Page 1

1-/2-Channel

S

S

R

WB

R

WA

CODE – Decimal

100

064128192 256

PERCENT OF NOMINAL

END-TO-END RESISTANCE – % R

AB

75

50

25

0

www.BDTIC.com/ADI

a

FEATURES

256 Positions

AD5260 – 1-Channel

AD5262 – 2-Channel (Independently Programmable)

Potentiometer Replacement

20 k⍀, 50 k⍀, 200 k⍀

Low Temperature Coefficient 35 ppm/ⴗC

4-Wire SPI-Compatible Serial Data Input

5 V to 15 V Single-Supply; ⴞ5.5 V Dual-Supply Operation

Power ON Mid-Scale Preset

APPLICATIONS

Mechanical Potentiometer Replacement

Instrumentation: Gain, Offset Adjustment

Stereo Channel Audio Level Control

Programmable Voltage to Current Conversion

Programmable Filters, Delays, Time Constants

Line Impedance Matching

Low Resolution DAC Replacement

GENERAL DESCRIPTION

The AD5260/AD5262 provide a single- or dual-channel, 256position, digitally controlled variable resistor (VR) device.* These

devices perform the same electronic adjustment function as a

potentiometer or variable resistor. Each channel of the AD5260/

AD5262 contains a fixed resistor with a wiper contact that taps the

fixed resistor value at a point determined by a digital code loaded

into the SPI-compatible serial-input register. The resistance between

the wiper and either end point of the fixed resistor varies linearly

with respect to the digital code transferred into the VR latch. The

variable resistor offers a completely programmable value of resistance,

between the A terminal and the wiper or the B terminal and the wiper.

The fixed A to B terminal resistance of 20 kW, 50 kW, or 200 kW has

a nominal temperature coefficient of 35 ppm/∞C. Unlike the majority

of the digital potentiometers in the market, these devices can operate

up to 15 V or ± 5 V provided proper supply voltages are furnished.

Each VR has its own VR latch, which holds its programmed resistance

value. These VR latches are updated from an internal serial-to-parallel

shift register, which is loaded from a standard 3-wire serial-input

digital interface. The AD5260 contains an 8-bit serial register

while the AD5262 contains a 9-bit serial register. Each bit is clocked

into the register on the positive edge of the CLK. The AD5262

address bit determines the corresponding VR latch to be loaded

with the last 8 bits of the data word during the positive edging of

CS strobe. A serial data output pin at the opposite end of the serial

register enables simple daisy chaining in multiple VR applications

without additional external decoding logic. An optional reset pin

(PR) forces the wiper to the mid-scale position by loading 80

the VR latch.

*The terms digital potentiometers, VR, and RDAC are used interchangeably.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

15 V Digital Potentiometers

AD5260/AD5262

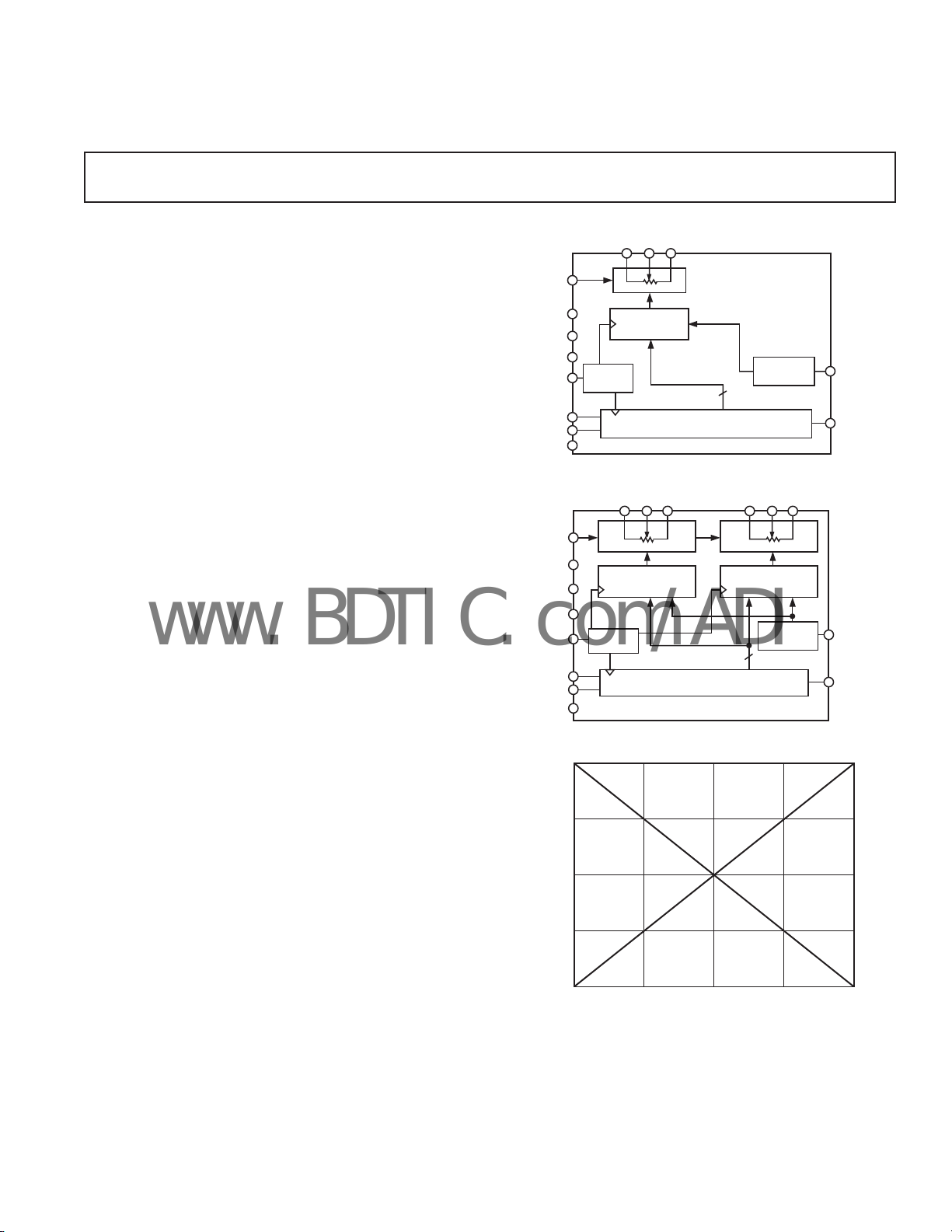

FUNCTIONAL BLOCK DIAGRAMS

AWB

HDN

V

DD

V

SS

V

L

CS

CLK

SDI

GND

HDN

V

DD

V

SS

V

L

CS

CLK

SDI

GND

into

H

RDAC

REGISTER

LOGIC

SERIAL INPUT REGISTER

A1 W1 B1

RDAC1 REGISTER

LOGIC

SERIAL INPUT REGISTER

AD5262

Figure 1. RWA and RWB vs. Code

The AD5260/AD5262 are available in thin surface-mount TSSOP-14

and TSSOP-16 packages. All parts are guaranteed to operate over

the extended industrial temperature range of –40∞C to +85∞C.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

AD5260

POWER-ON

RESET

8

A2 W2 B2

RDAC2 REGISTER

POWER-ON

RESET

8

PR

SDO

PR

SDO

Page 2

(VDD = +15 V, VSS = 0 V or, VDD = +5 V, VSS = –5 V, VL = +5 V, VA = +5 V,

www.BDTIC.com/ADI

AD5260/AD5262–SPECIFICATIONS

VB = 0 V, – 40ⴗC < TA < +85ⴗC unless otherwise noted.)

ELECTRICAL CHARACTERISTICS 20 kW, 50 kW, 200 kW VERSIONS

Parameter Symbol Conditions Min Typ

DC CHARACTERISTICS RHEOSTAT MODE Specifications apply to all VRs

Resistor Differential NL

Resistor Nonlinearity

Nominal Resistor Tolerance

Resistance Temperature Coefficient R

Wiper Resistance R

Channel Resistance Matching (AD5262 only) R

Resistance Drift R

2

2

3

R-DNL RWB, VA=NC –1 ± 1/4 +1 LSB

R-INL RWB, VA=NC –1 ± 1/2 +1 LSB

R

AB

/TWiper = No Connect 35 ppm/∞C

AB

W

WB/RWB

AB

TA = 25∞C –30 30 %

IW = 1 V/R

Ch 1 and 2 R

AB

WB, DX = 80H

DC CHARACTERISTICS POTENTIOMETER DIVIDER MODE Specifications apply to all VRs

Resolution N 8 Bits

Differential Nonlinearity

Integral Nonlinearity

Voltage Divider Temperature Coefficient DV

Full-Scale Error V

Zero-Scale Error V

RESISTOR TERMINALS

Voltage Range

Capacitance

5

6

Ax, Bx C

Capacitance6 Wx C

Common-Mode Leakage Current I

Shut Down Current

4

4

7

DNL –1 ± 1/4 +1 LSB

INL –1 ± 1/2 +1 LSB

/DTCode = 80

WFSE

WZSE

V

A, B, W

A,B

W

CM

I

SHDN

W

Code = FF

Code = 00

f = 5 MHz, 25 pF

measured to GND, Code = 80

f = 1 MHz, 55 pF

measured to GND, Code = 80

VA =VB = V

H

H

H

H

/2 1 nA

DD

H

–2 –1 +0 LSB

01 2LSB

V

SS

DIGITAL INPUTS and OUTPUTS

Input Logic High V

Input Logic Low V

Input Logic High V

Input Logic Low V

Output Logic High (SDO) V

Output Logic Low (SDO) V

Input Current

Input Capacitance

8

6

IH

IL

IH

IL

OH

OL

I

IL

C

IL

VL = 3 V, VSS = 0 V 2.1 V

VL = 3 V, VSS = 0 V 0.6 V

R

IOL = 1.6 mA, V

= 2 kW to 5 V 4.9 V

PULL-UP

= 5 V 0.4 V

LOGIC

VIN = 0 V or 5 V ± 1 mA

2.4 V

POWER SUPPLIES

Logic Supply V

Power Single-Supply Range V

Power Dual-Supply Range V

Logic Supply Current I

Positive Supply Current I

Negative Supply Current I

Power Dissipation

9

L

DD RANGE

DD/SS RANGE

L

DD

SS

P

DISS

VSS = 0 V 4.5 16.5 V

VL =5 V 60 mA

VIH = 5 V or VIL = 0 V 1 mA

VSS = –5 V 1 mA

VIH = 5 V or VIL = 0 V, 0.3 mW

= +5 V, VSS = –5 V

V

DD

2.7 5.5 V

± 4.5 ± 5.5 V

Power Supply Sensitivity PSS DVDD = +5 V, ± 10% 0.003 0.01 %/%

DYNAMIC CHARACTERISTICS

6, 10

Bandwidth –3 dB BW RAB = 20 kW/50 kW/200 kW 310/130/30 kHz

Total Harmonic Distortion THD

V

Settling Time t

W

Crosstalk

11

S

C

T

W

VA = 1 V

f=1 kHz, R

VA = +5 V, VB = –5 V, 5 ms

± 1 LSB error band, R

VA = VDD, VB=0 V,

Measure V

, VB = 0 V, 0.014 %

RMS

= 20 kW

AB

= 20 kW

AB

with Adjacent

W

RDAC Making Full-Scale 1 nV–s

Code Change (AD5262 only)

Analog Crosstalk C

Resistor Noise Voltage e

TA

N_WB

VA1= VDD, VB1= 0V,

Measure V

= 5 V p-p @ f = 10 kHz, –64 dB

V

W2

R

= 20 kW/200 kW (AD5262 only)

AB

W1

with

RWB = 20 kW 13 nV/÷Hz

f = 1 kHz

1

Max Unit

60 150 W

0.1 %

0.05 %

5 ppm/∞C

V

DD

5 mA

0.8 V

5pF

V

–2–

REV. 0

Page 3

AD5260/AD5262

www.BDTIC.com/ADI

Parameter Symbol Conditions Min Typ Max Unit

INTERFACE TIMING CHARACTERISTICS apply to all parts

Clock Frequency f

Input Clock Pulsewidth t

Data Setup Time t

Data Hold Time t

CLK to SDO Propagation Delay

13

CS Setup Time t

CS High Pulsewidth t

Reset Pulsewidth t

CLK Fall to CS Rise Hold Time t

CS Rise to Clock Rise Setup t

NOTES

The AD5260/AD5262 contains 1,968 transistors. Die Size: 89 mil. × 105 mil. 9,345 sq. mil.

1

Typicals represent average readings at 25°C and VDD = +5 V, VSS = –5 V.

2

Resistor position nonlinearity error R-INL is the deviation from an ideal value measured between the maximum resistance and the minimum resistance wiper positions.

R-DNL measures the relative step change from ideal between successive tap positions. Parts are guaranteed monotonic. I

3

VAB = VDD, Wiper (VW) = No connect.

4

INL and DNL are measured at VW with the RDAC configured as a potentiometer divider similar to a voltage output D/A converter. VA = VDD and VB = 0V. DNL

specification limits of ± 1 LSB maximum are Guaranteed Monotonic operating conditions.

5

Resistor terminals A, B, W have no limitations on polarity with respect to each other.

6

Guaranteed by design and not subject to production test.

7

Measured at the Ax terminals. All Ax terminals are open-circuit in shutdown mode.

8

Worst-case supply current consumed when input all logic-input levels set at 2.4 V, standard characteristic of CMOS logic.

9

P

is calculated from (IDD ⫻ VDD). CMOS logic level inputs result in minimum power dissipation.

DISS

10

All dynamic characteristics use VDD = +5 V, VSS = –5 V, VL = +5 V.

11

Measured at a VW pin where an adjacent VW pin is making a full-scale voltage change.

12

See timing diagram for location of measured values. All input control voltages are specified with tR=tF= 2ns (10% to 90% of 3 V) and timed from a voltage level of 1.5 V.

Switching characteristics are measured using VL = 5 V.

13

Propagation delay depends on value of VDD, RL, and CL.

Specifications subject to change without notice.

CLK

CH

DS

DH

t

PD

CSS

CSW

RS

CSH

CS1

, t

CL

6, 12

25 MHz

Clock level high or low 20 ns

10 ns

10 ns

RL = 1 kΩ, CL < 20pF 1 160 ns

5ns

20 ns

50 ns

0ns

10 ns

= VDD/R for both VDD= +5 V, VSS=–5V.

W

ABSOLUTE MAXIMUM RATINGS

(TA = 25°C, unless otherwise noted.)

1

VDD to GND . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, +15 V

V

to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 V, –7 V

SS

V

to VSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 V

DD

V

, VB, VW to GND . . . . . . . . . . . . . . . . . . . . . . . . . . VSS, V

A

AX – BX, AX – WX, BX – W

X

DD

Intermittent2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 20 mA

Continuous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 5 mA

Digital Inputs and Output Voltage to GND . . . . . . . 0 V, 7 V

Operating Temperature Range . . . . . . . . . . . . –40°C to +85°C

Maximum Junction Temperature (T

) . . . . . . . . . . . 150°C

J MAX

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . 300°C

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

Thermal Resistance

3

θ

JA

TSSOP-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206°C/W

TSSOP-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150°C/W

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause permanent

damage to the device. This is a stress rating only; functional operation of the device

at these or any other conditions above those listed in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

2

Maximum terminal current is bounded by the maximum current handling of the

switches, maximum power dissipation of the package, and maximum applied

voltage across any two of the A, B, and W terminals at a given resistance setting.

3

Package Power Dissipation = (T

J MAX

– TA)/ θ

JA

REV. 0

–3–

Page 4

AD5260/AD5262

WARNING!

ESD SENSITIVE DEVICE

www.BDTIC.com/ADI

ORDERING GUIDE

Package Package No. of Parts Branding

Model R

AD5260BRU20 20 –40∞C to +85∞CTSSOP-14 RU-14 96 AD5260B20

AD5260BRU20-REEL7 20 –40∞C to +85∞CTSSOP-14 RU-14 1000 AD5260B20

AD5260BRU50 50 –40∞C to +85∞CTSSOP-14 RU-14 96 AD5260B50

AD5260BRU50-REEL7 50 –40∞C to +85∞CTSSOP-14 RU-14 1000 AD5260B50

AD5260BRU200 200 –40∞C to +85∞CTSSOP-14 RU-14 96 AD5260B200

AD5260BRU200-REEL7 200 –40∞C to +85∞CTSSOP-14 RU-14 1000 AD5260B200

AD5262BRU20 20 –40∞C to +85∞CTSSOP-16 RU-16 96 AD5262B20

AD5262BRU20-REEL7 20 –40∞C to +85∞CTSSOP-16 RU-16 1000 AD5262B20

AD5262BRU50 50 –40∞C to +85∞CTSSOP-16 RU-16 96 AD5262B50

AD5262BRU50-REEL7 50 –40∞C to +85∞CTSSOP-16 RU-16 1000 AD5262B50

AD5262BRU200 200 –40∞C to +85∞CTSSOP-16 RU-16 96 AD5262B200

AD5262BRU200-REEL7 200 –40∞C to +85∞CTSSOP-16 RU-16 1000 AD5262B200

*

Line 1 contains part number, line 2 contains differentiating detail by part type and ADI logo symbol, line 3 contains date code YWW.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the AD5260/AD5262 features proprietary ESD protection circuitry, permanent damage may occur

on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions

are recommended to avoid performance degradation or loss of functionality.

(kW) Temperature Description Option per Container Information

AB

*

–4–

REV. 0

Page 5

AD5260/AD5262

www.BDTIC.com/ADI

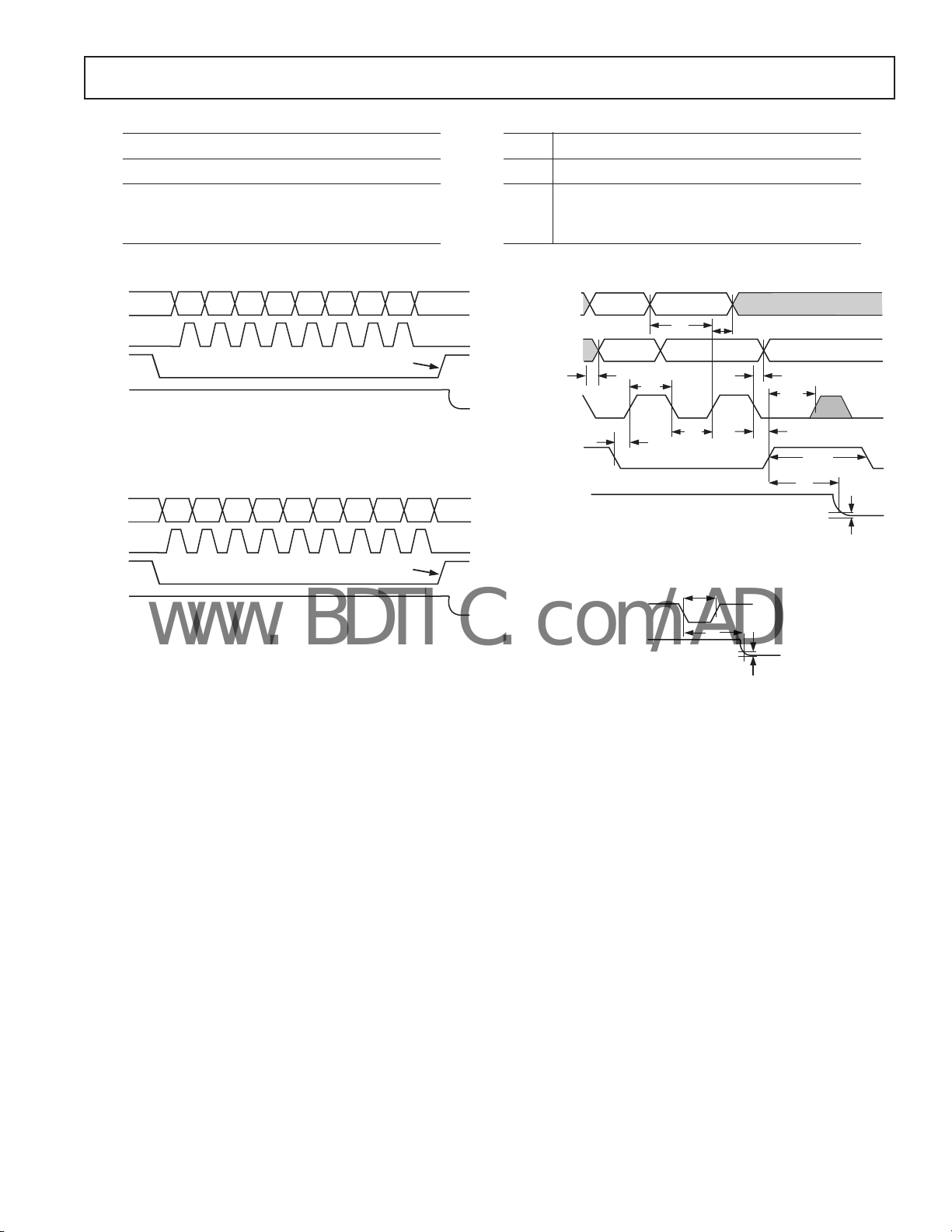

Table I. AD5260 8-Bit Serial-Data Word Format

DATA

B7 B6 B5 B4 B3 B2 B1 B0

D7 D6 D5 D4 D3 D2 D1 D0

MSB LSB

7

2

1

CLK

V

OUT

SDI

CS

0

1

0

1

0

1

0

D7 D6 D5 D4 D3 D2 D1 D0

RDAC REGISTER LOAD

Figure 2a. AD5260 Timing Diagram

1

CLK

V

SDI

CS

OUT

0

1

0

1

0

1

0

D7 D6 D5 D4 D3 D2 D1 D0A0

RDAC REGISTER LOAD

Figure 2b. AD5262 Timing Diagram

Table II. AD5262 9-Bit Serial-Data Word Format

ADDR DATA

B8 B7 B6 B5 B4 B3 B2 B1 B0

A0 D7 D6 D5 D4 D3 D2 D1 D0

0

2

8

2

(DATA OUT)

MSB LSB

7

2

1

SDI

(DATA IN)

SDO

CLK

CS

V

OUT

Ax OR Dx Dx

0

1

ⴕ

x OR DⴕxDⴕx

A

0

1

0

1

0

V

DD

0V

t

DH

t

DS

t

CH

t

CL

t

CSS

ⴞ1 LSB ERROR BAND

t

PD_MAX

t

CS1

t

CSH

0

2

t

CSW

t

S

ⴞ1 LSB

Figure 2c. Detail Timing Diagram

PR

V

OUT

1

0

V

DD

0V

ⴞ1 LSB ERROR BAND

t

RS

t

S

ⴞ1 LSB

Figure 2d. Preset Timing Diagram

REV. 0

–5–

Page 6

AD5260/AD5262

TOP VIEW

(Not to Scale)

1

2

3

4

5

6

7

8

A2

A1

W1

V

DD

SHDN

CLK

SDI

SDO

V

L

V

SS

AD5262

16

15

14

13

12

11

10

9

GND

PR

CS

B1

B2

W2

www.BDTIC.com/ADI

AD5260 PIN CONFIGURATION

SDO

14

NC

13

V

12

L

V

11

SS

10

GND

9

PR

8

CS

V

SHDN

CLK

SDI

A

W

B

DD

1

2

3

AD5260

4

TOP VIEW

5

(Not to Scale)

6

7

AD5260 PIN FUNCTION DESCRIPTIONS

Pin

Number Mnemonic Description

1A A Terminal

2W Wiper Terminal

3B B Terminal

4V

DD

Positive power supply, specified

for operation at both 5 V or 15 V.

(Sum of |V

| + |VSS| £ 15 V)

DD

5 SHDN Active low input. Terminal A

open-circuit. Shutdown controls.

Variable Resistors of RDAC.

6 CLK Serial Clock Input, positive edge

triggered.

7 SDI Serial Data Input

8 CS Chip Select Input, Active Low.

When CS returns high, data will

be loaded into the RDAC register.

9 PR Active low preset to mid-scale; sets

RDAC registers to 80

.

H

10 GND Ground

11 V

SS

Negative Power Supply, specified

for operation from 0 V to –5 V.

12 V

L

Logic Supply Voltage, needs to be

same voltage as the digital logic

controlling the AD5260.

13 NC No Connect (Users should not

connect anything other than dummy

pad on this pin)

14 SDO Serial Data Output, Open Drain

transistor requires pull-up resistor.

AD5262 PIN CONFIGURATION

AD5262 PIN FUNCTION DESCRIPTIONS

Pin

Number Mnemonic Description

1SDO Serial Data Output, Open Drain

transistor requires pull-up resistor.

2A1A Terminal RDAC #1

3W1 Wiper RDAC #1, address A0 = 0

2

4B1B Terminal RDAC #1

5V

DD

Positive power supply, specified for

operation at both 5 V or 15 V.

(Sum of |V

|+|VSS|£ 15 V)

DD

6 SHDN Active low input. Terminal A

open-circuit. Shutdown controls

Variable Resistors #1 through #2.

7 CLK Serial Clock Input, positive edge

triggered.

8 SDI Serial Data Input.

9 CS Chip Select Input, Active Low.

When CS returns high, data in

the serial input register is decoded,

based on the address Bit A0, and

loaded into the target RDAC register.

10 PR Active low preset to mid-scale sets

RDAC registers to 80

.

H

11 GND Ground

12 V

SS

Negative Power Supply, specified

for operation at both 0 V or –5 V

13 V

(Sum of |V

L

Logic Supply Voltage, needs to be

| + |VSS| <15 V).

DD

same voltage as the digital logic

controlling the AD5262.

14 B2 B Terminal RDAC #2

15 W2 Wiper RDAC #2, address A0 = 1

2

16 A2 A Terminal RDAC #2

–6–

REV. 0

Page 7

AD5260/AD5262

www.BDTIC.com/ADI

THEORY OF OPERATION

The AD5260/AD5262 provide a single- or dual-channel, 256-position

digitally controlled variable resistor (VR) device and operate up to

15 V maximum voltage. Changing the programmed VR settings

is accomplished by clocking an 8-/9-bit serial data word into the

SDI (Serial Data Input) pin. For the AD5262, the format of this

data word is one address bit. A0 represents the first bit B8, then

followed by eight data bits B7–B0 with MSB first. Tables I and II

provide the serial register data word format. See Table III for the

AD5262 address assignment to decode the location of the VR latch

receiving the serial register data in bits B7 through B0. VR outputs

can be changed one at a time in random sequence. The AD5260/

AD5262 presets to a mid-scale, simplifying fault condition recovery at power-up. Mid-scale can also be achieved at any time by

asserting the PR pin. Both parts have an internal power ON preset

that places the wiper in a mid-scale preset condition at power ON.

Operation of the power ON preset function depends only on the

state of the V

L

pin.

The AD5260/AD5262 contains a power shutdown SHDN pin,

which places the RDAC in an almost zero power consumption

state where terminals Ax are open circuited, and the wiper W is connected to B, resulting in only leakage currents being consumed in

the VR structure. In the shutdown mode, the VR latch settings are

maintained so that, returning to operational mode from power

shutdown, the VR settings return to their previous resistance values.

Table III. AD5262 Address Decode Table

A0 Latch Loaded

0 RDAC#1

1 RDAC#2

DIGITAL INTERFACING

The AD5260/AD5262 contains a 4-wire SPI-compatible

digital interface (SDI, SDO, CS, and CLK). For the AD5260,

the 8-bit serial word must be loaded with MSB first, and the

format of the word is shown in Table I. For the AD5262, the

9-bit serial word must be loaded with address bit A0 first, then

MSB of the data. The format of the word is shown in Table II.

CS

CLK

SDI

SDO

PR

GND

V

L

RDAC

LATCH

#1

PR

RDAC

LATCH

#2

PR

A0

SER

REG

D7

D6

D5

D4

D3

D2

D1

D0

POWER-

ON

PRESET

EN

ADDR

DEC

V

DD

A1

W1

B1

A2

W2

B2

SHDN

V

SS

Figure 3. AD5262 Block Diagram

The positive-edge sensitive CLK input requires clean transitions

to avoid clocking incorrect data into the serial input register.

Standard logic families work well. If mechanical switches are used

for product evaluation, they should be debounced by a flip-flop or

other suitable means. Figure 3 shows more detail of the internal

digital circuitry. When CS is low, the clock loads data into the

serial register on each positive clock edge (see Table IV).

Table IV. Truth Table

CLK CS PR SHDN Register Activity

LLHH No SR effect, enables SDO pin

≠* LH HShift one bit in from the SDI pin.

The eighth previously entered bit is

shifted out of the SDO pin.

X ≠ HH Load SR data into RDAC latch

XHHH No Operation

XXLH Sets all RDAC latches to Mid-Scale,

wiper centered, and SDO latch

cleared.

XH≠ HLatches all RDAC latches to 80

.

H

XHHL Open circuits all resistor A–terminals,

connects W to B, turns off SDO

output transistor.

*≠ = positive edge, X = don’t care, SR = shift register

The data setup and data hold times in the specification table

determine the data valid time requirements. The AD5260 uses

an 8-bit serial input data register word that is transferred to the

internal RDAC register when the CS line returns to logic high.

For the AD5262 the last 9 bits of the data word entered into the

serial register are held when CS returns high. Any extra bits are

ignored. At the same time CS goes high, it gates the address

decoder enabling AD5262 one of two positive edge-triggered

AD5262 RDAC latches (see Figure 4).

AD5260/AD5262

CLK

SDI

CS

ADDR

DECODE

SERIAL

REGISTER

RDAC 1

RDAC 2

Figure 4. Equivalent Input Control Logic

The target RDAC latch is loaded with the last 8 bits of the serial data

word completing one RDAC update. For the AD5262, two separate

9-bit data words must be clocked in to change both VR settings.

During shutdown (SHDN) the SDO output pin is forced to the

off (logic high state) to disable power dissipation in the pull-up

resistor. See Figure 5 for equivalent SDO output circuit schematic.

SHDN

CS

SDI

CLK

PR

SERIAL

REGISTER

DQ

RS

CK

SDO

Figure 5. Detail SDO Output Schematic of the AD5260

REV. 0

–7–

Page 8

AD5260/AD5262

www.BDTIC.com/ADI

All digital inputs are protected with a series input resistor and

parallel Zener ESD structure as shown in Figure 6. This applies

to digital input pins CS, SDI, SDO, PR, SHDN, and CLK.

340⍀

LOGIC

Figure 6. ESD Protection of Digital Pins

A, B, W

V

SS

Figure 7. ESD Protection of Resistor Terminals

LAYOUT AND POWER SUPPLY BYPASSING

It is a good practice to employ compact, minimum-lead length

layout design. The leads to the input should be as direct as possible

with a minimum conductor length. Ground paths should

have low resistance and low inductance.

Similarly, it is also a good practice to bypass the power supplies

with quality capacitors for optimum stability. Supply leads to the

device should be bypassed with 0.01 mF–0.1 mF disc or chip ceram-

ics

capacitors. Low-ESR 1 mF to 10 mF tantalum or electrolytic

capaci

tors should also be applied at the supplies to minimize any

transient

disturbance (see Figure 8). Notice the digital ground

should also be joined remotely to the analog ground to minimize

the ground bounce.

V

DD

V

SS

ⴙ

C1

C3

10F

0.1F

ⴙ

C2

C4

10F

0.1F

V

DD

V

GND

SS

of this data sheet. An internal level shift circuit ensures that the

common-mode voltage range of the three terminals extends

from V

SS

to V

regardless of the digital input level.

DD

POWER-UP SEQUENCE

Since there are diodes to limit the voltage compliance at terminals A, B, and W (see Figure 9), it is important to power V

DD/VSS

first before applying any voltage to terminals A, B, and W. Otherwise, the diode will be forward biased such that V

DD/VSS

will be

powered unintentionally and may affect the rest of the user’s circuit.

The ideal power-up sequence is in the following order: GND,

V

, VSS, VL, Digital Inputs, and V

DD

V

, VB, VW, and Digital Inputs is not important as long as they

A

are powered after V

DD/VSS

.

. The order of powering

A/B/W

Daisy-Chain Operation

The serial-data output (SDO) pin contains an open drain

n-channel FET. This output requires a pull-up resistor to transfer data to the next package’s SDI pin. This allows for daisy

chaining several RDACs from a single processor serial data line.

The pull-up resistor termination voltage can be larger than the V

DD

supply voltage. It is recommended to increase the Clock period

when using a pull-up resistor to the SDI pin of the following device

in series because capacitive loading at the daisy-chain node

SDO-SDI between devices may induce time delay to subsequent

devices. Users should be aware of this potential problem to achieve

data transfer successfully (see Figure 10). If two AD5260s are daisychained, this requires a total of 16 bits of data. The first 8 bits,

complying with the format shown in Table I, go to U2, and the

second 8 bits with the same format go to U1. The CS should be

kept low until all 16 bits are clocked into their respective serial

registers, and the CS is then pulled high to complete the operation.

V

DD

SCLK SS

AD5260 AD5260

U1

CLK

CS

R

P

2.2k⍀

SDOSDIMOSIC

CS

U2

SDOSDI

CLK

Figure 8. Power Supply Bypassing

TERMINAL VOLTAGE OPERATING RANGE

Figure 10. Daisy-Chain Configuration

The AD5260/AD5262 positive VDD and negative VSS power

supply defines the boundary conditions for proper 3-terminal

digital potentiometer operation. Supply signals present on terminals A, B, and W that exceed V

or VSS will be clamped by the

DD

internal forward biased diodes (see Figure 9).

V

DD

A

W

B

V

SS

Figure 9. Maximum Terminal Voltages Set by VDD and V

The ground pin of the AD5260/AD5262 device is primarily used

as a digital ground reference, which needs to be tied to the PCB’s

common ground. The digital input control signals to the AD5260/

AD5262 must be referenced to the device ground pin (GND),

RDAC STRUCTURE

The RDAC contains a string of equal resistor segments, with an

array of analog switches, that act as the wiper connection. The

number of positions is the resolution of the device. The AD5260/

AD5262 have 256 connection points allowing it to provide better

than 0.4% set-ability resolution. Figure 11 shows an equivalent

structure of the connections between the three terminals that

make up one channel of the RDAC. The SW

always be ON, while one of the switches SW(0) to SW(2

will be ON one at a time depending on the resistance position

decoded from the data bits. Since the switch is not ideal, there is

a 60 W wiper resistance, R

supply voltage and temperature. The lower the supply voltage, the

SS

higher the wiper resistance. Similarly, the higher the temperature,

. Wiper resistance is a function of

W

the higher the wiper resistance. Users should be aware of the

contribution of the wiper resistance when accurate prediction of

the output resistance is needed.

and must satisfy the logic level defined in the specification table

–8–

and SWB will

A

N

– 1)

REV. 0

Page 9

AD5260/AD5262

S

R

WB

R

WA

R

AB

= 20K⍀

D – CODE in decimal

20

064128192 256

R

WA

(D), R

WB

(D) ⴚ k⍀

16

12

8

4

0

www.BDTIC.com/ADI

Ax

HDN

RS

Note that in the zero-scale condition a finite wiper resistance of

60 W is present. Care should be taken to limit the current flow

between W and B in this state to no more than 20 mA to avoid

degradation or possible destruction of the internal switches.

R

D7

D6

D5

D4

D3

D2

D1

D0

S

Like the mechanical potentiometer the RDAC replaces, the

AD5260/AD5262 parts are totally symmetrical. The resistance

R

S

between the wiper W and terminal A also produces a digitally

controlled complementary resistance R

Wx

symmetrical programmability of the various terminal connections.

When R

is used, the B–terminal can be let floating or tied to the

WA

wiper. Setting the resistance value for R

value of resistance and decreases as the data loaded in the latch

RDAC

LATCH

AND

DECODE

DIGITAL CIRCUITRY

OMITTED FOR CLARITY

RS

= RAB/2

R

S

Bx

N

Figure 11. Simplified RDAC Architecture

PROGRAMMING THE VARIABLE RESISTOR

Rheostat Operation

The nominal resistances of the RDAC between terminals A and B

are available with values of 20 kW, 50 kW, and 200 kW. The final

three digits of the part number determine the nominal resistance

value, e.g., 20 kW = 20; 50 kW = 50; 200 kW = 200. The nominal

resistance (R

) of the VR has 256 contact points accessed by the

AB

wiper terminal, plus the B terminal contact. The 8-bit data in the

is increased in value. The general equation for this operation is:

D

-

RD

WA AB W

For example, R

256

=

()

AB

¥+

256

= 20 kW, when VA = 0 V and B–terminal is open,

the following output resistance R

RDAC latch codes. The result will be the same if terminal B is

tied to W:

DR

(DEC) (W)Output State

256 60 Full-Scale

128 10060 Mid-Scale

1 19982 1 LSB

0 20060 Zero-Scale

RDAC latch is decoded to select one of the 256 possible settings.

Assuming a 20 kW part is used, the wiper’s first connection starts

at the B terminal for data 00

. Since there is a 60 W wiper contact

H

resistance, such connection yields a minimum of 60 W resistance

between terminals W and B. The second connection is the first tap

point corresponds to 138 W (R

for data 01

. The third connection is the next tap point represent-

H

ing 216 W (78 2 60) for data 02

= RAB/256 RW = 78 W 60 W)

WB

and so on. Each LSB data

H

value increase moves the wiper up the resistor ladder until the last

tap point is reached at 19982 W [R

1 LSB RW]. The wiper

AB

does not directly connect to the B terminal. See Figure 11 for a

simplified diagram of the equivalent RDAC circuit.

The general equation determining the digitally programmed

output resistance between W and B is:

RD

WB AB W

D

256

RR

=¥+

()

where D is the decimal equivalent of the binary code which is

loaded in the 8-bit RDAC register, and R

is the nominal end-

AB

to-end resistance.

For example, R

= 20 kW, when VB = 0 V and A–terminal is

AB

open circuit, the following output resistance values R

set for the following RDAC latch codes. The result will be the

same if terminal A is tied to W:

DR

WB

(DEC) (W)Output State

256 19982 Full-Scale (R

– 1 LSB + RW)

AB

128 10060 Mid-Scale

1 138 1 LSB

060Zero-Scale (wiper contact resistance)

REV. 0

will be

WB

(1)

Figure 12. AD5260/AD5262 Equivalent RDAC Circuit

The typical distribution of the nominal resistance RAB from

channel to channel matches within ± 1%. Device-to-device matching is process lot dependent with the worst case of ± 30% variation.

On the other hand, since the resistance element is processed in

thin film technology, the change in R

low 35 ppm/∞C temperature coefficient.

–9–

RR

will be set for the following

WA

WA

AB

. Figure 12 shows the

WA

starts at a maximum

WA

(2)

with temperature has a

Page 10

AD5260/AD5262

CODE – Decimal

POTENTIOMETER MODE INL – LSB

0 256

–1.0

32 64 96 128 160 192 224

–0.8

–0.4

–0.2

0.2

0.6

1.0

–0.6

0

0.4

0.8

VDD = ⴙ5V

V

SS

= ⴚ5V

R

AB

= 20k⍀

TA = ⴙ25ⴗC

T

A

= ⴚ40ⴗC

T

A

= ⴙ125ⴗC

T

A

= ⴙ85ⴗC

www.BDTIC.com/ADI

—Typical Performance Characteristics

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

RHEOSTAT MODE INL – LSB

–0.1

–0.2

0 256

ⴞ5V

32 64 96 128 160 192 224

CODE – Decimal

ⴙ12V

TPC 1. R-INL vs. Code vs.

Supply Voltages

0.5

0.4

0.3

T

= ⴚ40ⴗC

0.2

0.1

–0.1

–0.2

–0.3

POTENTIOMETER MODE DNL – LSB

–0.4

–0.5

A

T

= ⴙ25ⴗC

T

A

0

0 256

32 64 96 128 160 192 224

CODE – Decimal

= ⴙ85ⴗC

A

TA = ⴙ125ⴗC

TPC 4. DNL vs. Code,

DD/VSS

= ±5 V

V

ⴙ5V

ⴙ15V

0.10

ⴙ12V

0.05

0

–0.05

–0.10

–0.15

RHEOSTAT MODE DNL – LSB

–0.20

–0.25

0 256

32 64 96 128 160 192 224

ⴙ5V

CODE – Decimal

TPC 2. R-DNL vs. Code vs.

Supply Voltages

0.3

0.2

0.1

0

–0.1

–0.2

–0.3

POTENTIOMETER MODE INL – LSB

–0.4

0 25632 64 96 128 160 192 224

ⴞ5V

ⴙ5V

ⴙ15V

CODE – Decimal

TPC 5. INL vs. Code vs.

Supply Voltages

ⴞ5V

ⴙ15V

TPC 3. INL vs. Code, VDD/VSS = ±5 V

0.5

0.4

0.3

0.2

ⴞ5V

0.1

0

–0.1

–0.2

–0.3

POTENTIOMETER MODE DNL – LSB

–0.4

–0.5

0 25632 64 96 128 160 192 224

ⴙ5V

CODE – Decimal

ⴙ15V

TPC 6. DNL vs. Code vs.

Supply Voltages

1.0

0.5

0

–0.5

POTENTIOMETER MODE INL – LSB

–1.0

0 20

TPC 7. INL vs. Supply Voltages

AVG +3

AVG

AVG –3

51015

VDD – VSS – V

2.0

1.5

1.0

0.5

0

–0.5

–1.0

RHEOSTAT MODE INL – LSB

–1.5

–2.0

0 20

AVG +3

AVG

AVG –3

51015

VDD – VSS – V

TPC 8. R-INL vs. Supply Voltages

–10–

124

104

84

64

44

WIPER RESISTANCE – ⍀

24

4

TPC 9. Wiper ON Resistance vs.

Bias Voltage

RON @ VDD/VSS = ⴙ5V/0V

@ VDD/VSS = ⴙ5V/ⴚ5V

R

ON

RON @ VDD/VSS = ⴙ15V/0V

ⴚ5 15

ⴚ13 11

7

V

– V

DD

REV. 0

Page 11

AD5260/AD5262

www.BDTIC.com/ADI

0

–0.5

VDD/VSS = +15V/0V

–1.0

= ⴞ5V

V

–1.5

FSE – LSB

–2.0

–2.5

–40 100

–20 20 80

060

TEMPERATURE – ⴗC

DD/VSS

VDD/VSS = +5V/0V

40

TPC 10. Full-Scale Error

28.0

27.5

27.0

26.5

– A

26.0

LOGIC

I

25.5

25.0

24.5

–40 125

TPC 13. I

VDD/VSS = +15V/0V

VDD/VSS = ⴞ5V

–7 26 92

TEMPERATURE – ⴗC

LOGIC

59

vs. Temperature

2.5

2.0

1.5

1.0

ZSE – LSB

0.5

0

–40 100

VDD/VSS = +5V/0V

= ⴞ5V

V

DD/VSS

VDD/VSS = +15V/0V

–20 20 80

TEMPERATURE – ⴗC

40060

TPC 11. Zero-Scale Error

1k

V

= 5V/0V V

DD/VSS

– A

100

LOGIC

I

VDD/VSS = 5V/0V V

10

1234

0 5

TPC 14. I

LOGIC

VIH – V

vs. Digital Input

LOGIC

= 3V

LOGIC

= 5V

Voltage

1

V

= ⴙ5V

LOGIC

V

= ⴙ5V

IH

V

= 0V

IL

0.1

0.01

SUPPLY CURRENT – A

SS

/I

DD

I

0.001

–40 125

VDD/VSS = ⴙ15V/0V

VDD/VSS = ⴞ5V

–7 26 92

TEMPERATURE – ⴗC

59

TPC 12. Supply Current vs.

Temperature

80

70

60

50

20k⍀

40

30

20

10

–10

RHEOSTAT MODE TEMPCO – ppm/ⴗC

–20

50k⍀

0

200k⍀

0 256

64 96 160 224

CODE – Decimal

19212832

TPC 15. Rheostat Mode Tempco

D

RWB/DT vs. Code

120

100

50k⍀

80

60

20k⍀

40

20

0

–20

200k⍀

–40

POTENTIOMETER MODE TEMPCO – ppm/ⴗC

–60

0 256

64 96 160 224

CODE – Decimal

19212832

TPC 16. Potentiometer Mode

D

VWB/DT vs. Code

6

TA = 25ⴗC

0

–6

–12

–18

–24

GAIN – dB

–30

–36

–42

–48

–54

1k 1M

CODE = FF

10k 100k

FREQUENCY – Hz

H

80

H

40

H

20

H

10

H

08

H

04

H

02

H

01

H

TPC 17. Gain vs. Frequency vs.

= 20 k

Code, R

AB

W

REV. 0

–11–

Page 12

AD5260/AD5262

www.BDTIC.com/ADI

6

TA = 25ⴗC

0

–6

–12

–18

–24

–30

GAIN – dB

–36

–42

–48

–54

1k 1M

CODE = FF

10k 100k

FREQUENCY – Hz

H

80

H

40

H

20

H

10

H

08

H

04

H

02

H

01

H

TPC 18. Gain vs. Frequency vs. Code

R

= 50 k

AB

NORMALIZED GAIN FLATNESS – 0.1dB/DIV

W

CODE = 80

VDD/V

T

0dB

100 100k1k 10k

= 25ⴗC

A

SS

H

= ⴞ5V

R = 200k⍀

R = 50k⍀

FREQUENCY – Hz

R = 20k⍀

6

TA = 25ⴗC

0

–6

–12

–18

–24

–30

GAIN – dB

–36

–42

–48

–54

1k 100k

CODE = FF

FREQUENCY – Hz

80

40

20

10

08

04

02

01

10k

H

H

H

H

H

H

H

H

H

TPC 19. Gain vs. Frequency vs.

Code R

600

500

400

– A

300

LOGIC

I

200

100

0

10k 10M

= 200 k

AB

VDD/VSS = +5V/0V

100k

FREQUENCY – Hz

W

V

DD/VSS

CODE FF

= ⴞ5V

CODE 55

1M

6

0

–6

–12

–18

f

–3dB

–24

–30

GAIN – dB

–36

–42

–48

–3dB

BANDWIDTHS

–54

1k 1M

f

= 310kHz, R = 20k⍀

f

–3dB

= 30kHz, R = 200k⍀

–3dB

= 131kHz, R = 50k⍀

10k 100k

FREQUENCY – Hz

VIN = 50mV rms

= ⴞ5V

V

DD/VSS

TPC 20. –3 dB Bandwidth

600

H

H

500

400

300

PSRR – dB

200

100

0

100 1M

CODE = 80

–PSRR @ VDD = ⴞ5V DC ⴞ 10% p-p AC

+PSRR @ V

1k

FREQUENCY – Hz

, VA = VDD, VB = 0V

H

= ⴞ5V DC ⴞ 10% p-p AC

DD

10k

100k

TPC 21. Normalized Gain

Flatness vs. Frequency

20mV/DIV

5V/DIV

1s/DI V

TPC 24. Mid-Scale Glitch

Energy, Code 80

to 7F

H

TPC 22. I

5V/DIV

5V/DIV

TPC 25. Large Signal Settling Time

H

vs. Frequency

LOGIC

20s/DIV

TPC 23. PSRR vs. Frequency

10mV/DIV

40ns/DIV

TPC 26. Digital Feedthrough vs. Time

–12–

REV. 0

Page 13

AD5260/AD5262

www.BDTIC.com/ADI

100

VA = VB = OPEN

= 25ⴗC

T

A

10

– mA

WB_MAX

1

R

0.1

THEORETICAL I

0.01

0 256

AB

32 64 96 128 160 192 224

CODE – Decimal

TPC 27. I

R

= 50k⍀

MAX

= 20k⍀

AB

R

AB

vs. Code

= 200k⍀

0.10

CODE = 80

VDD = VSS = ⴞ5V

SS = 135 UNITS

0.05

0

–0.05

–0.10

–0.15

CHANGE IN TERMINAL RESISTANCE – %

–0.20

0 500

H

100 200 250 300 350 400 450

50 150

HOURS OF OPERATION AT 150ⴗC

AVG –3

AVG

AVG +3

TPC 28. Long-Term Resistance Drift

TEST CIRCUITS

Test Circuits 1 to 9 define the test conditions used in the product specification table.

Vⴙ

DUT

A

B

W

V+ = V

DD

1LSB = V+/2

V

MS

N

V+

40

CODE SET TO MID-SCALE

T

= 150ⴗC

A

3 LOTS

SAMPLE SIZE = 135

30

20

FREQUENCY

10

0

–0.40 –0.30–0.20 –0.10 0 0.10 0.20

–0.50

CHANNEL-TO-CHANNEL RAB MATCH – %

TPC 29. Channel-to-Channel

Resistance Matching (AD5262)

V

A

V

DD

A

W

B

V+ = V

10%

DD

PSRR (dB) = 20 LOG

PSS (%/ %) =

V

MS

⌬VMS%

⌬V

DD

( )

%

⌬V

⌬V

MS

DD

Test Circuit 1. Potentiometer Divider

Nonlinearity Error (INL, DNL)

NC

NC = NO CONNECT

DUT

A

B

W

I

W

V

MS

Test Circuit 2. Resistor Position Nonlinearity Error

(Rheostat Operation; R-INL, R-DNL)

DUT

A

V

MS2

W

B

IW = VDD/R

V

W

V

MS1

RW = [V

NOMINAL

– V

MS1

MS2

]/I

W

Test Circuit 3. Wiper Resistance

Test Circuit 4. Power Supply Sensitivity (PSS, PSSR)

OFFSET

GND

A

V

DUT

IN

B

+13V

W

AD8610

–13V

V

OUT

Test Circuit 5. Gain vs. Frequency

0.1V

R

=

SW

I

DUT

B

A = NC

W

I

SW

CODE = 00

VSS TO V

SW

H

0.1V

DD

Test Circuit 6. Incremental ON Resistance

NC

V

DD

DUT

V

A

W

B

GND

SS

I

CM

V

CM

Test Circuit 7. Common-Mode Leakage Current

REV. 0

–13–

NC

Page 14

AD5260/AD5262

V

U1

V

O

W

B

A

R2

200k⍀

C2

4.7pF

V

i

R1

47k⍀

C1

25pF

www.BDTIC.com/ADI

TEST CIRCUITS (continued)

CS

CLK

SDI

DIGITAL INPUT

VOLTAGE

LOGIC

I

LOGIC

C

GND

SS

V

DD

SCLK

MOSI

CS

CLK

SDI

GND

Figure 13. Bipolar Operation from Dual Supplies

Gain Control Compensation

Test Circuit 8. V

V

DD

DUT

V

SS

Current vs. Digital Input Voltage

LOGIC

NC

I

CM

V

CM

GND

NC

A

W

B

Digital potentiometers are commonly used in gain control as in

the noninverting gain amplifier shown in Figure 14.

Test Circuit 9. Analog Crosstalk

Figure 14. Typical Noninverting Gain Amplifier

PROGRAMMING THE POTENTIOMETER DIVIDER

Voltage Output Operation

The digital potentiometer easily generates output voltages at wiperto-B and wiper-to-A to be proportional to the input voltage at

A-to-B. Ignore the effect of the wiper resistance at the moment.

For example, connecting A-terminal to 5 V and B-terminal to

ground produces an output voltage at the wiper-to-B starting at

zero volts up to 1 LSB less than 5 V. Each LSB of voltage is equal

to the voltage applied across terminal AB divided by the 256 position of the potentiometer divider. Since the AD5260/AD5262

operates from dual supplies, the general equation defining the

output voltage at V

with respect to ground for any given input

W

voltage applied to terminals AB is:

VD

()

WABB

D

256

VV

=¥+

(3)

Operation of the digital potentiometer in the divider mode results

in more accurate operation over temperature. Unlike the rheostat

mode, the output voltage is dependent on the ratio of the internal

resistors R

and RWB and not the absolute values; therefore, the

WA

drift reduces to 5 ppm/∞C.

Notice that when the RDAC B terminal parasitic capacitance is

connected to the op amp noninverting node, it introduces a zero

for the 1/b

term with +20 dB/dec, whereas a typical op amp GBP

O

has –20 dB/dec characteristics. A large R2 and finite C1 can cause

this Zero’s frequency to fall well below the crossover frequency.

Hence the rate of closure becomes 40 dB/dec and the system has

0∞ phase margin at the crossover frequency. The output may ring

or oscillate if the input is a rectangular pulse or step function.

Similarly, it is also likely to ring when switching between two

gain values because this is equivalent to a step change at the input.

Depending on the op amp GBP, reducing the feedback resistor

may extend the Zero’s frequency far enough to overcome the problem. A better approach, however, is to include a compensation

capacitor C2 to cancel the effect caused by C1. Optimum compensation occurs when R1 C1 = R2 C2. This is not an option

because of the variation of R2. As a result, one may use the relationship above and scale C2 as if R2 is at its maximum value. Doing so

may overcompensate and compromise the performance slightly

when R2 is set at low values. However, it will avoid the ringing or

oscillation at the worst case. For critical applications, C2 should

be found empirically to suit the need. In general, C2 in the range

of a few pF to no more than a few tenths of pF is usually adequate

APPLICATIONS

Bipolar DC or AC Operation from Dual Supplies

The AD5260/AD5262 can be operated from dual supplies enabling

control of ground referenced AC signals or bipolar operation.

The AC signal, as high as V

, can be applied directly across

DD/VSS

terminals A–B with output taken from terminal W. See Figure 13

for a typical circuit connection.

for the compensation.

Similarly, there are W and A terminal capacitances connected to

the output (not shown). Fortunately their effect at this node is less

significant, and the compensation can be avoided in most cases.

Programmable Voltage Reference

For voltage divider mode operation, Figure 15, it is common

to buffer the output of the digital potentiometer unless the load is

much larger than R

. Not only does the buffer serve the pur-

WB

pose of impedance conversion, but it also allows a heavier load

to be driven.

–14–

+5.0V

V

DD

ⴞ2.5V p-p

D = 80

V

SS

ⴞ5V p-p

H

–5.0V

REV. 0

Page 15

AD5260/AD5262

www.BDTIC.com/ADI

5V

1

U1

V

IN

GND

2

V

OUT

AD1582

AD5260

3

5V

A

W

AD8601

B

A1

V

O

Figure 15. Programmable Voltage Reference

8-Bit Bipolar DAC

Figure 16 shows a low cost 8-bit bipolar DAC. It offers the same

number of adjustable steps but not the precision of conventional

DACs. The linearity and temperature coefficients, especially at low

values codes, are skewed by the effects of the digital potentiometer

wiper resistance. The output of this circuit is:

Ê

V

=-

Á

O REF

Ë

256

V

i

V

IN

V

TRIM

GND

D

2

U1

OUT

ADR425

ˆ

¥

1

˜

¯

AD5260

+5V

REF

V

U2

W

BA

R R

W1

+5V

OP2177

A1

–5V

ⴚ5V

OP2177

A2

REF

+5V

–5V

(4)

V

O

Figure 16. 8-Bit Bipolar DAC

Bipolar Programmable Gain Amplifier

For applications that require bipolar gain, Figure 17 shows one

implementation. Digital potentiometer U1 sets the adjustment

range. The wiper voltage at W2 can therefore be programmed

between V

and –KVi at a given U2 setting. Configuring A2 in

i

the noninverting mode allows linear gain and attenuation. The

transfer function is:

V

O

V

i

Ê

R

1

=+

Á

Ë

Ê

ˆ

2

R

D

¥¥+

˜

Á

1

256

¯

Ë

where K is the ratio of R

U2

AD5262

W2

A2 B2

V

i

A1 B1

W1

U1

AD5262

OP2177

A1

2

1

KK

()

V

SS

set by U1.

–KV

WB1/RWA1

V

DD

-

OP2177

A2

i

ˆ

˜

¯

V

DD

R2

C1

V

SS

R1

(5)

V

O

Figure 17. Bipolar Programmable Gain Amplifier

Similar to the previous example, in the simpler (and much more

usual) case, where K = 1, a single digital pot AD5260, and U1

is replaced by a matched pair of resistors to apply V

and – Vi at

i

the ends of the digital pot. The relationship becomes:

Ê

V

=+

Oi

Á

Ë

ˆ

Ê

R

D

2122

˜

Á

R

256

¯

Ë

ˆ

V

-

¥1

1

˜

¯

(6)

If R2 is large, a few picofarad compensation capacitors may be

needed to avoid any gain peaking.

Table VIII shows the result of adjusting D, with A2 configured as a

unity gain, a gain of 2, and a gain of 10. The result is a bipolar

amplifier with linearly programmable gain and 256-step resolution.

Table VIII. Result of Bipolar Gain Amplifier

DR1

= •, R2 = 0 R1 = R2 R2 = 9R1

0–1 –2 –10

64 –0.5 –1 –5

128 0 0 0

192 0.5 1 5

255 0.968 1.937 9.680

Programmable Voltage Source with Boosted Output

For applications that require high current adjustment such as a

laser diode driver or turnable laser, a boosted voltage source can

be considered (see Figure 18).

V

i

5V

A

W

U1

B

A1

10k⍀

R1

P1

N1

SIGNAL

U1= AD5260

A1= AD8601, AD8605, AD8541

P1= FDP360P, NDS9430

N1= FDV301N, 2N7002

C

LO

V

O

R

BIAS

C

I

L

Figure 18. Programmable Boosted Voltage Source

In this circuit, the inverting input of the op amp forces the VO to be

equal to the wiper voltage set by the digital potentiometer. The

load current is then delivered by the supply via the P-Ch FET P1.

The N-Ch FET N

simplifies the op amp driving requirement.

1

A1 needs to be the rail-to-rail input type. Resistor R1 is needed to

prevent P1 from not turning off once it is on. The choice of R1 is a

balance between the power loss of this resistor and the output turnoff time. N1 can be any general-purpose signal FET; on the other

hand, P1 is driven in the saturation state, and therefore its power

handling must be adequate to dissipate (V

– VO) IL power. This

i

circuit can source a maximum of 100 mA at 5 V supply. Higher

current can be achieved with P1 in a larger package. Note, a single

N-Ch FET can replace P1, N1, and R1 altogether. However, the output swing will be limited unless separate power supplies are used.

For precision application, a voltage reference such as ADR423,

ADR292, and AD1584 can be applied at the input of the digital

potentiometer.

Programmable 4-to-20 mA Current Source

A programmable 4-to-20 mA current source can be implemented

with the circuit shown in Figure 19. REF191 is a unique low

supply headroom and high current handling precision reference

REV. 0

–15–

Page 16

AD5260/AD5262

www.BDTIC.com/ADI

that can deliver 20 mA at 2.048 V. The load current is simply the

voltage across terminals B-to-W of the digital pot divided by RS.

VD

¥

REF

I

=

L

R

ⴙ5V

2U1

V

IN

3

SLEEP

GND

4

S

REF191

V

OUT

–2.048V TO V

0 TO (2.048 ⴙ V

6

C1

1F

L

AD5260

)

L

U2

OP1177

+5V

–5V

B

W

A

–

R

S

102⍀

+

R

L

100⍀

(7)

V

L

I

L

Figure 19. Programmable 4-to-20 mA Current Source

The circuit is simple, but be aware that dual-supply op amps are

ideal because the ground potential of REF191 can swing from

–2.048 V at zero scale to V

at full scale of the potentiometer

L

setting. Although the circuit works under single supply, the programmable resolution of the system will be reduced.

Programmable Bidirectional Current Source

For applications that require bidirectional current control or higher

voltage compliance, a Howland current pump can be a solution

(see Figure 20). If the resistors are matched, the load current is:

RA RBR

+

221

()

I

=

LW

AD5260

A

B

–5V

RB

+5V

W

/

V

+15V

OP2177

A1

–15V

¥

R1

150k⍀

C2

10pF

R1

150k⍀

15k⍀

C1

10pF

+15V

AD8016

–15V

14.95k⍀

R2

A2

R2A

2

R

L

50⍀

R

L

500⍀

(8)

V

I

L

L

Figure 20. Programmable Bidirectional Current Source

Programmable Low-Pass Filter

Digital potentiometer AD5262 can be used to construct a second

order Sallen Key Low-Pass Filter (see Figure 21). The design

equations are:

2

V

O

=

V

i

=

w

O

Q

=+

RC R C

w

O

w

2

O

++

S

S

Q

1

RR CC

1212

1

11122

2

w

O

(9)

(10)

(11)

Users can first select some convenient values for the capacitors.

To achieve maximally flat bandwidth where Q = 0.707, let C1 be

twice the size of C2

and let R1 = R2. As a result, users can adjust

R1 and R2 to the same settings to achieve the desirable bandwidth.

C1

+2.5V

R2R1

V

i

B

A

W

R

ADJUSTED TO

SAME SETTINGS

B

A

W

R

C2

AD8601

–2.5V

V

O

Figure 21. Sallen Key Low-Pass Filter

Programmable Oscillator

In a classic Wien-bridge oscillator, Figure 22, the Wien network

(R, R’, C, C’) provides positive feedback, while R1 and R2

provide negative feedback. At the resonant frequency, f

, the

o

overall phase shift is zero, and the positive feedback causes the

circuit to oscillate. With R = R’, C = C’, and R2 = R2A//(R2B+

R

), the oscillation frequency is:

DIODE

11

==

w

OO

RC

f

or

RC

2

p

(12)

where R is equal to RWA such that:

D

256

R

–

256

R

AB

(13)

=

At resonance, setting

RR2

2=

1

(14)

balances the bridge. In practice, R2/R1 should be set slightly larger

than 2 to ensure the oscillation can start. On the other hand, the

alternate turn-on of the diodes D1 and D2 ensures R2/R1 to be

smaller than 2 momentarily and therefore stabilizes the oscillation.

Once the frequency is set, the oscillation amplitude can be tuned

by R2B since:

2

OD D

3

2VIRBV

=+

–16–

(15)

REV. 0

Page 17

AD5260/AD5262

V

O

A

B

R1

R2

V

i

W

www.BDTIC.com/ADI

VO, ID, and VD are interdependent variables. With proper selection

of R2B, an equilibrium will be reached such that VO converges. R2B

can be in series with a discrete resistor to increase the amplitude,

but the total resistance cannot be too large to saturate the output.

In both circuits in Figures 21 and 22, the frequency tuning requires

that both RDACs be adjusted to the same settings. Since the two

channels will be adjusted one at a time, an intermediate state will

occur that may not be acceptable for certain applications. As a

result, different devices can also be used in daisy-chained mode so

that parts can be programmed to the same setting simultaneously.

FREQUENCY

ADJUSTMENT

10k⍀

B

R

A

AD5262

C

2.2nF

R1 = R1 = R2B = AD5262

D1 = D2 = 1N4148

W

1k⍀

VN

R1

VP

2.2nF

+5V

OP1177

–5V

R2B

10k⍀

W

C

10k⍀

AB

W

U1

R2A

2.1k⍀

AB

AMPLITUDE

ADJUSTMENT

R

V

O

D1

D2

Figure 22. Programmable Oscillator with

Amplitude Control

Resistance Scaling

The AD5260/AD5262 offer 20 kW, 50 kW, and 200 kW nominal

resistance. For users who need lower resistance and still maintain the

numbers of step adjustment, they can parallel multiple devices. For

example, Figure 23 shows a simple scheme of paralleling both

channels of the AD5262. To adjust half of the resistance linearly

per step, users need to program both channels coherently with

the same settings.

V

DD

W1

A2

W2

B2

A1

B1

A

R2

R1

R2 << R1

W

B

Figure 24. Lowering the Nominal Resistance

Figures 23 and 24 show that the digital potentiometers change steps

linearly. On the other hand, log taper adjustment is usually preferred in applications like audio control. Figure 25 shows another

way of resistance scaling. In this circuit, the smaller the R2 with

respect to R

, the more the pseudo-log taper characteristic behaves.

AB

Figure 25. Resistor Scaling with Log Adjustment

Characteristics

RDAC CIRCUIT SIMULATION MODEL

The internal parasitic capacitances and the external capacitive

loads dominate the ac characteristics of the RDACs. Configured

as a potentiometer divider, the –3 dB bandwidth of the AD5260

(20 kW resistor) measures 310 kHz at half scale. TPC 20 provides

the large signal BODE plot characteristics of the three available

resistor versions 20 kW, 50 kW, and 200 kW. A parasitic simulation

model is shown in Figure 26. Listing I provides a macro model

net list for the 20 kW RDAC.

RDAC

20k⍀

AB

C

A

25pF

Figure 26. RDAC Circuit Simulation Model for RDAC = 20 k

C

W

C

B

25pF

55pF

W

W

LD

Figure 23. Reduce Resistance by Half with Linear

Adjustment Characteristics

In voltage divider mode, a much lower resistance can be achieved

by paralleling a discrete resistor as shown in Figure 24. The equivalent resistance becomes:

R

WB eq W_

R

WA eq W_

REV. 0

D

=§§

=-

RR R

()

256

Ê

D

Á

256

Ë

+

12

ˆ

RR R

12

§§

()

˜

¯

(16)

+1

(17)

Listing I. Macro Model Net List for RDAC

PARAM D=256, RDAC=20E3

*

SUBCKT DPOT (A,W,B)

*

CA A 0 25E-12

RWA A W {(1-D/256)*RDAC+60}

CW W 0 55E-12

RWB W B {D/256*RDAC+60}

CB B 0 25E-12

*

.ENDS DPOT

–17–

Page 18

AD5260/AD5262

www.BDTIC.com/ADI

DIGITAL POTENTIOMETER FAMILY SELECTION GUIDE

Number Terminal Interface Nominal Resolution Power Supply

Part of VRs per Voltage Data Resistance (No. of Wiper Current

Number Package Range (V) Control (k⍀) Positions) (IDD) (A) Packages Comments

AD5201 1 ± 3, 5.5 3-Wire 10, 50 33 40 mSOIC-10 Full AC Specs, Dual

AD5220 1 5.5 UP/DOWN 10, 50, 100 128 40 PDIP, SO-8, No Rollover,

AD7376 1 ± 15, 28 3-Wire 10, 50, 100, 128 100 PDIP-14, Single 28 V or Dual

1000 SOL-16, ± 15 V Supply Operation

AD5200 1 ± 3, 5.5 3-Wire 10, 50 256 40 mSOIC-10 Full AC Specs, Dual

AD8400 1 5.5 3-Wire 1, 10, 50, 100 256 5 SO-8 Full AC Specs

AD5260 1 ± 5, 15 3-Wire 20, 50, 200 256 60 TSSOP-14 5 V to 15 V or ± 5 V

AD5241 1 ± 3, 5.5 2-Wire 10, 100, 256 50 SO-14, I

AD5231 1 ± 2.75, 5.5 3-Wire 10, 50, 100 1024 20 TSSOP-16 Nonvolatile Memory,

AD5222 2 ± 3, 5.5 UP/DOWN 10, 50, 100, 128 80 SO-14, No Rollover, Stereo,

AD8402 2 5.5 3-Wire 1, 10, 50, 256 5 PDIP, SO-14, Full AC Specs, nA

AD5207 2 ± 3, 5.5 3-Wire 10, 50, 100 256 40 TSSOP-14 Full AC Specs, Dual

AD5232 2 ± 2.75, 5.5 3-Wire 10, 50, 100 256 20 TSSOP-16 Nonvolatile Memory,

2

AD5235

AD5242 2 ± 3, 5.5 2-Wire 10, 100, 256 50 SO-16, I

AD5262 2 ± 5, 15 3-Wire 20, 50, 200 256 60 TSSOP-16 5 V to 15 V or ± 5 V

AD5203 4 5.5 3-Wire 10, 100 64 5 PDIP, SOL-24, Full AC Specs, nA

AD5233 4 ± 2.75, 5.5 3-Wire 10, 50, 100 64 20 TSSOP-24 Nonvolatile Memory,

AD5204 4 ± 3, 5.5 3-Wire 10, 50, 100 256 60 PDIP, SOL-24, Full AC Specs, Dual

AD8403 4 5.5 3-Wire 1, 10, 50, 100 256 5 PDIP, SOL-24, Full AC Specs, nA

AD5206 6 ± 3, 5.5 3-Wire 10, 50, 100 256 60 PDIP, SOL-24, Full AC Specs, Dual

1

For the most current information on digital potentiometers, check the website at: www.analog.com/DigitalPotentiometers

2

Future product, consult factory for latest status.

2 ± 2.75, 5.5 3-Wire 25, 250 1024 20 TSSOP-16 Nonvolatile Memory,

1000 TSSOP-14 TC < 50 ppm/∞C

1000 TSSOP-14 Power-On-Reset,

100 TSSOP-14 Shutdown Current

1000 TSSOP-16 TC < 50 ppm/∞C

1

Supply, Power-OnReset, Low Cost

mSOIC-8 Power-On-Reset

TSSOP-14

Supply, Power-On-Reset

Operation,

TC < 50 ppm/∞C

2

C Compatible,

Direct Program, I/D,

± 6 dB settability

TC < 50 ppm/∞C

Supply, Power-OnReset, SDO

Direct Program, I/D,

± 6 dB Settability

Direct Program,

TC < 50 ppm/∞C

2

C Compatible,

Operation,

TC < 50 ppm/∞C

TSSOP-24 Shutdown Current

Direct Program, I/D,

± 6 dB Settability

TSSOP-24 Supply, Power-On-Reset

TSSOP-24 Shutdown Current

TSSOP-24 Supply, Power-On-Reset

–18–

REV. 0

Page 19

OUTLINE DIMENSIONS

www.BDTIC.com/ADI

Dimensions shown in inches and (mm).

14-Lead TSSOP

(RU-14)

0.201 (5.10)

0.193 (4.90)

AD5260/AD5262

PIN 1

0.006 (0.15)

0.002 (0.05)

SEATING

PLANE

PIN 1

0.006 (0.15)

0.002 (0.05)

14

0.0256

(0.65)

BSC

0.201 (5.10)

0.193 (4.90)

16

8

0.177 (4.50)

0.169 (4.30)

71

0.0433 (1.10)

MAX

0.0118 (0.30)

0.0075 (0.19)

0.0079 (0.20)

0.0035 (0.090)

16-Lead TSSOP

(RU-16)

9

0.177 (4.50)

0.169 (4.30)

81

0.0433 (1.10)

MAX

0.256 (6.50)

0.246 (6.25)

0.256 (6.50)

0.246 (6.25)

8ⴗ

0ⴗ

0.028 (0.70)

0.020 (0.50)

8ⴗ

REV. 0

SEATING

PLANE

0.0256 (0.65)

BSC

0.0118 (0.30)

0.0075 (0.19)

0.0079 (0.20)

0.0035 (0.090)

–19–

0ⴗ

0.028 (0.70)

0.020 (0.50)

Page 20

C02695–0–3/02(0)

www.BDTIC.com/ADI

–20–

PRINTED IN U.S.A.

Loading...

Loading...