Page 1

ACPL-332J

SHIELD

SHIELD

D

R

I

V

E

R

V

E

DESAT

V

CC2

V

OUT

V

CLAMP

V

EE

V

CC1

V

S

FAULT

ANODE

CATHODE

V

CLAMP

V

LED

6, 7

5, 8

2

3

1, 4

13

11

14

9, 12

10

16

15

DESAT

UVLO

LED1

LED2

SHIELD

SHIELD

D

R

I

V

E

R

V

E

DESAT

V

CC2

V

OUT

V

CLAMP

V

EE

V

CC1

V

S

FAULT

ANODE

CATHODE

V

CLAMP

V

LED

6, 7

5, 8

2

3

1, 4

13

11

14

9, 12

10

16

15

DESAT

UVLO

LED1

LED2

Lead (Pb) Free

RoHS 6 fully

compliant

RoHS 6 fully compliant options available;

-xxxE denotes a lead-free product

2.5 Amp Output Current IGBT Gate Driver Optocoupler

with Integrated (VCE) Desaturation Detection, UVLO

Fault Status Feedback and Active Miller Clamping

Data Sheet

Description

The ACPL-332J is an advanced 2.5 A output current,

easy-to-use, intelligent gate driver which makes IGBT

VCE fault protection compact, aordable, and easy-to

implement. Features such as integrated VCE detection,

under voltage lockout (UVLO), “soft” IGBT turn-o, isolated

open collector fault feedback and active Miller clamping

provide maximum design exibility and circuit protection.

The ACPL-332J contains a GaAsP LED. The LED is optically

coupled to an integrated circuit with a power output

stage. ACPL-332J is ideally suited for driving power IGBTs

and MOSFETs used in motor control inverter applications.

The voltage and current supplied by these optocouplers

make them ideally suited for directly driving IGBTs with

ratings up to 1200 V and 150 A. For IGBTs with higher

ratings, the ACPL-332J can be used to drive a discrete

power stage which drives the IGBT gate. The ACPL-332J

has an insulation voltage of V

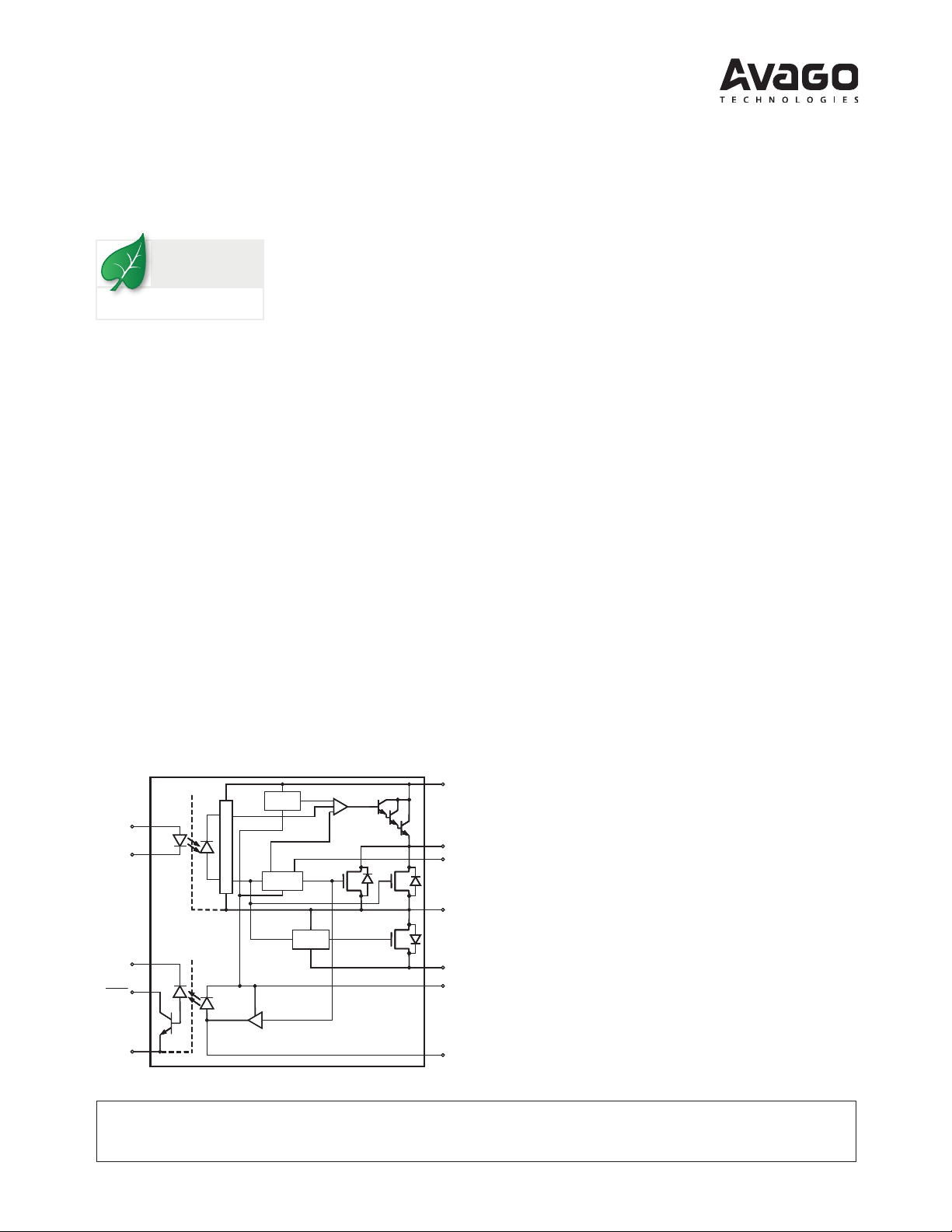

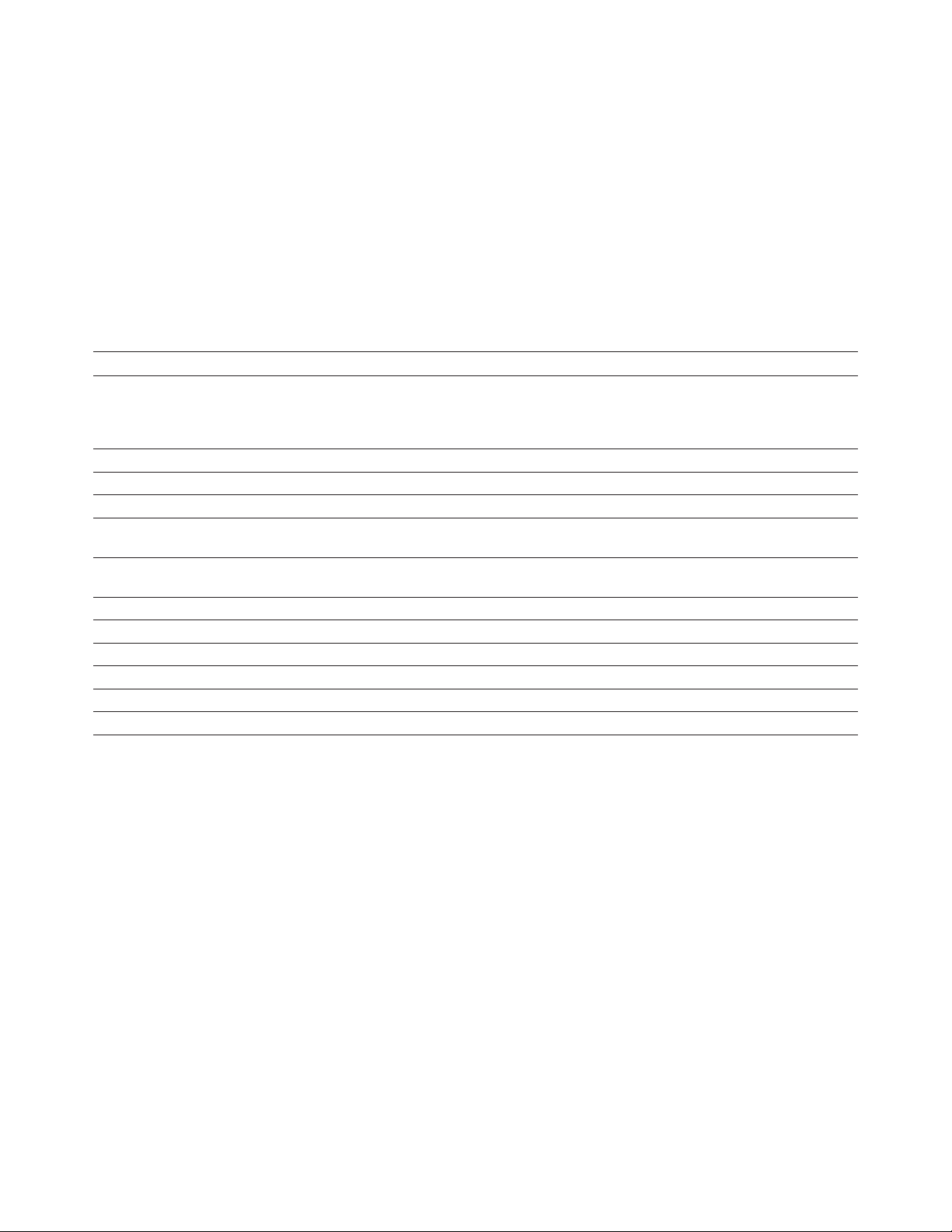

Block Diagram

Features

• Under Voltage Lock-Out Protection (UVLO) with

Hysteresis

• Desaturation Detection

• Miller Clamping

• Open Collector Isolated fault feedback

• “Soft” IGBT Turn-o

• Fault Reset by next LED turn-on (low to high) after

fault mute period

• Available in SO-16 package

• Safety approvals: UL approved, 3750 V

CSA approved, IEC/EN/DIN-EN 60747-5-2 approved

V

= 891 V

IORM

PEAK

Specications

• 2.5 A maximum peak output current

= 891 V

IORM

CAUTION: It is advised that normal static precautions be taken in handling and assembly

of this component to prevent damage and/or degradation which may be induced by ESD.

PEAK

.

• 2.0 A minimum peak output current

• 250 ns maximum propagation delay over temperature

range

• 100 ns maximum pulse width distortion (PWD)

• 15 kV/µs minimum common mode rejection (CMR) at

VCM = 1500 V

• I

< 5 mA maximum supply current

CC(max)

• Wide VCC operating range: 15 V to 30 V over

temperature range

• 1.7 A Miller Clamp. Clamp pin short to VEE if not used

• Wide operating temperature range: –40°C to 100°C

Applications

• Isolated IGBT/Power MOSFET gate drive

• AC and brushless DC motor drives

• Industrial inverters and Uninterruptible Power Supply

(UPS)

for 1 minute,

RMS

Page 2

Pin Description

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

Pin Symbol Description

1 V

2 V

S

CC1

3 FAULT Fault output. FAULT changes from a high impedance state

4 V

S

5 CATHODE Cathode

6 ANODE Anode

7 ANODE Anode

8 CATHODE Cathode

9 V

10 V

11 V

12 V

13 V

EE

CLAMP

OUT

EE

CC2

14 DESAT Desaturation voltage input. When the voltage on DESAT

15 V

16 V

LED

E

Input Ground

Positive input supply voltage. (4.5 V to 5.5 V)

to a logic low output within 5 µs of the voltage on the

DESAT pin exceeding an internal reference voltage of 7 V.

FAULT output is an open collector which allows the FAULT

outputs from all ACPL-332J in a circuit to be connected

together in a “wired OR” forming a single fault bus for interfacing directly to the micro-controller.

Input Ground

Output supply voltage.

Miller clamp

Gate drive voltage output

Output supply voltage.

Positive output supply voltage

exceeds an internal reference voltage of 6.5 V while the

IGBT is on, FAULT output is changed from a high impedance

state to a logic low state within 5 µs.

LED anode. This pin must be left unconnected for guaranteed data sheet performance. (For optical coupling testing

only)

Common (IGBT emitter) output supply voltage.

Ordering Information

ACPL-332J is UL Recognized with 3750 Vrms for 1 minute per UL1577.

Option

Part number

ACPL-332J -000E SO-16 X X 45 per tube

-500E

Package

To order, choose a part number from the part number column and combine with the desired option from the option

column to form an order entry.

Example 1:

ACPL-332J-500E to order product of SO-16 Surface Mount package in Tape and Reel packaging with IEC/EN/DIN EN

60747-5-2 Safety Approval in RoHS compliant.

Example 2:

ACPL-332J-000E to order product of SO-16 Surface Mount package in tube packaging with IEC/EN/DIN EN 60747-5-

2 Safety Approval and RoHS compliant.

Option datasheets are available. Contact your Avago sales representative or authorized distributor for information.

Remarks: The notation ‘#XXX’ is used for existing products, while (new) products launched since 15th July 2001 and

RoHS compliant option will use ‘-XXXE‘.

Surface

Mount Tape& Reel

X X X

IEC/EN/DIN EN

60747-5-2 QuantityRoHS Compliant

850 per reel

2

Page 3

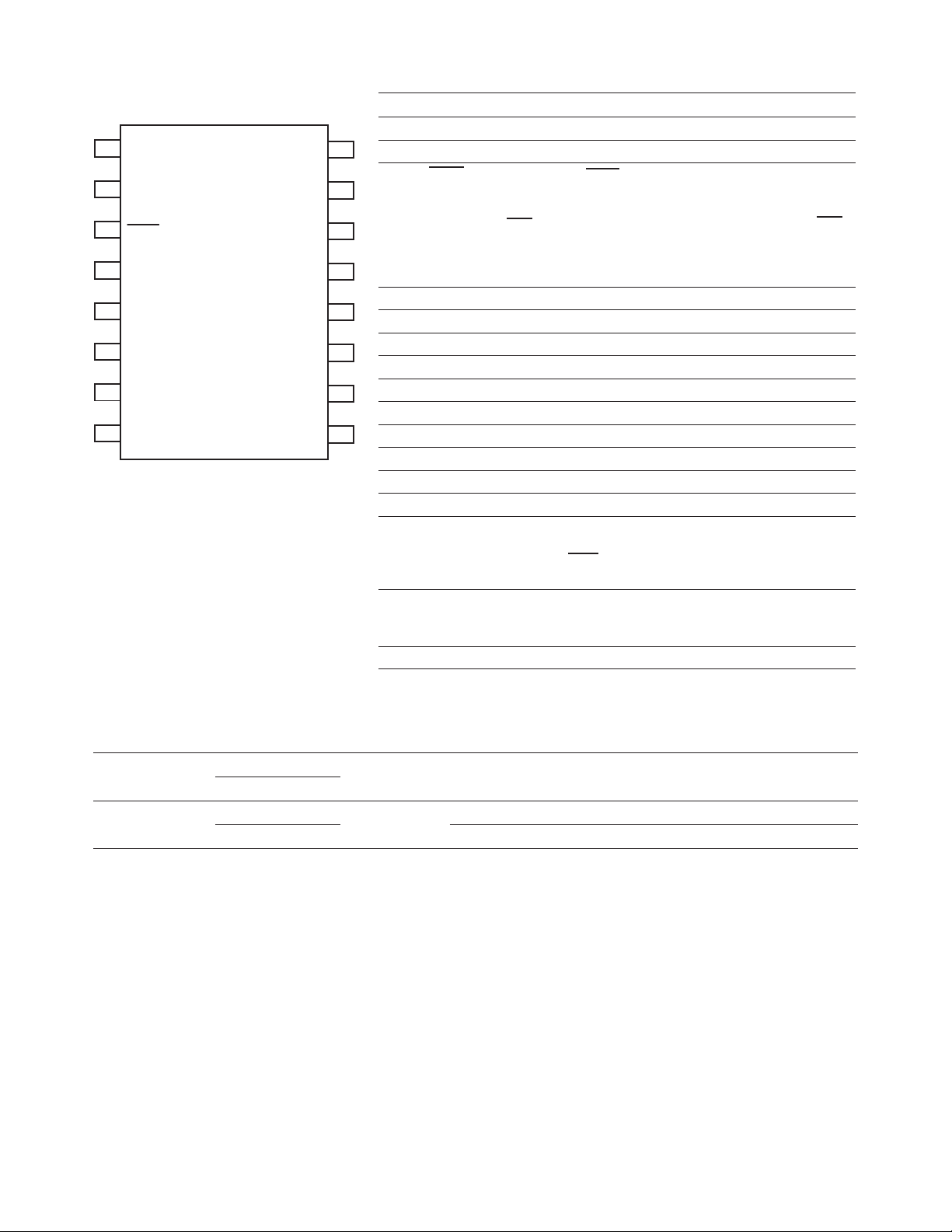

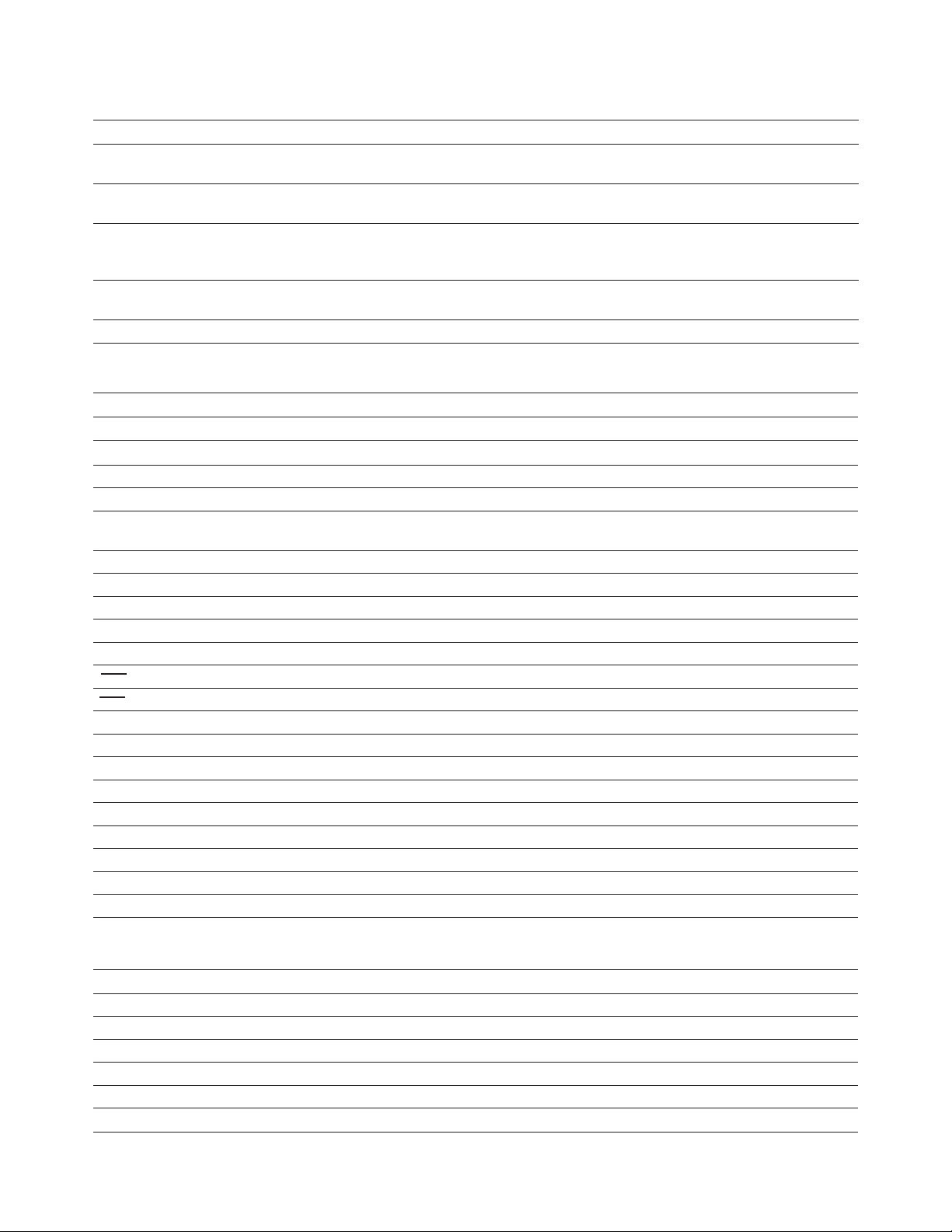

Package Outline Drawings

9

0.295 ± 0.010

(7.493 ± 0.254)

10111213141516

87654321

0.018

(0.457)

0.138 ± 0.005

(3.505 ± 0.127)

9°

0.406 ± 0.10

(10.312 ± 0.254)

0.408 ± 0.010

(10.363 ± 0.254)

0.025 MIN.

0.008 ± 0.003

(0.203 ± 0.076)

STANDOFF

0.345 ± 0.010

(8.763 ± 0.254)

0- 8 °

0.018

(0.457)

0.050

(1.270)

ALL LEADS

TO BE

COPLANAR

± 0.002

A 332J

YYWW

TYPE NUMBER

DATE CODE

0.458 (11.63)

0.085 (2.16)

0.025 (0.64)

LAND PATTERN RECOMMENDATION

ACPL-332J 16-Lead Surface Mount Package

Dimensions in inches (millimeters)

Notes: Initial and continued variation in the color of the ACPL-332J’s white mold compound is normal and does note aect device performance or

reliability.

Floating Lead Protrusion is 0.25 mm (10 mils) max.

3

Page 4

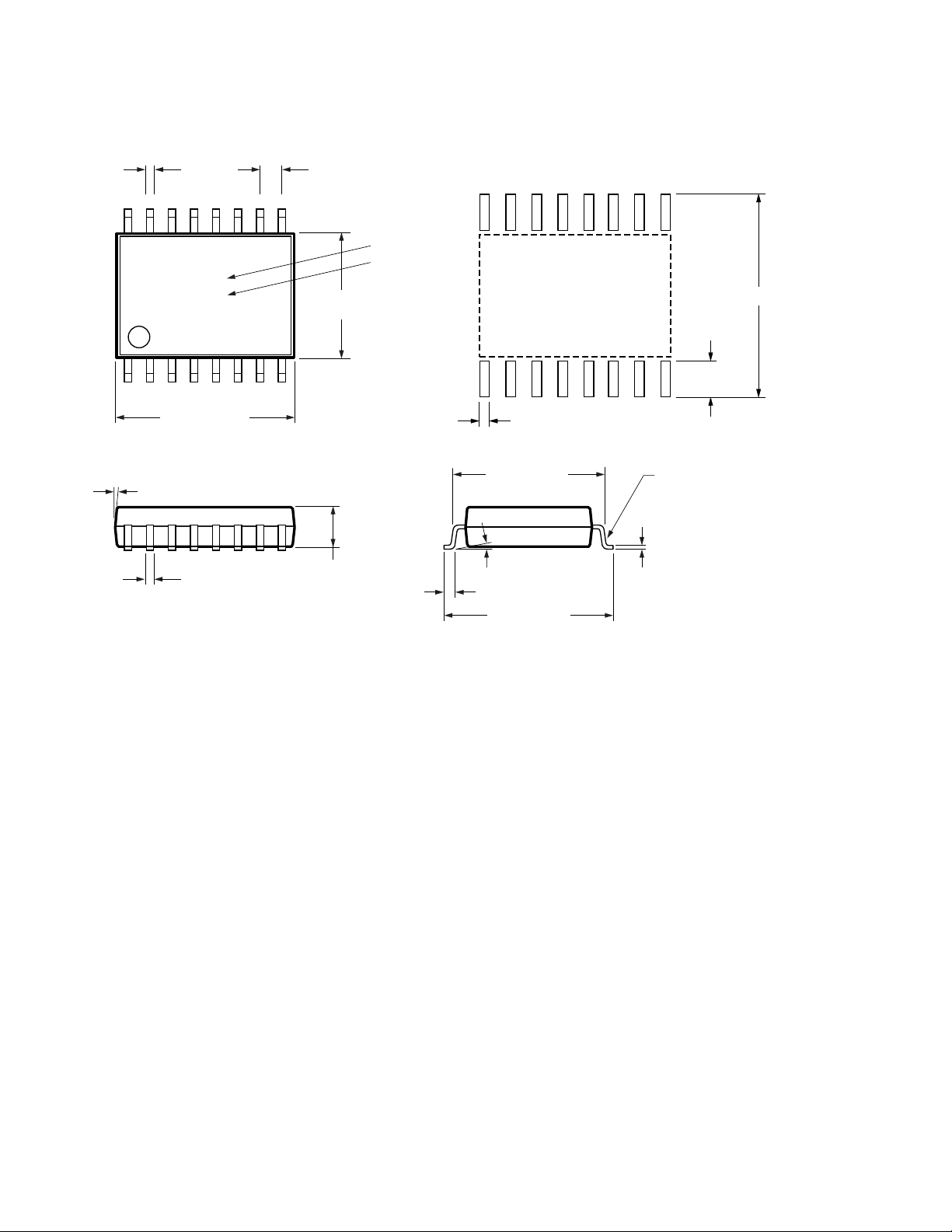

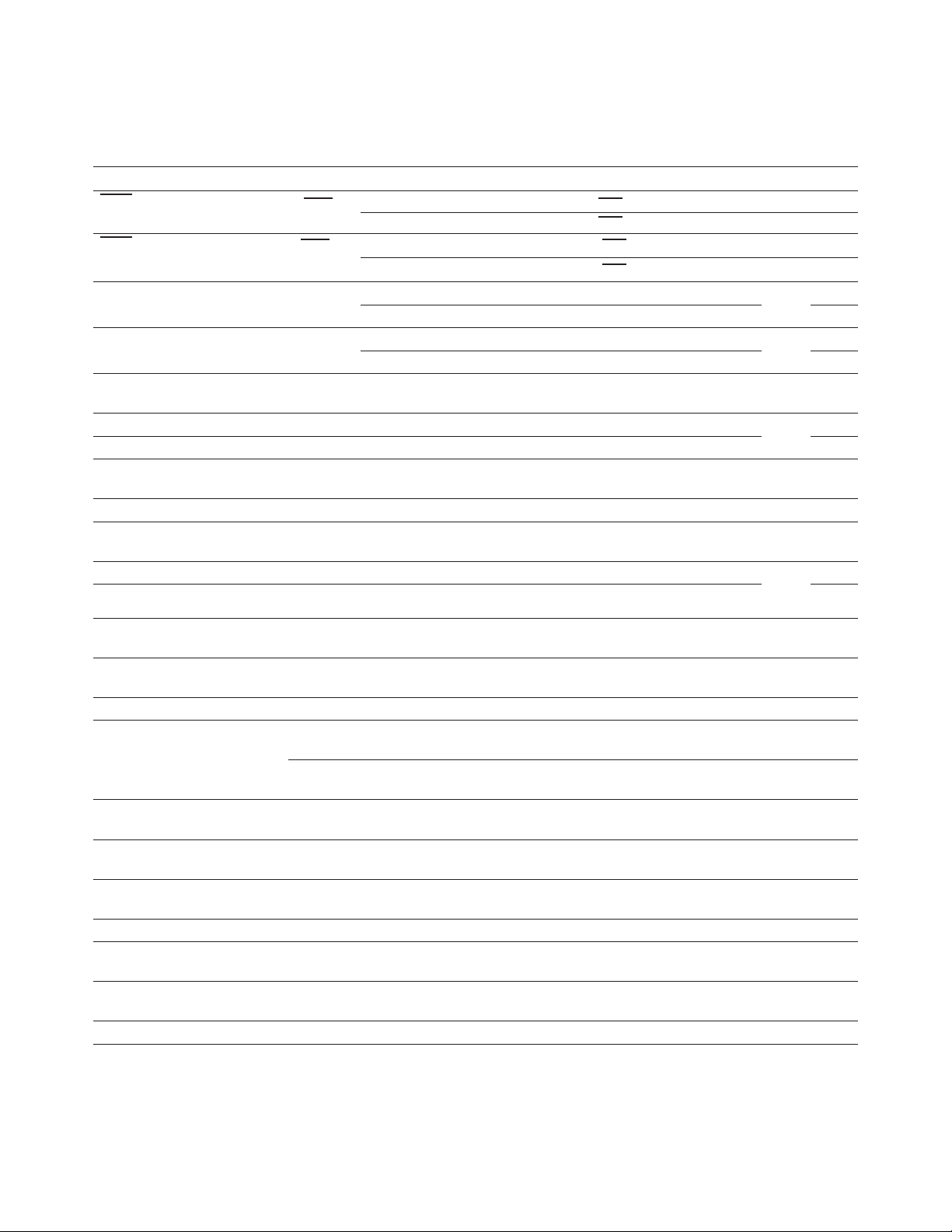

Solder Reow Thermal Prole

0

TIME (SECONDS)

TEMPERATURE ( °C)

200

100

50 150100 200 250

300

0

30

SEC.

50 SEC.

30

SEC.

160 °C

140 °C

150 °C

PEAK

TEMP.

245°C

PEAK

TEMP.

240 °C

PEAK

TEMP.

230 °C

SOLDERING

TIME

200 °C

PREHEATING TIME

150 °C, 90 + 30 SEC.

2.5 °C ± 0.5 °C/SEC.

3°C + 1 °C/ - 0.5 °C

TIGHT

TYPICAL

LOOSE

ROOM

TEMPERATURE

PREHEATING RATE 3 °C + 1 °C/ - 0.5 ° C/SEC.

REFLOW HEATING RATE 2.5°C ± 0.5°C/SEC.

217 °C

RAMP-DOWN

6 °C/SEC. MAX.

RAMP-UP

3 °C/SEC. MAX.

150 - 200 °C

260 +0/-5 °C

t 25 °C to PEAK

60 to 150 SEC.

20-40 SEC.

TIME WITHIN 5°C of ACTUAL

PEAK TEMPERATURE

t

p

t

s

PREHEAT

60 to 180 SEC.

t

L

T

L

T

smax

T

smin

25

T

p

TIME

TEMPERATURE

NO TES:

THE TIME FROM 25°C to PEAK TEMPERATURE = 8 MINUTES MAX.

T

smax

= 200 °C, T

smin

= 150 °C

Note: Non-halide ux should be used.

Recommended Pb-Free IR Prole

Note: Non-halide ux should be used.

4

Page 5

Regulatory Information

The ACPL-332J is approved by the following organizations:

IEC/EN/DIN EN 60747-5-2

Approval under:

IEC 60747-5-2 :1997 + A1:2002

EN 60747-5-2:2001 + A1:2002

DIN EN 60747-5-2 (VDE 0884 Teil 2):2003-01

UL

Approval under UL 1577, component recognition

program up to V

= 3750 V

ISO

. File E55361.

RMS

CSA

Approval under CSA Component Acceptance Notice #5,

File CA 88324.

Table 1. IEC/EN/DIN EN 60747-5-2 Insulation Characteristics*

Description Symbol Characteristic Unit

Installation classication per DIN VDE 0110/1.89, Table 1

for rated mains voltage ≤ 150 V

for rated mains voltage ≤ 300 V

for rated mains voltage ≤ 600 V

rms

rms

rms

Climatic Classication 55/100/21

Pollution Degree (DIN VDE 0110/1.89) 2

Maximum Working Insulation Voltage V

Input to Output Test Voltage, Method b**,

V

x 1.875=VPR, 100% Production Test with tm=1 sec, Partial discharge < 5 pC

IORM

Input to Output Test Voltage, Method a**,

V

x 1.5=VPR, Type and Sample Test, tm=60 sec, Partial discharge < 5 pC

IORM

Highest Allowable Overvoltage (Transient Overvoltage t

= 10 sec) V

ini

V

V

IORM

PR

PR

IOTM

Safety-limiting values – maximum values allowed in the event of a failure.

Case Temperature T

Input Current I

Output Power P

Insulation Resistance at TS, VIO = 500 V R

S

S, INPUT

S, OUTPUT

S

I – IV

I – IV

I – III

891 V

1670 V

1336 V

6000 V

175

400 mA

1200 mW

9

>10

peak

peak

peak

peak

°C

W

* Isolation characteristics are guaranteed only within the safety maximum ratings which must be ensured by protective circuits in application.

Surface mount classication is class A in accordance with CECCOO802.

** Refer to the optocoupler section of the Isolation and Control Components Designer’s Catalog, under Product Safety Regulations section IEC/EN/

DIN EN 60747-5-2, for a detailed description of Method a and Method b partial discharge test proles.

Dependence of Safety Limiting Values on Temperature. (take from DS AV01-0579EN Pg.7)

5

Page 6

Table 2. Insulation and Safety Related Specications

Parameter Symbol ACPL-332J Units Conditions

Minimum External Air Gap

(Clearance)

Minimum External Tracking

(Creepage)

Minimum Internal Plastic Gap

(Internal Clearance)

Tracking Resistance

(Comparative Tracking Index)

Isolation Group IIIa Material Group (DIN VDE 0110, 1/89, Table 1)

L(101) 8.3 Mm Measured from input terminals to output terminals,

shortest distance through air.

L(102) 8.3 Mm Measured from input terminals to output terminals,

shortest distance path along body.

0.5 Mm Through insulation distance conductor to conductor,

usually the straight line distance thickness between

the emitter and detector.

CTI >175 V DIN IEC 112/VDE 0303 Part 1

Table 3. Absolute Maximum Ratings

Parameter Symbol Min. Max. Units Note

Storage Temperature T

Operating Temperature T

Output IC Junction Temperature T

Average Input Current I

Peak Transient Input Current,

S

A

J

F(AVG)

I

F(TRAN)

(<1 µs pulse width, 300pps)

Reverse Input Voltage V

“High” Peak Output Current I

“Low” Peak Output Current I

Positive Input Supply Voltage V

FAULT Output Current I

FAULT Pin Voltage V

Total Output Supply Voltage (V

R

OH(PEAK)

OL(PEAK)

CC1

FAULT

FAULT

- VEE) -0.5 33 V

CC2

Negative Output Supply Voltage (VE - VEE) -0.5 15 V 6

Positive Output Supply Voltage (V

Gate Drive Output Voltage V

Peak Clamping Sinking Current I

Miller Clamping Pin Voltage V

DESAT Voltage V

Output IC Power Dissipation P

Input IC Power Dissipation P

- VE) -0.5 33 - (VE - VEE) V

CC2

O(PEAK)

Clamp

Clamp

DESAT

O

I

Solder Reow Temperature Prole See Package Outline Drawings section

-55 125 °C

-40 100 °C 2

125 °C 2

25 mA 1

1.0 A

5 V

2.5 A 3

2.5 A 3

-0.5 5.5 V

8.0 mA

-0.5 V

-0.5 V

CC1

CC2

V

V

1.7 A

-0.5 V

V

E

CC2

VE + 10 V

V

600 mW 2

150 mW 2

Table 4. Recommended Operating Conditions

Parameter Symbol Min. Max. Units Note

Operating Temperature T

Total Output Supply Voltage (V

A

- VEE) 15 30 V 7

CC2

Negative Output Supply Voltage (VE - VEE) 0 15 V 4

Positive Output Supply Voltage (V

Input Current (ON) I

Input Voltage (OFF) V

- VE) 15 30 - (VE - VEE) V

CC2

F(ON)

F(OFF)

6

- 40 100 °C 2

8 12 mA

- 3.6 0.8 V

Page 7

Table 5. Electrical Specications (DC)

Unless otherwise noted, all typical values at TA = 25°C, V

- VEE = 30 V, VE - VEE = 0 V;

CC2

all Minimum/Maximum specications are at Recommended Operating Conditions. Positive Supply Voltage used.

Parameter Symbol Min. Typ. Max. Units Test Conditions Fig. Note

FAULT Logic Low Output

Voltage

FAULT Logic High Output

Current

High Level

Output Current

Low Level

Output Current

Low Level Output Current

During Fault Condition

High Level Output Voltage V

Low Level Output Voltage V

Clamp Pin Threshold Voltage V

Clamp Low Level

Sinking Current

High Level Supply Current I

Low Level Supply Current I

Blanking Capacitor

Charging Current

Blanking Capacitor

Discharge Current

DESAT Threshold V

UVLO Threshold V

UVLO Hysteresis (V

Threshold Input Current

Low to High

Threshold Input Voltage

High to Low

Input Forward Voltage V

Temperature Coecient

of Input Forward Voltage

Input Reverse Breakdown

Voltage

Input Capacitance C

V

FAULTL

I

FAULTH

I

OH

I

OL

I

OLF

OH

OL

tClamp

I

CL

CC2H

CC2L

I

CHG

I

DSCHG

DESAT

UVLO+

V

UVLO-

UVLO+

- V

UVLO-

I

FLH

V

FHL

F

DVF/DT

BV

R

IN

0.1 V I

0.1 V I

0.003 µA V

0.003 µA V

-0.5 -1.5 A VO = V

-2.0 A VO = V

FAULT

FAULT

FAULT

FAULT

= 1.1 mA, V

= 1.1 mA, V

= 5.5 V, V

= 3.3 V, V

- 4 2, 4, 215

CC2

– 15 3

CC2

CC1

CC1

CC1

CC1

= 5.5V

= 3.3V

= 5.5V

= 3.3V

0.5 1.5 A VO = VEE + 2.5 3, 5, 225

2.0 A VO = VEE + 15 3

90 140 230 mA V

- VEE = 14 V 6

OUT

VCC-3.5 VCC-2.5 V IO = 100 mA 4, 6, 237, 8, 9

VCC-2.9 VCC-2.0 V IO = -650 µA 23

0.17 0.5 V IO = 100 mA 5, 7,

24

2.0 V

0.35 1.1 A VO = VEE + 2.5 8

2.5 5 mA IO = 0 mA 9, 10,

2.5 5 mA IO = 0 mA

-0.13 -0.24 -0.33 mA V

10 30 mA V

6 6.5 7.5 V V

= 2 V 11, 27 9, 10

DESAT

= 7.0 V 28

DESAT

-VE >V

CC2

UVLO-

25,

26

12 9

10.5 11.6 12.5 V VO > 5 V 7, 9,

9.2 10.3 11.1 V VO < 5 V 7, 9,

0.4 1.3 V

)

2.0 8 mA IO = 0 mA, VO > 5 V

0.8 V

1.2 1.6 1.95 V IF = 10 mA

A

5 V

-1.3 mV/°C

IR = 10 mA

70 pF f = 1 MHz, VF = 0 V

9

11

12

7

Page 8

Table 6. Switching Specications (AC)

Unless otherwise noted, all typical values at TA = 25°C, V

- VEE = 30 V, VE - VEE = 0 V;

CC2

all Minimum/Maximum specications are at Recommended Operating Conditions. Only Positive Supply Voltage used.

Parameter Symbol Min. Typ. Max. Units Test Conditions Fig. Note

Propagation Delay Time

to High Output Level

Propagation Delay Time

to Low Output Level

Pulse Width Distortion PWD -100 20 100 ns 14, 17

Propagation Delay

Dierence Between

Any Two Parts or Channels

Rise Time t

Fall Time t

DESAT Sense to

90%VO Delay

DESAT Sense to

10% VO Delay

DESAT Sense to Low Level

FAULT Signal Delay

DESAT Sense to DESAT

Low Propagation Delay

DESAT Input Mute t

RESET to High Level FAULT

Signal Delay

Output High Level Common

Mode Transient Immunity

Output Low Level Common

Mode Transient Immunity

t

PLH

100 180 250 ns

Rg = 10 W,

Cg = 10 nF,

f = 10 kHz,

t

(t

PHL

PHL

- t

100 180 250 ns 1, 13,

)

-350 350 ns 17, 16

PLH

Duty Cycle = 50%,

IF = 10 mA,

V

= 30 V

CC2

PDD

R

F

t

DESAT(90%)

t

DESAT(10%)

t

DESAT(FAULT)

50 ns

50 ns

0.15 0.5 µs

2 3 µs

0.25 0.5 µs

C

= 100pF, Rg = 10 W,

DESAT

Cg = 10 nF, V

C

DESAT

Cg = 10 nF, V

C

DESAT

CC2

= 100pF, Rg = 10 W,

CC2

= 100pF, RF = 2.1 kW,

= 30 V

= 30 V

Rg = 10 W, Cg = 10 nF,

V

= 30 V

CC2

t

DESAT(LOW)

0.25 µs

C

= 100pF, RF = 2.1 kW,

DESAT

Rg = 10 W, Cg = 10 nF,

V

= 30 V

CC2

DESAT(MUTE)

t

RESET(FAULT )

5 µs 37 20

0.3 1 2.0 µs

C

= 100pF, RF = 2.1 kW,

DESAT

Rg = 10 W, Cg = 10 nF,

V

0.8 1.5 2.5 µs

= 5.5V, V

CC1

C

= 100pF, RF = 2.1 kW,

DESAT

CC2

= 30 V

Rg = 10 W, Cg = 10 nF,

V

= 3.3V, V

CC1

CC2

= 30 V

|CMH| 15 25 kV/µs TA = 25°C, IF = 10 mA

VCM = 1500 V, V

CC2

= 30 V

|CML| 15 25 kV/µs TA = 25°C, VF = 0 V

VCM = 1500 V, V

CC2

= 30 V

1, 13,

13, 15

14, 15,

16, 29

14, 15,

16, 29

17, 30, 3719

18, 19,

20, 30,

37

30, 37 18

30, 37 19

31, 32,

21

33, 34

31, 32,

22

33, 34

8

Page 9

Table 7. Package Characteristics

Parameter Symbol Min. Typ. Max. Units Test Conditions Fig. Note

Input-Output Momentary

Withstand Voltage

Input-Output Resistance R

Input-Output Capacitance C

Output IC-to-Pins 9 &10

Thermal Resistance

Notes:

1. Derate linearly above 70°C free air temperature at a rate of 0.3 mA/°C.

2. In order to achieve the absolute maximum power dissipation specied, pins 4, 9, and 10 require ground plane connections and may require

airow. See the Thermal Model section in the application notes at the end of this data sheet for details on how to estimate junction temperature

and power dissipation. In most cases the absolute maximum output IC junction temperature is the limiting factor. The actual power dissipation

achievable will depend on the application environment (PCB Layout, air ow, part placement, etc.). See the Recommended PCB Layout section

in the application notes for layout considerations. Output IC power dissipation is derated linearly at 10 mW/°C above 90°C. Input IC power

dissipation does not require derating.

3. Maximum pulse width = 10 µs. This value is intended to allow for component tolerances for designs with IO peak minimum = 2.0 A. Derate

linearly from 3.0 A at +25°C to 2.5 A at +100°C. This compensates for increased I

4. This supply is optional. Required only when negative gate drive is implemented.

5. Maximum pulse width = 50 µs.

6. See the Slow IGBT Gate Discharge During Fault Condition section in the applications notes at the end of this data sheet for further details.

7. 15 V is the recommended minimum operating positive supply voltage (V

threshold of 12.5V. For High Level Output Voltage testing, VOH is measured with a dc load current. When driving capacitive loads, VOH will

approach VCC as IOH approaches zero units.

8. Maximum pulse width = 1.0 ms.

9. Once VO of the ACPL-332J is allowed to go high (V

IGBT protection. UVLO is needed to ensure DESAT is functional. Once V

DESAT detection and UVLO features of the ACPL-332J work in conjunction to ensure constant IGBT protection.

10. See the DESAT fault detection blanking time section in the applications notes at the end of this data sheet for further details.

11. This is the “increasing” (i.e. turn-on or “positive going” direction) of V

12. This is the “decreasing” (i.e. turn-o or “negative going” direction) of V

13. This load condition approximates the gate load of a 1200 V/150A IGBT.

14. Pulse Width Distortion (PWD) is dened as |t

15. As measured from IF to VO.

16. The dierence between t

17. As measured from ANODE, CATHODE of LED to V

18. This is the amount of time from when the DESAT threshold is exceeded, until the FAULT output goes low.

19. This is the amount of time the DESAT threshold must be exceeded before V

voltage dependent.

20. Auto Reset: This is the amount of time when V

Reset) topic in the application information section.

21. Common mode transient immunity in the high state is the maximum tolerable dVCM/dt of the common mode pulse, VCM, to assure that the

output will remain in the high state (i.e., VO > 15 V or FAULT > 2 V). A 100 pF and a 2.1 kΩ pull-up resistor is needed in fault detection mode.

22. Common mode transient immunity in the low state is the maximum tolerable dVCM/dt of the common mode pulse, VCM, to assure that the

output will remain in a low state (i.e., VO < 1.0 V or FAULT < 0.8 V).

23. To clamp the output voltage at VCC - 3 VBE, a pull-down resistor between the output and VEE is recommended to sink a static current of 650 µA

while the output is high. See the Output Pull-Down Resistor section in the application notes at the end of this data sheet if an output pull-down

resistor is not used.

PHL

and t

V

ISO

3750 V

rms

RH < 50%, t = 1 min.,

TA = 25°C

9

I-O

I-O

q

09-10

CC2

- t

PHL

PLH

between any two ACPL-332J parts under the same test conditions.

PLH

OUT

will be asserted low after DESAT threshold is exceeded. See the Description of Operation (Auto

OUT

> 10

1.3 pF freq=1 MHz

30 °C/W TA = 25°C

- VE > V

| for any given unit.

), the DESAT detection feature of the ACPL-332J will be the primary source of

UVLO

UVLO+

- V

CC2

CC2

W

OPEAK

- VE) to ensure adequate margin in excess of the maximum V

CC2

> 12.5 V, DESAT will remain functional until V

E

- V

E

begins to go low, and the FAULT output to go low. This is supply

OUT

V

I-O

due to changes in VOL over temperature.

= 500 V 7

< 9.2 V. Thus, the

UVLO-

6, 7

UVLO+

9

Page 10

1.0

1.5

2.0

2.5

3.0

-40 -20 0 20 40 60 80 100

TA- TEMPERATURE -oC

I

OH

- OUTPUT HIGH CURRENT - A

0

1

2

3

4

5

-40 -20 0 20 40 60 80 100

TA- TEMPERATURE -oC

I

OL

- OUTPUT LOW CURRENT

-----V

OUT=VEE

+15V

___V

OUT=VEE

+2.5V

-3

-2.5

-2

-1.5

-1

-0.5

0

-40 -20 0 20 40 60 80 100

TA- TEMPERATURE -oC

(V

OH

- V

CC

) - HIGH OUTPUT VOLTAGE DROP - V

------I

OUT

= -100mA

____I

OUT

= -650uA

0

0.05

0.1

0.15

0.2

0.25

-40 -20 0 20 40 60 80 100

TA- TEMPERATURE -oC

V

OL

- OUTPUT LOW VOLTAGE - V

Figure 1. VOUT propagation delay waveforms

I

F

V

OUT

t

PHL

t

PLH

t

f

t

r

10%

50%

90%

Figure 2. IOH vs. temperature Figure 3. IOL vs. temperature

Figure 4. VOH vs. temperature Figure 5. VOL vs. temperature

10

Page 11

0

1

2

3

4

-40 -20 0 20 40 60 80 100

TA-TEMPERATURE-oC

I

CL

- CLAMP LOW LEVEN SINKING CURRENT

15 20 25 30

2.25

2.35

2.45

2.55

2.65

V

CC2

- OUTPUR SUPPLY VOLTAGE - V

I

CC2

- OUTPUT SUPPLY CURRENT - mA

---------I

Cc 2H

_

________

I

CC2L

2.00

2.25

2.50

2.75

3.00

3.25

3.50

-40 -20 0 20 40 60 80 100

TA - TEMPERATURE - oC

I

CC2

- OUTPUT SUPPLY CURRENT - mA

----- ----I

CC2 H

_

________

I

CC2L

-0.35

-0.30

-0.25

-0.20

-40 -20 0 20 40 60 80 100

TA- TEMPERATURE -oC

I

CH

- BLANKING CAPACITOR

CHARGING CURRENT - mA

28.0

28.5

29.0

29.5

30.0

0 0.2 0.4 0.6 0.8 1

IOH - OUTPUT HIGH CURRENT - A

V

OH

- HIGH OUTPUT VOLTAGE DROP - V

_ _ _ _ 100oC

______ 25oC

--------- -40oC

Figure 6. VOH vs. I

0

1

2

3

4

5

6

7

8

0 0.5 1 1.5 2 2.5

IoL - OUTPUT LOW CURRENT - A

V

OL

- LOW OUTPUT VOLTAGE DROP - V

_ _ _ _ 100oC

______ 25oC

--------- -40oC

OH

Figure 7. VOL vs. I

OL

Figure 8. ICL vs. temperature

Figure 10. I

11

vs. V

CC2

CC2

Figure 9. I

Figure 11. I

vs. temperature

CC2

vs. temperature

CHG

Page 12

100

150

200

250

300

15 20 25 30

Vcc - SUPPLY VOLTAGE - V

T

P

- PROPAGATION DELAY - ns

----------t

PLH

_______t

PHL

100

150

200

250

300

0 10 20 30 40 50

LOAD RESISTANCE - ohm

T

P

- PROPAGATION DELAY - ms

----------t

PLH

_______t

PHL

0

100

200

300

0 10 20 30 40 50

LOAD CAPACITANCE - nF

----------t

PLH

_______t

PHL

T

P

- PROPAGATION DELAY - ms

Figure 12. DESAT threshold vs. temperature

6.0

6.5

7.0

7.5

-40 -20 0 20 40 60 80 100

TA- TEMPERATURE -oC

V

DESAT

- DESAT THRESHOLD - V

100

150

200

250

300

-40 -20 0 20 40 60 80 100

TA- TEMPERATURE -oC

T

P

- PROPAGATION DELAY - ns

----------t

PLH

_______t

PHL

Figure 13. Propagation delay vs. temperature

Figure 14. Propagation delay vs. supply voltage

Figure 16. Propagation delay vs. load capacitance

12

Figure 15. Propagation delay vs. load resistance

Page 13

1.0

1.5

2.0

2.5

3.0

-40 -20 0 20 40 60 80 100

TA- TEMPERATURE -oC

T

DESAT

- DESAT Sense to 10% Vo Delay - us

-------V

cc2

=15V

_____V

cc2

=30V

0.0

1.0

2.0

3.0

4.0

10 20 30 40 50

LOAD RESISTANCE - ohm

-------V

cc2

=15V

_____V

cc2

=30V

T

DESAT10%

- DESAT Sense to 10% Vo Delay - us

0.000

0.004

0.008

0.012

0 10 20 30 40 50

LOAD CAPACITANCE - nF

-------V

cc2

=15V

_____V

cc2

=30V

T

DESAT10%

- DESAT Sense to 10% Vo Delay - ms

100

150

200

250

300

-40 -20 0 20 40 60 80 100

TA- TEMPERATURE -oC

T

DESAT90%

- DESAT Sense to 90% Vo Delay - ns

Figure 17. DESAT sense to 90% VOUT delay vs. temperature

Figure 18. DESAT sense to 10% VOUT delay vs. temperature

Figure 19. DESAT sense to 10% VOUT delay vs. load resistance

13

Figure 20. DESAT sense to 10% VOUT delay vs. load capacitance

Page 14

Figure 21. IOH Pulsed test circuit

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

10mA

+

_

0.1µF

0.1µF

15V Pulsed

I

OUT

30V

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

10mA

+

_

0.1µF0.1µF

0.1µF0.1µF

15V Pulsed

I

OUT

30V

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

+

_

0.1µF

0.1µF

15V Pulsed

I

OUT

30V

+

_

0.1µF

0.1µF

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF

0.1µF

100mA

V

OUT

30V

10mA

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF0.1µF

0.1µF0.1µF

100mA

V

OUT

30V

10mA10mA

Figure 22. IOL Pulsed test circuit

Figure 23. VOH Pulsed test circuit

14

Page 15

Figure 24. VOL Pulsed test circuit

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF

0.1µF

100mA

V

OUT

30V

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF0.1µF

0.1µF0.1µF

100mA

V

OUT

30V

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF

0.1µF

I

CC2

30V

10mA

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF0.1µF

0.1µF0.1µF

I

CC2

30V

10mA10mA

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF

0.1µF

30V

I

CC2

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF0.1µF

0.1µF0.1µF

30V

I

CC2

Figure 25. I

Figure 26. I

15

CC2H

CC2L

test circuit

test circuit

Page 16

Figure 27. I

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF

0.1µF

I

CHG

30V

10mA

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF

0.1µF

I

CHG

30V

10mA10mA

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF

0.1µF

7V

30V

+

_

IDSCHG

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF

0.1µF

7V

30V

+

_

IDSCHG

10nF

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF

0.1µF

V

OUT

30V

10Ω

10mA, 10kHz,

50% Duty Cycle

10nF10nF

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

0.1µF0.1µF

V

OUT

30V

10mA, 10kHz,

50% Duty Cycle

Pulsed test circuit

CHG

Figure 28. I

Figure 29. t

16

DSCHG

, t

PLH

test circuit

, tf, tr, test circuit

PHL

Page 17

V

CM

10

10nF

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

0.1µF

SCOPE

30V

430Ω

2.1kΩ

0.1µF

15pF

5V

V

CM

10Ω

10nF10nF

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

0.1µF0.1µF

SCOPE

30V

0.1µF0.1µF

15pF15pF

5V5V

V

CM

10Ω

10nF

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

0.1µF

SCOPE

30V

430Ω

2.1kΩ

0.1µF

15pF

5V

V

CM

10nF10nF

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

0.1µF0.1µF

SCOPE

30V

0.1µF0.1µF

15pF15pF

5V5V

Figure 30. t

10nF

+

_

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

5V

0.1µF

0.1µF

V

OUT

30V

10Ω

V

IN

2.1kΩ

V

FAULT

10mA

10nF

+

_

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

5V

0.1µF0.1µF

0.1µF0.1µF

V

OUT

30V

V

IN

V

FAULT

10mA10mA

fault test circuit

DESAT

Figure 31. CMR Test circuit LED2 o

Figure 32. CMR Test Circuit LED2 on

17

Page 18

10

10nF

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

0.1µF

SCOPE

30V

V

CM

430Ω

2.1kΩ

0.1µF

15pF

5V

1010Ω

10nF10nF

0.1µF0.1µF

SCOPE

30V

V

CM

10

10nF

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

0.1µF

SCOPE

30V

430

2.1k

0.1µF

15pF

5V

SCOPE

2.1kΩ

0.1µF

15pF

5V

Ω

Ω

Figure 33. CMR Test circuit LED1 o

Figure 34. CMR Test Circuit LED1 on

18

Page 19

SHIELD

SHIELD

D

R

I

V

E

R

V

E

DESAT

V

CC2

V

OUT

V

CLAMP

V

EE

V

CC1

V

S

FAULT

ANODE

CATHODE

V

CLAMP

V

LED

6, 7

5, 8

2

3

1, 4

13

11

14

9, 12

10

16

15

DESAT

UVLO

LED1

LED2

SHIELD

SHIELD

D

R

I

V

E

R

V

E

DESAT

V

CC2

V

OUT

V

CLAMP

V

EE

V

CC1

V

S

FAULT

ANODE

CATHODE

V

CLAMP

V

LED

6, 7

5, 8

2

3

1, 4

13

11

14

9, 12

10

16

15

DESAT

UVLO

LED1

LED2

Application Information

Product Overview Description

The ACPL-332J is a highly integrated power control device

that incorporates all the necessary components for a

complete, isolated IGBT / MOSFET gate drive circuit with

fault protection and feedback into one SO-16 package.

Active Miller clamp function eliminates the need of

negative gate drive in most application and allows the

use of simple bootstrap supply for high side driver. An

optically isolated power output stage drives IGBTs with

power ratings of up to 150 A and 1200 V. A high speed

internal optical link minimizes the propagation delays

between the microcontroller and the IGBT while allowing

the two systems to operate at very large common mode

voltage dierences that are common in industrial motor

drives and other power switching applications. An output

IC provides local protection for the IGBT to prevent

damage during over current, and a second optical link

provides a fully isolated fault status feedback signal for

the microcontroller. A built in “watchdog” circuit, UVLO

monitors the power stage supply voltage to prevent IGBT

caused by insucient gate drive voltages. This integrated

IGBT gate driver is designed to increase the performance

and reliability of a motor drive without the cost, size, and

complexity of a discrete design.

Two light emitting diodes and two integrated circuits

housed in the same SO-16 package provide the input

control circuitry, the output power stage, and two optical

channels. The output Detector IC is designed manufactured on a high voltage BiCMOS/Power DMOS process.

The forward optical signal path, as indicated by LED1,

transmits the gate control signal. The return optical signal

path, as indicated by LED2, transmits the fault status

feedback signal.

Under normal operation, the LED1 directly controls the

IGBT gate through the isolated output detector IC, and

LED2 remains o. When an IGBT fault is detected, the

output detector IC immediately begins a “soft” shutdown

sequence, reducing the IGBT current to zero in a controlled manner to avoid potential IGBT damage from

inductive over voltages. Simultaneously, this fault status

is transmitted back to the input via LED2, where the fault

latch disables the gate control input and the active low

fault output alerts the microcontroller.

During power-up, the Under Voltage Lockout (UVLO)

feature prevents the application of insucient gate

voltage to the IGBT, by forcing the ACPL-332J’s output

low. Once the output is in the high state, the DESAT (VCE)

detection feature of the ACPL-332J provides IGBT protection. Thus, UVLO and DESAT work in conjunction to

provide constant IGBT protection.

19

Figure 35. Block Diagram of ACPL-332J

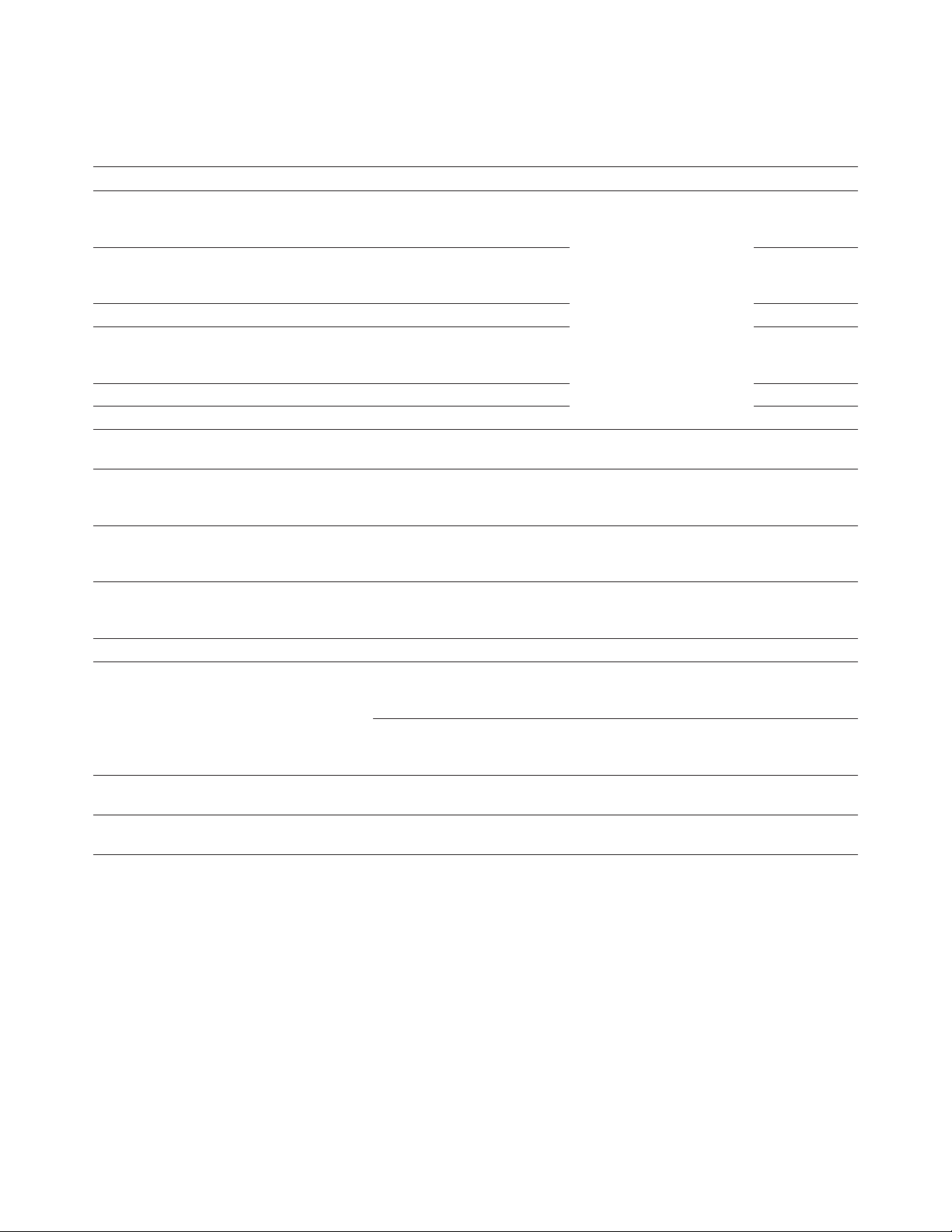

Recommended Application Circuit

The ACPL-332J has an LED input gate control, and an

open collector fault output suitable for wired ‘OR’ applications. The recommended application circuit shown

in Figure 36 illustrates a typical gate drive implementation using the ACPL-332J. The following describes about

driving IGBT. However, it is also applicable to MOSFET.

Depending upon the MOSFET or IGBT gate threshold requirements, designers may want to adjust the VCC supply

voltage (Recommended VCC = 17.5V for IGBT and 12.5V

for MOSFET).

The two supply bypass capacitors (0.1 µF) provide the

large transient currents necessary during a switching

transition. Because of the transient nature of the charging

currents, a low current (5mA) power supply suces. The

desaturation diode D

trr below 75ns (e.g. ERA34-10) and capacitor C

necessary external components for the fault detection

circuitry. The gate resistor RG serves to limit gate charge

current and controls the IGBT collector voltage rise

and fall times. The open collector fault output has a

passive pull-up resistor RF (2.1 kW) and a 330 pF ltering

capacitor, CF. A 47 kW pull down resistor R

V

provides a predictable high level output voltage

OUT

(VOH). In this application, the IGBT gate driver will shut

down when a fault is detected and fault reset by next

cycle of IGBT turn on. Application notes are mentioned at

the end of this datasheet.

600V/1200V fast recovery type,

DESAT

PULL-DOWN

BLANK

are

on

Page 20

Figure 36. Recommended application circuit (Single Supply) with desaturation detection and active Miller Clamp

+

_

+

_

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

R

G

100 Ω

C

BLANK

D

DESAT

Q1

Q2

+

V

CE

-

R

F

R

R

PULL-DOWN

+ HVDC

- HVDC

3-PHASE

AC

+

V

CE

-

0.1µF 0.1µF

0.1µF

C

F

7

+

_

-

I

F

V

DESAT

V

OUT

FAULT

6.5V

50%

t

DESAT(LOW)

10%

t

DESAT(10%)

90%

t

DESAT(90%)

50%

t

DESAT(FAULT)

t

DESAT(MUTE))

50%

t

RESET(FAULT)

Reset done

during the

next LED

turn-on

I

F

V

DESAT

V

OUT

FAULTFAULT

6.5V

50%

t

DESAT(LOW)

10%

t

DESAT(10%)

90%

t

DESAT(90%)

50%

t

DESAT(FAULT)

t

DESAT(MUTE))

50%

t

RESET(FAULT)

Reset done

during the

next LED

turn-on

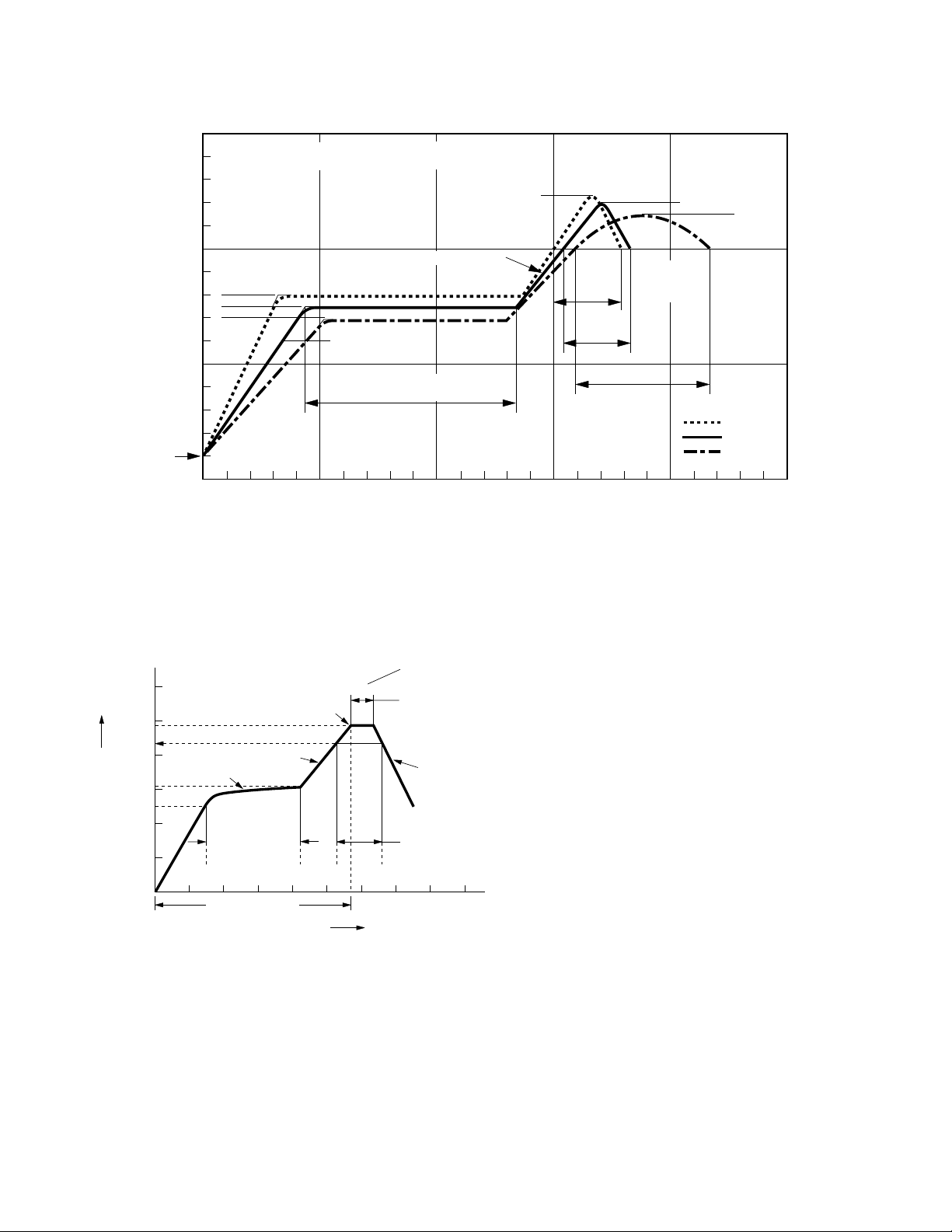

Description of Operation

Normal Operation

During normal operation, V

of the ACPL-332J is con-

OUT

trolled by input LED current IF (pins 5, 6, 7 and 8), with

the IGBT collector-to-emitter voltage being monitored

through DDESAT. The FAULT output is high. See Figure 37.

Fault Condition

The DESAT pin monitors the IGBT Vce voltage. When the

voltage on the DESAT pin exceeds 6.5 V while the IGBT is

on, V

the IGBT and prevent large di/dt induced voltages. Also

Figure 37. Fault Timing diagram

20

is slowly brought low in order to “softly” turn-o

OUT

activated is an internal feedback channel which brings

the FAULT output low for the purpose of notifying the

micro-controller of the fault condition.

Fault Reset

Once fault is detected, the output will be muted for 5 µs

(minimum). All input LED signals will be ignored during

the mute period to allow the driver to completely soft

shut-down the IGBT. The fault mechanism can be reset by

the next LED turn-on after the 5us (minimum) mute time.

See Figure 37.

Page 21

Output Control

Slow IGBT Gate Discharge during Fault Condition

The outputs (V

and FAULT) of the ACPL-332J are con-

OUT

trolled by the combination of IF, UVLO and a detected

IGBT Desat condition. Once UVLO is not active (V

> V

), VOUT is allowed to go high, and the DESAT (pin

UVLO

CC2

- VE

14) detection feature of the ACPL-332J will be the primary

source of IGBT protection. UVLO is needed to ensure

DESAT is functional. Once V

remain functional until V

UVLO-

> 10.5 V, DESAT will

UVLO+

< 11.1 V. Thus, the DESAT

detection and UVLO features of the ACPL-332J work in

conjunction to ensure constant IGBT protection.

Desaturation Detection and High Current Protection

The ACPL-332J satises these criteria by combining a high

speed, high output current driver, high voltage optical

isolation between the input and output, local IGBT desaturation detection and shut down, and an optically

isolated fault status feedback signal into a single 16-pin

surface mount package.

The fault detection method, which is adopted in the

ACPL-332J, is to monitor the saturation (collector)

voltage of the IGBT and to trigger a local fault shutdown

sequence if the collector voltage exceeds a predetermined threshold. A small gate discharge device slowly

reduces the high short circuit IGBT current to prevent

damaging voltage spikes. Before the dissipated energy

can reach destructive levels, the IGBT is shut o. During

the o state of the IGBT, the fault detect circuitry is simply

disabled to prevent false ‘fault’ signals.

The alternative protection scheme of measuring IGBT

current to prevent desaturation is eective if the short

circuit capability of the power device is known, but

this method will fail if the gate drive voltage decreases

enough to only partially turn on the IGBT. By directly

measuring the collector voltage, the ACPL-332J limits the

power dissipation in the IGBT even with insucient gate

drive voltage. Another more subtle advantage of the desaturation detection method is that power dissipation in

the IGBT is monitored, while the current sense method

relies on a preset current threshold to predict the safe

limit of operation. Therefore, an overly conservative over

current threshold is not needed to protect the IGBT.

When a desaturation fault is detected, a weak pull-down

device in the ACPL-332J output drive stage will turn on

to ‘softly’ turn o the IGBT. This device slowly discharges

the IGBT gate to prevent fast changes in drain current

that could cause damaging voltage spikes due to lead

and wire inductance. During the slow turn o, the large

output pull-down device remains o until the output

voltage falls below VEE + 2 Volts, at which time the large

pull down device clamps the IGBT gate to VEE.

DESAT Fault Detection Blanking Time

The DESAT fault detection circuitry must remain disabled

for a short time period following the turn-on of the IGBT

to allow the collector voltage to fall below the DESAT

threshold. This time period, called the DESAT blanking

time is controlled by the internal DESAT charge current,

the DESAT voltage threshold, and the external DESAT

capacitor.

The nominal blanking time is calculated in terms of

external capacitance (C

(V

C

), and DESAT charge current (I

DESAT

BLANK

x V

DESAT

/ I

CHG

the recommended 100pF capacitor is 100pF * 6.5 V / 240

µA = 2.7 µsec.

The capacitance value can be scaled slightly to adjust the

blanking time, though a value smaller than 100 pF is not

recommended. This nominal blanking time represents

the longest time it will take for the ACPL-332J to respond

to a DESAT fault condition. If the IGBT is turned on while

the collector and emitter are shorted to the supply rails

(switching into a short), the soft shut-down sequence

will begin after approximately 3 µsec. If the IGBT collector

and emitter are shorted to the supply rails after the IGBT

is already on, the response time will be much quicker due

to the parasitic parallel capacitance of the DESAT diode.

The recommended 100pF capacitor should provide

adequate blanking as well as fault response times for

most applications.

), FAULT threshold voltage

BLANK

CHG

) as t

BLANK

=

. The nominal blanking time with

I

F

X Active X X Low

X X Yes Low Low

OFF X X X Low

ON Not Active No High High

UVLO (V

– VE) Desat Condition Detected on Pin 14 Pin 3 (FAULT) Output V

CC2

21

OUT

Page 22

Under Voltage Lockout

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

R

G

R

PULL-DOWN

V

CC

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

R

G

R

PULL-DOWN

V

CC

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

R

G

V

CC

100 Ω

100pF

D

DESAT

The ACPL-332J Under Voltage Lockout (UVLO) feature is

designed to prevent the application of insucient gate

voltage to the IGBT by forcing the ACPL-332J output

low during power-up. IGBTs typically require gate

voltages of 15 V to achieve their rated V

At gate voltages below 13 V typically, the V

CE(ON)

CE(ON)

voltage.

voltage

increases dramatically, especially at higher currents. At

very low gate voltages (below 10 V), the IGBT may operate

in the linear region and quickly overheat. The UVLO

function causes the output to be clamped whenever insucient operating supply (V

exceeds V

(the positive-going UVLO threshold), the

UVLO+

) is applied. Once V

CC2

CC2

UVLO clamp is released to allow the device output to turn

on in response to input signals. As V

0 V (at some level below V

UVLO+

tion circuitry becomes active. As V

(above V

), the UVLO clamp is released. Before the

UVLO+

is increased from

CC2

), rst the DESAT protec-

is further increased

CC2

time the UVLO clamp is released, the DESAT protection

is already active. Therefore, the UVLO and DESAT Fault

detection feature work together to provide seamless protection regardless of supply voltage (V

CC2

).

Active Miller Clamp

A Miller clamp allows the control of the Miller current

during a high dV/dt situation and can eliminate the use

of a negative supply voltage in most of the applications.

During turn-o, the gate voltage is monitored and the

clamp output is activated when gate voltage goes below

2V (relative to VEE). The clamp voltage is VOL+2.5V typ

for a Miller current up to 1100mA. The clamp is disabled

when the LED input is triggered again.

Figure 38. Output pull-down resistor.

DESAT Pin Protection Resistor

The freewheeling of yback diodes connected across

the IGBTs can have large instantaneous forward voltage

transients which greatly exceed the nominal forward

voltage of the diode. This may result in a large negative

voltage spike on the DESAT pin which will draw substantial current out of the driver if protection is not used. To

limit this current to levels that will not damage the driver

IC, a 100 ohm resistor should be inserted in series with

the DESAT diode. The added resistance will not alter the

DESAT threshold or the DESAT blanking time.

Other Recommended Components

The application circuit in Figure 36 includes an output

pull-down resistor, a DESAT pin protection resistor, a

FAULT pin capacitor, and a FAULT pin pullup resistor and

Active Miller Clamp connection.

Output Pull-Down Resistor

During the output high transition, the output voltage

rapidly rises to within 3 diode drops of V

current then drops to zero due to a capacitive load, the

output voltage will slowly rise from roughly V

to V

the output voltage to V

R

to sink a static current of several 650 µA while the output

is high. Pull-down resistor values are dependent on the

amount of positive supply and can be adjusted according

to the formula, R

within a period of several microseconds. To limit

CC2

PULL-DOWN

between the output and VEE is recommended

pull-down

-3(VBE), a pull-down resistor,

CC2

= [V

-3 * (VBE)] / 650 µA.

CC2

22

. If the output

CC2

CC2

-3(VBE)

Figure 39. DESAT pin protection.

Capacitor on FAULT Pin for High CMR

Rapid common mode transients can aect the fault pin

voltage while the fault output is in the high state. A 330

pF capacitor should be connected between the fault pin

and ground to achieve adequate CMOS noise margins at

the specied CMR value of 15 kV/µs. The added capacitance does not increase the fault output delay when a

desaturation condition is detected.

Page 23

Pull-up Resistor on FAULT Pin

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

+

_

R

G

Q1

Q2

+

V

CE

-

R

PULL-DOWN

+ HVDC

- HVDC

3-PHASE

AC

+

V

CE

-

0.1µF 0.1µF

0.1µF

Optional R

1

Optional R

2

R

G

Optional R

1

Optional R

2

*

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

V

E

V

LED

DESAT

V

CC2

V

EE

V

OUT

V

CLAMP

V

EE

V

S

V

CC1

FAULT

V

S

CATHODE

ANODE

ANODE

CATHODE

+

_

+

_

R

G

Q1

Q2

+

V

CE

-

R

PULL-DOWN

+ HVDC

- HVDC

3-PHASE

AC

+

V

CE

-

0.1µF 0.1µF

0.1µF

Optional R

1

Optional R

2

R

3

9

R

G

Optional R

1

Optional R

2

R

3

*

The FAULT pin is an open collector output and therefore

requires a pull-up resistor to provide a high-level signal.

Also the FAULT output can be wire ‘OR’ed together with

other types of protection (e.g. over-temperature, overvoltage, over-current ) to alert the microcontroller.

Other Possible Application Circuit (Output Stage)

Figure 40. IGBT drive with negative gate drive, external booster and desaturation detection (V

should be connected to VEE when it is not used)

CLAMP

VCLAMP is used as secondary gate discharge path. * indicates component required for negative gate drive topology

Figure 41. Large IGBT drive with negative gate drive, external booster. V

23

control secondary discharge path for higher power application.

CLAMP

Page 24

Related Application Notes

AN5314 – Active Miller Clamp

AN5315 – “Soft” Turn-o Feature

AN1087 – Thermal Data for Optocouplers

AN1043 – Common-Mode Noise : Sources and Solutions

For product information and a complete list of distributors, please go to our web site: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies Limited in the United States and other countries.

Data subject to change. Copyright © 2005-2008 Avago Technologies Limited. All rights reserved.

AV02-0120EN - April 18, 2008

Loading...

Loading...