Datasheet AD5232BRU50-REEL7, AD5232BRU50, AD5232BRU100-REEL7, AD5232BRU100, AD5232BRU10-REEL7 Datasheet (Analog Devices)

...Page 1

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

a

AD5232

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2001

*

8-Bit Dual Nonvolatile Memory

Digital Potentiometer

FEATURES

Nonvolatile Memory Preset Maintains Wiper Settings

Dual Channel, 256-Position Resolution

Full Monotonic Operation DNL < 1 LSB

10 k, 50 k, 100 k Terminal Resistance

Linear or Log Taper Settings

Push-Button Increment/Decrement Compatible

SPI-Compatible Serial Data Input with Readback

Function

3 V to 5 V Single Supply or 2.5 V Dual Supply

Operation

14 Bytes of User EEMEM Nonvolatile Memory for

Constant Storage

Permanent Memory Write Protection

100-Year Typical Data Retention T

A

= 55C

APPLICATIONS

Mechanical Potentiometer Replacement

Instrumentation: Gain, Offset Adjustment

Programmable Voltage-to-Current Conversion

Programmable Filters, Delays, Time Constants

Line Impedance Matching

Power Supply Adjustment

DIP Switch Setting

GENERAL DESCRIPTION

The AD5232 device provides a nonvolatile, dual-channel,

digitally controlled variable resistor (VR) with 256-position

resolution. These devices perform the same electronic adjustment function as a potentiometer or variable resistor. The

AD5232’s versatile programming via a microcontroller allows

multiple modes of operation and adjustment.

In the direct program mode a predetermined setting of the RDAC

register can be loaded directly from the microcontroller.

Another key mode of operation allows the RDAC register to be

refreshed with the setting previously stored in the EEMEM

register. When changes are made to the RDAC register to establish a new wiper position, the value of the setting can be saved

into the EEMEM by executing an EEMEM save operation.

Once the settings are saved in the EEMEM register these values

will be automatically transferred to the RDAC register to set the

wiper position at system power ON. Such operation is enabled

by the internal preset strobe and the preset can also be accessed

externally.

All internal register contents can be read out of the serial data

output (SDO). This includes the RDAC1 and RDAC2 registers,

the corresponding nonvolatile EEMEM1 and EEMEM2 registers, and the 14 spare USER EEMEM registers available for

constant storage.

*Patent pending.

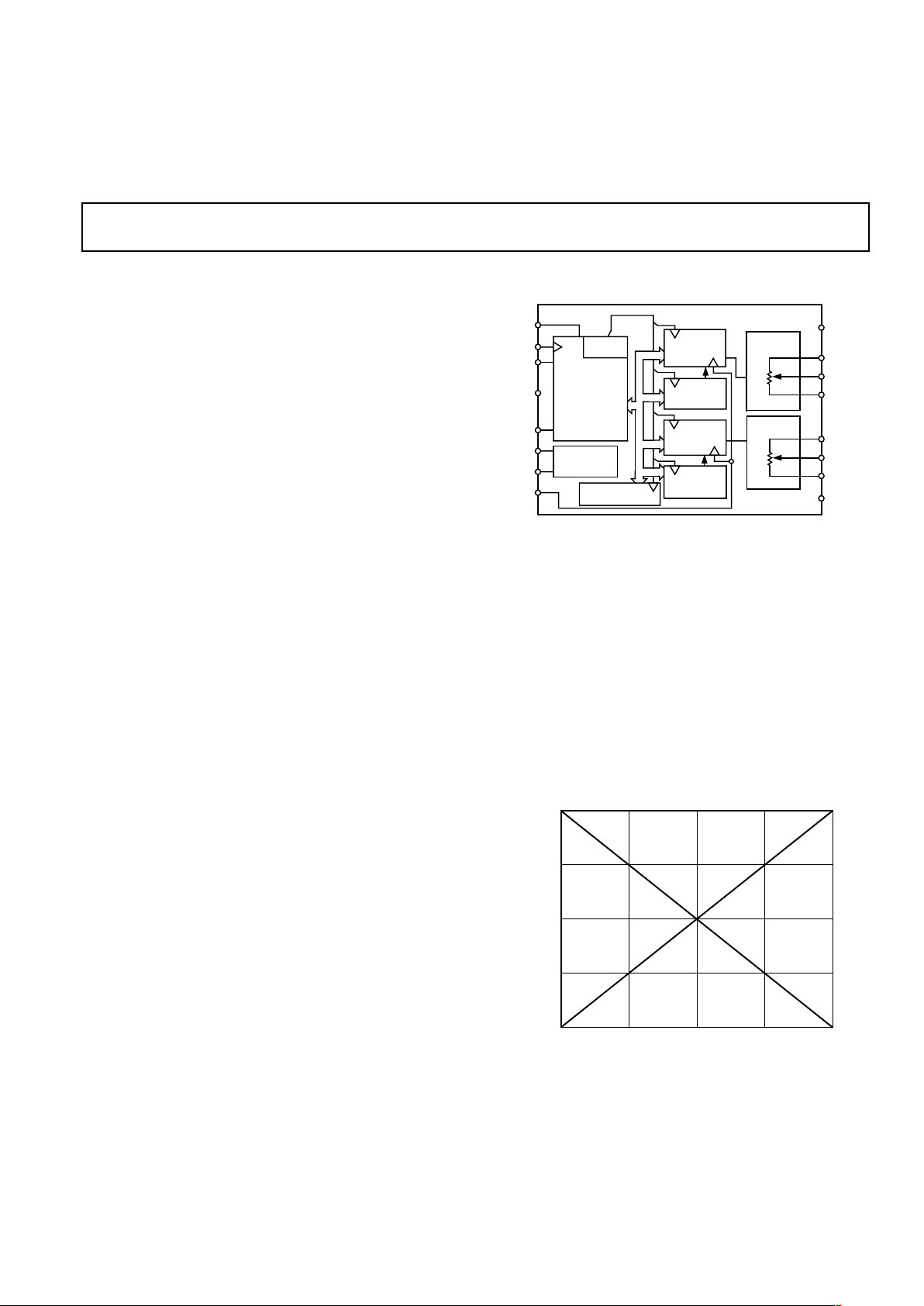

FUNCTIONAL BLOCK DIAGRAM

RDAC1

REGISTER

EEMEM1

RDAC2

REGISTER

EEMEM

CONTROL

14 BYTES

USER EEMEM

EEMEM2

AD5232

RDAC1

RDAC2

CS

CLK

WP

PR

SDI

GND

SDO

RDY

SDO

SERIAL

INTERFACE

ADDR

DECODE

V

DD

V

SS

A1

W1

B1

A2

W2

B2

SDI

The basic mode of adjustment is the increment and decrement

command controlling the present setting of the Wiper position

setting (RDAC) register. An internal scratch pad RDAC register

can be moved UP or DOWN one step of the nominal terminal

resistance between terminals A and B. This linearly changes the

wiper to B terminal resistance (R

WB

) by one position segment of

the devices’ end-to-end resistance (R

AB

). For exponential/logarithmic changes in wiper setting, a left/right shift command

adjusts levels in ±6 dB steps, which can be useful for audio and

light alarm applications.

The AD5232 is available in a thin TSSOP-16 package. All parts

are guaranteed to operate over the extended industrial temperature range of –40°C to +85°C. An evaluation board is available,

Part Number: AD5232EVAL.

CODE – Decimal

100

75

0

0 25664

PERCENT OF NOMINAL

END-TO-END RESISTANCE – % R

AB

128 192

50

25

R

WB

R

WA

Figure 1. Symmetrical RDAC Operation

Page 2

REV. 0

–2–

AD5232–SPECIFICA TIONS

ELECTRICAL CHARACTERISTICS, 10 k, 50 k, 100 k VERSIONS

( VDD = 3 V 10% or 5 V 10% and V

SS

= 0 V, VA = +VDD, VB = 0 V, –40C < TA < +85C unless otherwise noted.)

Parameter Symbol Conditions Min Typ1Max Unit

DC CHARACTERISTICS

RHEOSTAT MODE – Specifications Apply to All VRs

Resistor Differential Nonlinearity

2

R-DNL RWB, VA = NC –1 ±1/2 +1 LSB

Resistor Nonlinearity

2

R-INL RWB, VA = NC –0.4 +0.4 % FS

Nominal Resistor Tolerance ⌬R

AB

–40 +20 %

Resistance Temperature Coefficient ⌬R

AB

/⌬T 600 ppm/°C

Wiper Resistance R

W

IW = 100 µA, V

DD

= 5.5 V, Code = 1E

H

5 100 Ω

R

W

IW = 100 µA, V

DD

= 3 V, Code = 1E

H

200 Ω

POTENTIOMETER DIVIDER MODE — Specifications Apply to All VRs

Resolution N 8 Bits

Differential Nonlinearity

3

DNL –1 ±1/2 +1 LSB

Integral Nonlinearity

3

INL –0.4 +0.4 % FS

Voltage Divider Temperature Coefficient ⌬V

W

/⌬T Code = Half-Scale 15 ppm/°C

Full-Scale Error V

WFSE

Code = Full-Scale –3 0 % FS

Zero-Scale Error V

WZSE

Code = Zero-Scale 0 +3 % FS

RESISTOR TERMINALS

Terminal Voltage Range

4

V

A,B,W

V

SS

V

DD

V

Capacitance

5

Ax, Bx C

A,B

f = 1 MHz, Measured to GND,

Code = Half-Scale 45 pF

Capacitance

5

Wx C

W

f = 1 MHz, Measured to GND,

Code = Half-Scale 60 pF

Common-Mode Leakage Current

5, 6

I

CM

VW = VDD/2 0.01 1 µA

DIGITAL INPUTS AND OUTPUTS

Input Logic High V

IH

With Respect to GND, VDD = 5 V 2.4 V

Input Logic Low V

IL

With Respect to GND, VDD = 5 V 0.8 V

Input Logic High V

IH

With Respect to GND, VDD= 3 V 2.1 V

Input Logic Low V

IL

With Respect to GND, VDD = 3 V 0.6 V

Input Logic High V

IH

With Respect to GND, VDD = +2.5 V, 2.0 V

V

SS

= –2.5 V

Input Logic Low V

IL

With Respect to GND, VDD = +2.5 V, 0.5 V

V

SS

= –2.5 V

Output Logic High (SDO and RDY) V

OH

R

PULL-UP

= 2.2 kΩ to 5 V 4.9 V

Output Logic Low V

OL

IOL = 1.6 mA, V

LOGIC

= 5 V 0.4 V

Input Current I

IL

VIN = 0 V or V

DD

±2.5 µA

Input Capacitance

5

C

IL

4pF

POWER SUPPLIES

Single-Supply Power Range V

DD

VSS = 0 V 2.7 5.5 V

Dual-Supply Power Range V

DD/VSS

±2.25 ±2.75 V

Positive Supply Current I

DD

VIH = VDD or VIL = GND 3.5 10 µA

Programming Mode Current I

DD(PG)

VIH = VDD or VIL = GND 35 mA

Read Mode Current

7

I

DD(XFR)

VIH = VDD or VIL = GND 0.9 3 9 mA

Negative Supply Current I

SS

VIH = VDD or VIL = GND,

V

DD

= +2.5 V, V

SS

= –2.5 V 3.5 10 µA

Power Dissipation

8

P

DISS

VIH = VDD or VIL = GND 0.018 0.05 mW

Power Supply Sensitivity

5

PSS ⌬VDD = 5 V ±10% 0.002 0.01 %/%

Page 3

–3–

REV. 0

nV/√Hz

Parameter Symbol Conditions Min Typ1Max Unit

DYNAMIC CHARACTERISTICS

5, 9

Bandwidth –3 dB, BW_10 kΩ, R = 10 kΩ 500 kHz

Total Harmonic Distortion THD

W

VA = 1 V rms, VB = 0 V, f = 1 kHz,

R

AB

= 10 kΩ 0.022 %

THD

W

VA =1 V rms, VB = 0 V, f = 1 kHz,

R

AB

= 50 kΩ, 100 kΩ 0.045 %

V

W

Settling Time t

S

VDD=5V,VSS=0V,VA = VDD, VB = 0 V,

V

W

= 0.50% Error Band, Code 00H to 80

H

For RAB = 10 kΩ/50 kΩ/100 kΩ 0.65/3/6 µs

Resistor Noise Voltage e

N_WB

RWB = 5 kΩ, f = 1 kHz 9

Crosstalk (C

W1/CW2

)C

T

VA = VDD, VB = 0 V, Measure VW with

Adjacent VR Making Full-Scale Code Change

–5 nV-s

Analog Crosstalk (C

W1/CW2

)CTAV

A1

= VDD, V

B1

= 0 V, Measure V

W1

with VW2 = 5 V p-p @ f = 10 kHz,

Code1 = 80H; Code2 = FF

H

–70 dB

INTERFACE TIMING CHARACTERISTICS – Applies to All Parts

5, 10

Clock Cycle Time (t

CYC

)t

1

20 ns

CS Setup Time t

2

10 ns

CLK Shutdown Time to CS Rise t

3

1t

CYC

Input Clock Pulsewidth t 4 , t

5

Clock Level High or Low 10 ns

Data Setup Time t

6

From Positive CLK Transition 5 ns

Data Hold Time t

7

From Positive CLK Transition 5 ns

CS to SDO-SPI Line Acquire t

8

40 ns

CS to SDO-SPI Line Release t

9

50 ns

CLK to SDO Propagation Delay

11

t

10

RP = 2.2 kΩ, CL < 20 pF 50 ns

CLK to SDO Data Hold Time t

11

RP = 2.2 kΩ, CL < 20 pF 0 ns

CS High Pulsewidth

12

t

12

10 ns

CS High to CS High

12

t

13

4t

CYC

RDY Rise to CS Fall t

14

0ns

CS Rise to RDY Fall Time t

15

0.1 0.15 ms

Read/Store to Nonvolatile EEMEM

13

t

16

Applies to Command 2H, 3H, 9

H

25 ms

CS Rise to Clock Rise/Fall Setup t

17

10 ns

Preset Pulsewidth (Asynchronous) t

PRW

Not Shown in Timing Diagram 50 ns

Preset Response Time to RDY High t

PRESP

PR Pulsed Low to Refreshed

Wiper Positions 70 µs

FLASH/EE MEMORY RELIABILITY CHARACTERISTICS

Endurance

14

100 K Cycles

Data Retention

15

100 Years

NOTES

1

Typical parameters represent average readings at 25°C and VDD = 5 V.

2

Resistor position nonlinearity error R-INL is the deviation from an ideal value measured between the maximum resistance and the minimum resistance wiper

postions. R-DNL measures the relative step change from ideal between successive tap positions. Parts are guaranteed monotonic. IW ~ 50 µA @ V

DD

= 2.7 V and

IW ~ 400 µA @ V

DD

= 5 V for the R

AB

= 10 kΩ version, IW ~ 50 µA for the R

AB

= 50 kΩ and IW ~ 25 µA for the R

AB

= 100 kΩ version. See Figure 13.

3

INL and DNL are measured at VW with the RDAC configured as a potentiometer divider similar to a voltage output D/A converter. VA = VDD and VB = VSS. DNL

specification limits of ±1 LSB maximum are Guaranteed Monotonic operating conditions. See Figure 14.

4

Resistor terminals A, B, W have no limitations on polarity with respect to each other. Dual Supply Operation enables ground-referenced bipolar signal adjustment.

5

Guaranteed by design and not subject to production test.

6

Common-mode leakage current is a measure of the dc leakage from any terminal A, B, W to a common-mode bias level of VDD/2.

7

Transfer (XFR) Mode current is not continuous. Current consumed while EEMEM locations are read and transferred to the RDAC register. See TPC 9.

8

P

DISS

is calculated from (IDD VDD) + (ISS VSS).

9

All dynamic characteristics use VDD = +2.5 V and VSS= –2.5 V unless otherwise noted.

10

See timing diagram for location of measured values. All input control voltages are specified with tR = tF = 2.5 ns (10% to 90% of 3 V) and timed from a voltage level

of 1.5 V. Switching characteristics are measured using both VDD = 3 V or 5 V.

11

Propagation delay depends on value of VDD, R

PULL_UP

, and CL. See applications text.

12

Valid for commands that do not activate the RDY pin.

13

RDY pin low only for instruction commands 8, 9, 10, 2, 3, and the PR hardware pulse: CMD_8 ~ 1 ms; CMD_9,10 ~ 0.12 ms; CMD_2,3 ~ 20 ms. Device operation

at TA = –40°C and V

DD

< 3 V extends the save time to 35 ms.

14

Endurance is qualified to 100,000 cycles as per JEDEC Std. 22 method A117 and measured at VDD = 2.7 V, TA = –40°C to +85°C, typical endurance at 25°C is

700,000 cycles.

15

Retention lifetime equivalent at junction temperature (TJ) = 55°C as per JEDEC Std. 22, Method A117. Retention lifetime based on an activation energy of 0.6eV

will derate with junction temperature as shown in Figure 23 in the Flash/EE Memory description section of this data sheet. The AD5232 contains 9,646

transistors. Die size: 69 mil 115 mil, 7,993 sq. mil.

Specifications subject to change without notice

AD5232

Page 4

REV. 0

–4–

AD5232

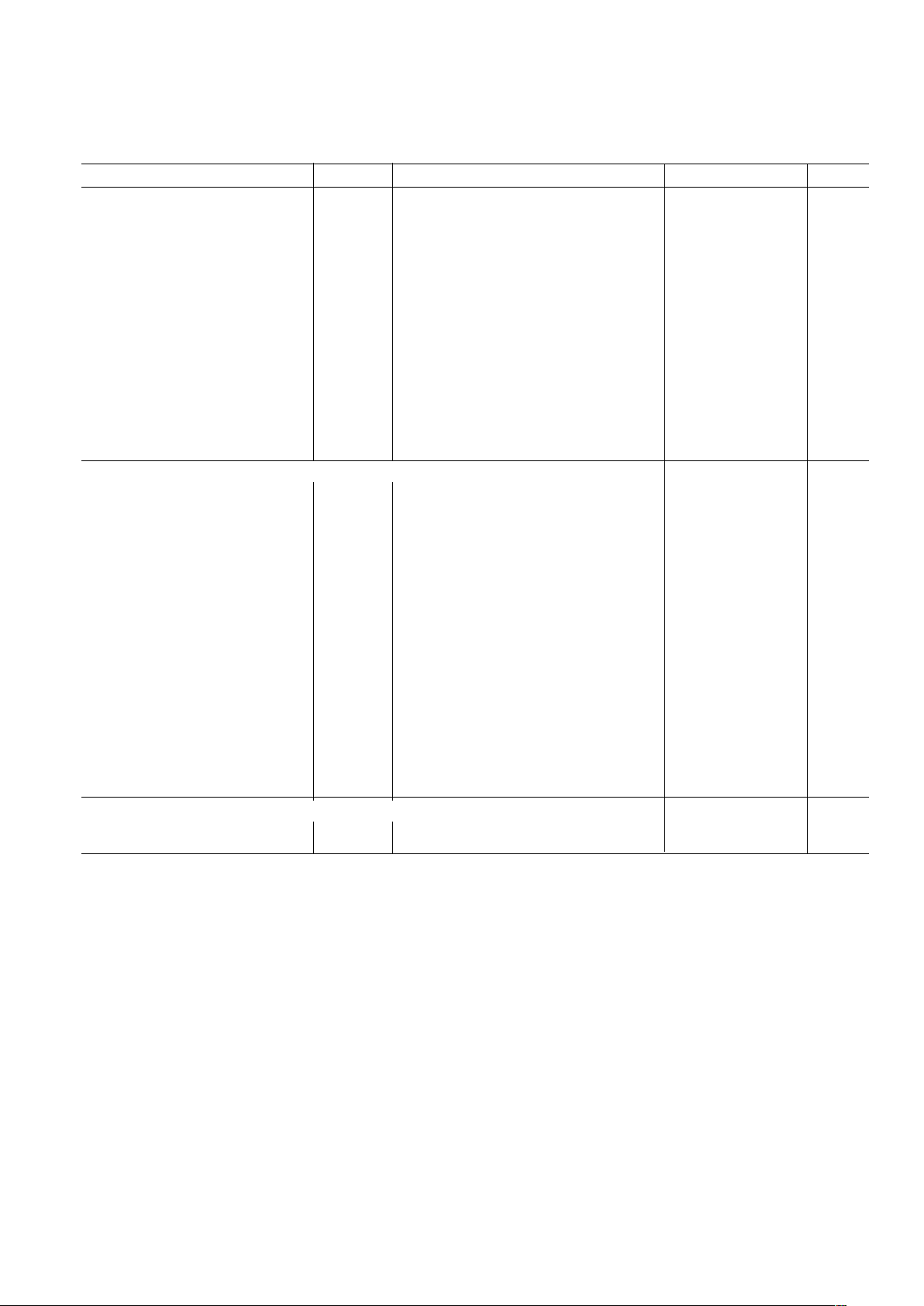

CPOL = 1

t

12

t

13

t

3

t

17

t

9

t

11

t

5

t

4

t

2

t

1

CLK

t

8

*

MSB LSB OUT

MSB

LSB

RDY

CPHA = 1

t

10

t

7

t

6

t

14

t

15

t

16

*

NOT DEFINED, BUT NORMALLY LSB OF CHARACTER PREVIOUSLY TRANSMITTED.

THE CPOL = 1 MICROCONTROLLER COMMAND ALIGNS THE INCOMING DATA TO THE POSITIVE EDGE OF THE CLOCK.

CS

SDO

SDI

Figure 2a. CPHA = 1 Timing Diagram

t

12

t

13

t

3

t

17

t

9

t

11

t

5

t

4

t

2

t

1

CLK

CPOL = 0

t

8

MSB OUT LSB

SDO

MSB IN

LSB

SDI

RDY

CPHA = 0

t

10

t

7

t

6

t

14

t

15

t

16

*

NOT DEFINED, BUT NORMALLY MSB OF CHARACTER JUST RECEIVED.

THE CPOL = 0 MICROCONTROLLER COMMAND ALIGNS THE INCOMING DATA TO THE POSITIVE EDGE OF THE CLOCK.

*

CS

Figure 2b. CPHA = 0 Timing Diagram

Page 5

REV. 0

AD5232

–5–

ORDERING GUIDE

Number of

Number of End-to-End Temperature Package Package Devices per Branding*

Model Channels R

AB

(k) Range (°C) Description Option Container Information

AD5232BRU10 2 10 –40 to +85 TSSOP-16 RU-16 96 5232B10

AD5232BRU10-REEL7 2 10 –40 to +85 TSSOP-16 RU-16 1,000 5232B10

AD5232BRU50 2 50 –40 to +85 TSSOP-16 RU-16 96 5232B50

AD5232BRU50-REEL7 2 50 –40 to +85 TSSOP-16 RU-16 1,000 5232B50

AD5232BRU100 2 100 –40 to +85 TSSOP-16 RU-16 96 5232BC

AD5232BRU100-REEL7 2 100 –40 to +85 TSSOP-16 RU-16 1,000 5232BC

*Line 1 contains ADI logo symbol and the data code YYWW, line 2 contains detail model number listed in this column.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the AD5232 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS

1

(TA = 25°C, unless otherwise noted)

VDD to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . .–0.3 V, +7 V

V

SS

to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . +0.3 V, –7 V

V

DD

to VSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 V

V

A

, VB, VW to GND . . . . . . . . . . . . . VSS– 0.3 V, V

DD

+ 0.3 V

A

X

– BX, AX – WX, BX – W

X

Intermittent2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±20 mA

Continuous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±2 mA

Digital Inputs and Output Voltage to

GND . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V, V

DD

+0.3 V

Operating Temperature Range

3

. . . . . . . . . . . –40°C to +85°C

Maximum Junction Temperature (T

J

Max) . . . . . . . . 150°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature, Soldering

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

Package Power Dissipation . . . . . . . . . . . . . (T

J

Max – TA)/

JA

Thermal Resistance Junction-to-Ambient JA,

TSSOP-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150°C/W

Thermal Resistance Junction-to-Case

JC

,

TSSOP-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28°C/W

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

2

Maximum terminal current is bounded by the maximum current handling of the

switches, maximum power dissipation of the package, and maximum applied

voltage across any two of the A, B, and W terminals at a given resistance.

3

Includes programming of nonvolatile memory.

Page 6

REV. 0

–6–

AD5232

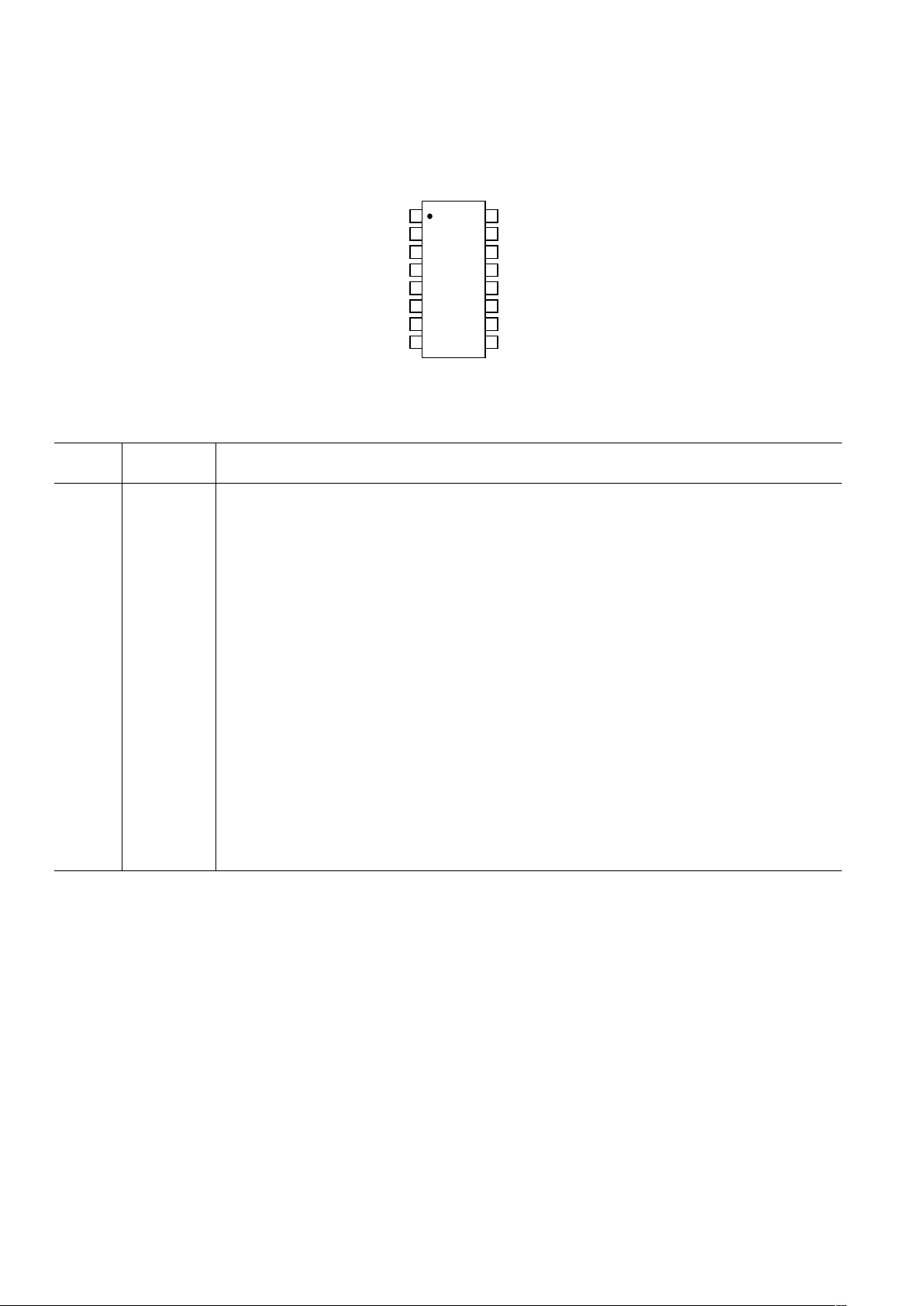

PIN FUNCTION DESCRIPTIONS

Pin

Number Mnemonic Description

1 CLK Serial Input Register Clock Pin. Shifts in one bit at a time on positive clock edges.

2 SDI Serial Data Input Pin. MSB Loaded First.

3 SDO Serial Data Output Pin. Open Drain Output requires external pull-up resistor. Commands 9 and 10

activate the SDO output. See Table II. Other commands shift out the previously loaded SDI bit

pattern delayed by 16 clock pulses. This allows daisy-chain operation of multiple packages.

4 GND Ground Pin, Logic Ground Reference.

5V

SS

Negative Supply. Connect to zero volts for single supply applications.

6 A1 A Terminal of RDAC1

7 W1 Wiper Terminal of RDAC1, ADDR(RDAC1) = 0

H

8 B1 B Terminal of RDAC1

9 B2 B Terminal of RDAC2

10 W2 Wiper Terminal of RDAC2, ADDR(RDAC2) = 1

H

11 A2 A Terminal of RDAC2

12 V

DD

Positive Power Supply Pin

13 WP Write Protect Pin. When active low, WP prevents any changes to the present register contents, except

PR and CMD 1 and 8 will refresh RDAC register from EEMEM. Execute a NOP instruction before

returning WP to logic high.

14 PR Hardware Override Preset Pin. Refreshes the scratch pad register with current contents of the EEMEM

register. Factory default loads midscale 80

H

until EEMEM is loaded with a new value by the user

(PR is activated at the logic high transition).

15 CS Serial Register Chip Select Active Low. Serial register operation takes place when CS returns to logic high.

16 RDY Ready. Active-high open drain output, requires pull-up resistor. Identifies completion of commands

2, 3, 8, 9, 10, and PR.

TOP VIEW

(Not to Scale)

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

CLK

SDI

SDO

GND

V

SS

A1

W1

B1

RDY

CS

PR

WP

V

DD

A2

W2

B2

AD5232

PIN CONFIGURATION

Page 7

REV. 0

AD5232

–7–

OPERATIONAL OVERVIEW

The AD5232 digital potentiometer is designed to operate as a

true variable resistor replacement device for analog signals that

remain within the terminal voltage range of V

SS

< V

TERM

< VDD.

The basic voltage range is limited to a |V

DD

– VSS| < 5.5 V. The

digital potentiometer wiper position is determined by the RDAC

register contents. The RDAC register acts as a scratch pad,

register allowing as many value changes as necessary to place the

potentiometer wiper in the correct position. The scratch pad

register can be programmed with any position value using the

standard SPI serial interface mode by loading the complete

representative data word. Once a desirable position is found,

this value can be saved into a corresponding EEMEM

register.

Thereafter the wiper position will always be set at that position

for any future ON-OFF-ON power supply sequence. The

EEMEM save process takes approximately 25 ms, during this

time the shift register is locked preventing any changes from

taking place. The RDY pin indicates the completion of this

EEMEM save.

SCRATCH PAD AND EEMEM PROGRAMMING

The scratch pad register (RDAC register) directly controls the

position of the digital potentiometer wiper. When the scratch

pad register is loaded with all zeros, the wiper will be connected

to the B-Terminal of the variable resistor. When the scratch pad

register is loaded with midscale code (1/2 of full-scale position),

the wiper will be connected to the middle of the variable resistor. And when the scratch pad is loaded with full-scale code, all

1s, the wiper will connect to the A-Terminal. Since the scratch

pad register is a standard logic register, there is no restriction on

the number of changes allowed. The EEMEM registers have a

program erase/write cycle limitation described in the Flash/

EEMEM Reliability section.

BASIC OPERATION

The basic mode of setting the variable resistor wiper position

(programming the scratch pad register) is accomplished by

loading the serial data input register with the command instruction #11, which includes the desired wiper position data. When

the desired wiper position is found, the user loads the serial data

input register with the command instruction #2, which copies

the desired wiper position data into the corresponding nonvolatile EEMEM register. After 25 ms the wiper position will be

permanently stored in the corresponding nonvolatile EEMEM

location. Table I provides an application-programming example

listing the sequence of serial data input (SDI) words and the

corresponding serial data output appearing at the SDO pin in

hexadecimal format.

At system power-on, the scratch pad register is refreshed with

the value last saved in the EEMEM register. The factory preset

EEMEM value is midscale. The scratch pad (wiper) register can

be refreshed with the current contents of the nonvolatile

EEMEM register under hardware control by pulsing the PR pin.

Table I. Set Two Digital POTs to Independent Data Values

then Save Wiper Positions in Corresponding Nonvolatile

EEMEM Registers

SDI SDO Action

B040

H

XXXXHLoads 40H data into RDAC1 register,

Wiper W1 moves to 1/4 full-scale position.

20xx

H

B040

H

Saves copy of RDAC1 register contents

into corresponding EEMEM0 register.

B180

H

20xx

H

Loads 80H data into RDAC2 register,

Wiper W2 moves to 1/2 full-scale position.

21xx

H

B180

H

Saves copy of RDAC2 register contents

into corresponding EEMEM1 register.

Be aware that the PR pulse first sets the wiper at midscale when

brought to logic zero, and then on the positive transition to logic

high, it reloads the DAC wiper register with the contents of

EEMEM. Many additional advanced programming commands

are available to simplify the variable resistor adjustment process.

For example, the wiper position can be changed one step at a

time by using the software-controlled Increment/Decrement

instruction or, by 6 dB at a time, with the Shift Left/Right

instruction command. Once an Increment, Decrement, or Shift

command has been loaded into the shift register, subsequent CS

strobes will repeat this command. This is useful for push-button

control applications. See the Advanced Control Modes description following Table I. A serial data output SDO pin is

available for daisy chaining and for readout of the internal

register contents. The serial input data register uses a 16-bit

[instruction/address/data] WORD.

EEMEM PROTECTION

Write protect (WP) disables any changes of the scratch pad

register contents regardless of the software commands, except

that the EEMEM setting can be refreshed using commands 8

and PR. Therefore, the write-protect (WP) pin provides a hardware EEMEM protection feature. Execute a NOP command

before returning WP to logic high.

DIGITAL INPUT/OUTPUT CONFIGURATION

All digital inputs are ESD-protected high input impedance that

can be driven directly from most digital sources. PR and WP,

which are active at logic low, must be biased to V

DD

if they are

not being used. No internal pull-up resistors are present on any

digital input pins.

The SDO and RDY pins are open-drain digital outputs where

pull-up resistors are needed only if using these functions. A

resistor value in the range of 1 kΩ to 10 kΩ optimizes the power

and switching speed trade-off.

Page 8

REV. 0

–8–

AD5232

SERIAL DATA INTERFACE

The AD5232 contains a 4-wire SPI-compatible digital interface

(SDI, SDO, CS, and CLK), and uses a 16-bit serial data word

loaded MSB first. The format of the SPI-compatible word is

shown in Table II. The chip select (CS) pin needs to be held

low until the complete data word is loaded into the SDI pin.

When CS returns high, the serial data word is decoded according to the instructions in Table III. The Command Bits (Cx)

control the operation of the digital potentiometer. The Address

Bits (Ax) determine which register is activated. The Data Bits

(Dx) are the values that are loaded into the decoded register.

Table IV provides an address map of the EEMEM locations.

The last instruction executed prior to a period of no programming activity should be the No Operation (NOP) instruction.

This will place the internal logic circuitry in a minimum power

dissipation state.

VALID

COMMAND

COUNTER

COMMAND

PROCESSOR

AND ADDRESS

DECODE

SERIAL

REGISTER

CLK

SDI

5V

R

PULLUP

SDO

GND

PR

WP

CS

AD5232

Figure 3. Equivalent Digital Input-Output Logic

The equivalent serial data input and output logic is shown in

Figure 3. The open-drain output SDO is disabled whenever chip

select CS is logic high. The SPI interface can be used in two slave

modes CPHA = 1, CPOL = 1 and CPHA = 0, CPOL = 0.

CPHA and CPOL refer to the control bits, which dictate

SPI timing in these MicroConverters

®

and microprocessors:

ADuC812/ADuC824, M68HC11, and MC68HC16R1/916R1.

ESD protection of the digital inputs is shown in Figures 4a and 4b.

LOGIC

PINS

V

DD

GND

INPUTS

300

AD5232

Figure 4a. Equivalent ESD Digital Input Protection

V

DD

GND

INPUT

300

WP

AD5232

Figure 4b. Equivalent WP Input Protection

DAISY CHAINING OPERATION

The serial data output pin (SDO) serves two purposes. It can

be used to read out the contents of the wiper setting and

EEMEM values usin g in struction 10 and 9 respectively. The

remaining instructions (#0–8, #11–15) are valid for daisychaining multiple devices in simultaneous operations.

Daisy-chaining minimizes the number of port pins required

from the controlling IC (see Figure 5). The SDO pin contains

an open drain N-Channel FET that requires a pull-up resistor if

this function is used. As shown in Figure 5, users need to tie

the SDO pin of one package to the SDI pin of the next

package. Users may need to increase the clock period because

the pull-up resistor and the capacitive loading at the SDO-SDI

interface may require additional time delay between subsequent

packages. If t w o AD5232’s are daisy-chained, 32 bits of data

are required. The first 16 bits go to U 2 and the second 16

bits with the same format go to U1. The 16 bits are formatted

to contain the 4-bit instruction, followed by the 4-bit address,

then the 8 bits of data. The CS should be kept low until all 32

bits are locked into their respective serial registers. The CS

is then pulled high to complete the operation.

SDI SDO

CLK

+V

R

P

2k

C

SDI SDO

CLK

CS CS

U1 U2

AD5232 AD5232

Figure 5. Daisy-Chain Configuration Using SDO

MicroConverter is a registered trademark of Analog Devices, Inc.

Table II. 16-Bit Serial Data Word

MSB B14 B13 B12 B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 LSB

AD5232

C3 C2 C1 C0 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0

Command bits are identified as Cx, address bits are Ax, and data bits are Dx. Command instruction codes are defined

in Table III.

Page 9

REV. 0

AD5232

–9–

Table III. Instruction/Operation Truth Table

Instruction Byte 1 Data Byte 0

Inst B15 B8 B7 B0

No. C3 C2 C1 C0 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0 Operation

0 0000XXXX XX X XXXX X No Operation (NOP). Do nothing.

1 0001000A0 XX X XXXX X Write contents of EEMEM(A0) to

RDAC(A0) Register. This command

leaves device in the Read Program power

state. To return part to the idle state,

perform NOP instruction #0.

2 0010000A0 XX X XXXX X SAVE WIPER SETTING. Write con-

tents of RDAC(ADDR) to EEMEM(A0)

3 0011 << ADDR >> D7 D6 D5 D4 D3 D2 D1 D0 Write contents of Serial Register Data

Byte 0 to EEMEM(ADDR).

4 0100000A0 XXXXXXXX Decrement 6 dB right shift contents of

RDAC(A0), stops at all “Zeros.”

5 0101XXXX XXXXXXXX Decrement All 6 dB right shift contents

of all RDAC Registers, stops at all “Zeros.”

6 0110000A0 XXXXXXXX Decrement contents of RDAC(A0) by

“One,” stops at all “Zeros.”

7 0111XXXX XXXXXXXX Decrement contents of all RDAC Regis-

ters by “One,” stops at all “Zeros.”

8 10000000 XXXXXXXX RESET. Load all RDACs with their cor-

responding EEMEM previously-saved

values.

9 1001 << ADDR >> XXXXXXXX Write contents of EEMEM(ADDR) to

Serial Register Data Byte 0.

10 1010000A0 XXXXXXXX Write contents of RDAC(A0) to Serial

Register Data Byte 0.

11 1011000A0 D7D6D5D4D3D2D1D0 Write contents of Serial Register Data

Byte 0 to RDAC(A0).

12 1100000A0 XXXXXXXX Increment 6 dB left shift contents of

RDAC(A0), stops at all “Ones.”

13 1101XXXX XXXXXXXX Increment all 6 dB left shift contents

of all RDAC Registers, stops at all “Ones.”

14 1110000A0 XXXXXXXX Increment contents of RDAC(A0) by

“One,” stops at all “Ones.”

15 1111XXXX XXXXXXXX Increment contents of all RDAC Regis-

ters “One,” stops at all “Ones.”

NOTES

1. The SDO output shifts out the last eight bits of data clocked into the serial register for daisy-chain operation. Exception: following Instruction #9 or #10 the selected internal

register data will be present in data byte 0. Instructions following #9 and #10 must be a full 16-bit data word to completely clock out the contents of the serial register.

2. The RDAC register is a volatile scratch pad register that is refreshed at power-on from the corresponding nonvolatile EEMEM register.

3. The increment, decrement, and shift commands ignore the contents of the shift register Data Byte 0.

4. Execution of the Operation column noted in the table takes place when the CS strobe returns to logic high.

5. Execution of a NOP instruction minimizes power dissipation.

Page 10

REV. 0

–10–

AD5232

Also the left shift commands were modified so that if the data in

the RDAC register is greater than or equal to midscale and the

data is left shifted then the data in the RDAC register is set to

full-scale. This makes the left shift function as close to ideally

logarithmic as is possible.

The right shift #4 and #5 commands will be ideal only if the

LSB is zero (i.e., ideal logarithmic–no error). If the LSB is a

one then the right shift function generates a linear half LSB

error, which translates to a code dependent logarithmic error

for odd codes only as shown in the attached plots, (see Figure

5). The plot shows the errors of the odd codes for the AD5232.

0000 0000

0000 0001

0000 0010

0000 0100

0000 1000

0001 0000

0010 0000

0100 0000

1000 0000

1111 1111

1111 1111

LEFT SHIFT

1111 1111

0111 1111

0011 1111

0001 1111

0000 1111

0000 0111

0000 0011

0000 0001

0000 0000

0000 0000

0000 0000

RIGHT SHIFT

LEFT

SHIFT

(+6 dB)

RIGHT

SHIFT

(–6 dB)

Figure 6. Detail Left and Right Shift Function for the

8-Bit AD5232

Actual conformance to a logarithmic curve between the data

contents in the RDAC register and the wiper position for each

Right Shift #4 and #5 command execution contains an error

only for the odd codes. Even codes are ideal except zero right

shift or greater than half-scale left shift. The graph in Figure 7

shows plots of Log_Error [i.e., 20 × log 10 (error/code)]. For

example, code 3 Log_Error = 20 × log 10 (0.5/3) = –15.56 dB,

which is the worst case. The plot of Log_Error is more significant at the lower codes.

CODE, FROM 1 TO 255 BY 2

20 40 60 80 100 0 120

140

160 180 200 220 240 260

0

–10

–20

–30

–40

–50

–60

dB

LOG_ERROR (CODE) FOR 8-BIT

Figure 7. Plot of Log_Error Conformance for Odd Codes

Only (Even Codes Are Ideal)

ADVANCED CONTROL MODES

The AD5232 digital potentiometer contains a set of user programming features to address the wide applications available to these

universal adjustment devices. Key programming features include:

Independently Programmable Read and Write to all registers.

• Simultaneous refresh of all RDAC wiper registers from

corresponding internal EEMEM registers.

•

Increment and Decrement instructions for each RDAC wiper

register.

• Left and right bit shift of all RDAC wiper registers to achieve

6 dB level changes.

• Nonvolatile storage of the present scratch pad RDAC register

values into the corresponding EEMEM register.

• Fourteen extra bytes of user-addressable electrical-erasable memory.

Increment and Decrement Commands

The increment and decrement commands (#14, #15, #6, #7)

are useful for the basic servo adjustment application. This command simplifies microcontroller software coding by eliminating

the need to perform a readback of the current wiper position,

then add one to the register contents using the microcontroller’s

adder. The microcontroller simply sends an increment command

(#14) to the digital POT, which will automatically move the

wiper to the next resistance segment position. The master increment command (#15) will move all POT wipers by one position

from their present position to the next resistor segment position.

The direction of movement is referenced to Terminal B. Thus

each increment #15 command will move the wiper tap position

farther away from Terminal B.

Logarithmic Taper Mode Adjustment

Programming instructions allow a decrement and an increment

wiper position control by individual POT or in a ganged POT

arrangement where both wiper positions are changed at the

same time. These settings are activated by the 6 dB decrement

and 6 dB increment instructions #4 and #5 and #12 and #13

respectively. For example, starting with the wiper connected to

Terminal B executing nine increment instructions (#12) would

move the wiper in +6 dB steps from the 0% of R

BA

(B terminal)

position to the 100% of R

BA

position of the AD5232 8-Bit

potentiometer. The 6 dB increment instruction doubles the

value of the RDAC register contents each time the command is

executed. When the wiper position is greater than midscale, the

last 6 dB increment instruction will cause the wiper to go to the

Full-Scale 255 code position. Any additional +6 dB instruction

will no longer change the wiper position from full scale (RDAC

register code = 255).

Figure 6 illustrates the operation of the 6 dB shifting function

on the individual RDAC register data bits for the 8-bit AD5232

example. Each line going down the table represents a successive

shift operation. Very important: the left shift #12 and #13 commands were modified so that if the data in the RDAC register is

equal to zero and the data is left shifted, it is then set to code 1.

Page 11

REV. 0

AD5232

–11–

USING ADDITIONAL INTERNAL NONVOLATILE EEMEM

The AD5232 contains additional internal user storage registers

(EEMEM) for saving constants and other 8-bit data. Table IV

provides an address map of the internal nonvolatile storage

registers shown in the functional block diagram as EEMEM1,

EEMEM2, and bytes of USER EEMEM.

Table IV. EEMEM Address Map

EEMEM EEMEM Contents of Each

Address Device EEMEM (ADDR)

(ADDR) AD5232 (8B)

0000 RDAC1

0001 RDAC2

0010 USER 1

0011 USER 2

0100 USER 3

0101 USER 4

*** ***

1111 USER 14

NOTES

1

RDAC data stored in EEMEM locations are transferred to their

corresponding RDAC REGISTER at Power ON, or when

instructions Inst#1 and Inst#8 are executed.

2

USER <data> is internal nonvolatile EEMEM registers available

to store and retrieve constants using Inst#3 and Inst#9 respectively.

3

AD5232 EEMEM locations are 1 byte each (8 bits).

4

Execution of instruction #1 leaves the device in the Read Mode power consumption state. After the last Instruction #1 is executed, the user should

perform a NOP, Instruction #0 com mand to return the device to the low

power idle state.

V

DD

A

W

B

V

SS

Figure 8. Maximum Terminal Voltages Set by VDD and V

SS

DETAIL POTENTIOMETER OPERATION

The actual structure of the RDAC is designed to emulate the

performance of a mechanical potentiometer. The patent-pending

RDAC contains multiple strings of connected resistor segments,

with an array of analog switches that act as the wiper connection

to several points along the resistor array. The number of points

is the resolution of the device. For example, the AD5232 has

256 connection points allowing it to provide better than 0.5%

setability resolution. Figure 9 provides an equivalent diagram of the connections between the three terminals that

make up one channel of the RDAC. The SW

A

and SWB will

always be ON, while one of the switches SW(0) to SW(2

N

–1)

will be ON one at a time depending upon the resistance step

decoded from the Data Bits. The resistance contributed by R

W

must be accounted for in the output resistance. The SWA and

SW

B

will always be ON while one of the switches SW(0) to

SW(2

N

–1) will be ON one at a time, depending upon the

resistance step decoded from the Data Bits. The resistance

contributed by R

W

must be accounted for in the output resistance.

SW

A

SW(2

N

–

1)

A

X

W

X

SW(2

N

–

2)

SW

(1)

SW

(0)

SW

B

B

X

RDAC

WIPER

REGISTER

AND

DECODER

R

S = RAB

/2

N

R

S

R

S

R

S

DIGITAL

CIRCUITRY

OMITTED FOR

CLARITY

Figure 9. Equivalent RDAC Structure (Patent Pending)

Table V. RDAC and Digital Register Address Map

Register Address Name of Register*

(ADDR) AD5232 (8B)

0000 RDAC1

0001 RDAC2

*RDACx registers contain data determining the

position of the variable resistor wiper.

TERMINAL VOLTAGE OPERATING RANGE

The digital potentiometer’s positive VDD and negative VSS power

supply defines the boundary conditions for proper three-terminal

programmable resistance operation. Signals present on terminals

A, B, W that exceed V

DD

or VSS will be clamped by a forward

biased diode; see Figure 8.

The ground pin of the AD5232 device is primarily used as a

digital ground reference, which needs to be tied to the PCBs’

common ground. The digital input logic signals to the AD5232

must be referenced to the devices’ ground pin (GND), and

satisfy the logic minimum input high level and the maximum

low level defined in the specification table of this data sheet.

An internal level-shift circuit between the digital interface and

the wiper switch control ensures that the common-mode voltage

range of the three-terminals A, W, and B extends from V

SS

to VDD.

Page 12

REV. 0

–12–

AD5232

Table VI. Nominal Individual Segment Resistor Values ()

Segment Resistor Size

for R

AB

End-to-End Values

10 k Version 50 k Version 100 k Version

8-Bit 78.10 390.5 781.0

PROGRAMMING THE VARIABLE RESISTOR

Rheostat Operation

The nominal resistances of the RDAC between terminals A and B

are available with values of 10 kΩ, 50 kΩ, and 100 kΩ. The final

digits of the part number determine the nominal resistance value,

e.g., 10 kΩ = 10; 100 kΩ = 100. The nominal resistance (R

AB

) of

the AD5232 VR has 256 contact points accessed by the wiper

terminal, plus the B terminal contact. The 8-bit data word in the

RDAC latch is decoded to select one of the 256 possible settings.

The general transfer equation, which determines the digitally

programmed output resistance between Wx and Bx, is:

R

WB

(Dx) = (Dx)/2N × RBA + R

W

(1)

Where N is the resolution of the VR, Dx is the data contained in

the RDACx latch, and R

BA

is the nominal end-to-end resistance.

For example, the following output resistance values will be set

for the following RDAC latch codes (applies to the 8-bit, 10 kΩ

potentiometers):

Table VII. Nominal Resistance Value at Selected Codes for

R

AB

= 10 k

D (DEC) R

WB

(V) Output State

255 10011 Full-Scale

128 5050 Midscale

1891 LSB

0 50 Zero-Scale*(Wiper Contact Resistance)

*Note that in the zero-scale condition a finite wiper resistance of 50 Ω is present. Care

should be taken to limit the current flow between W and B in this state to a

maximum continuous value of 2 mA to avoid degradation or possible de struction of the internal switch metalization. Intermittent current operation to

20 mA is allowed.

CODE – Decimal

100

75

0

0 25664

PERCENT OF NOMINAL

END-TO-END RESISTANCE – % R

AB

128 192

50

25

R

WB

R

WA

Figure 10. Symmetrical RDAC Operation

Like the mechanical potentiometer the RDAC replaces, the

AD5232 parts are totally symmetrical. The resistance between

the wiper W and terminal A also produces a digitally controlled

resistance R

WA

. Figure 10 shows the symmetrical programmability of the various terminal connections. When these terminals

are used the B–terminal should be tied to the wiper. Setting the

resistance value for R

WA

starts at a maximum value of resistance

and decreases as the data loaded in the latch is increased in

value. The general transfer equation for this operation is:

R

WA

(Dx) = (2N-Dx)/2N × RBA + R

W

(2)

where N is the resolution of the VR, Dx is the data contained in

the RDACx latch, and R

BA

is the nominal end-to-end resistance.

For example, the following output resistance values will be set

for the following RDAC latch codes (applies to 8-bit, 10 kΩ

potentiometers).

Table VIII. Nominal Resistance Value at Selected

Codes for R

AB

= 10 k

D (DEC) R

WA

(W) Output State

255 89 Full-Scale

128 5050 Midscale

1 10011 1 LSB

0 10050 Zero-Scale

The multichannel AD5232 has a ±0.2% typical distribution of

internal channel-to-channel R

BA

match. Device-to-device

matching is process-lot-dependent and exhibits a –40% to +20%

variation. The change in R

BA

with temperature has a 600 ppm/°C

temperature coefficient.

Device

Resolution

Page 13

REV. 0

AD5232

–13–

PROGRAMMING THE POTENTIOMETER DIVIDER

Voltage Output Operation

The digital potentiometer easily generates an output voltage

proportional to the input voltage applied to a given terminal.

For example, connecting A-terminal to 5 V and B-terminal to

ground produces an output voltage at the wiper which can be

any value starting at zero volts up to 5 V. Each LSB of voltage is

equal to the voltage applied across terminal AB divided by the

2

N

position resolution of the potentiometer divider. The general

equation defining the output voltage with respect to ground for

any given input voltage applied to terminals AB is:

V

W

(Dx) = Dx/2N × VAB + V

B

(3)

Operation of the digital potentiometer in the divider mode results in

more accurate operation over temperature. Here the output voltage is

dependent on the ratio of the internal resistors, not the absolute

value; therefore, the drift improves to 15 ppm/°C. There is no

voltage polarity restriction between terminals A, B, and W, as long

as the terminal voltage (V

TERM

) stays within VSS < V

TERM

< VDD.

OPERATION FROM DUAL SUPPLIES

The AD5232 can be operated from dual supplies enabling control of ground-referenced ac signals. See Figure 11 for a typical

circuit connection.

~

2V p-p

AD5232

V

SS

GND

SDI

CLK

SS

SCLK

MOSI

GND

V

DD

C

1V p-p

V

DD

+2.75V

–2.5V

CS

Figure 11. Operation from Dual Supplies

C

A

AB

C

B

C

W

RDAC

10k

W

60pF

C

A

= 45pF CB = 45pF

Figure 12. RDAC Circuit Simulation Model for RDAC = 10 k

Ω

The internal parasitic capacitances and the external capacitive loads

dominate the ac characteristics of the RDACs. Configured as a

potentiometer divider the –3 dB bandwidth of the AD5232BRU10

(10 kΩ resistor) measures 500 kHz at half scale. Figure TPC 10

provides the large signal BODE plot characteristics of the three

resistor versions 10 kΩ, 50 kΩ, and 100 kΩ. A parasitic simulation model has been developed, and is shown in Figure 12.

Listing I provides a macro model net list for the 10 kΩ RDAC:

Listing I. Macro Model Net List for RDAC

.PARAM DW=255, RDAC=10E3

*

.SUBCKT DPOT (A,W,B)

*

CA A 0 {45E-12}

RAW A W {(1-DW/256)*RDAC+50}

CW W 0 60E-12

RBW W B {DW/256*RDAC+50}

CB B 0 {45E-12}

*

.ENDS DPOT

APPLICATION PROGRAMMING EXAMPLES

The following command sequence examples have been developed

to illustrate a typical sequence of events for the various features

of the AD5232 nonvolatile digital potentiometer.

[PCB = Printed Circuit Board containing the AD523x part].

Instruction numbers (Commands), addresses and data appearing at SDI and SDO pins are listed in hexadecimal.

Table IX. Set Two Digital POTs to Independent Data Values

SDI SDO Action

B140

H

XXXX

H

Loads 40H data into RDAC2 register,

Wiper W2 moves to 1/4 full-scale

position.

B080

H

B140

H

Loads 80H data into RDAC1 register,

Wiper W1 moves to 1/2 Full-Scale

position.

Page 14

REV. 0

–14–

AD5232

Table X. Active Trimming of One POT Followed by a Save to

Nonvolatile Memory (PCB Calibrate)

SDI SDO Action

B040

H

XXXXHLoads 40H data into RDAC1 register,

Wiper W1 moves to 1/4 full-scale

position.

E0XX

H

B040

H

Increments RDAC1 register by one to

41

H

, Wiper W1 moves one resistor

segment away from terminal B.

E0XX

H

E0XX

H

Increments RDAC1 register by one to

42

H

, Wiper W1 moves one more

resistor segment away from terminal B.

Continue until desired wiper position

reached.

20XX

H

E0XX

H

Saves RDAC1 register data into

corresponding nonvolatile EEMEM1

memory ADDR = 0H.

EQUIPMENT CUSTOMER STARTUP SEQUENCE FOR A

PCB CALIBRATED UNIT WITH PROTECTED SETTINGS

PCB setting: Tie WP to GND [prevents changes in PCB

wiper set position]

Power V

DD

and V

SS

with respect to GND

Optional: Strobe PR pin [ensures full power ON preset of

wiper register with EEMEM contents in unpredictable supply

sequencing environments]

Table XI. Using Left Shift by One to Change Circuit Gain in

6 dB Steps

SDI SDO Action

C1XXHXXXXHMoves Wiper W2 to double the present

data value contained in RDAC2 register, in the direction of the A terminal.

C1XX

H

XXXXHMoves Wiper W2 to double the present

data value contained in RDAC2 register, in the direction of the A terminal.

Table XII. Storing Additional Data in Nonvolatile Memory

SDI SDO Action

3280

H

XXXXHStores 80H data into spare EEMEM

location USER1.

3340

H

XXXXHStores 40H data into spare EEMEM

location USER2.

Table XIII. Reading Back Data from Various Memory Locations

SDI SDO Action

94XX

H

XXXXHPrepares data read from USER3 location.

Assumption: USER3 previously loaded

with 80

H

.

00XX

H

XX80

H

NOP instruction #0 sends 16-bit word

out of SDO where the last 8 bits contain the contents of USER3 location.

NOP command ensures device returns

to idle power dissipation state.

Analog Devices offers the AD5232EVAL board for sale to

simplify evaluation of these programmable devices controlled by

a personal computer via the printer port.

TEST CIRCUITS

Figures 13 to 22 define the test conditions used in the product

specification’s table.

A

W

B

NC

I

W

DUT

V

MS

NC = NO CONNECT

Figure 13. Resistor Position Nonlinearity Error (Rheostat

Operation; R-INL, R-DNL)

A

W

B

DUT

V

MS

V+

V+ = V

DD

1LSB = V+/2

N

Figure 14. Potentiometer Divider Nonlinearity Error Test

Circuit (INL, DNL)

A

W

B

DUT

I

W

V

MS1

V

MS2

V

W

R

W

=

[

V

MS1

– V

MS2

]

/I

W

Figure 15. Wiper Resistance Test Circuit

A

W

B

V

MS

V+ = V

DD

10%

PSRR (dB) = 20 LOG

V

MS

V

DD

(

)

~

V

A

V

DD

V

MS

%

V

DD

%

PSS (%/%) =

V+

Figure 16. Power Supply Sensitivity Test Circuit (PSS, PSRR)

~

OFFSET BIAS

OFFSET

GND

ABDUT

W

5V

V

IN

V

OUT

OP279

Figure 17. Inverting Gain Test Circuit

Page 15

REV. 0

AD5232

–15–

~

OFFSET BIAS

OFFSET

GND

ABDUT

W

5V

V

IN

V

OUT

OP279

Figure 18. Noninverting Gain Test Circuit

~

OFFSET

GND

A

B

DUT

W

+15V

V

IN

V

OUT

OP42

–15V

2.5V

Figure 19. Gain vs. Frequency Test Circuit

+

_

DUT

CODE = OO

H

0.1V

V

SS

TO V

DD

R

SW

=

0.1V

I

SW

ISW

W

B

Figure 20. Incremental ON Resistance Test Circuit

DUT

V

SS

ICM

W

B

V

DD

NC

NC

V

CM

GND

A

NC = NO CONNECT

Figure 21. Common-Mode Leakage Current Test Circuit

W2

B2

V

DD

A2

~

V

IN

NC

W1

RDAC

1

A1

B1

V

SS

V

OUT

RDAC

2

C

= 20 log [V

/V

]

Figure 22. Analog Crosstalk Test Circuit

Flash/EEMEM Reliability

The Flash/EE Memory array on the AD5232 is fully qualified

for two key Flash/EE memory characteristics, namely Flash/EE

Memory Cycling Endurance and Flash/EE Memory Data

Retention.

Endurance quantifies the ability of the Flash/EE memory to be

cycled through many Program, Read, and Erase cycles. In real

terms, a single endurance cycle is composed of four independent, sequential events. These events are defined as:

a. Initial page erase sequence

b. Read/verify sequence

c. Byte program sequence

d. Second read/verify sequence

During reliability qualification Flash/EE memory is cycled from

00

H

to FFH until a first fail is recorded, signifying the endurance

limit of the on-chip Flash/EE memory.

As indicated in the specification pages of this data sheet, the

AD5232 Flash/EE Memory Endurance qualification has been

carried out in accordance with JEDEC Specification A117 over

the industrial temperature range of –40°C to +85°C. The results

allow the specification of a minimum endurance figure over supply

and temperature of 100,000 cycles, with an endurance figure of

700,000 cycles being typical of operation at 25°C.

Retention quantifies the ability of the Flash/EE memory to retain

its programmed data over time. Again, the AD5232 has been

qualified in accordance with the formal JEDEC Retention Lifetime Specification (A117) at a specific junction temperature

(T

J

= 55°C). As part of this qualification procedure, the Flash/EE

memory is cycled to its specified endurance limit described above,

before data retention is characterized. This means that the Flash/EE

memory is guaranteed to retain its data for its full-specified retention lifetime every time the Flash/EE memory is reprogrammed. It

should also be noted that retention lifetime, based on an activation energy of 0.6 eV, will derate with T

J

as shown in Figure 23.

T

J

JUNCTION TEMPERA TURE – C

300

250

0

40

RETENTION – Y ears

200

150

100

50

50 60 70 80 90 100 110

ADI TYPICAL

PERFORMANCE

AT

T

J

= 55C

Figure 23. Flash/EE Memory Data Retention

Page 16

REV. 0

–16–

AD5232

DIGITAL CODE

2.00

–0.50

–2.00

0

IINL ERROR – LSB

1.50

0

–1.00

–1.50

1.00

0.50

64 128 192

1.75

1.25

0.75

–0.25

–0.75

–1.25

–1.75

0.25

INL TA = –40C

INL TA = +85C

INL TA = +25C

256

V

DD

= 2.7V

VSS = 0V

TPC 1. INL vs. Code, TA = –40⬚C, +25⬚C, +85⬚C Overlay

DIGITAL CODE

2.00

–0.50

–2.00

1

DNL ERROR – LSB

1.50

0

–1.00

–1.50

1.00

0.50

64 128 192

1.75

1.25

0.75

–0.25

–0.75

–1.25

–1.75

0.25

DNL TA = –40C

DNL TA = +25C

DNL TA = +85C

256

V

DD

= 2.7V

V

SS

= 0V

TPC 2. DNL vs. Code, TA = –40⬚C, +25⬚C, +85⬚C Overlay

CODE – Decimal

0.20

–0.20

0

32

64

96

128

0.15

0.00

–0.05

–0.10

–0.15

0.10

0.05

160 192 224 256

V

DD

= 5.5V, V

SS

= 0V

T

A

= 25C

R-DNL – LSB

TPC 3. R-DNL vs. Code RAB = 10 kΩ, 50 kΩ, 100 kΩ Overlay

2000

0

032

RHEOSTAT MODE TEMPCO – ppm/C

64 96 128

160

1000

500

1500

192 224 256

CODE – Decimal

TA = –40C/+85C

V

A

= NO CONNECT

R

WB

MEASURED

V

DD

= 5V

TPC 4. ∆RWB/∆T vs. Code RAB = 10 kΩ, VDD = 5 V

70

032

POTENTIOMETER MODE TEMPCO – ppm/C

64 96 128

160 192 224 256

VDD = 5V

T

A

= –40C/+85C

V

A

= 2.00V

V

B

= 0V

–10

60

30

20

10

0

50

40

CODE – Decimal

TPC 5. ∆VWB/∆T vs. Code RAB = 10 kΩ, VDD = 5 V

0.001

–50 –35

I

CM

– A

–20 –510

25

0.01

40 55 70

TEMPERATURE – C

0.1

1

85

VDD = +2.5V

V

CM

= 0V

V

SS

= –2.5V

SEE FIGURE 21

TPC 6. ICM vs. Temperature

–T ypical Performance Characteristics

Page 17

REV. 0

AD5232

–17–

–50 –35

I

DD

–

A

–20 –510

25240 55 70

TEMPERATURE – C

4

85

VDD = 5.5V

VDD = 2.7V

TPC 7. IDD vs. Temperature

TPC 8. IDD vs. Time (Save) Program Mode

FREQUENCY – Hz

12

6

–42

1k 10k

GAIN – dB

0

–6

–30

–12

–18

–24

–36

100k 1M

f

–3dB

= 500kHz, R = 10k

VIN = 100mV rms

V

DD

= +2.5V, V

SS

= –2.5V

R

L

= 1M

f

–3dB

= 45kHz, R = 100k

f

–

3dB

= 95kHz, R = 50k

TA = 25C

TPC 10. –3 dB Bandwidth vs. Resistance

FREQUENCY – Hz

10

10

THD + NOISE – %

1

0.1

0.01

0.001

100 1k 10k 100k

RAB = 10k

RAB = 50k, 100k

TA = 25C

VDD = 5V

FILTER = 22kHz

TPC 11. Total Harmonic Distortion vs. Frequency

CODE

0

1

R

w

–

64 128 192

10

20

30

40

50

60

70

80

90

100

110

256

TA = 25C

V

DD

= 2.7V

TPC 12. Wiper On-Resistance vs. Code

TPC 9. I

DD

vs. Time Read Mode

Page 18

REV. 0

–18–

AD5232

FREQUENCY– Hz

0

–60

1k

GAIN – dB

–30

100k10k

–6

–36

–42

–48

–54

–24

–12

–18

1M

VDD = +2.7V

V

SS

= –2.7V

V

A

= 100mV rms

T

A

= 25C

V

A

DATA = 80

H

DATA = 40

H

DATA = 20

H

DATA = 10

H

DATA = 08

H

DATA = 04

H

DATA = 02

H

DATA = 01

H

R

AB

= 10k

TPC 13. Gain vs. Frequency vs. Code, R

AB

= 10 k

Ω

FREQUENCY – Hz

0

–60

1k

GAIN – dB

–30

100k10k

–6

–36

–42

–48

–54

–24

–12

–18

1M

VDD = +2.7V

V

SS

= –2.7V

V

A

= 100mV rms

T

A

= 25C

V

A

DATA = 80

H

DATA = 40

H

DATA = 20

H

DATA = 10

H

DATA = 08

H

DATA = 04

H

DATA = 02

H

DATA = 01

H

RAB = 50k

TPC 14. Gain vs. Frequency vs. Code, R

AB

= 50 k

Ω

FREQUENCY – Hz

0

–60

1k

GAIN – dB

–30

100k10k

–6

–36

–42

–48

–54

–24

–12

–18

1M

VDD = +2.7V

V

SS

= –2.7V

V

A

= 100mV rms

T

A

= 25C

V

A

DATA = 80

H

DATA = 40

H

DATA = 20

H

DATA = 10

H

DATA = 08

H

DATA = 04

H

DATA = 02

H

DATA = 01

H

RAB = 100k

TPC 15. Gain vs. Frequency vs. Code, R

AB

= 100 k

Ω

FREQUENCY – Hz

80

0

1k

PSRR REJECTION – dB

40

100k10k

20

1M

60

TA = 25C

V

DD

= 5.5V 100mV ac

V

SS

= 0V, VB = 5V, VA = 0V

MEASURE at V

W

WITH CODE = 80

H

RAB = 100k

RAB = 50k

RAB = 10k

TPC 16. PSRR vs. Frequency

FREQUENCY – kHz

120

20

1

C

TA

ANALOG CROSSTALK REJECTION – dB

60

10

40

100

80

VDD = VA2 = +2.75V

V

SS

= VB2 = –2.75V

V

IN

= +2.5V

P

RAB = 100k

RAB = 50k

RAB = 10k

SEE TEST CIRCUIT, FIGURE 22

100

TA = 25C

TPC 17. Analog Crosstalk vs. Frequency

Page 19

REV. 0

AD5232

–19–

Number Resolution Power

of VRs Terminal Interface Nominal (Number Supply

Part per Voltage Data Resistance of Wiper Current

Number Package Range (V) Control (k) Positions) (I

DD

)(A) Packages Comments

AD5201 1 ±3, +5.5 3-wire 10, 50 33 40 µSOIC-10 Full ac Specs, Dual

Supply, Pwr-On-Reset,

Low Cost

AD5220 1 5.5 UP/ 10, 50, 100 128 40 PDIP, SO-8, No Rollover,

DOWN µSOIC-8 Pwr-On-Reset

AD7376 1 ±15 , +28 3-wire 10, 50, 100, 1000 128 100 PDIP-14, Single 28 V

SOL-16, or Dual ±15 V

TSSOP-14 Supply Operation

AD5200 1 ±3 , +5.5 3-wire 10, 50 256 40 µSOIC-10 Full ac Specs,

Dual Supply,

Pwr-On-Reset

AD8400 1 5.5 3-wire 1, 10, 50, 100 256 5 SO-8 Full ac Specs

AD5260 1 ±5, +15 3-wire 20, 50, 200 256 60 TSSOP-14 +5 V to+15 V or ±5 V

Operation,

TC < 50 ppm/°C

AD5241 1 ±3, +5.5 2-wire 10, 100, 1000 256 50 SO-14, I

2

C Compatible,

TSSOP-14 TC < 50 ppm/°C

AD5231 1 ±2.75, +5.5 3-wire 10, 50, 100 1024 10 TSSOP-16 Nonvolatile Memory,

Direct Program, I/D,

±6 dB Settability

AD5222 2 ±3, +5.5 UP/ 10, 50, 100, 1000 128 80 SO-14, No Rollover, Stereo,

DOWN TSSOP-14 Pwr-On-Reset,

TC < 50 ppm/°C

AD8402 2 5.5 3-wire 1, 10, 50, 100 256 5 PDIP, SO-14, Full ac Specs, nA

TSSOP-14 Shutdown Current

AD5207 2 ±3, +5.5 3-wire 10, 50, 100 256 40 TSSOP-14 Full ac Specs, Dual

Supply, Pwr-OnReset, SDO

AD5232 2 ±2.75, +5.5 3-wire 10, 50, 100 256 10 TSSOP-16 Nonvolatile Memory,

Direct Program, I/D,

±6 dB Settability

AD5235* 2 ±2.75, +5.5 3-wire 25, 250 1024 20 TSSOP-16 Nonvolatile Memory,

Direct Program,

TC < 50 ppm/°C

AD5242 2 ±3, +5.5 2-wire 10, 100, 1000 256 50 SO-16, I

2

C Compatible,

TSSOP-16 TC < 50 ppm/°C

AD5262* 2 ±5, +15 3-wire 20, 50, 200 256 60 TSSOP-16 +5 V to +15 V or ±5 V

Operation,

TC < 50 ppm/°C

AD5203 4 5.5 3-wire 10, 100 64 5 PDIP, SOL-24, Full ac Specs, nA

TSSOP-24 Shutdown Current

AD5233 4 ±2.75, +5.5 3-wire 10, 50, 100 64 10 TSSOP-16 Nonvolatile Memory,

Direct Program,

I/D, ±6 dB Settability

AD5204 4 ±3, +5.5 3-wire 10, 50, 100 256 60 PDIP, SOL-24, Full ac Specs,

TSSOP-24 Dual Supply,

Pwr-On-Reset

AD8403 4 5.5 3-wire 1, 10, 50, 100 256 5 PDIP, SOL-24, Full ac Specs, nA

TSSOP-24 Shutdown Current

AD5206 6 ±3, +5.5 3-wire 10, 50, 100 256 60 PDIP, SOL-24, Full ac Specs,

TSSOP-24 Dual Supply,

Pwr-On-Reset

*Future Product, consult factory for latest status.

Latest Digital Potentiometer Information located at: www.analog.com/DigitalPotentiometers

DIGITAL POTENTIOMETER FAMILY SELECTION GUIDE

Page 20

REV. 0

–20–

C02618–1–10/01(0)

PRINTED IN U.S.A.

AD5232

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

PRINTED IN U.S.A.

16-Lead TSSOP

(RU-16)

16

9

81

0.256 (6.50)

0.246 (6.25)

0.177 (4.50)

0.169 (4.30)

PIN 1

0.201 (5.10)

0.193 (4.90)

SEATING

PLANE

0.006 (0.15)

0.002 (0.05)

0.0118 (0.30)

0.0075 (0.19)

0.0256 (0.65)

BSC

0.0433 (1.10)

MAX

0.0079 (0.20)

0.0035 (0.090)

0.028 (0.70)

0.020 (0.50)

8

0

Loading...

Loading...