Page 1

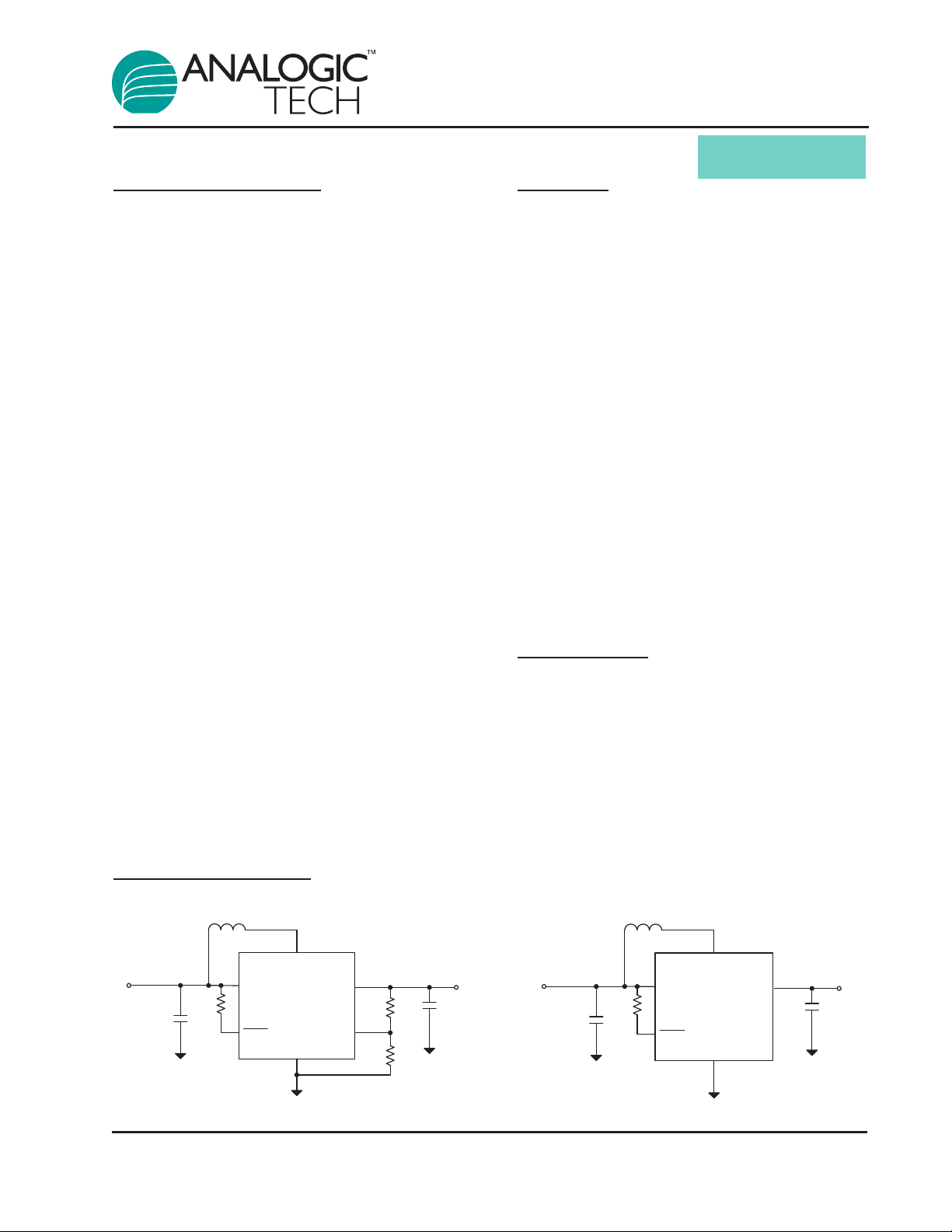

AAT1217

FB

VIN

SHDN

GND

VOUT

AAT1217-1.2

C

IN

4.7µF

V

IN

: 0.85 V

L1

4.7µH

R1

1.02MΩ

R2

604kΩ

V

OUT

:

3.3V,100 mA

SW

R3

1MΩ

C

OUT

4.7µF

FB

VIN

SHDN

GND

VOUT

AAT1217-3.3

C

IN

4.7µF

V

IN

:0.85V

L1

4.7µH

V

OUT

:

3.3V,100 mA

SW

R3

1MΩ

C

OUT

4.7µF

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

General Description

The AAT1217 a high efficiency, synchronous, fixed

frequency, step-up converter designed for singlecell or dual-cell alkaline, NiMH, or NiCd batterypowered applications. The high 1.2MHz switching

frequency and completely integrated control circuitry minimize the total solution footprint area

while maintaining excellent regulation, ripple, and

transient response throughout the full load range.

Pulse skipping mode operation and low quiescent

current allow the AAT1217 to maintain high efficiency performance for light load and sleep mode

conditions. With a 1.2A peak switch current limit,

the AAT1217 is capable of delivering 100mA to the

load from a single AA cell or up to 400mA from dual

AA cells. The AAT1217 has a 0.85V start-up voltage with operation down to 0.5V.

The AAT1217 is available in a Pb-free, space-saving low profile (1mm) 6-pin TSOT23 package and

is rated over the -40°C to +85°C ambient temperature range.

SwitchReg

™

Features

•VINOperation Range: 0.5V to V

•V

Range: 2.5V to 5.5V

OUT

• 100mA Output from a Single AA Cell Input

• 400mA Output from a Dual AA Cell Input

• High Efficiency: Up to 93% Efficiency

• Low Start-Up Voltage: 0.85V Typical

• Internal Synchronous Rectifier

—V

≤ 4.5V: No External Schottky Diode

OUT

• Fixed Frequency Pulse Width Modulation

(PWM) Current-Mode Control Scheme with

Internal Compensation

• 1.2MHz Fixed Switching Frequency

• 1.2A Current Limit

• Light Load Pulse Skipping Mode Operation

• Low 80µA No Load Input Current

• Over-Current Protection

• EMI Reduction Anti-Ringing Control Circuitry

• Low Shutdown Current: <1.0µA

• -40°C to +85°C Ambient Temperature Range

• Low Profile (1mm) TSOT23-6 Package

OUT

Applications

• Cellular and Smart Phones

• Digital Still and Video Cameras

• Microprocessors and DSP Core Supplies

• MP3 Player

• Portable Instruments

• Wireless and DSL Modems

Typical Application

1217.2007.07.1.0 1

Page 2

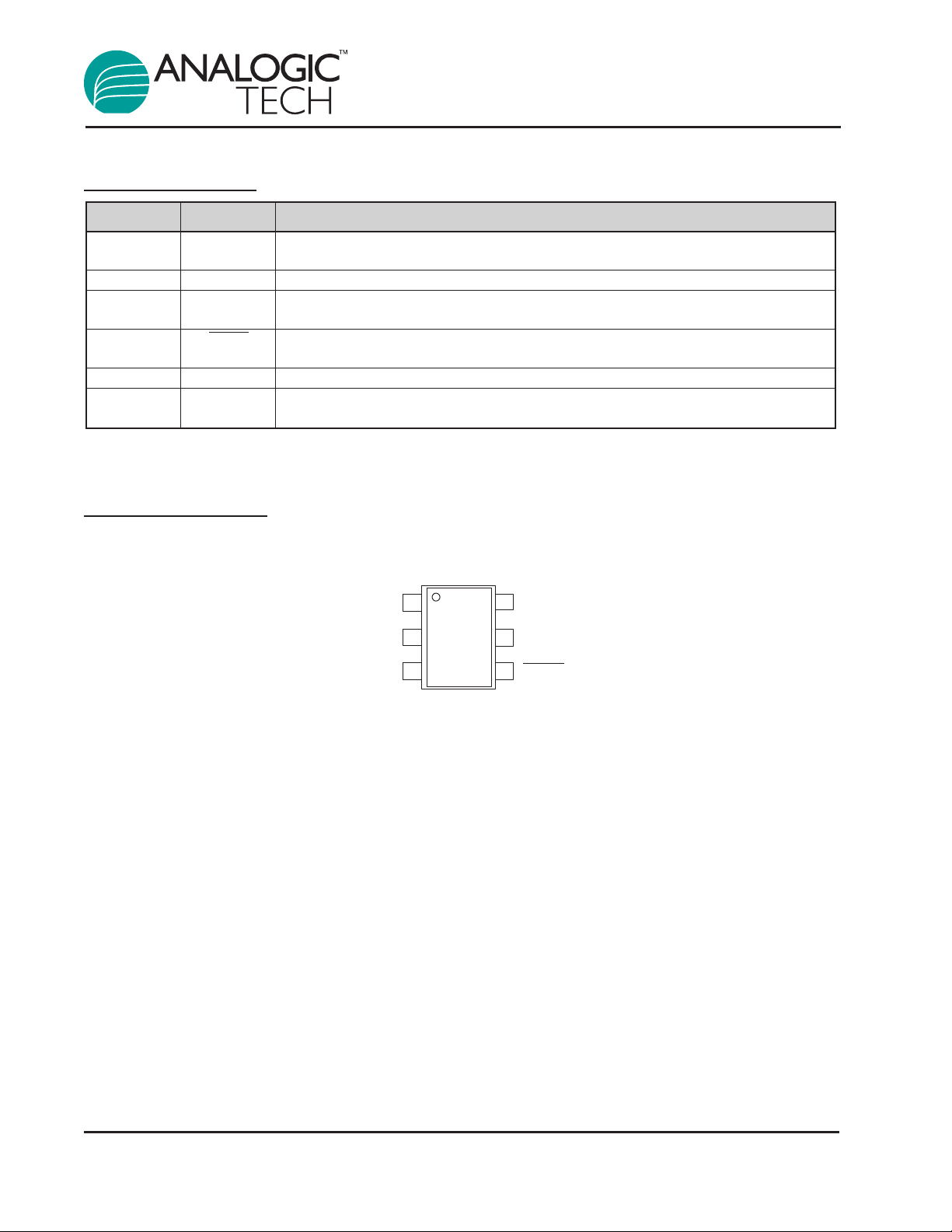

Pin Descriptions

GND

VIN

VOUT

SHDN

FB

SW

1

2

3

4

5

6

Pin # Symbol Function

1 SW Power Switch Pin. Ties to the drains of the PMOS synchronous rectifier and the

2 GND Ground Pin

3 FB Feedback Input Pin. Connect FB to the center point of the external resistor divider.

4 SHDN

5 VOUT Power Output Pin. Tied to the source of the PMOS synchronous rectifier.

6 VIN Power Supply Input. Must be closely decoupled to GND, Pin 2, with a 4.7µF or greater

Pin Configuration

AAT1217

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

NMOS switch.

The feedback threshold voltage is 1.23V.

Shutdown Signal Input. Logic high enables the IC. Logic low disables the IC. Shutdown

current is <1µA.

ceramic capacitor.

TSOT23-6

(Top View)

2 1217.2007.07.1.0

Page 3

AAT1217

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

Absolute Maximum Ratings

1

Symbol Description Value Units

V

IN

V

SW

VFB, V

SHDN

V

OUT

T

A

T

STORAGE

T

LEAD

T

J

Thermal Information

Input Supply Voltage -0.3 to 6 V

SW Voltage -0.3 to 6 V

FB, SHDN Voltages -0.3 to 6 V

VOUT Voltage -0.3 to 6 V

Operating Ambient Temperature Range

2

-40 to 85 °C

Storage Temperature Range -65 to 150 °C

Lead Temperature (Soldering, 10s) 300 °C

Operating Junction Temperature Range

3

2

-40 to 150 °C

Symbol Description Value Units

θ

JA

P

D

Maximum Thermal Resistance 190 °C/W

Maximum Power Dissipation 526 mW

1. Absolute Maximum Ratings are those values beyond which the life of a device may be impaired.

2. TJis calculated from the ambient temperature TAand power dissipation PDaccording to the following formula: TJ= TA+ PDx θJA.

3. Mounted on an FR4 board.

1217.2007.07.1.0 3

Page 4

AAT1217

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

Electrical Characteristics

VIN= 1.2V, V

= 3.3V, TA= 25°C, unless otherwise noted.

OUT

1

Symbol Description Conditions Min Typ Max Units

Minimum Start-Up Voltage I

Minimum Operating Voltage V

Output Voltage Range 2.5 5.5 V

Output Voltage Accuracy

3

Reference Voltage TA= -40°C to +85°C 1.192 1.230 1.268 V

/ Reference Voltage Line V

Regulation VIN= 2.4V to 4.2V, I

/ Reference Voltage Load V

Regulation VIN= 3.6V, I

Quiescent Current (Shutdown) V

Quiescent Current (Active) V

V

∆V

OUT/VOUT

∆V

∆V

OUT/VOUT

∆I

V

V

IN

OUT

FB

OUT

I

Q

IN

Quiescent Current (Active) Measured on V

I

LNMOS

I

LPMOS

R

DS(ON)L

R

DS(ON)H

I

CL

NMOS Switch Leakage VSW= 5V 0.1 5 µA

PMOS Switch Leakage VSW= 0V 0.1 5 µA

NMOS Switch ON Resistance

PMOS Switch ON Resistance

NMOS Current Limit 750 1200 mA

∆t(ICL) Current Limit Delay to Output 40 ns

D

F

V

I

SHDN

T

MAX

OSC

SHDN

SD

Maximum Duty Cycle VFB= 1.15V, TA= -40°C to +85°C 80 85 %

Switching Frequency TA= -40°C to +85°C 0.9 1.2 1.5 MHz

SHDN Input Low 0.35

SHDN Input High 1.00

SHDN Input Current V

Thermal Shutdown

= 1mA 0.85 1

OUT

= V

SHDN

I

OUT

V

IN

OUT

V

OUT

V

IN

OUT

V

OUT

SHDN

IN

source. V

V

OUT

V

OUT

V

OUT

V

OUT

SHDN

IN

= 10mA; TA= -40°C to +85°C -4 +4 %

= 1.2V to 2.4V, I

OUT

= 10mA,

= 3.3V

= 10mA,

OUT

= 5.0V

= 1.2V, I

= 10mA to 100mA

OUT

= 3.3V

= 10mA to 400mA

OUT

= 5.0V

= 0 0.01 1

= 1.8V, Current from input voltage

= V

SHDN

OUT

IN

, V

SHDN

= V

IN

= 3.3V 0.35

= 5V 0.30

= 3.3V 0.60

= 5V 0.55

= 5.5V 0.01 1 µA

0.5 0.65

0.2

0.4

0.003

0.004

115 µA

300 500

160

Hysteresis 20

V

%/V

%/mA

Ω

Ω

V

°C

1. Specifications over the temperature range are guaranteed by design, characterization, and correlation with statistical process controls.

2. Not including the current into internal resistance divider.

3. For fixed 3.3V and 5.0V output voltage version. The adjustable output voltage is guaranteed by reference voltage accuracy.

4 1217.2007.07.1.0

Page 5

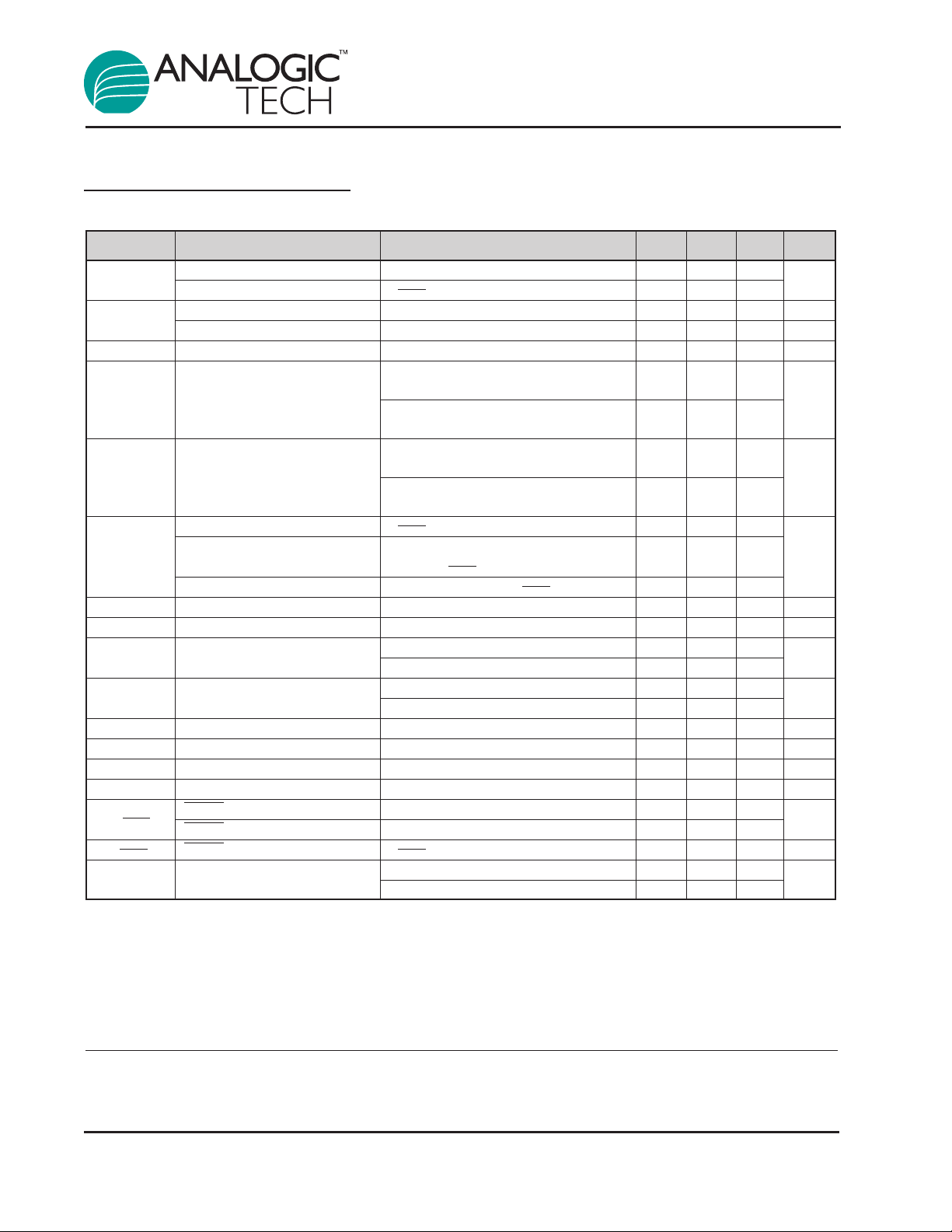

Typical Characteristics

Minimum Start-Up Voltage vs. Output Current

(V

OUT

= 3.3V; TA= 25°°C)

Output Current (mA)

Start-Up Voltage (V)

0 20 40 60 80 100 120 140 160 180 200

0.6

0.75

0.9

1.05

1.2

1.35

1.5

Maximum Output Current vs. Input Voltage

(L = 4.7µH; TA= 25°°C)

Input Voltage (V)

Maximum Output

Current (mA)

0.5 1 1.5 2 2.5 3 3.5 44.5

0

200

400

600

800

1000

V

OUT

= 5V

V

OUT

= 3.3V

Output Voltage vs. Output Current

(V

OUT

= 3.3V; TA= 25°°C)

Output Current (mA)

Output Voltage (V)

0 100 200 300 400 500 600

3.1

3.2

3.3

3.4

3.5

VIN= 1.2V

VIN= 1.5V

VIN= 2.4V

Output Voltage vs. Output Current

(V

OUT

= 5V; TA= 25°°C)

Output Current (mA)

Output Voltage (V)

0 100 200 300 400 500 600

4.8

4.9

5

5.1

5.2

VIN = 1.2V

VIN= 1.5V

VIN= 2.4V

VIN= 3.6V

Efficiency vs. Output Current

(V

O

UT

= 3.3V; TA= 25°°C)

Output Current (mA)

Efficiency (%)

0.1 1 10 100 1000

0

10

2

0

3

0

40

5

0

6

0

7

0

8

0

90

100

VIN= 2.4V

VIN= 1.2V

VIN= 1.5V

Efficiency vs. Output Current

(V

O

UT

= 5V; TA= 25°°C)

Output Current (mA)

Efficiency (%)

0.1 1 10 100 1000

0

1

0

20

30

40

50

60

70

80

9

0

1

00

VIN= 1.2V

VIN= 1.5V

VIN= 3.6V

VIN= 2.4V

AAT1217

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

1217.2007.07.1.0 5

Page 6

Typical Characteristics

Load Transient Response

(VIN= 1.5V; V

OUT

= 3.3V; CFF= 100pF)

I

OUT

50mA/div

V

OUT

100mV/div

(AC)

Time (100µs/div)

0A

40mA

100mA

Pulse Skipping Mode Operation

(VIN= 1.8V; V

OUT

= 3.3V; I

OUT

= 5mA)

V

SW

2V/div

V

OUT

50mV/div

(AC)

Time (1ms/div)

0V

Anti-Ringing Operation at SW

(VIN= 2.4V; V

OUT

= 5V; I

OUT

= 20mA)

V

SW

2V/div

0V

Time (400ns/div)

No Load Input Current vs. Input Voltage

(V

O

UT

= 3.3V; TA= 25°°C; No Load)

Input Voltage (V)

Input Current (µA)

1

.5

1

.8

2

.1

2

.4

2

.7 3

50

60

70

8

0

9

0

1

00

1

10

120

130

140

150

Output Voltage vs. Temperature

Temperature (°°C)

Output Voltage (V)

-50 -25 0 25 50 75 100

3

.25

3.26

3.27

3.28

3

.29

3.3

3

.31

3

.32

3.33

3.34

3.35

AAT1217

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

6 1217.2007.07.1.0

Page 7

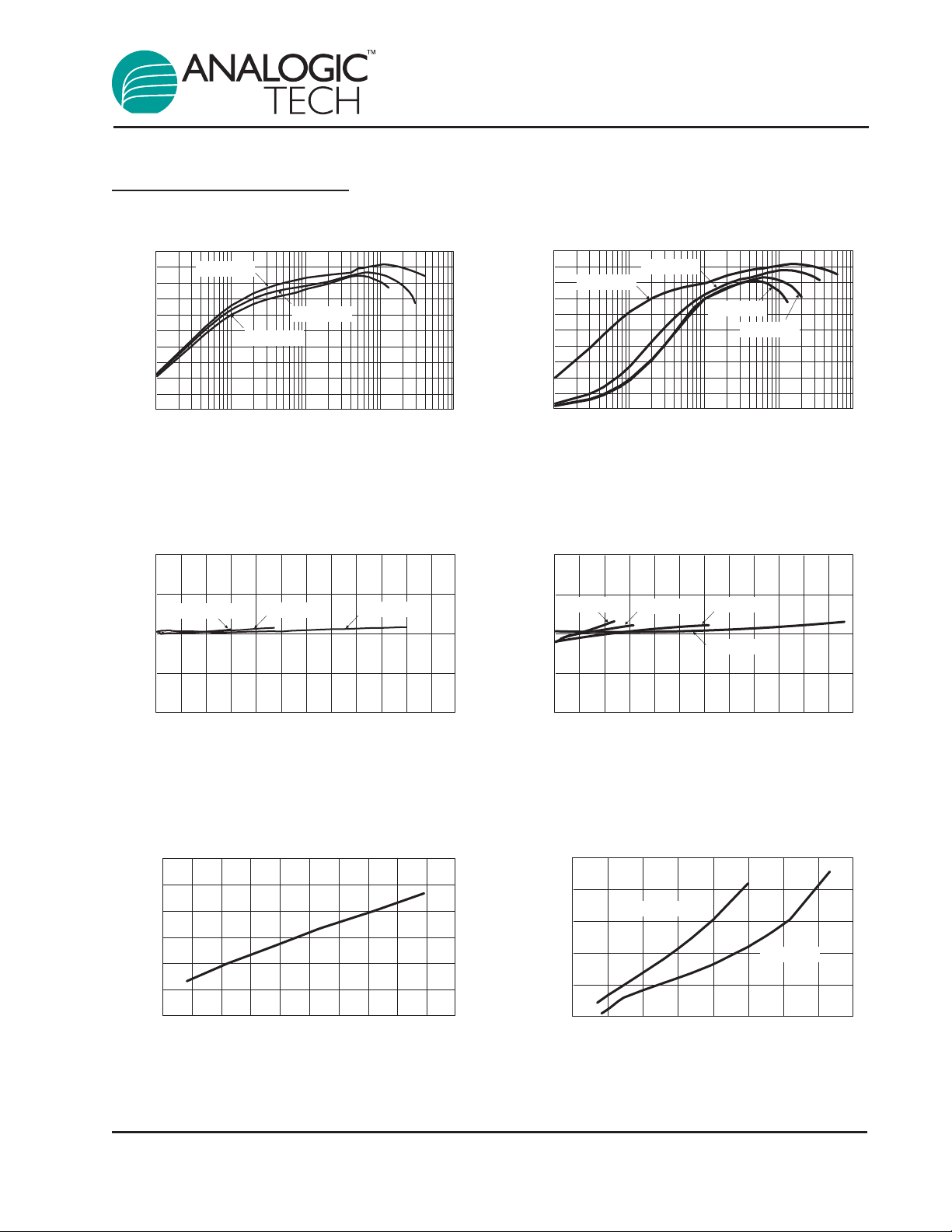

Functional Block Diagram

C

OUT

R

1

R2

PWM

Logic

Shutdown

Control

+

–

Comp

–

E

A

+

V

O

UT

G

ND

SHDN

F

B

VOUT

Oscillator

1.2MHz

Antiringing

Control

Bandgap

1

.23V

Start-Up

O

scillator

+

–

VOUT

G

OOD

MUX

Current

Sense

Slope

C

ompensation

T

o V

IN

2

.3V

L1

V

IN

V

IN

S

W

–

+

C

IN

AAT1217

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

Functional Description

The AAT1217 is a synchronous step-up DC-DC converter. It utilizes internal MOSFET switches to

achieve high efficiency over the full load current

range. It operates at a fixed switching frequency of

1.2MHz, and uses the slope compensated current

mode pulse width modulation (PWM) architecture.

1V; the typical start-up voltage is 0.85V.

Synchronous Rectification

The AAT1217 integrates a synchronous rectifier to

improve efficiency as well as to eliminate the need

The device can operate with an input voltage below

for an external Schottky diode. The synchronous

rectifier is used to reduce the conduction loss contributed by the forward voltage of an external

Schottky diode. The synchronous rectifier is realized by a P-channel MOSFET (PMOS) with gate

1217.2007.07.1.0 7

control circuitry that incorporates relatively complicated timing concerns. An external Schottky diode

is required when the output voltage is greater than

4.5V.

Low Voltage Start-Up

The AAT1217 can start-up with supply voltages

down to 0.85V. During start-up, the internal low

voltage start-up circuitry controls the internal

NMOS switch. The AAT1217 leaves the start-up

mode once V

parator (VOUT GOOD) monitors the output voltage

and places the chip into normal operation once

V

exceeds 2.3V. The AAT1217’s control circuit-

OUT

ry is biased by VINduring start-up and biased by

V

once V

OUT

VIN, the AAT1217’s operation will be independent

of VIN.

exceeds 2.3V. An internal com-

OUT

exceeds VIN. When V

OUT

OUT

exceeds

Page 8

V

OUT

= 1.23V · 1 +

R1

R2

AAT1217

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

Current Mode Operation

The AAT1217 is based on a slope compensated

current mode PWM control topology. It operates at

a fixed frequency of 1.2MHz. At the beginning of

each clock cycle, the main switch (NMOS) is turned

on and the inductor current starts to ramp. After the

maximum duty cycle or the sense current signal

equals the error amplifier (EA) output, the main

switch is turned off and the synchronous switch

(PMOS) is turned on. This control topology features cycle-by-cycle current limiting which can prevent the main switch from overstress and the external inductor from saturating.

Pulse Skipping Mode Operation

At very light load, the AAT1217 automatically

switches into pulse skipping mode operation to

improve efficiency. During this mode, the PWM

control will skip some pulses to maintain regulation.

If the load increases and the output voltage drops,

the device will automatically switch back to normal

PWM mode and maintain regulation.

Anti-Ringing Control

An anti-ringing circuitry is included to remove the

high frequency ringing that appears on the SW pin

when the inductor current goes to zero. In this

case, a ringing on the SW pin is induced due to

remaining energy stored in parasitic components of

switch and inductor. The anti-ringing circuitry

clamps the voltage internally to the battery voltage

and therefore dampens this ringing.

Application Information

Adjustable Output Voltage

An external resistor divider is used to set the output

voltage. The output voltage of the switching regulator (V

Table 1 lists the recommended resistor values for

particular output voltage settings.

Table 1: Resistor Selection for Output Voltage

Fixed Output Voltage

AAT1217 has two fixed output voltage options:

3.3V and 5V. An internal resistor divider is connected to the FB pin inside the package which eliminates the need for external feedback resistors.

When designing with the fixed output voltage

option, remember to leave the FB pin open; otherwise the output voltage will be affected. However, a

feed-forward capacitor can still be added between

the FB and VOUT pins to enhance the control loop

performance.

) is determined by the following equation:

OUT

V

OUT

3.3V 1.02M 604k

5.0V 1.02M 332k

R1(ΩΩ) R2(ΩΩ)

Setting.

Inductor Selection

Device Shutdown

When SHDN is set logic high, the AAT1217 is put

into active mode operation. If SHDN is set logic

low, the device is put into shutdown mode and consumes less than 1µA of current. After start-up, the

internal circuitry is supplied by V

shutdown mode is enabled, the internal circuitry

will be supplied by the input source again.

8 1217.2007.07.1.0

, however, if

OUT

The high switching frequency of 1.2MHz allows for

small surface mount inductors. For most applications, the AAT1217 operates with inductors from

2.2µH to 10µH. Use the following equations to

select the proper inductor value for a particular

application condition:

Page 9

I

I

P

EAK

= +

I

O

UT

· V

O

UT

η · V

IN

V

I

N

· (V

O

UT

- V

I

N

)

2L · FSW · V

OUT

∆IL = ; D =

=

V

IN

· (V

OUT

- VIN)

L · F

S

W

· V

O

UT

VIN · D

L · F

S

W

V

OUT

- V

IN

V

O

UT

∆I

L

IDC =

I

OUT

· V

OUT

η · V

IN

I

PEAK

= IDC +

∆I

L

2

Peak Inductor Current

PEAK

I

DC Component (Average) of the Inductor

DC

Current

∆ILPeak-Peak Inductor Ripple Current

I

Output (Load) Current

OUT

V

Output Voltage

OUT

V

Input Voltage

IN

η AAT1217 Efficiency (consult the perform-

ance graphs in the “Typical Characteristics”

section of the data sheet)

D Steady-State Duty Cycle

F

Switching Frequency

SW

L Inductor Value

For a given chosen inductor value and application

conditions make sure the peak inductor current does

not exceed the maximum current rating of the selected vendor’s inductor. For optimum load transient and

efficiency, low DCR inductors should be selected.

Table 2 lists some typical surface mount inductors

that are suitable for typical AAT1217 applications.

AAT1217

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

Input Capacitor

A surface mount 4.7µF or greater, X5R or X7R,

ceramic capacitor is suggested for the input capacitor. The input capacitor provides a low impedance

loop for the edges of pulsed current drawn by the

AAT1217. Low ESR/ESL X7R and X5R ceramic

capacitors are ideal for this function. To minimize

stray inductance, the capacitor should be placed

as close as possible to the IC. This keeps the high

frequency content of the input current localized,

minimizing EMI and input voltage ripple. Always

examine the ceramic capacitor DC voltage coefficient characteristics to get the proper value. For

example, the capacitance of a 10µF, 6.3V, X5R

ceramic capacitor with 5.0V DC applied is actually

about 6µF.

A laboratory test set-up typically consists of two long

wires running from the bench power supply to the

evaluation board input voltage pins. The inductance

of these wires, along with the low-ESR ceramic input

capacitor, can create a high Q network that may

affect converter performance. This problem often

becomes apparent in the form of excessive ringing

in the output voltage during load transients which

can produce errors in loop phase and gain measurements. Since the inductance of a short printed

circuit board (PCB) trace feeding the input voltage is

significantly lower than the power leads from the

bench power supply, most actual applications do not

exhibit this problem. In applications where the input

power source lead inductance cannot be reduced to

a level that does not affect the converter performance, a high ESR tantalum or aluminum electrolytic

capacitor should be placed in parallel with the low

ESR, ESL bypass input ceramic capacitor. The introduction of the high ESR capacitor dampens the high

Q network and stabilizes the AAT1217.

1217.2007.07.1.0 9

Page 10

AAT1217

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

Part Number L (µH) Max DCR (mΩΩ) Rated DC Current (A) Size WxLxH (mm)

2.2 123 1.15

Sumida CDH28D11/S 4.7 238 0.75 3x3.3x1.2

10 431 0.53

2.2 140 (typ) 1.12

Coiltronics SD3112 4.7 246 (typ) 0.8 3.1x3.1x1.2

10 446 (typ) 0.55

2.2 100 1

TDK VLF3012A 4.7 190 0.74 2.8x2.6x1.2

10 410 0.49

2.2 71.2 1.75

Sumida CR43 4.7 108.7 1.15 4.3x4.8x3.5

10 182 1.04

2.2 31.3 2.04

Sumida CDRH4D28 4.7 72 1.32 5.0x5.0x3.0

10 128 1

Toko D53LC

4.7 45 1.87

10 90 1.33

5.0x5.0x3.0

Table 2. Typical Surface Mount Inductors.

Output Capacitor

The output capacitor limits the output ripple and provides holdup during large load transitions. A 4.7µF to

10µF, X5R or X7R, ceramic capacitor is suggested

for the output capacitor. Typically the recommended

capacitor range provides sufficient bulk capacitance

to stabilize the output voltage during large load transitions and has the ESR and ESL characteristics

necessary for low output voltage ripple.

In addition, the output voltage droop during load

transient is dominated by the capacitance of the

ceramic output capacitor. During a step increase in

load current, the ceramic output capacitor alone

supplies the load current until the loop responds.

Within several switching cycles, the loop responds

and the inductor current increases to match the

load current demand. Larger output capacitor values help to reduce the voltage droop during large

load current transients.

External Diode Selection

An external Schottky diode is required when the

output voltage is above 4.5V. The Schottky diode is

optional for output voltages ≤ 4.5V, but can

improve efficiency by about 2% to 3%.

Load Disconnect in Shutdown

In conventional synchronous step-up converters, a

conduction path exists from input to output through

the backgate (body diode) of the P-channel MOSFET during shutdown. Special application circuitry

can disconnect the load from the battery during

shutdown (see Figure 1).

PCB Layout Guidance

The AAT1217 typically operates at 1.2MHz. This is a

considerably high frequency for DC-DC converters.

PCB layout is important to guarantee satisfactory

performance. It is recommended to make traces of

the power loop, especially where the switching node

is involved, as short and wide as possible. First of

all, the inductor, input and output capacitor should

be as close as possible to the device. Feedback and

shutdown circuits should avoid the proximity of large

AC signals involving the power inductor and switching node. The optional rectifier diode (D1 in Figure

1) can improve efficiency and alleviate the stress on

the integrated MOSFETs. The diode should also be

close to the inductor and the chip to form the shortest possible switching loop. While the two-layer PCB

shown in Figures 2 and 3 is enough for most applications, large and integral multi-layer ground planes

10 1217.2007.07.1.0

Page 11

AAT1217

FB

VIN

SHDN

GND

VOUT

AAT1217

C

IN

4.7µF

VIN 0.85V

L1

4.7µH

C

OUT

4.7µF

R1

1.02MΩ

R2

604kΩ

VOUT

3.3V,100 mA

1

2

34

5

SW

6

D1

MBR 0520

R3

510k Ω

ON/ OFF Cont rol

Q1

Si 2305 DS

Q2

2N3904

R4

510kΩ

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

are ideal for high power applications. Large areas of

copper have lower resistance and help to dissipate

heat. The converter's ground should join the system

ground to which it supplies power at one point only.

Figure 1 is the schematic for a highly efficient load

disconnect application circuit for the AAT1217. An

example PCB layout for the AAT1217 is shown in

Figures 2 and 3.

Figure 1. AAT1217 High Efficiency Load Disconnect Application Circuit

Figure 2. AAT1217 Evaluation Board Layout Figure 3. AAT1217 Evaluation Board Layout

Example Top Layer Example Bottom Layer

1217.2007.07.1.0 11

Page 12

Ordering Information

Part Dimensions

0.40 ±± 0.10 0.95 BSC

1.60 BSC

0.45 ±± 0.15

0.25 BSC

0.127 BSC

Detail "A"

2.80 BSC

1.00 ±± 0.10

0.000

++ 0.100

- 0.000

1.00

++10°

-0°

2.90 BSC

Top View

End View

Detail "A"

Side View

All AnalogicTech products are offered in Pb-free packaging. The term “Pb-free” means

semiconductor products that are in compliance with current RoHS standards, including

the requirement that lead not exceed 0.1% by weight in homogeneous materials. For more

information, please visit our website at http://www.analogictech.com/pbfree.

AAT1217

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

Output Voltage

1

Adj. TSOT23-6 VZMYY AAT1217ICA-1.2-T1

Fixed 3.3V TSOT23-6 WAMYY AAT1217ICA-3.3-T1

Fixed 5.0V TSOT23-6 WBMYY AAT1217ICA-5.0-T1

Package Information

Package Marking

TSOT23-6

2

Part Number (Tape and Reel)

3

All dimensions in millimeters.

1. Please contact sales for other voltage options.

2. YY = Manufacturing Date Code.

3. Sample stock is generally held on part numbers listed in BOLD.

12 1217.2007.07.1.0

Page 13

AAT1217

600mA, 1.2MHz, Micropower

Synchronous Step-Up Converter

© Advanced Analogic Technologies, Inc.

AnalogicTech cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in an AnalogicTech product. No circuit patent licenses, copyrights, mask work

rights, or other intellectual property rights are implied. AnalogicTech reserves the right to make changes to their products or specifications or to discontinue any product or service without notice. Except as provided in AnalogicTech’s terms and conditions of sale, AnalogicTech assumes no liability whatsoever, and AnalogicTech disclaims any express or implied warranty relating to the sale and/or use of AnalogicTech products including liability or warranties relating to fitness for a particular purpose, merchantability, or infringement of any patent,

copyright or other intellectual property right. In order to minimize risks associated with the customer’s applications, adequate design and operating safeguards must be provided by the

customer to minimize inherent or procedural hazards. Testing and other quality control techniques are utilized to the extent AnalogicTech deems necessary to support this warranty.

Specific testing of all parameters of each device is not necessarily performed. AnalogicTech and the AnalogicTech logo are trademarks of Advanced Analogic Technologies Incorporated.

All other brand and product names appearing in this document are registered trademarks or trademarks of their respective holders.

Advanced Analogic Technologies, Inc.

830 E. Arques Avenue, Sunnyvale, CA 94085

Phone (408) 737- 4600

Fax (408) 737- 4611

1217.2007.07.1.0 13

Page 14

Loading...

Loading...