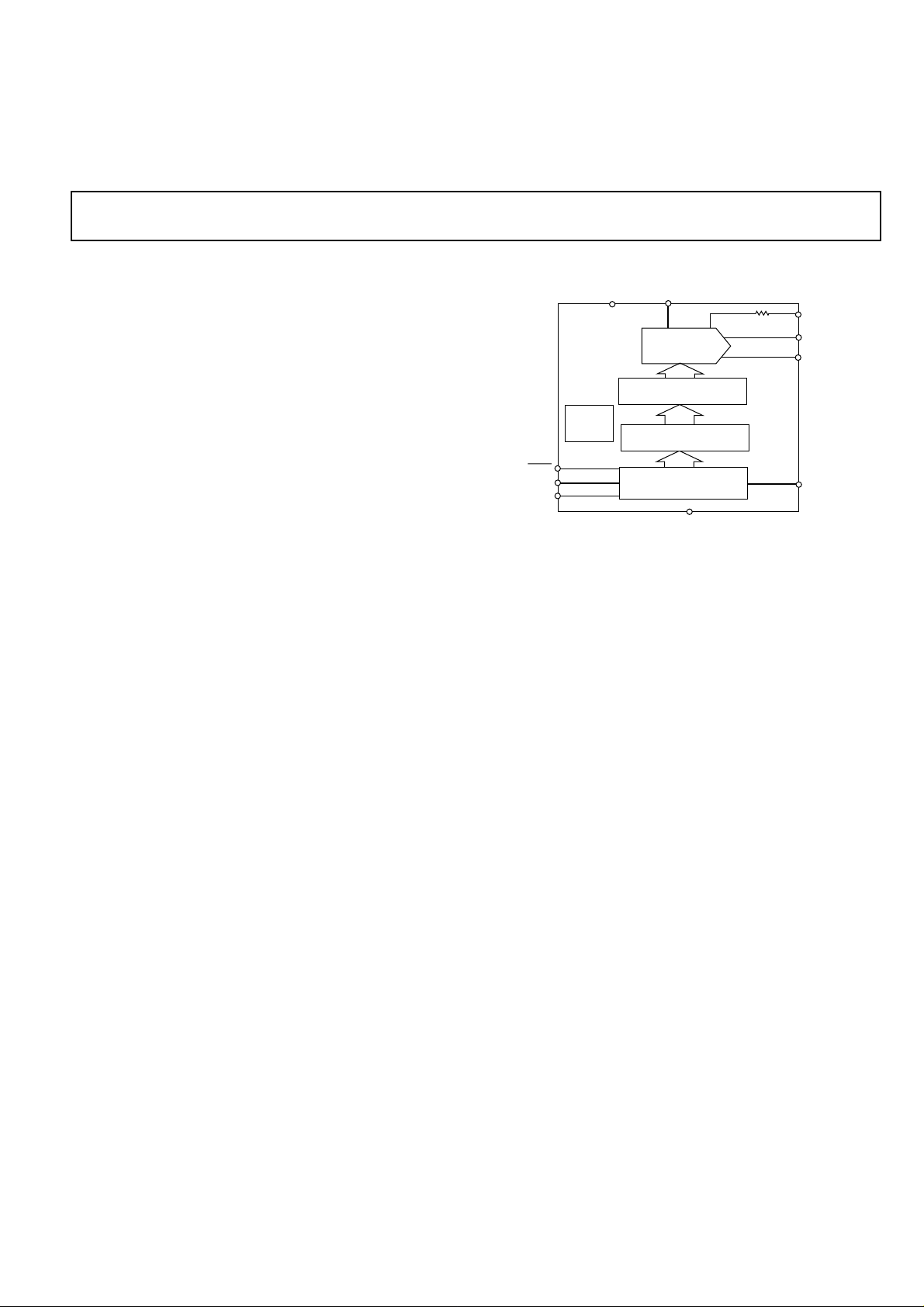

FUNCTIONAL BLOCK DIAGRAM

V

REF

12/14

BIT

R-2R DAC

DAC REGISTER

INPUT LATCH

CONTROL LOGIC &

INPUT SHIFT REGISTER

GND

R

R

FB

I

OUT1

I

OUT2

SDO

SYNC

SCLK

SDIN

AD5444/

AD5446

Power On

Reset

V

DD

GENERAL DESCRIPTION

The AD5444/5446 are CMOS 12 and 14-bit Current

Output digital-to-analog converters respectively.

These devices operate from a +2.5 V to 5.5 V power supply, making them suited to battery powered applications

and many other applications.

These DACs utilize double buffered 3-wire serial interface

that is compatible with SPI

TM

, QSPITM, MICROWIRE

TM

The applied external reference input voltage (V

mines the full scale output current. An integrated feedback

resistor (R

voltage output when combined with an external Current to

Voltage precision amplifier.

The AD5444/5446 DACs are available in small 10-lead

MSOP packages.

and most DSP interface standards.

On power-up, the internal shift register and latches are

filled with zeros and the DAC output is at zero scale.

As a result of manufacture on a CMOS sub micron

process, they offer excellent four quadrant multiplication

characteristics, with large signal multiplying bandwidths

of 10MHz.

*US Patent Number 5,689,257

SPI and QSPI are trademarks of Motorola, Inc.

MICROWIRE is a trademark of National Semiconductor Corporation.

REV. PrB Oct, 2003

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide W eb Site: http://www .analog.com

Fax: 781/326-8703 Analog Devices, Inc., 2003

) deter-

REF

) provides temperature tracking and full scale

FB

Page 2

PRELIMINARY TECHNICAL DA T A

AD5444/AD5446–SPECIFICATIONS

1

(VDD = 2.5 V to 5.5 V, V

AC performance with AD8038 unless otherwise noted.)

Parameter Min Typ Max Units Conditions

STATIC PERFORMANCE

AD5444

Resolution 12 Bits

Relative Accuracy ±

Differential Nonlinearity ±

AD5446

Resolution 14 Bits

Relative Accuracy ±2 LSB

Differential Nonlinearity ±1 LSB Guaranteed Monotonic

Total Unadjusted Error ±2.44 mV

Gain Error ±1.22 mV

Gain Error Temp Coefficient

Output Leakage Current ±10 n A Data = 0000H, TA = 25°C, I

Output Voltage Compliance 1.23 V

REFERENCE INPUT

Reference Input Range ±10 V

V

Input Resistance 8 9.3 12 kΩ Input resistance TC = -50ppm/°C

REF

RFB Resistance 8 9.3 12 kΩ Input resistance TC = -50ppm/°C

Input Capacitance

Zero Code 3 6 pF

Full Scale Code 5 8 pF

DIGITAL INPUTS/OUTPUTS

Input High Voltage, V

Input Low Voltage, V

Output High Voltage, V

Output Low Voltage, V

Input Leakage Current, I

Input Capacitance 10 pF

DYNAMIC PERFORMANCE

Reference Multiplying BW 1 0 MHz V

Output Voltage Settling Time V

AD5440 40 tb d n s Measured to +/-1mV of FS

AD5447 80 tb d n s Measured to +/-1mV of FS

Digital Delay 20 40 ns Interface delay time

10% to 90% Dettling Time 10 30 ns Rise and Fall time, V

Digital to Analog Glitch Impulse

Multiplying Feedthrough Error DAC latch loaded with all 0s.

Output Capacitance

IOUT1 5 p F DAC Latches Loaded with all 0s

IOUT2 1 0 pF DAC Latches Loaded with all 0s

Digital Feedthrough 0. 1 nV -s Feedthrough to DAC output with CS high

= +10 V, I

REF

2

IH

IL

OL

x = O V. All specifications T

OUT

2

2

2.0 V VDD = 3.6 V to 5 V

1.7 V VDD = 2.5 V to 3.6 V

OH

VDD -1 V VDD = 4.5 V to 5 V, I

VDD - 0.5 V VDD = 2.5 V to 3.6 V, I

IL

2

to T

MIN

0.5

½

±5 ppm FSR/

±50 n A Data = 0000H, I

unless otherwise noted. DC performance measured with OP177,

MAX

LSB

LSB Guaranteed Monotonic

°C

OUT1

OUT1

0.8 V VDD = 2.7 V to 5.5 V

0.7 V VDD = 2.5 V to 2.7 V

SOURCE

0.4 V VDD = 4.5 V to 5 V, I

SINK

0.4 V VDD = 2.5 V to 3.6 V, I

= 200uA

SOURCE

= 200uA

= 200uA

SINK

= 200uA

1 µA

= +/-3.5V, DAC loaded all 1s

REF

= 10V, R

REF

LOAD

= 100Ω, C

LOAD

DAC latch alternately loaded with 0s and 1s.

= 10V, R

100Ω, C

LOAD

REF

= 15pF

LOAD

3 nV -s 1 LSB change around Major Carry, V

-75 dB Reference = 1MHz.

Reference = 10MHz.

10 pF DAC Latches Loaded with all 1s

5 pF DAC Latches Loaded with all 1s

and Alternate Loading of all 0s and all 1s.

= 15pF

=

=0V

REF

–2– REV. PrB

Page 3

PRELIMINARY TECHNICAL DA T A

AD5444/AD5446

(VDD = 2.5 V to 5.5 V, V

= +10 V, I

REF

x = O V. All specifications T

OUT

MIN

to T

unless otherwise noted. DC performance measured with OP177,

MAX

AC performance with AD8038 unless otherwise noted.)

Parameter Min Typ Max Units Conditions

Total Harmonic Distortion -8 0 dB V

= 3.5 V pk-pk, All 1s loaded, f = 1kHz

REF

Digital THD, Clock = 1MHz

50kHz f

OUT

75 dB

Output Noise Spectral Density 25 nV/√Hz @ 1kHz

SFDR performance (Wideband)

Update = 1MHz, V

= 3.5V

REF

Update = 1MHz

50kHz Fout 78 dB

20kHz Fout 78 dB

SFDR performance (NarrowBand) Update = 1MHz, V

= 3.5V

REF

50kHz Fout 87 dB

20kHz Fout 87 dB

Intermodulation Distortion 78 dB f1 = 20kHz, f2 = 25kHz, Update=1MHz,

V

=3.5V

REF

POWER REQUIREMENTS

Power Supply Range 2.5 5.5 V

I

DD

Power Supply Sensitivity

NOTES

1

Temperature range is as follows: Y Version: –40°C to +125°C.

2

Guaranteed by design and characterisation, not subject to production test.

Specifications subject to change without notice.

2

1 µA Logic Inputs = 0 V or V

0.001 %/% ∆VDD = ±5%

DD

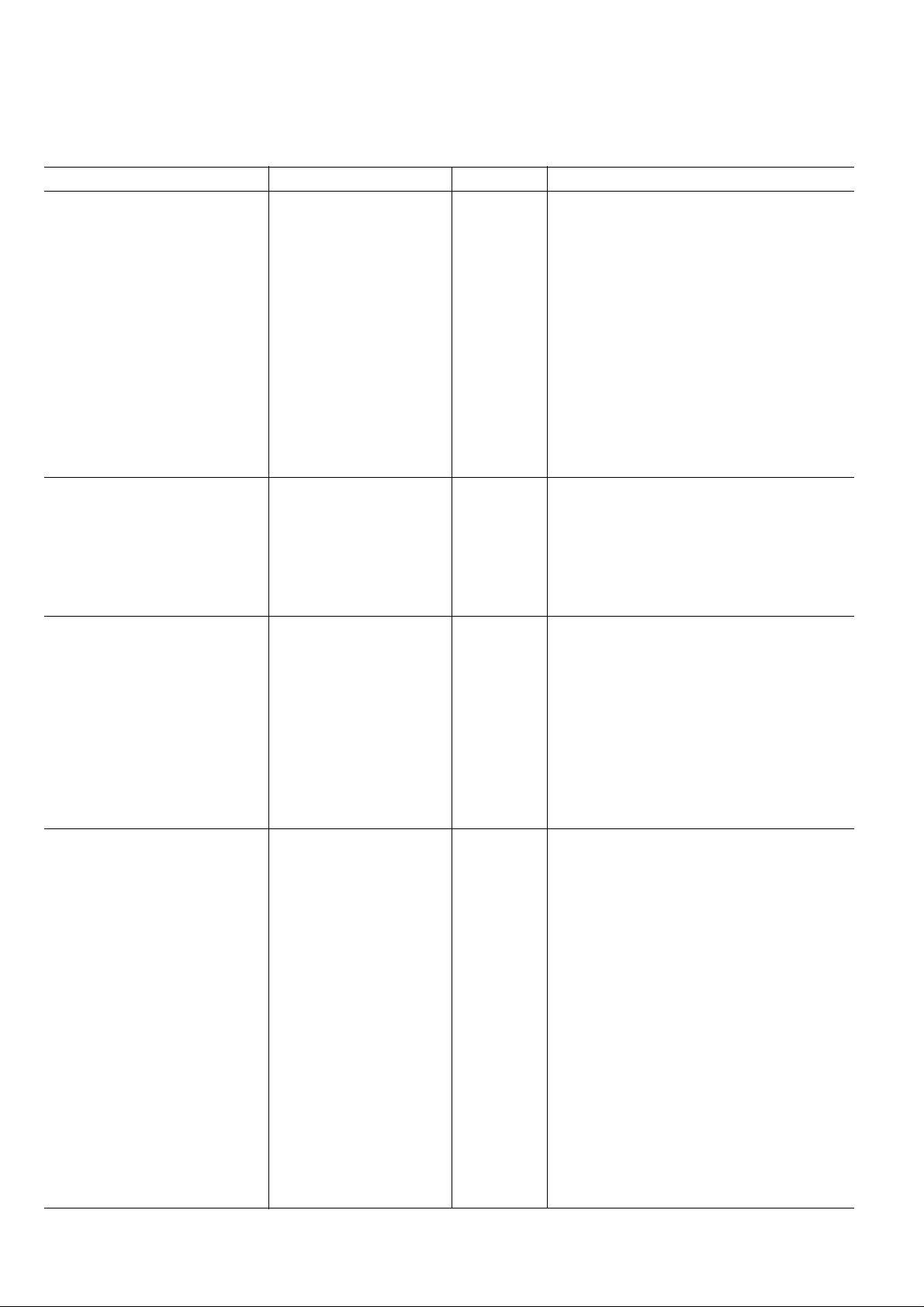

TIMING CHARACTERISTICS

Parameter VDD = 4.5 V to 5.5 V VDD = 2.5 V to 5.5 V Units Conditions/Comments

f

SCLK

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

NOTES

1

See Figures 1. Temperature range is as follows: Y Version: –40°C to +125°C. Guaranteed by design and characterisation, not subject to

production test. All input signals are specified with tr =tf = 5ns (10% to 90% of VDD) and timed from a voltage level of (VIL + VIH)/2.

Specifications subject to change without notice.

SCLK

SYNC

DIN

tba 50 MHz max Max Clock frequency

20 ns min SCLK Cycle time

8 ns min SCLK High Time

8 ns min SCLK Low Time

8 ns min

5 ns min Data Setup Time

4.5 ns min Data Hold Time

5 ns min SYNC rising edge to SCLK active edge

30 ns min Minimum SYNC high time

t

8

t

4

t

6

t

5

DB15

(V

= +5 V, I

REF

t

1

t

2

2 = O V. All specifications T

OUT

SYNC falling edge to SCLK active edge setup

t

3

DB0

t

7

MIN

to T

unless otherwise noted.)

MAX

time

1

Figure 1. Timing Diagram.

–3–REV. PrB

Page 4

AD5444/AD5446

PRELIMINARY TECHNICAL DA T A

ABSOLUTE MAXIMUM RATINGS

(TA = +25°C unless otherwise noted)

1, 2

VDD to GND –0.3 V to +7 V

V

REF, RFB

I

OUT

Logic Inputs & Output

to GND –12 V to +12 V

1 to GND –0.3 V to +7 V

3

-0.3V to VDD +0.3 V

Operating Temperature Range

Industrial (Y Version) –40°C to +125°C

Storage Temperature Range –65°C to +150°C

Junction Temperature +150°C

10 lead MSOP θ

Thermal Impedance 206°C/W

JA

Lead Temperature, Soldering (10seconds) 300°C

IR Reflow, Peak Temperature (<20 seconds) +235°C

NOTES

1

Stresses above those listed under “Absolute Maximum Ratings” may cause permanent

damage to the device. This is a stress rating only and functional operation of the device

at these or any other conditions above those listed in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability. Only one absolute maximum rating may

be applied at any one time.

2

Transient currents of up to 100mA will not cause SCR latchup.

3

Overvoltages at SCLK, SYNC, DIN, will be clamped by internal diodes.

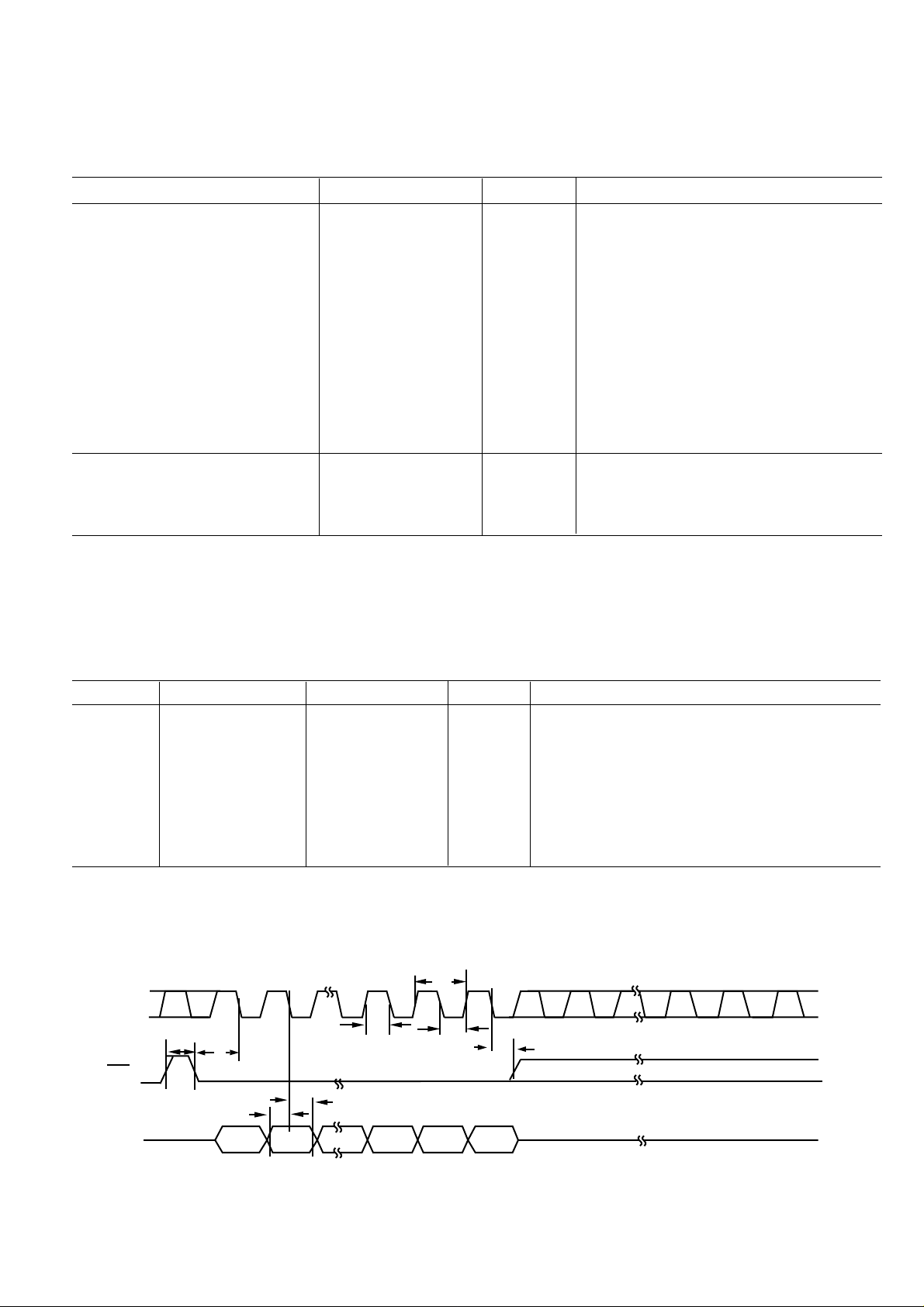

ORDERING GUIDE

Model Resolution INL Temperature Range Package Description Branding Package Option

AD5444YRM 12

AD5446YRM 14

±0.5

±2

-40 oC to +125 oC MSOP RM-10

-40 oC to +125 oC MSOP RM-10

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD5444/5446 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions

are recommended to avoid performance degradation or loss of functionality.

–4– REV. PrB

Page 5

PRELIMINARY TECHNICAL DA T A

MSOP Mnemonic Function

AD5444/AD5446

PIN FUNCTION DESCRIPTION

1I

2I

1 DAC Current Output.

OUT

2 DAC Analog Ground. This pin should normally be tied to the analog ground of the system.

OUT

3 GND Ground Pin.

4 SCLK Serial Clock Input. By default, data is clocked into the input shift register on the falling edge of

the serial clock input. Alternatively, by means of the serial control bits, the device may be

configured such that data is clocked into the shift register on the rising edge of SCLK.

5 SDIN Serial Data Input. Data is clocked into the 16-bit input register on the active edge of the serial

clock input. By default, on power up, data is clocked into the shift register on the falling edge of

SCLK. The control bits allow the user to change the active edge to rising edge.

6 SYNC Active Low Control Input. This is the frame synchronization signal for the input data. When

SYNC goes low, it powers on the SCLK and DIN buffers and the input shift register is

enabled. Data is loaded to the shift register on the active edge of the following clocks.

7 SDO Serial Data Output. This allows a number of parts to be daisychained. By default, data is clocked

into the shift register on the falling edge and out via SDO on the rising edge of SCLK. Data will

always be clocked out on the alternate edge to loading data to the shift register. Writing the

Readback control word to the shift register makes the DAC register contents available for

readback on the SDO pin, clocked out on the opposite edges to the active clock edge.

8V

9V

10 R

DD

REF

FB

Positive power supply input. These parts can be operated from a supply of +2.5 V to +5.5 V.

DAC reference voltage input pin.

DAC feedback resistor pin. Establish voltage output for the DAC by connecting to external

amplifier output.

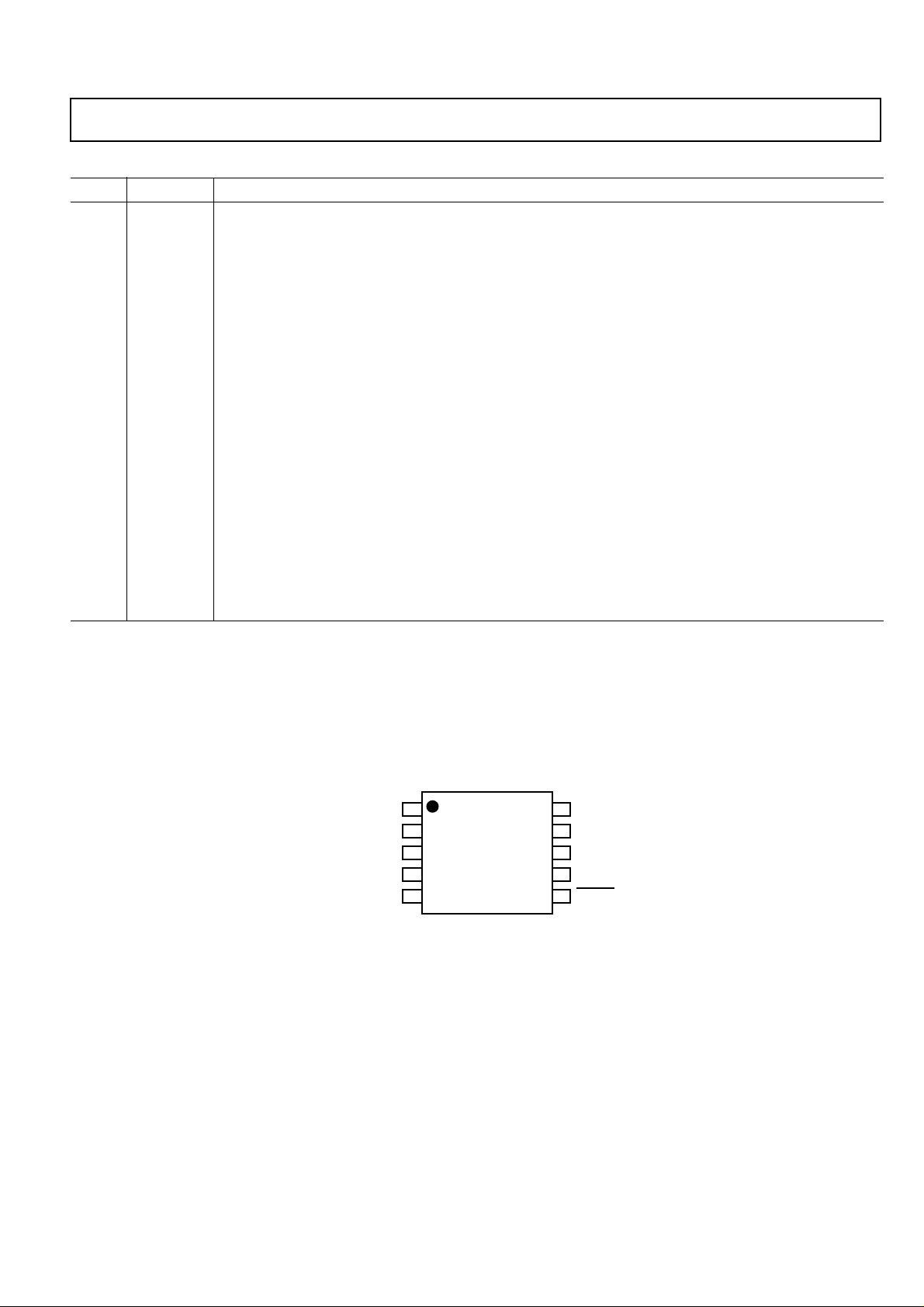

PIN CONFIGURATION

MSOP (RM-10)

GND

SDIN

1

2

3

4

5

AD5444/

AD5446

Not to Scale)

(

I

OUT1

I

OUT2

SCLK

16

15

14

13

12

RFB

VREF

VDD

SDO

SYNC

–5–REV. PrB

Page 6

PRELIMINARY TECHNICAL DA T A

AD5444/AD5446

TERMINOLOGY

Relative Accuracy

Relative accuracy or endpoint nonlinearity is a measure of the maximum deviation from a straight line passing through the

endpoints of the DAC transfer function. It is measured after adjusting for zero and full scale and is normally expressed in

LSBs or as a percentage of full scale reading.

Differential Nonlinearity

Differential nonlinearity is the difference between the measured change and the ideal 1 LSB change between any two adjacent codes. A specified differential nonlinearity of -1 LSB max over the operating temperature range ensures monotonicity.

Gain Error

Gain error or full-scale error is a measure of the output error between an ideal DAC and the actual device output. For

these DACs, ideal maximum output is V

tance.

Output Leakage Current

Output leakage current is current which flows in the DAC ladder switches when these are turned off. For the I

nal, it can be measured by loading all 0s to the DAC and measuring the I

line when the DAC is loaded with all 1s

I

OUT2

Output Capacitance

Capacitance from I

OUT1

or I

to AGND.

OUT2

Output Current Settling Time

This is the amount of time it takes for the output to settle to a specified level for a full scale input change. For these devices, it is specifed with a 100 Ω resistor to ground. The settling time specification includes the digital delay from SYNC

rising edge to the full scale output change.

Digital to Analog Glitch lmpulse

The amount of charge injected from the digital inputs to the analog output when the inputs change state. This is normally

specified as the area of the glitch in either pA-secs or nV-secs depending upon whether the glitch is measured as a current

or voltage signal.

Digital Feedthrough

When the device is not selected, high frequency logic activity on the device digital inputs may be capacitivelly coupled

through the device to show up as noise on the I

feedthrough.

Multiplying Feedthrough Error

This is the error due to capacitive feedthrough from the DAC reference input to the DAC I

loaded to the DAC.

Total Harmonic Distortion (THD)

The DAC is driven by an ac reference. The ratio of the rms sum of the harmonics of the DAC output to the fundamental

value is the THD. Usually only the lower order harmonices are included, such as second to fifth.

2

2

2

THD

= 20log √(V

V

2

+ V

3

+ V

1

4

+ V

2

)

5

Digital Intermodulation Distortion

Second order intermodulation (IMD) measurements are the relative magnitudes of the fa and fb tones generated digitally

by the DAC and the second order products at 2fa-fb and 2fb-fa.

Compliance Voltage Range

The maximum range of (output) terminal voltage for which the device will provide the specified characteristics.

Spurious-Free Dynamic Range(SFDR)

It is the usable dynamic range of a DAC before spurious noise interferes or distorts the fundamental signal. SFDR is the

measure of difference in amplitude between the fundamental and the largest harmonically or nonharmonically related spur

from dc to full Nyquist bandwidth (half the DAC sampling rate or fs/2). Narrow band SFDR is a measure of SFDR over

an arbitrary window size, in this case 50% of hte fundamental. Digital SFDR is a measure of the usable dymanic range of

the DAC when the signal is a digitally generated sine wave.

– 1 LSB. Gain error of the DACs is adjustable to zero with external resis-

REF

termi-

current. Minimum current will flow in the

OUT1

pins and subsequently into the following circuitry. This noise is digital

OUT

terminal, when all 0s are

OUT1

OUT1

–6– REV. PrB

Page 7

PRELIMINARY TECHNICAL DA T A

Typical Performance Characteristics

TPC 1. INL vs. Code (12-Bit DAC)

TPC 2. INL vs. Code (14-Bit DAC)

AD5444/AD5446

TPC 3. DNL vs. Code (12-Bit DAC)

TPC 4. DNL vs. Code (14-Bit DAC)

TPC 7. DNL vs. Reference Voltage

TPC 5. INL vs Reference Voltage

TPC 8. DNL vs Code - Biased Mode

TPC 6. DNL vs. Code (10-Bit DAC)

TPC 9. TUE vs Code

–7–REV. PrB

Page 8

AD5444/AD5446

PRELIMINARY TECHNICAL DA T A

TPC10. Linearity Errors vs. V

TPC 13. DNL Error vs. Reference -

Biased Mode

DD

TPC11. INL vs Code - Biased Mode

TPC 14. Supply Current vs. Clock Freq

TPC 12. INL Error vs. Reference -

Biased Mode

TPC 15. Logic Threshold vs Supply

Voltage

TPC 16.

TPC 17.

–8– REV. PrB

TPC 18

Page 9

PRELIMINARY TECHNICAL DA T A

AD5444/AD5446

TPC 19. Supply Current vs Logic Input

Voltage

TPC 22. Reference Multiplying

Bandwidth - small signal

TPC 20. Reference Multiplying

Bandwidth - small signal

TPC 23. Reference Multiplying

Bandwidth - large signal

TPC 21. Reference Multiplying

Bandwidth - large signal

TPC 24. Settling Time

TPC 25. Midscale Transition and

Digital Feedthrough

TPC 26. Power Supply Rejection vs

Frequency

–9–REV. PrB

TPC 27. Noise Spectral Density vs

Frequency

Page 10

AD5444/AD5446

PRELIMINARY TECHNICAL DA T A

GENERAL DESCRIPTION

DAC SECTION

The AD5444 and AD5446 are 12 and 14 bit current output DACs consisting of a segmented (4-Bits) inverting R2R ladder configuration.

The feedback resistor R

has a value of R. The value of R

FB

is typically 9.3kΩ (minimum 8kΩ and maximum 12kΩ).

If I

is kept at the same potential as GND, a constant

OUT1

current flows in each ladder leg, regardless of digital input

code. Therefore, the input resistance presented at V

REF

is

always constant and nominally of value R. The DAC output (I

) is code-dependent, producing various resis-

OUT

tances and capacitances. External amplifier choice should

take into account the variation in impedance generated by

the DAC on the amplifiers inverting input node.

Access is provided to the V

, RFB, and I

REF

terminals

OUT1

of the DAC, making the device extremely versatile and

allowing it to be configured in several different operating

modes, for example, to provide a unipolar output and in

four quadrant multiplication in bipolar mode. Note that a

matching switch is used in series with the internal R

FB

feedback resistor. If users attempt to measure RFB, power

must be applied to V

to achieve continuity.

DD

SERIAL INTERFACE

The AD5444/5446 have an easy to use 3-wire interface

which is compatible with SPI/QSPI/MicroWire and DSP

interface standards. Data is written to the device in 16 bit

words. This 16-bit word consists of 2 control bits and

either 12 or 14 data bits as shown in Figure 2. The

AD5446 uses all 14 bits of DAC data. The AD5444 uses

twelve bits and ignores the two LSBs.

DAC Control Bits C1, C0

Control bits C1 and C0 the user to load and update the

new DAC code and to change the active clock edge. By

default the shift register clocks data in on the falling edge,

this can be changed via the control bits. In this case, the

DAC core is inoperative until the next data frame. A

power cycle resets this back to default condition.

On chip power on reset circuitry ensures the device

powers on with zeroscale loaded to the DAC register and

line.

I

OUT

TABLE III. DAC CONTROL BITS

C1 C0 Funtion Implemented

0 0 Load and Update(Power On Default)

0 1 Reserved

1 0 Reserved

1 1 Clock Data to shift register On Rising Edge

SYNCSYNC

SYNC Function

SYNCSYNC

SYNC is an edge-triggered input that acts as a frame

synchronization signal and chip enable. Data can only be

transferred into the device while SYNC is low. To start

the serial data transfer, SYNC should be taken low observing the minimum SYNC falling to SCLK falling

edge setup time, t

.

4

After the falling edge of the 16th SCLK pulse, bring

SYNC high to transfer data from the input shift register to

the DAC register.

CIRCUIT OPERATION

Unipolar Mode

Using a single op amp, these devices can easily be

configured to provide 2 quadrant multiplying operation or

a unipolar output voltage swing as shown in Figure 3.

When an output amplifier is connected in unipolar mode,

the output voltage is given by:

V

= -D/2n x V

OUT

REF

Where D is the fractional representation of the digital

word loaded to the DAC, and n is the number of bits.

D= 0 to 4095 (12-Bit AD5444)

= 0 to 16383 (14-Bit AD5446)

Note that the output voltage polarity is opposite to the

V

polarity for dc reference voltages.

REF

DB15 (MSB)

C1 C0

CONTROL BITS

DB11 DB10

DB9

DB8

DB7 DB6 DB5 DB4

DB3 DB2

DATA BITS

Figure 2a. AD5444 12 bit Input Shift Register Contents

DB15 (MSB)

C1 C0

CONTROL BITS

DB13 DB12

DB11

DB10

DB9 DB8 DB7 DB6

DB5 DB4

DATA BITS

Figure 2b. AD5446 14 bit Input Shift Register Contents

–10– REV. PrB

DB1

DB3

DB0

DB2

DB0 (LSB)

X

DB0 (LSB)

DB1

DB0

X

Page 11

PRELIMINARY TECHNICAL DA T A

V

DD

V

DD

V

REF

NOTES:

1

R1 AND R2 USED ONLY IF GAIN ADJUSTMENT IS REQUIRED.

2

C1 PHASE COMPENSATION (1pF - 5pF) MAY BE REQUIRED

IF A1 IS A HIGH SPEED AMPLIFIER.

V

AD5450/1/2/3

REF

R

1

SYNC

SCLK SDIN

uController

Figure 3. Unipolar Operation

These DACs are designed to operate with either negative

or positive reference voltages. The V

used by the internal digital logic to drive the DAC

switches’ ON and OFF states.

These DACs are also designed to accommodate ac reference input signals in the range of -10V to +10V.

With a fixed 10 V reference, the circuit shown above will

give an unipolar 0V to -10V output voltage swing. When

V

is an ac signal, the circuit performs two-quadrant

IN

multiplication.

The following table shows the relationship between digital

code and expected output voltage for unipolar operation.

(AD5444, 12-Bit device).

Table I. Unipolar Code Table

Digital Input Analog Output (V)

1111 1111 1111 -V

1000 0000 0000 -V

0000 0000 0001 -V

0000 0000 0000 -V

REF

REF

REF

REF

R

2

C

RFB

IOUT1

GND

1

A1

AGND

power pin is only

DD

(4095/4096)

(2048/4096) = -V

(1/4096)

(0/4096) = 0

V

REF

OUT

/2

= 0 to -V

REF

AD5444/AD5446

Bipolar Operation

In some applications, it may be necessary to generate full

4-Quadrant multplying operation or a bipolar output

swing. This can be easily accomplished by using another

external amplifier and some external resistors as shown in

Figure 4. In this circuit, the second amplifier A2 provides

a gain of 2. Biasing the external amplifier with an offset

from the reference voltage results in full 4-quadrant

multiplying operation. The transfer function of this circuit

shows that both negative and positive output voltages are

created as the input data (D) is incremented from code

OUT

= - V

OUT

= + V

OUT

= (V

zero (V

scale (V

V

Where D is the fractional representation of the digital

word loaded to the DAC and n is the resolution of the

DAC.

D= 0 to 4095 (12-Bit AD5444)

= 0 to 16383 (14-Bit AD5446)

When V

is an ac signal, the circuit performs four-

IN

quadrant multiplication.

Table II. shows the relationship between digital code and

the expected output voltage for bipolar operation

(AD5444, 12-Bit device).

Digital Input Analog Output (V)

1111 1111 1111 +V

1000 0000 0000 0

0000 0000 0001 -V

0000 0000 0000 -V

Stability

In the I-to-V configuration, the I

inverting node of the op amp must be connected as close

as possible, and proper PCB layout techniques must be

employed. Since every code change corresponds to a step

function, gain peaking may occur if the op amp has

limited GBP and there is excessive parasitic capacitance at

the inverting node. This parasitic capacitance introduces a

pole into the open loop response which can cause ringing

or instability in the closed loop applications circuit.

) to midscale (V

REF

).

REF

x D / 2

REF

n-1

)

- VREF

- 0V ) to full

OUT

Table II. Bipolar Code Table

(2047/2048)

REF

(2047/2048)

REF

(0/2048)

REF

of the DAC and the

OUT

V

REF

± 10V

R3

20kΩ

R2

C1

RFB

IOUT1

GND

NOTES:

1

R1 AND R2 ARE USED ONLY IF GAIN ADJUSTMENT IS REQUIRED.

ADJUST R1 FOR V

2

MATCHING AND TRACKING IS ESSENTIAL FOR RESISTOR PAIRS

R3 AND R4.

3

C1 PHASE COMPENSATION (1pF-5pF) MAY BE REQUIRED

IF A1/A2 IS A HIGH SPEED AMPLIFIER.

A1

AGND

= 0V WITH CODE 10000000 LOADED TO DAC.

OUT

R4

10kΩ

R1

V

REF

SYNC

uController

V

DD

V

DD

AD5450/1/2/3

SCLK SDIN

Figure 4. Bipolar Operation (4 Quadrant Multiplication)

–11–REV. PrB

R5

20kΩ

A2

V

= -V

REF

to +V

REF

OUT

Page 12

PRELIMINARY TECHNICAL DA T A

AD5444/AD5446

An optional compensation capacitor, C1 can be added in

parallel with R

Too small a value of C1 can produce ringing at the

output, while too large a value can adversely affect the

settling time. C1 should be found empirically but 1-2pF is

generally adequate for the compensation.

SINGLE SUPPLY APPLICATIONS

Voltage Switching Mode of Operation

Figure 5 shows these DACs operating in the voltageswitching mode. The reference voltage, V

the I

OUT1

pin, I

output voltage is available at the V

configuration, a positive reference voltage results in a

positive output voltage making single supply operation

possible. The output from the DAC is voltage at a

constant impedance (the DAC ladder resistance). Thus an

op-amp is necessary to buffer the output voltage. The

reference input no longer sees a constant input impedance,

but one that varies with code. So, the voltage input should

be driven from a low impedance source.

V

IN

for stability as shown in figures 3 and 4.

FB

is applied to

is connected to AGND and the

OUT2

V

DD

RFB

V

DD

IOUT1

GND

NOTES:

1

ADDITIONAL PINS OMITTED FOR CLARITY

2

C1 PHASE COMPENSATION (1pF-5pF) MAY BE REQUIRED

IF A1 IS A HIGH SPEED AMPLIFIER.

V

REF

IN

terminal. In this

REF

R

R

1

2

V

OUT

V

= 5V

REF

DD

V

GND

C

RFB

DD

IOUT1

IOUT2

1

1/2 AD8552

V

OUT = 0 to +2.5V

ADR03

V

V

IN

OUT

GND

+

5V

-2.5V

V

1/2 AD8552

-

5V

NOTES:

1

ADDITIONAL PINS OMITTED FOR CLARITY

2

C1 PHASE COMPENSATION (1pF-5pF) MAY BE REQUIRED

IF A1 IS A HIGH SPEED AMPLIFIER.

Figure 6. Positive Voltage output with minimum of

components.

ADDING GAIN

In applications where the output voltage is required to be

greater than V

, gain can be added with an additional

IN

external amplifier or it can also be achieved in a single

stage. It is important to take into consideration the effect

of temperature coefficients of the thin film resistors of the

DAC. Simply placing a resistor in series with the RFB

resistor will causing mis-matches in the Temperature

coefficients resulting in larger gain temperature coefficient

errors. Instead, the circuit of Figure 7 is a recommended

method of increasing the gain of the circuit. R1, R2 and

R3 should all have similar temperature coefficients, but

they need not match the temperature coefficients of the

DAC. This approach is recommended in circuits where

gains of great than 1 are required.

Figure 5. Single Supply Voltage Switching Mode Operation.

It is important to note that VIN is limited to low voltages

because the switches in the DAC ladder no longer have

the same source-drain drive voltage. As a result their on

resistance differs and this degrades the integral linearity of

the DAC. Also, VIN must not go negative by more than

0.3V or an internal diode will turn on, exceeding the max

ratings of the device. In this type of application, the full

range of multiplying capability of the DAC is lost.

POSITIVE OUTPUT VOLTAGE

Note that the output voltage polarity is opposite to the

V

polarity for dc reference voltages. In order to achieve

REF

a positive voltage output, an applied negative reference to

the input of the DAC is preferred over the output

inversion through an inverting amplifier because of the

resistors tolerance errors. To generate a negative

reference, the reference can be level shifted by an op amp

such that the V

and GND pins of the reference

OUT

become the virtual ground and -2.5V respectively as

shown in Figure 6.

V

DD

C

R

2

V

IN

NOTES:

1

ADDITIONAL PINS OMITTED FOR CLARITY

2

C1 PHASE COMPENSATION (1pF-5pF) MAY BE REQUIRED

IF A1 IS A HIGH SPEED AMPLIFIER.

V

V

REF

GND

RFB

DD

IOUT1

IOUT2

1

V

OUT

R

3

GAIN = R2 + R3

R

2

R2

R1 = R2R3

R2 + R3

Figure 7. Increasing Gain of Current Output DAC

USED AS A DIVIDER OR PROGRAMMABLE GAIN

ELEMENT

Current Steering DACs are very flexible and lend

themselves to many different applications. If this type of

DAC is connected as the feedback element of an op-amp

and R

then the output voltage is inversely proportional to the

digital input fraction D. For D = 1-2

is used as the input resistor as shown in Figure 8,

FB

n

the output voltage

is

–12– REV. PrB

Page 13

PRELIMINARY TECHNICAL DA T A

AD5444/AD5446

V

OUT

= -V

IN

V

IN

/D = -V

IN

V

/(1-2-n)

DD

error source can be minimized. Table IV. suggests some

of the suitable dc references available from Analog

Devices that are suitable for use with this range of current

output DACs.

RFB

V

DD

V

IOUT1

GND

NOTES:

1

ADDITIONAL PINS OMITTED FOR CLARITY

REF

V

OUT

Figure 8. Current Steering DAC used as a divider or

Programmable Gain Element

As D is reduced, the output voltage increases. For small

values of the digital fraction D, it is important to ensure

that the arnplifier does not saturate and also that the

required accuracy is met. For example, an eight bit DAC

driven with the binary code 10H (00010000), i.e., 16

decimal, in the circuit of Figure 8 should cause the output

voltage to be sixteen times V

. However, if the DAC has

IN

a linearity specification of +/- 0.5LSB then D

can in fact have the weight anywhere in the range 15.5/256

to 16.5/256 so that the possible output voltage will be in

the range 15.5V

to 16.5VIN—an error of + 3% even

IN

though the DAC itself has a maximum error of 0.2%.

DAC leakage current is also a potential error source in

divider circuits. The leakage current must be

counterbalanced by an opposite current supplied from the

op amp through the DAC. Since only a fraction D of the

current into the V

terminal is routed to the I

REF

OUT1

ter-

minal, the output voltage has to change as follows:

Output Error Voltage Due to Dac Leakage

= (Leakage x R)/D

where R is the DAC resistance at the V

terminal. For a

REF

DAC leakage current of 10nA, R = 10 kilohm and a gain

(i.e., 1/D) of 16 the error voltage is 1.6mV.

AMPLIFIER SELECTION

The primary requirement for the current-steering mode is

an amplifier with low input bias currents and low input

offset voltage. The input offset voltage of an op amp is

multiplied by the variable gain (due to the code dependent

output resistance of the DAC) of the circuit. A change in

this noise gain between two adjacent digital fractions

produces a step change in the output voltage due to the

amplifier’s input offset voltage. This output voltage

change is superimposed upon the desired change in output

between the two codes and gives rise to a differential

linearity error, which if large enough could cause the

DAC to be non-monotonic.

The input bias curent of an op amp also generates an

offset at the voltage output as a result of the bias current

flowing in the feedback resistor R

. Most op amps have

FB

input bias currents low enough to prevent any significant

errors in 12-Bit applications, however for 14-Bit

applications some consideration should be given to

selecting an appropriate amplifier.

Common mode rejection of the op amp is important in

voltage switching circuits, since it produces a code

dependent error at the voltage output of the circuit. Most

op amps have adequate common mode rejection for use at

8-, 10- and 12-Bit resolution.

Provided the DAC switches are driven from true wideband

low impedance sources (V

and AGND) they settle

IN

quickly. Consequently, the slew rate and settling time of a

voltage switching DAC circuit is determined largely by

the output op amp. To obtain minimum settling time in

this configuration, it is important to minimize capacitance

at the V

node (voltage output node in this application)

REF

of the DAC. This is done by using low inputs capacitance

buffer amplifiers and careful board design.

Most single supply circuits include ground as part of the

analog signal range, which in turns requires an

ampliferthat can handle rail to rail signals, there is a large

range of single supply amplifiers available from Analog

Devices.

REFERENCE SELECTION

When selecting a reference for use with the AD5426 series

of current output DACs, pay attention to the references

output voltage temperature coefficient specification. This

parameter not only affects the full scale error, but can also

affect the linearity (INL and DNL) performance. The

reference temperature coefficient should be consistent with

the system accuracy specifications. For example, an 8-bit

system required to hold its overall specification to within

1LSB over the temperature range 0-50

maximum system drift with temperature should be less than

78ppm/

range to overall specification within 2LSBs requires a

maximum drift of 10ppm/

o

C. A 14-Bit system with the same temperature

o

C. By choosing a precision

o

C dictates that the

reference with low output temperature coefficient this

–13–REV. PrB

PCB LAYOUT AND POWER SUPPLY DECOUPLING

In any circuit where accuracy is important, careful

consideration of the power supply and ground return

layout helps to ensure the rated performance. The printed

circuit board on which the AD5426/AD5432/AD5443 is

mounted should be designed so that the analog and digital

sections are separated, and cofined to certain areas of the

board. If the DAC is in a system where multiple devices

require an AGND-to-DGND connection, the connection

should be made at one point only. The star ground point

should be established as close as possible to the device.

These DACs should have ample supply bypassing of 10

µF in parallel with 0.1 µF on the supply located as close

to the package as possible, ideally right up against the

device. The 0.1 µF capacitor should have low Effective

Page 14

PRELIMINARY TECHNICAL DA T A

AD5444/AD5446

Table IV. Listing of suitable ADI Precision References recommended for use with these DACs.

Reference Output Voltage Initial Tolerance Temperature Drift 0.1Hz to 10Hz noise Package

ADR01 10 V 0.1% 3ppm/oC20µVp-p SC70, TSOT, SOIC

ADR02 5 V 0.1% 3ppm/

ADR03 2.5 V 0.2% 3ppm/

ADR425 5 V 0.04% 3ppm/oC 3.4µVp-p MSOP, SOIC

Table V. Listing of some precision ADI Op Amps suitable for use with these DACs.

o

C10µVp-p SC70, TSOT, SOIC

o

C10µVp-p SC70, TSOT, SOIC

Part # Max Supply Voltage V VOS(max)

OP97

OP1177

±

20 25 0.1 0.9 0.2

±

18 60 2 1.3 0.7

µµ

µVIB(max) nA GBP MHz Slew Rate V/

µµ

µµ

µs

µµ

AD8551 ±6 5 0.05 1.5 0.4

Table VI. Listing of some High Speed ADI Op Amps suitable for use with these DACs.

Part # Max Supply Voltage V BW @ ACL MHz Slew Rate V/

µµ

µsVOS(max)

µµ

µµ

µVI

µµ

(max) nA

B

AD8065 ±12 145 180 1500 0.01

AD8021 ±12 200 100 1000 1000

AD8038 ±5 350 425 3000 0.75

AD9631 ±5 320 1300 10000 7000

Series Resistance (ESR) and Effective Series Inductance

(ESI), like the common ceramic types that provide a low

impedance path to ground at high frequencies, to handle

transient currents due to internal logic switching. Low

ESR 1 µF to 10 µF tantalum or electrolytic capacitors

should also be applied at the supplies to minimize

transient disturbance and filter out low frequency ripple.

Fast switching signals such as clocks should be shielded

with digital ground to avoid radiating noise to other parts

of the board, and should never be run near the reference

inputs.

Avoid crossover of digital and analog signals. Traces on

opposite sides of the board should run at right angles to

each other. This reduces the effects of feedthrough

through the board. A microstrip technique is by far the

best, but not always possible with a doublesided board. In

this technique, the component side of the board is

dedicated to ground plane while signal traces are placed

on the solder side.

It is good practice to employ compact, minimum lead

length PCB layout design. Leads to the input should be as

short as possible to minimize IR drops and stray

inductance.

The PCB metal traces between V

and RFB should also

REF

be matched to minimize gain error. To maximize on high

frequency performance, the I-to-V amplifier should be

located as close to the device as possible.

–14– REV. PrB

Page 15

PRELIMINARY TECHNICAL DA T A

Overview of AD54xx devices

AD5444/AD5446

Part # Resolution #DACs IN L t

AD5403182

±0.25

20ns Parallel CP-40 10 MHz BW, 17 ns CS Pulse Width, 4-

Interface Package Features

S

Quadrant Multiplying Resistors

AD5410181

±0.25

20ns Serial RU -16 10 MHz BW, 50 MHz Serial, 4- Quadrant

Multiplying Resistors

AD5413182

±0.25

20ns Serial RU -24 10 MHz BW, 50 MHz Serial, 4- Quadrant

Multiplying Resistors

AD5424 8 1

AD5425 8 1

AD5426 8 1

AD5428282

AD5429282

AD5450281

AD5404110 2

±0.25

±0.25

±0.25

±0.25

±0.25

±0.25

±0.5

60ns Parallel RU-16, CP-20 10 MHz BW, 17 ns CS Pulse Width

100ns Serial RM-10 Byte Load,10 MHz BW, 50 MHz Serial

100ns Serial RM-10 10 MHz BW, 50 MHz Serial

60ns Parallel RU-2 0 10 MHz BW, 17 ns CS Pulse Width

100ns Serial RU-10 10 MHz BW, 50 MHz Serial

100ns Serial RJ-8 10 MHz BW, 50 MHz Serial

25ns Parallel CP-40 10 MHz BW, 17 ns CS Pulse Width, 4-

Quadrant Multiplying Resistors

AD5411110 1

±0.5

25ns Serial RU -16 10 MHz BW, 50 MHz Serial, 4- Quadrant

Multiplying Resistors

AD5414110 2

±0.5

25ns Serial RU -24 10 MHz BW, 50 MHz Serial, 4- Quadrant

Multiplying Resistors

AD5432 10 1

AD5433 10 1

AD5439210 2

AD5440210 2

AD5451210 1

±0.5

±0.5

±0.5

±0.5

±0.25

110ns Serial RM-10 10 MHz BW, 50 MHz Serial

70ns Parallel RU-20, CP-20 10 MHz BW, 17 ns CS Pulse Width

110ns Serial RU-16 10 MHz BW, 50 MHz Serial

70ns Parallel RU-2 4 10 MHz BW, 17 ns CS Pulse Width

110ns Serial RJ-8 10 MHz BW, 50 MHz Serial

AD540521 2 2 ±1 120ns Parallel CP-40 10 MHz BW, 17 ns CS Pulse Width, 4-

Quadrant Multiplying Resistors

AD5412112 1

±1

160ns Serial RU-16 10 MHz BW, 50 MHz Serial, 4- Quadrant

Multiplying Resistors

AD5415212 2

±1

160ns Serial RU-24 10 MHz BW, 50 MHz Serial, 4- Quadrant

Multiplying Resistors

AD5443 12 1 ± 1 160ns Serial RM-10 10 MHz BW, 50 MHz Serial

AD5445 12 1 ± 1 120ns Parallel RU-20, CP-20 10 MHz BW, 17 ns CS Pulse Width

AD544721 2 2 ±1 120ns Parallel R U-2 4 10 MHz BW, 17 ns CS Pulse Width

AD544921 2 2 ±1 160ns Serial RU-16 10 MHz BW, 50 MHz Serial

AD5452212 1

AD5453214 1

1

Future parts, contact factory for availability

2

In development, contact factory for availability

±0.5

±2

160ns Serial RJ-8, RM-8 10 MHz BW, 50 MHz Serial

180ns Serial RJ-8, RM-8 10 MHz BW, 50 MHz Serial

0.122 (3.10)

0.114 (2.90)

0.006 (0.15)

0.002 (0.05)

SEATING

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8 Lead MSOP

(RM-8)

0.122 (3.10)

0.114 (2.90)

5

8

1

PIN 1

0.0256 (0.65) BSC

0.120 (3.05)

0.112 (2.84)

0.018 (0.46)

0.008 (0.20)

PLANE

0.199 (5.05)

0.187 (4.75)

4

0.043 (1.09)

0.037 (0.94)

0.011 (0.28)

0.003 (0.08)

–15–REV. PrB

0.120 (3.05)

0.112 (2.84)

33

27

0.028 (0.71)

0.016 (0.41)

Loading...

Loading...