Page 1

Low Voltage, Resistor Programmable

a

FEATURES

User-Programmable Temperature Setpoint

2.08C Setpoint Accuracy

4.08C Preset Hysteresis

Wide Supply Range (+2.7 V dc to +7.0 V dc)

Wide Temperature Range (–408C to +1508C)

Low Power Dissipation (230 mW @ 3.3 V)

APPLICATIONS

Industrial Process Control

Thermal Control Systems

CPU Monitoring (i.e., Pentium)

Computer Thermal Management Circuits

Fan Control

Handheld/Portable Electronic Equipment

GENERAL DESCRIPTION

The AD22105 is a solid state thermostatic switch. Requiring

only one external programming resistor, the AD22105 can be set

to switch accurately at any temperature in the wide operating

range of –40°C to +150°C. Using a novel circuit architecture,

the AD22105 asserts an open collector output when the ambient

temperature exceeds the user-programmed setpoint temperature.

The AD22105 has approximately 4°C of hysteresis which prevents

rapid thermal on/off cycling.

Thermostatic Switch

AD22105

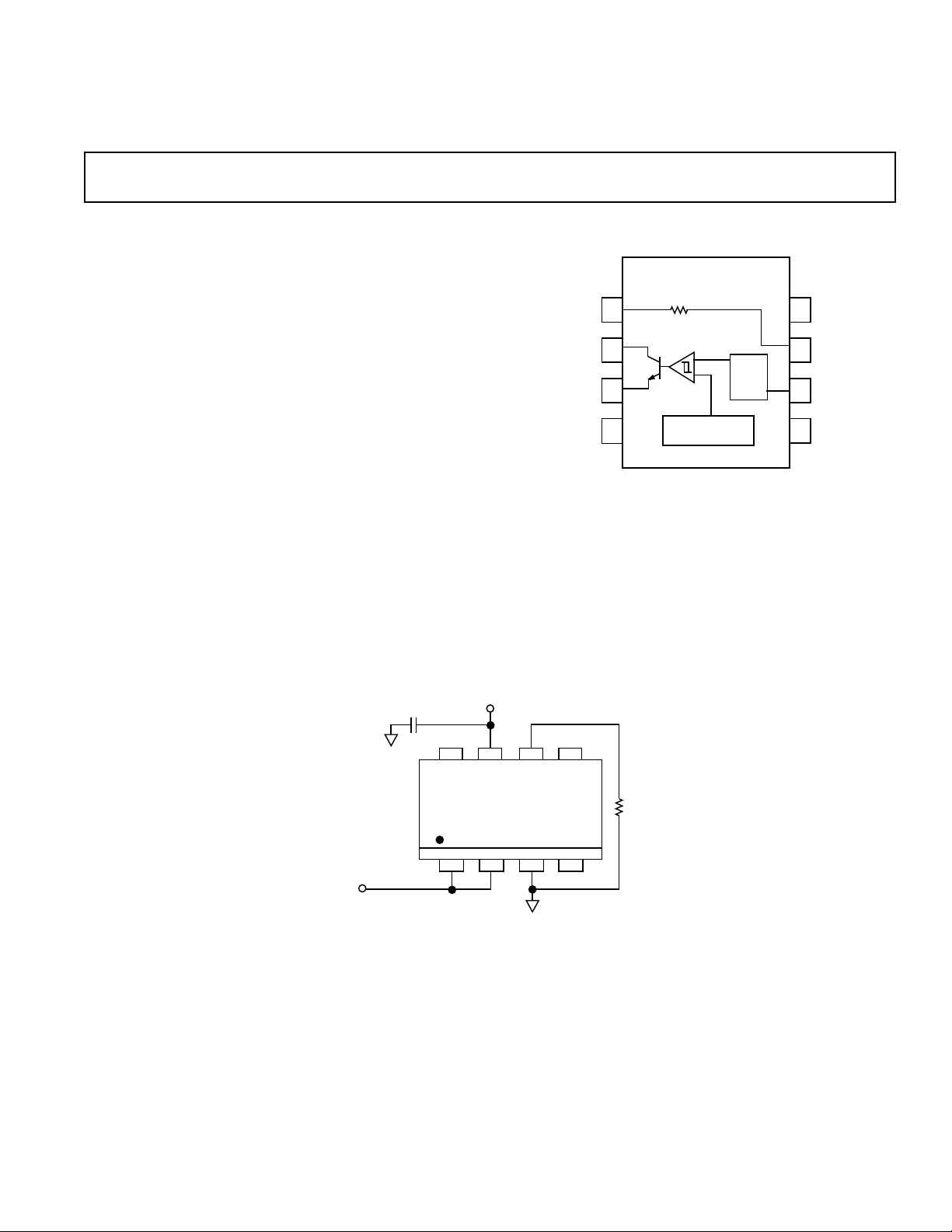

FUNCTIONAL BLOCK DIAGRAM

AD22105

R

PULL–UP

OUT

GND

NC

1

2

3

4

The AD22105 is designed to operate on a single power supply

voltage from +2.7 V to +7.0 V facilitating operation in battery

powered applications as well as in industrial control systems.

Because of low power dissipation (230 µW @ 3.3 V), selfheating errors are minimized and battery life is maximized.

An optional internal 200 kΩ pull-up resistor is included to

facilitate driving light loads such as CMOS inputs.

Alternatively, a low power LED indicator may be driven directly.

200kΩ

TEMPERATURE

SENSOR

SET–

POINT

8

NC

V

S

7

R

6

SET

NC

5

+2.7V TO +7.0V

8

12

OUT

Figure 1. Typical Application Circuit

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

65

7

AD22105

TOP VIEW

4

3

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 617/329-4700 Fax: 617/326-8703

R

SET

© Analog Devices, Inc., 1996

Page 2

AD22105–SPECIFICATIONS

(VS = 3.3 V, TA = +258C, R

= internal 200 kV, unless otherwise noted)

LOAD

Parameter Symbol Conditions Min Typ Max Units

TEMPERATURE ACCURACY

Ambient Setpoint Accuracy ACC ±0.5 ±2.0 °C

Temperature Setpoint Accuracy ACC

T

Power Supply Rejection PSR +2.7 V1 < V

–40°C ≤ TA ≤ +125°C ±3.0 °C

< +7.0 V ±0.05 ±0.15 °C/V

S

HYSTERESIS

Hysteresis Value HYS 4.1 °C

OPEN COLLECTOR OUTPUT

Output Low Voltage V

OL

I

= 5 mA 250 400 mV

SINK

POWER SUPPLY

Supply Range V

Supply Current, Output “LOW” IS

Supply Current, Output “HIGH” IS

INTERNAL PULL-UP RESISTOR R

TURN-ON SETTLING TIME t

NOTES

1

The AD22105 will operate at voltages as low as +2.2 V.

Specifications subject to change without notice.

- kΩ

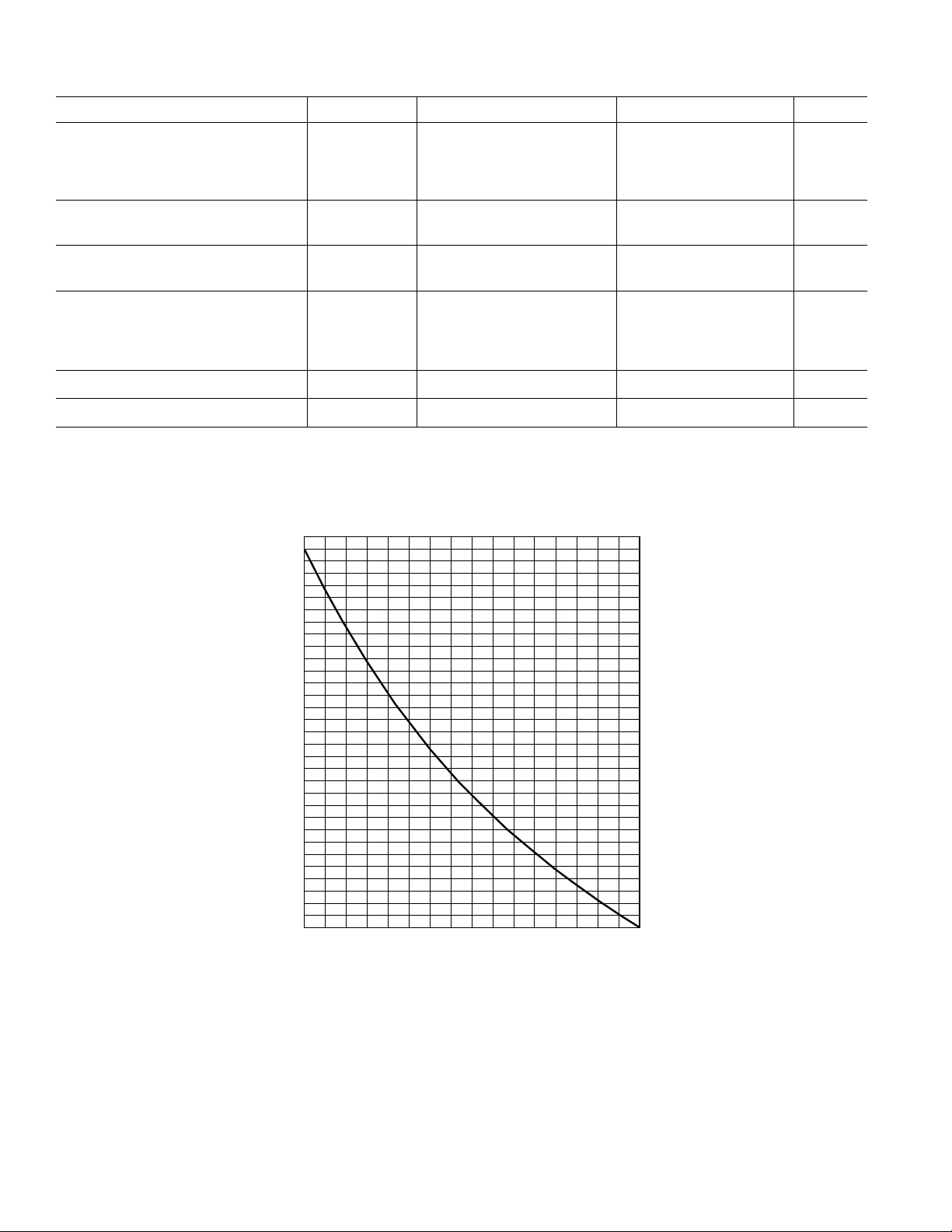

R

80

75

70

65

60

55

50

45

40

SET

35

30

25

20

15

10

5

0

–50 150–25

ON

S

ON

OFF

PULL-UP

39MΩ °C

= ––––––––––––——— – 90.3kΩ

R

SET

T

(°C) + 281.6 °C

SET

25 50 75 100 125

0

SET POINT TEMPERATURE – °C

+2.7 +7.0 V

120 µA

90 µA

140 200 260 kΩ

5 µs

Figure 2. Setpoint Resistor Values

REV. 0–2–

Page 3

AD22105

1

2

3

4

8

7

6

5

NC = NO CONNECT

AD22105

R

PULL-UP

NC

R

SET

V

S

NC

OUT

GND

NC

TOP VIEW

(Not to Scale)

ABSOLUTE MAXIMUM RATINGS*

PIN CONFIGURATION

Maximum Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . +11 V

Maximum Output Voltage (Pin 2) . . . . . . . . . . . . . . . . +11 V

Maximum Output Current (Pin 2) . . . . . . . . . . . . . . . 10 mA

Operating Temperature Range . . . . . . . . . . –50°C to +150°C

Dice Junction Temperature . . . . . . . . . . . . . . . . . . . . +160°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +160°C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . +300°C

*Stresses above those listed under “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress rating only and functional

operation of the device at these or any other conditions above those listed in the

operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

PIN DESCRIPTION

Pin No. Description

ORDERING GUIDE

Package Package

Model Description Option

AD22105AR 8-Lead SOIC SO-8

AD22105AR-REEL7 8-Lead SOIC SO-8

1R

2 OUT

3 GND

4 No Connection

5 No Connection

6R

7V

Internal 200 kΩ (Optional)

PULL-UP,

, Temperature Setpoint Resistor

SET

S

8 No Connection

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD22105 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

REV. 0 –3–

Page 4

AD22105–Typical Performance Characteristics

4

3

2

1

0

ERROR – °C

–1

–2

–3

–4

–50 150–25 0 25 50 75 100 125

GUARANTEED LIMIT (+)

GUARANTEED LIMIT (–)

TEMPERATURE – °C

Figure 3. Error vs. Setpoint

±

0.1

±

0.3

±

0.5

±

ERROR – °C/%

0.7

±

0.9

±

1.1

–50 150–25 0 25 50 75 100 125

TEMPERATURE – °C

4.4

4.2

4.0

3.8

HYSTERESIS – °C

3.6

3.4

3.2

–50 150–25 0 25 50 75 100 125

TEMPERATURE – °C

Figure 6. Hysteresis vs. Setpoint

2.0

1.5

1.0

0.5

0.0

ERROR – °C

–0.5

–1.0

–1.5

–2.0

3745 6

+125°C

+25°C

–40°C

V

S

Figure 4. Setpoint Error Due to R

90

80

70

– µA

S

I

60

50

40

–50 150–25 0 25 50 75 100 125

VS = 7V

VS = 5V

VS = 3V

TEMPERATURE – °C

Tolerance

SET

Figure 5. Supply Current vs. Temperature (V

= HIGH)

OUT

Figure 7. Setpoint Error vs. Supply Voltage

120

VS = 7V

110

100

90

– µA

S

I

80

70

60

–50 150–25 0 25 50 75 100 125

VS = 5V

VS = 3V

TEMPERATURE – °C

Figure 8. Supply Current vs. Temperature (V

= LOW)

OUT

–4–

REV. 0

Page 5

AD22105

0.4

0.3

0.2

OUT

V

0.1

0.0

Figure 9. V

16

14

12

10

– sec

τ

8

6

4

2

0 1200400 800

10µA 10mA1mA100µA1µA

OUT

I

OUT

vs. I

OUT

FLOW RATE – CFM

TA = +150°C

TA = +25°C

(V

OUT

TA = –40°C

= LOW)

250

200

150

– °C/W

JA

θ

100

50

0 1200

400 800

FLOW RATE – CFM

Figure 11. Thermal Resistance vs. Flow Rate

100

90

80

70

60

50

40

% OF FINAL VALUE

30

20

10

0

06010 20 30 40 50

MOVING AIR

(1200 CFM)

STILL AIR

TIME – sec

Figure 10. Thermal Response vs. Flow Rate

Figure 12. Thermal Response Time

REV. 0 –5–

Page 6

AD22105

PRODUCT DESCRIPTION

The AD22105 is a single supply semiconductor thermostat

switch that utilizes a unique circuit architecture to realize the

combined functions of a temperature sensor, setpoint comparator,

and output stage all in one integrated circuit. By using one

external resistor, the AD22105 can be programmed to switch at

any temperature selected by the system designer in the range of

–40°C to +150°C. The internal comparator is designed to switch

very accurately as the ambient temperature rises past the

setpoint temperature. When the ambient temperature falls, the

comparator relaxes its output at a somewhat lower temperature

than that at which it originally switched. The difference between

the “switch” and “unswitch” temperatures, known as the hysteresis,

is designed to be nominally 4°C.

THE SETPOINT RESISTOR

The setpoint resistor is determined by the equation:

=

39 MΩ°C

(°C)+281.6°C

T

SET

–90.3kΩ

Eq. 1

R

SET

The setpoint resistor should be connected directly between the

R

pin (Pin 6) and the GND pin (Pin 3). If a ground plane is

SET

used, the resistor may be connected directly to this plane at the

closest available point.

The setpoint resistor, R

, can be of nearly any resistor type,

SET

but its initial tolerance and thermal drift will affect the accuracy

of the programmed switching temperature. For most applications,

a 1% metal-film resistor will provide the best tradeoff between

cost and accuracy. Calculations for computing an error budget

can be found in the section “Effect of Resistor Tolerance and

Thermal Drift on Setpoint Accuracy.”

Once R

has been calculated, it may be found that the calcu-

SET

lated value does not agree with readily available standard

resistors of the chosen tolerance. In order to achieve an R

SET

value as close as possible to the calculated value, a compound

resistor can be constructed by connecting two resistors in series

or in parallel. To conserve cost, one moderately precise resistor

and one lower precision resistor can be combined. If the moderately precise resistor provides most of the necessary resistance,

the lower precision resistor can provide a fine adjustment. Consider an example where the closest standard 1% resistor has only

90% of the value required for R

. If a 5% series resistor is

SET

used for the remainder, then its tolerance only adds 5% of 10%

or 0.5% additional error to the combination. Likewise, the 1%

resistor only contributes 90% of 1% or 0.9% error to the combination. These two contributions are additive resulting in a total

compound resistor tolerance of 1.4%.

EFFECT OF RESISTOR TOLERANCE AND THERMAL DRIFT ON SETPOINT ACCURACY

Figure 3 shows the typical accuracy error in setpoint temperature

as a function of the programmed setpoint temperature. This

curve assumes an ideal resistor for R

. The graph of Figure 4

SET

may be used to calculate additional setpoint error as a function

of resistor tolerance. Note that this curve shows additional error

beyond the initial accuracy error of the part and should be

added to the value found in the specifications table. For example,

consider using the AD22105 programmed to switch at +125°C.

Figure 4 indicates that at +125°C, the additional error is

approximately –0.2°C/% of R

. If a 1% resistor (of exactly

SET

correct nominal value) is chosen, then the additional error could

be –0.2°C/% × 1% or –0.2°C. If the closest standard resistor

value is 0.6% away from the calculated value, then the total

error would be 0.6% for the nominal value and 1% for the

tolerance or (1.006) × (1.10) or 1.01606 (about 1.6%). This

could lead to an additional setpoint error as high as 0.32°C.

For additional accuracy considerations, the thermal drift of the

setpoint resistor can be taken into account. For example, consider that the drift of the metal film resistor is 100 ppm/°C.

Since this drift is usually referred to +25°C, the setpoint resistor

can be in error by an additional 100 ppm/°C × (125°C – 25°C) or

1%. Using a setpoint temperature of 125°C as discussed above,

this error source would add an additional –0.2°C (for positive drift)

making the overall setpoint error potentially –0.52°C higher than

the original accuracy error.

Initial tolerance and thermal drift effects of the setpoint resistor

can be combined and calculated by using the following

equation:

R

MAX

= R

×(1 +ε)× 1+TC×(T

NOM

()

SET

–25°C)

where:

R

R

is the worst case value that the setpoint resistor can be at

MAX

T

,

SET

is the standard resistor with a value closest to the desired

NOM

R

,

SET

ε is the 25°C tolerance of the chosen resistor (usually 1%,

5%, or 10%),

T

T

Once calculated, R

is the temperature coefficient of the available resistor,

C

is the desired setpoint temperature.

SET

may be compared to the desired R

MAX

SET

from Equation 1. Continuing the example from above, the

required value of R

SET

at a T

of 125°C is 5.566 kΩ. If the

SET

nearest standard resistor value is 5.600 kΩ, then its worst case

maximum value at 125°C could be 5.713 kΩ. Again this is

+2.6% higher than R

leading to a total additional error of

SET

–0.52°C beyond that given by the specifications table.

THE HYSTERESIS AND SELF-HEATING

The actual value of the hysteresis generally has a minor

dependence on the programmed setpoint temperature as shown

in Figure 6. Furthermore, the hysteresis can be affected by selfheating if the device is driving a heavy load. For example, if the

device is driving a load of 5 mA at an output voltage (given by

Figure 9) of 250 mV, then the additional power dissipation

would be approximately 1.25 mW. With a θ

of 190°C/W in

JA

free air the internal die temperature could be 0.24°C higher

than ambient leading to an increase of 0.24°C in hysteresis. In

the presence of a heat sink or turbulent environment, the

additional hysteresis will be less.

REV. 0–6–

Page 7

AD22105

OUTPUT SECTION

The output of the AD22105 is the collector of an NPN transistor.

When the ambient temperature of the device exceeds the

programmed setpoint temperature, this transistor is activated

causing its collector to become a low impedance. A pull-up

resistor, such as the internal 200 kΩ provided, is needed to

observe a change in the output voltage. For versatility, the

optional pull-up resistor has not been permanently connected

to the output pin. Instead, this resistor is undedicated and

connects from Pin 7 (V

R

(R

a single connection should be made from Pin 1

PULL-UP

) to Pin 2 (OUT).

PULL-UP

) to Pin 1 (R

S

). In order to use

PULL-UP

The 200 kΩ pull-up resistor can drive CMOS loads since

essentially no static current is required at these inputs. When

driving “LS” and other bipolar family logic inputs a parallel

resistor may be necessary to supply the 20 µA–50 µA I

(High

IH

Level Input Current) specified for such devices. To determine

the current required, the appropriate manufacturer’s data sheet

should be consulted. When the output is switched, indicating an

over temperature condition, the output is capable of pulling

down with 10 mA at a voltage of about 375 mV. This allows for

a fan out of 2 with standard bipolar logic and 20 with “LS”

family logic.

Low power indicator LEDs (up to 10 mA) can be driven

directly from the output pin of the AD22105. In most cases a

small series resistor (usually of several hundred ohms) will be

required to limit the current to the LED and the output

transistor of the AD22105.

MOUNTING CONSIDERATIONS

If the AD22105 is thermally attached and properly protected, it

can be used in any measuring situation where the maximum

range of temperatures encountered is between –40°C and

+150°C. Because plastic IC packaging technology is employed,

excessive mechanical stress must be avoided when fastening the

device with a clamp or screw-on heat tab. Thermally conductive

epoxy or glue is recommended for typical mounting conditions.

In wet or corrosive environments, an electrically isolated metal

or ceramic well should be used to protect the AD22105.

THERMAL ENVIRONMENT EFFECTS

The thermal environment in which the AD22105 is used

determines two performance traits: the effect of self-heating on

accuracy and the response time of the sensor to rapid changes in

temperature. In the first case, a rise in the IC junction temperature above the ambient temperature is a function of two variables:

the power consumption of the AD22105 and the thermal

resistance between the chip and the ambient environment, θ

.

JA

Self-heating error can be derived by multiplying the power

dissipation by θ

Because errors of this type can vary widely for

JA.

surroundings with different heat sinking capacities, it is

necessary to specify θ

under several conditions. Table I shows

JA

how the magnitude of self-heating error varies relative to the

environment. A typical part will dissipate about 230 µW at

room temperature with a 3.3 V supply and negligible output

loading. In still air, without a “heat sink,” Table I indicates a

of 190°C/W, which yields a temperature rise of 0.04°C.

θ

JA

Thermal rise of the die will be considerably less in an environment of turbulent or constant moving air or if the device is in

direct physical contact with a solid (or liquid) body.

Response of the AD22105 internal die temperature to abrupt

changes in ambient temperatures can be modeled by a single

time constant exponential function. Figure 11 shows typical

response plots for moving and still air. The time constant, τ

(time to reach 63.2% of the final value), is dependent on θ

JA

and

the thermal capacities of the chip and the package. Table I lists

the effective τ for moving and still air. Copper printed circuit

board connections were neglected in the analysis; however, they

will sink or conduct heat directly through the AD22105’s solder

plated copper leads. When faster response is required, a thermally conductive grease or glue between the AD22105 and the

surface temperature being measured should be used.

Table I. Thermal Resistance (SO-8)

Medium uJA (8C/Watt) t (sec)*

Moving Air** 100 3.5

Without Heat Sink

Still Air 190 15

Without Heat Sink

NOTES

**The time constant is defined as the time to reach 63.2% of the final tempera-

ture change.

**1200 CFM.

USING THE AD22105 AS A COOLING SETPOINT DETECTOR

The AD22105 can be used to detect transitions from higher

temperatures to lower temperatures by programming the

setpoint temperature 4°C greater than the desired trip point

temperature. The 4°C is necessary to compensate for the

nominal hysteresis value designed into the device. A more

precise value of the hysteresis can be obtained from Figure 6. In

this mode, the logic state of the output will indicate a HIGH for

under temperature conditions. The total device error will be

slightly greater than the specification value due to uncertainty in

hysteresis.

APPLICATION HINTS

EMI Suppression

Noisy environments may couple electromagnetic energy into the

node causing the AD22105 to falsely trip or untrip. Noise

R

SET

sources, which typically come from fast rising edges, can be

coupled into the device capacitively. Furthermore, if the output

signal is brought close the R

OUT pin to the R

pin potentially causing oscillation. Stray

SET

pin, energy can couple from the

SET

capacitance can come from several places such as, IC sockets,

multiconductor cables, and printed circuit board traces. In some

cases, it can be corrected by constructing a Faraday shield

around the R

pin, for example, by using a shielded cable with

SET

the shield grounded. However, for best performance, cables

should be avoided and the AD22105 should be soldered directly

to a printed circuit board whenever possible. Figure 13 shows a

sample printed circuit board layout with low inter-pin capacitance and Faraday shielding. If stray capacitance is unavoidable,

and interference or oscillation occurs, a low impedance capacitor should be connected from the R

pin to the GND pin.

SET

This capacitor must be considerably larger than the estimated

stray capacitance. Typically several hundred picofarads will correct the problem.

REV. 0 –7–

Page 8

AD22105

Leakage at the R

Leakage currents at the R

SET

Pin

pin, such as those generated from a

SET

moist environment or printed circuit board contamination, can

have an adverse effect on the programmed setpoint temperature

of the AD22105. Depending on its source, leakage current can

flow into or out of the R

pin. Consequently, the actual

SET

setpoint temperature could be higher or lower than the intended

setpoint temperature by about 1°C for each 75 nA of leakage.

With a 5 V power supply, an isolation resistance of 100 MΩ

would create 50 nA of leakage current giving a setpoint

temperature error of about 0.7°C (the R

potential). A guard ring can be placed around the R

pin is near ground

SET

node to

SET

protect against leakage from the power supply pin (as shown in

Figure 13).

V

S

C1

R

SET

0.1574 (4.00)

0.1497 (3.80)

PIN 1

0.0098 (0.25)

0.0040 (0.10)

SEATING

PLANE

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Lead SOIC

(SO-8)

0.1968 (5.00)

0.1890 (4.80)

8

5

0.2440 (6.20)

41

0.2284 (5.80)

0.0500

(1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

0.0098 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

C2099–6–1/96

x 45°

PIN 1

OUT

Figure 13. Suggested PCB Layout

GND

PRINTED IN U.S.A.

REV. 0–8–

Loading...

Loading...