Page 1

AD420

V

CC

4kV

40V

BOOST

I

OUT

V

OUT

FAULT

DETECT

GNDCAP 1

OFFSET

TRIM

V

LL

REF OUT

REF IN

DATA OUT

CLEAR

LATCH

CLOCK

DATA IN

RANGE

SELECT 1

RANGE

SELECT 2

1.25kV

REFERENCE

CLOCK

16-BIT

DAC

DATA I/P

REGISTER

SWITCHED

CURRENT

SOURCES

AND

FILTERING

CAP 2

Serial Input 16-Bit

a

FEATURES

4 mA–20 mA, 0 mA–20 mA or 0 mA–24 mA Current Output

16-Bit Resolution and Monotonicity

ⴞ0.012% Max Integral Nonlinearity

ⴞ0.05% Max Offset (Trimmable)

ⴞ0.15% Max Total Output Error (Trimmable)

Flexible Serial Digital Interface (3.3 MBPS)

On-Chip Loop Fault Detection

On-Chip 5 V Reference (25 ppm/ⴗC Max)

Asynchronous CLEAR Function

Maximum Power Supply Range of 32 V

Output Loop Compliance of 0 V to V

24-Lead SOIC and PDIP Packages

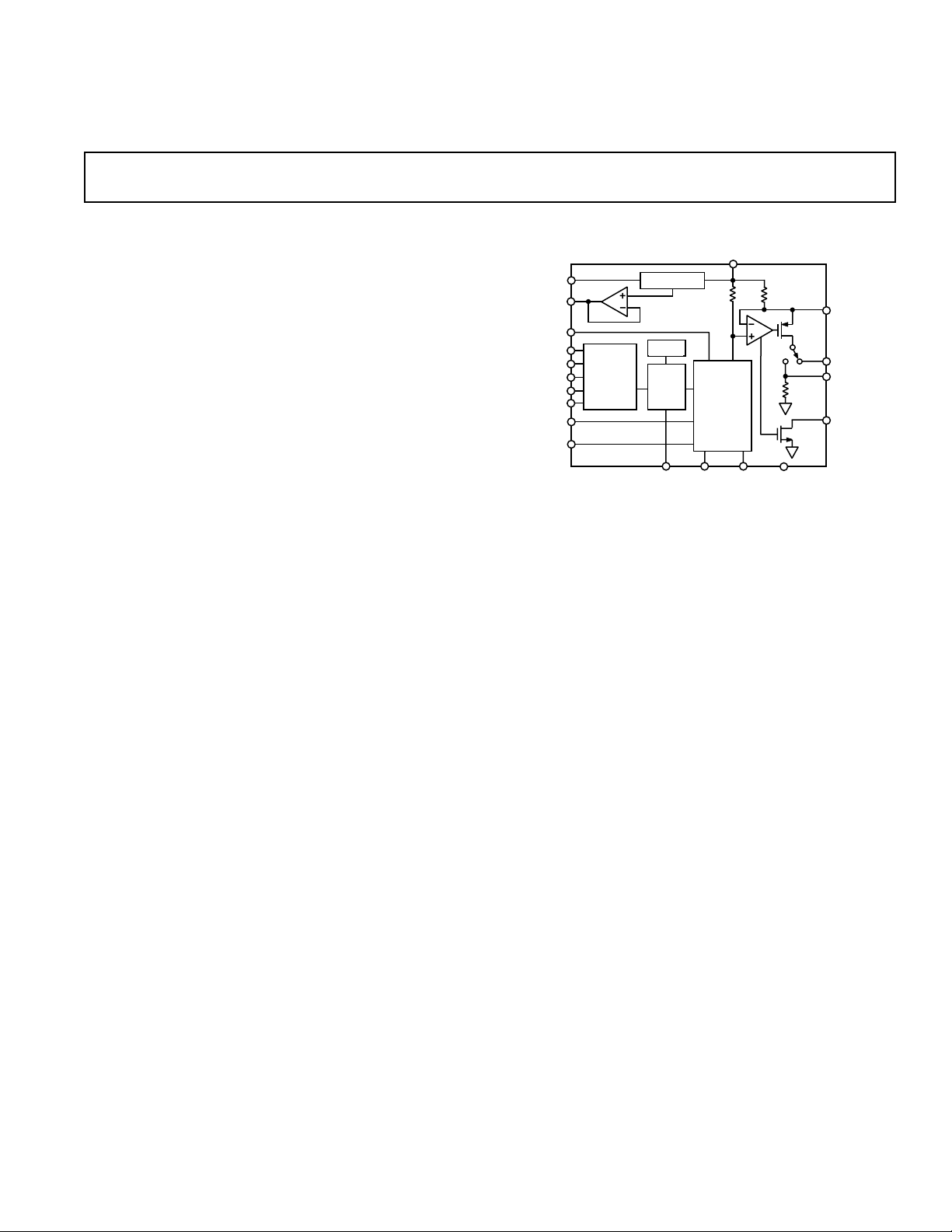

PRODUCT DESCRIPTION

The AD420 is a complete digital to current loop output converter, designed to meet the needs of the industrial control

market. It provides a high precision, fully integrated, low cost

single-chip solution for generating current loop signals in a

compact 24-lead SOIC or PDIP package.

The output current range can be programmed to 4 mA–20 mA,

0 mA–20 mA or an overrange function of 0 mA–24 mA. The

AD420 can alternatively provide a voltage output from a separate pin that can be configured to provide 0 V–5 V, 0 V–10 V,

±5 V or ±10 V with the addition of a single external buffer

amplifier.

The 3.3M Baud serial input logic design minimizes the cost of

galvanic isolation and allows for simple connection to commonly used microprocessors. It can be used in three-wire or

asynchronous mode and a serial-out pin is provided to allow

daisy chaining of multiple DACs on the current loop side of the

isolation barrier.

The AD420 uses sigma-delta (Σ∆) DAC technology to achieve

16-bit monotonicity at very low cost. Full-scale settling to 0.1%

occurs within 3 ms. The only external components that are required (in addition to normal transient protection circuitry) are

two low cost capacitors which are used in the DAC output filter.

If the AD420 is going to be used at extreme temperatures and

supply voltages, an external output transistor can be used to

minimize power dissipation on the chip via the “BOOST” pin.

The FAULT DETECT pin signals when an open circuit occurs

in the loop. The on-chip voltage reference can be used to supply

a precision +5 V to external components in addition to the

AD420 or, if the user desires temperature stability exceeding

25 ppm/°C, an external precision reference such as the AD586

can be used as the reference.

SPI is a registered trademark of Motorola.

MICROWIRE is a registered trademark of National Semiconductor.

REV. F

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

– 2.5 V

CC

4 mA–20 mA, 0 mA–20 mA DAC

AD420

FUNCTIONAL BLOCK DIAGRAM

The AD420 is available in a 24-lead SOIC and PDIP over the

industrial temperature range of –40°C to +85°C.

PRODUCT HIGHLIGHTS

1. The AD420 is a single chip solution for generating 4 mA–

20 mA or 0 mA–20 mA signals at the “controller end” of the

current loop.

2. The AD420 is specified with a power supply range

from 12 V to 32 V. Output loop compliance is 0 V to

V

– 2.5 V.

CC

3. The flexible serial input can be used in three-wire mode

with SPI

chronous mode which minimizes the number of control

signals required.

4. The serial data out pin can be used to daisy chain any number of AD420s together in three-wire mode.

5. At power-up the AD420 initializes its output to the low end

of the selected range.

6. The AD420 has an asynchronous CLEAR pin which sends

the output to the low end of the selected range (0 mA,

4 mA, or 0 V).

7. The AD420 BOOST pin accommodates an external transistor to off-load power dissipation from the chip.

8. The offset of ±0.05% and total output error of ±0.15% can

be trimmed if desired, using two external potentiometers.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1999

®

or MICROWIRE® microcontrollers, or in asyn-

Page 2

AD420–SPECIFICATIONS

(TA = T

, VCC = +24 V, unless otherwise noted)

MIN–TMAX

AX-32 Version

1

Parameter Min Typ Max Units Comments

RESOLUTION 16 Bits

CHARACTERISTICS R

I

OUT

= 500 Ω

L

Operating Current Ranges 4 20 mA

020mA

024mA

Current Loop Voltage Compliance 0 V

Settling Time (to 0.1% of FS)

Output Impedance (Current Mode) 25 MΩ

Accuracy

3

2

2.5 3 ms

– 2.5 V V

CC

Monotonicity 16 Bits

Integral Nonlinearity ±0.002 ±0.012 %

Offset (0 mA or 4 mA) (T

= +25°C) ±0.05 %

A

Offset Drift 20 50 ppm/°C

Total Output Error (20 mA or 24 mA) (T

Total Output Error Drift 20 50 ppm/°C

4

PSRR

CHARACTERISTICS

V

OUT

= +25°C) ±0.15 %

A

510 µA/V

FS Output Voltage Range (Pin 17) 0 5 V

VOLTAGE REFERENCE

REF OUT

Output Voltage (T

= +25°C) 4.995 5.0 5.005 V

A

Drift ±25 ppm/°C

Externally Available Current 5 mA

Short Circuit Current 7 mA

REF IN

Resistance 30 kΩ

V

LL

Output Voltage 4.5 V

Externally Available Current 5 mA

Short Circuit Current 20 mA

DIGITAL INPUTS

(Logic 1) 2.4 V

V

IH

(Logic 0) 0.8 V

V

IL

(V

= 5.0 V) ±10 µA

I

IH

IN

I

(V

= 0 V) ±10 µA

IL

IN

Data Input Rate (“3-Wire” Mode) No Minimum 3.3 MBPS

Data Input Rate (“Asynchronous” Mode) No Minimum 150 kBPS

DIGITAL OUTPUTS

FAULT DEFECT

(10 kΩ Pull-Up Resistor to V

V

OH

(10 kΩ Pull-Up Resistor to V

V

OL

V

@ 2.5 mA 0.6 V

OL

) 3.6 4.5 V

LL

)0.20.4V

LL

DATA OUT

(IOH = –0.8 mA) 3.6 4.3 V

V

OH

VOL (IOL = 1.6 mA) 0.3 0.4 V

POWER SUPPLY

Operating Range V

CC

12 32 V

Quiescent Current 4.2 5.5 mA

Quiescent Current (External VLL)3mA

TEMPERATURE RANGE

Specified Performance –40 +85 °C

NOTES

1

X refers to package designator, R or N.

2

External capacitor selection must be as described in Figure 5.

3

Total Output Error includes Offset and Gain Error. Total Output Error and Offset Error are with respect to the Full-Scale Output and are measured with an ideal

+5 V reference. If the internal reference is used, the reference errors must be added to the Offset and Total Output Errors.

4

PSRR is measured by varying VCC from 12 V to its maximum 32 V.

Specifications subject to change without notice.

REV. F–2–

Page 3

ABSOLUTE MAXIMUM RATINGS*

AD420

V

CC

4kV 40V

BOOST

I

OUT

V

OUT

FAULT

DETECT

GND

CAP 1

OFFSET

TRIM

V

LL

REF OUT

REF IN

DATA OUT

CLEAR

LATCH

CLOCK

DATA IN

RANGE

SELECT 1

RANGE

SELECT 2

1.25kV

REFERENCE

CLOCK

16-BIT

DAC

DATA I/P

REGISTER

19

20

21

23

14

15

16

17

18

6

7

8

9

10

11

2

3

4

5

SWITCHED

CURRENT

SOURCES

AND

FILTERING

CAP 2

VCC to GND

AD420AR/AN-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 V

to GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

I

OUT

CC

Digital Inputs to GND . . . . . . . . . . . . . . . . . . . –0.5 V to +7 V

Digital Output to GND . . . . . . . . . . . . . –0.5 V to V

and REF OUT: Outputs Safe for Indefinite Short to Ground

V

LL

+ 0.3 V

LL

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . +300°C

Thermal Impedance:

SOIC (R) Package . . . . . . . . . . . . . . . . . . . . . .θ

PDIP (N) Package . . . . . . . . . . . . . . . . . . . . . . θ

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

= 75°C/W

JA

= 50°C/W

JA

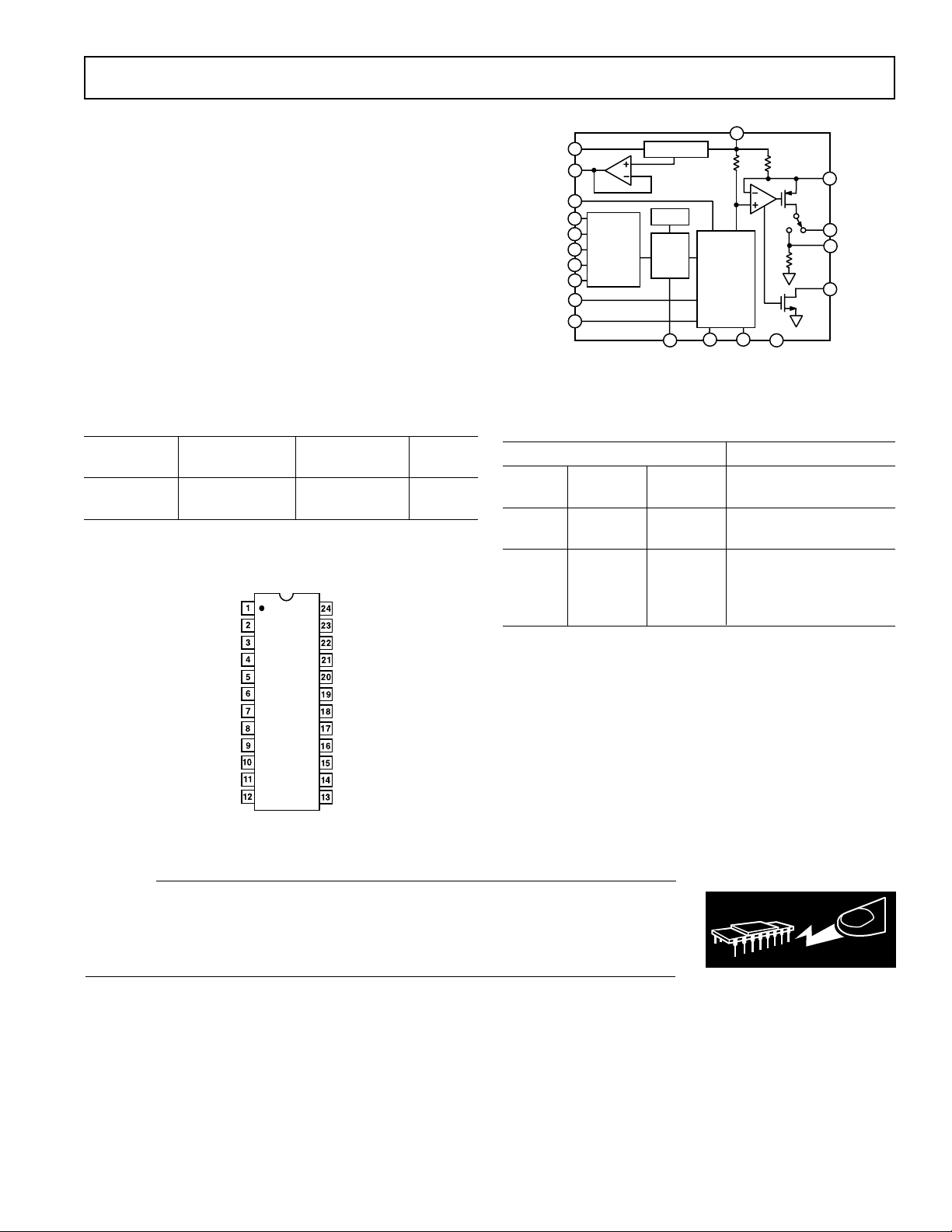

AD420

Figure 1. Functional Block Diagram

ORDERING GUIDE

Temperature Max Operating Package

Model Range Voltage Options*

AD420AN-32 – 40°C to +85°C 32 V N-24

AD420AR-32 –40°C to +85°C 32 V R-24

*N = Plastic DIP, R = Plastic SOIC.

PIN DESIGNATIONS

NC

V

FAULT DETECT

RANGE SELECT 2

RANGE SELECT 1

CLEAR

LATCH

CLOCK

DATA IN

DATA OUT

GND

NC

LL

AD420

TOP VIEW

(Not to Scale)

NC = NO CONNECT

NC

V

CC

NC

CAP2

CAP1

BOOST

I

OUT

V

OUT

OFFSET TRIM

REF IN

REF OUT

NC

Table I. Truth Table

Inputs

Range Range

CLEAR Select 2 Select 1 Operation

0 X X Normal Operation

1 X X Output at Bottom of Span

X 0 0 0 V–5 V Range

X 0 1 4 mA–20 mA Range

X 1 0 0 mA–20 mA Range

X 1 1 0 mA–24 mA Range

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD420 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. F –3–

WARNING!

ESD SENSITIVE DEVICE

Page 4

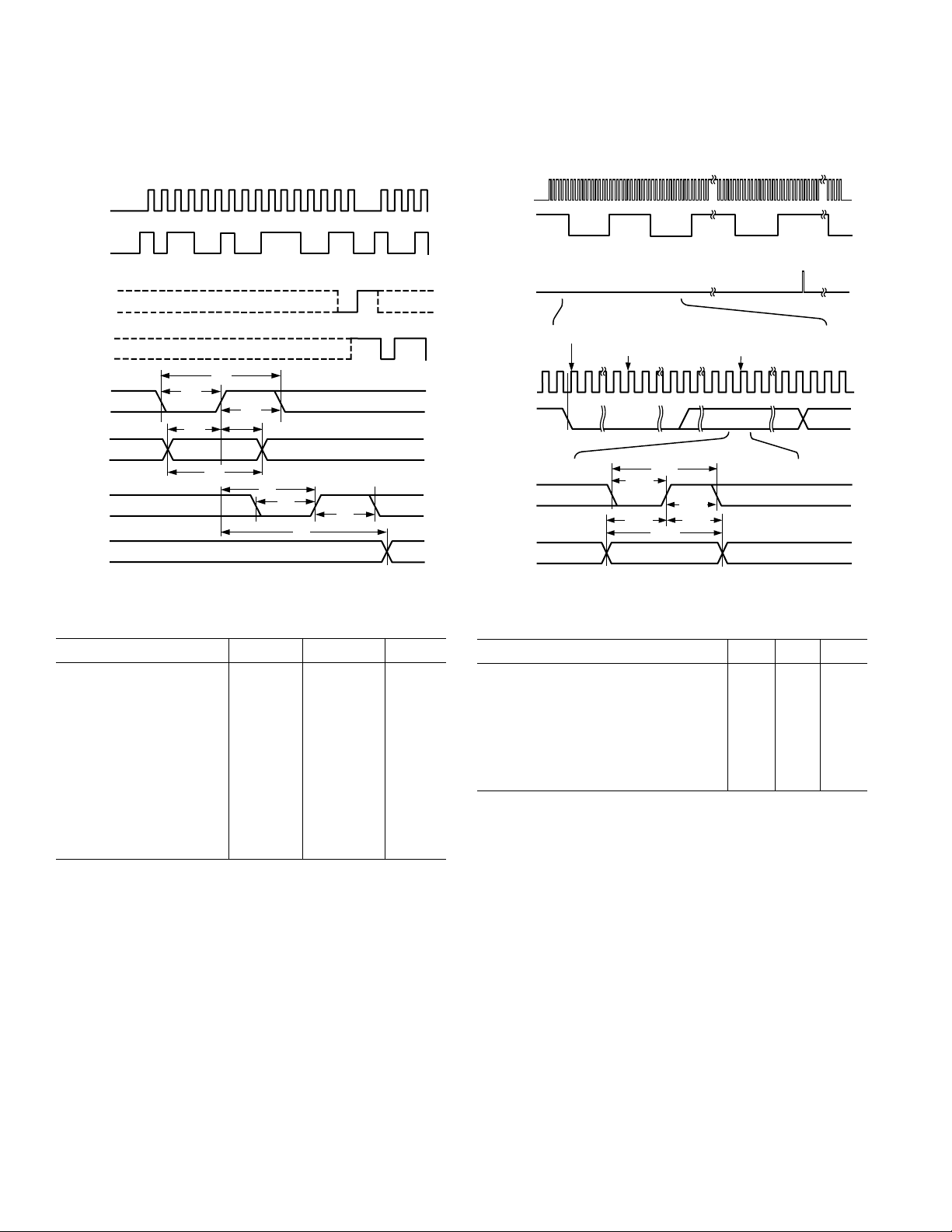

AD420

CLOCK

DATA IN

CLOCK

DATA IN

t

ADH

t

ACK

t

ADW

t

ACL

t

ADS

START

BIT

01 100

BIT 15

BIT 14

BITs

13-1

BIT 0

STOP

BIT

NEXT

START

BIT

(INTERNALLY GENERATED LATCH)

EXPANDED TIME VIEW BELOW

CLOCK COUNTER STARTS HERE

CONFIRM START BIT

SAMPLE BIT 15

0 1 2 8 16 24

START BIT

DATA BIT 15

BIT 14

EXPANDED TIME VIEW BELOW

t

ACH

CLOCK

DATA IN

Timing Requirements

THREE-WIRE INTERFACE

CLOCK

WORD "N" WORD "N + 1"

1

DATA IN

LATCH

DATA OUT

CLOCK

DATA IN

LATCH

DATA OUT

0 1 1 0 0 1

B15

B14

(MSB)

B13

t

B12

CL

t

DS

0 0 1 1 1 0 0 1 1 1

B9B8B7B6B5B4B3B2B1

B11

B10

WORD "N – 1"

t

CK

t

t

DH

t

DW

(TA = –40ⴗC to +85ⴗC, VCC = +12 V to +32 V)

0 0 1

B0

B15

B14

B13

WORD "N"

01 1

B14

B13

B12

B12

(LSB)

1

B15

CH

t

LD

t

LL

t

t

LH

SD

Figure 2. Timing Diagram for Three-Wire Interface

Table II. Timing Specification for Three-Wire Interface

Parameter Label Limit Units

Data Clock Period t

Data Clock Low Time t

Data Clock High Time t

Data Stable Width t

Data Setup Time t

Data Hold Time t

Latch Delay Time t

Latch Low Time t

Latch High Time t

Serial Output Delay Time t

Clear Pulsewidth t

Three-Wire Interface Fast Edges on Digital Input

With a fast rising edge (<10 ns) on one of the serial inputs

(CLOCK, DATA IN, LATCH) while another input is logic

high, the part may be triggered into a test mode and the contents of the data register may become corrupted, which may

result in the output being loaded with an incorrect value. If fast

edges are expected on the digital input lines, it is recommended

that the latch line remain at Logic 0 during serial loading of the

DAC. Similarly, the clock line should remain low during updates

of the DAC via the latch pin. Alternatively, the addition of

small value capacitors on the digital lines will slow down the

edge.

CK

CL

CH

DW

DS

DH

LD

LL

LH

SD

CLR

300 ns min

80 ns min

80 ns min

125 ns min

40 ns min

5 ns min

80 ns min

80 ns min

80 ns min

225 ns max

50 ns min

Figure 3. Timing Diagram for Asynchronous Interface

Table III. Timing Specifications for Asynchronous Interface

Parameter Label Limit Units

Asynchronous Clock Period t

Asynchronous Clock Low Time t

Asynchronous Clock High Time t

Data Stable Width (Critical Clock Edge) t

Data Setup Time (Critical Clock Edge) t

Data Hold Time (Critical Clock Edge) t

Clear Pulsewidth t

ACK

ACL

ACH

ADW

ADS

ADH

CLR

400 ns min

50 ns min

150 ns min

300 ns min

50 ns min

20 ns min

50 ns min

ASYNCHRONOUS INTERFACE

Note in the timing diagram for asynchronous mode operation

each data word is “framed” by a START (0) bit and a STOP

(1) bit. The data timing is with respect to the rising edge of the

CLOCK at the center of each bit cell. Bit cells are 16 clocks

long, and the first cell (the START bit) begins at the first clock

following the leading (falling) edge of the START bit. Thus the

MSB (D15) is sampled 24 clock cycles after the beginning of

the START bit, D14 is sampled at clock number 40, and so on.

During any “dead time” before writing the next word the

DATA IN pin must remain at Logic 1.

The DAC output updates when the STOP bit is received. In

the case of a “framing error” (the STOP bit sampled as a 0) the

AD420 will output a pulse at the DATA OUT pin one clock

period wide during the clock period subsequent to sampling the

STOP bit. The DAC output will not update if a “framing error”

is detected.

REV. F–4–

Page 5

AD420

PIN DESCRIPTION

Pin # Symbol Function

1, 12, 13, 24 NC No Connection. No internal connections inside device.

2V

LL

3 FAULT DETECT FAULT DETECT, connected to a pull-up resistor, is asserted low when the

4 RANGE SELECT 2 Selects the converter’s output operating range. One output voltage range and three

5 RANGE SELECT 1 output current ranges are available.

6 CLEAR Valid V

7 LATCH In the three-wire interface mode a rising edge parallel loads the serial input register

8 CLOCK Data Clock Input. The clock period is equal to the input data bit rate in the three-

9 DATA IN Serial Data Input.

10 DATA OUT Serial Data Output. In the three-wire interface mode, this output can be used for

11 GND Ground (Common).

14 REF OUT +5 V Reference Output.

15 REF IN Reference Input.

16 OFFSET TRIM Offset Adjust.

17 V

18 I

OUT

OUT

19 BOOST Connect to an external transistor to reduce the power dissipated in the AD420

20 CAP 1 These pins are used for internal filtering. Connect capacitors between each of these

21 CAP 2 pins and V

22 NC No Connection. Do not connect anything to this pin.

23 V

CC

Auxiliary buffered +4.5 V digital logic voltage. This pin is the internal supply voltage

for the digital circuitry and can be used as a termination for pull-up resistors. An

external +5 V power supply can be connected to V

voltage, thus reducing the internal power dissipation. The V

. It will override this buffered

LL

pin should be decoupled

LL

to GND with a 0.1 µF capacitor. See Power Supplies and Decoupling section.

output current does not match the DAC’s programmed value, for example, in

case the current loop is broken.

will unconditionally force the output to go to the minimum of its

IH

programmed range. After CLEAR is removed the DAC output will remain at this

value. The data in the input register is unaffected.

data into the DAC. To use the asynchronous mode connect LATCH through a

current limiting resistor to VCC.

wire interface mode and is 16 times the bit rate in asynchronous mode.

daisy-chaining multiple AD420s. In the asynchronous mode a positive pulse will

indicate a framing error after the stop-bit is received.

Voltage Output.

Current Output.

output transistor, if desired.

. Refer to the description of current output operation.

CC

Power Supply Input. The VCC pin should always be decoupled to GND with a

0.1 µF capacitor. See Power Supplies and Decoupling section.

DEFINITIONS OF SPECIFICATIONS

RESOLUTION: For 16-bit resolution, 1 LSB = 0.0015% of the

FSR. In the 4 mA–20 mA range 1 LSB = 244 nA.

INTEGRAL NONLINEARITY: Analog Devices defines integral nonlinearity as the maximum deviation of the actual, adjusted DAC output from the ideal analog output (a straight line

drawn from 0 to FS – 1 LSB) for any bit combination. This is

also referred to as relative accuracy.

DIFFERENTIAL NONLINEARITY: Differential nonlinearity

is the measure of the change in the analog output, normalized to

full scale, associated with an LSB change in the digital input code.

Monotonic behavior requires that the differential linearity error be

greater than –1 LSB over the temperature range of interest.

MONOTONICITY: A DAC is monotonic if the output either

increases or remains constant for increasing digital inputs with

the result that the output will always be a single-valued function

of the input.

REV. F –5–

GAIN ERROR: Gain error is a measure of the output error

between an ideal DAC and the actual device output with all 1s

loaded after offset error has been adjusted out.

OFFSET ERROR: Offset error is the deviation of the output

current from its ideal value expressed as a percentage of the fullscale output with all 0s loaded in the DAC.

DRIFT: Drift is the change in a parameter (such as gain and

offset) over a specified temperature range. The drift temperature

coefficient, specified in ppm/°C, is calculated by measuring the

parameter at T

, 25°C, and T

MIN

and dividing the change in

MAX

the parameter by the corresponding temperature change.

CURRENT LOOP VOLTAGE COMPLIANCE: The voltage

compliance is the maximum voltage at the I

pin for which

OUT

the output current will be equal to the programmed value.

Page 6

AD420

AD420

V

CC

4kV 40V

BOOST

I

OUT

V

OUT

FAULT

DETECT

GND

CAP 1

OFFSET

TRIM

V

LL

REF OUT

REF IN

DATA OUT

CLEAR

LATCH

CLOCK

DATA IN

RANGE

SELECT 1

RANGE

SELECT 2

1.25kV

REFERENCE

CLOCK

16-BIT

DAC

DATA I/P

REGISTER

19

20

21

23

14

15

16

17

18

6

7

8

9

10

11

2

3

4

5

SWITCHED

CURRENT

SOURCES

AND

FILTERING

CAP 2

THEORY OF OPERATION

The AD420 uses a sigma-delta (Σ∆) architecture to carry out

the digital-to-analog conversion. This architecture is particularly

well suited for the relatively low bandwidth requirements of the

industrial control environment because of its inherent monotonicity at high resolution.

In the AD420 a second order modulator is used to keep complexity and die size to a minimum. The single bit stream from

the modulator controls a switched current source that is then

filtered by two, continuous time resistor-capacitor sections. The

capacitors are the only external components that have to be

added for standard current-out operation. The filtered current is

amplified and mirrored to the supply rail so that the application

simply sees a 4 mA–20 mA, 0 mA–20 mA, or 0 mA–24 mA

current source output with respect to ground. The AD420 is

manufactured on a BiCMOS process that is well suited to implementing low voltage digital logic with high performance and

high voltage analog circuitry.

The AD420 can also provide a voltage output instead of a current loop output if desired. The addition of a single external

amplifier allows the user to obtain 0 V–5 V, 0 V–10 V, ±5 V, or

±10 V.

The AD420 has a loop fault detection circuit that warns if the

voltage at I

attempts to rise above the compliance range, due

OUT

to an open-loop circuit or insufficient power supply voltage. The

FAULT DETECT is an active low open drain signal so that one

can connect several AD420s together to one pull-up resistor for

global error detection. The pull-up resistor can be tied to the

pin, or an external +5 V logic supply.

V

LL

The I

current is controlled by a PMOS transistor and

OUT

internal amplifier as shown in the functional block diagram. The

internal circuitry that develops the fault output avoids using a

comparator with “window limits” since this would require an

actual output error before the FAULT DETECT output becomes

active. Instead, the signal is generated when the internal amplifier in the output stage of the AD420 has less than approximately

one volt remaining of drive capability (when the gate of the

output PMOS transistor nearly reaches ground). Thus the

FAULT DETECT output activates slightly before the compliance limit is reached. Since the comparison is made within the

feedback loop of the output amplifier, the output accuracy is

maintained by its open-loop gain, and no output error occurs

before the fault detect output becomes active.

The three-wire digital interface, comprising DATA IN, CLOCK,

and LATCH, interfaces to all commonly used serial microprocessors without the addition of any external glue logic. Data is

loaded into an input register under control of CLOCK and is

loaded to the DAC when LATCH is strobed. If a user wants to

minimize the number of galvanic isolators in an intrinsically safe

application, the AD420 can be configured to run in “asynchronous” mode. This mode is selected by connecting the LATCH

pin to V

through a current limiting resistor. The data must

CC

then be combined with a start and stop bit to “frame” the information and trigger the internal LATCH signal.

Figure 4. Functional Block Diagram

REV. F–6–

Page 7

AD420

6

7

8

9

C1 C2

V

CC

20 21

500V

RSPAN

15 11

GND

RANGE

SELECT1

RANGE

SELECT2

CLEAR

LATCH

CLOCK

DATA IN

AD420

19

4

2

V

LL

I

OUT

(4mA–20mA)

R

LOAD

18

5kV

RSPAN2

V

REF

14

23

16

10kV

RZERO

5

BOOST

0.1mF

0.1mF

APPLICATIONS

CURRENT OUTPUT

The AD420 can provide 4 mA–20 mA, 0 mA–20 mA, or 0 mA–

24 mA output without any active external components. Filter

capacitors C1 and C2 can be any type of low cost ceramic capacitors. To meet the specified full-scale settling time of 3 ms,

low dielectric absorption capacitors (NPO) are required. Suit-

able values are C1 = 0.01 µF and C2 = 0.01 µF.

V

CC

0.1mF

RANGE

SELECT 1

RANGE

SELECT 2

CLEAR

LATCH

CLOCK

DATA IN

V

LL

C1 C2

2

REF

OUT

14

20 21 23

AD420

15

REF

IN

5

4

6

7

8

9

0.1mF

I

(4mA–20mA)

OUT

18

R

LOAD

11

GND

Figure 5. Standard Configuration

DRIVING INDUCTIVE LOADS

When driving inductive or poorly defined loads connect a

0.01 µF capacitor between I

(Pin 18) and GND (Pin 11).

OUT

This will ensure stability of the AD420 with loads beyond

50 mH. There is no maximum capacitance limit. The capacitive

component of the load may cause slower settling, though this

may be masked by the settling time of the AD420. A programmed change in the current may cause a back EMF voltage

on the output that may exceed the compliance of the AD420.

To prevent this voltage from exceeding the supply rails connect

protective diodes between I

and each of VCC and GND.

OUT

Table IV. Buffer Amplifier Configuration

R1 R2 R3 V

OUT

Open Open 0 0 V–5 V

Open R R 0 V–10 V

R Open R ±5 V

R2R2R±10 V

Suitable R = 5 kΩ.

OPTIONAL SPAN AND ZERO TRIM

For those users who would like lower than specified values of

offset and gain error, Figure 7 shows a simple way to trim these

parameters. Care should be taken to select low drift resistors

because they will affect the temperature drift performance of the

DAC.

The adjustment algorithm is iterative. The procedure for trimming the AD420 in the 4 mA–20 mA mode can be accomplished as follows:

STEP I . . . OFFSET ADJUST

Load all zeros. Adjust RZERO for 4.00000 mA of output

current.

STEP II . . . GAIN ADJUST

Load all ones. Adjust RSPAN for 19.99976 mA (FS – 1 LSB) of

output current.

Return to STEP I and iterate until convergence is obtained.

VOLTAGE-MODE OUTPUT

Since the AD420 is a single supply device, it is necessary to add

an external buffer amplifier to the V

pin to obtain a selec-

OUT

tion of bipolar output voltage ranges as shown in Figure 6.

V

C1

21

AD420

15

REF

IN

Figure 6.

CC

C2

23

11

0.1mF0.1mF

GND

V

OUT

17

R1

R2

R3

V

OUT

V

LL

2

RANGE

SELECT 1

RANGE

SELECT 2

CLEAR

LATCH

CLOCK

DATA IN

REV. F –7–

5

4

6

7

8

9

REF

OUT

20

14

Figure 7. Offset and Gain Adjust

Variation of RZERO between REF OUT (5 V) and GND leads

to an offset adjust range from –1.5 mA to 6 mA, (1.5 mA/V

centered at 1 V).

The 5 kΩ RSPAN2 resistor is connected in parallel with the

internal 40 Ω sense resistor, which leads to a gain increase of

+0.8%.

As RSPAN is changed to 500 Ω, the voltage on REF IN is

attenuated by the combination of RSPAN and the 30 kΩ

REF IN input resistance. When added together with RSPAN2

this results in an adjustment range of –0.8% to +0.8%.

Page 8

AD420

V

CC

GND

LATCH

CLOCK

DATA IN

V

LL

CLOCK

+5V

DATA

ISOLATIONGALVANIC

BARRIER

+24V

11

2

8

23

7

9

100kV

AD420

THREE-WIRE INTERFACE

Figure 8 shows the AD420 connected in the three-wire interface

mode. The AD420 data input block contains a serial input shift

register and a parallel latch. The contents of the shift register are

controlled by the DATA IN signal and the rising edges of the

CLOCK. Upon request of the LATCH pin the DAC and internal latch are updated from the shift register parallel outputs.

The CLOCK should remain inactive while the DAC is updated.

Refer to the timing requirements for three-wire interface.

FAULT DETECT

V

DAC2

DATA

OUT

I

OUT

V

CC

CC

R

LOAD

LATCH

CLOCK

DATA IN

FAULT

DETECT

LATCH

CLOCK

DATA

IN

GND

V

AD420

DAC1

DATA

OUT

I

OUT

V

CC

CC

R

LOAD

10kV

V

LL

FAULT

DETECT

LATCH

CLOCK

DATA

IN

GND

AD420

Figure 8. Three-Wire Interface Using Multiple DACs with

Joint Fault Detect

USING MULTIPLE DACS WITH FAULT DETECT

The three-wire interface mode can utilize the serial DATA

OUT for easy interface to multiple DACs. To program the two

AD420s in Figure 8, 32 data bits are required. The first 16 bits

are clocked into the input shift register of DAC1. The next 16

bits transmitted pass the first 16 bits from the DATA OUT pin

of DAC1 to the input register of DAC2. The input shift registers of the two DACs operate as a single 32-bit shift register,

with the leading 16 bits representing information for DAC2 and

the trailing 16 bits serving for DAC1. Each DAC is then updated upon request of the LATCH pin. The daisy-chain can be

extended to as many DACs as required.

ASYNCHRONOUS INTERFACE USING OPTOCOUPLERS

The AD420 connected in ASYNCHRONOUS INTERFACE

mode with optocouplers is shown in Figure 9. Asynchronous

operation minimizes the number of control signals required for

isolation of the digital system from the control loop. The resistor

connected between the LATCH pin and V

activate this mode. For operation with V

is required to

CC

below 18 V use a

CC

50 kΩ pull-up resistor, from 18 V–32 V use 100 kΩ. Asynchro-

nous mode requires that the clock run at 16 times the data bit

rate, therefore to operate at the maximum input data rate of

150 kBPS an input clock of 2.4 MHz is required. The actual

data rate achieved may be limited by the type of optocouplers

chosen. The number of control signals can further be reduced

by creating the appropriate clock signal on the current loop side

of the isolation barrier. If optocouplers with relatively slow rise

and fall times are used, Schmitt triggers may be required on the

digital inputs to prevent erroneous data being presented to the

DAC.

Figure 9. Asynchronous Interface Using Optocouplers

REV. F–8–

Page 9

MICROPROCESSOR INTERFACE SECTION

DATA IN

CLOCK

LATCH

SO

SK

AD420

MICROWIRE

G1

V

CC

28V

20V

12V

4V

–60 –40 –20 0 20 40 60 80 100

TEMPERATURE –

8C

25V

WHEN USING SOIC PACKAGED DEVICES, AN

EXTERNAL BOOST TRANSISTOR IS REQUIRED

FOR OPERATION IN THIS AREA

AD420 OR AD420-32

32V

AD420-TO-MC68HC11 (SPI BUS) INTERFACE

The AD420 interface to the Motorola SPI (Serial Peripheral

Interface) is shown in Figure 10. The MOSI, SCK, and SS pins

of the HC11 are respectively connected to the DATA IN,

CLOCK, and LATCH pins of the AD420. The majority of the

interfacing issues are done in the software initialization. A typical routine such as the one shown below begins by initializing

the state of the various SPI data and control registers.

INIT LDAA #$2F ;SS = 1; SCK = 0; MOSI = 1

STAA PORTD ;SEND TO SPI OUTPUTS

LDAA #$38 ;SS, SCK, MOSI = OUTPUTS

STAA DDRD ;SEND DATA DIRECTION INFO

LDAA #$50 ;DABL INTRPTS, SPI IS MASTER & ON

STAA SPCR ;CPOL = 0, CPHA = 0, 1MHZ BAUDRATE

NEXTPT LDAA MSBY ;LOAD ACCUM W/UPPER 8 BITS

BSR SENDAT ;JUMP TO DAC OUTPUT ROUTINE

JMP NEXTPT ;INFINITE LOOP

SENDAT LDY #$1000 ;POINT AT ON-CHIP REGISTERS

BCLR $08,Y,$20 ;DRIVE SS (LATCH) LOW

STAA SPDR ;SEND MS-BYTE TO SPI DATA REG

WAIT1 LDAA SPSR ;CHECK STATUS OF SPIE

BPL WAIT1 ;POLL FOR END OF X-MISSION

LDAA LSBY ;GET LOW 8 BITS FROM MEMORY

STAA SPDR ;SEND LS-BYTE TO SPI DATA REG

WAIT2 LDAA SPSR ;CHECK STATUS OF SPIE

BPL WAIT2; ;POLL FOR END OF X-MISSION

BSET $08,Y,$20 ;DRIVE SS HIGH TO LATCH DATA

RTS

The SPI data port is configured to process data in 8-bit bytes.

The most significant data byte (MSBY) is retrieved from

memory and processed by the SENDAT routine. The SS pin is

driven low by indexing into the PORTD data register and clear

Bit 5. The MSBY is then sent to the SPI data register where it is

automatically transferred to the AD420 internal shift resister.

The HC11 generates the requisite eight clock pulses with data

valid on the rising edges. After the MSBY is transmitted, the

least significant byte (LSBY) is loaded from memory and transmitted in a similar fashion. To complete the transfer, the

LATCH pin is driven high when loading the complete 16-bit

word into the AD420.

AD420

Figure 11. AD420-to-MICROWIRE Interface

EXTERNAL BOOST FUNCTION

The external boost transistor reduces the power dissipated in

the AD420 by reducing the current flowing in the on-chip

output transistor (dividing it by the current gain of the external

circuit). A discrete NPN transistor with a breakdown voltage,

, greater than 32 V can be used as shown in Figure 12.

BV

CEO

MJD31C

OR

1kV

2N3053

R

LOAD

19

BOOST

AD420

I

OUT

0.022mF

18

Figure 12. External Boost Configuration

The external boost capability has been developed for those users

who may wish to use the AD420, in the SOIC package, at the

extremes of the supply voltage, load current, and temperature

range. The PDIP package (because of its lower thermal resistance) will operate safely over the entire specified voltage, temperature, and load current ranges without the boost transistor.

The plot in Figure 13 shows the safe operating region for both

package types. The boost transistor can also be used to reduce

the amount of temperature induced drift in the part. This will

minimize the temperature induced drift of the on-chip voltage

reference, which improves drift and linearity.

MOSI

68HC11

SCK

SS

Figure 10. AD420-to-68HC11 (SPI) Interface

AD420-TO-MICROWIRE INTERFACE

The flexible serial interface of the AD420 is also compatible

with the National Semiconductor MICROWIRE interface. The

MICROWIRE interface is used in microcontrollers such as the

COP400 and COP800 series of processors. A generic interface

to use the MICROWIRE interface is shown in Figure 11. The

G1, SK, and SO pins of the MICROWIRE interface are respectively connected to the LATCH, CLOCK, and DATA IN pins

of the AD420.

REV. F –9–

DATA IN

CLOCK

LATCH

AD420

Figure 13. Safe Operating Region

Page 10

AD420

AD420 PROTECTION

TRANSIENT VOLTAGE PROTECTION

The AD420 contains ESD protection diodes which prevent

damage from normal handling. The industrial control environment can, however, subject I/O circuits to much higher transients. In order to protect the AD420 from excessively high

voltage transients such as those specified in IEC 801, external

power diodes and a surge current limiting resistor may be required, as shown in Figure 14. The constraint on the resistor is

that during normal operation the output voltage level at I

OUT

must remain within its voltage compliance limit

(I

× (Rp + R

OUT

LOAD

) ≤ V

– 2.5 V)

CC

and the two protection diodes and resistor must have appropriate power ratings.

V

CC

V

AD420

CC

GND

I

OUT

R

P

R

LOAD

Figure 14. Output Transient Voltage Protection

BOARD LAYOUT AND GROUNDING

The AD420 ground pin, designated GND, is the “high quality”

ground reference point for the device. Any external loads on the

REF OUT and V

pins of the AD420 should be returned to

OUT

this reference point. Analog and digital ground currents should

not share a common path. Each signal should have an appropriate analog or digital signal return routed close to it. Using this

approach, signal loops enclose a small area, minimizing the

inductive coupling of noise. Wide PC tracks, large gauge wire,

and ground planes are highly recommended to provide low

impedance signal paths.

POWER SUPPLIES AND DECOUPLING

The AD420 supply pins, VCC (Pin 23) and VLL (Pin 2), should

be decoupled to GND with 0.1 µF capacitors to eliminate high

frequency noise that may otherwise get coupled into the analog

system. High frequency ceramic capacitors are recommended.

The decoupling capacitors should be located in close proximity

to the pins and the ground line to have maximum effect. Further

reductions in noise, and improvements in performance, may be

achieved by using a larger value capacitor on the V

LL

pin.

REV. F–10–

Page 11

0.210

(5.33)

MAX

0.200 (5.05)

0.125 (3.18)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

24-Lead Plastic DIP

(N-24)

1.275 (32.30)

1.125 (28.60)

24

112

PIN 1

0.022 (0.558)

0.014 (0.356)

0.100

(2.54)

BSC

13

0.060 (1.52)

0.015 (0.38)

0.070 (1.77)

0.045 (1.15)

0.280 (7.11)

0.240 (6.10)

0.150

(3.81)

MIN

SEATING

PLANE

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.195 (4.95)

0.115 (2.93)

24-Lead Small Outline (SOIC)

(R-24)

AD420

C1870e–0–9/99

0.6141 (15.60)

0.5985 (15.20)

24 13

PIN 1

0.0118 (0.30)

0.0040 (0.10)

0.0500

(1.27)

BSC

0.0192 (0.49)

0.0138 (0.35)

0.2992 (7.60)

121

0.1043 (2.65)

0.0926 (2.35)

SEATING

PLANE

0.2914 (7.40)

0.4193 (10.65)

0.3937 (10.00)

0.0125 (0.32)

0.0091 (0.23)

0.0291 (0.74)

0.0098 (0.25)

0.0500 (1.27)

8°

0°

0.0157 (0.40)

x 45°

REV. F –11–

PRINTED IN U.S.A.

Loading...

Loading...