Page 1

Quad, 15 V, 256-Position, Digital

Potentiometer with Pin Selectable SPI/I

FEATURES

256-position, 4-channel

End-to-end resistance 20 kΩ, 50 kΩ, 200 kΩ

Pin selectable SPI® or I

Power-on preset to midscale

Two package address decode pins AD0 and AD1

Rheostat mode temperature coefficient 30 ppm/°C

Voltage divider temperature coefficient 5 ppm/°C

Wide operating temperature range –40°C to +125°C

5 V to 15 V single supply; ±5 V dual supply

APPLICATIONS

Mechanical potentiometer replacement

Optical network adjustment

Instrumentation: gain, offset adjustment

Stereo channel audio level control

Automotive electronics adjustment

Programmable power supply

Programmable filters, delays, time constants

Line impedance matching

Low resolution DAC/trimmer replacement

Base station power amp biasing

Sensor calibration

GENERAL DESCRIPTION

The AD5263 is the industry’s first quad-channel, 256-position,

digital potentiometer

device performs the same electronic adjustment function as

mechanical potentiometers or variable resistors, with enhanced

resolution, solid-state reliability, and superior low temperature

coefficient performance.

Each channel of the AD5263 offers a completely programmable

value of resistance between the A terminal and the wiper, or

between the B terminal and the wiper. The fixed A-to-B

terminal resistance of 20 kΩ, 50 kΩ, or 200 kΩ has a nominal

temperature coefficient of ±30 ppm/°C and a ±1% channel-to-

2

C® compatible interface

1

with a selectable digital interface. This

2

AD5263

channel matching tolerance. Another key feature of this part is

the ability to operate from +4.5 V to +15 V, or at ±5 V.

Wiper position programming presets to midscale upon poweron. Once powered, the VR wiper position is programmed by

either the 3-wire SPI or 2-wire I

2

I

C mode, additional programmable logic outputs enable users

to drive digital loads, logic gates, and analog switches in their

systems.

The AD5263 is available in a narrow body TSSOP-24. All parts

are guaranteed to operate over the automotive temperature

range of –40°C to +125°C.

For single- or dual-channel applications, refer to the

AD5260/AD5280 or AD5262/AD5282.

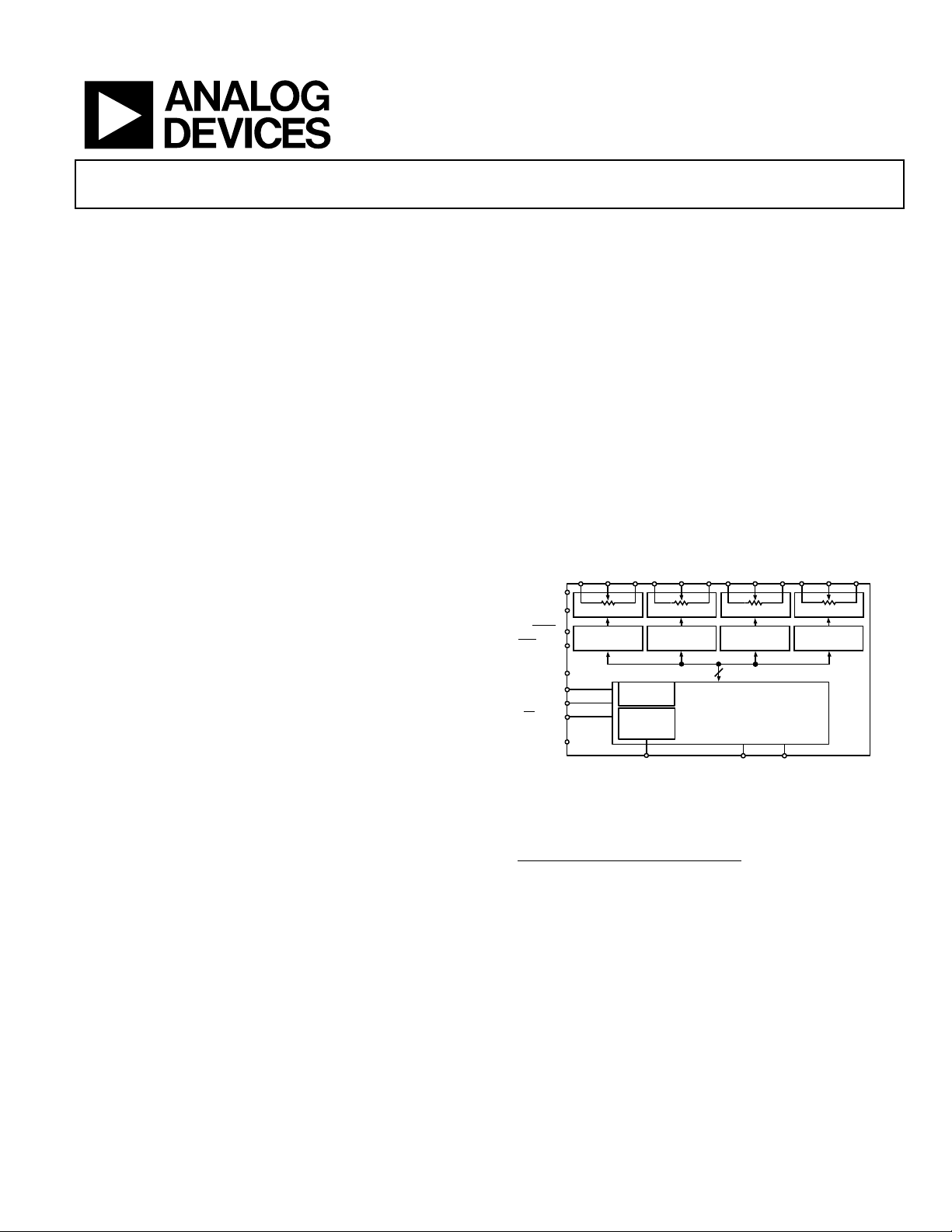

FUNCTIONAL BLOCK DIAGRAM

A1

V

DD

V

SS

SHDN

RES/AD1

V

L

CLK/SCL

SDI/SDA

CS/AD0

GND

1

The terms digital potentiometer, VR, and RDAC are used interchangeably.

Purchase of licensed I2C components of Analog Devices or one of its sublicensed

Associated Companies conveys a license for the purchaser under the Philips I

Patent Rights to use these components in an I

conforms to the I

W1 B1 A2

RDAC 1

REGISTER

2

C Standard Specification as defined by Philips.

REGISTER

ADDRESS

DECODER

2

SPI/I

C

SELECT

LOGIC

DIS

2

C compatible interface. In the

W2 B2

RDAC 2

SERIAL INPUT

Figure 1.

REGISTER

A3

RDAC 3

REGISTER

8

NC/O2

W3

B3 A4

SDO/O1

2

C system, provided that the system

W4 B4

RDAC 4

REGISTER

AD5263

2

C

C

03142-0-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.326.8703 © 2003 Analog Devices, Inc. All rights reserved.

Page 2

AD5263

TABLE OF CONTENTS

Electrical Characteristics—20 kΩ, 50 kΩ, 200 kΩ Versions ....... 3

Applications..................................................................................... 20

Timing Characteristics—20 kΩ, 50 kΩ, 200 kΩ Versions........... 4

Absolute Maximum Ratings............................................................ 5

Typical Performance Characteristics ............................................. 6

Test Circuits..................................................................................... 11

SPI Compatible Digital Interface (DIS = 0)................................ 12

I2C Compatible Digital Interface (DIS = 1).................................13

Operation......................................................................................... 14

Programming the Variable Resistor .........................................14

Programming the Potentiometer Divider ............................... 15

Pin Selectable Digital Interface................................................. 15

SPI Compatible 3-Wire Serial Bus (DIS = 0).......................... 15

I2C Compatible 2-Wire Serial Bus (DIS = 1) .......................... 16

Additional Programmable Logic Output ................................17

Self-Contained Shutdown Function ........................................ 17

Multiple Devices on One Bus ...................................................17

Level Shift for Negative Voltage Operation............................. 17

ESD Protection ........................................................................... 18

Terminal Voltage Operating Range.......................................... 18

Power-Up Sequence ................................................................... 18

V

Power Supply ................................................................... 18

LOGIC

Layout and Power Supply Bypassing ....................................... 18

Bipolar DC or AC Operation from Dual Supplies................. 20

Gain Control Compensation.................................................... 20

Programmable Voltage Reference ............................................ 20

8-Bit Bipolar DAC ...................................................................... 21

Bipolar Programmable Gain Amplifier................................... 21

Programmable Voltage Source with Boosted Output............ 21

Programmable 4–20 mA Current Source ............................... 22

Programmable Bidirectional Current Source......................... 22

Programmable Low-Pass Filter ................................................ 23

Programmable Oscillator.......................................................... 23

Resistance Scaling ...................................................................... 24

Resistance Tolerance, Drift, and Temperature Coefficient

Mismatch Considerations

Pin Configuration and Pin Function Descriptions.................... 25

Pin Configuration ...................................................................... 25

Pin Function Descriptions........................................................ 25

Outline Dimensions....................................................................... 26

ESD Caution................................................................................ 26

Ordering Guide............................................................................... 26

......................................................... 24

RDAC Circuit Simulation Model ............................................. 19

REVISION HISTORY

Revision 0: Initial Version

Rev. 0 | Page 2 of 28

Page 3

AD5263

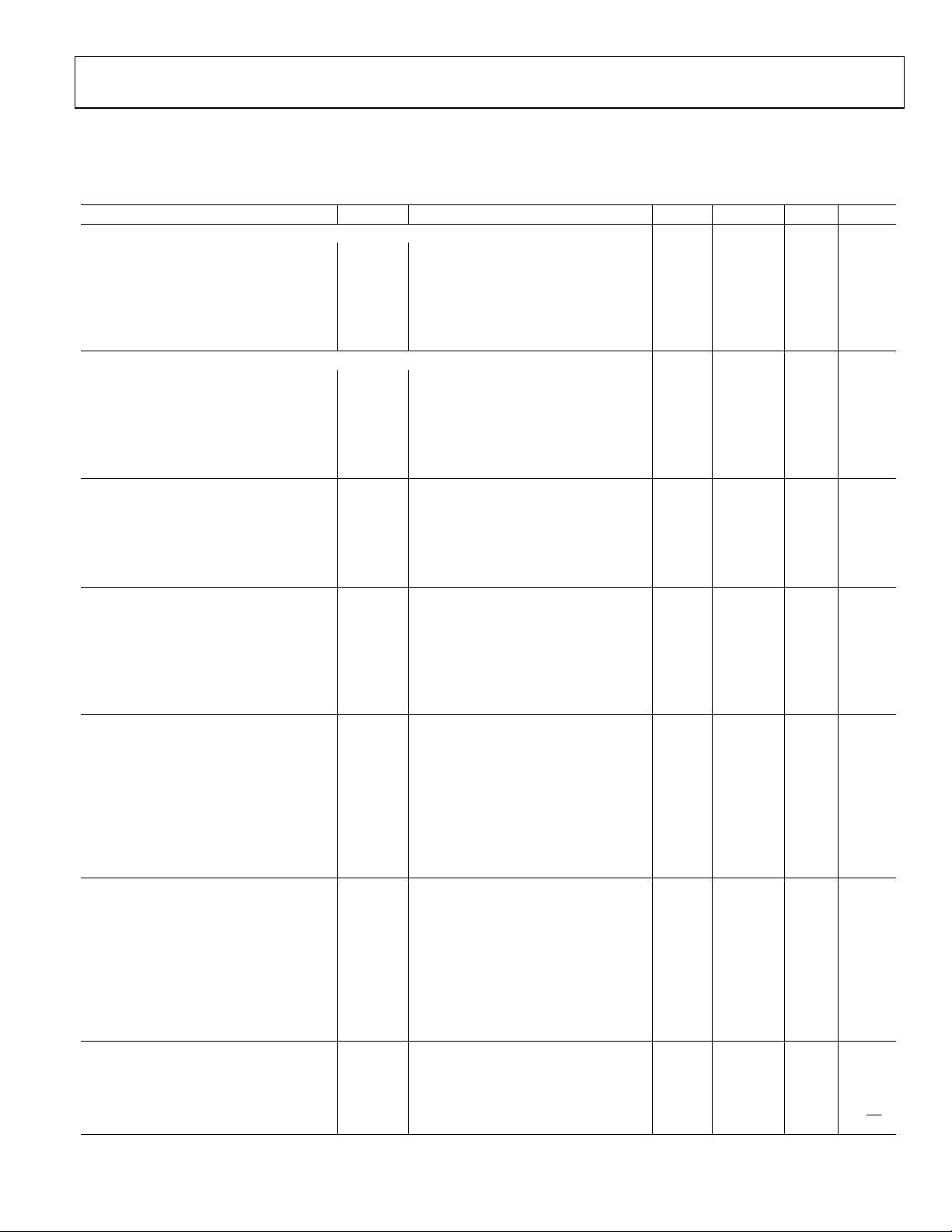

ELECTRICAL CHARACTERISTICS—20 kΩ, 50 kΩ, 200 kΩ VERSIONS

(VDD = +5 V, VSS = –5 V, VL = +5 V, VA = +VDD, VB = 0 V, –40°C < TA < +125°C, unless otherwise noted.)

Table 1.

Parameter Symbol Conditions Min Typ1 Max Unit

DC CHARACTERISTICS—RHEOSTAT MODE (Specifications apply to all VRs.)

Resistor Differential NL2 R-DNL RWB, VA=NC –1 ±1/4 +1 LSB

Resistor Nonlinearity2 R-INL RWB, VA=NC –1 ±1/2 +1 LSB

Nominal Resistor Tolerance3 ∆RAB T

∆RWB/∆T 30 ppm/°C Resistance Mode Temperature

Coefficient

∆RWA/∆T 30 ppm/°C

Wiper Resistance RW I

DC CHARACTERISTICS—POTENTIOMETER DIVIDER MODE (Specifications apply to all VRs.)

Resolution N 8 Bits

Differential Nonlinearity4 DNL –1 ±1/4 +1 LSB

Integral Nonlinearity4 INL –1 ±1/2 +1 LSB

Voltage Divider Temperature Coefficient ∆VW/∆T Code = 0x80 5 ppm/°C

Full-Scale Error V

Zero-Scale Error V

Code = 0xFF –2 –1 +0 LSB

WFSE

Code = 0x00 0 +1 +2 LSB

WZSE

RESISTOR TERMINALS

Voltage Range5 V

Capacitance6 Ax, Bx C

V

A,B,W

f = 1 MHz, measured to GND, Code = 0x80 25 pF

A,B

Capacitance6 Wx CW f = 1 MHz, measured to GND, Code = 0x80 55 pF

Common-Mode Leakage ICM V

Shutdown Current

7

I

0.02 5 µA

SHDN

DIGITAL INPUTS

Input Logic High VIH 2.4 V

Input Logic Low VIL 0.8 V

Input Logic High (SDA and SCL) VIH V

Input Logic Low (SDA and SCL) VIL V

Input Current IIL V

Input Capacitance6 C

5 pF

IL

DIGITAL OUTPUTS

SDA VOL I

VOL I

O1, O2 VOH I

O1, O2 VOL I

SDO VOH R

SDO VOL I

Three-State Leakage Current IOZ V

Output Capacitance6 C

3 8 pF

OZ

POWER SUPPLIES

Logic Supply

Power Single-Supply Range V

Power Dual-Supply Range V

Logic Supply Current

8

9

VL 2.7 5.5 V

DD RANGE

DD/SS RANGE

I

L

Positive Supply Current IDD V

Negative Supply Current ISS V

Power Dissipation10 P

V

DISS

Power Supply Sensitivity PSS ∆VDD = +5 V ± 10% 0.002 0.01 %/%

DYNAMIC CHARACTERISTICS

6, 11

Bandwidth (3 dB) BW RAB = 20 kΩ/50 kΩ/200 kΩ 300/150/35 kHz

Total Harmonic Distortion THDW V

VW Settling Time

Resistor Noise Voltage e

12

tS V

RWB = 10 kΩ, f = 1 kHz, RS = 0 9

N_WB

= 25°C –30 30 %

A

= 1 V/RAB 60 150 Ω

W

V

SS

= VB = VDD/2 1 nA

A

= 0 V 0.7 × VL VL + 0.5 V

SS

= 0 V –0.5 0.3 × VL V

SS

= 0 V or +5 V ±1 µA

IN

= 3 mA 0.4 V

SINK

= 6 mA 0.6 V

SINK

= 40 µA 4 V

SOURCE

= 1.6 mA 0.4 V

SINK

= 2.2 kΩ to VDD V

L

= 3 mA 0.4 V

SINK

= 0 V or +5 V ±1 µA

IN

– 0.1 V

DD

V

DD

VSS = 0 V VL 16.5 V

±4.5 ±7.5 V

V

= +5 V 25 60 µA

L

= +5 V or VIL = 0 V 1 µA

IH

= –5 V 1 µA

SS

= +5 V or VIL = 0 V, VDD = +5 V, VSS = –5 V 0.6 mW

IH

= 1 V rms, VB = 0 V, f = 1 kHz, RAB = 20 kΩ 0.05 %

A

= 10 V, VB = 0 V, ±1 LSB error band 2 µs

A

Hz

nV/√

Rev. 0 | Page 3 of 28

Page 4

AD5263

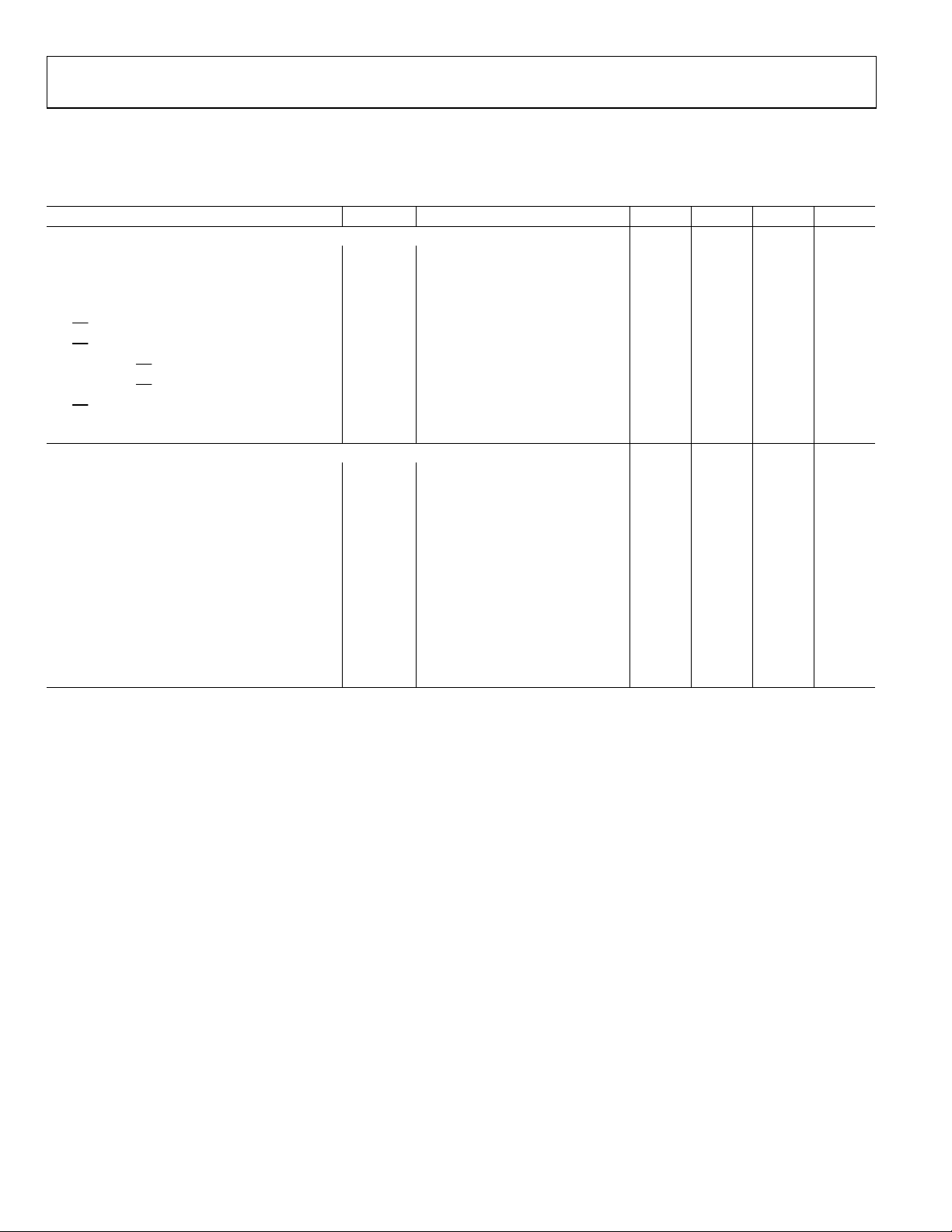

TIMING CHARACTERISTICS—20 kΩ, 50 kΩ, 200 kΩ VERSIONS

(V

= +5 V, V

DD

Table 2.

Parameter Symbol Conditions Min Typ1 Max Unit

SPI INTERFACE TIMING CHARACTERISTICS (Specifications Apply to All Parts

Clock Frequency f

Input Clock Pulsewidth tCH,tCL Clock level high or low 20 ns

Data Setup Time tDS 10 ns

Data Hold Time tDH 10 ns

CS Setup Time

CS High Pulsewidth

CLK Fall to CS Fall Hold Time

CLK Fall to CS Rise Hold Time

CS Rise to Clock Rise Setup

Reset Pulsewidth t

I2C INTERFACE TIMING CHARACTERISTICS (Specifications Apply to All Parts

SCL Clock Frequency f

t

Bus Free Time between STOP and START t1 1.3 µs

BUF

t

t

t

t

t

t

Hold Time (Repeated START) t2

HD;STA

Low Period of SCL Clock t3 1.3 µs

LOW

High Period of SCL Clock t4 0.6 50 µs

HIGH

Setup Time for START Condition t5 0.6 µs

SU;STA

HD;DAT

Data Setup Time t7 100 ns

SU;DAT

tF Fall Time of both SDA and SCL Signals t8 300 ns

tR Rise Time of Both SDA and SCL Signals t9 300 ns

t

NOTES

1

2

3

4

5

6

7

8

9

10

11

12

13

Setup Time for STOP Condition t10 0.6 µs

SU;STO

Typicals represent average readings at 25°C and VDD = +5 V, VSS = –5 V.

Resistor position nonlinearity error (R-INL) is the deviation from an ideal value measured between the maximum resistance and the minimum resistance wiper

positions. R-DNL measures the relative step change from ideal between successive tap positions. Parts are guaranteed monotonic. IW = VDD/R for both VDD = +5 V and

VSS = –5 V.

VAB = VDD, Wiper (VW) = no connect.

INL and DNL are measured at VW with the RDAC configured as a potentiometer divider similar to a voltage output D/A converter. VA = VDD and VB = 0 V.

DNL specification limits of ±1 LSB maximum are guaranteed monotonic operating conditions.

Resistor Terminals A, B, and W have no limitations on polarity with respect to each other.

Guaranteed by design and not subject to production test.

Measured at the Ax terminals. All Ax terminals are open circuited in shutdown mode.

VL is limited to VDD or 5.5 V, whichever is less.

Worst-case supply current consumed when all logic-input levels set at 2.4 V, standard characteristic of CMOS logic.

P

is calculated from (IDD × VDD). CMOS logic level inputs result in minimum power dissipation.

DISS

All dynamic characteristics use VDD = +5 V, VSS = –5 V, VL = +5 V.

Settling time depends on value of VDD, RL, and CL.

See timing diagrams for location of measured values. All input control voltages are specified with tR = tF = 2 ns (10% to 90% of +3 V) and timed from a voltage level

of 1.5 V. Switching characteristics are measured using V

= –5 V, VL = +5 V, VA = +VDD, VB = 0 V, –40°C < TA < +125°C unless otherwise noted.)

SS

6, 13

)

25 MHz

CLK

15 ns

t

CSS

t

20 ns

CSW

t

0 ns

CSH0

t

0 ns

CSH1

10 ns

t

CS1

RS

400 kHz

SCL

6, 13

)

After this period, the first clock

5 ns

0.6 µs

pulse is generated.

Data Hold Time t6 0.9 µs

= +5 V.

L

Rev. 0 | Page 4 of 28

Page 5

AD5263

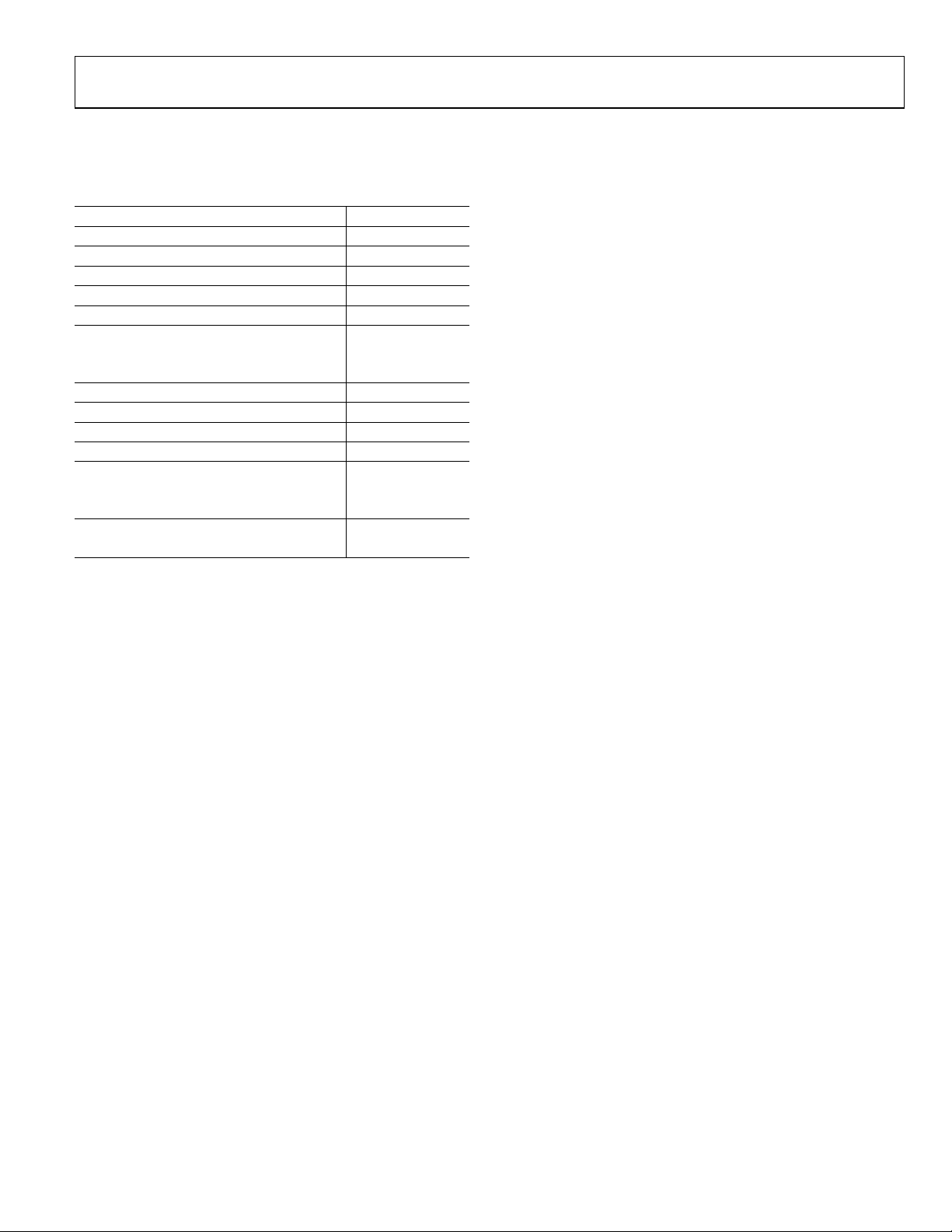

ABSOLUTE MAXIMUM RATINGS

(TA = +25°C, unless otherwise noted.)

Table 3.

Parameter Value

VDD to GND –0.3 V to +16.5 V

VSS to GND 0 V to +7.5 V

VDD to VSS +16.5 V

VL to GND –0.3 V to +6.5 V

VA, VB, VW to GND VSS to V

DD

Terminal Current, Ax-Bx, Ax-Wx, Bx-Wx

Pulsed1 ±20 mA

Continuous ±3 mA

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Digital Inputs and Output Voltage to GND 0 V to +7 V

Operating Temperature Range –40°C to +85°C

Maximum Junction Temperature (T

) 150°C

J MAX

Storage Temperature –65°C to +150°C

Lead Temperature (Soldering, 10 sec) 300°C

Vapor Phase (60 sec) 215°C

Infrared (15 sec) 220°C

Thermal Resistance2 θJA

TSSOP-24 143°C/W

1

Maximum terminal current is bounded by the maximum current handling of

the switches, maximum power dissipation of the package, and maximum

applied voltage across any two of the A, B, and W terminals at a given

resistance.

2

Package power dissipation: (T

JMAX

– TA)/θJA.

Rev. 0 | Page 5 of 28

Page 6

AD5263

TYPICAL PERFORMANCE CHARACTERISTICS

(RAB = 20 kΩ unless otherwise noted.)

1

±5V

15/0V

03142-0-073

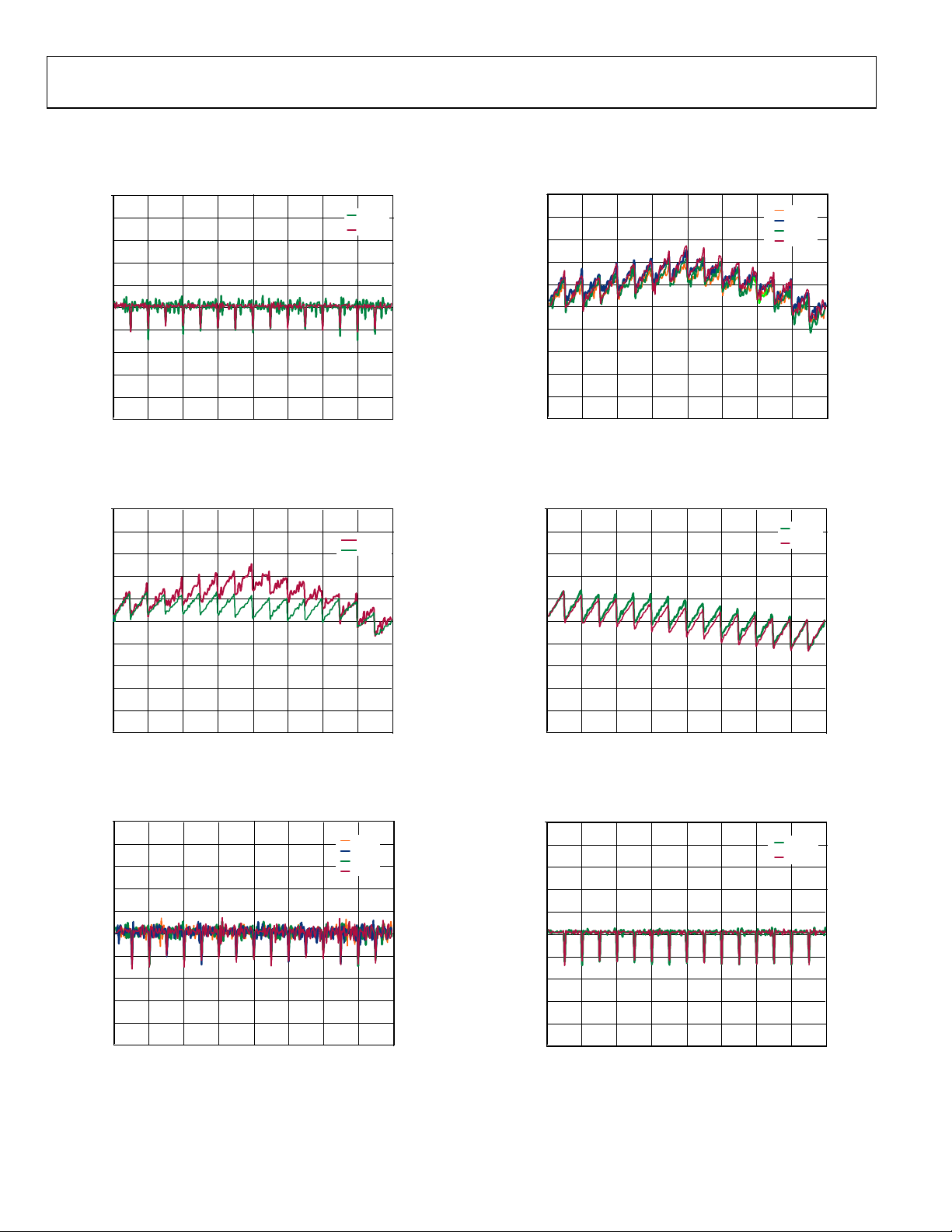

RHEOSTAT MODE DNL (LSB)

0.6

0.4

0.2

–0.2

–0.4

–0.6

–0.8

0.8

0

–1

32

64 96 1280

CODE (Decimal)

Figure 2. R-DNL vs. Code vs. Supply Voltage

160 192 224 256

1

0.8

0.6

0.4

0.2

0

–0.2

–0.4

RHEOSTAT MODE INL (LSB)

–0.6

–0.8

–1

32

64 96 1280

Figure 5. R-INL vs. Code; V

CODE (Decimal)

–40°C

25°C

85°C

125°C

160 192 224 256

= ±5 V

DD

03142-0-004

1

0.8

0.6

0.4

0.2

0

–0.2

–0.4

RHEOSTAT MODE INL (LSB)

–0.6

–0.8

–1

32

64 96 1280

Figure 3. R-INL vs. Code vs. Supply Voltage

1

0.8

0.6

0.4

0.2

0

–0.2

–0.4

RHEOSTAT MODE DNL (LSB)

–0.6

–0.8

–1

32

64 96 1280

Figure 4. R-DNL vs. Code; V

CODE (Decimal)

CODE (Decimal)

±5V

15/0V

160 192 224 256

–40°C

25°C

85°C

125°C

160 192 224 256

= ±5 V

DD

03142-0-002

03142-0-003

1

0.8

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

POTENTIOMETER MODE INL (LSB)

–0.8

–1

32

64 96 1280

CODE (Decimal)

160 192 224 256

±5V

15/0V

03142-0-005

Figure 6. INL vs. Code vs. Supply Voltage

1

0.8

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

POTENTIOMETER MODE DNL (LSB)

–0.8

–1

32

64 96 1280

CODE (Decimal)

160 192 224 256

±5V

15/0V

03142-0-006

Figure 7. DNL vs. Code vs. Supply Voltage

Rev. 0 | Page 6 of 28

Page 7

AD5263

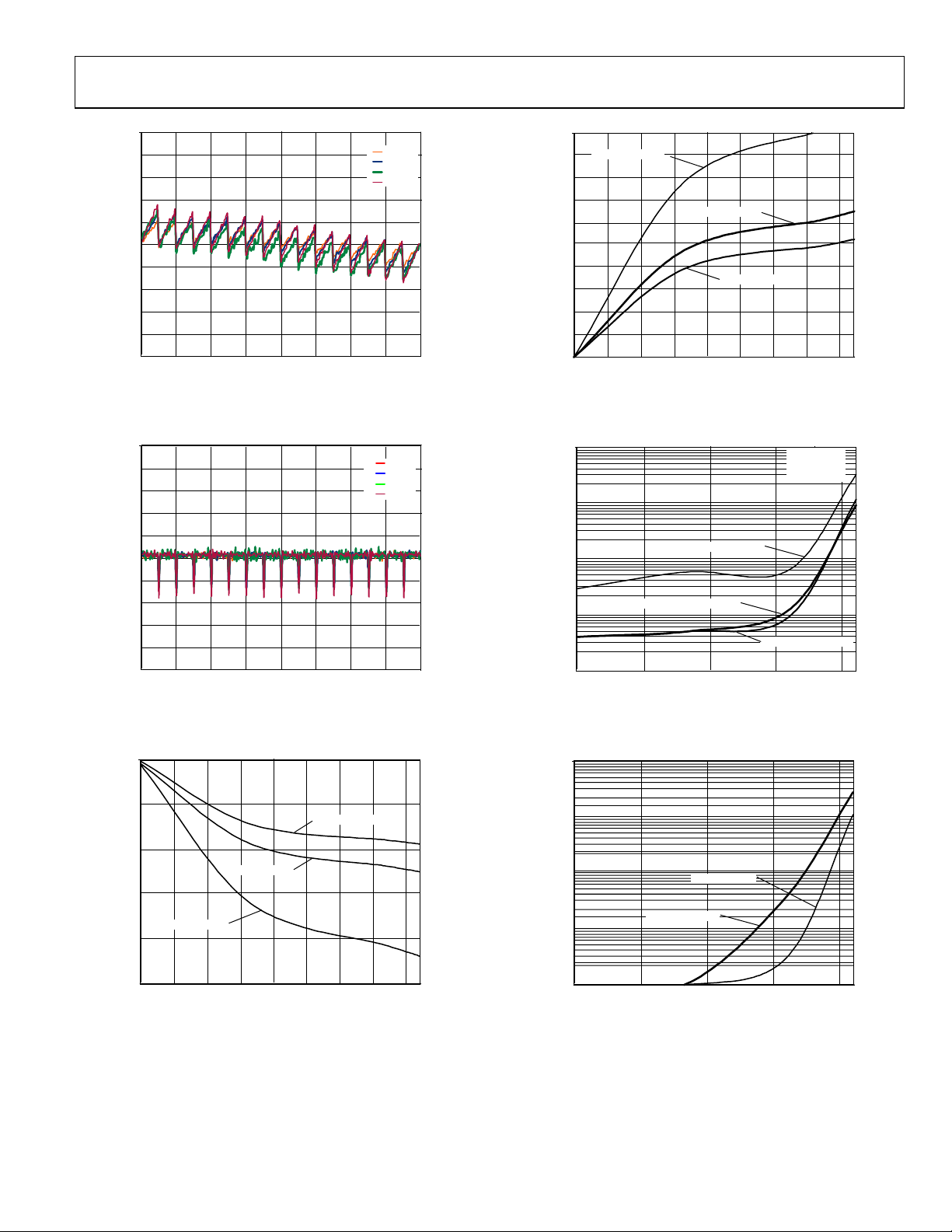

POTENTIOMETER MODE INL (LSB)

0.8

0.6

0.4

0.2

–0.2

–0.4

–0.6

–0.8

1

–40°C

25°C

85°C

125°C

0

–1

32

64 96 1280

CODE (Decimal)

Figure 8. INL vs. Code; V

160 192 224 256

= ±5 V

DD

03142-0-007

2

VDD/VSS = 4.5/0V

1.8

1.6

1.4

1.2

1

0.8

ZSE (LSB)

0.6

0.4

0.2

0

–20

0

VDD/VSS = ±5V

VDD/VSS = 16.5/0V

40 100

20 60 80–40

TEMPERATURE (°C)

03142-0-010

120

Figure 11. Zero-Scale Error vs. Temperature

1

0.8

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

POTENTIOMETER MODE DNL (LSB)

–0.8

–1

0

–0.5

–1

–1.5

FSE (LSB)

–2

32

64 96 1280

Figure 9. DNL vs. Code; V

VDD/VSS = 4.5/0V

CODE (Decimal)

VDD/VSS = ±5V

–40°C

25°C

85°C

125°C

160 192 224 256

= ±5 V

DD

VDD/VSS = 16.5/0V

03142-0-008

SUPPLY CURRENT (µA)

SS

/I

DD

I

0.001

SHUTDOWN CURRENT (µA)

0.01

0.1

0.01

10

1

0.1

ISS@ VDD/VSS = ±5V

IDD @ VDD/VSS = 15/0V

0

40

TEMPERATURE (°C)

TEMPERATURE (°C)

Figure 12. Supply Current vs. Temperature

10

1

VDD/VSS = ±5V

VDD/VSS = 15/0V

V

= 5V

LOGIC

= 5V

V

IH

= 0V

V

IL

IDD@VDD/VSS = ±5V

80–40

120

03142-0-011

–2.5

20 60 80–40

–20

0

40 100

TEMPERATURE (°C)

Figure 10. Full-Scale Error vs. Temperature

03142-0-009

120

Rev. 0 | Page 7 of 28

0.001

0

40

TEMPERATURE (°C)

80–40

Figure 13. Shutdown Current vs. Temperature

03142-0-012

120

Page 8

AD5263

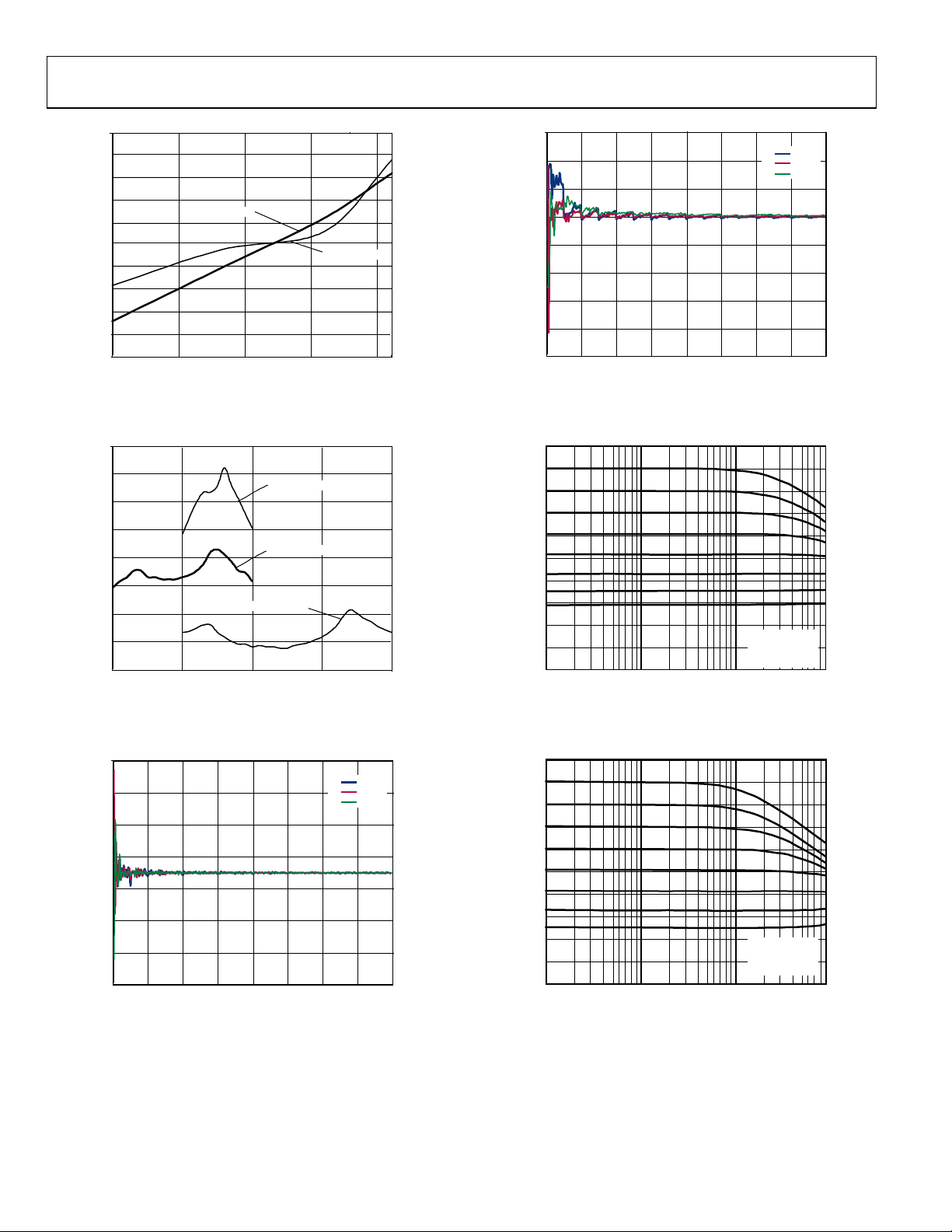

27

26

25

(µA)

LOGIC

24

I

VDD/VSS = 15/0V

VDD/VSS = ±5V

150

100

–50

–100

20k

Ω

50k

Ω

200k

50

0

Ω

23

22

0

Figure 14. I

85

80

75

70

65

60

WIPER RESISTANCE (Ω)

55

50

45

0

40

TEMPERATURE (°C)

vs. Temperature

LOGIC

RON @ VDD/VSS = 15/0V

510–5 15

V

(V)

BIAS

Figure 15. Wiper ON Resistance vs. Bias Voltage

80–40

RON @ VDD/VSS = 5/0V

RON @ VDD/VSS = ±5V

120

03142-0-013

03142-0-014

–150

–200

POTENTIOMETER MODE TEMPCO (ppm/°C)

–250

32

64 96 1280

CODE (Decimal)

Figure 17. Potentiometer Mode Tempco ∆R

0

–6

–12

–18

–24

–30

–36

GAIN (dB)

–42

–48

–54

–60

1k

0x80

0x40

0x20

0x10

0x08

0x04

0x02

0x01

FREQUENCY (Hz)

Figure 18. Gain vs. Frequency vs. Code; R

160 192 224 256

/∆T vs. Code

WB

= 25°C

T

A

= 50mV rms

V

A

=±5V

V

DD/VSS

100k10k

= 20 kΩ

AB

1M

03142-0-016

03142-0-017

700

500

300

100

–100

–300

RHEOSTAT MODE TEMPCO (ppm/°C)

–500

–700

32

64 96 1280

CODE (Decimal)

Figure 16. Rheostat Mode Tempco ∆R

20kΩ

50kΩ

200kΩ

160 192 224 256

/∆T vs. Code

WB

03142-0-015

Rev. 0 | Page 8 of 28

0

–6

–12

–18

–24

–30

–36

GAIN (dB)

–42

–48

–54

–60

1k

0x80

0x40

0x20

0x10

0x08

0x04

0x02

0x01

FREQUENCY (Hz)

Figure 19. Gain vs. Frequency vs. Code; R

TA = 25°C

=50mVrms

V

A

=±5V

V

DD/VSS

100k10k

03142-0-018

1M

= 50 kΩ

AB

Page 9

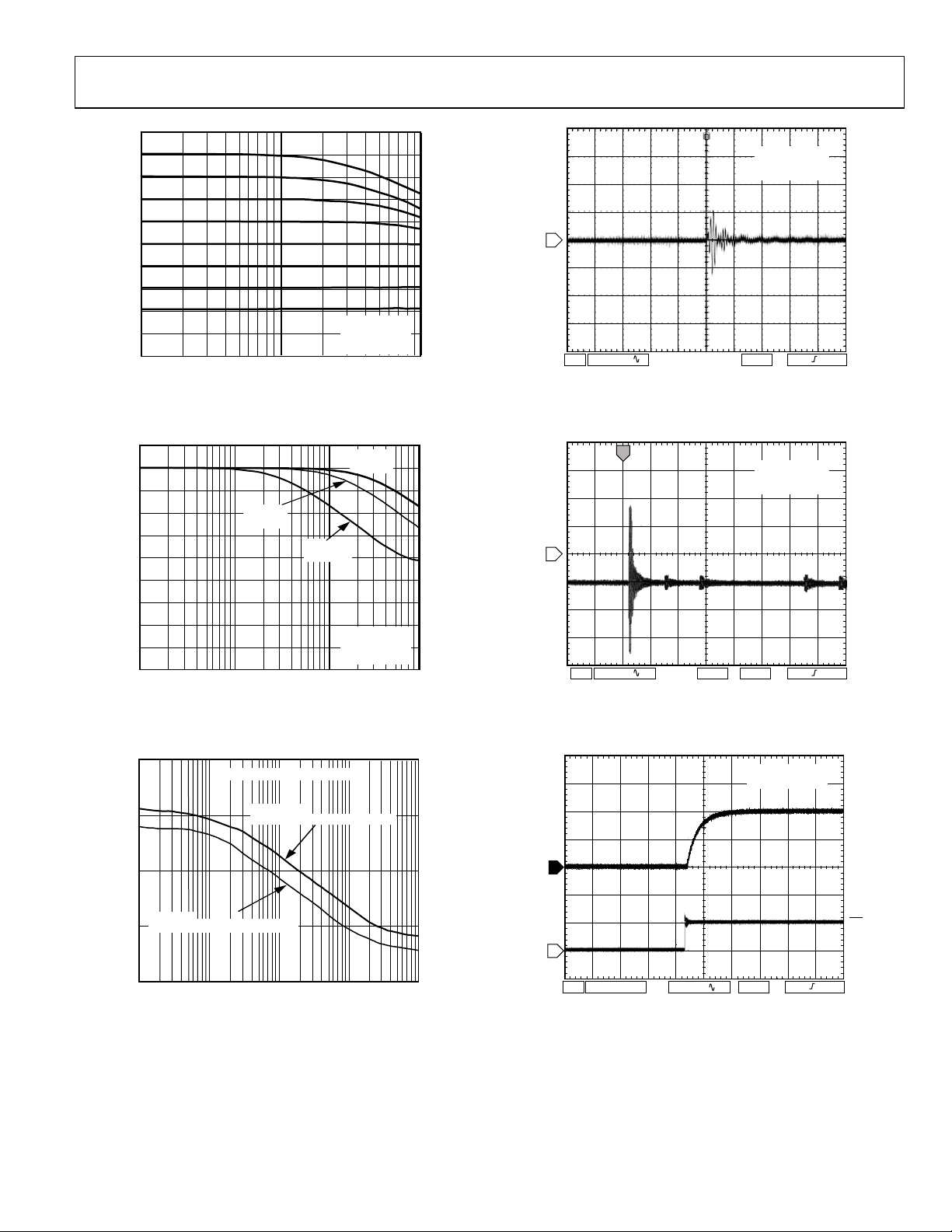

AD5263

0

–6

–12

–18

–24

–30

–36

GAIN (dB)

–42

–48

–54

–60

1k

Figure 20. Gain vs. Frequency vs. Code; R

0x80

0x40

0x20

0x10

0x08

0x04

0x02

0x01

FREQUENCY (Hz)

TA = 25°C

= 50mV rms

V

A

V

DD/VSS

= 200 kΩ

AB

=±5V

Code = 0x80

VDD/VSS = ±5.5V

=±5V

V

B/VA

V

1

03142-0-019

100k10k

Ch 1 50.0mV M 100ns A CH2 2.70 V

Figure 23. Digital Feedthrough

W

03142-0-022

GAIN (dB)

PSRR (–dB)

–12

–18

–24

–30

–36

–42

–48

–54

–60

–6

80

60

40

20

0

0

1k

100

Figure 21. –3 db Bandwidth

+PSRR @

V

= ±5V DC ± 10% p-p AC

DD/VSS

Figure 22. PSRR v s. Frequency

R = 50kΩ

150kHz

R = 200kΩ

35kHz

TA = 25°C

V

V

FREQUENCY (Hz)

CODE = 0x80, VA = VDD, VB = 0V

–PSRR @

V

DD/VSS

FREQUENCY (Hz)

100k10k

= ±5V DC ± 10% p-p AC

10k1k

100k

R = 20kΩ

300kHz

= ±5V

DD/VSS

= 50mV rms

A

1M

1M

03142-0-020

03142-0-021

T

1

Ch 1 50.0mV T 20.00% M 2.00µs A CH2 2.00 V

VDD/VSS = 5/0V

= 5V

V

A

= 0V

V

B

Figure 24. Midscale Glitch; Code 0x80–ox7F

(4.7 nF Capacitor Used from Wiper to Ground)

VDD/VSS = ±5.5V

=±5V

V

A/VB

1

2

Ch 1 5.00V Ch 2 5.00 V M 400ns A CH1 2.70 V

Figure 25. Large Signal Settling Time; Code 0x00–0xFF

V

W

03142-0-023

V

W

CS

03142-0-024

Rev. 0 | Page 9 of 28

Page 10

AD5263

1

RAB = 20k

TA = 25°C

1.5

2

RAB = 20k

TA = 25°C

Ω

Ω

INL (LSB)

–0.5

0.5

–1

Avg – 3

σ

Avg

σ

Avg – 3

0

5

10 15 200

|VDD– VSS| (–V)

03142-0-025

Figure 26. INL vs. Supply Voltage

R-INL (LSB)

–0.5

–1.5

0.5

1

Avg + 3

σ

0

–1

–2

5

10 15 200

|VDD– VSS| (V)

Avg

Avg – 3

σ

03142-0-026

Figure 27. R-INL vs. Supply Voltage

Rev. 0 | Page 10 of 28

Page 11

AD5263

TEST CIRCUITS

DUT

DUT

W

B

DD

GND

SS

V

LOGIC

A1

W1

N/C

CTA = 20 log[V

A

B

+15V

W

AD8610

–15V

0.1V

RSW=

I

SW

CODE = 0x00

I

SW

VSS TO V

0.1V

DD

NC

I

A

CM

W

B

V

CM

NC

03142-0-036

I

LOGIC

+

–

03142-0-037

Current vs. Digital Input Voltage

LOGIC

RDAC1

V

V

B1

DD

SS

OUT/VIN

RDAC2

W2

B2

]

A2

V

OUT

03142-0-035

03142-0-038

V

OUT

03142-0-034

Figure 28 to Figure 38 define the test conditions used in the

product specification table.

DUT

A

V+

W

B

Figure 28. Test Circuit for Potentiometer Divider Nonlinearity Error (INL, DNL)

NO CONNECT

DUT

A

W

B

Figure 29. Test Circuit for Resistor Position Nonlinearity Error

(Rheostat Operation; R-INL, R-DNL)

DUT

V

MS2

A

B

V

W

W

Figure 30. Test Circuit for Wiper Resistance

V

A

V

DD

A

V+

W

B

Figure 31. Test Circuit for Power Supply Sensitivity (PSS, PSSR)

A

DUT

V

IN

OFFSET

GND

OFFSET

BIAS

Figure 32. Test Circuit for Inverting Gain

V

IN

OFFSET

GND

A

DUT

OFFSET

BIAS

Figure 33. Test Circuit for Noninverting Gain

V+ = V

1LSB = V+/2

V

MS

V

MS

IW= VDD/R

V

RW= [V

MS1

V+ = V

DD

PSRR (dB) = 20 LOG

PSS (%/ %) =

V

MS

B

5V

W

OP279

5V

OP279

W

B

DD

I

W

NOMINAL

MS1

10%

∆

∆

V

V

N

03142-0-028

03142-0-029

– V

%

MS

%

DD

V

V

OUT

]/I

MS2

∆

V

( )

∆

V

OUT

03142-0-033

W

MS

DD

03142-0-032

03142-0-030

03142-0-031

V

IN

OFFSET

GND

2.5V

Figure 34. Test Circuit for Gain vs Frequency

Figure 35. Test Circuit for Incremental ON Resistance

V

DUT

V

Figure 36. Test Circuit for Common Mode Leakage Current

SCL

SCA

Figure 37. Test Circuit for V

V

IN

Figure 38. Test Circuit for Analog Crosstalk

Rev. 0 | Page 11 of 28

Page 12

AD5263

V

SPI COMPATIBLE DIGITAL INTERFACE (DIS = 0)

Table 4. AD5263 Serial Data-Word Format

Addr Data

B9 B8 B7 B6 B5 B4 B3 B2 B1 B0

A1 A0 D7 D6 D5 D4 D3 D2 D1 D0

MSB LSB

29 27 2

1

SDI

(DATA IN)

CLK

CS

V

OUT

0

1

0

t

CSHO

1

0

V

DD

0

Dx

t

CH

t

CSS

Figure 40. Detailed SPI Timing Diagram (V

0

Dx

t

DS

t

CL

t

SDI

CLK

CS

OUT

1

0

1

0

1

0

1

0

A0

A1

D7 D6

Figure 39. AD5263 Timing Diagram (V

CH

t

CSH1

= 5 V, VB = 0 V, VW = V

A

OUT

)

D5

t

CS1

D3

D4

D2 D1

RDAC REGISTER LOAD

= 5 V, VB = 0 V, VW = V

A

t

C-SW

t

S

D0

±LSB

OUT

03142-0-039

)

03142-0-040

Rev. 0 | Page 12 of 28

Page 13

AD5263

SDA

Y

S

Y

I2C COMPATIBLE DIGITAL INTERFACE (DIS = 1)

Table 5. I2C Write Mode Data-Word Format

S 0 1 0 1 1 AD1 AD0 W

Slave Address Byte Instruction Byte Data Byte

Table 6. I

S 0 1 0 1 1 AD1 AD0 R A D7 D8 D5 D4 D3 D2 D1 D0 A P

Slave Address Byte Data Byte

2

C Read Mode Data-Word Format

S = Start condition.

P = Stop condition.

A = Acknowledge.

A X A1 A0 RS SD O1 O2 X A D7 D6 D5 D4 D3 D2 D1 D0 A P

2

O1, O2 = Data to digital output pins O1, O2 in I

C mode, used

to drive external logic. The logic high level is determined by V

and the logic low level is GND.

L

AD1, AD0 = I2C device address bits. Must match with the logic

states at pins AD1, AD0. Refer to Figure 48.

A1, A0 = RDAC channel select.

RS = Software reset wiper (A1, A0) to midscale position.

SD = Shutdown active high; ties wiper (A1, A0) to Terminal A,

opens Terminal B, RDAC register contents are not disturbed. To

exit shutdown, the command SD = 0 must be executed for each

RDAC (A1, A0).

SCL

START B

MASTER

t

1

PS

SCL

0

SDA

t

8

t

2

1

0

FRAME 1 FRAME 2

SLAVE ADDRESS BYTE

TART B

MASTER

t

3

t

9

t

8

1

1 AD1 AD0 R/W

ACK BY

AD5263

1 919

SCL

0 1 0 1 1 AD1 AD0 R/W

SDA

FRAME 1

SLAVE ADDRESS BYTE

Figure 43. Reading Data from a Previously Selected RDAC Register in Write Mode

t

9

t

4

Figure 41. Detailed I

1 919

XA1 RSSDO1O2X

Figure 42

A0

INSTRUCTION BYTE

. Writing to the RDAC Register

W

= Write = 0.

R = Read = 1.

D7, D6, D5, D4, D3, D2, D1, D0 = Data Bits.

X = Don’t Care.

t

7

S

2

C Timing Diagram

ACK BY

AD5263

D7 D6 D5 D4 D3 D2 D1 D0

ACK BY

AD5263

FRAME 2

RDAC REGISTER

t

2

t

5

19

D7 D6 D5 D4 D3 D2 D1 D0

FRAME 3

DATA BYTE

NO ACK

BY MASTER

STOP BY

MASTER

ACK BY

AD5263

03142-0-043

P

STOP BY

MASTER

t

10

03142-0-041

03142-0-042

Rev. 0 | Page 13 of 28

Page 14

AD5263

−

OPERATION

The AD5263 is a quad-channel, 256-position, digitally

controlled, variable resistor (VR) device.

To program the VR settings, refer to the interface sections of the

previous pages. The part has an internal power-on preset that

places the wiper at midscale during power-on, which simplifies

the fault condition recovery at power-up. In addition, the shut-

SHDN

down

power consumption state where Terminal A is open circuited

and the wiper W is connected to Terminal B, resulting in only

leakage current consumption in the VR structure. During shutdown, the VR latch settings are maintained or new settings can

be programmed. When the part is returned from shutdown, the

corresponding VR setting will be applied to the RDAC.

PROGRAMMING THE VARIABLE RESISTOR

Rheostat Operation

The nominal resistance of the RDAC between Terminals A and

B is available in 20 kΩ, 50 kΩ, and 200 kΩ. The final two or

three digits of the part number determine the nominal

resistance value, e.g., 20 kΩ = 20; 50 kΩ = 50; 200 kΩ = 200. The

nominal resistance (R

accessed by the wiper terminal, plus the B terminal contact. The

8-bit data in the RDAC latch is decoded to select one of the 256

possible settings. Assuming a 20 kΩ part is used, the wiper's first

connection starts at the B terminal for data 0x00. Since there is a

60 Ω wiper contact resistance, such a connection yields a

minimum of 2 × 60 Ω resistance between Terminals W and B.

The second connection is the first tap point, and corresponds to

198 Ω (R

The third connection is the next tap point representing 216 Ω

= 78 Ω × 2 + 2 × 60 Ω) for data 0x02, and so on. Each LSB

(R

WB

data value increase moves the wiper up the resistor ladder until

the last tap point is reached at 19,982 Ω (R

Figure 44 shows a simplified diagram of the equivalent RDAC

circuit, where the last resistor string will not be accessed;

pin of AD5263 places the RDAC in an almost zero

Ax

SD BIT

R

S

D7

D6

D5

D4

D3

D2

D1

D0

DECODER

Figure 44. AD5263 Equivalent RDAC Circuit

= RAB/256 + RW = 78 Ω + 2 × 60 Ω) for data 0x01.

WB

R

S

R

S

RDAC

LATCH

AND

R

S

) of the VR has 256 contact points

AB

Wx

Bx

– 1 LSB + 2 × RW).

AB

03142-0-044

therefore, there is 1 LSB less of the nominal resistance at full

scale in addition to the wiper resistance.

The general equation determining the digitally programmed

output resistance between Terminals W and B is

WB

D

DR

)(

256

AB

(1)

RR

×+×= 2

W

where:

D

is the decimal equivalent of the binary code loaded in the

8-bit RDAC register.

is the end-to-end resistance.

R

AB

R

is the wiper resistance contributed by the ON resistance of

W

one internal switch.

In summary, if R

= 20 kΩ and the A terminal is open-

AB

circuited, the following RDAC latch codes result in the

corresponding output resistance, R

Table 7. Codes and Corresponding R

D (dec) R

(Ω) Output State

WB

WB

.

Resistances

WB

255 19,982 Full-Scale (RAB – 1 LSB + RW)

128 10,120 Midscale

1 198 1 LSB

0 120 Zero-Scale (Wiper Contact Resistance)

Note that in the zero-scale condition a finite wiper resistance of

120 Ω is present. Care should be taken to limit the current flow

between W and B in this state to a maximum pulse current of

no more than 20 mA. Otherwise, degradation or possible

destruction of the internal switch contact can occur.

Similar to the mechanical potentiometer, the resistance of the

RDAC between the wiper W and Terminal A also produces a

digitally controlled complementary resistance, R

. When these

WA

terminals are used, the B terminal can be opened. Setting the

resistance value for R

starts at a maximum value of resistance

WA

and decreases as the data loaded in the latch increases in value.

The general equation for this operation is

256

256

D

ABWA

DR

= 2

)(

= 20 kΩ and the B terminal open-circuited, the

For R

AB

(2)

RR

×+×

W

following RDAC latch codes result in the corresponding output

resistance RWA:

Table 8. Codes and Corresponding R

D (dec) R

(Ω) Output State

WA

Resistances

WA

255 198 Full-Scale

128 10,120 Midscale

1 19,982 1 LSB

0 20,060 Zero-Scale

Rev. 0 | Page 14 of 28

Page 15

AD5263

The typical distribution of the end-to-end resistance RAB from

channel to channel matches within ±1%. Device to device

matching is process lot dependent and is possible to have ±30%

variation. Since the resistance element is processed in thin film

technology, the change in R

with temperature has a very low

AB

temperature coefficient of 30 ppm/°C.

PROGRAMMING THE POTENTIOMETER DIVIDER

Voltage Output Operation

The digital potentiometer easily generates a voltage divider at

wiper-to-B and wiper-to-A proportional to the input voltage

from Terminals A to B. Unlike the polarity from V

which must be positive, the voltage across A-B, W-A, and W-B

can be at either polarity, provided that V

is powered by a

SS

negative supply.

to VSS,

DD

Standard logic families work well. If mechanical switches are

used for product evaluation, they should be debounced by a

flip-flop or other suitable means. When

CS

is low, the clock

loads data into the serial register on each positive clock edge

(see Figure 39).

Table 9. AD5263 Address Decode Table

A1 A0 Latch Loaded

0 0 RDAC 1

0 1 RDAC 2

1 0 RDAC 3

1 1 RDAC 4

If ignoring the effect of the wiper resistance for approximation,

connecting the A terminal to 5 V and the B terminal to ground

produces an output voltage from the wiper to B starting at 0 V

up to 1 LSB below 5 V. Each LSB step of voltage is equal to the

voltage applied across Terminals A-B divided by the 256

positions of the potentiometer divider. Since the AD5263 can be

powered by dual supplies, the general equation defining the

output voltage V

with respect to ground for any valid input

W

voltages applied to Terminals A and B is

−

D

)(

256

V

A

DV

W

D

256

+=

256

(3)

V

B

For a more accurate calculation, which includes the effect of

wiper resistance, V

DV

)( +=

W

can be found as

W

DR

)(

WB

V

A

256

WA

256

DR

)(

V

(4)

B

Operation of the digital potentiometer in the divider mode

results in a more accurate operation over temperature. Unlike

the rheostat mode, the output voltage is dependent mainly on

the ratio of the internal resistances R

and RWB, and not their

WA

absolute values; therefore, the temperature drift reduces to

5 ppm/°C.

PIN SELECTABLE DIGITAL INTERFACE

The AD5263 provides the flexibility of a selectable interface.

When the digital interface select (DIS) pin is tied low, the SPI

mode is engaged. When the DIS pin is tied high to the V

supply, the I

2

C mode is engaged.

L

SPI COMPATIBLE 3-WIRE SERIAL BUS (DIS = 0)

The AD5263 contains a 3-wire SPI compatible digital interface

CS

(SDI,

address bits A1 and A0, followed by the data byte, MSB first.

The format of the word is shown in Table 4.

The positive-edge sensitive CLK input requires clean transitions

to avoid clocking incorrect data into the serial input register.

, and CLK). The 10-bit serial word must be loaded with

The data setup and data hold times in the specification table

determine the valid timing requirements. The AD5263 uses a

10-bit serial input data register word that is transferred to the

CS

internal RDAC register when the

line returns to logic high.

Note that only the last 10-bits that are clocked into the register

CS

are latched into the decoder. As

goes high, it activates the

address decoder and updates the corresponding channel

according to Table 9.

SHDN

During shutdown (

), the serial data output (SDO) pin is

forced to logic high in order to avoid power dissipation in the

external pull-up resistor. For an equivalent SDO output circuit

schematic, see Figure 45.

SHDN

CS

SERIAL

SDI

REGISTER

CLK

RES

Figure 45. Detailed SDO Output Schematic of the AD5263

Q

D

CK

RS

SDO

03142-0-045

During reset (

unlike

remain at midscale and will not revert to its pre-reset setting.

RES

), the wiper is set to midscale. Note that

SHDN

, when the part is taken out of reset, the wiper will

Daisy-Chain Operation

The serial data output (SDO) pin contains an open drain

N-channel FET. This output requires a pull-up resistor in order

to transfer data to the next package’s SDI pin. This allows for

daisy chaining several RDACs from a single processor serial

data line. The pull-up resistor termination voltage can be

greater than the V

increase the clock period when using a pull-up resistor to the

SDI pin of the following device because capacitive loading at the

daisy-chain node (SDO-SDI) between devices may induce time

delay to subsequent devices. Users should be aware of this

potential problem to achieve data transfer successfully (see

supply voltage. It is recommended to

DD

Rev. 0 | Page 15 of 28

Page 16

AD5263

Figure 46). If two AD5263s are daisy-chained, a total of 20 bits

of data is required. The first 10 bits, complying with the format

shown in Table 4, go to U2 and the second 10 bits, with the

CS

same for mat, go to U1.

are clocked into their respective serial registers. After this,

pulled high to complete the operation and load the RDAC latch.

Note that data appears on SDO on the negative edge of the

clock, thus making it available to the input of the daisy-chained

device on the rising edge of the next clock.

SPI

MOSI

CLK

CS

Figure 46. Daisy-Chain Configuration

I2C COMPATIBLE 2-WIRE SERIAL BUS (DIS = 1)

In the I2C compatible mode, the RDACs are connected to the

bus as slave devices.

Referring to Table 5 and Table 6, the first byte of the AD5263 is

a slave address byte, consisting of a 7-bit slave address and a

W

R/

bit. The five MSBs are 01011 and the following two bits are

determined by the state of the AD0 and AD1 pins of the device.

AD0 and AD1 allow the user to place up to four of the I

compatible devices on one bus.

The 2-wire I

1. The master initiates a data transfer by establishing a

2. In the write mode, the second byte is the instruction byte.

2

C serial bus protocol operates as follows:

START condition, which is when a high-to-low transition

on the SDA line occurs while SCL is high (see Figure 42).

The following byte is the slave address byte, which consists

of the 7-bit slave address followed by an R/

bit determines whether data will be read from or written to

the slave device.

The slave whose address corresponds to the transmitted

address responds by pulling the SDA line low during the

ninth clock pulse (this is termed the acknowledge bit). At

this stage, all other devices on the bus remain idle while the

selected device waits for data to be written to or read from

its serial register. If the R/

from the slave device. If the R/

write to the slave device.

The first bit (MSB) of the instruction byte is a don’t care.

The following two bits, labeled A1 and A0, are the RDAC

subaddress select bits.

should be kept low until all 20 bits

V

L

AD5263 AD5263

U1

SDI

CS

CLK

SDO

R

P

2.2kΩ

SDI

W

bit is high, the master will read

W

bit is low, the master will

U2

SDO

CLK

CS

W

bit. This R/

CS

is

03142-0-046

2

C

W

The fourth MSB (RS) is the midscale reset. A logic high on

this bit moves the wiper of the selected channel to the

center tap where R

= RWB. This feature effectively writes

WA

over the contents of the register, so that when taken out of

reset mode, the RDAC will remain at midscale.

The fifth MSB (SD) is the shutdown bit. A logic high causes

the selected channel to open circuit at Terminal A while

shorting the wiper to Terminal B. This operation yields

almost 0 Ω in rheostat mode or 0 V in potentiometer

mode. This SD bit serves the same function as the

SHDN

pin except that the

SHDN

pin affects all channels, as opposed to the SD bit,

pin reacts to active low. Also, the

SHDN

which affects only the channel being written to. It is

important to note that the shutdown operation does not

disturb the contents of the register. When brought out of

shutdown, the previous setting will be applied to the

RDAC.

The next two bits are O2 and O1. They are extra

programmable logic outputs that can be used to drive other

digital loads, logic gates, LED drivers, analog switches, etc.

The LSB is a don’t care (see Table 5).

After acknowledging the instruction byte, the last byte in

write mode is the data byte. Data is transmitted over the

serial bus in sequences of nine clock pulses (eight data bits

followed by an acknowledge bit). The transitions on the

SDA line must occur during the low period of SCL and

remain stable during the high period of SCL (see

Figure 42).

3. In the read mode, the data byte follows immediately after

the acknowledgment of the slave address byte. Data is

transmitted over the serial bus in sequences of nine clock

pulses (a slight difference with the write mode, where there

are eight data bits followed by an acknowledge bit).

Similarly, the transitions on the SDA line must occur

during the low period of SCL and remain stable during the

high period of SCL (see Figure 43).

Note that the channel of interest is the one that was

previously selected in the write mode. In the case where

users need to read the RDAC values of both channels, they

need to program the first channel in the write mode and

then change to the read mode to read the first channel

value. After that, they need to change back to the write

mode with the second channel selected and read the

second channel value in the read mode again. It is not

necessary for users to issue the Frame 3 data byte in the

write mode for subsequent readback operation. Refer to

Figure 43 for the programming format.

Rev. 0 | Page 16 of 28

Page 17

AD5263

+5V

O1

SHDN

AD5263

SDA

SCL

03142-0-047

4. After all data bits have been read or written, a STOP

condition is established by the master. A STOP condition is

defined as a low-to-high transition on the SDA line while

SCL is high. In write mode, the master will pull the SDA

line high during the tenth clock pulse to establish a STOP

condition (see Figure 42). In read mode, the master will

issue a no acknowledge for the ninth clock pulse (i.e., the

SDA line remains high). The master will then bring the

SDA line low before the tenth clock pulse, which goes high

to establish a STOP condition (see Figure 43).

A repeated write function gives the user flexibility to update the

RDAC output a number of times after addressing and

instructing the part only once. For example, after the RDAC has

acknowledged its slave address and instruction bytes in the

write mode, the RDAC output will update on each successive

byte. If different instructions are needed, the write/read mode

has to start again with a new slave address, instruction, and data

byte. Similarly, a repeated read function of the RDAC is also

allowed.

R

PULL-DOWN

Figure 47. Shutdown by Internal Logic Output

MULTIPLE DEVICES ON ONE BUS

Figure 48 shows four AD5263 devices on the same serial bus.

Each has a different slave address since the states of their AD0

and AD1 pins are different. This allows each RDAC within each

device to be written to or read from independently. The master

device output bus line drivers are open-drain pull-downs in a

2

fully I

C compatible interface.

R

R

P

P

ADDITIONAL PROGRAMMABLE LOGIC OUTPUT

The AD5263 features additional programmable logic outputs,

O1 and O2, which can be used to drive a digital load, analog

switches, and logic gates. O1 and O2 default to Logic 0. The

voltage level can swing from GND to V

. The logic states of O1

L

and O2 can be programmed in Frame 2 under write mode (see

Figure 42). These logic outputs have adequate current driving

capability to sink/source milliamperes of load.

Users can also activate O1 and O2 in three different ways

without affecting the wiper settings. They may do the following:

1. START, slave address byte, acknowledge, instruction byte with

O1 and O2 specified, acknowledge, STOP.

2. Complete the write cycle with STOP, then START, slave

address byte, acknowledge, instruction byte with O1 and O2

specified, acknowledge, STOP.

3. Do not complete the write cycle by not issuing the STOP, then

START, slave address byte, acknowledge, instruction byte with

O1 and O2 specified, acknowledge, STOP.

SELF-CONTAINED SHUTDOWN FUNCTION

Shutdown can be activated by strobing the

programming the SD bit in the write mode instruction byte. In

addition, shutdown can even be implemented with the device’s

digital output as shown in Figure 47. In this configuration, the

device will be shut down during power-up, but users are allowed

to program the device. Thus, when O1 is programmed high, the

device will exit from the shutdown mode and respond to the

new setting. This self-contained shutdown function allows

absolute shutdown during power-up, which is crucial in

hazardous environments, without adding extra components.

SHDN

pin or

SDA

MASTER

SDA SCL

AD1 AD1 AD1 AD1

AD0

AD5263

Figure 48. Multiple AD5263 Devices on One I

+5V

SDA SCL

AD0

AD5263

+5V

SDA SCL

AD0

AD5263

+5V

2

C Bus

SDA SCL

AD0

AD5263

SCL

LEVEL SHIFT FOR NEGATIVE VOLTAGE OPERATION

The digital potentiometer is popular in laser diode driver and

certain telecommunication equipment level-setting applications.

These applications are sometimes operated between ground and

some negative supply voltage so that the systems can be biased

at ground to avoid large bypass capacitors that may significantly

impede the ac performance. Like most digital potentiometers,

the AD5263 can be configured with a negative supply (see

Figure 49).

V

V

–5V

LEVEL SHIFTED

LEVEL SHIFTED

Figure 49. Biased at Negative Voltage

GND

SDA

SCL

However, the digital inputs must also be level shifted to allow

proper operation since the ground is now referenced to the

negative potential. As a result, Figure 50 shows one

implementation with a couple transistors and a few resistors.

AD5263

DD

SS

03142-0-050

03142-0-048

Rev. 0 | Page 17 of 28

Page 18

AD5263

+

V

V

When VIN is high, Q1 is turned on and its emitter is clamped at

one threshold above ground. This threshold appears at the base

of Q2, which causes Q2 to turn off. In this state, V

approaches –5 V. When V

is low, Q1 is turned off and the base

IN

OUT

of Q2 is pulled low, which in turn causes Q2 to turn on. In this

state, V

also needed for successful communication with the device.

5V

0V

approaches 0 V. Beware that proper time shifting is

OUT

R3

V

IN

1kΩ

R1

–5V

Q1

2N3906

10kΩ

2N3906

Q2

V

OUT

R2

10kΩ

0V

–5V

–5V

Figure 50. Level Shift for Bipolar Potential Operation

03142-0-051

ESD PROTECTION

All digital inputs are protected with a series input resistor and

parallel Zener ESD structures shown in Figure 51 and Figure 52.

This protection applies to digital input pins SDI/SDA,

CLK/SCL,

/AD0,

RES

/AD1, and

340Ω

V

SS

CS

Figure 51. ESD Protection of Digital Pins

A,B,W

LOGIC

SHDN

.

03142-0-052

V

DD

A

W

B

V

SS

03142-0-054

Figure 53. Maximum Terminal Voltages Set by V

and VSS

DD

POWER-UP SEQUENCE

Since the ESD protection diodes limit the voltage compliance at

Terminals A, B, and W (see Figure 53), it is important to power

V

and VSS before applying any voltage to Terminals A, B, and

DD

W; otherwise, the diodes will be forward biased such that V

will be powered unintentionally and may affect the rest

and V

SS

DD

of the circuit. The ideal power-up sequence is in the following

order: GND, V

order of powering V

, VSS, VL, digital inputs, and V

DD

, VB, VW, and digital inputs is not

A

important as long as they are powered after V

V

POWER SUPPLY

LOGIC

. The relative

A/B/W

and VSS.

DD

The AD5263 is capable of operating at high voltages beyond the

internal logic levels, which are limited to operation at 5 V. As a

result, V

always needs to be tied to a separate 2.7 V to 5.5 V

L

source to ensure proper digital signal levels. Logic levels must

be limited to V

be less than or equal to V

, regardless of VDD. In addition, VL should always

L

.

DD

LAYOUT AND POWER SUPPLY BYPASSING

It is a good practice to employ compact, minimum-lead length

layout design. The leads to the input should be as direct as

possible with a minimum conductor length. Ground paths

should have low resistance and low inductance.

V

SS

Figure 52. ESD Protection of Resistor Terminals

TERMINAL VOLTAGE OPERATING RANGE

The AD5263 positive VDD and negative VSS power supply defines

the boundary conditions for proper 3-terminal digital

potentiometer operation. Supply signals present on Terminals A,

B, and W that exceed V

forward biased diodes shown in Figure 53.

or VSS will be clamped by the internal

DD

03142-0-053

with quality capacitors for optimum stability. Supply leads to the

device should be bypassed with 0.01 µF to 0.1 µF ceramic disc

or chip capacitors. Low ESR 1 µF to 10 µF tantalum or

electrolytic capacitors should also be applied at the supplies to

minimize any transient disturbance and low frequency ripple

(see Figure 54). Notice the digital ground should also be joined

remotely to the analog ground at one point to minimize the

ground bounce.

Rev. 0 | Page 18 of 28

DD

+

10µF

+

10µF

C1

0.1µF

C2

0.1µF

C3

C4

SS

Figure 54. Power Supply Bypassing

V

DD

AD5263

V

SS

GND

03142-0-055

Similarly, it is also a good practice to bypass the power supplies

Page 19

AD5263

A

RDAC CIRCUIT SIMULATION MODEL

The internal parasitic capacitances and the external capacitive

loads dominate the ac characteristics of the RDACs. Configured

as a potentiometer divider, the –3 dB bandwidth of the AD5263

(20 kΩ resistor) measures 300 kHz at half scale. Figure 21

provides the large signal BODE plot characteristics of the three

available resistor versions: 20 kΩ, 50 kΩ, and 200 kΩ. A parasitic

simulation model is shown in Figure 55. The following code

provides a macro model net list for the 20 kΩ RDAC.

RDAC

C

25pF

20kΩ

A

C

55pF

B

C

B

25pF

W

Listing 1. Macro Model Net List for RDAC

.PARAM D=256, RDAC=20E3

*

.SUBCKT DPOT (A,W,B)

*

CA A 0 25E-12

RWA A W {(1-D/256)*RDAC+60}

CW W 0 55E-12

RWB W B {D/256*RDAC+60}

CB B 0 25E-12

*

.ENDS DPOT

W

Figure 55. RDAC Circuit Simulation Model for RDAC = 20 k

03142-0-069

Ω

Rev. 0 | Page 19 of 28

Page 20

AD5263

APPLICATIONS

BIPOLAR DC OR AC OPERATION FROM DUAL SUPPLIES

The AD5263 can be operated from dual supplies, enabling

control of ground referenced ac signals or bipolar operation.

The ac signal, as high as V

Terminals A-B with the output taken from Terminal W. See

Figure 56 for a typical circuit connection.

V

DD

µC

SCLK

MCSI

GND

Figure 56. Bipolar Operation from Dual Supplies

GAIN CONTROL COMPENSATION

The digital potentiometer is commonly used in gain control

such as the noninverting gain amplifier shown in Figure 57.

R1

47kΩ

C1

25pF

, can be applied directly across

DD/VSS

V

DD

SCL

SDA

GND

AD5263

A1

W1

B1

A2

W2

B2

V

SS

C2

4.7pF

R2

200kΩ

B

A

W

U1

VI

2

.

5

V

p

D = 0x90

V

O

+5.0V

5Vp-p

-

p

_

5.0V

03142-0-056

problem. A better approach is to include a compensation

capacitor C2 to cancel the effect caused by C1. Optimum

compensation occurs when R1 × C1 = R2 × C2 . This is not an

option, because of the variation of R2. As a result, one may use

the relationship above and scale C2 as if R2 is at its maximum

value. Doing so may overcompensate and compromise the

performance slightly when R2 is set at low values. However, it

will avoid the gain peaking, ringing, or oscillation in the worst

case. For critical applications, C2 should be found empirically to

suit the need. In general, C2 in the range of few pF to no more

than a few tenths of pF is usually adequate for the

compensation.

Similarly, there are W and A terminal capacitances connected to

the output (not shown); fortunately their effect at this node is

less significant and the compensation can be disregarded in

most cases.

PROGRAMMABLE VOLTAGE REFERENCE

For voltage divider mode operation (Figure 58), it is common to

buffer the output of the digital potentiometer unless the load is

much larger than R

purpose of impedance conversion, but also allows a heavier load

to be driven.

+5V

1

VIN

GND

. Not only does the buffer serve the

WB

U1

AD1582

VOUT

AD5263

3

+5V

A

W

AD8601

B

A1

V

O

Figure 58. Programmable Voltage Reference

03142-0-058

03142-0-057

Figure 57. Typical Noninverting Gain Amplifier

Notice the RDAC B terminal parasitic capacitance is connected

to the op amp noninverting node. It introduces a zero for the

1/βo term with +20 dB/dec, whereas a typical op amp GBP has

–20 dB/dec characteristics. A large R2 and finite C1 can cause

this zero's frequency to fall well below the crossover frequency.

Thus, the rate of closure becomes 40 dB/dec and the system has

o

phase margin at the crossover frequency. The output may

0

ring or oscillate if the input is a rectangular pulse or step

function. Similarly, it is also likely to ring when switching

between two gain values, because this is equivalent to a step

change at the input.

Depending on the op amp GBP, reducing the feedback resistor

may extend the zero's frequency far enough to overcome the

Rev. 0 | Page 20 of 28

Page 21

AD5263

I

V

8-BIT BIPOLAR DAC

Figure 59 shows a low cost, 8-bit, bipolar DAC. It offers the

same number of adjustable steps but not the precision as

compared to conventional DACs. The linearity and temperature

coefficient, especially at low values codes, are skewed by the

effects of the digital potentiometer wiper resistance. The output

of this circuit is

2

D

V

O

V

1

VIN

ADR425

GND

I

U1

VOUT

TRIM

256

−= 1

+5VREF

(5)

V

×

REF

AD5263

W

A

B

+15V

V+

OP2177

V–

A1

Figure 59. 8-Bit Bipolar DAC

–5VREF

+15V

V+

OP2177

V–

A2

–15V

V

O

03142-0-059

BIPOLAR PROGRAMMABLE GAIN AMPLIFIER

For applications requiring bipolar gain, Figure 60 shows one

implementation similar to the previous circuit. The digital

potentiometer U1 sets the adjustment range. The wiper voltage

at W2 can therefore be programmed between V

given U2 setting. Configuring A2 in the noninverting mode

allows linear gain and attenuation. The transfer function is

V

V

where

I

O

+=

1 (6)

K

is the ratio of R

AD5263

AD5263

Figure 60. Bipolar Programmable Gain Amplifier

R2

R1

D2

()

256

1

WB1/RWA 1

V

DD

V+

OP2177

_

V

A1

V

SS

U2

W2

B2

A2

A1

B1

W1

U1

−+××

KK

set by U1.

–KV

V+

OP2177

V

A2

I

V

_

V

and –KVI at a

I

DD

V

C1

SS

R2

R1

O

03142-0-060

Similar to the previous example, in the simpler (and much more

usual) case where K = 1, a single channel is used and U1 is

V

and –

V

replaced by a matched pair of resistors to apply

I

at

I

the ends of the digital potentiometer. The relationship becomes

2

×

R2

1

+= 1

O

R1

is large, a compensation capacitor of a few pF may be

If

V

R2

D2

×

256

−

(7)

V

×

I

needed to avoid any gain peaking.

Table 10 shows the result of adjusting D, with A2 configured

with unity gain, gain of 2, and gain of 10. The result is a bipolar

amplifier with linearly programmable gain and 256-step

resolution.

Table 10. Result of Bipolar Gain Amplifier

D

R1 = ∞, R2 = 0

R1 = R2 R2 = 9 × R1

0 –1 –2 –10

64 –0.5 –1 –5

128 0 0 0

192 0.5 1 5

255 0.968 1.937 9.680

PROGRAMMABLE VOLTAGE SOURCE WITH BOOSTED OUTPUT

For applications that require high current adjustment, such as a

laser diode driver or tunable laser, a boosted voltage source can

be considered. See Figure 61.

AD8601

+V

U2

–V

U3 2N7002

SIGNAL

V

U1

AD5263

IN

A

W

B

Figure 61. Programmable Booster Voltage Source

In this circuit, the inverting input of the op amp forces the V

to be equal to the wiper voltage set by the digital potentiometer.

The load current is then delivered by the supply via the Nchannel FET N1. N1 power handling must be adequate to

– V

dissipate power equal to (V

IN

) × IL . This circuit can

OUT

source a maximum of 100 mA with a 5 V supply. For precision

applications, a voltage reference such as ADR421, ADR03, or

ADR370 can be applied at the A terminal of the digital

potentiometer.

V

OUT

R

BIAS

C

C

I

L

LD

03142-0-061

OUT

Rev. 0 | Page 21 of 28

Page 22

AD5263

S

D

V

B

+

+×′

PROGRAMMABLE 4–20 mA CURRENT SOURCE PROGRAMMABLE BIDIRECTIONAL CURRENT

A programmable 4–20 mA current source can be implemented

with the circuit shown in Figure 62. The REF191 is a unique low

supply headroom and high current handling precision reference

that can deliver 20 mA at +2.048 V. The load current is simply

the voltage across Terminals B-W of the digital potentiometer

divided by R

I

L

:

S

×

REF

= (8)

R

2×

+5V

2

VIN

VOUT

3

SLEEP

REF191

GND

4

–2.048V to V

N

U1

6

L

0 to (2.048V + VL)

C1

1µF

AD5263

+5V

U2

V+

OP8510

V–

–5V

B

W

A

R

102Ω

S

I

V

L

L

R

100Ω

L

03142-0-062

Figure 62. Programmable 4–20 mA Current Source

The circuit is simple, but beware of two things. First, dualsupply op amps are ideal because the ground potential of the

REF191 can swing from –2.048 V at zero scale to V

at full scale

L

of the potentiometer setting. Although the circuit works with a

single supply, the programmable resolution of the system will be

reduced.

For applications that demand higher current capabilities, a few

changes to the circuit in Figure 62 will produce an adjustable

current in the range of hundreds of mA. First, the voltage reference needs to be replaced with a high current, low dropout

regulator, such as the ADP3333, and the op amp needs to be

swapped with a high current, dual-supply model, such as the

AD8532. Depending on the desired range of current, an appropriate value for R

must be calculated. Because of the high

S

current flowing to the load, the user must pay attention to the

load impedance so as not to drive the op amp past the positive rail.

SOURCE

For applications that require bidirectional current control or

higher voltage compliance, a Howland current pump can be a

solution (see Figure 63). If the resistors are matched, the load

current is

R1R2BR2A

I

=

+5V

A

AD5263

W

–5V

Figure 63. Programmable Bidirectional Current Source

R2B, in theory, can be made as small as needed to achieve the

current needed within A2’s output current driving capability. In

this circuit, OP2177 can deliver ±5 mA in either direction, and

the voltage compliance approaches +15 V. It can be shown that

the output impedance is

Z

= (10)

o

×

This output impedance can be infinite if resistors R1′ and R2′

match precisely with R1 and R2A+R2B, respectively. On the

other hand, it can be negative if the resistors are not matched.

As a result, C1 in the range of 1 pF to 10 pF is needed to prevent

oscillation.

R2

+15V

OP2177

–15V

A1

)(

V

×

(9)

WL

+15V

OP2177

–15V

R2A

R2

15kΩ

C1

10pF

A2

V+

V–

14.95kΩ

R

L

R1

150kΩ

C2

10pF

V+

V–

′

′

−

R1

150kΩ

)(2

R2AR1BR1R

)(

R2BR2A1R2RR1

+

R2B

50Ω

500Ω

03142-0-063

V

L

I

L

Rev. 0 | Page 22 of 28

Page 23

AD5263

C

C

2R2C1R1

−

1

PROGRAMMABLE LOW-PASS FILTER PROGRAMMABLE OSCILLATOR

In A/D conversion applications, it is common to include an

antialiasing filter to band-limit the sampling signal. Dualchannel digital potentiometers can be used to construct a

second order Sallen-Key low-pass filter (see Figure 64). The

design equations are

In a classic Wien-bridge oscillator (Figure 65), the Wien

network (R, R

R2 provide negative feedback. At the resonant frequency,

′, C, C′) provides positive feedback, while R1 and

f

, the

O

overall phase shift is zero, and the positive feedback causes the

circuit to oscillate.

V

O

=

V

ω

Q

2

I

S

=

O

=

×

2

ω

O

ω

O

S

Q

1

+

(11)

2

ω

++

O

(12)

C2C1R2R1

×××

11

(13)

C

×

Users can first select some convenient values for the capacitors.

To achieve maximally flat bandwidth where Q = 0.707, let C1 be

twice the size of C2, and let R1 = R2. As a result, the user can

adjust R1 and R2 to the same settings to achieve the desired

bandwidth.

C1

R1

ABWAB

V

I

RR

ADJUSTED TO

SAME SETTING

R2

C2

Figure 64. Sallen-Key Low-Pass Filter

C

W

C

V+

AD8601

V–

+2.5V

U1

–2.5V

V

O

03142-0-064

With R = R

′, C = C′, and R2 = R2A||(R2B + R

DIODE

), the

oscillation frequency is

ω

where

R

1

, or

=

O

R

R

is equal to RWA, such that

256

=

256

f

D

R

AB

1

=

O

(14)

R

π

2

(15)

At resonance, setting

R2

(16)

2=

R

R2/R1

balances the bridge. In practice,

should be set slightly

greater than 2 to ensure that the oscillation can start. On the

other hand, the alternating turn-on of the diodes D1 and D2

R2/R1

ensures that

is momentarily less than 2, thereby

stabilizing the oscillation.

Once the frequency is set, the oscillation amplitude can be

R2B

O

, and

, since

(17)

VR2BIV

+×=

DD

VD

are interdependent variables. With proper

R2B

, an equilibrium will be reached such that

R2B

can be in series with a discrete resistor to

V

O

tuned by

2

3

V

,

I

O

D

selection of

converges.

increase the amplitude, but the total resistance should not be so

large that it saturates the output.

FREQUENCY

ADJUSTMENT

2.2nF

R1 = R1' = R2B = AD5263

D1 = D2 = 1N4148

Figure 65. Programmable Oscillator with Amplitude Control

B

R

A

VP

W

10kΩ

VN

R1

1kΩ

C

2.2nF

+2.5V

OP1177

–2.5V

R2B

B

W

V+

V–

R2A

2.1kΩ

A

10kΩ

A

10kΩ

U1

R'

B

W

D1

D2

AMPLITUDE

ADJUSTMENT

V

O

03142-0-065

Rev. 0 | Page 23 of 28

Page 24

AD5263

RESISTANCE SCALING RESISTANCE TOLERANCE, DRIFT, AND

The AD5263 offers 20kΩ, 50kΩ, and 200kΩ nominal

resistances. Users who need a lower resistance and the same

number of step adjustments can place multiple devices in

parallel. For example, Figure 66 shows a simple scheme of using

two channels in parallel. To adjust half of the resistance linearly

per step, users need to program both channels to the same

settings.

V

DD

A1

B1

LED

W1

A2

W2

B2

03142-0-066

Figure 66. Reduce Resistance by Half with Linear Adjustment Characteristics

Applicable only to the voltage divider mode, by connecting a

discrete resistor in parallel as shown in Figure 67, a

proportionately lower voltage appears at Terminal A. This

translates into a finer degree of precision because the step size at

Terminal W will be smaller. The voltage can be found as

VD

DV

)( ×

W

×=

DD

()

+

AB

V

R2

R1

R1 << R

Figure 67. Decreasing Step Size by Lowering the Nominal Resistance

(

R1RR2

||256

DD

A

W

B

AB

AB

03142-0-067

||

)

(18)

R1R

Figure 66 and Figure 67 show applications in which the digital

potentiometers change steps linearly. On the other hand, log

taper adjustment is usually preferred in applications such as

volume control. Figure 68 shows another method of resistance

scaling which produces a pseudo-log taper output. In this

circuit, the smaller the value of R2 with respect to R

, the more

AB

the output approaches log type behavior.

V

I

A

R1

B

V

O

R2

TEMPERATURE COEFFICIENT MISMATCH

CONSIDERATIONS

In the rheostat mode operation, such as the gain control circuit

of Figure 69, the tolerance mismatch between the digital

potentiometer and the discrete resistor can cause repeatability

issues among various systems. Because of the inherent matching

of the silicon process, it is practical to apply the multichannel

device in this type of application. As such, R1 should be

replaced by one of the channels of the digital potentiometer. R1

should be programmed to a specific value while R2 can be used

for the adjustable gain. Although it adds cost, this approach

minimizes the tolerance and temperature coefficient mismatch

between R1 and R2. In addition, this approach also tracks the

resistance drift over time. As a result, these non-ideal

parameters become less sensitive to system variations.

R2

AB

W

AD8601

AD8601

U1

Drift

C1

V

O

U1

C1

V

O

03142-0-071

R1

V

I

*REPLACED WITH ANOTHER CHANNEL OF RDAC

Figure 69. Linear Gain Control with Tracking Resistance Tolerance and Drift

Notice that the circuit in Figure 70 can also be used to track the

tolerance, temperature coefficient, and drift in this particular

application. However, the characteristics of the transfer function

change from a linear to a pseudo-logarithmic gain function.

ARB

W

V

I

Figure 70. Nonlinear Gain Control with Tracking Resistance Tolerance and

03142-0-070

03142-0-068

Figure 68. Resistor Scaling with Log Adjustment Characteristics

Rev. 0 | Page 24 of 28

Page 25

AD5263

PIN CONFIGURATION AND PIN FUNCTION DESCRIPTIONS

PIN CONFIGURATION

1

B1

2

A1

AD5263

3

W1

TSSOP-24

4

B3

5

A3

6

W3

7

V

DD

TOP VIEW

8

GND

(Not to Scale)

9

DIS

10

V

LOGIC

11

SDI/SDA

CLK/SCL

12

Figure 71. 24-Lead TSSOP

PIN FUNCTION DESCRIPTIONS

Table 11.

Pin Name Description

1 B1 Resistor Terminal B1

2 A1 Resistor Terminal A1 (ADDR = 00)

3 W1 Wiper Terminal W1

4 B3 Resistor Terminal B3

5 A3 Resistor Terminal A3

6 W3 Wiper Terminal W3 (ADDR = 10)

7

V

DD

Positive Power Supply, specified for +5 V to +15 V operation.

8 GND Ground

9

DIS Digital Interface Select (SPI/I

10 V

2.7 V to 5.5 V Logic Supply Voltage. The logic supply voltage should always be less than or equal to VDD. In addition, logic

LOGIC

levels must be limited to the logic supply voltage regardless of V

11 SDI/SDA SDI = 3-Wire Serial Data Input. SDA = 2-Wire Serial Data Input/Output.

12 CLK/SCL Serial Clock Input

13

CS

/AD0

14

RES

/AD1

15

SHDN

16 SDO/O1 Serial Data Output in SPI Mode, open-drain transistor requires pull-up resistor.

Chip Select in SPI Mode. Device Address Bit 0 in I

RESET in SPI Mode. Device Address Bit 1 in I

Shutdown. Shorts wiper to Terminal B, opens Terminal A. Tie to +5 V supply if not used. Do not tie to V

Digital Output O1 in I

2

C Mode, can be used to drive external logic.