Page 1

Class D/1-Bit Audio Power Output Stage

R

R

AD1991

FEATURES

Class D/1-Bit Audio Power Output Stage

5 V Analog and Digital Supply Voltages

Power Stage Power Supply 8 V to 20 V

Output Power @ 0.1% THD + N

Stereo Mode

2 20 W @ 4 @ 14.4 V

2 20 W @ 8 @ 20 V

Mono Mode

1 40 W @ 4 @ 20 V

< 320 m (per Transistor)

R

ON

Efficiency > 85% @ Full Power/8

Clickless Mute Function

Turn-On and Turn-Off Pop Suppression

Short-Circuit Protection

Overtemperature Protection

Data Loss Protection

2-Channel BTL Outputs or

4-Channel Single-Ended Outputs

52-Lead Exposed Pad TQFP Package

Low Cost DMOS Process

APPLICATIONS

PC Audio Systems

Minicomponents

Automotive Amplifiers

Home Theater Systems

Televisions

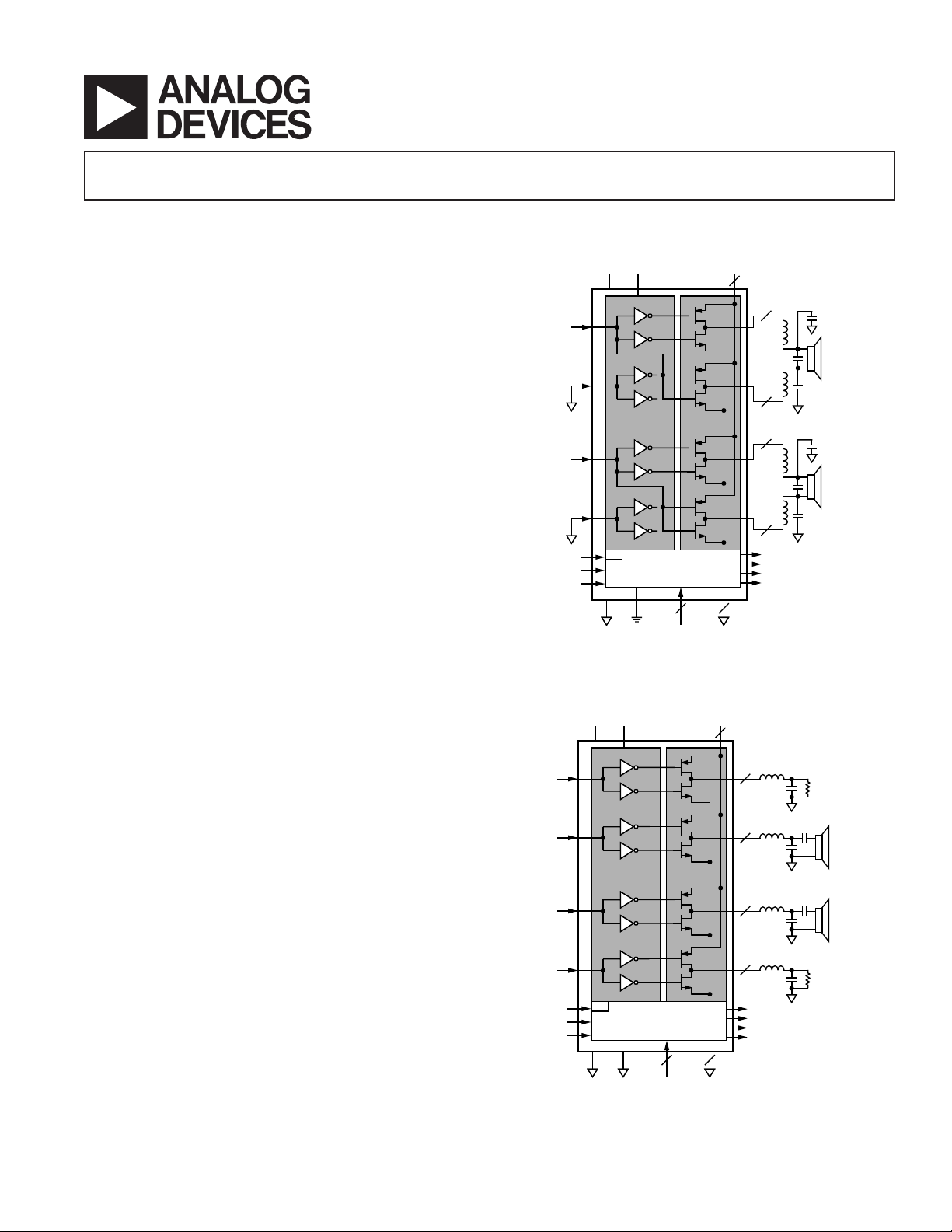

FUNCTIONAL BLOCK DIAGRAMS

2-Channel Mode

INA

LEFT

INPUT

INB

INC

RIGHT

INPUT

IND

CLK

ST/PDN

MUTE

AVDDDV

DD

LEVEL SHIFTER

AND

SWITCH CONTROL

ⴜn

THERMAL PROTECTION

SHORT-CIRCUIT PROTECTION

MUTE CONTROL

AGND DGND

CONTROL

TEST

H-BRIDGE

2 144

A1

A2

B1

B2

C1

C2

D1

D2

PGND

PV

DD

6

4-Channel Mode

OUTA

3

OUTB

3

OUTC

3

OUTD

3

CURRENT OVERLOAD

THERMAL SHUTDOWN

THERMAL WARNING

DATA LOSS

GENERAL DESCRIPTION

The AD1991 is a 2-channel BTL or 4-channel single-ended

class D audio power output stage. The part is configured during

reset to be in either 2-channel mode or 4-channel mode.

To protect the IC as well as the connected speakers, the AD1991

provides turn-on and turn-off pop suppression, short-circuit

protection, and overtemperature shutdown. To control the IC,

a power-down/reset input and a mute pin are available.

The output stage can be operated over a power supply range

from 8 V to 20 V.

In 2-channel mode, Transistors A1, B2, C1, and D2 are turned

on by a Logic 1 on inputs INA and INC, and Transistors A2,

INA

INB

INC

AVDDDV

DD

LEVEL SHIFTER

AND

SWITCH CONTROL

H-BRIDGE

PV

DD

6

A1

OUTA

A2

B1

B2

C1

C2

3

OUTB

3

OUTC

3

LOAD

REQUIRING

DC VOLTAGE

SUPPLY

B1, C2, and D1 are turned on by a Logic 0 on inputs INA and

24 14

TEST

D1

D2

PGND

OUTD

3

CURRENT OVERLOAD

THERMAL SHUTDOWN

THERMAL WARNING

DATA LOSS

LOAD

REQUIRING

DC VOLTAGE

SUPPLY

INC. In 4-channel mode, Transistors A1, B1, C1, and D1 are

turned on by a Logic 1 on the four inputs, and Transistors A2,

IND

B2, C2, and D2 are turned on by a Logic 0 on the four inputs

(see the Functional Block Diagrams).

CLK

ST/PDN

MUTE

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2003 Analog Devices, Inc. All rights reserved.

ⴜn

THERMAL PROTECTION

SHORT-CIRCUIT PROTECTION

MUTE CONTROL

AGND DGND

CONTROL

Page 2

AD1991–SPECIFICATIONS

(AVDD = 5 V, DVDD = 5 V, PV

1

Load Impedance = 8 , unless otherwise noted.)

= 20 V, Ambient Temperature = 25C,

DDX

Parameter Min Typ Max Unit Test Conditions

OUTPUT POWER P

(f = 1 kHz SINE WAVE)

O

EFFICIENCY 87 % f = 1 kHz, P

R

ON

2

20 W RL = 4 Ω, PV

20 W R

= 8 Ω, PV

L

DDX

DDX

= 20 W, RL = 8 Ω

O

Per High-Side Transistor 260 320 mΩ @ 1 A

Per Low-Side Transistor 190 235 mΩ @ 1 A

Temperature Coefficient 0.7 mΩ/°C

THERMAL WARNING ACTIVE 135 °CDie temperature

THERMAL SHUTDOWN ACTIVE 150 °CDie temperature

OVERCURRENT SHUTDOWN ACTIVE 3.8 5 6.75 A

POWER SUPPLIES

Supply Voltage AV

Supply Voltage DV

Supply Voltage PV

DD

DD

DDX

4.5 5.0 5.5 V

4.5 5.0 5.5 V

6.5 8 to 20 22.5 V

Power-Down Current

AV

DV

PV

DD

DD

DDX

614µA RST/PDN held low

113µA RST/PDN held low

17 µA RST/PDN held low

Operating Current

AV

DV

PV

DD

DD

DDX

1.8 2.75 mA

4 5.2 mA

40 mA 50:50 384 kHz square wave on

INA and INC

DIGITAL I/O

Input Voltage High 2.0 DV

DD

V

Input Voltage Low 1.2 V

Output Voltage High DV

– 0.8 V @ 2 mA

DD

Output Voltage Low 0.4 V @ 2 mA

Leakage Current on Digital Inputs 10 µA

NOTES

1

Performance of both channels is identical.

2

Measurement requires PWM modulator.

Specifications subject to change without notice.

= 14 V

= 20 V

DIGITAL TIMING CHARACTERISTICS

(Guaranteed over –40C to +85C, AVDD = DVDD = 5 V 10%, PV

Edge Speed = Slowest, Nonoverlap Time = Shortest.)

= 20 V 10%,

DDX

Symbol Parameter Min Typ Max Unit

t

PDL

t

PST

t

NOL

t

PDRP

t

MSU

t

MH

t

MPDL

Specifications subject to change without notice.

Input transition to output initial response 30 ns

Power transistor switching time 3.5 ns

Nonoverlap time 25 to 40 ns

RST/PDN minimum low pulsewidth 20 ns

Mode pin setup time before RST/PDN going high 5 ns

Mode pin hold time after RST/PDN going high 5 ns

MUTE asserted to output initial response 3 s

REV. 0–2–

Page 3

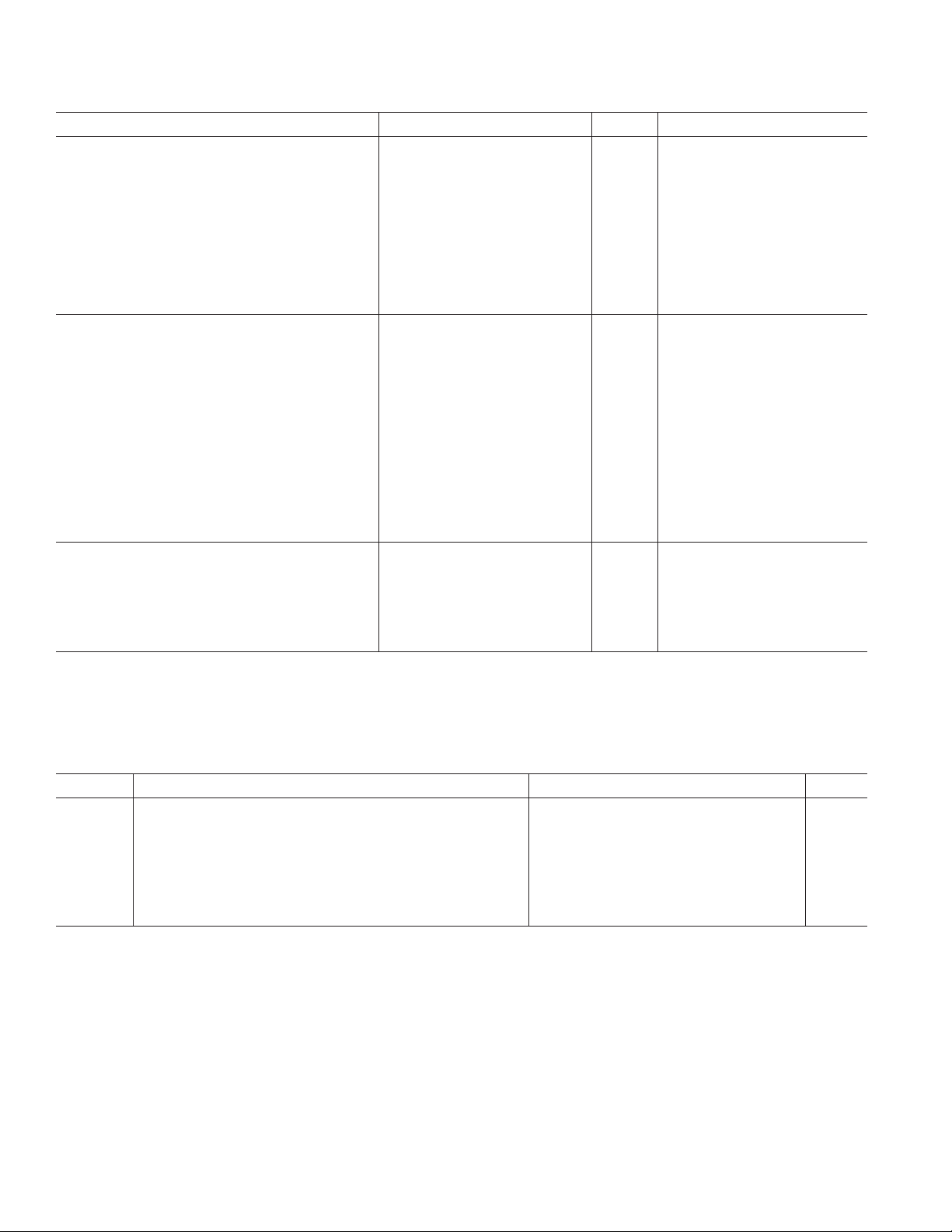

AD1991

R

M

INA

OUTA

OUTB

ST/PDN

t

PDL

t

PST

t

PST

t

NOL

t

t

PST

t

PDL

PST

t

NOL

Figure 1. Output Timing

t

PDRP

MODEx

t

MSU

Figure 2.

UTE

t

PST

OUTx

t

MPDL

RESET

Figure 3.

and Mode Timing

MUTE

Timing

t

MPDL

t

MH

t

PST

REV. 0

–3–

Page 4

AD1991

ABSOLUTE MAXIMUM RATINGS

(TA = 25°C, unless otherwise noted.)

1

AVDD, DVDD to AGND, DGND . . . . . . . . . . –0.3 V to +6.5 V

to PGNDx2 . . . . . . . . . . . . . . . . . . . –0.3 V to +30.0 V

PV

DDX

AGND to DGND to PGNDx . . . . . . . . . . . . –0.3 V to +0.3 V

to DVDD . . . . . . . . . . . . . . . . . . . . . . . –0.5 V to +0.5 V

AV

DD

Operating Temperature Range (Ambient)

Industrial . . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Maximum Junction Temperature . . . . . . . . . . . . . . . . . 150°C

Thermal Resistance3 . . . . . . . . . . . . . . . . . . . . . . . 1°C/W

θ

JC

Lead Temperature

Soldering (10 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . 260°C

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

AD1991ASV –40°C to +85°CThin Quad Flat Pack [TQFP] SV-52

AD1991ASVRL –40°C to +85°CThin Quad Flat Pack [TQFP] SV-52

EVAL-AD1991EB Evaluation Board

NOTES

1

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational

sections of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability. Only one absolute

maximum rating may be applied at any one time.

2

Including any induced voltage due to inductive load.

3

With respect to the temperature of the exposed pad.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

AD1991 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

REV. 0–4–

Page 5

PIN CONFIGURATION

AD1991

AGND

AGND

MODE1

AD1991

TOP VIEW

(Not to Scale)

INB

INA

ERR0

AV

DV

DD

DD

AGND

MODE0

MUTE

DGND

AGND

PGND2

IND

INC

PGND2

PGND2

CLK

RST/PDN

39

38

37

36

35

34

33

32

31

30

29

28

27

PGND2

OUTC

OUTC

OUTC

PV

DD2

PV

DD2

PV

DD2

OUTD

OUTD

OUTD

PGND2

PGND2

PGND2

PGND1

OUTA

OUTA

OUTA

PV

DD1

PV

DD1

PV

DD1

OUTB

OUTB

OUTB

PGND1

PGND1

PGND1

PGND1

PGND1

PGND1

52 51 50 49 48 43 42 41 4047 4 6 45 44

1

PIN 1

2

IDENTIFIER

3

4

5

6

7

8

9

10

11

12

13

14 15 16 17 18 19 20 21 22 23 24 25 26

ERR3

ERR2

ERR1

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic In/Out Description

1 PGND1 Negative power supply for high power Transistors A2 and B2.

2, 3, 4 OUTA O Output of transistor pair A1 and A2.

5, 6, 7 PV

DD1

Positive power supply for high power Transistors A1 and B1.

8, 9, 10 OUTB O Output of transistor pair B1 and B2.

11, 12, 13 PGND1 Negative power supply for high power Transistors A2 and B2.

14 ERR3 I/O Edge speed setting MSB during RESET/active low thermal shutdown error output during

normal operation.

15 ERR2 I/O Edge speed setting Bit 1 during RESET/active low thermal warning error output during

normal operation.

16 ERR1 I/O Nonoverlap time setting MSB during RESET/active thermal low shutdown error output

during normal operation.

17 ERR0 I/O Nonoverlap time setting Bit 1 during RESET/active low data-loss error output or low-side

transistor disable input during normal operation.

18 INA I Control pin for Transistors A1 and A2 always; also control pin for B1 and B2 in 2-channel mode.

19 INB I Edge speed setting LSB during RESET/during normal operation, control pin for Transistors

B1 and B2 in 4-channel mode; no function in 2-channel mode.

20 DV

DD

Positive power supply for low power digital circuitry.

21 DGND Negative power supply for low power digital circuitry.

22 MUTE I Active low clickless mute input.

23 INC I Control pin for Transistors C1 and C2 always; also control pin for D1 and D2 in 2-channel mode.

24 IND I Nonoverlap time setting LSB during RESET/during normal operation, control pin for Transis-

tors D1 and D2 in 4-channel mode; no function in 2-channel mode.

25 RST/PDN I Active low RESET/power-down input.

26 CLK I External clock input in external clock mode.

27, 28, 29 PGND2 Negative power supply for high power Transistors C2 and D2.

30, 31, 32 OUTD O Output of transistor pair D1 and D2.

33, 34, 35 PV

DD2

Positive power supply for high power Transistors C1 and D1.

36, 37, 38 OUTC O Output of transistor pair C1 and C2.

39, 40, 41, 42 PGND2 Negative power supply for high power Transistors C2 and D2.

43, 45, 48, 49 AGND Negative power supply for low power analog circuitry.

44 MODE0 Clock source select (referenced to AGND); normally connected to AGND.

46 AV

DD

Positive power supply for low power analog circuitry.

47 MODE1 I Channel mode select (referenced to AGND).

50, 51, 52 PGND1 Negative power supply for high power Transistors A2 and B2.

REV. 0

–5–

Page 6

AD1991

FUNCTIONAL DESCRIPTION

Device Architecture

The AD1991 is an 8-transistor, audio, power output stage. The

AD1991 is arranged internally as four transistor pairs that can

be used as two H-bridge outputs (2-channel mode) or as four

single-ended outputs (4-channel mode), using either two or four

TTL compatible inputs to control the transistors. A dead time

is automatically provided between the switching of the highside transistor and low-side transistor when the control inputs

change level, to ensure that both the high-side transistor and

low-side transistor are never on at the same time.

Clock Source and Channel Mode Selection

When the AD1991 is brought out of reset, the logic levels on

MODE0 and MODE1 are latched internally. MODE0 determines

the internal state machine clock source. MODE1 determines the

channel mode and the function of ERR0 (see Tables I and II.)

When the internal clock is used, the CLK pin should not be

connected.

Table I. Clock Source Selection

MODE0 CLK Source

0 Internal

1External

Table II. Channel Mode Selection

MODE1 Channel Mode ERR0 Function

0 2-Channel Mode Data Loss Detection Output

1 4-Channel Mode Low-Side Disable Input

2-Channel Mode

Two loads are connected differentially—across OUTA and OUTB

and across OUTC and OUTD. Inputs INB and IND are unused

and should be tied to an appropriate dc voltage (see the Edge

Speed and Nonoverlap Settings section). In this mode, ERR0 is

an error output used to indicate data loss, which occurs when

there are no transitions on INA or INC for more than 50 ms.

This signal condition is hazardous in 2-channel mode because it

can cause a potentially large and harmful dc voltage across the

differential loads. Table III shows the input/output relationship.

Table III. Input/Output Relationship in 2-Channel Mode

Input Controlled Output

INA OUTA, OUTB

INC OUTC, OUTD

4-Channel Mode

The 4-channel mode has two types of configuration: audio and

power supply. Neither of these configurations require data loss

detection. In the audio configuration, each single-ended load is

connected to the output through a blocking capacitor, which

prevents dc from reaching the load, thereby negating the need

for data loss detection. While in the power supply configuration,

it is desired to maintain a dc voltage on the load, also negating

the need for data loss detection. When used in the power supply

configuration, the four low-side transistors can also be disabled

and left permanently open if desired. This allows the loads to be

driven by switching only the high-side transistor on and off.

ERR0 is an input in 4-channel mode and is used to select

whether the four low-side transistors are enabled or disabled,

with 0 selecting disabled and 1 selecting enabled. Table IV

summarizes the function of ERR0 in this mode. Table V shows

the input/output relationship.

Table IV. ERR0 Function in 4-Channel Mode

ERR0 Low-Side Transistor Status

0 Disabled

1 Enabled

Table V. Input/Output Relationship in 4-Channel Mode

Input Controlled Output

INA OUTA

INB OUTB

INC OUTC

IND OUTD

1-Channel Mode

One load is connected differentially—across OUTA and OUTC,

and OUTB and OUTD. This mono operation is established

by configuring the part for 2-channel mode and externally

connecting INA to INC, OUTA to OUTC, and OUTB to

OUTD (see Figure 4).

Thermal Protection

The AD1991 features thermal protection. When the die temperature exceeds approximately 135°C, the thermal warning error

output (ERR2) is asserted. If the die temperature exceeds

approximately 150°C, the thermal shutdown error output (ERR3)

is asserted. If this occurs, the part shuts down to prevent damage

to the part. When the die temperature drops below approximately

120°C, both error outputs de-assert and the part returns to normal operation.

Overcurrent Protection

The AD1991 features overcurrent or short-circuit protection. If

the current through any power transistors exceeds 5 A, the part

is muted and the overcurrent error output (ERR1) is asserted.

This is a latched error and does not clear automatically. To clear

the error condition and restore normal operation, the part must

be reset or MUTE must be asserted and de-asserted.

REV. 0–6–

Page 7

INPUT

R

ST/PDN

MUTE

INA

INB

INC

IND

CLK

DV

DD

DD

LEVEL SHIFTER

AND

SWITCH CONTROL

n

THERMAL PROTECTION

SHORT-CIRCUIT PROTECTION

MUTE CONTROL

AGND DGND

CONTROL

TEST

A1

A2

B1

B2

H-BRIDGE

C1

C2

D1

D2

24 14

PGND

PV

DD

6

OUTA

3

OUTB

3

OUTC

3

OUTD

3

CURRENT OVERLOAD

THERMAL SHUTDOWN

THERMAL WARNING

DATA LOSS

AV

Figure 4. Functional Block Diagram (1-Channel Mode)

EDGE SPEED AND NONOVERLAP SETTINGS

The AD1991 allows the user to select from one of eight different

edge speeds and from one of eight different nonoverlap times.

This allows the user to make a trade-off between distortion,

efficiency, overshooting at the outputs, and EMI. The following

sections describe the method used to program the settings.

Edge Speed

The edge speed is set by using the three pins, ERR3, ERR2, and

INB, when RST/PDN is low. The levels on the three pins are

latched by the rising edge of RST/PDN. The latched value determines the edge speed thereafter, until RST/PDN is brought low.

Table VI shows the appropriate logic levels for the corresponding

edge speeds. Note that INB is internally inverted, resulting in

the nonmonotonic sequence in Table VI.

AD1991

Table VI. Edge Speed Settings

ERR3 ERR2 INB Edge Speed

0011 (Slowest Edge Speed)

0002

0113

0104

1015

1006

1117

1108 (Fastest Edge Speed)

Nonoverlap Time

The nonoverlap time is set by using the three pins, ERR1, ERR0,

and IND, when RST/PDN is low. The levels on the three pins

are latched by the rising edge of RST/PDN. The latched value

determines the nonoverlap time thereafter, until RST/PDN is

brought low. Table VII shows the appropriate logic levels for

the corresponding nonoverlap times. Note that IND is internally

inverted, resulting in the nonmonotonic sequence in Table VII.

Note that ERR3, ERR2, ERR1, and ERR0 are driven outputs

under normal operation and, therefore, should never be tied to a

dc voltage. The part contains internal 300 kΩ pull-up resistors

to pull these pins high during reset. If it is desired to set them

low to achieve a particular edge speed or nonoverlap time, this

should be done by pulling them low through resistors between

10 kΩ and 50 kΩ.

Table VII. Nonoverlap Time Settings

ERR1 ERR0 IND Nonoverlap Time

00 11 (Shortest Nonoverlap Time)

00 02

01 13

01 04

10 15

10 06

11 17

11 08 (Longest Nonoverlap Time)

REV. 0

–7–

Page 8

AD1991

APPLICATION CONSIDERATIONS

Good board layout and decoupling are vital for correct operation

of the AD1991. Due to the fact that the part switches high currents,

there is the potential for large PV

bounce each time a transis-

DD

tor transitions. This can cause unpredictable operation of the part.

To avoid this potential problem, close chip decoupling is essential. It is also recommended that the decoupling capacitors be

placed on the same side of the board as the AD1991 and connected

directly to the PV

and PGND pins. By placing the decoupling

DD

capacitors on the other side of the board and decoupling through

vias, the effectiveness of the decoupling is reduced. This is

because vias have inductive properties and, therefore, prevent

very fast discharge of the decoupling capacitors. Best operation

is achieved with at least one decoupling capacitor on each side of

the AD1991 or optionally two capacitors per side can be used to

further reduce the series resistance of the capacitor. If these

decoupling recommendations cannot be followed and decoupling

through vias is the only option, the vias should be made as large

as possible to increase surface area, thereby reducing inductance

and resistance.

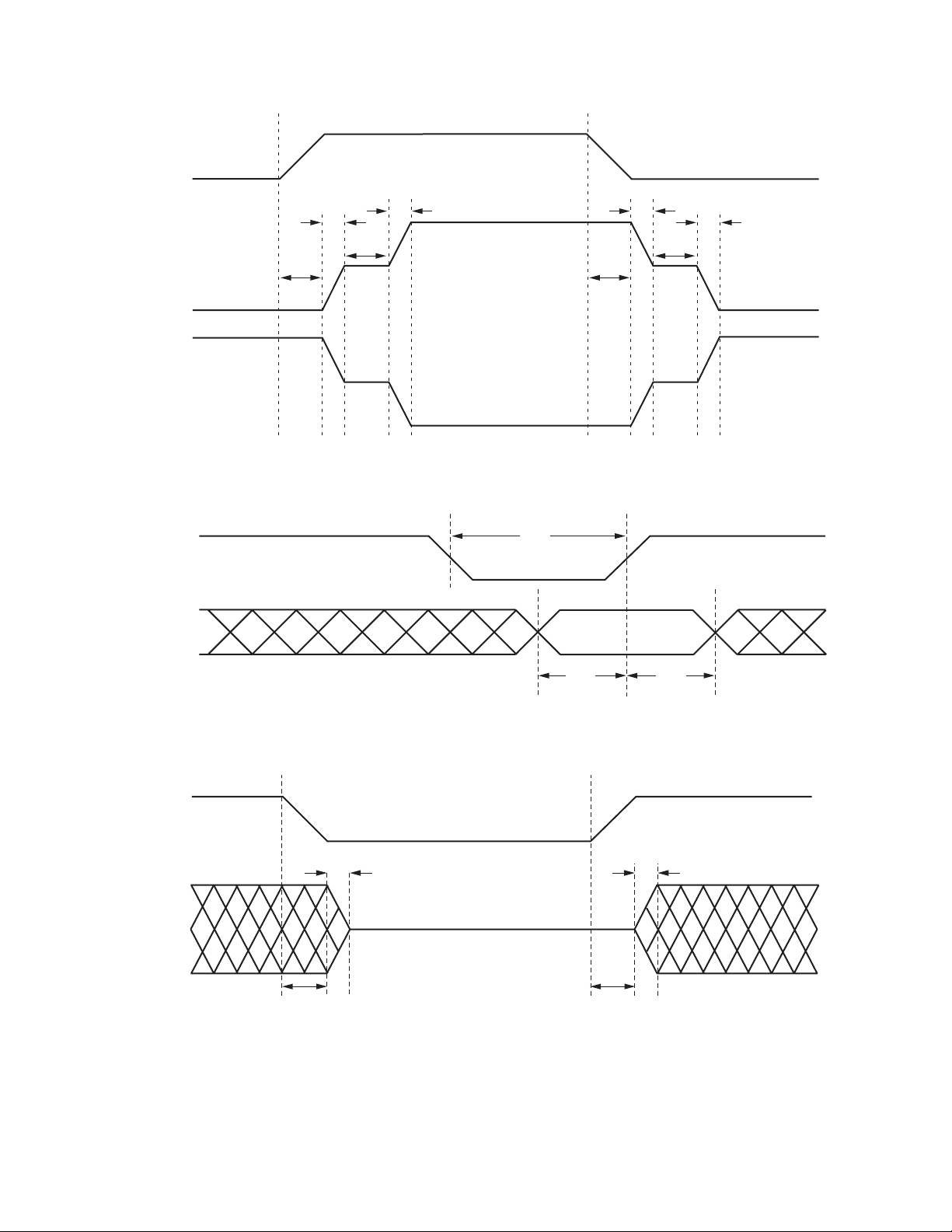

Figures 5 and 6 show two possible layouts to provide close chip

decoupling. In both cases, the PV

to PGND decoupling is as

DD

close as possible to the pins of the AD1991. One solution uses

surface-mount capacitors that offer low inductance; however, each

output (OUTA, OUTB, OUTC, and OUTD) must be brought

through vias to another layer of the board to be brought to the

LC filter. The other solution uses through-hole capacitors that

have higher inductance but allow the outputs to connect directly

to the LC filter. In this solution, the inductor for OUTA and

OUTC would span the PV

decoupling capacitors from PV

trace. These diagrams show four

DD

to PGND; however, this may

DD

not be necessary if capacitors with low series resistance are

used. Another close chip capacitor is used for AV

to AGND

DD

decoupling, with the actual power connections to the capacitors

being done through vias. This is quite acceptable since AV

DD

is

a low current stable supply. Finally, a close chip capacitor is used

to decouple DV

to DGND. This is quite important since DV

DD

DD

is a digital supply whose current will change dynamically and,

therefore, requires good decoupling. For both PV

and DVDD,

DD

additional reservoir capacitors should be used to augment the

close chip decoupling, especially for PV

, which usually has very

DD

large transients.

junction (die) and the case (package) for each watt of power

dissipated in the die. The AD1991 is specified with a

of

JC

1°C/W, which means that for each watt of power dissipated in

the part, the junction (or die) temperature will be 1ºC higher

than the case (or package) temperature.

The value of

, the difference between the case and ambient

CA

temperatures, is entirely dependent on the size of heat sink

attached to the case, the material used, the method of attachment, and the airflow over the heat sink. The value of

CA

is

specified as 26°C/W for no heat sink and no airflow over the device.

Finally,

is the sum of the JC and CA values, and will be

JA

between 1°C/W and 27°C/W depending on the heat sink used.

This is the temperature difference between the junction (die) and

ambient temperature around the case (package) for each watt

dissipated in the part.

The AD1991 is specified to have a thermal shutdown of typically

150°C die temperature. Good design procedures allow for a

margin, so the system should be designed such that the AD1991

die never goes above 140°C. Knowing the maximum desirable

die temperature, the efficiency of the AD1991, the maximum

ambient temperature, and the maximum power that will be

delivered to the load, the necessary

can be calculated. For an

CA

8 Ω load, the AD1991 has a typical efficiency of 87%, which

can be reduced slightly to be conservative. For this example,

assume an 85% efficiency. If the power delivered to the loads is

to be 2 ⫻ 20 W rms continuous power, the power dissipated in

the AD1991 can be calculated as follows:

Power Supplied to Loads = 40 W rms

⫻

Total Power Supplied to the AD1991 = (40/85

100) = 47 W rms

Power Dissipated in the AD1991 = 7 W rms

If the ambient temperature can reach 85°C maximum, the allowable

difference between the die temperature and ambient temperature

is (140 – 85) = 55°C. This gives a JA requirement of (55/7) =

7.9°C/W. This requires a heat sink that gives a

of 6.9°C/W.

CA

The size and type of heat sink required can now be calculated.

If adequate heat sinking is not applied to the AD1991, the system

will suffer from the AD1991 going into thermal shutdown. It is

advisable to also use the thermal warning output on the AD1991

to attenuate the power being delivered to help prevent thermal

shutdown.

THERMAL CONSIDERATIONS

Careful consideration must be given to heat sinking the AD1991,

particularly in applications where the ambient temperature can

be much higher than normal room temperature. The three

thermal resistances of

, CA, and

JC

should be known in

JA

order to correctly heat sink the part. These values specify the

temperature difference between two points, per unit power

dissipation.

specifies the temperature difference between the

JC

POWER-UP CONSIDERATIONS

Careful power-up is necessary when using the AD1991 to

ensure correct operation and to avoid possible latch-up issues.

The AD1991 should be held in RESET with MUTEB asserted

until all three power supplies have stabilized. Once the supplies

have stabilized, the part can be brought out of RESET, and

following this, MUTEB can be negated.

REV. 0–8–

Page 9

CAPCAP

PVDD PLANE

CAP

1

2

3

4

5

6

7

8

9

10

11

12

13

14 15 16 17 18 19 20 21 22 23 24 25 26

AGND PLANE

PGND

PLANE

AD1991

40414243444546474849505152

39

38

37

36

35

34

33

32

31

30

29

28

27

CAP CAP

CAP

Figure 5. Layout Using Surface-Mount Capacitors (4 × 10 nF or 2 × 22 nF Recommended)

PVDD PLANE

CAP

40414243444546474849505152

39

38

37

36

35

34

33

32

31

CAP CAP

30

29

28

27

CAPCAP

1

2

3

4

5

6

7

8

9

10

11

12

13

161514 26252423222120191817

AGND PLANE

PGND

PLANE

REV. 0

CAP

Figure 6. Layout Using Through-Hole Capacitors (4 × 10 nF or 2 × 22 nF Recommended)

–9–

Page 10

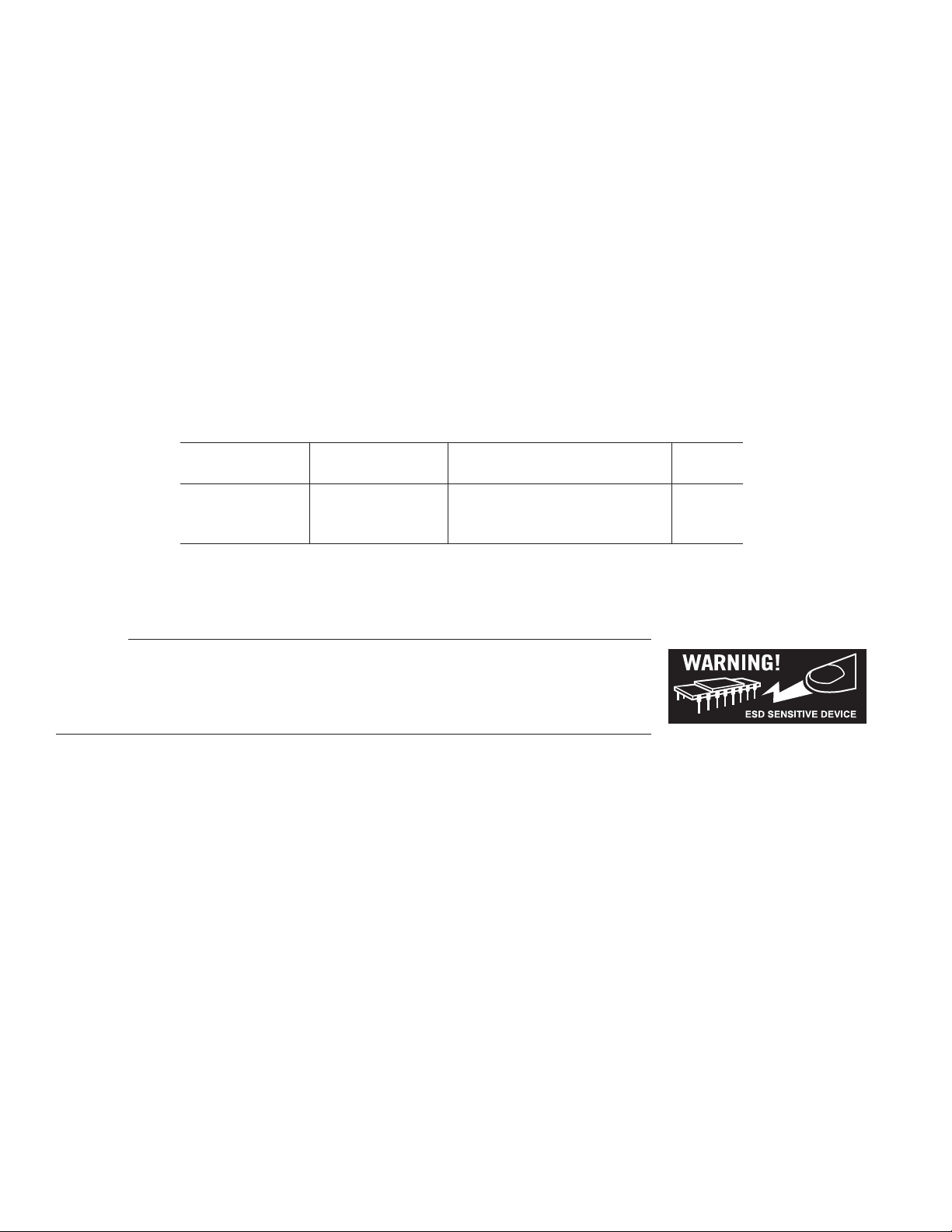

AD1991

DD

AD1991

PV

DD

PV

DD

PGND

ANALOG INPUT_L

GND

ANALOG INPUT_R

AV

DV

DD

DD

AV

DDDVDD

AGND DGND FEEDBACK

AGND

FEEDBACK

MODULATOR

DGND

AVDDDV

PWM_L

GND

PWM_R

AGND DGND PGND

Figure 7. Simplified System Schematic for Analog-In, Analog-Out System

REV. 0–10–

Page 11

OUTLINE DIMENSIONS

52-Lead Thin Quad Flat Package, Exposed Pad [TQFP/EP]

(SV-52)

Dimensions shown in millimeters

12.00

BSC SQ

1

TOP VIEW

(PINS DOWN)

4052

39

10.00

BSC SQ

40 52

39

BOTTOM VIEW

(PINS UP)

EXPOSED

PAD

1

6.50

SQ

AD1991

1.20

MAX

13

14

VIEW A

0.20

0.09

COMPLIANT TO JEDEC STANDARDS MS-026ACC

WITH THE EXCEPTION THAT THE EXPOSED DIE PAD SHALL BE

COPLANAR WITH BOTTOM OF PACKAGE WITHIN 0.05 MILLIMETERS.

27

26

SEATING

1.05

1.00

0.95

PLANE

27

26

0.15

0.05

0.65

BSC

VIEW A

7

3.5

0

0.75

0.60

0.45

0.38

0.32

0.22

13

14

REV. 0

–11–

Page 12

C03587–0–5/03(0)

–12–

Loading...

Loading...