Page 1

Current Sensor: ACS754SCB-200

5

4

1

2

3

Package CB-PSF

5

4

1

2

3

Package CB-PSS

Pin 1: VCC

Pin 2: GND

Pin 3: VOUT

AB SO LUTE MAX I MUM RAT INGS

Supply Voltage, VCC..........................................16 V

Reverse Supply Voltage, V

Output Voltage, V

Reverse Output Voltage, V

Output Current Source, I

Output Current Sink, I

Operating Temperature,

Ambient, T

Maximum Junction, T

Maximum Storage Temperature, T

OUT

, S range ....................... –20 to 85ºC

A

Terminal 4: IP+

Terminal 5: IP–

........................–16 V

RCC

........................................16 V

...................... –0.1 V

ROUT

OUT(Source)

OUT(Sink)

.......................10 mA

....................... 165°C

J(max)

S

................. 3 mA

....–65 to 170°C

The Allegro ACS75x family of current sensors provides economical and

precise solutions for current sensing in industrial, automotive, commercial, and

communications systems. The device package allows for easy implementation

by the customer. Typical applications include motor control, load detection and

management, power supplies, and overcurrent fault protection.

The device consists of a precision, low-offset linear Hall sensor circuit with a

copper conduction path located near the die. Applied current fl owing through

this copper conduction path generates a magnetic fi eld which is sensed by the

integrated Hall IC and converted into a proportional voltage. Device accuracy

is optimized through the close proximity of the magnetic signal to the Hall

transducer. A precise, proportional voltage is provided by the low-offset, chopperstabilized BiCMOS Hall IC, which is programmed for accuracy at the factory.

The output of the device has a positive slope (>V

/ 2) when an increasing

CC

current fl ows through the primary copper conduction path (from terminal 4 to

terminal 5), which is the path used for current sensing. The internal resistance of

this conductive path is typically 100 µΩ, providing low power loss. The thickness

of the copper conductor allows survival of the device at up to 5× overcurrent

conditions. The terminals of the conductive path are electrically isolated from the

sensor leads (pins 1 through 3). This allows the ACS75x family of sensors to be

used in applications requiring electrical isolation without the use of opto-isolators

or other costly isolation techniques.

The device is fully calibrated prior to shipment from the factory. The ACS75x

family is lead-free. All leads are coated with 100% matte tin, and there is no lead

inside the package. The heavy gauge leadframe is made of oxygen-free copper.

Features and Benefi ts

• Monolithic Hall IC for high reliability

• Single +5 V supply

• 3 kV

isolation voltage between terminals 4/5 and pins 1/2/3

RMS

• 35 kHz bandwidth

• End-of-line factory-trimmed for gain and offset

• Ultra-low power loss: 100 µΩ internal conductor resistance

• Ratiometric output from supply voltage

• Extremely stable output offset voltage

• Small package size, with easy mounting capability

• Output proportional to ac and dc currents

Applications

• Industrial systems

• Motor control

• Servo systems

• Power conversion

• Battery monitors

TÜV America

Certifi cate Number:

U8V 04 11 54214 001

ACS754200-DS, Rev. 3

Use the following complete part numbers when ordering:

Part Number Package

ACS754SCB-200-PSF Formed signal pins

ACS754SCB-200-PSS Straight signal pins

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 2

Current Sensor: ACS754SCB-200

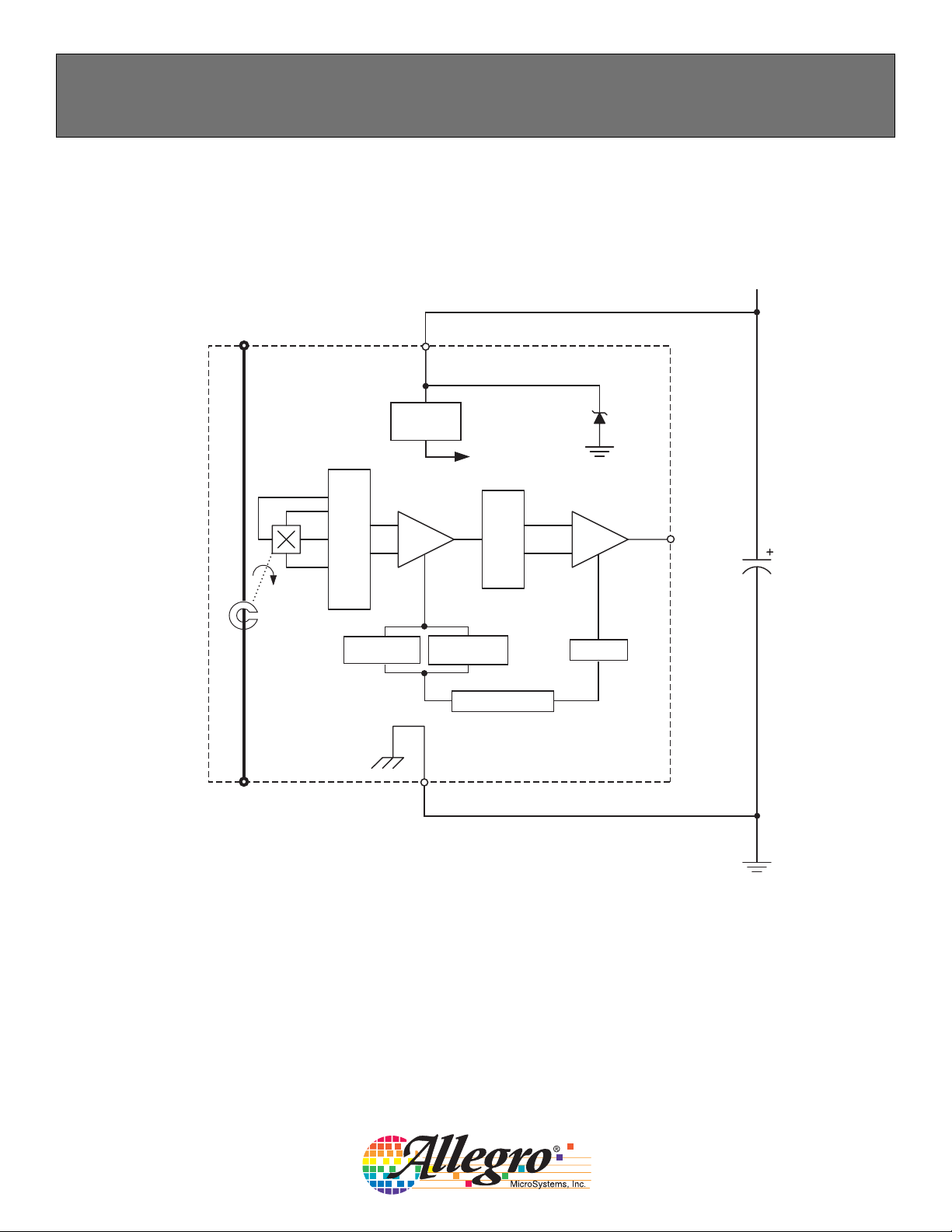

Functional Block Diagram

+5 V

IP–

Terminal 5

Cancellation

Dynamic Offset

Gain

VCC

Pin 1

Voltage

Regulator

To all subcircuits

Amp Out

Temperature

Coefficient

Filter

Trim Control

Offset

VOUT

Pin 3

0.1 µF

ACS754200-DS, Rev. 3

IP+

Terminal 4

GND

Pin 2

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

2

Page 3

Current Sensor: ACS754SCB-200

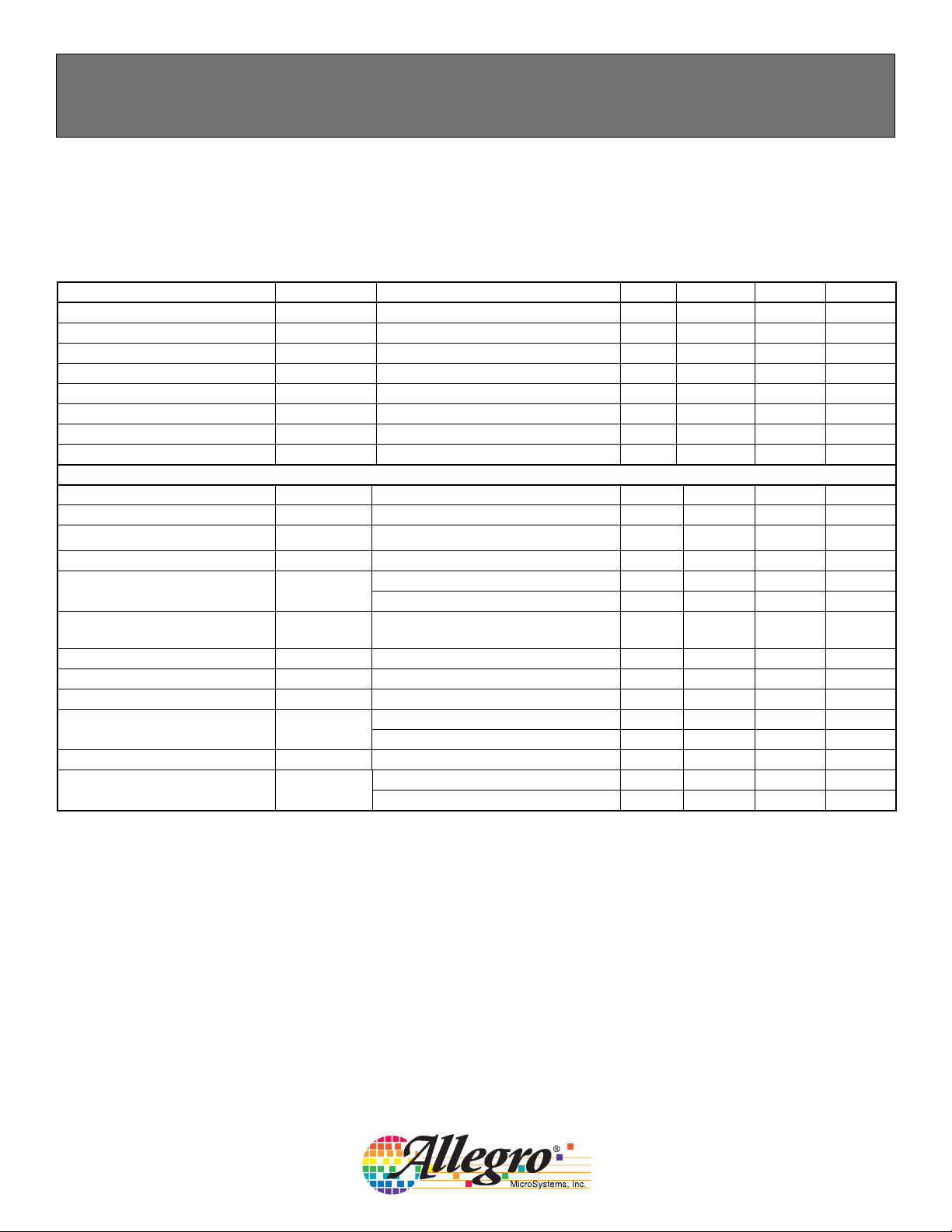

ELECTRICAL CHARACTERISTICS, over operating ambient temperature range unless otherwise stated

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Primary Sensed Current I

Supply Voltage V

Supply Current I

Output Resistance R

Output Capacitance Load C

Output Resistive Load R

Primary Conductor Resistance R

Isolation Voltage V

P

CC

CC

OUT

LOAD

LOAD

PRIMARYIP

ISO

VCC = 5.0 V, output open 6.5 8 10 mA

I

= 1.2 mA – 1 2 Ω

OUT

VOUT to GND – – 10 nF

VOUT to GND 4.7 – – kΩ

= ±50A; TA = 25°C – 100 – µΩ

Pins 1-3 and 4-5; 60 Hz, 1 minute 3.0 – – kV

PERFORMANCE CHARACTERISTICS, -20°C to +85°C, VCC = 5 V unless otherwise specifi ed

Propagation time t

Response time t

PROP

RESPONSEIP

Rise time t

r

IP = ±100 A, TA = 25°C – 4 – µs

= ±100 A, TA = 25°C – 11 – µs

IP = ±100 A, T A= 25°C – 10 – µs

Frequency Bandwidth f –3 dB, T = 25°C – 35 – kHz

Sensitivity Sens

Noise V

Nonlinearity E

Symmetry E

Zero Current Output Voltage V

Electrical Offset Voltage

(Magnetic error not included)

Magnetic Offset Error

Total Output Error

(Including all offsets)

NOISE

LIN

SYM

OUT(Q)

V

OE

I

ERROM

E

TOT

Over full range of IP , TA = 25°C – 10.0 – mV/A

Over full range of I

P

Peak-to-peak, TA = 25°C,

no external fi lter

Over full range of I

Over full range of I

P

P

I = 0 A, TA= 25°C – VCC / 2 – V

I = 0 A, TA = 25°C –10 – 10 mV

I = 0 A –20 – 20 mV

I = 0 A, after excursion of 200 A – ±0.15 ±0.50 A

Over full range of IP , TA = 25°C – ±1.0 – %

Over full range of I

P

–200 – 200 A

4.5 5.0 5.5 V

9.5 – 10.5 mV/A

–35 –mV

– – ±0.8 %

98 100 102 %

– – ±5.0 %

ACS754200-DS, Rev. 3

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

3

Page 4

Current Sensor: ACS754SCB-200

Defi nitions of Accuracy Characteristics

Sensitivity (Sens): The change in sensor output in response to a 1 A change through the primary conductor. The sensitivity is the

product of the magnetic circuit sensitivity (G / A) and the linear IC amplifi er gain (mV/G). The linear IC amplifi er gain is trimmed at the

factory to optimize the sensitivity (mV/A) for the full-scale current of the device.

Noise (V

The noise fl oor is derived from the thermal and shot noise observed in Hall elements. Dividing the noise (mV) by the sensitivity (mV/

A) provides the smallest current that the device is able to resolve.

Linearity (E

its full-scale amplitude. Linearity reveals the maximum deviation from the ideal transfer curve for this transducer. Nonlinearity in the

output can be attributed to the gain variation across temperature and saturation of the fl ux concentrator approaching the full-scale cur-

rent. The following equation is used to derive the linearity:

where

∆ gain = the gain variation as a function of temperature changes from 25ºC,

% sat = the percentage of saturation of the fl ux concentrator, which becomes signifi cant as the current

being sensed approaches full-scale ±IP , and

V

Symmetry (E

tive full-scale primary current. The following equation is used to derive symmetry:

Quiescent output voltage (V

nominally remains at VCC ⁄ 2. Thus, VCC = 5 V translates into V

of the Allegro linear IC quiescent voltage trim, magnetic hysteresis, and thermal drift.

): The product of the linear IC amplifi er gain (mV/G) and the noise fl oor for the Allegro Hall effect linear IC (≈1 G).

NOISE

): The degree to which the voltage output from the sensor varies in direct proportion to the primary current through

LIN

OUT(Q)

)

[

)

[{

OUT(Q)

can be attributed to the resolution

out_full-scale amperes

): The degree to which the absolute voltage output from the sensor varies in proportion to either a positive or nega-

SYM

100

= the output voltage (V) when the sensed current approximates full-scale ±IP .

OUT(Q)

∆ gain × % sat (

1–

[{

2(V

V

100

[

V

): The output of the sensor when the primary current is zero. For a unipolar supply voltage, it

V

out_full-scale amperes

out_half-scale amperes

out_+full-scale amperes

–V

OUT(Q)

out_–full-scale amperes

OUT(Q)

= 2.5 V. Variation in V

– V

– V

OUT(Q)

– V

OUT(Q)

Electrical offset voltage (VOE): The deviation of the device output from its ideal quiescent value of VCC ⁄ 2 due to nonmagnetic causes.

Magnetic offset error (I

netic offset error is highest when the magnetic circuit has been saturated, usually when the device has been subjected to a full-scale or

high-current overload condition. The magnetic offset is largely dependent on the material used as a fl ux concentrator. The larger mag-

netic offsets are observed at the lower operating temperatures.

Accuracy (E

total ouput error. The accuracy is illustrated graphically in the Output Voltage versus Current chart on the following page.

Accuracy is divided into four areas:

• 0 A at 25°C: Accuracy of sensing zero current fl ow at 25°C, without the effects of temperature.

• 0 A over temperature: Accuracy of sensing zero current fl ow including temperature effects.

• Full-scale current at 25°C: Accuracy of sensing the full-scale current at 25°C, without the effects of temperature.

• Full-scale current over ∆ temperature: Accuracy of sensing full-scale current fl ow including temperature effects.

ACS754200-DS, Rev. 3

): The accuracy represents the maximum deviation of the actual output from its ideal value. This is also known as the

TOT

): The magnetic offset is due to the residual magnetism (remnant fi eld) of the core material. The mag-

ERROM

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

4

Page 5

Current Sensor: ACS754SCB-200

Output voltage vs. current, illustrating sensor accuracy at 0 A and at full-scale current

–IP(A)

–200 A

Accuracy

vrOe∆Temperature

Accuracy

25°C Only

Increasing V

Average

V

OUT

(V)

OUT

Accuracy

25°C Only

Full Scale

200 A

Accuracy

vrOe∆Temperature

+IP(A)

ACS754200-DS, Rev. 3

Accuracy

25°C Only

Accuracy

vrOe∆Temperature

0A

Decreasing V

OUT

(V)

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

5

Page 6

Current Sensor: ACS754SCB-200

Typical Percentage Error versus Ambient Temperature

5

4

3

2

1

0

(% of 200 A)

-1

TOT

-2

E

-3

-4

-5

-200 25557080

+ 3 Sigma

Mean

– 3 Sigma

TA (°C)

ACS754200-DS, Rev. 3

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

6

Page 7

Current Sensor: ACS754SCB-200

Defi nitions of Dynamic Response Characteristics

Propagation delay (t

): The time required for the sensor output to refl ect a change in the primary current

PROP

signal. Propagation delay is attributed to inductive loading within the linear IC package, as well as in the inductive loop formed by the primary conductor geometry. Propagation delay can be considered as a fi xed time offset

and may be compensated.

Primary Current

Transducer Output

Propagation Time, t

PROP

t

Response time (t

RESPONSE

I (%)

90

0

): The time interval between a) when the primary current signal reaches 90% of its

fi nal value, and b) when the sensor reaches 90% of its output corresponding to the applied current.

I (%)

90

Primary Current

Transducer Output

Rise time (t

0

Response Time, t

): The time interval between a) when the sensor reaches 10% of its full scale value, and b) when

r

RESPONSE

t

it reaches 90% of its full scale value. The rise time to a step response is used to derive the bandwidth of the

current sensor, in which ƒ(–3 dB) = 0.35 / tr. Both tr and t

RESPONSE

are detrimentally affected by eddy current

losses observed in the conductive IC ground plane and, to varying degrees, in the ferrous fl ux concentrator

within the current sensor package.

Primary Current

Transducer Output

Rise Time, t

r

t

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

ACS754200-DS, Rev. 3

I (%)

90

10

0

7

Page 8

Current Sensor: ACS754SCB-200

Standards and Physical Specifi cations

Parameter Specifi cation

Flammability (package molding compound) UL recognized to UL 94V-0

UL60950-1:2003

Fire and Electric Shock

Creepage distance, current terminals to sensor pins 7.25 mm

Clearance distance, current terminals to sensor pins 7.25 mm

Package mass 4.63 g typical

EN60950-1:2001

CAN/CSA C22.2 No. 60950-1:2003

Step Response, IP = 0 to 200 A, no external fi lter

ACS754 Output (mV)

Excitation Signal

ACS754200-DS, Rev. 3

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

8

Page 9

Current Sensor: ACS754SCB-200

Device Branding Key (Two alternative styles are used)

ACS Allegro Current Sensor

754 Device family number

S Operating ambient temperature range code

ACS754

SCB200

YYWWA

ACS754

SCB200

L...L

YYWW

CB Package type designator

200 Maximum measurable current

YY

WW

A

ACS Allegro Current Sensor

754 Device family number

S Operating ambient temperature range code

CB Package type designator

200 Maximum measurable current

L...L

YY

WW

Manufacturing date code: Calendar year (last two digits)

Manufacturing date code: Calendar week

Manufacturing date code: Shift code

Manufacturing lot code

Manufacturing date code: Calendar year (last two digits)

Manufacturing date code: Calendar week

ACS754200-DS, Rev. 3

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

9

Page 10

Current Sensor: ACS754SCB-200

Package CB-PSF Package CB-PSS

The products described herein are manufactured under one or more of the following U.S. patents: 5,045,920; 5,264,783; 5,442,283; 5,389,889;

5,581,179; 5,517,112; 5,619,137; 5,621,319; 5,650,719; 5,686,894; 5,694,038; 5,729,130; 5,917,320; and other patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such de par tures from the detail spec i fi ca tions as may be required to

permit improvements in the per for mance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned to verify that

the information being relied upon is current.

Allegro products are not authorized for use as critical components in life-support devices or sys tems without express written approval.

The in for ma tion in clud ed herein is believed to be ac cu rate and reliable. How ev er, Allegro MicroSystems, Inc. assumes no re spon si bil i ty for its

use; nor for any in fringe ment of patents or other rights of third parties which may result from its use.

Copyright © 2004, 2005, AllegroMicrosystems, Inc.

10

115 Northeast Cutoff, Box 15036

ACS754200-DS, Rev. 3

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...