Page 1

1

C

1

2

C

2

DETECT

STROBE

+ SUPPLY V

HORN

3

4

5

6

IRED

7

I / O

89

1

Data Sheet

26110.10A

5358

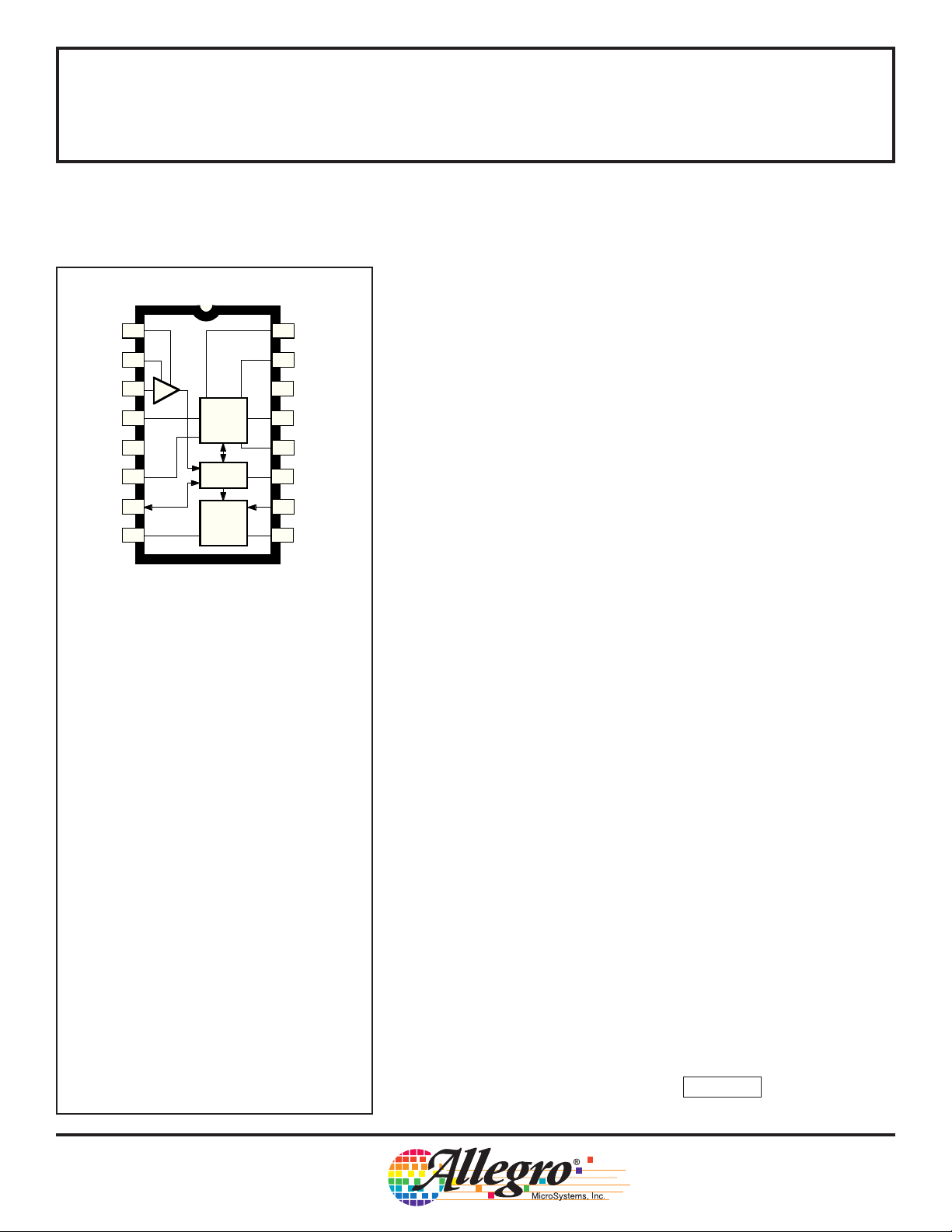

PHOTOELECTRIC SMOKE DETECTOR

WITH INTERCONNECT AND TIMER

The A5358CA is a low-current BiCMOS circuit providing all of the

required features for a photoelectric type smoke detector. This device

can be used in conjunction with an infrared photoelectric chamber to

16

TEST

HUSH

15

V

OSC. &

TIMING

DD

LOGIC

HORN

DRIVER

SS

– SUPPLY

14

TIMING RES.

13

OSC. CAP.

12

11

LED

10

FEEDBACK

HORN

Dwg. PC-007

2

sense scattered light from smoke particles. Special features are

incorporated in the design to facilitate calibration and testing of the

finished detector. The device is designed to comply with Underwriters

Laboratories Specification UL217 and British Standard BS 5446,

Part 1.

A variable-gain photo amplifier can be directly interfaced to an

infrared emitter/detector pair. The amplifier gain levels are determined

by two external capacitors that are then internally selected depending

on the operating mode. Low gain is selected during standby and timer

modes. During a local alarm this low gain is increased (internally) by

~10% to reduce false triggering. High gain is used during the pushbutton test and during standby to periodically monitor the chamber

sensitivity.

The internal oscillator and timing circuitry keeps standby power to

a minimum by sensing for smoke every 10 seconds in a 10 µs window.

A special three-stage speedup sensing scheme is incorporated to

minimize the time to an audible alarm and also to reduce false triggering. Also, two consecutive cycles of degraded chamber sensitivity are

required for a warning signal to occur.

ABSOLUTE MAXIMUM RATINGS

(Voltages are referenced to VSS)

Supply Voltage Range,

VDD.................................... -0.5 V to +15 V

Input Voltage Range,

VIN............................ -0.3 V to V

Input Current, IIN................................... 10 mA

Operating Temperature Range,

TA..................................... -25°C to +75°C

Storage Temperature Range,

TS................................... -55°C to +125°C

CAUTION: CMOS devices have input static

protection but are susceptible to damage if exposed

to extremely high static electrical charges.

+ 0.3 V

DD

The A5358CA is supplied in a low-cost 16-pin dual in-line plastic

package. It is rated for continuous operation over the temperature

range of -25°C to +75°C.

FEATURES

■ Interconnect Up to 50 Detectors

■ Piezoelectric Horn Driver

■ All Internal Low-Battery Detection

■ Power-ON Reset

■ Internal Timer & Control for Reduced Sensitivity

■ Built-In Circuits to Reduce False Triggering

■ 6 V to 12 V Operating Voltage Range

■ ESD-Protection Circuitry on All Pins

Always order by complete part number: A5358CA .

Page 2

5358

PHOTOELECTRIC SMOKE DETECTOR

with INTERCONNECT and TIMER

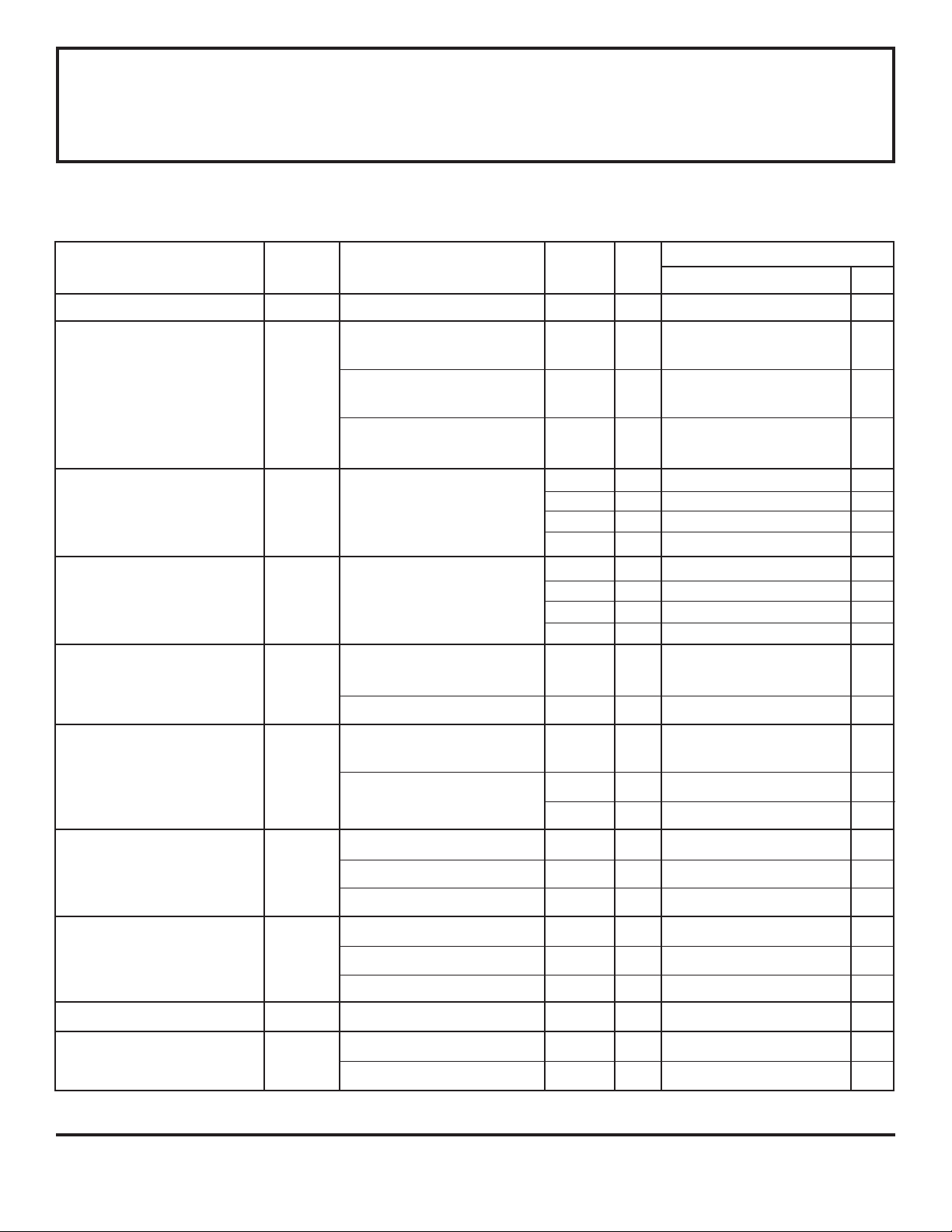

FUNCTIONAL BLOCK DIAGRAM

DETECT

STROBE

+ SUPPLY

9 V

3

C1

1

C2

2

4

6IRED

– SUPPLY

14

V

SS

V

DD

5

BAND-GAP

REFERENCE

+

–

LOW BATTERY

PHOTO AMP

+

–

V

DD

I / O

7

LOGIC

V

DD

15

HUSH

POWER-ON

OSCILLATOR

& TIMING

RESET

16

TEST

FEEDBACK

10

9

HORN

2

8

HORN

1

11

LED

TIMING RES.

13

12

OSC. CAP.

+V

+V

Dwg. FC-006

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1995, 1996 Allegro MicroSystems, Inc.

Page 3

5358

PHOTOELECTRIC SMOKE DETECTOR

with INTERCONNECT and TIMER

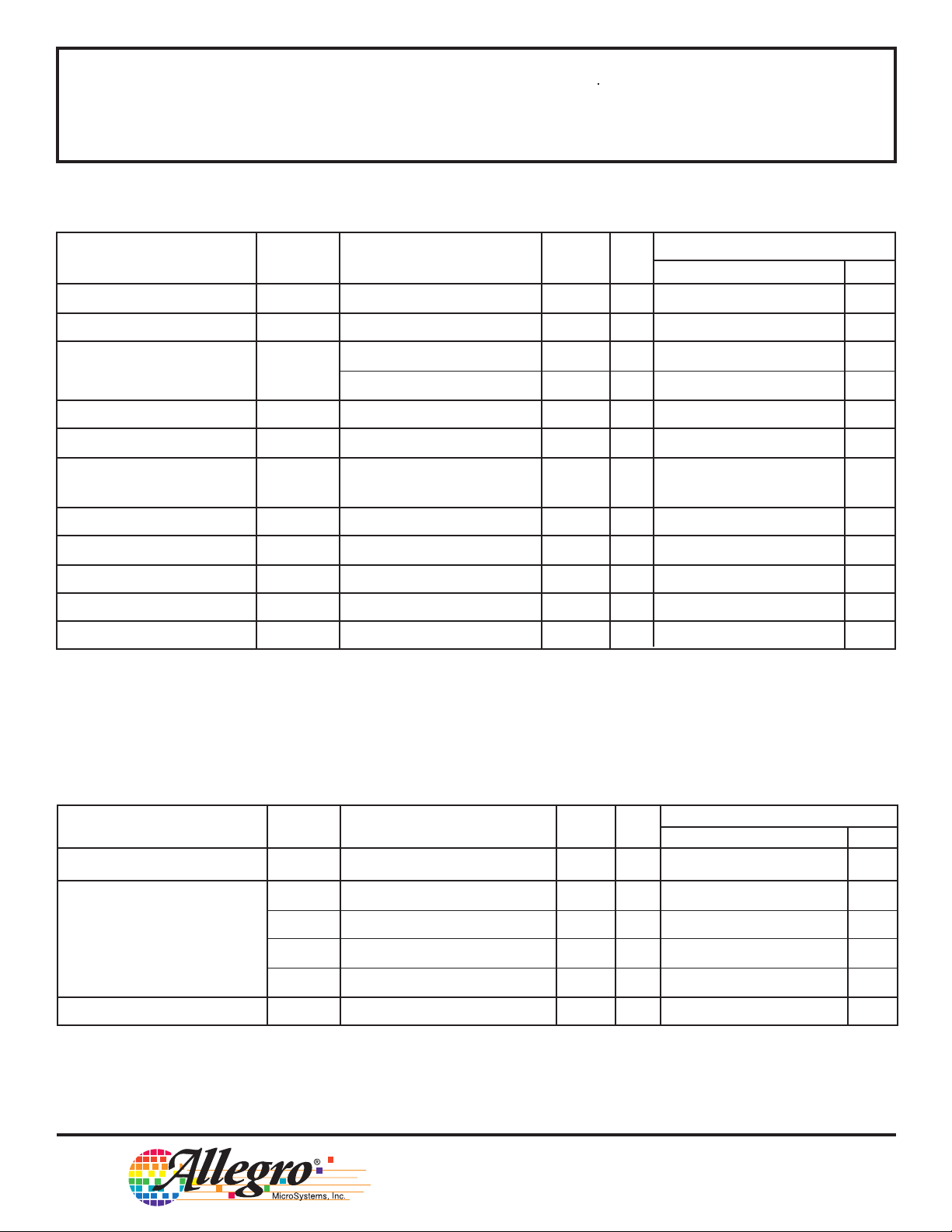

DC ELECTRICAL CHARACTERISTICS at T

= -25°C to +75°C*, V

A

(unless otherwise noted).

Test Limits

Characteristic Symbol Test Conditions Pin V

Supply Voltage Range V

Operating Supply Current I

Low-Level Input Voltage V

High-Level Input Voltage V

DD

DD

IH

Average Standby 5 12 – – 12 µA

Configured per Figure 1

During Strobe ON, I

OFF, 5 12 – – 2.0 mA

RED

Configured per Figure 1

During Strobe ON, I

ON, 5 12 – – 3.0 mA

RED

Configured per Figure 1

IL

5 – 6.0 – 12 V

79––1.5V

10 9 – – 2.7 V

16 9 – – 7.0 V

15 9 – – 0.5 V

793.2––V

10 9 6.3 – – V

16 9 8.5 – – V

15 9 1.6 – – V

= 0 V, in typical application

SS

Min. Typ. Max. Units

DD

Input Leakage High I

Input Leakage Low I

Input Pull-Down Current I

Low-Level Output Voltage V

High-Level Output Voltage V

Strobe Output Voltage V

IH

IL

IN

OL

OH

ST

VIN = VDD, Strobe Active, 1, 2 12 – – 100 nA

Pin 12 @ V

V

= V

IN

V

= VST, Strobe Active, 1, 2, 3 12 – – -100 nA

IN

Pin 12 @ V

V

= V

IN

DD

SS

DD

3, 10, 12 12 – – 100 nA

DD

10, 12 12 – – -100 nA

15, 16 12 – – -1.0 µA

V

= V

IN

DD

No Local Smoke, V

No Local Smoke, V

= V

IN

DD

= 17 V 7 12 – – 140 µA

IN

16, 15 9 0.25 – 10 µA

7920–80µA

IO = 10 mA 11 6.5 – – 0.6 V

= 16 mA 8, 9 6.5 – – 1.0 V

I

O

= 5 mA 13 6.5 – 0.5 – V

I

O

IO= -16 mA 8, 9 6.5 5.5 – – V

Inactive IO = -1 µA412

Active, I

= 100 µA to 500 µA4 9

O

VDD - 0.1

VDD - 5.25

––V

–

VDD - 4.75

V

Continued...

Page 4

5358

PHOTOELECTRIC SMOKE DETECTOR

with INTERCONNECT and TIMER

DC ELECTRICAL CHARACTERISTICS, continued

Test Limits

Characteristic Symbol Test Conditions Pin V

Line Regulation ∆V

ST(∆VDD)

Strobe Temperature Coeff. α

Output Voltage V

I

RED

Line Regulation ∆V

Temperature Coefficient α

I

RED

IRED(∆VDD)

High-Level Output Current I

OFF Leakage Current High I

OFF Leakage Current Low I

Low V

Alarm Threshold V

DD

Common Mode Voltage V

Smoke Comparator Ref. Volt. V

ST

IRED

IRED

OH

OZ

OZ

DD(th)

IC

REF

Active, V

VDD = 6 V to 12 V 4 – – 0.01 – %/°C

Inactive IO = 1 µA, TA = +25°C 6 12 – – 0.1 V

Active I

Active, VDD = 6 V to 12 V 6 – -35 – dB

VDD = 6 V to 12 V 6 – – +0.40 – %/°C

VDD = Alarm, I/O active, 7 9 -4.0 – – mA

V

= VDD - 2 V

O

VO = V

VO = V

Any Alarm Condition 1, 2, 3 Any Alarm Condition Internal -

= 6 V to 12 V 4 – – -60 – dB

DD

= -6 mA, TA = +25°C 6 9 2.85 3.1 3.35 V

O

DD

SS

11, 13 12 – – 1.0 µA

11, 13 12 – – -1.0 µA

5 - 6.9 7.2 7.5 V

Min. Typ. Max. Units

DD

VDD - 4

VDD - 3.7

–

–

VDD - 2

VDD - 3.3

V

V

* Limits over the operating temperature range are based on characterization data.

Characteristics are production tested at +25°C only.

Typical values are at +25°C and are given for circuit design information only.

AC ELECTRICAL CHARACTERISTICS at T

= -25°C to +75°C*, V

A

(unless otherwise noted).

Test Limits

Characteristic Symbol Test Conditions Pin V

Oscillator Period t

Led Pulse Period t

Led Pulse Width t

osc

led1

t

led4

t

led6

t

led7

w(led)

No Local or Remote Smoke 11 9 39 – 48 s

Remote Smoke Only 11 9 None – – –

Local Smoke or Test 11 9 0.60 0.67 0.74 s

Timer Mode, No Alarm 11 9 9.67 10.8 11.8 s

12 9 9.4 10.5 11.5 ms

11 9 9.5 – 11.5 ms

= 0 V, in typical application

SS

DD

Min. Typ. Max. Units

Continued...

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 5

5358

PHOTOELECTRIC SMOKE DETECTOR

with INTERCONNECT and TIMER

AC ELECTRICAL CHARACTERISTICS, continued.

Test Limits

Characteristic Symbol Test Conditions Pin V

Strobe Pulse Period t

st1

t

st2

t

st3

No Local or Remote Smoke 4 9 9.6 – 11.9 s

After 1 of 3 Valid Samples 4 9 2.42 2.70 2.96 s

After 2 of 3 Valid Samples 4 9 1.21 1.34 1.47 s

and During Local Alarm

DD

Min. Typ. Max. Units

Strobe Pulse Width t

Pulse Period t

I

RED

Pulse Width t

I

RED

Rise Time t

I

RED

Fall Time t

I

RED

I/O to Active Delay t

Rising Edge on I/O to Alarm t

Horn Warning Pulse Period t

t

st4

t

st5

t

st6

w(st)

ired1

t

ired2

t

ired3

t

ired4

t

ired5

t

ired6

w(ired)

r(ired)

f(ired)

d(io)

r(io)

horn

Remote Alarm 4 9 9.67 10.8 11.8 s

Chamber Test or Low Supply 4 9 38.9 – 47.1 s

Test, No Local Alarm

Pushbutton Test, No Alarm 4 9 300 336 370 ms

4 9 9.5 – 11.5 ms

No Local or Remote Smoke 6 9 9.6 – 11.9 s

After 1 of 3 Valid Samples 6 9 2.42 2.70 2.96 s

After 2 of 3 Valid Samples 6 9 1.21 1.34 1.47 s

and During Local Alarm

Remote Alarm 6 9 9.67 10.8 11.8 s

Chamber Test, No Local Alarm 6 9 38.9 – 47.1 s

Pushbutton Test, No Alarm 6 9 300 336 370 ms

6 9 94 – 116 µs

10% to 90% 6 – – 30 µs

90% to 10% 6 – – 200 µs

Local Alarm 7 9–0–s

No Local Alarm 7 9 – – 1.34 s

Low Supply and Degraded 8, 9 9 38.9 – 47.1 s

Chamber Sensitivity

Horn Warning Pulse Width t

w(horn)

Low Supply and Degraded 8, 9 9 9.5 – 11.5 ms

Chamber Sensitivity

Horn ON Time t

Horn OFF Time t

on(horn)

off(horn)

Local or Remote Alarm 8, 9 9 – 252 – ms

Local or Remote Alarm 8, 9 9 – 84 – ms

* Limits over the operating temperature range are based on characterization data.

Characteristics are production tested at +25°C only.

Typical values are at +25°C and are given for circuit design information only.

Page 6

5358

PHOTOELECTRIC SMOKE DETECTOR

with INTERCONNECT and TIMER

PIN AND CIRCUIT DESCRIPTION

(In Typical Application)

PIN 1 (C1)

A capacitor connected to this pin determines the gain

of the photo amplifier during the push-to-test mode and

during the chamber monitor test. A typical value for this

high-gain mode is 0.047 µF but should be selected

based on the photo chamber background reflections

reaching the detector and the desired level of sensitivity.

Ae ≈ 1+(C1/10) where C1 is in pF. Ae should not

exceed 10 000.

PIN 2 (C2)

A capacitor connected to this pin determines the gain

of the photo amplifier during standby. A typical value for

this low-gain mode is 4700 pF but should be selected

based on a specific photo chamber and the desired level

of sensitivity to smoke. Ae ≈ 1+(C2/10) where C2 is in pF.

Ae should not exceed 10 000. This gain increases by a

nominal 10% after a local alarm is detected (three consecutive detections). Coupling of other signals to C

(C1 and the DETECT inputs also) must be minimized.

A resistor must be installed in series with C2.

PIN 3 (DETECT)

This is the input to the photo amplifier and is connected to the cathode of the photo diode. The photo

diode is operated at zero bias and should have low darkleakage current and low capacitance.

PIN 4 (STROBE)

This output provides a strobed, regulated voltage of

V

– 5 V. The minus side of all internal and external

DD

photo amplifier circuitry is referenced to this pin.

2

PIN 5 (VDD)

This pin is connected to the most-positive supply

potential and can range from 6 V to 12 V with respect

to VSS.

PIN 6 (I

This output provides a pulsed base current for the

external npn transistor, which drives the IR emitter. Its

beta should be greater than 100. The I

active, to minimize noise impact, when the horn and

visible LED outputs are active.

PIN 7 (I/O)

A connection at this pin allows multiple smoke detectors to be interconnected. If a local smoke condition

occurs, this pin is driven high. As an input, this pin is

sampled nominally every 1.35 seconds during standby.

Any local-alarm condition causes this pin to be ignored as

an input.

This pin has an on-chip pull-down resistor and must

be left unconnected if not used. In application, there is a

series current-limiting resistor to other smoke alarms.

PIN 8 (HORN1)

PIN 9 (HORN2)

PIN 10 (FEEDBACK)

These three pins are used in conjunction with external

passive components and a self-resonating piezoelectric

transducer. HORN1 is connected to the piezo metal

support electrode; the complementary output, HORN2, is

connected to the ceramic electrode and the FEEDBACK

input to the feedback electrode.

RED

)

output is not

RED

A continuous modulated tone indicates either a local

or remote alarm condition. A short (10 ms) chirp indicates

a low-battery condition or degraded chamber sensitivity.

The low-battery chirp occurs almost simultaneous with the

visible LED flash. If the FEEDBACK pin is not used, it

must be connected to VDD or VSS.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Continued...

Page 7

5358

PHOTOELECTRIC SMOKE DETECTOR

with INTERCONNECT and TIMER

PIN AND CIRCUIT DESCRIPTION, continued

PIN 11 (LED)

This open-drain NMOS output is used to directly drive

a visible LED. The load for the low-battery test is applied

to this output. The low-battery test does not occur coincident with any other test or alarm signal. The LED also

indicates detector status as follows (with component

values as in the typical application, all times nominal):

Standby - Pulses every 43 seconds.

Local Smoke - Pulses every 0.67 second.

Remote Alarm - No pulses.

Test Mode - Pulses every 0.67 second.

Timer Mode - Pulses every 10 seconds.

PIN 12 (OSC. CAP.)

A capacitor between this pin and VDD, along with a

parallel resistor, forms part of a two-terminal oscillator and

sets the internal clock low time. With component values

as shown, this nominal time is 11 ms and essentially the

oscillator period.

PIN 13 (TIMING RES.)

A resistor between this pin and OSC. CAP. (pin 12) is

part of the two-terminal oscillator and sets the internal

clock high time, which is also the I

component values as shown, this nominal time is 105 µs.

pulse width. With

RED

cycle, I

gain is increased by internal selection of C1. Background

reflections in the smoke chamber can be used to simulate

a smoke condition. After the third I

test (three consecutive simulated smoke conditions)

activates the horn drivers and the I/O pin. When the

push-button is released, the input returns to VSS due to

the internal pull down. After one oscillator cycle, the

amplifier gain returns to normal and after three additional

I

RED

mode and returns to standby. This high-to-low transition

on pin 16 also resets and starts the 10 minute hush timer

(timer mode).

Pin Name Pin No. Configuration

I/O 7 Disabled as an output. A logic

pulses every 336 ms (nominal) and amplifier

RED

pulse, a successful

RED

pulses (less than one second), the device exits this

high on this pin places the photo

amplifier output on pin 1 or pin 2

as determined by pin 15. The

amplifier output appears as

pulses.

PIN 14 (VSS)

This pin is connected to the most negative supply

potential (usually ground).

PIN 15 (HUSH)

This input pin serves two purposes in normal operation. It serves as an enable for the internal 10-minute

(nominal) timer and also as the reference for the smoke

comparator during the timer mode. This reference is

established by a resistive divider between VDD and

STROBE (RX1 and RX2). This allows the detector to have

a different sensitivity set point during the timer mode. If

the timer mode is not used, this pin can be left open or

connected to VSS, which disables this mode.

PIN 16 (TEST)

This pin has an internal pull-down device and is used

to manually invoke two test modes and a Timer Mode.

The Push-to-Test Mode is initiated by a high logic

level on this pin (usually the depression of a normally

open push-button switch to VDD). After one oscillator

HUSH 15 If the I/O pin is high, this pin

controls the amplifier gain capaci

tor. If pin 15 is low, normal gain is

selected and the amplifier output

is on pin 1. If pin 15 is high,

supervisory gain is selected and

the amplifier output is on pin 2.

FEEDBACK 10 If pin 7 is high and pin 15 is low

(normal gain), taking this pin to a

high logic level increases the

amplifier gain by ~10% (hysteresis).

OSC. CAP. 12 This pin may be driven by an

external clock source. Driving

this pin low and high drives the

internal clock low and high. The

external RC network may remain

intact.

Page 8

5358

PHOTOELECTRIC SMOKE DETECTOR

with INTERCONNECT and TIMER

PIN AND CIRCUIT DESCRIPTION, continued

The Diagnostic Test Mode is initiated by pulling this

pin below VSS and continuously sourcing 400 µA from the

pin for at least one clock cycle on the OSC. CAP. pin.

This mode is used to facilitate calibration and test of the IC

and the assembled detector. In this mode, certain device

pins are reconfigured as described below. In this mode,

the I

pulse rate is increased to one every OSC. CAP.

RED

cycle and the STROBE pin is always active. To exit this

mode, the test pin is floated for at least one OSC. CAP.

cycle.

TYPICAL APPLICATION

CONNECT FOR TIMER MODE OR "HUSH" OPERATION

V

DD

X1

R

X2

R

8.2kΩ

5kΩ

4.7kΩ

SMOKE

CHAMBER

C

1

1

C

2

560Ω

200kΩ

2

3

4

5

V

DD

Pin Name Pin No. Configuration

HORN

1

8 This pin is reconfigured as the

smoke integrator output. Three

consecutive smoke detections

will cause this pin to go high

and three consecutive nosmoke detections cause this

pin to go low.

LED 11 This pin becomes a low-battery

indicator. The open-drain

NMOS output is normally OFF.

If V

falls below the low-

DD

battery threshold, the output

turns ON.

CONNECT FOR

NON-TIMER MODE

OPERATION

+

22µF

10MΩ

9 V

330Ω

OSC. &

TIMING

PUSH

TO

TEST

16

15

V

14

SS

1500pF

13

100kΩ

12

1kΩ

TO/FROM

OTHER

UNITS

100µF

+

22Ω

220Ω

6

7

8 9

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

LOGIC

HORN

DRIVER

11

1000pF 220kΩ

10

100kΩ

Dwg. EC-006

Page 9

5358

PHOTOELECTRIC SMOKE DETECTOR

with INTERCONNECT and TIMER

STANDBY TIMING DIAGRAM

(not to scale)

OSC. CAP

(PIN 12)

t

osc

INTERNAL

CLOCK

IRED

(PIN 6)

t

ired

t

w(ired)

STROBE

(PIN 4)

LED

(PIN 11)

SAMPLE

SMOKE

HORN

ENABLE

t

w(st)

t

w(led)

NO LOW SUPPLY

CHAMBER SENSITIVITY NORMAL

t

st

WARNING

CHIRP

t

led

t

horn

LOW SUPPLY OR

DEGRADED SENSITIVITY

WARNING CHIRPS ARE OFFSET

Dwg. WC-008

t

w(horn)

Page 10

5358

PHOTOELECTRIC SMOKE DETECTOR

with INTERCONNECT and TIMER

LOCAL ALARM TIMING DIAGRAM

(not to scale)

t

w(ired)

10%

IRED

(PIN 6)

t

ired3

90%

t

f(ired)

10%

t

ired4

t

ired6

STROBE

(PIN 4)

LED

(PIN 11)

I/O

(PIN 7)

HORN

ENABLE

t

st3

t

w(led)

LOCAL SMOKE

(REMOTE SMOKE =

DON'T CARE)

t

w(st)

t

led1

tt

on(horn)

NO SMOKE

3RD STROBE WITH SMOKE

off(horn)

3RD STROBE WITHOUT SMOKE

t

t

st4

(NO PULSES)

r(io)

REMOTE SMOKE

(NO LOCAL SMOKE)

t

st6

t

led6

(AS OUTPUT)(AS INPUT)(AS OUTPUT)

tt

on(horn) off(horn)

TEST

Dwg. WC-009

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 11

5358

PHOTOELECTRIC SMOKE DETECTOR

with INTERCONNECT and TIMER

Dimensions in Inches

(controlling dimensions)

16

0.280

0.240

0.014

9

0.008

0.300

BSC

0.430

MAX

0.210

MAX

7.11

6.10

0.015

MIN

1

0.070

0.045

16

1

1.77

1.15

0.022

0.014

8

0.775

0.100

BSC

0.735

Dimensions in Millimeters

(for reference only)

9

8

19.68

18.67

2.54

BSC

0.005

MIN

0.150

0.115

0.13

MIN

0.355

0.204

Dwg. MA-001-16A in

10.92

MAX

7.62

BSC

5.33

MAX

0.39

MIN

0.558

0.356

NOTES: 1. Lead thickness is measured at seating plane or below.

2. Lead spacing tolerance is non-cumulative.

3. Exact body and lead configuration at vendor’s option within limits shown.

3.81

2.93

Dwg. MA-001-16A mm

Page 12

5358

PHOTOELECTRIC SMOKE DETECTOR

with INTERCONNECT and TIMER

SAFETY & SECURITY ICs

SELECTION GUIDE

Part

Number Function

A3054KU/SU Multiplexed Two-Wire Hall-Effect Sensor

A5347CA Ionization-Type Smoke Detector with Interconnect and Timer

A5348CA Ionization-Type Smoke Detector with Interconnect, Timer, and Reverse-Battery Protection

A5349CA Ionization-Type Smoke Detector with Interconnect and Timer for AC Line Operation

A5350CA Ionization-Type Smoke Detector with Interconnect and Reverse-Battery Protection

A5358CA Photoelectric-Type Smoke Detector with Interconnect and Timer

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such departures from

the detail specifications as may be required to permit improvements in the design of its products.

The information included herein is believed to be accurate and reliable. However, Allegro

MicroSystems, Inc. assumes no responsibility for its use; nor for any infringements of patents or

other rights of third parties which may result from its use.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...