Page 1

3-Channel Digital Potentiometer with

FEATURES

3 channels:

Dual 512-position

Single 128-position

25 kΩ or 250 kΩ full-scale resistance

Low temperature coefficient:

Potentiometer divider 15 ppm/°C

Rheostat mode 35 ppm/°C

Nonvolatile memory retains wiper settings

Permanent memory write protection

Linear increment/decrement

±6 dB increment/decrement

2

C-compatible serial interface

I

2.7 V to 5.5 V single-supply operation

±2.25 V to ±2.75 V dual-supply operation

Power-on reset time

256 bytes general-purpose user EEPROM

11 bytes RDAC user EEPROM

GBIC and SFP compliant EEPROM

100-year typical data retention at T

APPLICATIONS

Mechanical potentiometer replacement

RGB LED backlight control

White LED brightness adjustment

Programmable gain and offset control

Programmable filters

GENERAL DESCRIPTION

The AD5255 provides dual 512-position and a single

128-position digitally controlled variable resistors

TSSOP package. This device performs the same electronic

adjustment function as a potentiometer, trimmer, or variable

resistor. Each VR offers a completely programmable value of

resistance between the A terminal and the wiper or the B

terminal and the wiper. The fixed A-to-B terminal resistance of

25 kΩ or 250 kΩ has a 1% channel-to-channel matching

tolerance and a nominal temperature coefficient of 35 ppm/°C.

Wiper position programming, EEPROM

writing is conducted via the standard 2-wire I

vious/default wiper position settings can be stored in memory,

and refreshed upon system power-up.

= 55°C

A

1

(VR) in a

2

reading, and EEPROM

2

C interface. Pre-

Nonvolatile Memory

AD5255

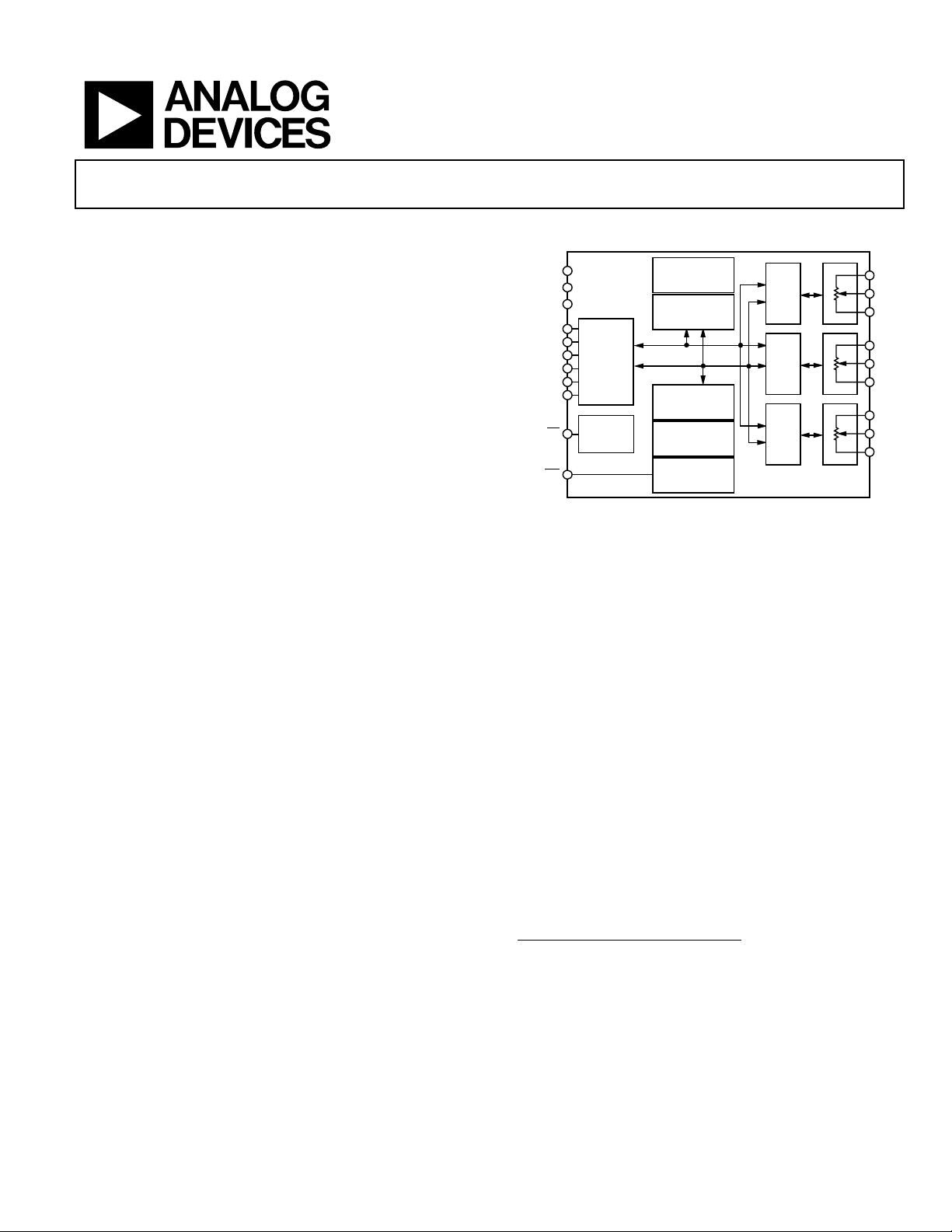

FUNCTIONAL BLOCK DIAGRAM

V

V

GND

SCL

SDA

A0_RDAC

A1_RDAC

A0_E

A1_E

WP

DD

SS

RS

2

I

C

SERIAL

INTERFACE

POWER-ON

RESET

256 BYTES

USER

EEPROM

32 BYTES

RDAC

EEPROM

DATA

CONTROL

COMMAND

DECODE

LOGIC

ADDRESS

DECODE

LOGIC

DECODE

LOGIC

Figure 1.

Additional features of the AD5255 include preprogrammed

linear and logarithmic increment/decrement wiper changing.

The actual resistor tolerances are stored in EEPROM so that the

actual end-to-end resistance is known, which is valuable for

calibration in precision applications.

The AD5255 is available in a 24-lead TSSOP package. All parts

are guaranteed to operate over the extended industrial temperature range of −40°C to +85°C.

1

The terms programmable resistor, variable resistor, RDAC, and digital

potentiometer are used interchangeably.

2

The terms nonvolatile memory, EEMEM, and EEPROM are used

interchangeably.

RDAC0

REGISTER

RDAC1

REGISTER

RDAC2

REGISTER

RDAC0

9 BIT

RDAC1

9 BIT

RDAC2

7 BIT

A0

A0

A0

W0

W0

W0

B0

B0

B0

A1

A1

A1

W1

W1

W1

B1

B1

B1

A2

A2

A2

W2

W2

W2

B2

B2

B2

04555-0-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

www.analog.com

Page 2

AD5255

TABLE OF CONTENTS

Electrical Characteristics ................................................................. 3

Digital Input/Output Configuration........................................ 16

Electrical Characteristics ................................................................. 5

Absolute Maximum Ratings............................................................ 6

ESD Caution.................................................................................. 6

Pin Configuration and Function Descriptions............................. 7

Typical Performance Characteristics ............................................. 8

Interface Descriptions.................................................................... 10

2

I

C Interface ................................................................................ 10

EEPROM Interface..................................................................... 11

RDAC I

Theory of Operation ...................................................................... 15

Linear Increment and Decrement Commands ......................15

Logarithmic Taper Mode Adjustment (±6 dB/step).............. 15

Using Additional Internal Nonvolatile EEPROM.................. 16

2

C Interface.................................................................... 12

REVISION HISTORY

Multiple Devices on One Bus ................................................... 16

Level Shift for Bidirectional Communication ........................ 16

Terminal Voltage Operation Range ......................................... 16

Power-Up Sequence ................................................................... 17

Layout and Power Supply Biasing ............................................ 17

RDAC Structure.......................................................................... 17

Calculating the Programmable Resistance ............................. 17

Programming the Potentiometer Divider............................... 18

Applications..................................................................................... 19

Laser Diode Driver (LDD) Calibration................................... 19

Outline Dimensions....................................................................... 20

Ordering Guide .......................................................................... 20

7/04—Revision 0: Initial Version

Rev. 0 | Page 2 of 20

Page 3

AD5255

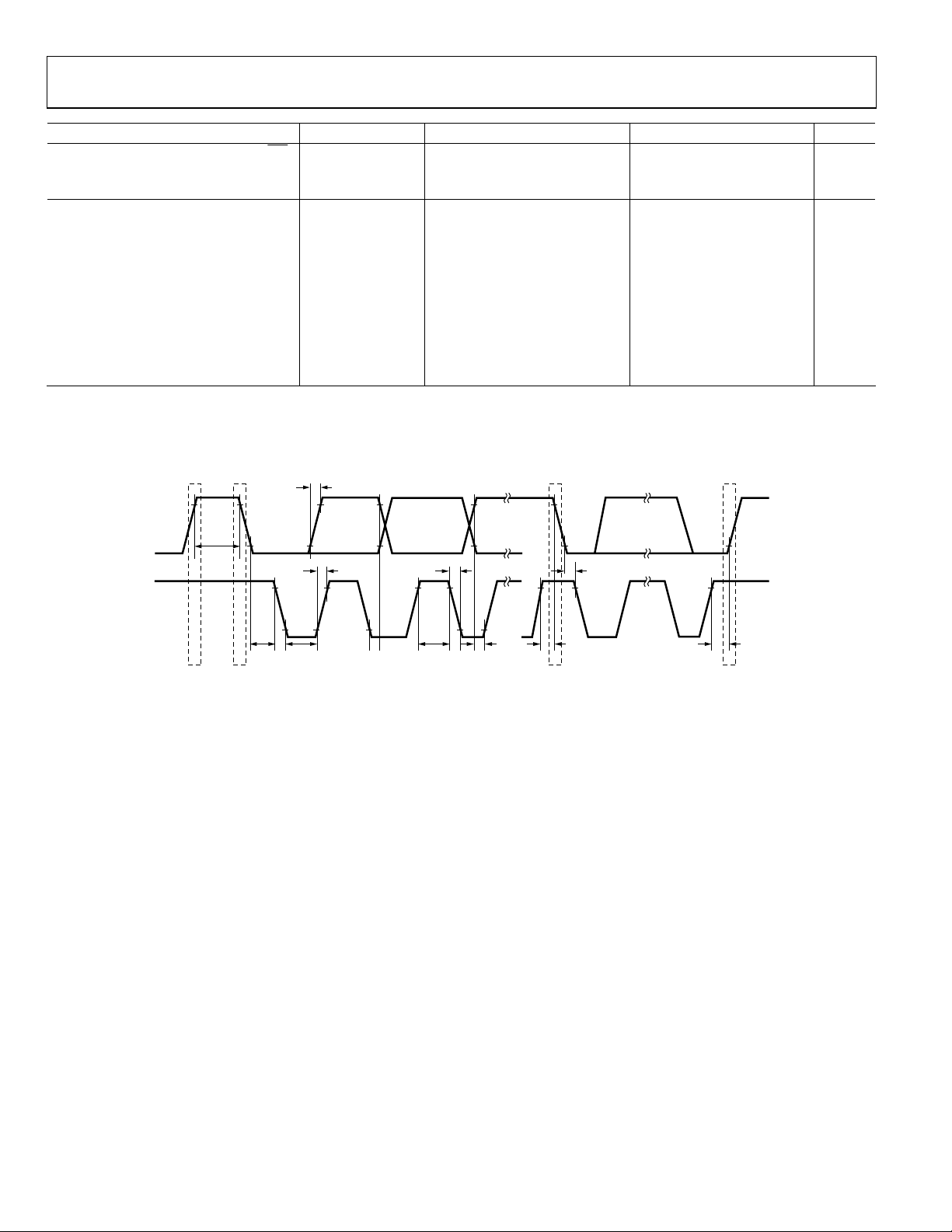

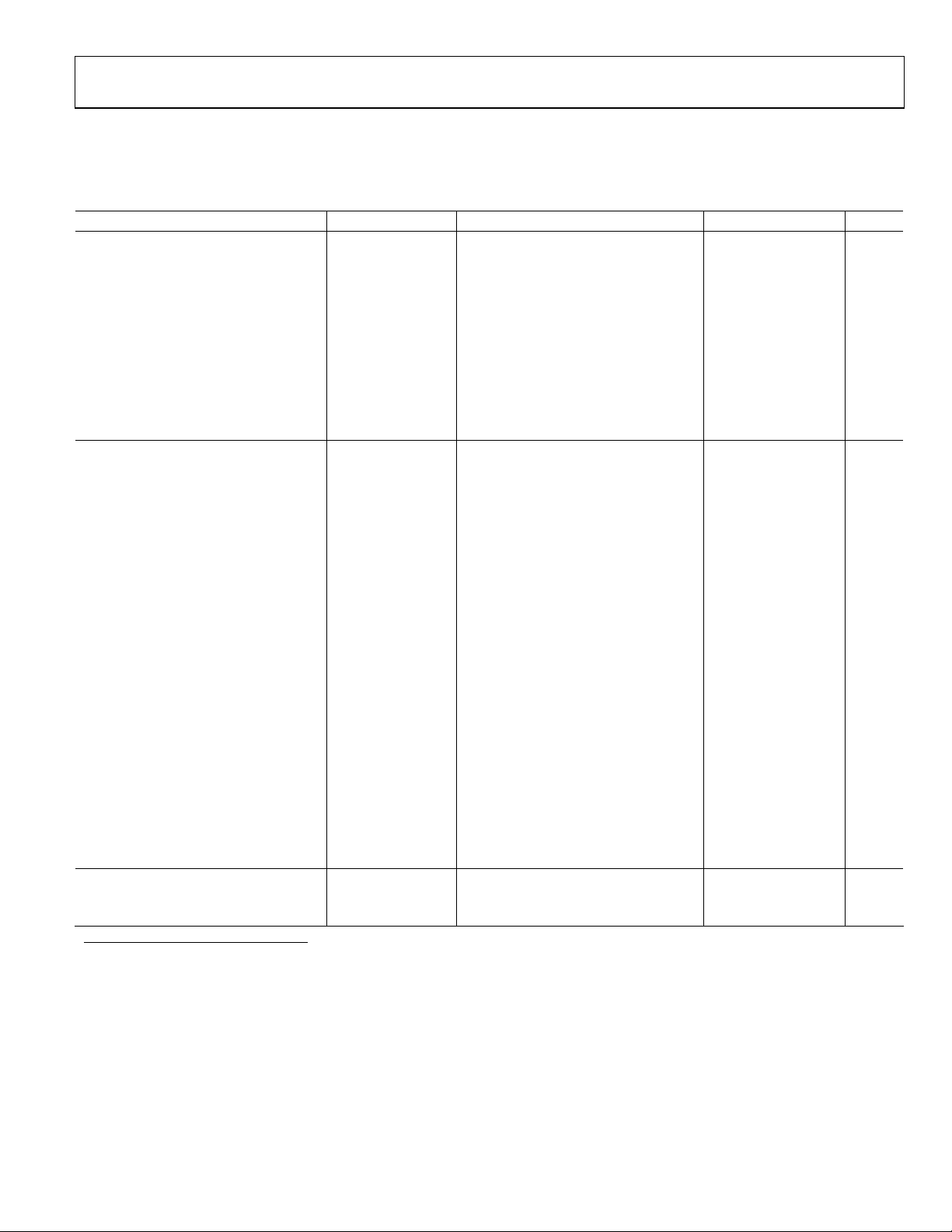

ELECTRICAL CHARACTERISTICS

Single supply: VDD = 2.7 V to 5.5 V and −40°C < TA < +85°C, unless otherwise noted.

Dual supply: V

Table 1.

Parameter Symbol Conditions Min Typ

DC CHARACTERISTICS,

RHEOSTAT MODE

Resistor Differential Nonlinearity

Resistor Integral Nonlinearity

Resistance Temperature Coefficent

Wiper Resistance R

Channel Resistance Matching ∆R

Nominal Resistor Tolerance ∆RAB/R

DC CHARACTERISTICS,

POTENTIOMETER DIVIDER MODE

Differential Nonlinearity

Integral Nonlinearity

Voltage Divider Temperature

Coefficent

Full-Scale Error V

Zero-Scale Error V

RESISTOR TERMINALS

Terminal Voltage Range

Capacitance5 Ax, Bx C

Capacitance5 Wx C

Common-Mode Leakage Current

DIGITAL INPUTS AND OUTPUTS

Input Logic High V

Input Logic Low V

Output Logic High (SDA) V

Output Logic Low V

WP Leakage Current

A0 Leakage Current I

= +2.25 V or +2.75 V, VSS = −2.25 V or −2.75 V and −40°C < TA < +85°C, unless otherwise noted.

DD

2

R-DNL RWB, 7-bit channel −0.75

RWB, 9-bit channels −2.5

2

R-INL RWB, 7-bit channel −0.5

R-INL RWB, 9-bit channels, VDD = 5.5 V −2.0

R-INL RWB, 9-bit channels, VDD = 2.7 V −4.0

6

(∆RWB/RWB)/∆T × 10

W

/∆R

AB1

AB2

AB

VDD = 5 V, IW = 1 V/R

VDD = 3 V, IW = 1 V/R

WB

WB

Ch 1 and 2 RWB, Dx = 0x1FF

Dx = 0x3FF −15

3

DNL 7-bit channel −0.5 +0.5 LSB

DNL 9-bit channels −2.0 +2.0 LSB

3

INL 7-bit channel −0.5 +0.5 LSB

INL 9-bit channels −2.0 +2.0 LSB

)/∆T × 106Code = half-scale

(∆V

W/VW

WFSE

7-bit channel/9-bit channel,

−1/−2.75

0/0 LSB

code = full-scale

WZSE

7-bit channel/9-bit channel,

0/0

code = zero-scale

4

V

A, B, W

A,B

f = 1 kHz, measured to GND,

V

SS

code = half-scale

W

f = 1 kHz, measured to GND,

code = half-scale

5, 8

I

CM

IH

VW = VDD/2

VDD = 5 V, VSS = 0 V 2.4

VDD/VSS = +2.7 V/0 V or

V

= ±2.5 V

DD/VSS

IL

VDD = 5 V, VSS = 0 V

VDD/VSS = +2.7 V/0 V or

= ±2.5 V

V

DD/VSS

R

OH

OL

I

WP

A0

= 2.2 kΩ to VDD = 5 V,

PULL-UP

= 0 V

V

SS

R

= 2.2 kΩ to VDD = 5 V,

PULL-UP

V

= 0 V

SS

WP = V

DD

A0 = GND

2.1

4.9

1

Max Unit

35

+0.75 LSB

+2.5 LSB

+0.5 LSB

+2.0 LSB

+4.0 LSB

ppm/°C

100 150 Ω

250 400 Ω

0.1

15

85

95

%

+15 %

ppm/°C

1/2.0 LSB

V

DD

V

pF

pF

0.01 1 µA

V

V

0.8 V

0.6 V

V

0.4 V

9 µA

3 µA

Rev. 0 | Page 3 of 20

Page 4

AD5255

A

Parameter Symbol Conditions Min Typ

Input Leakage Current (Excluding WP

I

I

VIN = 0 V or V

DD

1

Max Unit

±1 µA

and A0)

Input Capacitance

5

C

I

5

pF

POWER SUPPLIES

Single-Supply Power Range V

Dual-Supply Power Range VDD/V

Positive Supply Current I

Negative Supply Current I

EEMEM Data Storing Mode Current I

EEMEM Data Restoring Mode Current I

Power Dissipation

Power Supply Sensitivity

See the footnotes after Table 2.

6

5

DD

SS

DD

SS

DD_STORE

DD_RESTORE

P

DISS

P

SS

VSS = 0 V 2.7

VIH = VDD or VIL = GND, VSS = 0 V

VIH = VDD or VIL = GND,

V

= 2.5 V, VSS = −2.5 V

DD

VIH = VDD or VIL = GND

VIH = VDD or VIL = GND

VIH = VDD = 5 V or VIL = GND

∆VDD = 5 V ± 10%

±2.25

5.5 V

±2.75 V

5 15 µA

−5 −15 µA

35

2.5

mA

mA

25 75 µW

0.01 0.025 %/%

t

8

SD

t

1

t

6

t

7

t

10

04555-0-015

SCL

t

8

t

2

t

PS SP

3

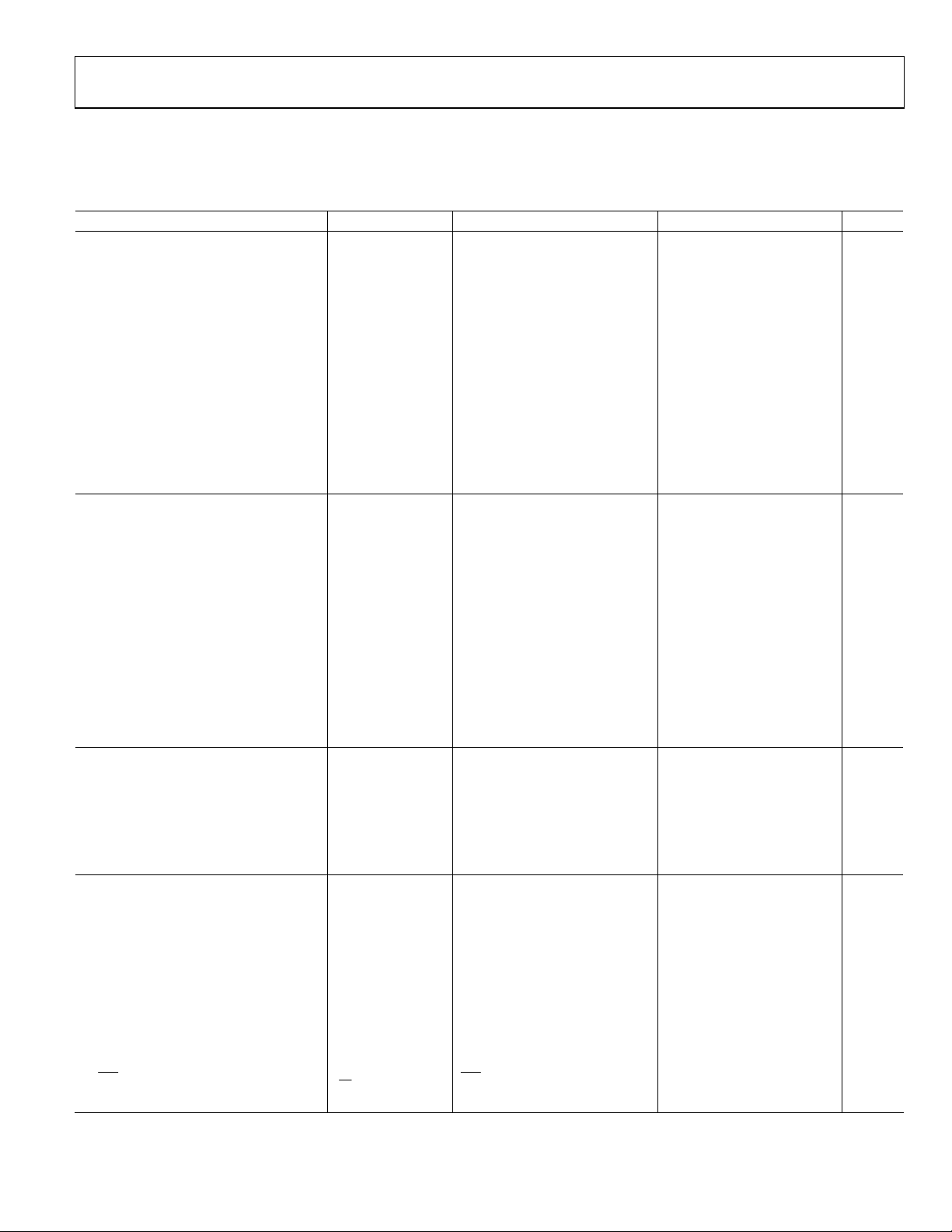

Figure 2. I

t

9

t

4

2

C Timing Diagram

t

5

Rev. 0 | Page 4 of 20

Page 5

AD5255

ELECTRICAL CHARACTERISTICS

Single Supply: VDD = 3 V to 5.5 V and −40°C < TA< +85°C, unless otherwise noted.

Dual Supply: V

Table 2.

Parameter Symbol Conditions Min Typ

DYNAMIC CHARACTERISTICS

Bandwidth −3 dB BW VDD/VSS = ±2.5 V, RAB = 25 kΩ/250 kΩ

Total Harmonic Distortion THD

VW Settling Time t

Resistor Noise Spectral Density e

Digital Crosstalk C

Analog Crosstalk C

INTERFACE TIMING CHARACTERISTICS

(apply to all parts) (Notes

SCL Clock Frequency f

t

Bus Free Time between Stop and

BUF

Start

t

Hold Time (Repeated Start) t

HD;STA

t

Low Period of SCL Clock t

LOW

t

High Period of SCL Clock t

HIGH

t

Setup Time for Start Condition t

SU;STA

t

Data Hold Time t

HD;DAT

t

Data Setup Time t

SU;DAT

tR Rise Time of Both SDA and SCL

Signals

tF Fall Time of Both SDA and SCL

Signals

t

Setup Time for Stop Condition t

SU;STO

EEMEM Data Storing Time t

EEMEM Data Restoring Time at

Power-On

EEMEM Data Restoring Time on

Restore

Command or Reset Operation

EEMEM Data Rewritable Time t

FLASH/EE MEMORY RELIABILITY

Endurance

Data Retention

1

Typical represent average readings at 25°C, VDD = 5 V.

2

Resistor position nonlinearity error R-INL is the deviation from an ideal value measured between the maximum resistance and the minimum resistance wiper

positions. R-DNL measures the relative step change from ideal between successive tap positions.

3

INL and DNL are measured at VW with the RDAC configured as a potentiometer divider similar to a voltage output D/A converter. VA = VDD and VB = 0 V.

4

Resistor Terminals A, B, W have no limitations on polarity with respect to each other.

5

Guaranteed by design and not subject to production test.

6

P

is calculated from (IDD × VDD). CMOS logic level inputs result in minimum power dissipation.

DISS

7

All dynamic characteristics use VDD = 5 V.

8

Bandwidth, noise, and settling time are dependent on the terminal resistance value chosen. The lowest R value results in the fastest settling time and highest

bandwidth. The highest R value results in the minimum overall power consumption.

9

See the timing diagram for location of measured values.

10

Endurance is qualified to 100,000 cycles as per JEDEC Std. 22 method A117 and measured at −40°C, +25°C, and +85°C, typical endurance at 25°C is 700,000 cycles.

11

Retention lifetime equivalent at junction temperature (TJ) = 55°C as per JEDEC Std. 22, Method A117. Retention lifetime based on an activation energy of 0.6eV

derates with junction temperature.

= +2.25 V or +2.75 V , VSS = −2.25 V or −2.75 V and −40°C < TA < + 85°C, unless otherwise noted.

DD

5, 7

W

S

VA = 1 V rms, VB = 0 V, f = 1 kHz

VA = VDD, VB = 0 V,

V

= 0.50% error band,

W

code 0x000 to 0x100, RAB = 25 kΩ/250 kΩ

N_WB

T

RAB = 25 kΩ/250 kΩ, TA = 25°C

VA = VDD, VB = 0 V, measure VW with

adjacent RDAC making full-scale

change

AT

Signal input at A0 and measure output

at W1, f = 1 kHz

8, 9

)

SCL

t

1

2

After this period the first clock pulse is

generated

3

4

5

6

7

t

8

t

9

10

EEMEM_STORE

t

EEMEM_RESTORE1

t

EEMEM_RESTORE2

EEMEM_REWRITE

10

11

55°C

1

Max Unit

125/12 kHz

0.05 %

4/36 µs

14/45 nV√Hz

−80 dB

−72 dB

400 kHz

1.3 µs

600 ns

1.3 µs

0.6 50 µs

600 ns

900 ns

100 ns

300 ns

300 ns

600 ns

26 ms

360 µs

360 µs

540 µs

100

kcycles

100 years

Rev. 0 | Page 5 of 20

Page 6

AD5255

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted.

Table 3.

Parameter Rating

VDD to GND −0.3 V, +7 V

VSS to GND +0.3 V, −7 V

VDD to V

SS

VA, VB, VW to GND

IA, IB, I

W

Intermittent

1

7 V

VSS − 0.3 V, VDD + 0.3 V

±20 mA

Continuous ±2 mA

Digital Inputs and Output Voltage to GND −0.3 V, VDD + 0.3 V

Operating Temperature Range

2

−40°C to +85°C

Maximum Junction Temperature (TJ max) 150°C

Storage Temperature −65°C to +150°C

Lead Temperature, Soldering

Vapor Phase (60 sec) 215°C

Infrared (15 sec) 220°C

Thermal Resistance Junction-to-Ambient

, TSSOP-24

θ

JA

_______________________ ________________________________

1

Includes programming of nonvolatile memory.

2

Maximum terminal current is bounded by the maximum current handling of

the switches, maximum power dissipation of the package, and maximum

applied voltage across any two of the A, B, and W terminals at a given

resistance.

143°C/W

Stresses greater than those listed under Absolute Maximum

Ratings may cause permanent damage to the device. This is a

stress rating only and functional operation of the device at these

or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. 0 | Page 6 of 20

Page 7

AD5255

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

A0_EE

A1_RDAC

A0_RDAC

WP

SCL

SDA

DGND

, AV

V

SS

W2

1

2

3

4

RS

5

(Not to Scale)

6

7

8

9

SS

10

A2

11

12

B2

NC = NO CONNECT

AD5255

TOP VIEW

24

A1_EE

23

TEST0 (NC)

22

TEST1 (NC)

21

TEST2 (NC)

20

TEST3 (NC)

19

C

18

A0

17

W0

16

B0

15

B1

14

W1

13

A1

, AV

DD

DD

04555-0-034

Figure 3. Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 A1_EE I2C Device Address 1 for EEMEM.

2 A1_RDAC I2C Device Address 1 for RDAC.

3 A0_RDAC I2C Device Address 0 for RDAC.

4

RS Resets the scratchpad register with current contents of the EEMEM register. Factory defaults to midscale before

any programming.

5

WP Write Protect. When active low, WP prevents any changes to the present register contents, except that RESET

and Commands 1 and 8 still refresh the RDAC register from EEMEM.

6 SCL Serial Input Register Clock. Shifts in one bit at a time on the positive clock edges.

7 SDA Serial Data Input. Shifts in one bit at a time on the positive clock edges. The MSB is loaded first.

8 DGND Ground. Logic ground reference.

9 V

SS

Negative Supply. Connect to 0 V for single-supply applications.

10 A2 A terminal of RDAC2.

11 W2 Wiper terminal of RDAC2.

12 B2 B terminal of RDAC2.

13 A1 A terminal of RDAC1.

14 W1 Wiper terminal of RDAC1.

15 B1 B terminal of RDAC1.

16 B0 B terminal of RDAC0.

17 W0 Wiper terminal of RDAC0.

18 A0 A terminal of RDAC0.

19 V

DD

Positive Power Supply.

20 TEST3 Test Pin 3. Do not connect.

21 TEST2 Test Pin 2. Do not connect.

22 TEST1 Test Pin 1. Do not connect.

23 TEST0 Test Pin 0. Do not connect.

24 A0_EE I2C Device Address 0 for EEMEM.

Rev. 0 | Page 7 of 20

Page 8

AD5255

TYPICAL PERFORMANCE CHARACTERISTICS

1.0

TA = –40°C, 25°C, 85°C SUPERIMPOSED

V

= 5V

0.8

DD

0.6

0.4

0.2

0

INL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

Figure 4. INL—9-Bit RDAC

1.50

TA = –40°C, 25°C, 85°C SUPERIMPOSED

1.25

V

= 5V

DD

1.00

0.75

0.50

0.25

0

–0.25

DNL (LSB)

–0.50

–0.75

–1.00

–1.25

–1.50

Figure 5. DNL—9-Bit RDAC

1.0

TA = –40°C, 25°C, 85°C SUPERIMPOSED

V

= 5V

0.8

DD

0.6

0.4

0.2

0

–0.2

R-INL (LSB)

–0.4

–0.6

–0.8

–1.0

Figure 6. R-INL—9-Bit RDAC

25619264 1280 320 384 448 512

CODE (DECIMAL)

25619264 1280 320 384 448 512

CODE (DECIMAL)

25619264 1280 320 384 448 512

CODE (DECIMAL)

04555-0-002

04555-0-003

04555-0-004

1.0

0.8

0.6

0.4

0.2

0

–0.2

R-DNL (LSB)

–0.4

–0.6

–0.8

TA = –40°C, 25°C, 85°C SUPERIMPOSED

V

= 5V

DD

–1.0

Figure 7. R-DNL—9-Bit RDAC

0.5

TA = –40°C, 25°C, 85°C SUPERIMPOSED

V

= 5V

0.4

DD

0.3

0.2

0.1

0

INL (LSB)

–0.1

–0.2

–0.3

–0.4

–0.5

Figure 8. INL—7-Bit RDAC

0.5

TA = –40°C, 25°C, 85°C SUPERIMPOSED

V

= 5V

0.4

DD

0.3

0.2

0.1

0

DNL (LSB)

–0.1

–0.2

–0.3

–0.4

–0.5

Figure 9. DNL—7-Bit RDAC

25619264 1280 320 384 448 512

CODE (DECIMAL)

04555-0-005

644816 320809611

CODE (DECIMAL)

2128

04555-0-006

644816 320809611

CODE (DECIMAL)

2128

04555-0-007

Rev. 0 | Page 8 of 20

Page 9

AD5255

0.5

TA = –40°C, 25°C, 85°C SUPERIMPOSED

V

= 5V

0.4

DD

0.3

0.2

0.1

0

–0.1

R-INL (LSB)

–0.2

–0.3

–0.4

–0.5

Figure 10. R-INL—7-Bit RDAC

0.5

TA = –40°C, 25°C, 85°C SUPERIMPOSED

V

= 5V

0.4

DD

0.3

0.2

0.1

0

–0.1

R-DNL (LSB)

–0.2

–0.3

–0.4

–0.5

Figure 11. R-DNL—7-Bit RDAC

50

TA = –40°C, 85°C

V

= 5V

45

DD

VA = V

DD

VB = 0V

40

35

30

25

20

15

10

RHEOSTAT MODE TEMPCO (ppm/°C)

5

0

Figure 12. Temperature Coefficient (Rheostat Mode)

644816 320809611

CODE (DECIMAL)

2128

04555-0-008

644816 320809611

CODE (DECIMAL)

2128

04555-0-009

25619264 1280 320 384 448 512

CODE (DECIMAL)

04555-0-010

50

TA = –40°C, 85°C

V

= 5V

45

DD

V

= V

A

DD

VB = 0V

40

35

30

25

20

15

10

5

POTENTIOMETER MODE TEMPCO (ppm/°C)

0

25619264 1280 320 384 448 512

CODE (DECIMAL)

Figure 13. Temperature Coefficient (Potentiometer Mode)

10

8

IDD: VDD = 5.5V

6

4

2

I

: VDD = 2.7V

DD

0

–2

I

: VDD = 2.7V, VSS = 2.7V

S

–4

SUPPLY CURRENT (mA)

–6

–8

–10

–40 –20 0 20 40 60 80 100 120 140

TEMPERATURE (°C)

Figure 14. Supply Current vs. Temperature

110

TA = 25°C

100

90

80

70

(mA)

DD

I

60

V

= 5.5V

50

40

30

110

1

DD

V

= 2.7V

DD

10210310410510610

CLOCK FREQUENCY (Hz)

Figure 15. Supply Current vs. Clock Frequency

04555-0-011

04555-0-012

7

04555-0-013

Rev. 0 | Page 9 of 20

Page 10

AD5255

INTERFACE DESCRIPTIONS

I2C INTERFACE

All control and access to both EEPROM memory and the RDAC

registers are conducted via a standard 2-wire I

Figure 2 shows the timing characteristics of the I

Figure 16 and Figure 17 illustrate standard transmit and receive

2

bus signals in the I

C interface.

These figures use the following legend:

From master to slave

From slave to master

S = Start condition

P = Stop condition

A = Acknowledge (SDA low)

= Not acknowledge (SDA high)

A

2

C interface.

2

C bus.

= Read enable at high and write enable at low

R/

W

SLAVE ADDRESSS

SLAVE ADDRESSS

SLAVE ADDRESSS

R/W SLAVE ADDRESSS

READ OR WRITE

R/W

0 = WRITE

R/W

1 = WRITE

A DATA

(N BYTES + ACKNOWLEDGE)

A DATA A

DATA TRANSFERRED

(N BYTES + ACKNOWLEDGE)

2

Figure 16. I

C—Master Transmitting Data to Slave

A DATA A

DATA TRANSFERRED

(N BYTES + ACKNOWLEDGE

2

Figure 17. I

C—Master Reading Data from Slave

A/A P

REPEATED START

Figure 18. Combined Transmit/Read

R/W

READ OR WRITE

DATA A/A P

DATA A

A DATA

(N BYTES + ACKNOWLEDGE)

DIRECTION OF TRANSFER MAY

CHANGE AT THIS POINT

A/A

P

04555-0-016

04555-0-017

04555-0-018

Rev. 0 | Page 10 of 20

Page 11

AD5255

EEPROM INTERFACE

0011

01

EE

MEMORY ADDRESS MEMORY DATA MEMORY DATASAAAAA00

A/A

P

0 WRITE

Figure 19. EEPROM Write

0011

SLAVE ADDRESS MEMORY ADDRESSS

0 WRITE

01

EE

1 READ

AA P

W SLAVE ADDRESS MEMORY DATASR

MEMORY DATA MEMORY DATASAAAA00

Figure 20. EEPROM Current Read

Figure 21. EEPROM Random Read

The 256 bytes of EEPROM memory provided in the AD5255

are organized into 16 pages of 16 bytes each. The word size of

each memory location is one byte wide.

2

C slave address of the EEPROM is 10100(A1E)(A0E),

The I

where A1E and A0E are external pin-programmable address

bits. The 2-pin programmable address bits allow a total of four

2

AD5255 devices to be controlled by a single I

C master bus,

each having its own EEPROM.

An internal 8-bit address counter for the EEPROM is

automatically incremented following each read or write

operation. For read operations, the address counter is

incremented after each byte is read, and the counter rolls over

from Address 255 to 0.

For write operations, the address counter is incremented after

each byte is written. The counter rolls over from the highest

address of the current page to the lowest address of the current

page. For example, writing two bytes beginning at Address 31

causes the counter to roll back to Address 16 after the first byte

is written; then the address increments to 17 after the second

byte is written.

EEPROM Write

Each write operation issued to the EEPROM programs between

1 byte and 16 bytes (1 page) of memory. Figure 19 shows the

EEPROM write interface. The number of bytes of data, N, that

the user wants to send to the EEPROM is unrestricted. If more

REPEATED START

than 16 bytes of data are sent in a single write operation, the

address counter rolls back to the beginning address, and the

previously sent data is overwritten.

EEPROM Write-Acknowledge Polling

After each write operation, an internal EEPROM write cycle

begins. During the EEPROM internal write cycle, the I

interface of the device is disabled. It is necessary to determine if

the internal write cycle is complete and whether the I

interface is enabled. To do so, execute I

sending a start condition followed by the EEPROM slave

address plus the desired R/

responds with an ACK, the write cycle is complete and the

interface is ready to proceed with further operations. Otherwise,

the I

write cycle has been completed.

EEPROM Read

The AD5255 EEPROM provides two different read operations,

shown in Figure 20 and Figure 21. The number of bytes, N, read

from the EEPROM in a single operation is unrestricted. If more

than 256 bytes are read, the address counter rolls back to the

start address, and data previously read is read again.

Figure 20 shows the EEPROM current read operation. This

operation does not allow an address location to be specified,

and reads data beginning at the current address location stored

in the internal address counter.

(N BYTES + ACKNOWLEDGE)EEPROM SLAVE ADDRESS

A

(N BYTES + ACKNOWLEDGE)EEPROM SLAVE ADDRESS

A

1 READ

2

C interface must be polled again to determine whether the

(N BYTES + ACKNOWLEDGE)

2

C interface polling by

bit. If the AD5255 I2C interface

W

A/A

2

C

2

C

04555-0-019

P

04555-0-020

04555-0-021

Rev. 0 | Page 11 of 20

Page 12

AD5255

A random read operation is shown in Figure 21. This operation

changes the address counter to the specified memory address by

performing a dummy write and then performing a read

operation beginning at the new address counter location.

RDAC I2C INTERFACE

EEPROM Write Protection

Setting the WP pin to a logic low protects the EEPROM

memory from future write operations. In this mode, EEPROM

read operations and RDAC register loading operate normally.

1100

01

R

R

0 WRITE

SAAA11

1100

01

R

R

1 READ

SLAVE ADDRESS RDAC ADDRESSS

0 WRITE

AA P

W SLAVE ADDRESS RDAC DATASR

CMD/

REG

EE/RDA4A3A2A1A

AC

Figure 22. RDAC Write

Figure 23. RDAC Current Read

REPEATED START

Figure 24. RDAC Random Read

0

ARDAC EEPROM OR REGISTER DATA RDAC EEPROM OR REGISTER DATA

(N BYTES + ACKNOWLEDGE)RDAC SLAVE ADDRESS

1 READ

DATA DATASA AAAA10 0

(N BYTES + ACKNOWLEDGE)RDAC ADDRESSRDAC SLAVE ADDRESS

A

(N BYTES + ACKNOWLEDGE)

A/A

A/A

P

04555-0-022

P

A

04555-0-023

04555-0-024

SAAA10

1100

RDAC SLAVE ADDRESS

01

R

R

0 WRITE

CMD/

REG

1 CMD

C

2

3

C0A2A1A

1

0

C

C

Figure 25. RDAC Shortcut Command

Table 5. RDAC Register Addresses (CMD/

REG

= 0, EE/

RDAC

= 0)

A4 A3 A2 A1 A0 RDAC Byte Description

0 0 0 0 0 RDAC0 (D7)(D6)(D5)(D4)(D3)(D2)(D1)(D0) – RDAC0 8 LSBs

0 0 0 0 1 RDAC0 (X)(X)(X)(X)(X)(X)(X)(D8) – RDAC0 MSB

0 0 0 1 0 RDAC1 (D7)(D6)(D5)(D4)(D3)(D2)(D1)(D0) – RDAC1 8 LSBs

0 0 0 1 1 RDAC1 (X)(X)(X)(X)(X)(X)(X)(D8) – RDAC1 MSB

0 0 1 0 0 RDAC2 (X)(D6)(D5)(D4)(D3)(D2)(D1)(D0) – RDAC2 7 bits

0 0 1 0 1 Reserved

…to…

1 1 1 1 1

Rev. 0 | Page 12 of 20

P

A

04555-0-025

Page 13

AD5255

Table 6. RDAC R/W EEPROM Addresses (CMD/

A4 A3 A2 A1 A0 Byte Description

0 0 0 0 0 RDAC0 8 LSBs

0 0 0 0 1 RDAC0 MSB

0 0 0 1 0 RDAC1 8 LSBs

0 0 0 1 1 RDAC1 MSB

0 0 1 0 0 RDAC2 7 bits

0 0 1 0 1 11 bytes RDAC User EEPROM

…to…

0 1 1 1 1

Table 7. RDAC Command Table (CMD/

C3 C2 C1 C0 Command Description

0 0 0 0 NOP

0 0 0 1 Restore EEPROM to RDAC

0 0 1 0 Store RDAC to EEPROM

0 0 1 1 Decrement RDAC 6 dB

0 1 0 0 Decrement All RDACs 6 dB

0 1 0 1 Decrement RDAC 1 Step

0 1 1 0 Decrement All RDACs 1 Step

0 1 1 1 Reset. Restore EEPROM to all RDACs2

1 0 0 0 Increment RDACs 6 dB

1 0 0 1 Increment All RDACs 6 dB

1 0 1 0 Increment RDAC 1 Step

1 0 1 1 Increment All RDAC 1 Step

1 1 0 0 Reserved

…to…

1 1 1 1

REG

= 1)

1

Command leaves the device in the EEPROM read power state. Issue the NOP command to return the device to the idle state.

2

Command requires acknowledge polling after execution.

RDAC Interface Operation

Each programmable resistor wiper setting is controlled by

specific RDAC registers, as shown in Table 5. Each RDAC

register corresponds to an EEPROM memory location, which

provides nonvolatile wiper storage functionality.

RDAC registers and their corresponding EEPROM memory

locations are programmed and read independently from each

other. The RDAC register is refreshed by the EEPROM locations

either with a hardware reset via Pin 1, or by issuing one of the

various RDAC register load commands shown in the Table 7.

RDAC Write

Setting the wiper position requires an RDAC write operation,

shown in Figure 22. RDAC write operations follow a format

similar to the EEPROM write interface. The only difference

between an RDAC write and an EEPROM write operation is the

use of an RDAC address byte in place of the memory address

used in the EEPROM write operation. The RDAC address byte

is described in detail in Table 5 and Table 6.

REG

= 0, EE/

RDAC

= 1)

1

2

As with the EEPROM write operation, any RDAC EEPROM

2

(Shortcut Command 2) write operation disables the I

C

interface during the internal write cycle. Acknowledge polling,

as described in the EEPROM Interface section, is required to

determine whether the write cycle is complete.

RDAC Read

The AD5255 provides two RDAC read operations. The first,

shown in Figure 23, reads the contents of the current RDAC

address counter. Figure 24 illustrates the second read operation,

which allows users to specify which RDAC register to read by

first issuing a “dummy write” command to change the RDAC

address pointer, and then proceeding with the RDAC read

operation at the new address location.

The read-only RDAC EEPROM memory locations can also be

read by using the address and bits specified in Table 6.

Rev. 0 | Page 13 of 20

Page 14

AD5255

RDAC Shortcut Commands

Eleven “shortcut” commands are provided for easy manipulation

of RDAC registers and their corresponding EEPROM memory

locations. These commands are shown in Table 9. A more detailed

discussion about the RDAC shortcut commands can be found

in the Theory of Operation section.

The interface for issuing an RDAC shortcut command is shown

in Figure 25. All shortcut commands require acknowledge

polling to determine whether the command has finished

executing.

RDAC Resistor Tolerance

The end-to-end resistance tolerance for each RDAC channel is

stored in read-only memory during factory production. This

information is read by using the address and bits specified in

Tabl e 8.

Tolerance values are stored in percentage form. Figure 26 shows

the format of the tolerance data stored in memory. Each stored

tolerance uses two memory locations. The first location stores

the integer portion, while the second location stores the decimal

portion.

The resistance tolerance is stored in sign-magnitude format.

The MSB of the first memory location designates the sign

(0 = +, 1 = −) and the remaining 7 LSBs are designated for the

integer portion of the tolerance. All 8 bits of the second

memory location are represented the decimal portion of the

tolerance value.

Table 8. Addresses for Reading Tolerance (CMD/

REG

= 0, EE/

RDAC

= 1, A4 = 1)

A4 A3 A2 A1 A0 Data Byte Description

1 1 0 0 0 Sign and 7-Bit Integer Values of RDAC0 Tolerance (Read-Only)

1 1 0 0 1 8-Bit Decimal Value of RDAC0 Tolerance (Read-Only)

1 1 0 1 0 Sign and 7-Bit Integer Values of RDAC1 Tolerance (Read-Only)

1 1 0 1 1 8-Bit Decimal Value of RDAC1 Tolerance (Read-Only)

1 1 1 0 0 Sign and 7-Bit Integer Values of RDAC2 Tolerance (Read-Only)

1 1 1 0 1 8-Bit Decimal Value of RDAC2 Tolerance (Read-Only)

A AD6 D5 D4 D3 D2 D1 D0D7

6

5

4

3

2

1

SIGN 2

2

2

2

2

2

7 BITS FOR INTEGER NUMBERSIGN

0

2

2

Figure 26. Format of Stored Tolerance in Sign Magnitude with Bit Positions Descriptions Unit is in %. Only Data Bytes Shown.

–2

–1

2

–3

–4

2

2

8 BITS FOR DECIMAL NUMBER

AD6 D5 D4 D3 D2 D1 D0D7

–5

–6

–7

2

2

2

–8

2

04555-0-026

Rev. 0 | Page 14 of 20

Page 15

AD5255

THEORY OF OPERATION

The AD5255 digital potentiometer operates as a true variable

resistor. The RDAC register contents determine the resistor

wiper position. The RDAC register acts like a scratch-pad

register, allowing unlimited resistance setting changes. RDAC

2

register contents are changed using the AD5255’s serial I

C

interface. See the RDAC I2C Interface section for the format of

the data words and commands to program the RDAC registers.

Each RDAC register has a corresponding EEPROM memory

location, which provides nonvolatile storage of resistor wiper

position settings. The AD5255 provides commands to store the

RDAC register contents to their respective EEPROM memory

locations. During subsequent power-on sequences, the RDAC

registers are automatically loaded with the stored values.

Saving data from an RDAC register to EEPROM memory takes

approximately 25 ms and consumes 35 mA.

In addition to moving data between RDAC registers and

EEPROM memory, the AD5255 provides other shortcut

commands.

Table 9. AD5255 Shortcut Commands

No. Function

1 Restore EEPROM setting to RDAC

2. Store RDAC register contents to EEPROM

3 Decrement RDAC 6 dB (shift data bits right)

4 Decrement all RDACs 6 dB (shift all data bits right)

5 Decrement RDAC 1 step

6 Decrement all RDACs 1 step

7 Reset EEPROM setting to RDAC

8 Increment RDAC 6 dB (shift data bits left)

9 Increment all RDACs 6 dB (shift all data bits left)

10 Increment RDAC 1 step

11 Increment all RDACs 1 step

__________________________

1

Command leaves the device in the EEPROM read power state. Issue the NOP

command to return the device to the idle state.

2

Command requires acknowledge polling after execution.

1

2

2

LINEAR INCREMENT AND DECREMENT COMMANDS

The increment and decrement commands (Commands 10, 11,

5, and 6) are useful for linear step adjustment applications.

These commands simplify microcontroller software coding by

allowing the controller to send only an increment or decrement

command to the AD5255. The adjustment can be directed to an

individual RDAC or to all three RDACs.

LOGARITHMIC TAPER MODE ADJUSTMENT

(±6 dB/STEP)

The AD5255 accommodates logarithmic taper adjustment of

the RDAC wiper position(s) by shifting the register contents

left/right for increment/decrement operations. Commands 8, 9,

3, and 4 are used to logarithmically increment or decrement the

wiper positions individually or change all three channel settings

at the same time.

Incrementing the wiper position by +6 dB doubles the RDAC

register value, while decrementing by −6 dB halves it. Internally,

the AD5255 uses a shift register to shift the bits left and right to

achieve a logarithmic increment or decrement.

Nonideal ±6 dB step adjustment occurs under certain conditions.

Table 10 illustrates how the shifting function affects the data

bits of an individual RDAC. Each line going down the table

represents a successive shift operation. Note that the left-shift

commands (Commands 10 and 11) were modified such that if

the data in the RDAC register equals 0 and the data is shifted,

the RDAC register is set to Code 1. Similarly, if the data in the

RDAC register is greater than or equal to midscale and the data

is left shifted, the data in the RDAC register is automatically set

to full-scale. This makes the left-shift function as close as possible

to a logarithmic adjustment.

The right-shift commands (Commands 3 and 4) are ideal only

if the LSB is a 0 (ideal logarithmic = no error). If the LSB is 1,

the right-shift function generates a linear half LSB error.

Table 10. RDAC Register Contents after

±6 dB Step Adjustments

Left Shift (+6 dB/step) Right Shift (−6 dB/step)

0 0000 0000 1 1111 1111

0 0000 0001 0 1111 1111

0 0000 0010 0 0111 1111

0 0000 0100 0 0011 1111

0 0000 1000 0 0001 1111

0 0001 0000 0 0000 1111

0 0010 0000 0 0000 0111

0 0100 0000 0 0000 0011

0 1000 0000 0 0000 0001

1 0000 0000 0 0000 0000

1 1111 1111 0 0000 0000

1 1111 1111

Actual conformance to a logarithmic curve between the data

contents in the RDAC register and the wiper position for each

right-shift command (Commands 3 and 4) execution contains

an error only for odd numbers of bits. Even numbers of bits are

ideal. Figure 26 shows a plot of Log_Error, that is, 20 ×

Log10(error/code), for the AD5255.

Rev. 0 | Page 15 of 20

Page 16

AD5255

V

USING ADDITIONAL INTERNAL NONVOLATILE EEPROM

The AD5255 contains additional internal user EEPROM for

saving constants and other data. The user EEPROM I

word follows the same format as the general-purpose EEPROM

memory shown in Figure 19 and Figure 20. User EEPROM

memory addresses are shown in Table 6.

To support the use of multiple EEPROM modules on a single

2

I

C bus, the AD5255 features two external addressing pins, Pins

21 and 22 (A1_EE and A0_EE) to manually set the address of

the EEPROM included with the AD5255. This feature ensures

that the correct EEPROM memory is accessed when using

2

multiple memory modules on a single I

C bus.

DIGITAL INPUT/OUTPUT CONFIGURATION

All digital inputs are ESD protected. Digital inputs are high

impedance and can be driven directly from most digital sources.

The

resistor. Therefore, the user should place a pull-up resistor from

RESET

internal pull-down resistor. If not driven by an external source,

the AD5255 defaults to a write-protected state. ESD protection

of the digital inputs is shown in Figure 27.

digital input pin does not have an internal pull-up

RESET

to VDD if the function is not used. The WP pin has an

V

DD

2

C data

LEVEL SHIFT FOR BIDIRECTIONAL COMMUNICATION

While most legacy systems operate at one voltage, adding a new

component might require a different voltage. When two systems

transmit the same signal at two different voltages, use a level

shifter to allow the systems to communicate.

For example, a 3.3 V microcontroller (MCU) can be used along

with a 5 V digital potentiometer. A level shifter is required to

enable bidirectional communication.

Figure 29 shows one of many possible techniques to properly

level-shift signals between two devices. M1 and M2 are

N-channel FETs (2N7002). If V

threshold N-channel FETs (FDV301N) for M1 and M2.

= 3.3V V

DD1

R

SDA1

SCL1

3.3V

MCU

Figure 29. Level Shifting for Different Voltage Devices on an I

R

P

P

S

falls below 2.5 V, use low

DD

R

P

G

D

G

M1

D

S

M2

R

P

5V

AD5255

DD2

2

C Bus

= 5V

SDA2

SCL2

04555-0-029

INPUTS

WP

GND

Figure 27. Equivalent

WP

ESD Protection

04555-0-027

MULTIPLE DEVICES ON ONE BUS

Figure 28 shows four AD5255 devices on the same serial bus.

Each has a different slave address since the state of their AD0

and AD1 pins are different. This allows independent reading

and writing to each RDAC within each device.

+5V

R

R

P

P

MASTER

SDA

SCL SDA

AD1

AD0

V

DD

AD1

AD0

V

DD

SCL SDA

AD1

AD0

V

DD

SCL SDA

AD1

AD0

Figure 28. Multiple AD5255 Devices on a Single Bus

SDA

SCL

SCL

04555-0-028

TERMINAL VOLTAGE OPERATION RANGE

The AD5255 positive VDD and negative VSS power supply inputs

define the boundary conditions for proper 2-terminal

programmable resistance operation. Supply signals on terminals

W and B that exceed V

forward-biased diodes of the AD5255.

Figure 30. Maximum Terminal Voltages Set by V

The ground pin of the AD5255 is used as a digital ground

reference, and needs to be tied to the common ground of the

PCB. Reference the digital input control signals to the AD5255

ground pin, and satisfy the logic levels defined in the

Specifications tables.

or VSS are clamped by the internal

DD

V

DD

A

W

B

V

SS

04555-0-030

and V

DD

SS

Rev. 0 | Page 16 of 20

Page 17

AD5255

POWER-UP SEQUENCE

Since the ESD protection diodes limit the voltage compliance at

the A, B, and W terminals (Figure 30), it is important to power

before applying any voltage to the A, B, and W

V

DD/VSS

terminals. Otherwise, the diode is forward-biased such that

are powered unintentionally, which affects the rest of

V

DD/VSS

the circuit. The ideal power-up sequence is as follows: GND,

, VSS, digital inputs, and V

V

DD

, VW, and the digital inputs is not important as long as they

V

B

are powered after V

DD/VSS

. The order of powering VA,

A/B/W

.

Since the switches are nonideal, there is a 100 Ω wiper

resistance, R

. Wiper resistance is a function of supply voltage

W

and temperature; lower supply voltages and higher temperatures

result in higher wiper resistances. Consideration of wiper

resistance dynamics is important in applications in which

accurate prediction of output resistance is required.

SW

A

A

X

N

–1)

SW(2

LAYOUT AND POWER SUPPLY BIASING

It is always a good practice to use compact, minimum lead

length layout design. Make the leads to the input as direct as

possible with a minimum conductor length. Make sure that

ground paths have low resistance and low inductance.

Similarly, it is also good practice to bypass the power supplies

with quality capacitors. Use low equivalent series resistance

(ESR) 1 µF to 10 µF tantalum or electrolytic capacitors at the

supplies to minimize any transient disturbance and filter low

frequency ripple. Figure 31 illustrates the basic supplybypassing configuration for the AD5255.

AD5255

V

DD

+

C3

10µF

+

C4

10µF

V

SS

C1

0.1µF

C2

0.1µF

Figure 31. Power Supply Bypassing

V

DD

GND

V

SS

04555-0-031

RDAC STRUCTURE

The patent pending RDAC contains a string of equal resistor

segments, with an array of analog switches. The switches act as

the wiper connection.

The AD5255 has two RDACs with 512 connection points

allowing it to provide better than 0.2% set-ability resolution.

The AD5255 also contains a third RDAC with 128-step

resolution.

Figure 32 shows an equivalent structure of the connections

between the two terminals that make up one channel of an

RDAC. The SW

SW(0) to SW(2

depending on the resistance position decoded from the data bits

in the RDAC register.

switch is always on, while one of the switches,

B

N

− 1), may or may not be on at any given time

RDAC

WIPER

REGISTER

AND

DECODER

= RAB/2

R

S

DIGITAL

CIRCUITRY

OMITTED FOR

CLARITY

R

S

N

SW(2

R

S

SW(1)

R

S

N

SW(0)

SW

W

–2)

B

X

B

X

04555-0-032

Figure 32. Equivalent RDAC Structure

CALCULATING THE PROGRAMMABLE RESISTANCE

The nominal resistance of the RDAC between the A and B

terminals is available in 25 kΩ or 250 kΩ. The final two or three

digits of the part number determine the nominal resistance

value, for example, 25 kΩ = 25 and 250 kΩ = 250.

The following discussion describes the calculation of resistance

(d) at different codes of a 25 kΩ part for RDAC0. The 9-bit

R

WB

data word in the RDAC latch is decoded to select one of the 512

possible settings.

The first wiper connection starts at the B terminal for data 0x000.

(0) is 100 Ω of the wiper resistance and it is independent of

R

WB

the full-scale resistance. The second connection is the first tap

point where R

0x001. The third connection is the next tap point representing

(2) = 97.6 + 100 = 197.6 Ω for data 0x002, and so on. Each

R

WB

LSB data-value increase moves the wiper up the resistor ladder

until the last tap point is reached at R

Figure 32 for a simplified diagram of the equivalent RDAC

circuit.

These general equations determine the programmed output

resistance between W and B.

(1) becomes 48.8 Ω + 100 = 148.8 Ω for data

WB

(511) = 25051 Ω. See

WB

Rev. 0 | Page 17 of 20

Page 18

AD5255

For RDAC0 and RDAC1:

WB

512

AB

D

()

DR +×=

For RDAC2:

WB

128

AB

D

()

DR +×=

where D is the decimal equivalent of the data contained in the

RDAC register and R

is the wiper resistance.

W

The output resistance values in Table 11 are set for the given

RDAC latch codes with V

digital potentiometers.

Table 11. R

at Selected Codes for R

WB

D (DEC) RWB(d) (Ω) Output State

511 25051 Full scale

256 12600 Midscale

1 148.8 1 LSB

0 100 Zero scale (wiper contact resistance)

Note that in the zero-scale condition, a finite wiper resistance of

100 Ω is present. To avoid degradation or possible destruction

of the internal switches, care should be taken to limit the current

flow between W and B to no more than 20 mA intermittently or

2 mA continuously.

Channel-to-channel R

change in R

with temperature has a 35 ppm/°C temperature

WB

WB

coefficient.

Like the mechanical potentiometer that the RDAC replaces, the

AD5255 parts are totally symmetrical. The resistance between

the W wiper and the A terminal also produces a digitally

controlled complementary resistance, R

the B terminal can be floating or tied to the wiper. Setting the

resistance value for R

starts at a maximum value of resistance

WA

and decreases as the data loaded in the latch is increased in

value. The general transfer equations for this operation are as

follows.

For RDAC0 and RDAC1:

WB

512

D

−

512

()

DR +×

=

For RDAC2:

128

D

()

DR +×

WB

−

=

128

(1)

RR

W

(2)

RR

W

= 5 V, which applies to RAB = 25 kΩ

DD

= 25 kΩ

WB_FS

matching is better than 0.1%. The

. When RWA is used,

WA

(3)

RR

W

AB

(4)

RR

W

AB

For example, the following RDAC latch codes set the

corresponding output resistance values, which apply to

R

= 25 kΩ digital potentiometers.

AB

Table 12. R

(d) at Selected Codes for RAB = 25 kΩ

WA

D (DEC) RWA(d) (Ω) Output State

511 148.8 Full scale

256 12600 Midscale

1 25051 1 LSB

0 25100 Zero scale

The typical distribution of RAB from channel-to-channel is

±0.1% within the same package. Device-to-device matching is

process lot-dependent, with a worst-case variation of ±15%. R

AB

temperature coefficient is 35 ppm/°C.

PROGRAMMING THE POTENTIOMETER DIVIDER

Voltage Output Operation

The digital potentiometer can be configured to generate an

output voltage at the wiper terminal that is proportional to the

input voltages applied to the A and B terminals. Connecting the

A terminal to 5 V and the B terminal to ground produces an

output voltage at the wiper that can vary between 0 V to 5 V.

Each LSB of voltage is equal to the voltage applied across the A

and B terminals divided by the 2

potentiometer divider.

Since the AD5255 can operate from dual supplies, the general

equations defining the output voltage at V

ground for any given input voltages applied to the A and B

terminals are as follows.

For RDAC0 and RDAC1:

W

512

AB

D

()

DV +×=

For RDAC2:

W

128

AB

D

()

DV +×=

Equation 5 assumes that V

wiper resistance is nulled. Operation of the digital potentiometer

in the divider mode results in more accurate operation over

temperature. In this mode, the output voltage is dependent on

the ratio of the internal resistors, not on the absolute value;

therefore, the drift improves to 15 ppm/°C. There is no voltage

polarity restriction between the A, B, and W terminals as long as

the terminal voltage (V

TERM

N

position resolution of the

with respect to

W

(5)

VV

B

(6)

VV

B

is buffered so that the effect of

W

) stays within VSS < V

TERM

< VDD.

Rev. 0 | Page 18 of 20

Page 19

AD5255

APPLICATIONS

LASER DIODE DRIVER (LDD) CALIBRATION

The AD5255 can be used with any laser diode driver. Its high

resolution, compact footprint, and superior temperature drift

characteristics make it ideal for optical parameter setting.

The ADN2841 is a 2.7 Gbps laser diode driver that uses a

unique control algorithm to manage both the laser average

power and extinction ratio after initial factory calibration. It

stabilizes the laser data transmission by continuously

monitoring its optical power and by correcting the variations

caused by temperature and the laser degradation over time. In

the ADN2841, the I

Through its dual-loop power and extinction ratio control,

calibrated by the AD5255, the internal driver controls the bias

current I

and consequently the average power. It also

BIAS

regulates the modulation current, I

modulation current linearly with slope efficiency. Any changes

monitors the laser diode current.

MPD

, by changing the

MODP

in the laser threshold current or slope efficiency are, therefore,

compensated. As a result, this optical supervisory system

minimizes the laser characterization efforts, enabling designers

to apply comparable lasers from multiple sources.

V

V

CC

CC

AD5255

SDA

SCL

Figure 33. Optical Supervisory System

PSET

ERSET

ASET

ADN2841

04555-0-033

Rev. 0 | Page 19 of 20

Page 20

AD5255

OUTLINE DIMENSIONS

7.90

7.80

7.70

24

PIN 1

0.15

0.05

0.10 COPLANARITY

0.65

BSC

0.30

0.19

COMPLIANT TO JEDEC STANDARDS MO-153AD

13

121

1.20

MAX

SEATING

PLANE

4.50

4.40

4.30

6.40 BSC

0.20

0.09

8°

0°

0.75

0.60

0.45

Figure 34. 24-Lead Thin Shrink Small Outline Package [TSSOP]

(RU-24)

Dimensions shown in millimeters

ORDERING GUIDE

Temperature

Model

Range Package Description Package Option

AD5255BRU25 −40°C to +85°C Thin Shrink Small Outline Package RU-24 62 25

AD5255BRU25-RL7 −40°C to +85°C Thin Shrink Small Outline Package RU-24 1,000 25

AD5255BRU250 −40°C to +85°C Thin Shrink Small Outline Package RU-24 62 250

AD5255BRU250-RL7 −40°C to +85°C Thin Shrink Small Outline Package RU-24 1,000 250

Purchase of licensed I

Rights to use these components in an I

2

C components of Analog Devices or one of its sublicensed Associated Companies conveys a license for the purchaser under the Philips I2C Patent

2

C system, provided that the system conforms to the I2C Standard Specification as defined by Philips.

Full Container

Quantity RAB (kΩ)

© 2004 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D04555–0–7/04(0)

Rev. 0 | Page 20 of 20

Loading...

Loading...