Page 1

High Speed, High Current

DRIVER

1.0mA/K

AD53500

VCCV

CC

V

EE

V

EE

V

HDCPL

V

OUT

V

LDCPL

TV

CC

THERM

GNDGNDGNDGNDGND

V

H

DATA

DATA

INH

INH

V

L

39nF39nF

2V

a

FEATURES

–2 V to +6 V Output Range

2.5 ⍀ Output Resistance

2.5 ns Tr/Tf for a 3 V Step

300 MHz Toggle Rate

Can Drive 25 ⍀ Lines and Lower

Peak Dynamic Current Capability of 400 mA

Inhibit Leakage <1 A

On-Chip Temperature Sensor

APPLICATIONS

Automatic Test Equipment

Semiconductor Test Systems

Board Test Systems

Instrumentation and Characterization Equipment

Capability Pin Driver

AD53500

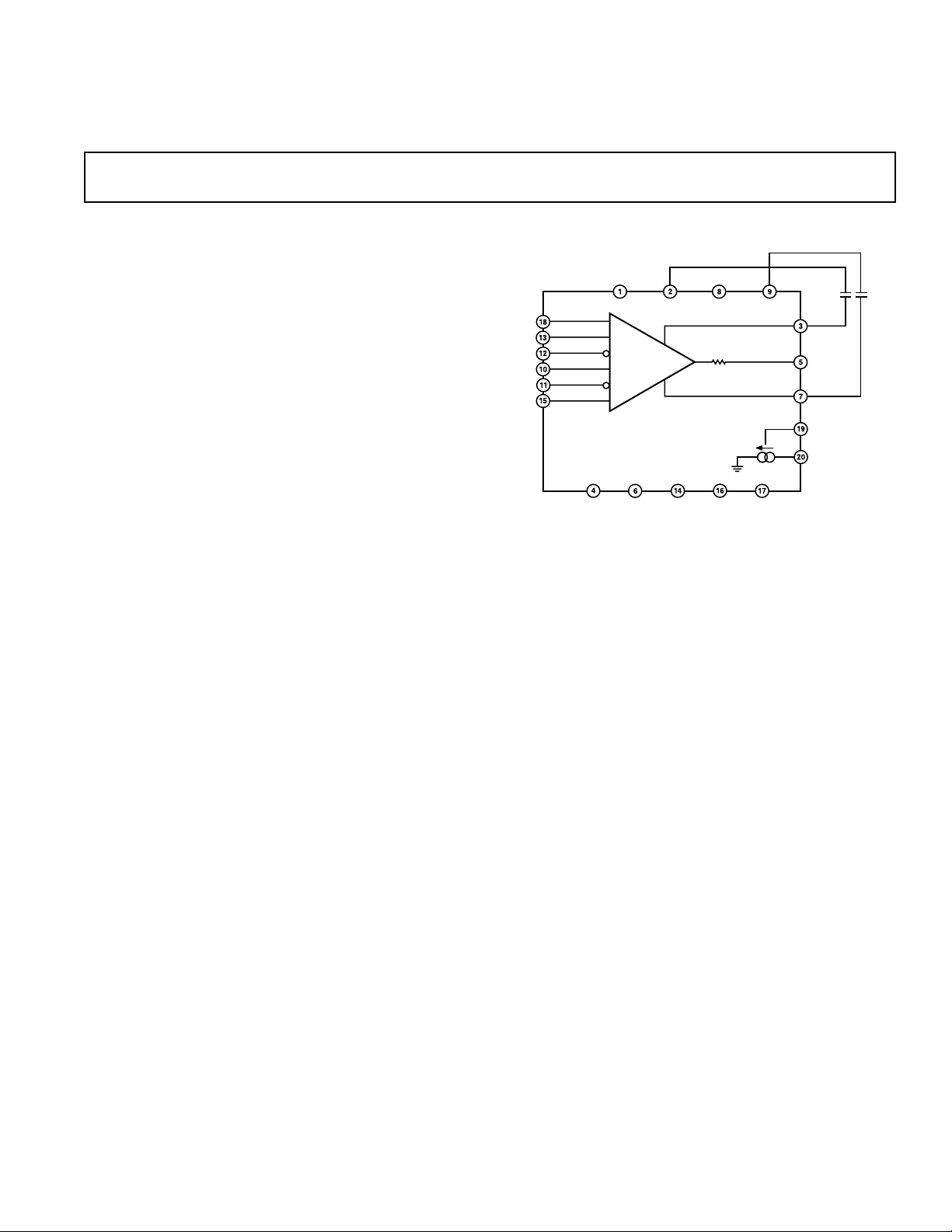

FUNCTIONAL BLOCK DIAGRAM

PRODUCT DESCRIPTION:

The AD53500 is a complete high speed driver designed for use

in digital or mixed signal test systems where high speed and high

output drive capabilities are needed. Combining a high speed

monolithic process and a unique surface mount package, this

product attains superb electrical performance while preserving

optimum packing densities and long-term reliability thanks to an

ultrasmall 20-lead, PSOP package with built-in heat sink.

High and low reference levels can be set within a –2 V to +6 V

range with low offset voltage and high gain accuracy. A 2.5 Ω

output resistance allows use of an external backmatch resistor for

application to 50 Ω, 25 Ω or other complex impedance load

requirements. Without a backmatch resistor it is also capable of

driving highly capacitive loads, typically achieving a rise/fall time

of less than 10 ns with a 1000 pF capacitance. To test I/O

devices, the pin driver can be switched into a high impedance

state (Inhibit Mode), electrically removing the driver from the

path. The pin driver leakage current in inhibit is typically less

than 1 µA and output capacitance is typically less than 18 pF.

Transitions from HI/LO or to inhibit are controlled through the

data and inhibit inputs. The input circuitry utilizes high-speed

differential inputs with a common-mode range of –2 V to +5 V.

This allows for direct interface to the precision of differential

ECL timing or the simplicity of stimulating the pin driver from a

single-ended CMOS or TTL logic source or any combination

over the common-mode range. The analog logic HI/LO inputs

are equally easy to interface, typically requiring 50 µA of bias

current.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

Page 2

AD53500–SPECIFICATIONS

(All specifications are at TJ = +85ⴗC ⴞ 5ⴗC, +VS = +10 V ⴞ 3%, –VS = +6 V ⴞ 3%

unless otherwise noted. All temperature coefficients are measured over TJ = 75ⴗC–95ⴗC). (In test figures, voltmeter loading is 1 M⍀ or greater,

scope probe loading is 100 k⍀ in parallel with 5 pF.) 39 nF capacitors must be connected between VCC and V

Parameter Min Typ Max Units Test Conditions

DIFFERENTIAL INPUT CHARACTERISTICS

(DATA to DATA, INH to INH)

Common-Mode Input Voltage –2 +5 Volts

Differential Input Range ECL or TTL ECL = –0.8 V/–1.8 V, TTL = 0 V/5 V

Bias Current ±100 µAV

REFERENCE INPUTS

Bias Currents –50 +50 µAV

OUTPUT CHARACTERISTICS

Logic High Range +1 +6 Volts DATA = H, V

Logic Low Range –2 +2 Volts DATA = L, V

Amplitude (V

, VL Interaction –10 +10 mV 100 mV Output Amplitude

V

H

and VL) 0.1 8 Volts VL = –0.05 V, VH = +0.05 V and

H

Absolute Accuracy

Offset –100 +100 mV DATA = H, VH = 0 V, VL = –2 V

V

H

Gain + Linearity Error ±0.3 ±5% of V

V

H

Offset –100 +100 mV DATA = L, VL = 0 V, VH = +6 V

V

L

Gain + Linearity Error ± 0.3 ±5% of V

V

L

Offset TC, V

or V

H

L

0.5 mV/°CV

+ mV DATA = H, VL = –2 V, VH = +1 V to +6 V

H

+ mV DATA = L, VL = –2 V to +2 V, VH = +6 V

L

Output Resistance 1.5 2.5 5.5 Ω V

Dynamic Current Limit 400 mA C

Static Current Limit 60 180 mA Output to –2 V, V

–180 –60 mA DATA = H and Output to +6 V, V

DYNAMIC PERFORMANCE, DRIVE

and VL)

(V

H

Propagation Delay Time 2.5 ns Measured at 50%, V

Propagation Delay TC 1 ps/°C Measured at 50%, V

Delay Matching, Edge-to-Edge 100 ps Measured at 50%, V

Rise and Fall Time

1 V Swing 0.85 ns Measured 20%–80%, V

3 V Swing 2.5 ns Measured 10%–90%, V

5 V Swing 4.0 ns Measured 10%–90%, V

Rise and Fall Time TC

1 V Swing ±1 ps/°C Measured 20%–80%, V

3 V Swing ±2 ps/°C Measured 10%–90%, V

5 V Swing ±3 ps/°C Measured 10%–90%, V

Overshoot, Undershoot and Preshoot +5.0 +30 % of Step + mV V

Settling Time

to 15 mV 40 ns V

to 4 mV 8 µsV

Delay Change vs. Pulsewidth 100 ps V

Minimum Pulsewidth

3 V Swing 3.8 ns V

5 V Swing 5.5 ns V

Toggle Rate 300 MHz VL = –1.8 V, VH = –0.8 V, V

= –2 V, +5 V

CM

, VH = 5 V

L

= –2 V, VH = +6 V

V

L

, VH = 0 V, +5 V and –2 V, 0 V

L

= +3 V, VL = 0 V, I

H

+30 mA

= 39 nF, VH = +5 V, VL = 0 V

BYP

C

LOAD

VL = –2 V, DATA = L

= –400 mV

V

L

= –400 mV

V

L

= –400 mV

V

L

H–VL

= 0 V, VH = 0.5 V

L

= 0 V, VH = 0.5 V

L

= 0 V, VH = 2 V, Pulsewidth = 2.5 ns/

L

Period = 10 ns and Pulsewidth = 30 ns/

Period = 120 ns

= 0 V, VH = 3 V, Output = 2.7 V p-p,

L

Measure at 50%

= 0 V, VH = 5 V, Output = 4.5 V p-p,

L

Measure at 50%

and between VEE and V

HDCPL

= –2 V, VH = +1 V to +6 V

L

= –2 V to +2 V, VH = +6 V

L

= 0, –30 mA,

OUT

= 1000 pF, Tr/Tf = 10 ns

= +6 V, VL = –1 V,

H

= +400 mV,

H

= +400 mV,

H

= +400 mV,

H

= 0 V, VH = 1 V

L

= 0 V, VH = 3 V

L

= 2 V, VH = 3 V

L

= 0 V, VH = 1 V

L

= 0 V, VH = 3 V

L

= 0 V, VH = 5 V

L

= 0.5 V, 1 V, 3 V, 8 V

> 600 mV p-p

OUT

LDCPL

= +6 V,

H

.

–2–

REV. 0

Page 3

Parameter Min Typ Max Units Test Conditions

WARNING!

ESD SENSITIVE DEVICE

DYNAMIC PERFORMANCE, INHIBIT

Delay Time, Active to Inhibit 2 10 ns Measured at 50%, V

= –2 V, 50 Ω Terminated to Ground

V

L

Delay Time, Inhibit to Active 2 10 ns Measured at 50%, V

= –2 V, 50 Ω Terminated to Ground

V

L

I/O Spike <200 mV, p-p V

Output Leakage –1.0 +1.0 µAV

= 0 V, VL = 0 V

H

= –2 V to +6 V

OUT

Output Capacitance 18 pF Driver Inhibited

PSRR, Drive Mode 35 dB VS = V

± 3%

S

POWER SUPPLIES

Total Supply Range 16 V

Positive Supply +10 V

Negative Supply –6 V

Positive Supply Current 85 95 mA

Negative Supply Current 88 98 mA

Total Power Dissipation 1.37 1.54 W

Temperature Sensor Gain Factor 1.0 µA/K R

NOTES

Connecting or shorting the decoupling capacitors to ground will result in the destruction of the device.

Specifications subject to change without notice.

= 10 kΩ, V

LOAD

= +2 V,

H

= +2 V,

H

SOURCE

AD53500

= +10 V

ABSOLUTE MAXIMUM RATINGS

1

Power Supply Voltage

to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +11 V

+V

S

to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –7 V

–V

S

to –VS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +18 V

+V

S

Inputs

DATA, DATA, INH, INH . . . . . . . . . . . . . . . . +5 V, –3 V

DATA to DATA, INH to INH . . . . . . . . . . . . . . . . ±3 V

, VL to GND . . . . . . . . . . . . . . . . . . . . . . . . . +7 V, –3 V

V

H

to VL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +10 V, 0 V

V

H

Outputs

Short Circuit Duration to Ground . . . . . . . Indefinite

V

OUT

V

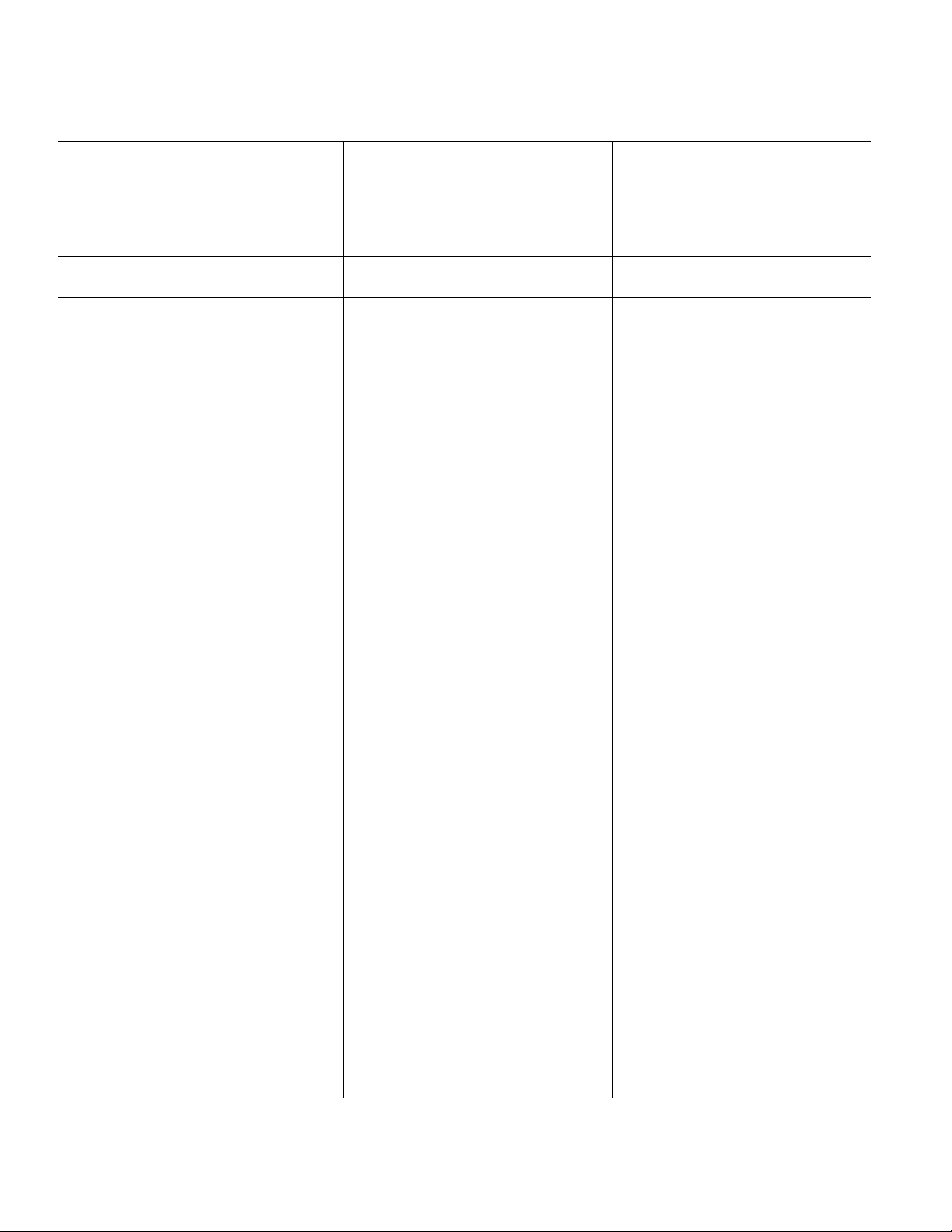

Range in Inhibit Mode . . . . . . . . . . . . . See Figure 1

OUT

V

V

. . . . . . . . Do Not Connect Except for Cap to V

HDCPL

. . . . . . . . . Do Not Connect Except for Cap to V

LDCPL

CC

EE

2

3

3

THERM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +VS, 0 V

Environmental

Operating Temperature (Junction) . . . . . . . . . . . . . .+175°C

Storage Temperature . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 sec)

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

sections of this specification is not implied. Absolute maximum limits apply

individually, not in combination. Exposure to absolute maximum rating conditions

for extended periods may affect device reliability.

2

Output short circuit protection is guaranteed as long as proper heat sinking is

employed to ensure compliance with the operating temperature limits.

3

The V

dc-current drive capability.

4

To ensure lead coplanarity (±0.002 inches) and solderability, handling with bare

hands should be avoided and the device should be stored in environments at 24°C

± 5°C (75°F ± 10°F) with relative humidity not to exceed 65%.

HDCPL

and V

capacitors may be replaced by a low value resistor for higher

LDCPL

4

. . . . . . . . . . +260°C

V

OUT

V

= (MAX) = +7V

OUT

7

6

5

4

3

2

1

, V

V

H

–2

V

= (MIN) = –3V

OUT

FIGURE 1 SHOWS THE MAXIMUM ALLOWABLE LIMITS FOR V

OF V

AND V

HIGH

LIMITS, AS STATED BEFORE, ARE MAXIMUM RATINGS ONLY, AND SHOULD NOT

BE USED AS THE PART'S NORMAL OPERATING RANGE. THIS RANGE APPLIES

ONLY TO SUPPLIES OF +VS = +10V AND –VS = –6V AND SHOULD BE DERATED

PROPORTIONALLY FOR LOWER SUPPLIES.

WHEN THE DRIVER IS OPERATING IN INHIBIT MODE. THE

LOW

2345

–1

–2

–3

V

HIGH

/ V

6

OUT

LOW

1

–1

Figure 1. Absolute Maximum Ratings for V

L

AS A FUNCTION

OUT

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD53500 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. 0

–3–

Page 4

AD53500

PIN CONFIGURATION

Table I. Pin Driver Truth Table

Output

V

HDCPL

V

LDCPL

V

V

GND

V

OUT

GND

V

V

INH

CC

CC

EE

EE

10

1

2

3

4

5

AD53500

TOP VIEW

6

(Not to Scale)

7

8

9

20

19

18

17

16

15

14

13

12

11

THERM

TV

CC

V

H

GND

GND

V

L

GND

DATA

DATA

INH

DATA DATA INH INH State

0101V

1001V

L

H

0110Hi-Z

1010Hi-Z

Table II. Package Thermal Characteristics

Air Flow, FM JC, ⴗC/W JA, ⴗC/W

50 3.28 49.1

400 3.91 33.74

PIN FUNCTION DESCRIPTIONS

Pin Name Pin Number Description

V

CC

1, 2 Positive Power Supply. Both pins should be connected to minimize inductance and allow

maximum speed of operation. V

should be decoupled to GND with a low inductance

CC

0.1 µF capacitor.

V

EE

8, 9 Negative Power Supply. Both pins should be connected to keep the inductance down and

allow maximum speed of operation. V

should be decoupled to GND with a low inductance

EE

0.1 µF capacitor.

GND 4, 6, 14, 16, 17 Device Ground. These pins should be connected to the circuit board’s ground plane at the

pins.

V

L

15 Analog input that sets the voltage level of a Logic 0 of the driver. Determines the driver out-

put for DATA > DATA.

V

H

18 Analog input that sets the voltage level of a Logic 1 of the driver. Determines the driver out-

put for DATA > DATA.

V

OUT

V

HDCPL

5 The Driver Output.

3 Internal supply decoupling for the output stage. This pin is connected to VCC through a

39 nF (minimum) capacitor.

V

LDCPL

7 Internal supply decoupling for the output stage. This pin is connected to VEE through a

39 nF (minimum) capacitor.

INH, INH 10, 11 Differential inputs that control the high impedance state of the driver. When INH > INH, the

driver goes into a high impedance state.

DATA, DATA 13, 12 Differential inputs that determine the high and low state of the driver. Driver output is high

for DATA > DATA.

TV

CC

19 Temperature Sensor Startup Pin. This pin should be connected to VCC.

THERM 20 Temperature sensor output pin. A resistor (10 kΩ) should be connected between THERM

and V

. The approximate die temperature can be determined by measuring the current

CC

through the resistor. The typical scale factor is 1 µA/K.

ORDERING GUIDE

Shipment Method,

Package Quantity Per Package

Model Description Shipping Container Option

AD53500JRP 20-Lead Power SOIC Tube, 38 Pieces RP-20

–4–

REV. 0

Page 5

AD53500

RISING-EDGE SLEW

CONTROL CURRENT

5V

V+

V

HDCPL

LEVEL-SHIFTED

LOGIC DRIVE

V

H

V–

Q49

OUT

Q50

Q48

APPLICATION INFORMATION

Power Supply Distribution, Bypassing and Sequencing

The AD53500 draws substantial transient currents from its

power supplies when switching between states and careful design of the power distribution and bypassing is key to obtaining

specified performance. Supplies should be distributed using

broad, low inductance traces or (preferably) planes in a multilayered board with a dedicated ground-plane layer. All of the

device’s power supply pins should be used to minimize the internal inductance presented by the part’s bond wires. Each supply

must be bypassed to ground with at least one 0.1 µF capacitor;

chip-style capacitors are preferable as they minimize inductance.

One or more 10 µF (or greater) Tantalum capacitors per board

are also advisable to provide additional local energy storage.

The AD53500’s current-limit circuitry also requires external

bypass capacitors. Figure 2 shows a simplified schematic of the

positive current-limit circuit. Excessive collector current in

output transistor Q49 creates a voltage drop across the 5 Ω

resistor, which turns on PNP transistor Q48. Q48 diverts the

rising-edge slew current, shutting down the current mirror and

removing the output stage’s base drive. The V

HDCPL

pin should

be bypassed to the positive supply with a 0.039 µF capacitor,

while the V

pin (not shown) requires a similar capacitor to

LDCPL

the negative supply. These capacitors ensure that the AD53500

does not current-limit during normal output transitions up its

full 8 V rated step size. Both capacitors must have minimumlength connections to the AD53500. Here again, chip capacitors

are ideal.

Several points about the current-limit circuitry should be noted.

First, the limiting currents are not tightly controlled, as they are

functions of both absolute transistor V

and junction tempera-

BE

ture; higher dc output current is available at lower junction

temperatures. Second, it is essential to connect the V

HDCPL

capacitor to the positive supply (and the V

capacitor to the

LDCPL

negative supply)—failure to do so causes considerable thermal

stress in the current-limiting resistor(s) during normal supply

sequencing and may ultimately cause them to fail, rendering the

part nonfunctional. Finally, the AD53500 may appear to function normally for small output steps (less than 3 V or so) if one

or both of these caps is absent, but it may exhibit excessive rise

or fall times for steps of larger amplitude.

The AD53500 does not require special power-supply sequencing. However, good design practice dictates that digital and

analog control signals not be applied to the part before the supplies are stable. Violating this guideline will not normally destroy the part, but the active inputs can draw considerable

current until the main supplies are applied.

Figure 2. Simplified Schematic of the AD53500 Output

Stage and Positive Current-Limit Circuitry

REV. 0

–5–

Page 6

AD53500

J7

SIDE SMA

R8

47V

50V

V

OUT

C20

1000pF

C3

C17

C16

0.039mF

3

4

5

6

7

C19

S

+V

0.1mF

IL+

OUT

V

0.039mF

IL–

U3

AD53500

H

L

THV

19 17 1 2

C2

0.1mF

H

V

L

V

C1

0.1mF

50V

SMA

J4

THERM

50V

SMA

J3

C14

0.1mF

R3

50V

V

13*1210*

18

15

20

50V

SMA

J5

DATA

INH

16 14 9 8

11

50V

SMA

J6

C15

0.1mF

R2

50V

0.1mF

S

–V

–5.2V

EE

V

GND

CC

V

C11

0.1mF

C10

0.1mF

C9

0.1mF

VL–2V

VH–VSTHERM

LINE.

OUT

TO BE MOUNTED ON ITS SIDE FOR BEST IMPEDANCE

OUT

NOTES:

1. 50V TERMINATION TO BE AS CLOSE TO RECEIVER AS POSSIBLE.

(END OF TRACE MARKED BY *). THROUGH SMA CONNECTS BETWEEN

MC10EL16 OUTPUTS AND DUT.

2. NO VIAS ALLOWED ON V

3. SMA ON V

MATCH.

4. ONE DIMENSION OF BOARD TO BE 4 1/2 INCHES.

5. DUT PACKAGE IS TO BE CENTERED ON BOARD.

6. ALL RESISTORS AND NONELECTROLYTIC CAPS ARE 0805-SIZE

SURFACE MOUNT.

7. SEE DATA FOR HIDDEN POWER AND GROUND PINS ON LOGIC GATES.

8. ALL 100nF BYPASS CAPACITORS TO BE LOCATED CLOSE TO PACKAGE.

9. PCB IS TO BE FOUR-LAYER WITH POWER GND ( ) AND –2V AS INNER

PLANES.

S

–5.2V

+V

C8

0.1mF

C5

1mF

C6

1mF

7

U1

MC10EL16

98

2

50V

J1

SMA

R6

DATA

C7

R1

–5.2V

45

50V

C22

C13

S

GND

1

TP

JP1

–2V

0.1mF

0.01mF

JP2

S

–V

+V

1

1

TP

TP

JP3

192103114125136147158

P1

R4

50V

–5.2V

6

45

3

50V

C21

C12

–2V

0.1mF

0.01mF

7

U2

MC10EL16

98

2

50V

J2

SMA

INH

6

3

R5

50V

1mF

C4

1mF

DB15

Figure 3. Evaluation Board Schematic

–6–

REV. 0

Page 7

OUTLINE DIMENSIONS

SEATING

PLANE

0.0118 (0.30)

0.0040 (0.10)

0.0201 (0.51)

0.0130 (0.33)

0.1043 (2.65)

0.0926 (2.35)

0.0500

(1.27)

BSC

STANDOFF

0.0500 (1.27)

0.0057 (0.40)

88

08

0.0295 (0.75)

0.0098 (0.25)

3 458

0.5118 (13.00)

0.4961 (12.60)

0.4193 (10.65)

0.3937 (10.00)

0.2992 (7.60)

0.2914 (7.40)

PIN 1

0.3340 (8.61)

0.3287 (8.35)

0.1890 (4.80)

0.1791 (4.55)

20

1

11

10

HEAT

SINK

Dimensions shown in inches and (mm).

20-Lead Thermally Enhanced Small Outline Package (PSOP)

(RP-20)

AD53500

C3527–2–4/99

REV. 0

PRINTED IN U.S.A.

–7–

Loading...

Loading...