Page 1

A

256-Position SPI/I2C Selectable

FEATURES

256-position

End-to-end resistance 5 kΩ, 10 kΩ, 50 kΩ, 100 kΩ

Compact MSOP-10 (3 mm × 4.9 mm) package

Pin selectable SPI/I

Extra package address decode pin AD0

Full read/write of wiper register

Power-on preset to midscale

Single supply 2.7 V to 5.5 V

Low temperature coefficient 45 ppm/°C

Low power, I

Wide operating temperature –40°C

SDO output allows multiple device daisy-chaining

Evaluation board available

APPLICATIONS

Mechanical potentiometer replacement in new designs

Transducer adjustment of pressure, temperature, position,

chemical, and optical sensors

RF amplifier biasing

Automotive electronics adjustment

Gain control and offset adjustment

GENERAL OVERVIEW

The AD5161 provides a compact 3 mm × 4.9 mm packaged

solution for 256-position adjustment applications. These devices

perform the same electronic adjustment function as mechanical

potentiometers or variable resistors, with enhanced resolution,

solid-state reliability, and superior low temperature coefficient

performance.

The wiper settings are controllable through a pin selectable SPI

2

C compatible digital interface, which can also be used to

or I

read back the wiper register content. When the SPI mode is

used, the device can be daisy-chained (SDO to SDI), allowing

several parts to share the same control lines. In the I

address pin AD0 can be used to place up to two devices on the

same bus. In this same mode, command bits are available to

reset the wiper position to midscale or to shut down the device

into a state of zero power consumption.

Operating from a 2.7 V to 5.5 V power supply and consuming

less than 5 µA allows for usage in portable battery-operated

applications.

2

C compatible interface

= 8 µA

DD

to +125°C

2

C mode,

Digital Potentiometer

AD5161

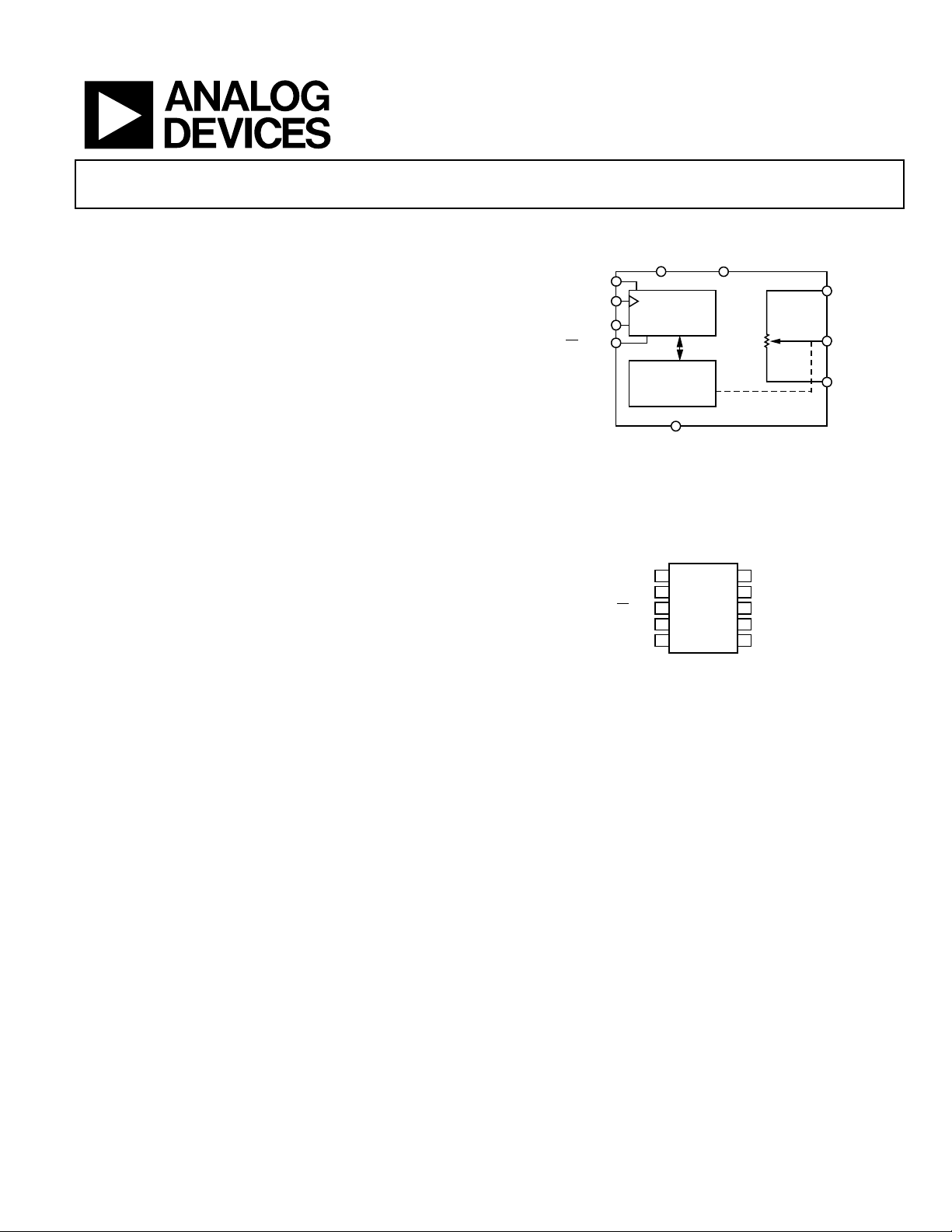

FUNCTIONAL BLOCK DIAGRAM

SDO/NCV

DD

SDI/SDA

CLK/SCL

DIS

CS/AD0

SPI OR I2C

INTERFACE

WIPER

REGISTER

GND

Figure 1.

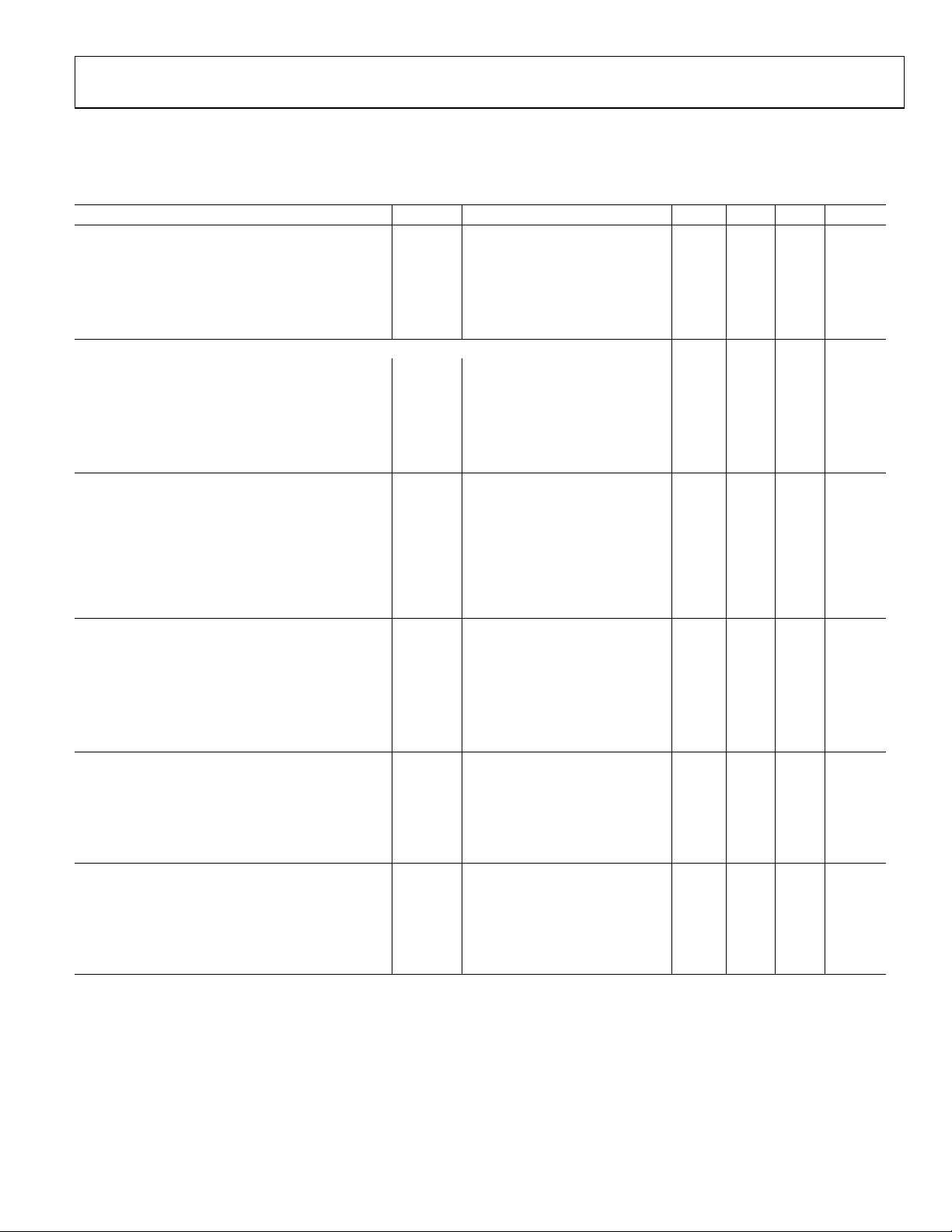

PIN CONFIGURATION

10

9

8

7

6

W

V

DD

DIS

GND

CLK/SCL

CS/ADO

SDO/NC

SDI/SD

1

A

2

B

3

4

5

AD5161

TOP VIEW

(Not to Scale)

Figure 2.

Note:

The terms digital potentiometer, VR, and RDAC are used interchangeably.

Purchase of licensed I2C components of Analog Devices or one of its sublicensed

Associated Companies conveys a license for the purchaser under the Philips I

Patent Rights to use these components in an I

conforms to the I

2

C Standard Specification as defined by Philips.

2

C system, provided that the system

A

W

B

2

C

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.326.8703 © 2003 Analog Devices, Inc. All rights reserved.

Page 2

AD5161

TABLE OF CONTENTS

Electrical Characteristics—5 kΩ Version ...................................... 3

Level Shifting for Bidirectional Interface................................ 17

Electrical Characteristics—10 kΩ, 50 kΩ, 100 kΩ Versions ....... 4

Timing Characteristics—5 kΩ, 10 kΩ, 50 kΩ, 100 kΩ Versions 5

Absolute Maximum Ratings1.......................................................... 6

Typical Performance Characteristics ............................................. 7

Test Circuits..................................................................................... 11

SPI Interface .................................................................................... 12

I2C Interface..................................................................................... 13

Operation......................................................................................... 14

Programming the Variable Resistor......................................... 14

Programming the Potentiometer Divider............................... 15

Pin Selectable Digital Interface................................................. 15

REVISION HISTORY

Revision 0: Initial Version

ESD Protection ........................................................................... 17

Terminal Voltage Operating Range.......................................... 17

Power-Up Sequence ................................................................... 17

Layout and Power Supply Bypassing ....................................... 17

Pin Configuration and Function Descriptions........................... 18

Pin Configuration ...................................................................... 18

Pin Function Descriptions ........................................................ 18

Outline Dimensions....................................................................... 19

Ordering Guide .......................................................................... 19

ESD Caution................................................................................ 19

Rev. 0 | Page 2 of 20

Page 3

AD5161

ELECTRICAL CHARACTERISTICS—5 kΩ VERSION

(VDD = 5 V ± 10%, or 3 V ± 10%; VA = +VDD; VB = 0 V; –40°C < TA < +125°C; unless otherwise noted.)

Table 1.

Parameter Symbol Conditions Min Typ1 Max Unit

DC CHARACTERISTICS—RHEOSTAT MODE

Resistor Differential Nonlinearity2 R-DNL RWB, V

Resistor Integral Nonlinearity2 R-INL RWB, V

Nominal Resistor Tolerance3 ∆RAB T

Resistance Temperature Coefficient ∆RAB/∆T VAB = VDD, Wiper = no connect 45 ppm/°C

Wiper Resistance RW 50 120 Ω

DC CHARACTERISTICS—POTENTIOMETER DIVIDER MODE (Specifications apply to all VRs)

Resolution N 8 Bits

Differential Nonlinearity4 DNL –1.5 ±0.1 +1.5 LSB

Integral Nonlinearity4 INL –1.5 ±0.6 +1.5 LSB

Voltage Divider Temperature Coefficient ∆VW/∆T Code = 0x80 15 ppm/°C

Full-Scale Error V

Zero-Scale Error V

Code = 0xFF –6 –2.5 0 LSB

WFSE

Code = 0x00 0 +2 +6 LSB

WZSE

RESISTOR TERMINALS

Voltage Range5 V

Capacitance6 A, B C

GND VDD V

A,B,W

A,B

Capacitance6 W CW

Shutdown Supply Current7 I

DD_SD

Common-Mode Leakage ICM V

DIGITAL INPUTS AND OUTPUTS

Input Logic High VIH 2.4 V

Input Logic Low VIL 0.8 V

Input Logic High VIH V

Input Logic Low VIL V

Input Current IIL V

Input Capacitance6 C

5 pF

IL

POWER SUPPLIES

Power Supply Range V

2.7 5.5 V

DD RANGE

Supply Current IDD V

Power Dissipation8 P

V

DISS

Power Supply Sensitivity PSS

DYNAMIC CHARACTERISTICS

6, 9

Bandwidth –3dB BW_5K RAB = 5 kΩ, Code = 0x80 1.2 MHz

Total Harmonic Distortion THDW VA = 1 V rms, VB = 0 V, f = 1 kHz 0.05 %

VW Settling Time tS

Resistor Noise Voltage Density e

RWB = 2.5 kΩ, RS = 0 6 nV/√Hz

N_WB

= no connect –1.5 ±0.1 +1.5 LSB

A

= no connect –4 ±0.75 +4 LSB

A

= 25°C –30 +30 %

A

f = 1 MHz, measured to GND,

45 pF

Code = 0x80

f = 1 MHz, measured to GND,

60 pF

Code = 0x80

VDD = 5.5 V 0.01 1 µA

= VB = VDD/2 1 nA

A

= 3 V 2.1 V

DD

= 3 V 0.6 V

DD

= 0 V or 5 V ±1 µA

IN

= 5 V or VIL = 0 V 3 8 µA

IH

= 5 V or VIL = 0 V, VDD = 5 V 0.2 mW

IH

= +5 V ± 10%,

∆V

DD

±0.02 ±0.05 %/%

Code = Midscale

= 5 V, VB = 0 V, ±1 LSB error

V

A

1 µs

band

Rev. 0 | Page 3 of 20

Page 4

AD5161

ELECTRICAL CHARACTERISTICS—10 kΩ, 50 kΩ, 100 kΩ VERSIONS

(VDD = 5 V ± 10%, or 3 V ± 10%; VA = VDD; VB = 0 V; –40°C < TA < +125°C; unless otherwise noted.)

Table 2.

Parameter Symbol Conditions Min Typ1 Max Unit

DC CHARACTERISTICS—RHEOSTAT MODE

Resistor Differential Nonlinearity2 R-DNL RWB, V

Resistor Integral Nonlinearity2 R-INL RWB, V

Nominal Resistor Tolerance3 ∆RAB T

Resistance Temperature Coefficient ∆RAB/∆T

Wiper Resistance RW V

DC CHARACTERISTICS—POTENTIOMETER DIVIDER MODE (Specifications apply to all VRs)

Resolution N 8 Bits

Differential Nonlinearity4 DNL –1 ±0.1 +1 LSB

Integral Nonlinearity4 INL –1 ±0.3 +1 LSB

Voltage Divider Temperature Coefficient ∆VW/∆T Code = 0x80 15 ppm/°C

Full-Scale Error V

Zero-Scale Error V

Code = 0xFF –3 –1 0 LSB

WFSE

Code = 0x00 0 1 3 LSB

WZSE

RESISTOR TERMINALS

Voltage Range5 V

Capacitance6 A, B C

GND VDD V

A,B,W

A,B

Capacitance6 W CW

Shutdown Supply Current7 I

DD_SD

Common-Mode Leakage ICM V

DIGITAL INPUTS AND OUTPUTS

Input Logic High VIH 2.4 V

Input Logic Low VIL 0.8 V

Input Logic High VIH V

Input Logic Low VIL V

Input Current IIL V

Input Capacitance6 C

5 pF

IL

POWER SUPPLIES

Power Supply Range V

2.7 5.5 V

DD RANGE

Supply Current IDD V

Power Dissipation8 P

DISS

Power Supply Sensitivity PSS

DYNAMIC CHARACTERISTICS

6, 9

Bandwidth –3dB BW

Total Harmonic Distortion THDW

VW Settling Time (10 kΩ/50 kΩ/100 kΩ) tS

Resistor Noise Voltage Density e

R

N_WB

= no connect –1 ±0.1 +1 LSB

A

= no connect –2 ±0.25 +2 LSB

A

= 25°C –30 +30 %

A

V

AB

= VDD,

45 ppm/°C

Wiper = no connect

= 5 V 50 120 Ω

DD

f = 1 MHz, measured to

45 pF

GND, Code = 0x80

f = 1 MHz, measured to

60 pF

GND, Code = 0x80

VDD = 5.5 V 0.01 1 µA

= VB = VDD/2 1 nA

A

= 3 V 2.1 V

DD

= 3 V 0.6 V

DD

= 0 V or 5 V ±1 µA

IN

= 5 V or VIL = 0 V 3 8 µA

IH

= 5 V or VIL = 0 V,

V

IH

V

= 5 V

DD

= +5 V ± 10%,

∆V

DD

0.2 mW

±0.02 ±0.05 %/%

Code = Midscale

= 10 kΩ/50 kΩ/100 kΩ,

R

AB

600/100/40 kHz

Code = 0x80

=1 V rms, VB = 0 V,

V

A

f = 1 kHz, R

= 5 V, VB = 0 V,

V

A

= 10 kΩ

AB

0.05 %

2 µs

±1 LSB error band

= 5 kΩ, RS = 0 9 nV/√Hz

WB

Rev. 0 | Page 4 of 20

Page 5

AD5161

TIMING CHARACTERISTICS—5 kΩ, 10 kΩ, 50 kΩ, 100 kΩ VERSIONS

(VDD = +5V ± 10%, or +3V ± 10%; VA = VDD; VB = 0 V; –40°C < TA < +125°C; unless otherwise noted.)

Table 3.

Parameter Symbol Conditions Min Typ1 Max Unit

SPI INTERFACE TIMING CHARACTERISTICS

Clock Frequency f

Input Clock Pulsewidth tCH, tCL Clock level high or low 20 ns

Data Setup Time tDS 5 ns

Data Hold Time tDH 5 ns

CS Setup Time

CS High Pulsewidth

CLK Fall to CS Fall Hold Time

CLK Fall to CS Rise Hold Time

CS Rise to Clock Rise Setup

I2C INTERFACE TIMING CHARACTERISTICS

SCL Clock Frequency f

t

Bus Free Time between STOP and START t1 1.3 µs

BUF

t

t

t

t

t

t

Hold Time (Repeated START) t2

HD;STA

Low Period of SCL Clock t3 1.3 µs

LOW

High Period of SCL Clock t4 0.6 50 µs

HIGH

Setup Time for Repeated START Condition t5 0.6 µs

SU;STA

Data Hold Time t6 0.9 µs

HD;DAT

Data Setup Time t7 100 ns

SU;DAT

tF Fall Time of Both SDA and SCL Signals t8 300 ns

tR Rise Time of Both SDA and SCL Signals t9 300 ns

t

Setup Time for STOP Condition t10 0.6 µs

SU;STO

NOTES

1

Typical specifications represent average readings at +25°C and VDD = 5 V.

2

Resistor position nonlinearity error R-INL is the deviation from an ideal value measured between the maximum resistance and the minimum resistance wiper

positions. R-DNL measures the relative step change from ideal between successive tap positions. Parts are guaranteed monotonic.

3

VAB = VDD, Wiper (VW) = no connect.

4

INL and DNL are measured at VW with the RDAC configured as a potentiometer divider similar to a voltage output D/A converter. VA = VDD and VB = 0 V.

DNL specification limits of ±1 LSB maximum are guaranteed monotonic operating conditions.

5

Resistor terminals A, B, W have no limitations on polarity with respect to each other.

6

Guaranteed by design and not subject to production test.

7

Measured at the A terminal. The A terminal is open circuited in shutdown mode.

8

P

is calculated from (IDD × VDD). CMOS logic level inputs result in minimum power dissipation.

DISS

9

All dynamic characteristics use VDD = 5 V.

10

See timing diagram for location of measured values. All input control voltages are specified with tR = tF = 2 ns (10% to 90% of 3 V) and timed from a voltage

level of 1.5 V.

11

See timing diagrams for locations of measured values.

6, 10

(Specifications Apply to All Parts)

CLK

t

15 ns

CSS

40 ns

t

CSW

t

0 ns

CSH0

t

0 ns

CSH1

t

10 ns

CS1

6, 11

(Specifications Apply to All Parts)

400 kHz

SCL

After this period, the first clock pulse is

0.6 µs

25 MHz

generated.

Rev. 0 | Page 5 of 20

Page 6

AD5161

ABSOLUTE MAXIMUM RATINGS1

(TA = +25°C, unless otherwise noted.)

Table 4

Parameter Value

VDD to GND –0.3 V to +7 V

VA, VB, VW to GND VDD

1

I

±20 mA

MAX

Digital Inputs and Output Voltage to GND 0 V to +7 V

Operating Temperature Range –40°C to +125°C

Maximum Junction Temperature (T

) 150°C

JMAX

Storage Temperature –65°C to +150°C

Lead Temperature (Soldering, 10 sec) 300°C

Thermal Resistance2 θJA: MSOP-10 200°C/W

NOTES

1

Maximum terminal current is bounded by the maximum current handling of

the switches, maximum power dissipation of the package, and maximum

applied voltage across any two of the A, B, and W terminals at a given

resistance.

2

Package power dissipation = (T

JMAX

– TA)/θJA.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only and functional operation of the device at these or

any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Rev. 0 | Page 6 of 20

Page 7

AD5161

TYPICAL PERFORMANCE CHARACTERISTICS

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

RHEOSTAT MODE INL (LSB)

–0.6

–0.8

–1.0

3209664 128 160 192 224 256

Figure 3. R-INL vs. Code vs. Supply Voltages

CODE (Decimal)

5V

3V

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

POTENTIOMETER MODE DNL (LSB)

–0.8

–1.0

64

32096

Figure 6. DNL vs. Code, V

128 160 192 224 256

CODE (Decimal)

= 5 V

DD

–40°C

+25°C

+85°C

+125°C

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

RHEOSTAT MODE DNL (LSB)

–0.6

–0.8

–1.0

3209664 128 160 192 224 256

CODE (Decimal)

5V

3V

Figure 4. R-DNL vs. Code vs. Supply Voltages

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

POTENTIOMETER MODE INL (LSB)

–0.8

–1.0

3209664 128 160 192 224 256

Figure 5. INL vs. Code, V

CODE (Decimal)

DD

= 5 V

_

40°C

+25°C

+85°C

+125°C

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

POTENTIOMETER MODE INL (LSB)

–0.8

–1.0

3209664 128 160 192 224 256

CODE (Decimal)

5V

3V

Figure 7. INL vs. Code vs. Supply Voltages

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

POTENTIOMETER MODE DNL(LSB)

–0.8

–1.0

3209664 128 160 192 224 256

CODE (Decimal)

5V

3V

Figure 8. DNL vs. Code vs. Supply Voltages

Rev. 0 | Page 7 of 20

Page 8

AD5161

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

RHEOSTAT MODE INL (LSB)

–0.6

–0.8

–1.0

–40

°C

+25°C

+85°C

+125°C

3209664 128 160 192 224 256

Figure 9. R-INL vs. Code, V

CODE (Decimal)

DD

= 5 V

2.5

2.0

1.5

1.0

ZSE, ZERO-SCALE ERROR (µA)

0.5

0

0 40 80 120–40

0 40 80 120–40

VDD = 5.5V

VDD = 2.7V

TEMPERATURE (°C)

Figure 12. Zero-Scale Error vs. Temperature

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

RHEOSTAT MODE DNL (LSB)

–0.6

–0.8

–1.0

FSE, FULL-SCALE ERROR (LSB)

2.5

2.0

1.5

1.0

0.5

64

32096

Figure 10. R-DNL vs. Code, V

128 160 192 224 256

CODE (Decimal)

= 5 V

DD

_

40°C

+25°C

+85°C

+125°C

= 2.7V

V

DD

= 5.5V

V

DD

10

1

SUPPLY CURRENT (µA)

DD

I

0.1

70

60

50

40

30

20

SHUTDOWN CURRENT (nA)

A

I

10

VDD = 5.5V

V

= 2.7V

DD

0 40 80 120–40

TEMPERATURE (°C)

Figure 13. Supply Current vs. Temperature

VDD = 5V

0

0 40 80 120–40

0 40 80 120–40

TEMPERATURE (°C)

Figure 11. Full-Scale Error vs. Temperature

Rev. 0 | Page 8 of 20

0

0

40 80 120–40

TEMPERATURE (°C)

Figure 14. Shutdown Current vs. Temperature

Page 9

AD5161

g

/

g

VWB/

200

150

100

50

0

RHEOSTAT MODE TEMPCO (ppm/°C)

–50

3209664 128 160 192 224 256

ure 15. Rheostat Mode Tempco ∆R

Fi

CODE (Decimal)

∆T vs. Code

WB

160

140

120

100

80

60

40

20

0

POTENTIOMETER MODE TEMPCO (ppm/°C)

–20

3209664 128 160 192 224 256

ure 16. Potentiometer Mode Tempco ∆

Fi

CODE (Decimal)

∆T vs. Code

REF LEVEL

0.000dB

0

–6

–12

–18

–24

–30

–36

–42

–48

–54

–60

1k

START 1 000.000Hz STOP 1 000 000.000Hz

Figure 17. Gain vs. Frequency vs. Code, R

/DIV

6.000dB

0x80

0x40

0x20

0x10

0x08

0x04

0x02

0x01

10k 100k 1M

MARKER 1 000 000.000Hz

MAG (A/R) –8.918dB

= 5 kΩ

AB

REF LEVEL

0.000dB

0

–6

–12

–18

–24

–30

–36

–42

–48

–54

–60

1k 10k 100k 1M

START 1 000.000Hz STOP 1 000 000.000Hz

Figure 18. Gain vs. Frequency vs. Code, R

REF LEVEL

0.000dB

0

–6

–12

–18

–24

–30

–36

–42

–48

–54

–60

1k

START 1 000.000Hz STOP 1 000 000.000Hz

Figure 19. Gain vs. Frequency vs. Code, R

REF LEVEL

0.000dB

0

–6

–12

–18

–24

–30

–36

–42

–48

–54

–60

1k

START 1 000.000Hz STOP 1 000 000.000Hz

Figure 20. Gain vs. Frequency vs. Code, R

/DIV

6.000dB

0x80

0x40

0x20

0x10

0x08

0x04

0x02

0x01

/DIV

6.000dB

0x80

0x40

0x20

0x10

0x08

0x04

0x02

0x01

10k 100k 1M

/DIV

6.000dB

0x80

0x40

0x20

0x10

0x08

0x04

0x02

0x01

10k 100k 1M

MARKER 510 634.725Hz

MAG (A/R) –9.049dB

= 10 kΩ

AB

MARKER 100 885.289Hz

MAG (A/R) –9.014dB

= 50 kΩ

AB

MARKER 54 089.173Hz

MAG (A/R) –9.052dB

= 100 kΩ

AB

Rev. 0 | Page 9 of 20

Page 10

AD5161

REF LEVEL

–5.000dB

–5.5

–6.0

–6.5

–7.0

–7.5

–8.0

–8.5

–9.0

R = 100kΩ

–9.5

–10.0

–10.5

10k 100k 1M 10M

START 1 000.000Hz STOP 1 000 000.000Hz

60

40

PSRR (dB)

20

/DIV

0.500dB

R = 50kΩ

R = 10kΩ

Figure 21. –3 dB Bandwidth @ Code = 0x80

CODE = 0x80, VA= VDD, VB = 0V

PSRR @ VDD = 3V DC ± 10% p-p AC

5kΩ – 1.026 MHz

10kΩ – 511 MHz

50kΩ – 101 MHz

100kΩ – 54 MHz

R = 5kΩ

1

2

Ch 1 200mV

B

Ch 2 5.00 V

W

B

M 100ns A CH2 3.00 V

W

VW

CLK

Figure 24. Digital Feedthrough

VA = 5V

VB = 0V

1

2

VW

CS

PSRR @ VDD = 5V DC ± 10% p-p AC

0

Figure 22. PSRR v s. Frequency

900

800

700

600

500

(µA)

400

DD

I

300

200

100

0

10k

Figure 23. I

10k100 100k 1M1k

FREQUENCY (Hz)

VDD= 5V

CODE = 0x55

CODE = 0xFF

100k 1M 10M

FREQUENCY (Hz)

vs. Frequency

DD

Ch 1 100mV

B

Ch 2 5.00 V

W

B

M 200ns A CH1 152mV

W

Figure 25. Midscale Glitch, Code 0x80–0x7F

VA = 5V

V

= 0V

B

1

2

Ch 1 5.00V

B

Ch 2 5.00 V

W

B

M 200ns A CH1 3.00 V

W

VW

CS

Figure 26. Large Signal Settling Time, Code 0xFF–0x00

Rev. 0 | Page 10 of 20

Page 11

AD5161

TEST CIRCUITS

A

OFFSET

BIAS

DUT

NC

A

B

W

DUT

A

W

B

RSW=

CODE = 0x00

I

SW

VSS TO V

W

OP279

B

5V

AD8610

0.1V

I

SW

DD

I

CM

+15V

–15V

0.1V

V

OUT

V

OUT

V

CM

Figure 27 to Figure 35 illustrate the test circuits that define the

test conditions used in the product specification tables.

DUT

A

V+

W

B

Figure 27. Test Circuit for Potentiometer Divider Nonlinearity Error (INL, DNL)

NO CONNECT

DUT

A

W

B

Figure 28. Test Circuit for Resistor Position Nonlinearity Error

(Rheostat Operation; R-INL, R-DNL)

DUT

V

MS2

A

B

V

W

Figure 29. Test Circuit for Wiper Resistance

V

A

V

DD

A

V+

W

B

V+ = V

1LSB = V+/2

V

IW= VDD/R

W

V

RW= [V

MS1

V+ = V

PSRR (dB) = 20 LOG

PSS (%/ %) =

V

MS

DD

N

V

MS

I

W

MS

NOMINAL

– V

]/I

MS2

W

MS1

10%

DD

∆V

MS

( )

∆V

DD

%

∆V

MS

%

∆V

DD

V

IN

OFFSET

GND

Figure 32. Test Circuit for Noninverting Gain

V

IN

OFFSET

GND

2.5V

Figure 33. Test Circuit for Gain vs. Frequency

DUT

W

B

Figure 34. Test Circuit for Incremental ON Resistance

V

DUT

DD

V

GND

SS

Figure 30. Test Circuit for Power Supply Sensitivity (PSS, PSSR)

DUT

OFFSET

BIAS

B

5V

W

OP279

OFFSET

GND

A

V

IN

Figure 31. Test Circuit for Inverting Gain

NC

NC = NO CONNECT

Figure 35. Test Circuit for Common-Mode Leakage current

V

OUT

Rev. 0 | Page 11 of 20

Page 12

AD5161

V

SPI INTERFACE

Table 5. AD5161 Serial Data-Word Format

B7 B6 B5 B4 B3 B2 B1 B0

D7 D6 D5 D4 D3 D2 D1 D0

MSB LSB

7

2

2

0

1

SDI

0

1

CLK

0

1

CS

0

1

OUT

0

Figure 36. AD5161 SPI Interface Timing Diagram

D6 D5 D4 D3 D2 D1 D0

D7

RDAC REGISTER LOAD

= 5 V, VB = 0 V, VW = V

(V

A

OUT

)

1

SDI

(DATA IN)

CLK

VOUT

0

1

0

t

1

CS

0

V

DD

0

Figure 37. SPI Interface Detailed Timing Diagram (V

Dx Dx

CSHO

t

CSS

t

t

CH

DS

t

CL

t

CH

t

CSH1

t

CS1

t

CSW

t

S

±1LSB

= 5 V, VB = 0 V, VW = V

A

OUT

)

Rev. 0 | Page 12 of 20

Page 13

AD5161

A

Y

Y

I2C INTERFACE

Table 6. Write Mode

S 0 1 0 1 1 0 AD0

Slave Address Byte Instruction Byte Data Byte

Table 7. Read Mode

S 0 1 0 1 1 0 AD0 R A D7 D6 D5 D4 D3 D2 D1 D0 A P

Slave Address Byte Data Byte

A X RS SD X X X X X A D7 D6 D5 D4 D3 D2 D1 D0 A P

W

S = Start Condition

P = Stop Condition

A = Acknowledge

X = Don’t Care

W

= Write

SCL

SD

PS

SCL

0 1 0 1 1 0 AD0 R/W

SDA

START BY

MASTER

t

8

t

2

t

1

t

3

t

9

t

8

Figure 38. I

ACK BY

FRAME 1 FRAME 2

SLAVE ADDRESS BYTE

AD5161

Figure 39

1 919

SCL

0 1 0 1 1 0 AD0 R/W

SDA

START B

MASTER

FRAME 1

SLAVE ADDRESS BYTE

t

t

6

t

2

C Interface Detailed Timing Diagram

1 919

XRS X X X X X

. Writing to the RDAC Register

Figure 40. Reading Data from a Previously Selected RDAC Register in Write Mode

9

4

SD

INSTRUCTION BYTE

ACK BY

AD5161

R = Read

RS = Reset wiper to Midscale 80

H

SD = Shutdown connects wiper to B terminal and open

circuits A terminal. It does not change contents of wiper

register.

D7, D6, D5, D4, D3, D2, D1, D0 = Data Bits

t

2

t

7

D7 D6 D5 D4 D3 D2 D1 D0

t

5

19

D7 D6 D5 D4 D3 D2 D1 D0

ACK BY

AD5161

FRAME 2

RDAC REGISTER

FRAME 3

DATA BYTE

NO ACK

BY MASTER

STOP B

MASTER

PS

ACK BY

AD5161

t

10

STOP BY

MASTER

Rev. 0 | Page 13 of 20

Page 14

AD5161

−

OPERATION

The AD5161 is a 256-position digitally controlled variable

resistor (VR) device.

The general equation determining the digitally programmed

output resistance between W and B is

An internal power-on preset places the wiper at midscale

during power-on, which simplifies the fault condition recovery

at power-up.

PROGRAMMING THE VARIABLE RESISTOR

Rheostat Operation

The nominal resistance of the RDAC between terminals A and

B is available in 5 kΩ, 10 kΩ, 50 kΩ, and 100 kΩ. The final two

or three digits of the part number determine the nominal

resistance value, e.g., 10 kΩ = 10; 50 kΩ = 50. The nominal

resistance (R

the wiper terminal, plus the B terminal contact. The 8-bit data

in the RDAC latch is decoded to select one of the 256 possible

settings. Assume a 10 kΩ part is used, the wiper’s first

connection starts at the B terminal for data 0x00. Since there is a

60 Ω wiper contact resistance, such connection yields a

minimum of 60 Ω resistance between terminals W and B. The

second connection is the first tap point, which corresponds to

99 Ω (R

The third connection is the next tap point, representing 177 Ω

(2 × 39 Ω + 60 Ω) for data 0x02, and so on. Each LSB data value

increase moves the wiper up the resistor ladder until the last tap

point is reached at 9961 Ω (R

a simplified diagram of the equivalent RDAC circuit where the

last resistor string will not be accessed; therefore, there is 1 LSB

less of the nominal resistance at full scale in addition to the

wiper resistance.

) of the VR has 256 contact points accessed by

AB

= RAB/256 + RW = 39 Ω + 60 Ω) for data 0x01.

WB

– 1 LSB + RW). Figure 41 shows

AB

A

SD BIT

R

S

D7

D6

D5

D4

D3

D2

D1

D0

DECODER

Figure 41. AD5161 Equivalent RDAC Circuit

RDAC

LATCH

AND

R

S

R

S

W

R

S

B

D

DR

)(

where

WB

D

is the decimal equivalent of the binary code loaded in

256

AB

the 8-bit RDAC register,

R

is the wiper resistance contributed by the on resistance of

W

(1)

RR

+×=

W

R

is the end-to-end resistance, and

AB

the internal switch.

In summary, if R

circuited, the following output resistance R

= 10 kΩ and the A terminal is open

AB

will be set for the

WB

indicated RDAC latch codes.

Table 8. Codes and Corresponding R

Resistance

WB

D (Dec.) RWB (Ω) Output State

255 9,961 Full Scale (RAB – 1 LSB + RW)

128 5,060 Midscale

1 99 1 LSB

0 60 Zero Scale (Wiper Contact Resistance)

Note that in the zero-scale condition a finite wiper resistance of

60 Ω is present. Care should be taken to limit the current flow

between W and B in this state to a maximum pulse current of

no more than 20 mA. Otherwise, degradation or possible

destruction of the internal switch contact can occur.

Similar to the mechanical potentiometer, the resistance of the

RDAC between the wiper W and terminal A also produces a

digitally controlled complementar y resistance R

. When these

WA

terminals are used, the B terminal can be opened. Setting the

resistance value for R

starts at a maximum value of resistance

WA

and decreases as the data loaded in the latch increases in value.

The general equation for this operation is

256

DR

)(

= 10 kΩ and the B terminal open circuited, the

For R

AB

D

=

256

ABWA

following output resistance R

(2)

RR

+×

W

will be set for the indicated

WA

RDAC latch codes.

Table 9. Codes and Corresponding R

Resistance

WA

D (Dec.) RWA (Ω) Output State

255 99 Full Scale

128 5,060 Midscale

1 9,961 1 LSB

0 10,060 Zero Scale

Typical device to device matching is process lot dependent and

may vary by up to ±30%. Since the resistance element is

processed in thin film technology, the change in R

AB

with

temperature has a very low 45 ppm/°C temperature coefficient.

Rev. 0 | Page 14 of 20

Page 15

AD5161

PROGRAMMING THE POTENTIOMETER DIVIDER

Voltage Output Operation

The digital potentiometer easily generates a voltage divider at

wiper-to-B and wiper-to-A proportional to the input voltage at

A-to-B. Unlike the polarity of V

positive, voltage across A-B, W-A, and W-B can be at either

polarity.

If ignoring the effect of the wiper resistance for approximation,

connecting the A terminal to 5 V and the B terminal to ground

produces an output voltage at the wiper-to-B starting at 0 V up

to 1 LSB less than 5 V. Each LSB of voltage is equal to the

voltage applied across terminal AB divided by the 256 positions

of the potentiometer divider. The general equation defining the

output voltage at V

with respect to ground for any valid input

W

voltage applied to terminals A and B is

W

256

D

DV

)(

256

V

+=

A

For a more accurate calculation, which includes the effect of

wiper resistance, V

)( += (4)

DV

W

, can be found as

W

)(

DR

WB

V

256

A

Operation of the digital potentiometer in the divider mode

results in a more accurate operation over temperature. Unlike

the rheostat mode, the output voltage is dependent mainly on

the ratio of the internal resistors R

absolute values. Therefore, the temperature drift reduces to

15 ppm/°C.

to GND, which must be

DD

D

−

(3)

V

B

256

)(

DR

WA

V

256

B

and RWB and not the

WA

internal RDAC register when the

Extra MSB bits are ignored.

Daisy-Chain Operation

The serial data output (SDO) pin contains an open-drain

N-channel FET. This output requires a pull-up resistor in order

to transfer data to the next package’s SDI pin. This allows for

daisy-chaining several RDACs from a single processor serial

data line. The pull-up resistor termination voltage can be larger

than the V

supply voltage. It is recommended to increase the

DD

clock period when using a pull-up resistor to the SDI pin of the

following device because capacitive loading at the daisy-chain

node SDO-SDI between devices may induce time delay to

subsequent devices. Users should be aware of this potential

problem to achieve data transfer successfully (see Figure 42). If

two AD5161s are daisy-chained, a total of at least 16 bits of data

is required. The first eight bits, complying with the format

shown in Table 5, go to U2 and the second eight bits with the

same format go to U1.

CS

clocked into their respective serial registers. After this,

pulled high to complete the operation and load the RDAC latch.

If the data word during the

bits, any additional MSBs will be discarded.

µC

MOSI

SC

AD5161 AD5161

U1

SDI

CS

CS

line returns to logic high.

should be kept low until all 16 bits are

CS

is

CS

low period is greater than 16

V

DD

R

P

2.2k

Ω

CLKCLK

SDISDO

CS CLK

U2

SDO

PIN SELECTABLE DIGITAL INTERFACE

The AD5161 provides the flexibility of a selectable interface.

When the digital interface select (DIS) pin is tied low, the SPI

2

mode is engaged. When the DIS pin is tied high, the I

C mode is

engaged.

SPI Compatible 3-W re Serial Bus (DIS = 0) i

The AD5161 contains a 3-wire SPI compatible digital interface

CS

(SDI,

first. The format of the word is shown in Table 5.

The positive-edge sensitive CLK input requires clean transitions

to avoid clocking incorrect data into the serial input register.

Standard logic families work well. If mechanical switches are

used for product evaluation, they should be debounced by a

flip-flop or other suitable means. When

loads data into the serial register on each positive clock edge

(see Figure 36).

The data setup and data hold times in the specification table

determine the valid timing requirements. The AD5161 uses an

8-bit serial input data register word that is transferred to the

, and CLK). The 8-bit s erial word must be loaded MSB

CS

is low, the clock

Rev. 0 | Page 15 of 20

Figure 42. Daisy-Chain Configuration

I2C Compatible 2-W re Serial Bus (DIS = 1) i

The AD5161 can also be controlled via an I2C compatible serial

bus with DIS tied high. The RDACs are connected to this bus as

slave devices.

The first byte of the AD5161 is a slave address byte (see Table 6

W

and Table 7). It has a 7-bit slave address and a R/

MSBs of the slave address are 010110, and the following bit is

determined by the state of the AD0 pin of the device. AD0

2

allows the user to place up to two of the I

C compatible devices

on one bus.

2

The 2-wire I

C serial bus protocol operates as follows:

1. The master initiates data transfer by establishing a START

condition, which is when a high-to-low transition on the

SDA line occurs while SCL is high (see Figure 39). The

following byte is the slave address byte, which consists of

bit. The six

Page 16

AD5161

the 7-bit slave address followed by an R/W bit (this bit

determines whether data will be read from or written to

the slave device).

The slave whose address corresponds to the transmitted

address responds by pulling the SDA line low during the

ninth clock pulse (this is termed the acknowledge bit). At

this stage, all other devices on the bus remain idle while the

selected device waits for data to be written to or read from

W

its serial register. If the R/

from the slave device. On the other hand, if the R/

low, the master will write to the slave device.

2. A write operation contains an extra instruction byte that a

read operation does not contain. Such an instruction byte

in write mode follows the slave address byte. The first bit

(MSB) of the instruction byte is a don’t care.

The second MSB, RS, is the midscale reset. A logic high on

this bit moves the wiper to the center tap where R

This feature effectively writes over the contents of the

register, and thus, when taken out of reset mode, the RDAC

will remain at midscale.

The third MSB, SD, is a shutdown bit. A logic high causes

an open circuit at terminal A while shorting the wiper to

terminal B. This operation yields almost 0 Ω in rheostat

mode or 0 V in potentiometer mode. It is important to note

that the shutdown operation does not disturb the contents

of the register. When brought out of shutdown, the

previous setting will be applied to the RDAC. Also, during

shutdown, new settings can be programmed. When the

part is returned from shutdown, the corresponding VR

setting will be applied to the RDAC.

The remainder of the bits in the instruction byte are don’t

cares (see Table 6).

3. After acknowledging the instruction byte, the last byte in

write mode is the data byte. Data is transmitted over the

serial bus in sequences of nine clock pulses (eight data bits

followed by an acknowledge bit). The transitions on the

SDA line must occur during the low period of SCL and

remain stable during the high period of SCL (see Table 6).

4. In the read mode, the data byte follows immediately after

the acknowledgment of the slave address byte. Data is

transmitted over the serial bus in sequences of nine clock

pulses (a slight difference with the write mode, where there

are eight data bits followed by an acknowledge bit).

Similarly, the transitions on the SDA line must occur

during the low period of SCL and remain stable during the

high period of SCL (see Figure 40).

bit is high, the master will read

W

bit is

= RWB.

WA

5. When all data bits have been read or written, a STOP

condition is established by the master. A STOP condition is

defined as a low-to-high transition on the SDA line while

SCL is high. In write mode, the master will pull the SDA

line high during the tenth clock pulse to establish a STOP

condition (see Figure 39). In read mode, the master will

issue a No Acknowledge for the ninth clock pulse (i.e., the

SDA line remains high). The master will then bring the

SDA line low before the tenth clock pulse which goes high

to establish a STOP condition (see Figure 40).

A repeated write function gives the user flexibility to update the

RDAC output a number of times after addressing and

instructing the part only once. During the write cycle, each data

byte will update the RDAC output. For example, after the RDAC

has acknowledged its slave address and instruction bytes, the

RDAC output will update after these two bytes. If another byte

is written to the RDAC while it is still addressed to a specific

slave device with the same instruction, this byte will update the

output of the selected slave device. If different instructions are

needed, the write mode has to start again with a new slave

address, instruction, and data byte. Similarly, a repeated read

function of the RDAC is also allowed.

Readback RDAC Value

The AD5161 allows the user to read back the RDAC values in

the read mode. Refer to Table 6 and Table 7 for the

programming format.

Multiple Devices on One Bus

Figure 43 shows two AD5161 devices on the same serial bus.

Each has a different slave address since the states of their AD0

pins are different. This allows each RDAC within each device to

be written to or read from independently. The master device

2

output bus line drivers are open-drain pull-downs in a fully I

C

compatible interface.

+5V

R

MASTER

Figure 43. Multiple AD5161 Devices on One I

R

P

P

+5V

SDA SCL

AD0 AD0

AD5161

SDA SCL

AD5161

2

C Bus

SDA

SCL

Rev. 0 | Page 16 of 20

Page 17

AD5161

D

LEVEL SHIFTING FOR BIDIRECTIONAL INTERFACE

While most legacy systems may be operated at one voltage, a

new component may be optimized at another. When two

systems operate the same signal at two different voltages, proper

level shifting is needed. For instance, one can use a 3.3 V

2

PROM to interface with a 5 V digital potentiometer. A level

E

shifting scheme is needed to enable a bidirectional

communication so that the setting of the digital potentiometer

2

can be stored to and retrieved from the E

PROM. Figure 44

shows one of the implementations. M1 and M2 can be any

N-channel signal FETs, or if V

falls below 2.5 V, low threshold

DD

FETs such as the FDV301N.

= 3.3V V

V

DD1

R

SDA1

SCL1

P

3.3V

E2PROM

R

P

G

S

D

M1

R

P

G

S

D

M2

AD5161

Figure 44. Level Shifting for Operation at Different Potentials

=

5V

DD2

R

P

SDA2

SCL2

5V

ESD PROTECTION

All digital inputs are protected with a series input resistor and

parallel Zener ESD structures shown in Figure 45 and Figure 46.

This applies to the digital input pins SDI/SDA, CLK/SCL, and

CS

/AD0.

340Ω

Figure 45. ESD Protection of Digital Pins

A,B,W

Figure 46. ESD Protection of Resistor Terminals

LOGIC

V

ss

V

SS

TERMINAL VOLTAGE OPERATING RANGE

The AD5161 VDD and GND power supply defines the boundary

conditions for proper 3-terminal digital potentiometer

operation. Supply signals present on terminals A, B, and W that

exceed V

or GND will be clamped by the internal forward

DD

biased diodes (see Figure 47).

V

D

A

W

B

V

SS

Figure 47. Maximum Terminal Voltages Set by V

DD

and V

SS

POWER-UP SEQUENCE

Since the ESD protection diodes limit the voltage compliance at

terminals A, B, and W (see Figure 47), it is important to power

/GND before applying any voltage to terminals A, B, and W;

V

DD

otherwise, the diode will be forward biased such that V

will be

DD

powered unintentionally and may affect the rest of the user’s

circuit. The ideal power-up sequence is in the following order:

GND, V

powering V

, digital inputs, and then V

DD

, VB, VW, and the digital inputs is not important as

A

long as they are powered after V

DD

. The relative order of

A/B/W

/GND.

LAYOUT AND POWER SUPPLY BYPASSING

It is a good practice to employ compact, minimum lead length

layout design. The leads to the inputs should be as direct as

possible with a minimum conductor length. Ground paths

should have low resistance and low inductance.

Similarly, it is also a good practice to bypass the power supplies

with quality capacitors for optimum stability. Supply leads to the

device should be bypassed with disc or chip ceramic capacitors

of 0.01 µF to 0.1 µF. Low ESR 1 µF to 10 µF tantalum or

electrolytic capacitors should also be applied at the supplies to

minimize any transient disturbance and low frequency ripple

(see Figure 48). Note that the digital ground should also be

joined remotely to the analog ground at one point to minimize

the ground bounce.

V

DD

+

C1C3

10

µ

F 0.1µF

V

DD

AD5161

GND

Figure 48. Power Supply Bypassing

Rev. 0 | Page 17 of 20

Page 18

AD5161

A

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

PIN CONFIGURATION

1

A

2

B

3

CS/ADO

4

SDO/NC

5

SDI/SD

AD5161

TOP VIEW

(Not to Scale)

Figure 49.

10

9

8

7

6

W

V

DD

DIS

GND

CLK/SCL

PIN FUNCTION DESCRIPTIONS

Table 10.

Pin Name Description

1 A A Terminal.

2 B B Terminal.

3

CS

/AD0

CS

: Chip Select Input, Active Low. When CS

returns high, data will be loaded into the DAC

register.

AD0: Programmable address bit 0 for multiple

package decoding.

4 SDO/NC

SDO: Serial Data Output. Open-drain transistor

requires pull-up resistor.

NC: No Connect.

5 SDI/SDA SDI: Serial Data Input.

SDA: Serial Data Input/Output.

6 CLK/SCL Serial Clock Input. Positive edge triggered.

7 GND Digital Ground.

8 DIS

9 V

DD

10 W

Digital Interface Select (SPI/I

SPI when DIS = 0, I

2

C when DIS = 1.

Positive Power Supply.

W Terminal.

2

C Select).

Rev. 0 | Page 18 of 20

Page 19

AD5161

3

OUTLINE DIMENSIONS

.00 BSC

6

10

3.00 BSC

1

PIN 1

0.50 BSC

0.95

0.85

0.75

0.15

0.00

0.27

0.17

COPLANARITY

0.10

COMPLIANT TO JEDEC STANDARDS MO-187BA

Figure 50. 10-Lead Mini Small Outline Package [MSOP]

4.90 BSC

5

1.10 MAX

SEATING

PLANE

0.23

0.20

0.17

8°

0°

(RM-10)

Dimensions shown in millimeters

0.80

0.40

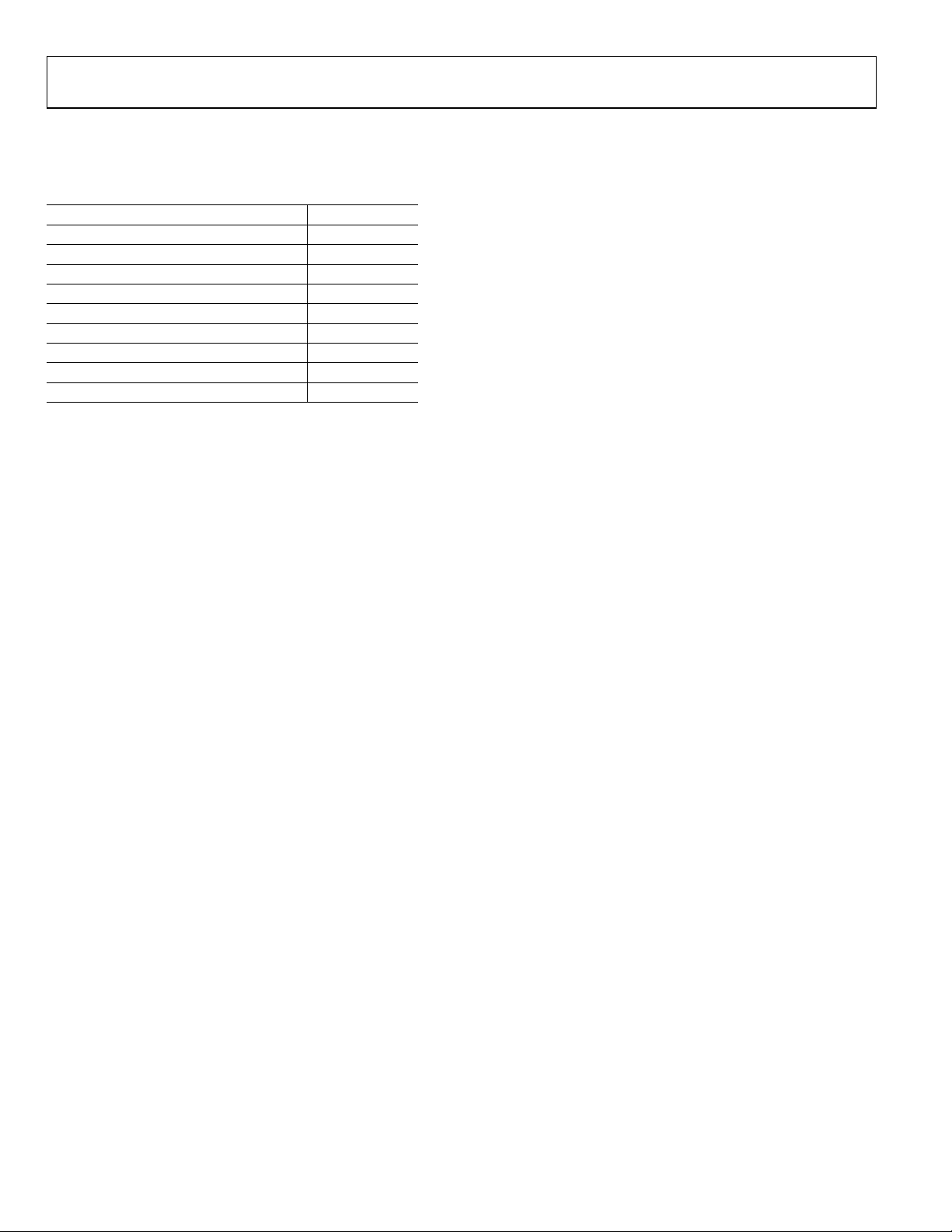

ORDERING GUIDE

Model RAB (Ω) Temperature Package Description Package Option Branding

AD5161BRM5 5k –40°C to +125°C MSOP-10 RM-10 D0C

AD5161BRM5-RL7 5k –40°C to +125°C MSOP-10 RM-10 D0C

AD5161BRM10 10k –40°C to +125°C MSOP-10 RM-10 D0D

AD5161BRM10-RL7 10k –40°C to +125°C MSOP-10 RM-10 D0D

AD5161BRM50 50k –40°C to +125°C MSOP-10 RM-10 D0E

AD5161BRM50-RL7 50k –40°C to +125°C MSOP-10 RM-10 D0E

AD5161BRM100 100k –40°C to +125°C MSOP-10 RM-10 D0F

AD5161BRM100-RL7 100k –40°C to +125°C MSOP-10 RM-10 D0F

AD5161EVAL See Note 1 Evaluation Board

1

The evaluation board is shipped with the 10 kΩ RAB resistor option; however, the board is compatible with all available resistor value options.

The AD5161 contains 2532 transistors. Die size: 30.7 mil × 76.8 mil = 2358 sq. mil.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on the

human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. 0 | Page 19 of 20

Page 20

AD5161

NOTES

© 2003 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective companies.

C03435–0–5/03(0)

Rev. 0 | Page 20 of 20

Loading...

Loading...