Page 1

®

ASD™

ACS402-5SB4

AC Switch Family

QUAD AC LINE SWITCH ARRAY

MAIN APPLICATIONS

AC Line switch for appliance control systems

n

Drive of low power high inductive or resistive

n

loads like:

- solenoid, relay, valve, dispenser

- micro-motor

- door lock

- low power lamp bulb

- pump

- fan

FEATURES

4 high voltage AC switch array

n

V

n

DRM/VRRM

Avalanche controlled device

n

I

n

T(RMS)

I

n

n

n

) = 0.4 A for the total array

T(RMS

Gate triggering current : IGT<10mA

Switch integrated driver

= 500V

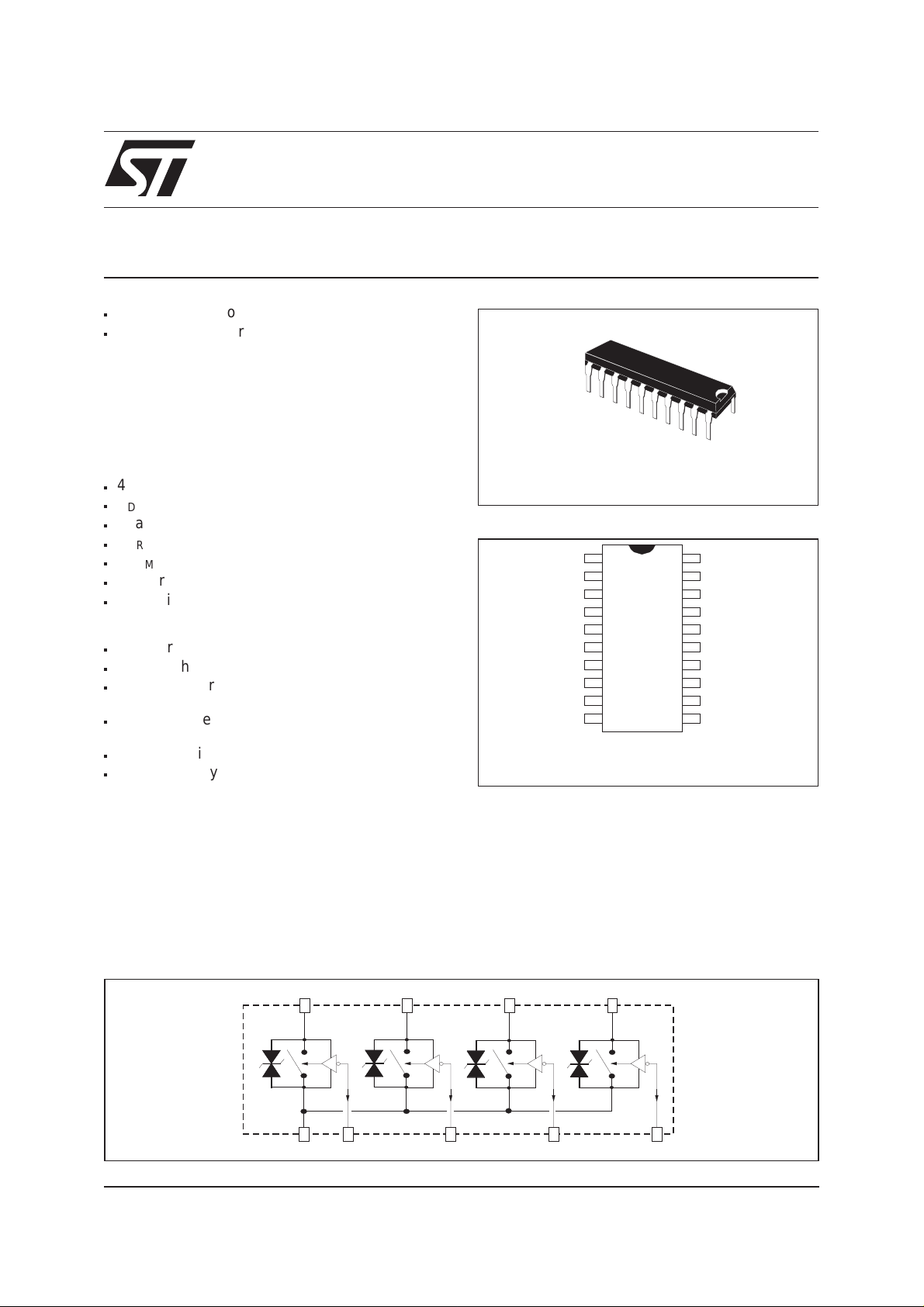

PIN OUT CONNECTION

= 0.2 A per switch

OUT1

OUT2

BENEFITS

n

Miniaturizes 4 switches in 1 package.

n

Reducestheswitchcomponentcountbyupto80%.

n

Needs no more external protection snubber &

OUT3

OUT4

varistor.

n

Enables the equipment to meet IEC1000-4-5

standard.

n

Interfaces directly with the microcontroller.

n

Eliminates any stressing gate kick back on the

note : pins 1, 3, 5, 7, 9, 12, 14, 16, 18, 20 not connected.

microcontroller.

DESCRIPTION

The ACS402belongstotheAClineswitchesarray

family built around the ASD™ concept. This high

performance planar technology device includes 4

bi-directional a.c. switches able to control an 0.2 A

resistive or inductive load.

Each ACS™ switch integrates a high voltage

clamping structure to absorb the inductive turn off

energy and a gate level shifter driver to separate

the digital controller from each main switch. It is

triggered with a negative gate current flowing out

of the gate pin.

Note:

For further technical information, please refer to the Application note AN1172

DIL20

1

G1

G2

G3

G4

COMCOM

FUNCTIONAL DIAGRAM

ACS402

D1

November 1999 - Ed: 3B

S1

Com

OUT1

ON

D2

G1 G2 G3 G4

OUT2

S2

ON

D3

OUT3

S3

ON

S4

D4

OUT4

ON

1/6

Page 2

ACS402-5SB4

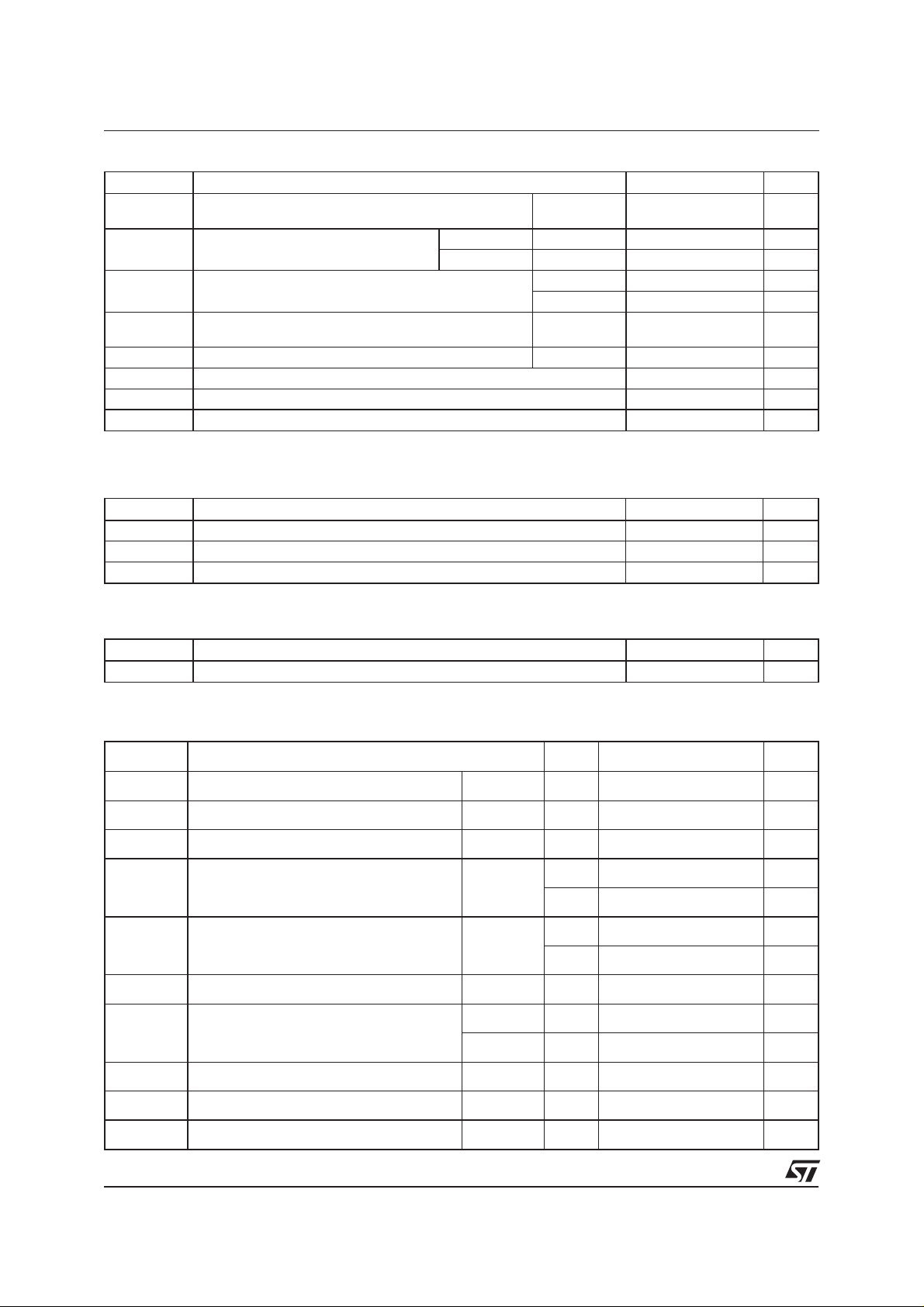

ABSOLUTE RATINGS (limiting values)

Symbol Parameter Value Unit

V

DRM

V

RRM

I

T(RMS)

I

TSM

dI/dt Critical rate of rise of on-state current

V

PP

Tstg Storage temperature range - 40 to + 150 °C

Tj Operating junction temperature range 0 to + 110 °C

Tl Maximum lead temperature for soldering during 10s 260 °C

note 1 : according to test described by IEC 1000-4-5 standard & Figure 3.

SWITCH GATE CHARACTERISTICS (maximum values)

Symbol Parameter Value Unit

P

G (AV)

I

GM

V

GM

Repetitive peak off-state voltage Tj = 25 °C 500 V

RMS on-state current full cycle sine

wave 50 to 60 Hz

Non repetitive surge peak on-state current

Tj initial = 25°C, full cycle sine wave

= 20mA with tr = 100ns

I

G

Non repetitive line peak pulse voltage

per switch Tamb = 90 °C 0.2 A

total array Tamb = 75 °C 0.4 A

F =50 Hz 5 A

F =60 Hz 5.5 A

Repetitive

20 A/µs

F =120 Hz

note 1

2kV

Average gate power dissipation 0.1 W

Peak gate current (tp = 20µs) 1 A

Peak positive gate voltage (respect to the pin COM) 5 V

THERMAL RESISTANCE

Symbol Parameter Value Unit

Rth (j-a) Junction to ambient 90 °C/W

ELECTRICAL CHARACTERISTICS PER SWITCH

For either positive or negative polarity of pin OUT1, OUT2, OUT3, OUT4 voltage respect to pin COM voltage

Symbol Test conditions Values Unit

I

V

V

V

I

DRM

I

RRM

GT

I

I

GT

GD

H

L

TM

VD= 12V (DC) RL= 140Ω Tj=25°C MAX 10 mA

VD= 12V (DC) RL= 140Ω Tj=25°C MAX 1 V

V

OUT=VDRMRL

I

= 100mA gate open Tj=25°C TYP 25 mA

OUT

= 3.3kΩ Tj=110°C MIN 0.2 V

MAX 60 mA

IG= 20mA Tj=25°C TYP 30 mA

MAX 65 mA

I

= 0.3A tp= 380µs Tj=25°C MAX 1.1 V

OUT

V

OUT=VDRM

V

OUT=VRRM

Tj=25°C MAX 2 µA

Tj=110°C MAX 50 µA

dV/dt V

(dI/dt)c (dV

V

CL

2/6

= 400V gate open Tj=110°C MIN 500 V/µs

OUT

/dt)c = 10V/µs Tj=110°C MIN 0.1 A/ms

OUT

ICL= 1mA tp = 1ms Tj=25°C TYP 600 V

Page 3

ACS402-5SB4

AC LINE SWITCH BASIC APPLICATION

The ACS402 device is well adapted to washing machine, dishwasher, tumble drier, refrigerator, water

heater and cookware. It has been designed especially to switch ON and OFF low power loads such as solenoid, valve, relay, micro-motor, pump, fan, door lock and low wattage lamp bulb.

Pin COM: Common drive reference to connect to the power line neutral

Pin G: Switch Gate input to connect to the digital controller

Pin OUT: Switch Output to connect to the load

Each ACS™ switch is triggered with a negative gate current flowing out of the gate pin G. It can be driven

directly by the digital controller through a resistor as shown on the typical application diagram. Note that no

protection device (zener or capacitors) should be added between gates and common terminals.

In appliances systems, this ACS™ switch intends to drive low power load in full cycle ON / OFF mode. The

turn off commutation characteristics of these loads can be classified in 3 groups as shown in table 1.

Thanks to its thermal and turn off commutation performances, each switch of the ACS402 is able to drive

an inductive or resistive load up to 0.2 A with no additional turn off snubber.

Table 1: Load grouping versus their turn off commutation requirement (230V AC applications).

LOAD

IRMS

(A)

POWER

(dI/dt)c

FACTOR

(A/ms)

(dV/dt)c

(V/µs)

TURN-OFF

DELAY

Door lock Lamp < 0.3 1 0.15 0.15 < 10

< 0.6 1 0.4 0.15 < 20

Relay Valve

< 0.1 > 0.7 < 0.05 < 5 < 10

Dispenser

Micro-motor

Pump Fan < 0.2 > 0.2 < 0.1 < 10 < 10

< 0.6 > 0.2 < 0.3 < 10 < 20

TYPICAL APPLICATION DIAGRAM

VALVE / DISPENSER DOOR LOCK RELAY PUMP/FAN

L

MAINS

N

OUT1

S1

OUT2

S2

OUT3

S3

M

OUT4

ACS402

S4

(ms)

D1

COM

ON

G1 G2 G3 G4

PA0

Vcc

ON

D2

PA1 PA3PA2

Vss

ST72 MCU

ON

D3

D4

ON

3/6

Page 4

ACS402-5SB4

SWITCH-OFF OPERATION

At the end of the last conduction half-cycle, the load current reaches the holding current level IH, and the

ACS™ switch turns off. Because of the inductance L of the load, the current flows through the avalanche

diode D and decreases linearly to zero. During this time, the voltage across the switch is limited to the

clamping voltage V

Theenergy stored in the inductanceof the loaddepends on theholding current I

10H); it can reach about 20 mJ and is dissipated inthe clamping section that is especiallydesigned for that

purpose.

CL

.

andthe inductance (up to

H

Fig 1: Turn-off operation of the ACS402 switch

Fig 2: ACS402 switch static characteristic.

with an electro valve: waveform of the gatecurrent

, pin OUT current I

I

G

(10 mA/div)

I

H

V

OUT

(200V/div)

I

OUT

& voltage V

OUT

.

OUT

VCL= 650V

ime (400µs/div)

T

I

OUT

I

H

V

OUT

V

CL

AC LINE TRANSIENT VOLTAGE RUGGEDNESS

Each ACS402 switch is able to sustain safely the AC line transient voltages either by clamping the low energy spikes or by breaking over under high energy shocks, even with high turn-on current rises.

The test circuit of the figure 3 isrepresentative ofthe final ACS™ application andis alsoused to stress the

ACS™ switch according to the IEC1000-4-5 standard conditions. Thanks to the load, the ACS™ switch

sustainsthe voltage spikesup to 2kV above the peak line voltage. Itwill break oversafely even onresistive

load where the turn on current rise is high as shown on figure 4. Such non repetitive test can be done 10

times on each AC line voltage polarity.

Fig 3: Overvoltage ruggedness test circuit for

resistive and inductive loads according to IEC

1000-4-5 standard.

R = 150Ω,L=5µH, V

PP

= 2kV.

RL

AC LINE &

SURGE VOLTAGE

GENERATOR

4/6

VAC+V

PP

OUT

ACSxx

S

ON

D

GCOM

G

R

= 220

Ω

Fig 4: Current and voltage of the ACS™ during

IEC 1000-4-5 standard test with a 220Ω -10µH

load & V

= 2kV.

PP

Vout (200 V/div)

Iout (2 A/div)

dI/dt = 100 A/µs

Page 5

ACS402-5SB4

Fig 5: Relative variation of gate trigger current

versus junction temperature

IGT[Tj]/IGT[Tj=25°C]

2.00

1.75

1.50

1.25

1.00

0.75

0.50

0.25

0.00

0 25 50 75 100 125

Tj(°C)

Fig 7: On state characteristics @Tj max

=0.90 V & RT=0.3 Ω (maximum values)

V

TO

Pon V I R x I

=+.. .

22

TO T RMS T T RMS

IOUT (A)

5

2

1

0.8

0.6

0.5

0.4

0.3

0.2

0.1

0.07

0.05

0.5 0.75 1 1.25 1.5 1.75 2

() ()

Π

VTM (V)

2

Fig 6: Relative variation of holding & latching

currents versus junction temperature

IH[Tj]/IH[Tj=25°C] & IL [T j]/IL [T j= 2 5 ° C ]

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0 25 50 75 100 125

Tj(°C)

Fig 8: Maximum total RMS current versus ambient

temperature on an inductive load (PF>0.1) and a

low repetitive rate (F<1Hz)

0.7

0.6

Total

Maximum

RMS current

0.5

0.4

(A)

0.3

0.2

0.1

0

0 20 40 60 80 100 120

AmbientTemperature (°C)

Fig 9: Relative variation of thermal impedance

junction to ambient versus pulse duration (epoxy

printed circuit board FR4, 35µm copper layout

thickness).

Zth(j-a)/Rth(j-a)

1E+0

1E-1

1 switch

1E-2

1E-3

1E-4 1E-3 1E-2 1E-1 1E+0 1E+1 1E+2 5E+2

4 switches

tp (s)

5/6

Page 6

ACS402-5SB4

ORDERING INFORMATION

ACS 4 02 - 5 S B 4

TM

C Switch

A

PACKAGE MECHANICAL DATA

DIL20 Plastic

a1

b

Z

20

B

e3

D

e

11

101

Number

of

Switch

I

L

I

TRMS

02 = 0.2A

F

E

V

DRM

5 = 500V

DIL

plastic

20 pins

Gate

Sensitivity

S = 10mA

DIMENSIONS

REF.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

a1 0.38 0.015

B 1.40 1.65 0.055 0.065

b 0.45 0.018

b1

b1 0.25 0.010

D 26.3 1.035

E 10.90 0.430

e 2.54 0.100

e3 22.86 0.900

F 6.6 0.260

I 4.32 0.170

L 3.3 0.130

Z 1.84 0.072

Ordering type Marking Package Weight Base qty Delivery mode

ACS402-5SB4 ACS4025 DIL20 1.4g. 19 Tube

n

Epoxy meets UL94,V0

TM: ASD and ACS are trademarks of STMicroelectronics .

Informationfurnishedisbelievedtobeaccurateandreliable.However,STMicroelectronicsassumesnoresponsibilityfortheconsequencesof

useofsuch information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 1999 STMicroelectronics - Printed in Italy - All rights reserved.

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia

Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

STMicroelectronics GROUP OF COMPANIES

http://www.st.com

6/6

Loading...

Loading...