Page 1

1

查询A500K050-BG272供应商

Advanced v.3

ProASIC

Features and Benefits

High Capacity

• 98,000 to 1.1 Million System Gates

• 14k to 138k Bits of Two-Port SRAM

• 210 to 623 User I/Os

Performance

• 33 MHz PCI 32-Bit

• Internal System Performance up to 250 MHz

• External System Performance up to 100 MHz

Low Power

• Low Impedance Flash Switches

• Segmented Hierarchical Routing Structure

• Small Efficient Logic Cells

High Performance Routing Hierarchy

• Ultra Fast Local Network

• Efficient Long Line Network

• High Speed Bus Network

• High Performance Global Network

Nonvolatile and Reprogrammable Flash

Technology

• Live at Power-Up

• No Configuration Boot Device Required

• Retains Programmed Design During Power-Down/

Power-Up Cycles

500K Family

™

I/O

• Mixed 2.5/3.3 Volt Support

• 3.3V, 33 MHz PCI Compliance (PCI Revision 2.2)

• Individually Selectable 2.5V or 3.3V I/Os and Slew Rate

(25, 50, and 100 mA/nsec)

Secure Programming

• Security Bit Prevents Read Back of Programming Bit

Stream

Standard FPGA and ASIC Design Flow

• Flexibility to Choose Vendor-Specific Front-End Tools

• Provide Efficient Design Through Front-End Timing and

Gate Optimization

ISP Support

• In-System Programming (ISP) with Silicon Sculptor and

Silicon Explorer II

Embedded Memory Netlist Generator for

SRAMs and FIFOs

• Ensures Optimal Usage of Embedded Memory Blocks

• Up to 133 MHz Synchronous and Asynchronous Operation

JTAG Support

• IEEE Std. 1149.1 (JTAG) Compliant

Individual ProASIC Device ID

• Control and Restrict IP Delivery to Individual ProASIC

Device

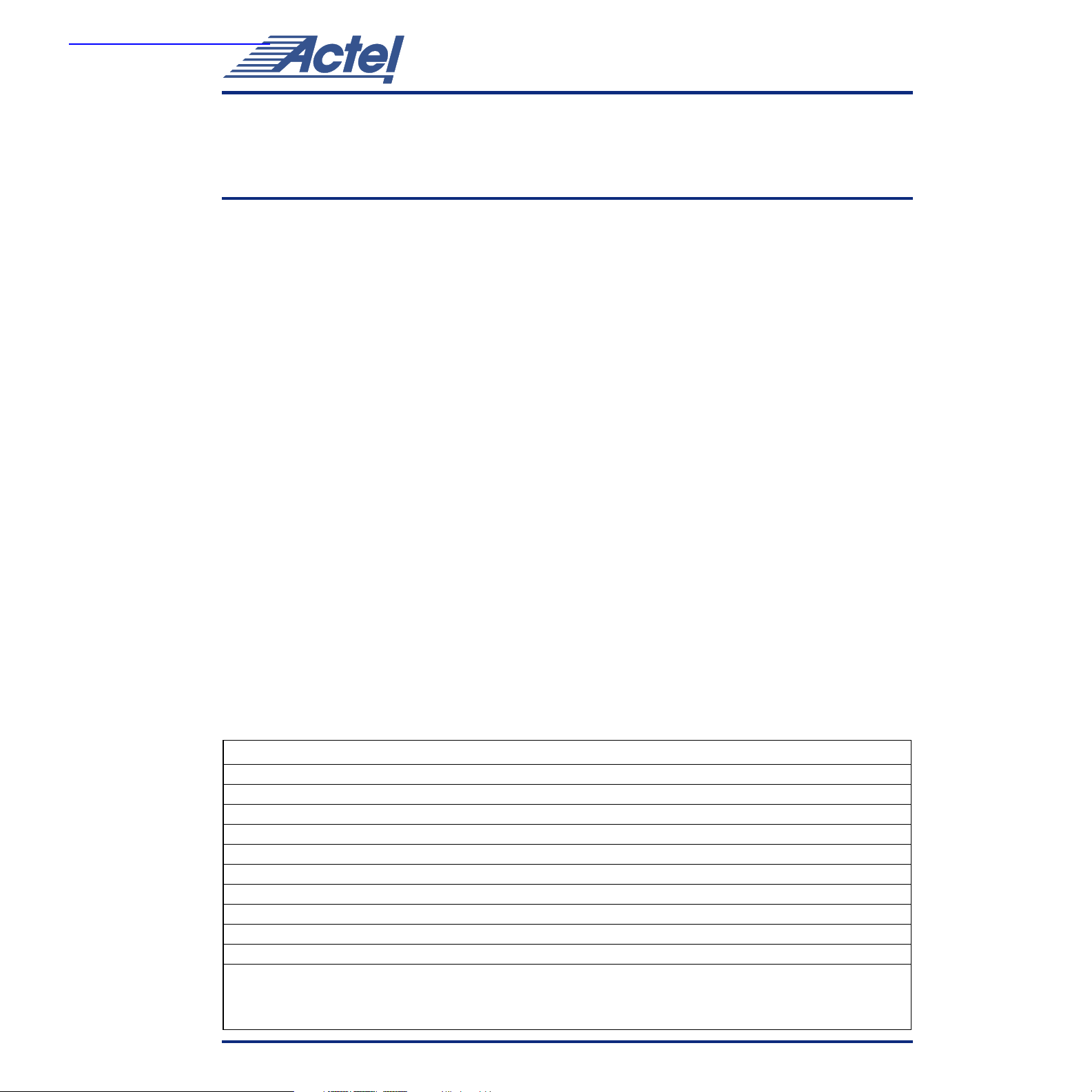

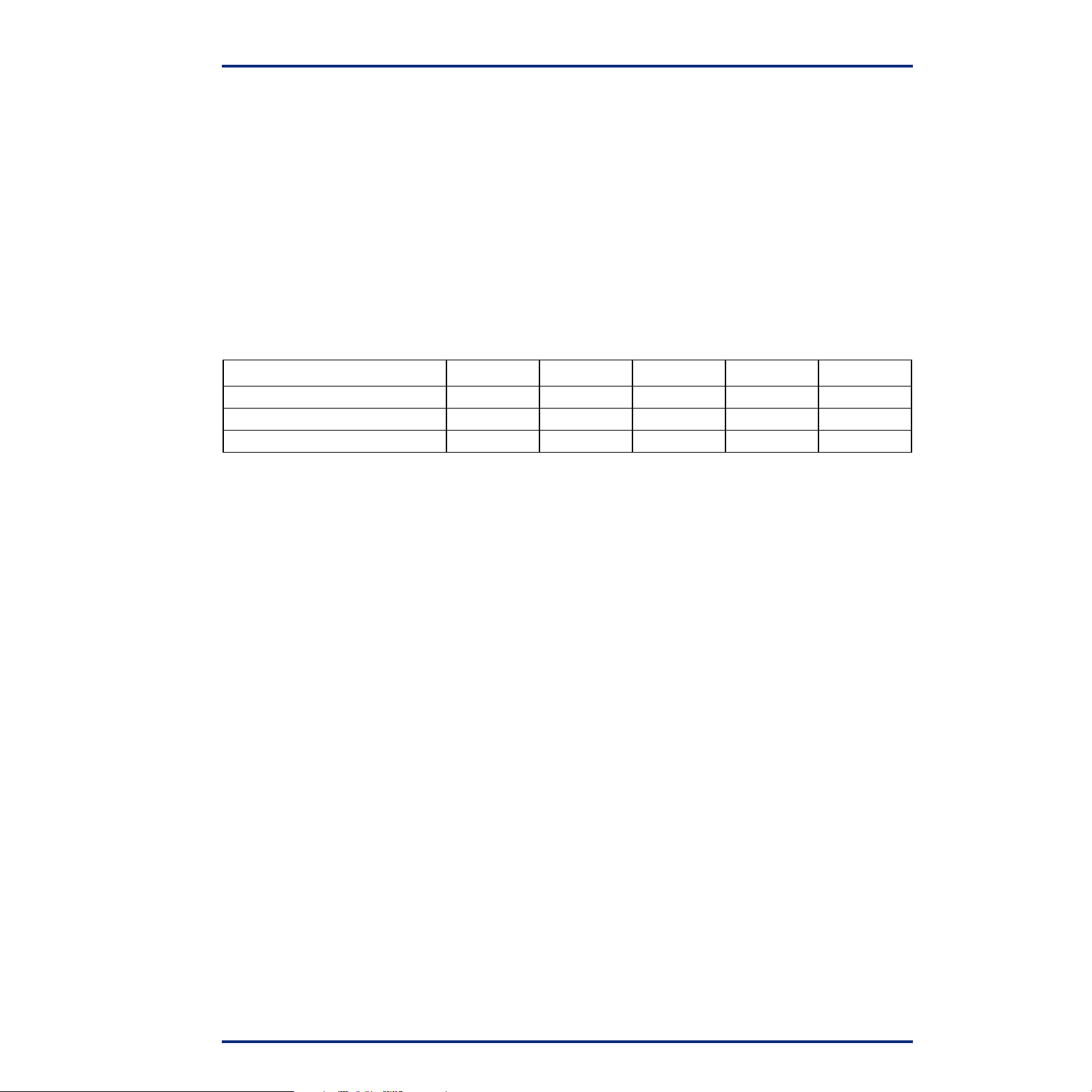

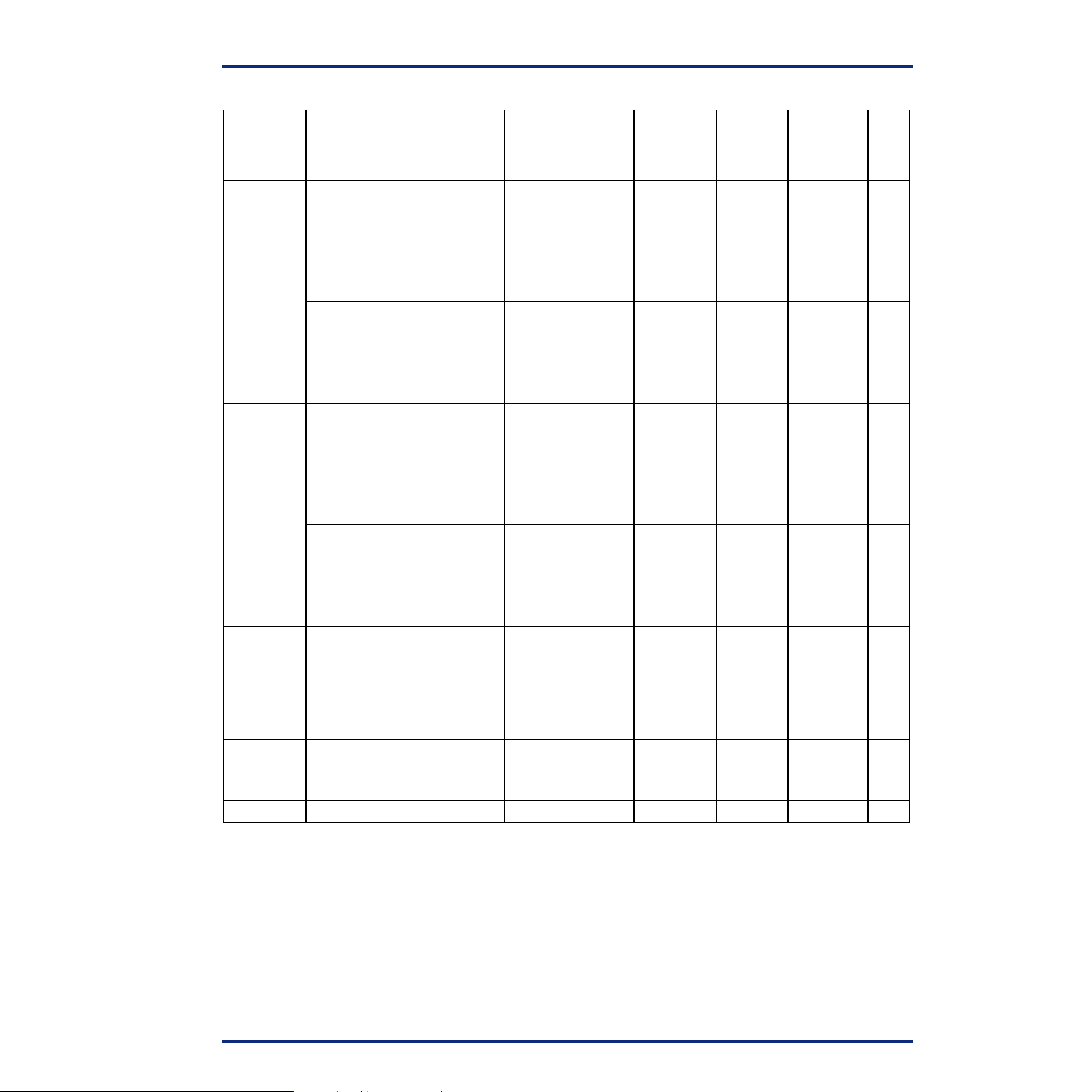

ProASIC Product Profile

Device A500K050 A500K130 A500K180 A500K270 A500K350 A500K440 A500K510

Maximum System Gates

Typical Gates

Maximum Flip-Flops

Embedded RAM Bits

Embedded RAM Blocks (256 X 9)

Logic Tiles

Global Clocks

Maximum User I/Os

JTAG

PCI

Package (by Pin Count)

PQFP

PBGA

FBGA

December 1999

© 1999 Actel Corporation

98,000 287,000 369,000 473,000 638,000 956,000 1,100,000

43,000 105,000 150,000 215,000 280,000 350,000 410,000

5,376 12,800 18,432 26,880 34,816 43,776 51,200

14k 46k 55k 65k 74k 124k 138k

6 202428325460

5,376 12,800 18,432 26,880 34,816 43,776 51,200

4444444

210 312 368 446 496 570 623

Yes Yes Yes Yes Yes Yes Yes

Yes Yes Yes Yes Yes Yes Yes

208

272

208

272, 456

208

456

580

208

456

580 580 580 580

Page 2

General Description

The ProASIC 500K family combines the advantages of ASICs

with the benefits of programmable devices through its

nonvolatile Flash technology. ProASIC 500K devices make it

possible to create high-density systems using existing ASIC or

FPGA design flows and tools, shortening time-to-production.

ASIC migration is not necessary for any volume because the

family offers cost effective reprogrammable solutions, ideal

for applications in the networking, telecom, computer, and

consumer markets.

The ProASIC 500K family offers seven devices with 98k to

1.1M system gates and includes up to 138k bits of embedded

Ordering Information

A500K130 – PQ 2081

two-port memory. These memory blocks include hardwired

FIFO circuitry as well as circuits to generate or check parity.

This minimizes external logic gate count and complexity

while maximizing flexibility and utility.

Process Technology

The ProASIC 500K family achieves its non-volatility and

reprogrammability through an advanced 4LM Flash-based

0.25µ channel length LVCMOS technology process. Standard

CMOS design techniques are used to implement logic and

control functions resulting in highly predictable performance

and gate array compatibility.

Package Lead Count

Package Type

BG = Ball Grid Array

PQ = Plastic Quad Flat Pack

FG = Fine Ball Grid Array

Speed Grade

Blank = Standard Speed

–1 = TBD

Part Number

A500K050 = 98,000 System Gates

A500K130 = 287,000 System Gates

A500K180 = 369,000 System Gates

A500K270 = 473,000 System Gates

A500K350 = 638,000 System Gates

A500K440 = 956,000 System Gates

A500K510 = 1,100,000 System Gates

Application (Ambient Temperature Range)

Blank = Commercial (0 to +70°C)

I = Industrial (–40 to +85°C)

PP = Pre-production

ES = Engineering Silicon (Room Temperature Only)

2

Page 3

✔

✔

✔

✔

✔

✔

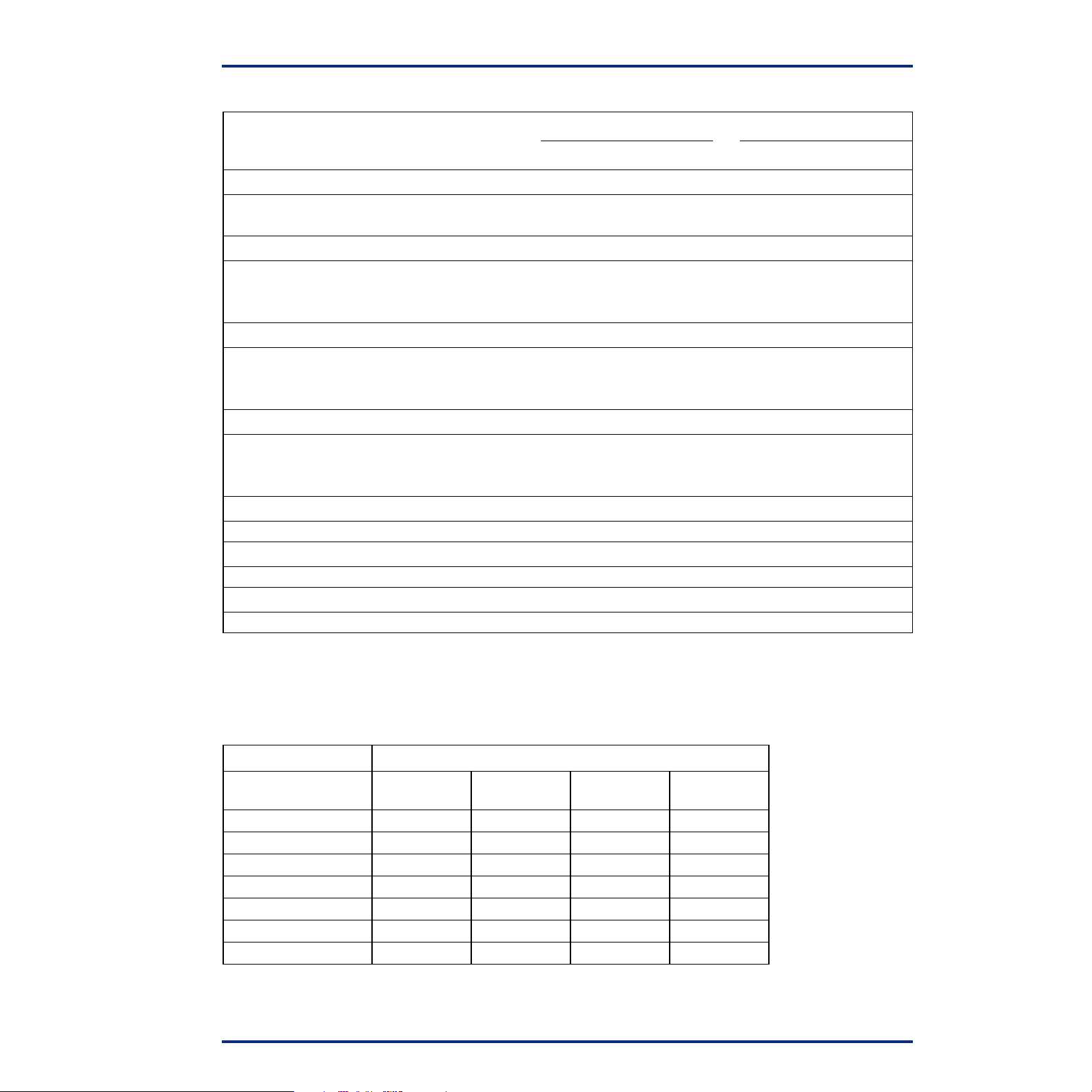

Product Plan

A500K050 Device

208-Pin Plastic Quad Flat Pack (PQFP)

272-Pin Plastic Ball Grid Array (PBGA)

A500K130 Device

™

ProASIC

500K Family

Speed Grade Application

Std –1* C I

✔

✔

PPP

PPP

208-Pin Plastic Quad Flat Pack (PQFP)

272-Pin Plastic Ball Grid Array (PBGA)

456-Pin Plastic Ball Grid Array (PBGA)

✔

PPP

PPP

PPP

A500K180 Device

208-Pin Plastic Quad Flat Pack (PQFP)

456-Pin Plastic Ball Grid Array (PBGA)

PPP

PPP

580-Pin Fine Ball Grid Array (FBGA) P P P P

A500K270 Device

208-Pin Plastic Quad Flat Pack (PQFP)

456-Pin Plastic Ball Grid Array (PBGA)

PPP

PPP

580-Pin Fine Ball Grid Array (FBGA) P P P P

A500K350 Device

580-Pin Fine Ball Grid Array (FBGA) P P P P

A500K440 Device

580-Pin Fine Ball Grid Array (FBGA) P P P P

A500K510 Device

580-Pin Fine Ball Grid Array (FBGA) P P P P

Contact your Actel sales representative for package availability.

Applications: C = Commercial Availability:

✔

= Limited Availability. Contact your Actel Sales representative for the latest

I = Industrial availability information.

*Speed Grade: –1 = TBD P = Planned

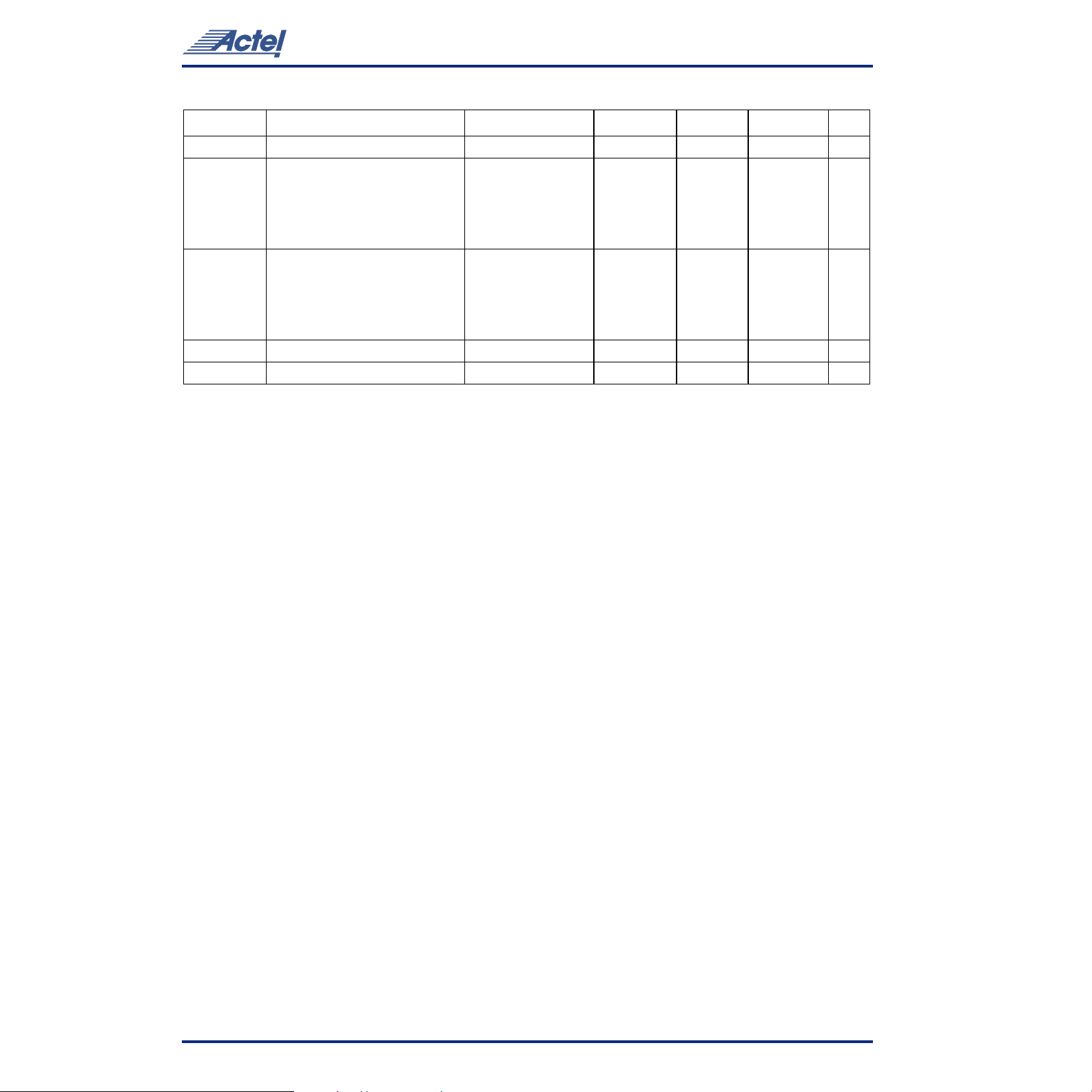

Plastic Device Resources

User I/Os

Device

208-Pin

A500K050 170 210 — —

A500K130 170 210 312 —

A500K180 170 — 368 368

A500K270 170 — 368 446

A500K350 — — — 496

A500K440 — — — 496

A500K510 — — — 496

Package Definitions (Contact your Actel sales representative for product availability.)

PQFP = Plastic Quad Flat Pack, PBGA = Plastic Ball Grid Array, FBGA = Fine Ball Grid Array

PQFP

PBGA

272-Pin

PBGA

456-Pin

FBGA

580-Pin

3

Page 4

ProASIC 500K Architecture

The ProASIC 500K family utilizes a proprietary architecture

that results in granularity comparable to gate arrays. Unlike

SRAM-based FPGAs, ProASIC devices do not utilize look-up

tables or architectural mapping during design. Instead,

designs are directly synthesized to gates that streamline the

design flow, increase design productivity, and eliminate

dependencies on vendor-specific design tools.

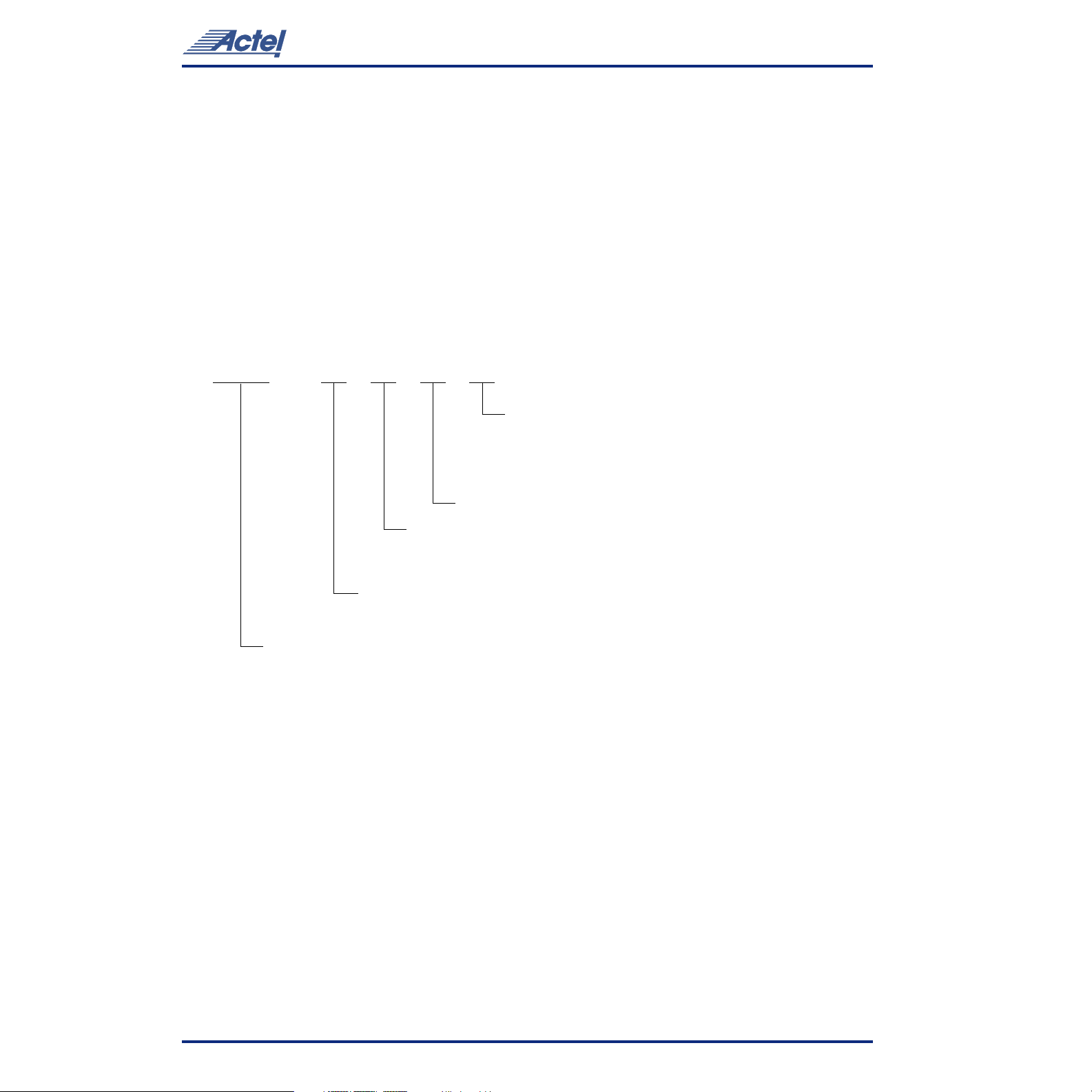

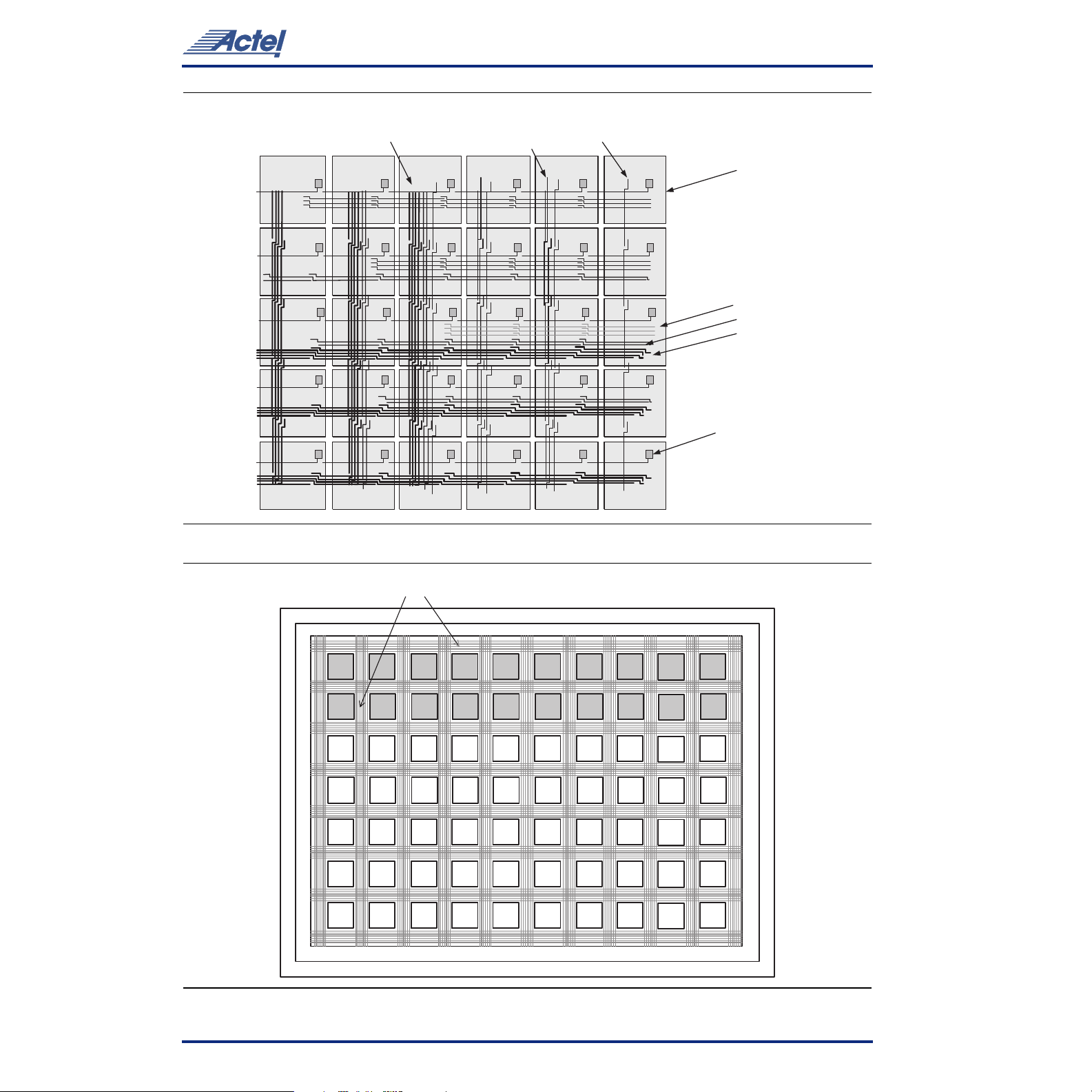

The ProASIC 500K device core consists of a Sea-of-Tiles

™

(Figure 1). Each tile (Figure 2) can be configured into a

3-input logic function (i.e. NAND gate, D-Flip-Flop, etc.) by

programming the appropriate interconnect Flash switches,

shown in Figure 3 on page 5. Gates and larger functions are

connected together, utilizing the four levels of routing

hierarchy. Flash memory bits are distributed throughout each

device providing non-volatile, reconfigurable interconnect

programming. Flash switches are programmed to connect

signal lines to the appropriate logic cell inputs and outputs.

Dedicated high-performance lines are connected as needed

for fast, low-skew clock distribution throughout the core.

Maximum core utilization is possible for virtually any design.

The ProASIC 500K devices also contain embedded two-port

SRAM blocks that have built in FIFO/RAM control logic.

Programming options include synchronous or asynchronous

operation, two-port RAM configurations, user defined depth

and width, and parity generation or checking. Table 2 on

page 9 lists the 24 basic memory configurations.

Figure 1 • The ProASIC Device Architecture

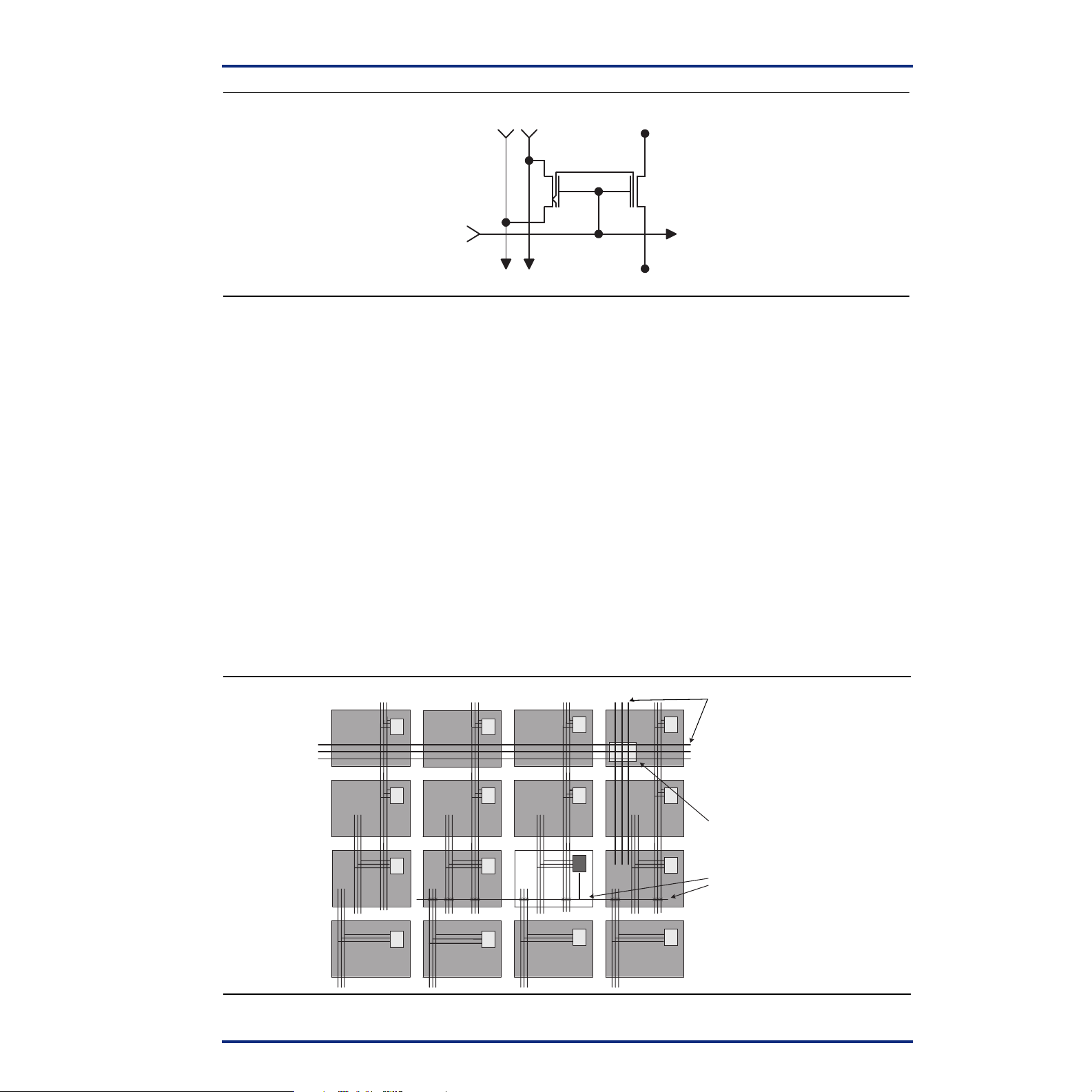

In 1

256x9 Two-Port SRAM

or FIFO Block

Logic Tile

Local Routing

Efficient Long

Line Routing

In 2 (CLK)

In 3 (Reset)

Figure 2 • Core Logic Tile

4

Page 5

Sel 1 Sel 2

Word

Figure 3 • Flash Switch

Routing Resources

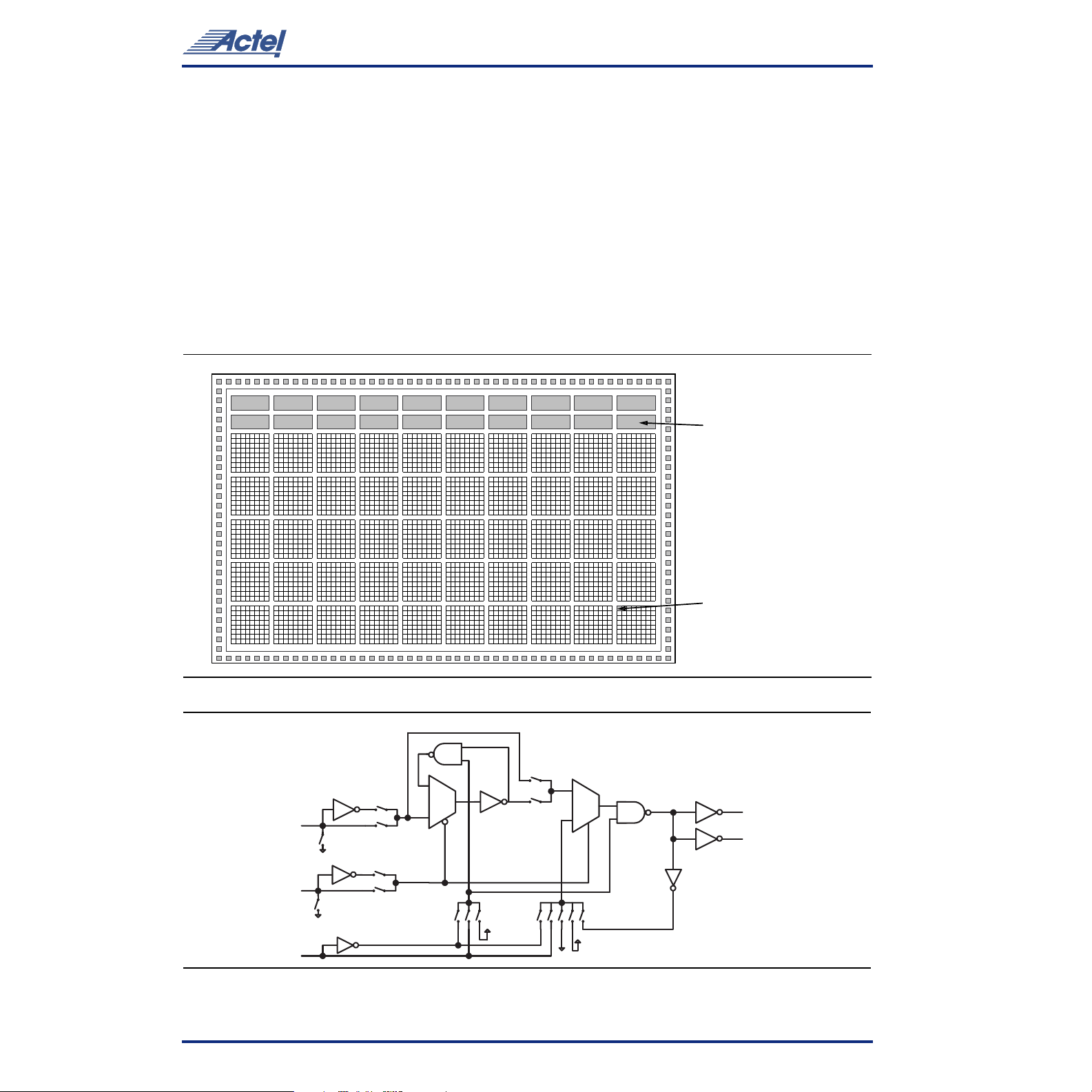

The routing structure of the ProASIC 500K devices is

designed to provide high performance through routing

flexibility. It is composed of four levels of hierarchical

resources: ultra fast local resources, efficient long line

resources, high speed bus resources, and high performance

global networks.

The ultra fast local resources are high speed dedicated lines

that allow the output of each tile to directly connect to every

input of the eight surrounding tiles (Figure 4).

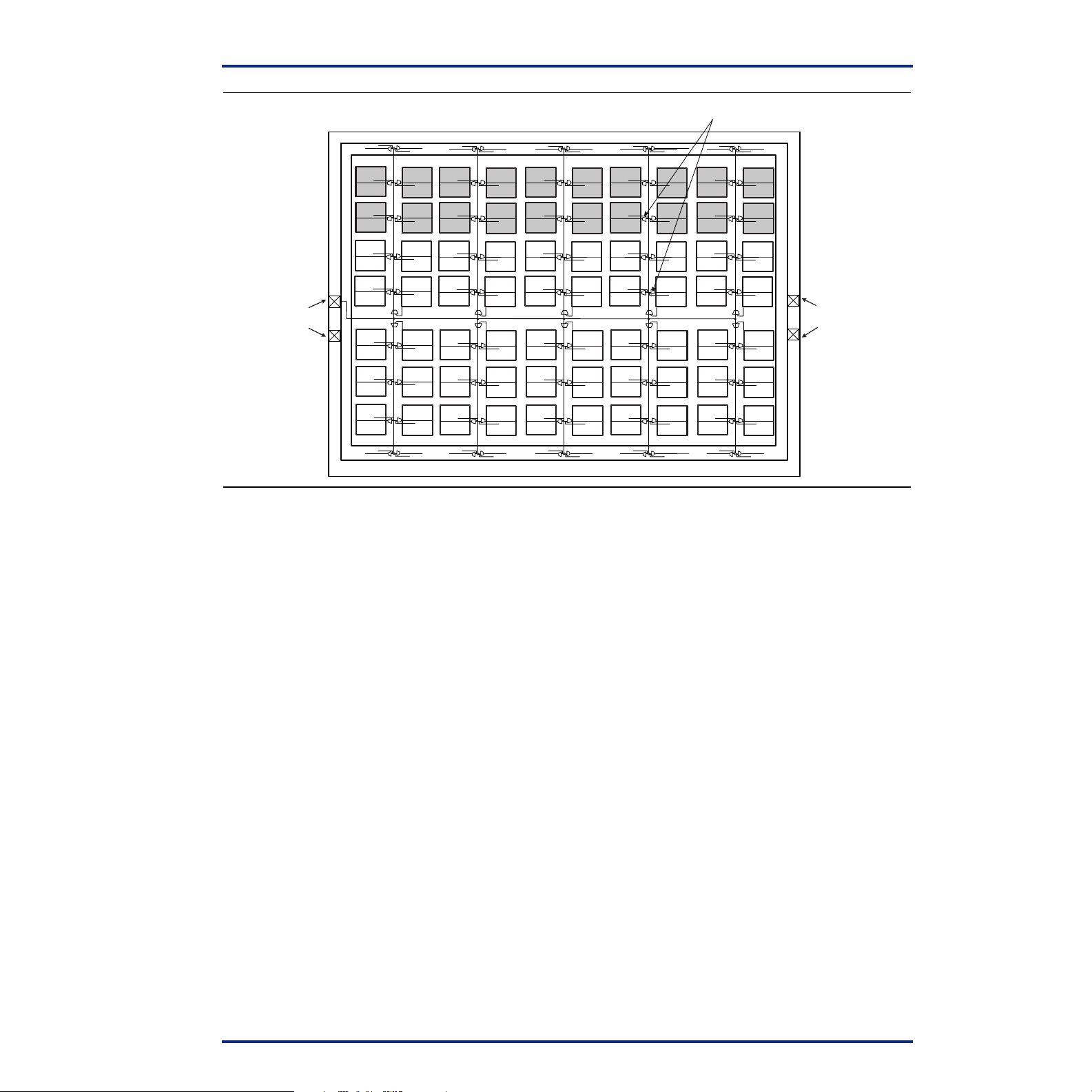

The efficient long line resources provide routing for longer

distance and higher fanout connections. These resources vary

in length (spanning 1, 2, or 4 tiles), run both vertically and

horizontally, and cover the entire ProASIC device (Figure 5

on page 6). Each tile can drive signals onto the efficient long

line resources, and the resources can access every input of a

tile. Active buffers are inserted automatically by the

ASICmaster software to limit the effects of loading due to

distance and fanout.

™

ProASIC

Switch In

Switch Out

500K Family

The high speed bus resources span across the entire device

with minimal delay and are used to route very long or very

high fanout nets. These resources run vertically and

horizontally, and provide multiple access to each group of

tiles throughout the device (Figure 6 on page 6).

The high performance global networks are low skew, high

fanout nets that are accessible from four dedicated pins or

from internal logic (Figure 7 on page 7). These nets are

typically used to distribute clocks, resets, and other high

fanout nets requiring a minimum skew. The global networks

are implemented as clock trees, and signals can be

introduced at any junction. These can be used hierarchically,

with signals accessing every input on all tiles.

L

L

L

L L

Figure 4 • Ultra Fast Local Resources

Efficient

Long Lines

L

Inputs

L

L

LL

L

Output

L L

L

L

L

(1, 2, or 4 tiles long)

Connection to

logic cell inputs

Ultra Fast

Local Lines

(connects a tile to the

adjacent tile, I/O buffer,

or memory block)

5

Page 6

4 Tiles Long

LL LLLL

LL LLLL

LL LLLL

LL LLLL

LL LLLL

2 Tiles Long

1 Tile Long

Logic Tile

1 Tile Long

2 Tiles Long

4 Tilss Long

Logic Cell

Figure 5 • Efficient Long Line Resources

High Speed Bus Resouces

PAD RING

PAD RING

I/O RING

I/O RING

PAD RING

Figure 6 • High Speed Bus Resources

6

Page 7

PAD RING

PAD RING

ProASIC

High Performace

Global Network

I/O RING

™

500K Family

Global

Pads

I/O RING

PAD RING

Figure 7 • High Performance Global Network

Global

Pads

7

Page 8

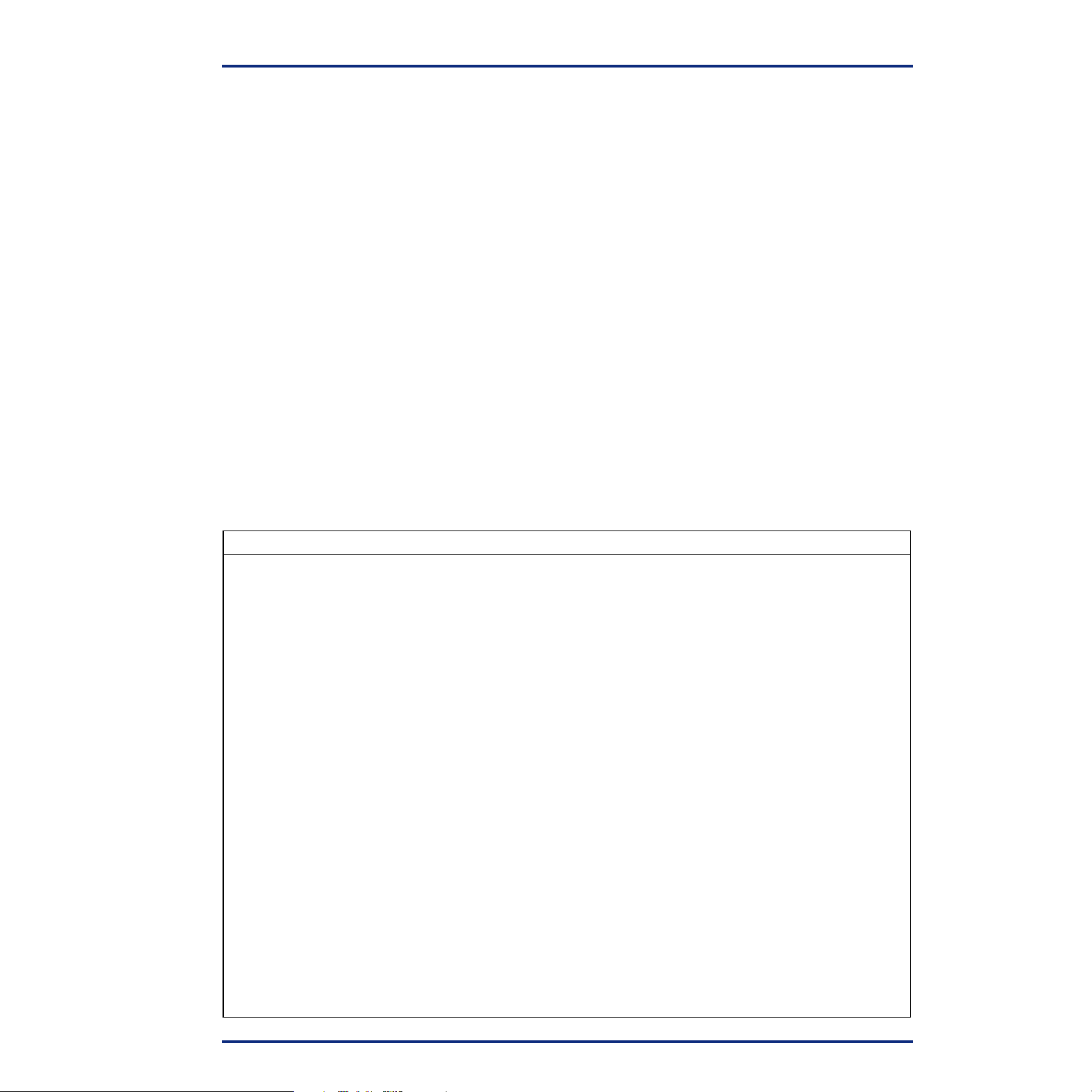

Input/Output Blocks

To meet the needs of complex system designs, the ProASIC

500K family offers devices with a large number of I/O pins,

with the A500K510 device offering up to 623 user I/O pins. If

the I/O pad is powered at 3.3V, each I/O can be selectively

configured at 2.5V and 3.3V compliant threshold levels.

Table 1 shows the various supply voltage configurations

available in the ProASIC devices. Figure 8 illustrates I/O

interfaces with other devices. All I/Os also include an ESD

protection circuit. Each I/O is tested according to the

following models:

Human Body Model (HBM)

1500V

(Per Mil Std 883 Method 3015)

Machine Model 200V

Table 1 • ProASIC Power Supply Voltages

V

DDP

Input T olerance

2.5V 3.3V

2.5V 3.3V, 2.5V

• Selectable drive strengths

• Selectable slew rates (25mA/s, 50mA/s, 100mA/s)

• Three-state enable

2.5V

Device

2.5V

Device

3.3V

Device

ProASIC

V

DDL

V

DDP

ProASIC

V

DDL

V

DDP

= 2.5V

= 2.5V

= 2.5V

= 3.3V

2.5V

Device

2.5V

Device

3.3V

Device

Output Drive

Note: V

DDL

is always 2.5V.

2.5V 3.3V, 2.5V

The I/O pads are fully configurable to provide the maximum

flexibility and speed. Each pad can be configured as an input,

an output, a three-state driver, or a bi-directional buffer

(Figure 9). I/O pads configured as inputs have the following

features:

• Individually selectable 2.5V or 3.3V compliant threshold

1

levels

• Optional pull-up resistor

I/O pads configured as outputs have the following features:

• Individually selectable 2.5V or 3.3V compliant output

1

signals

• 3.3V PCI compliant

• Ability to drive LVTTL and LVCMOS levels

• Selectable drive strengths

• Selectable slew rates (25mA/s, 50mA/s, 100mA/s)

• Three-state enable

I/O pads configured as bi-directional buffers have the

following features:

• Individually selectable 2.5V or 3.3V compliant output

signals and threshold levels

1

• 3.3V PCI compliant

• Ability to drive LVTTL and LVCMOS levels

• Optional pull-up resistor

1. If V

= 2.5V, pads are compliant to 2.5V level signals as defined by JEDEC

DDP

JESD 8-5.

Figure 8 • I/O Interfaces

3.3V/2.5V

Signal Control

Y

EN

A

3.3V/2.5V Signal Control

Drive Strength and Slew

Rate Control

Pull-up

Control

Pad

Figure 9 • I/O Block Schematic Representation

User Security and Traceability

2

The ProASIC 500K devices have a read-protect bit that, once

programmed, prevents the programmed contents from being

read from the part. To clear the read-protect bit, the entire

part must be erased. This capability lets you secure the

programmed design and prevent it from being read back and

duplicated. For traceability a 12-character alphanumeric user

part number field allows the user to assign a user part ID,

which can subsequently be read back by the programmer.

2. Available after completion of full qualification/characterization 2H, 2000.

8

Page 9

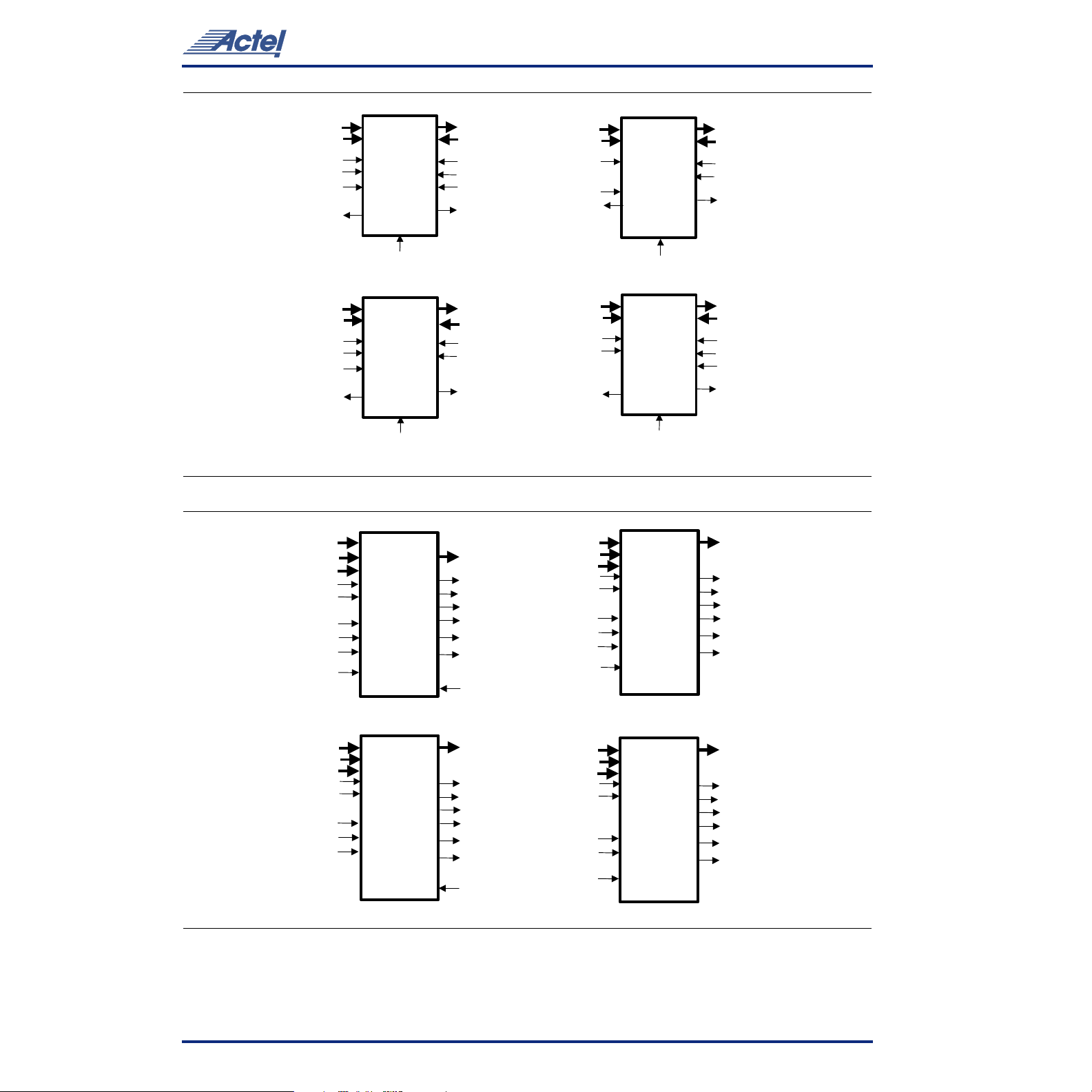

Embedded Memory Floorplan

The embedded memory is located across the top of the device

(see Figure 1 on page 4). Depending upon the device, 6 to 60

(256x9) blocks of memory are available to support a variety of

possible memory configurations. Each block can be

programmed as an independent memory or combined, using

dedicated memory routing resources, to form larger and more

complex memories.

Embedded Memory Configurations

The embedded memory in the ProASIC 500K family offers

great flexibility in memory configuration. Whereas other

programmable vendors typically provide single port memories

that can be transformed into a two-port memory at the loss of

half the memory, each ProASIC block is designed and

optimized as a two-port memory (1r1w). This provides 138k

total memory bits for two-port and single port memory usage

in the A500K510 device.

Each memory can be configured as a FIFO or SRAM, with

independent selection of synchronous or asynchronous read

and write ports (Table 2). However, multiple write ports are

not supported. Additional characteristics include

programmable FIFO flags and selectable depth, and parity

check and generation. Figure 10 and Figure 11 on page 10

™

ProASIC

500K Family

show the block diagram of the basic SRAM and FIFO blocks.

These memories are designed to operate at up to 133 MHz

when operated individually. Each block contains a 256 word

deep by 9-bit wide (1r, 1w) memory. The memory blocks,

shown in Figure 12 on page 11, may be combined in parallel

to form wider memories or stacked to form deeper memories.

This provides optimal bit widths of 9 (1 block), 18, 36, and 72,

and optimal depths of 256, 572, 768, and 1024. Refer to the

ProASIC Macro Library Guide for more information.

Figure 13 on page 11 shows an example of optimal memory

usage. Three memories have been compiled with various

widths and depths using 10 blocks and consuming all 23,040

bits. Figure 14 on page 11 shows an example of doubling up

memory to create extra read ports. In this example, 10 out of

60 blocks of the A500K510 are fully used, but yield an

effective 6,912 bits of multiple port memories. The

MEMORYmaster

™

software facilitates an easy means of

building wider and deeper memories for optimal memory

usage.

Table 2 • Basic Memory Configurations

Type Write Access Read Access Parity Library Cell Name

RAM Asynchronous Asynchronous Checked RAM256x9AA

RAM Asynchronous Asynchronous Generated RAM256x9AAP

RAM Asynchronous Synchronous T ransparent Chec ked RAM256xAST

RAM Asynchronous Synchronous T ransparent Gener ated RAM256xASTP

RAM Asynchronous Synchronous Pipelined Checked RAM256x9ASR

RAM Asynchronous Synchronous Pipelined Generated RAM256x9ASRP

RAM Synchronous Asynchronous Checked RAM256x9SA

RAM Synchronous Asynchronous Generated RAM256xSAP

RAM Synchronous Synchronous T r ansparent Chec ked RAM256x9SST

RAM Synchronous Synchronous T r ansparent Generated RAM256x9SSTP

RAM Synchronous Synchronous Pipelined Checked RAM256x9SSR

RAM Synchronous Synchronous Pipelined Generated RAM256x9SSRP

FIFO Asynchronous Asynchronous Checked FIFO256xAA

FIFO Asynchronous Asynchronous Generated FIFO256x9AAP

FIFO Asynchronous Synchronous Transparent Checked FIFO256xAST

FIFO Asynchronous Synchronous Transparent Generated FIFO256x9ASTP

FIFO Asynchronous Synchronous Pipelined Checked FIFO256x9ASR

FIFO Asynchronous Synchronous Pipelined Generated FIFO256x9ASRP

FIFO Synchronous Asynchronous Checked FIFO256x9SA

FIFO Synchronous Asynchronous Generated FIFO256xSAP

FIFO Synchronous Synchronous Transparent Checked FIFO256x9SST

FIFO Synchronous Synchronous Transparent Generated FIFO256x9SSTP

FIFO Synchronous Synchronous Pipelined Checked FIFO256x9SSR

FIFO Synchronous Synchronous Pipelined Generated FIFO256x9SSRP

9

Page 10

WDATA <0:8>

WADDR <0:7>

WRB

WBLKB

WCLK

WPE

WDATA <0:8>

WADDR <0:7>

WRB

WBLKB

WCLK

WPE

SRAM

(256 X 9)

SyncWrite &

Sync Read

Ports

PARODD

SRAM

(259 X 9)

Sync Write

&

Async Read

ports

PARODD

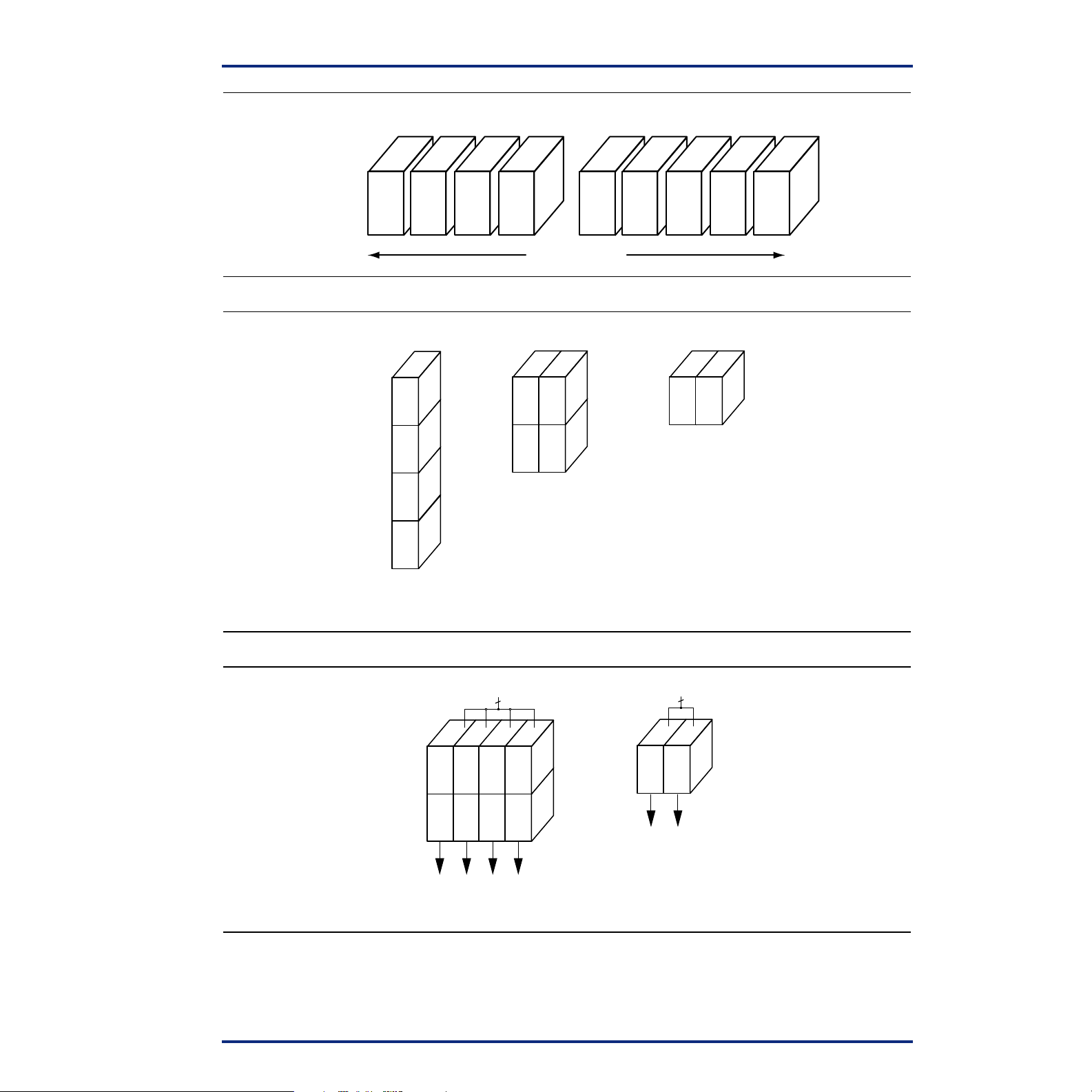

Figure 10 • Example SRAM Block Diagrams

RDATA <0:8>

RADDR <0:7>

RDB

RBLKB

RCLK

RPE

RDATA <0:8>

RADDR <0:7>

RDB

RBLKB

RPE

WDATA <0:8>

WADDR <0:7>

WRB

WBLKB

WPE

WDATA <0:8>

WADDR <0:7>

WRB

WBLKB

WPE

SRAM

(256 X 9)

Async Write

&

Async Read

Ports

PARODD

SRAM

(259 X 9)

Async Write

&

Sync Read

Ports

PARODD

RDATA <0:8>

RADDR <0:7>

RDB

RBLKB

RPE

RDATA <0:8>

RADDR <0:7>

RDB

RBLKB

RCLK

RPE

WDATA<0:8>

LEVEL<0:7>

LGDEP<0:2>

WRB

WBLKB

RDB

RBLKB

PARODD

WCLK

WDATA <0:8>

LEVEL <0:7>

LGDEP<0:2>

WRB

WBLKB

RDB

RBLKB

PARODD

FIFO

(256 X 9)

Sync Write &

Sync Read

Ports

FIFO

(256 X 9)

Async Write &

Sync Read

Ports

Figure 11 • Basic FIFO Block Diagrams

RDATA <0:8>

WPE

RPE

FULL

EMPTY

EQTH

GEQTH

RCLK

RDATA <0:8>

WPE

RPE

FULL

EMPTY

EQTH

GEQTH

RCLK

WDATA <0:8>

LEVEL <0:7>

LGDEP<0:2>

WRB

WBLKB

RDB

RBLKB

PARODD

WCLK

WDATA <0:8>

LEVEL <0:7>

LGDEP<0:2>

WRB

WBLKB

RDB

RBLKB

PARODD

FIFO

(256 X 9)

Sync Write &

Async Read

Ports

FIFO

(256 X 9)

Async Write &

Async.Read

Ports

RDATA <0:8>

WPE

RPE

FULL

EMPTY

EQTH

GEQTH

RDATA <0:8>

WPE

RPE

FULL

EMPTY

EQTH

GEQTH

10

Page 11

Word Width

ProASIC

™

500K Family

Word

256925692569256

Depth

Figure 12 • A500K510 Memory Block Architecture

Word Width

9

Word

Depth

256

9

9

18 bit x 512 word 1r1w

9

9

256

…

60 blocks

9

9

9

2569256925692569256

9

256

18 bit x 256 word 1r1w

9 bit x 1,024 word 1r1w

Figure 13 • Memories with Different Width and Depth

Word Width

9

9

Word

Depth

256

9

Read Ports

9 bit x 512 word, 4r1w

Figure 14 • Multiport Memory Usage

Total Memory Blocks Used = 10

Total Memory Bits = 23,040

Write Port Write Port

9

9

256

Read Ports

9 bit x 256 word, 2r1w

Total Memory Blocks Used = 10

Total Memory Bits = 6,912

11

Page 12

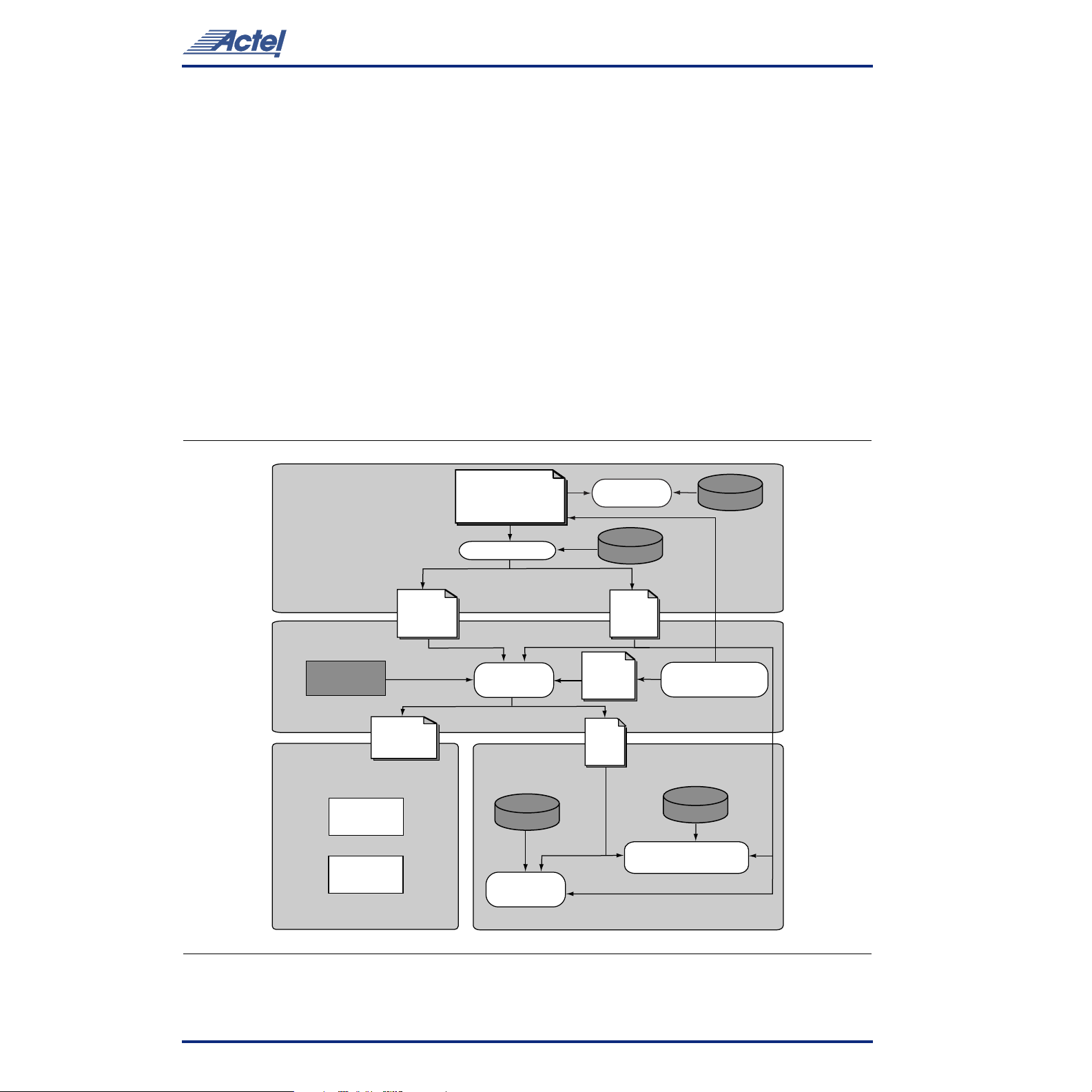

Design Environment

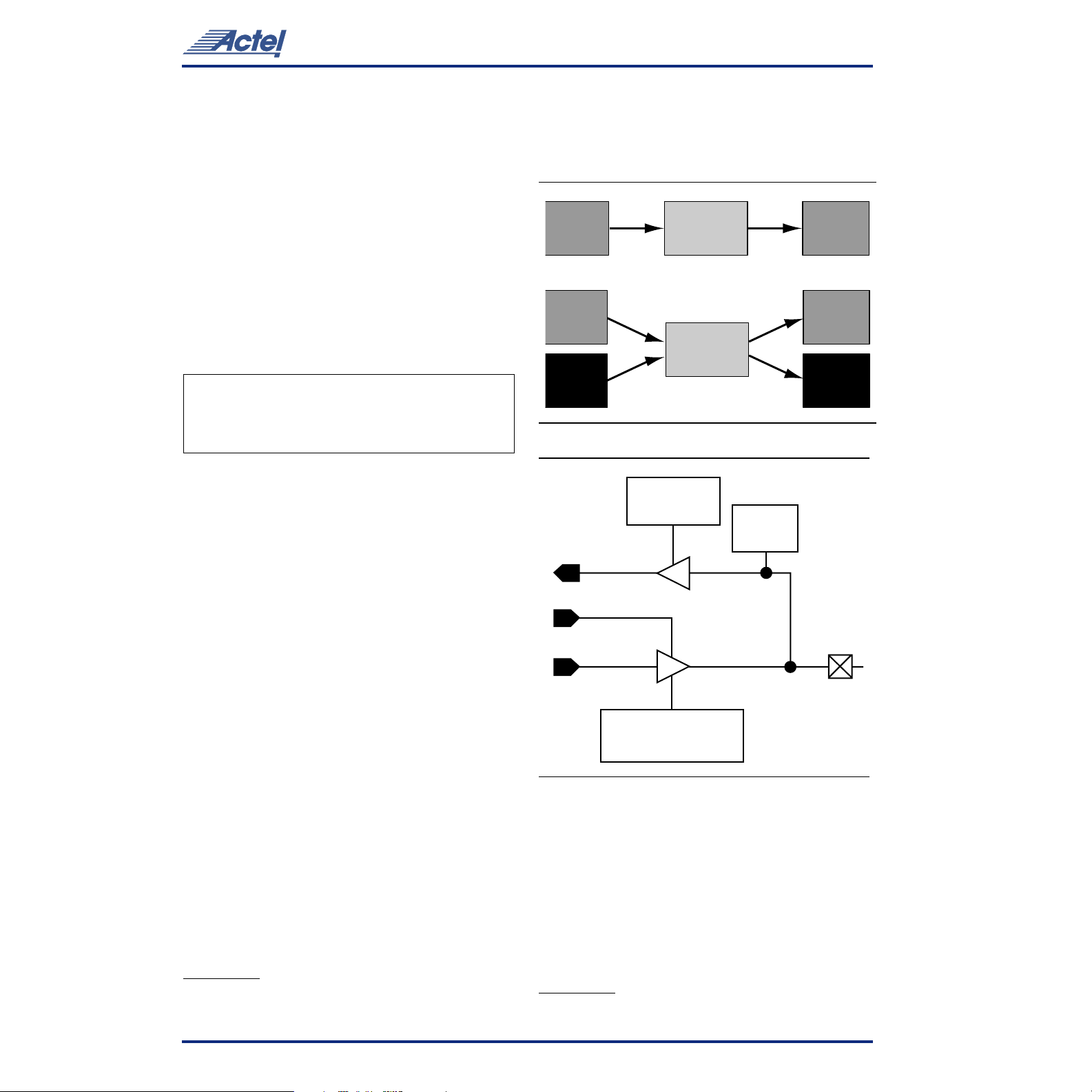

ProASIC devices are supported by Actel’s ASICmaster and

MEMORYmaster software, as well as third party CAE tools.

Using the standard VHDL or Verilog HDL descriptions, no

special HDL design techniques, as required by some FPGA

vendors, are needed. This allows designers to use technology

independent HDL code for ProASIC devices. This and the

ProASIC design flow ensure a seamless transition to an ASIC,

should production volumes warrant a migration to a gate

array or a standard cell product (Figure 15).

MEMORYmaster automatically generates memories from

inputs given by the designer. The designer can select the

depth and width, usage of parity generation or check, and

synchronous or asynchronous functionality of the ports. If it is

a synchronous read port, the designer can choose whether the

output is pipelined or transparent. MEMORYmaster allows

any bit width up to 252 (for the A500K270 device), but if an

intermediate bit width is chosen, such as 16 bits, the

remaining two bits are no longer accessible for other

memories. MEMORYmaster also enables optimal memory

stacking in 256 word increments. However, any word depth

may be compiled for up to 7,168 words.

Place and route is performed by Actel’s ASICmaster software.

Available for SunOS

®

, Solaris

®

®

, HP

, and Windows NT

®

, it

accepts standard netlists in Verilog, VHDL, and in EDIF 2.0.0,

performs place and route of the design into the selected

device, and provides post layout delay information for back

annotation simulation or static timing analysis. The

ASICmaster software also contains very powerful interactive

layout capabilities for the experienced user.

Once the design is finalized, the programming bitstream is

downloaded into the device programmer for ProASIC part

programming. ProASIC 500K devices can be programmed

with the Silicon Sculptor programmer. In-system

programming is also available using the Silicon Sculptor

programmer or Silicon Explorer II.

Design Creation/Verification

Design Implementation

P&R User

Constraints

Programming

Programming

Data

Silicon

Sculptor

Silicon

Explorer II

Forward

Constraints

High-Level

Design

(Verilog or VHDL)

Synthesis T ool

ASICmaster

(P&R T ool)

Backannotation

Timing

Libraries

Timing

Analyzer

Simulation

(behavioral)

Synthesis

Library

Structural

Netlist

Placement

Constraints

SDF

Timing

File

Simulation

Library

MEMORYmaster

Timing Analysis and Simulation

Simulation

Library

Simulation

(mixed-level structural)

Figure 15 • Design Flow

12

Page 13

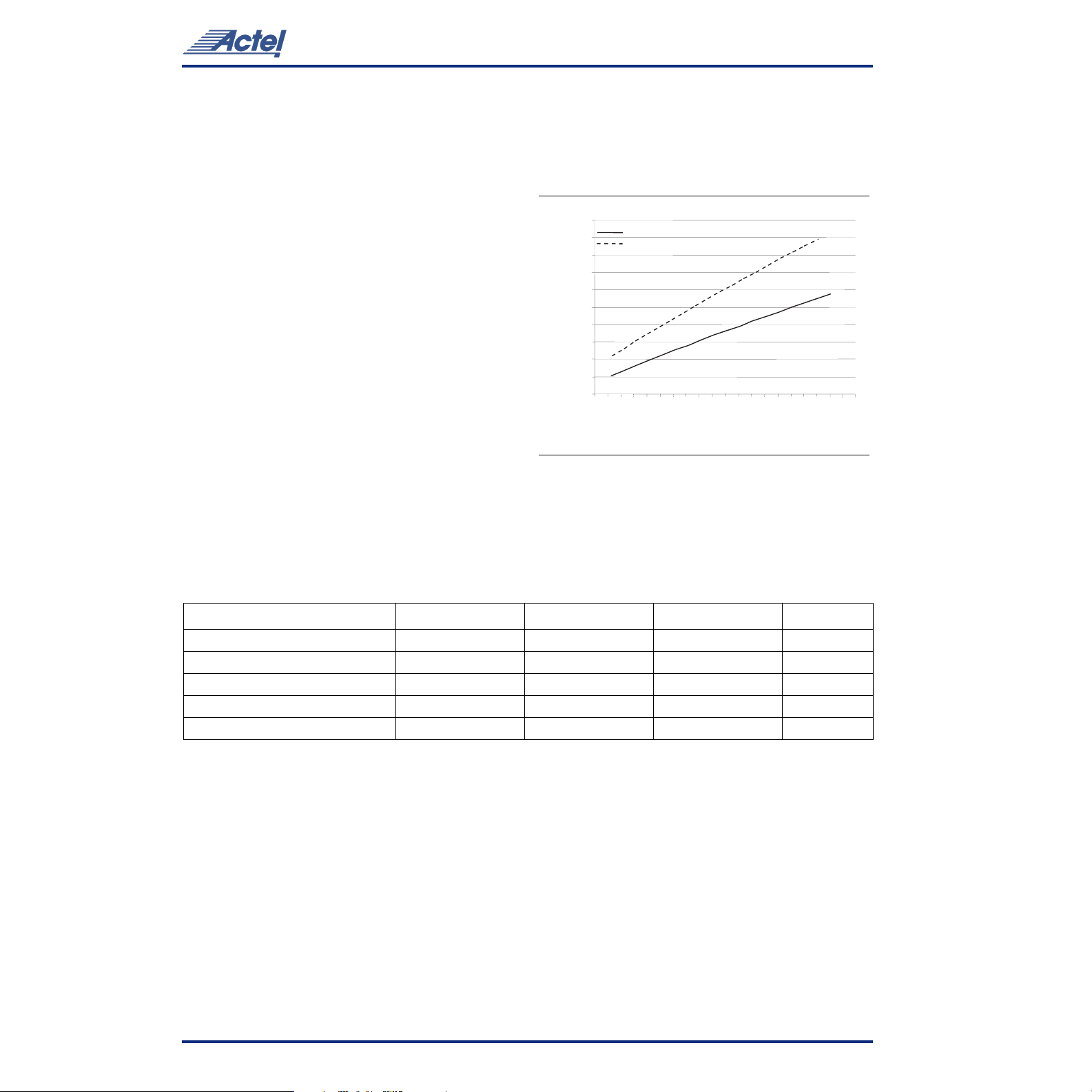

Package Thermal Characteristics

P

TJTA–

Θ

ja

------------------=

The ProASIC 500K family is available in a number of package

types. Actel has selected packages based on high pin count,

reliability factors, and superior thermal characteristics.

The ability of a package to conduct heat away from the

silicon, through the package, to the surrounding air is

expressed in terms of thermal resistance. This

junction-to-ambient thermal resistance is measured in

degrees Celsius/Watt and is represented as Theta ja

(

Θ

ja

The lower this thermal resistance, the easier it is for the

package to dissipate heat.

The maximum allowed power (P) for a package is a function

of the maximum junction temperature (T

ambient operating temperature (T

), the maximum

J

), and the

A

™

ProASIC

junction-to-ambient thermal resistance

500K Family

Θ

junction temperature is the maximum temperature on the

active surface of the IC and is 110° C. P is defined as

Θ

is a function of the rate of airflow in contact with the

).

ja

package, in linear feet per minute (lfpm). When the

estimated power consumption exceeds the maximum allowed

power, other means of cooling must be used, such as

increasing the airflow rate.

.

ja

Maximum

:

Package T ype Pin Count

Plastic Quad Flat Pack (PQFP) 208 3.5 20 17 ˚C/W

Plastic Ball Grid Array (PBGA) 272 3 20 16.5 ˚C/W

Plastic Ball Grid Array (PBGA) 456 3 18 14.5 ˚C/W

Θ

jc

Still Air

Θ

ja

300 ft/min Units

Θ

ja

Calculating Power Dissipation

ProASIC device power is calculated in the same manner as

LVCMOS gate arrays and includes both a static and an active

component. The active component is a function of both the

number of tiles utilized and the system speed. ASICmaster

provides an automatic power calculator that can be used to

quickly and easily calculate power dissipation. Power

dissipation can also be calculated using the following

formula:

P = V

DD

* I

DD

where:

= I

I

DD

STATIC

+ I

OUTPUT

+ I

LOGIC

and

I

OUTPUT

I

LOGIC

= I

I

STATIC

STATIC CORE

is the current due to the outputs switching.

is the current due to the internal logic

+ I

STATIC I/O

signals switching.

The static power (I

) is the amount of current drawn

STATIC

when no inputs are switching. This is equal to the Quiescent

Supply Current I

specified under DC Electrical

DDQ

Specifications beginning on page 16.

Active power includes both the current due to outputs

switching and the current due to internal logic signals

switching.

n

I

OUTPUT

=

∑

i 1=

CiVifiI

+⋅⋅()

DCi

where:

C

V

i

f

i

= Capacitance on the i th output pad

i

= Voltage swing on the i th output pad

= Switching frequency on the i th output pad

n = Number of outputs

I

DCi

In most cases I

= Average DC load on each pad, if any

can be approximated by the following

OUTPUT

formula, measured in mA:

I

OUTPUT

= n * C

typ

* V * f

avg

where:

n = Number of active outputs

C

typ

= Typical capacitance load on an output

V = Average voltage swing

f

avg

= Average switching frequency of the outputs.

Typically this is less than 25% of the clock

frequency

is represented by this formula, measured in mA:

I

LOGIC

I

LOGIC

= I

* G * f * F

E

where:

I

E

= Effective µA per gate per MHz of the Actel parts.

For the ProASIC products the value is 1.2

G = Number of gates used in the design, in thousands

13

Page 14

f = Operating frequency in MHz

F = Fraction of devices active on each clock edge. F

varies for different designs, but 0.15 is a

conservative and commonly used value.

For an A500K130 design that has 47,000 used gates, 20

memory blocks, 150 active outputs, an average load of 20pF,

and a 66 MHz clock, resulting in an average switching

frequency of 16.5 MHz, the power calculation appears below.

I

OUTPUT

= 150 * 20 * 10

–12

* 3.6 * 16.5 * 106 mA

= 140 mA

P

OUTPUT

I

LOGIC

= 3.6V * 140 mA = .5W

= 1.2 * 47 * 66 * 0.15 mA

= 558 mA

Therefore

I

LOGIC

P

Logic

= 558 mA

= 2.75V * 558 mA

= 1.5W

Assumptions .5k gates per 256x9 block

I

memory

= 1.2 * .5 * 66 * .15 * 20 mA

= 118 mA

P

memory

= 2.75V * 143 mA = .326

P = 1.5W + .5W + .32W = 2.32W

I

STATIC CORE

and I

STATIC I/O

are not included in this

calculation.

1000

900

800

700

600

500

400

300

200

Power Consumption (mW)

100

0

20

ProASIC

SRAM

30

110 instances of 16-bit binary counters

50 60

40

Frequency (MHz)

70

80

90

Figure 16 • Power Consumption of a 500K Device

100 120

Operating Conditions

Absolute Maximum Ratings

Parameter Condition Minimum Maximum Units

Supply Voltage Core (V

Supply Voltage IO Ring (V

DC Input Voltage –0.3 V

PCI DC Input Voltage –0.5 V

DC Input Clamp Current (IIK) V

Note: Stresses beyond those listed under Absolute Maximum ratings can cause permanent damage to the device. Exposure to maximum rated

conditions for extended periods can adversely affect device reliability. Operation of the device at these conditions or any others beyond

those listed in the Recommended Operating Conditions table on page 15 is not implied.

) –0.3 3.0 V

DDL

) –0.3 4.0 V

DDP

+ 0.3 V

DDP

+ 0.5 V

DDP

< 0 or > V

IN

DDP

–10 +10 mA

14

Page 15

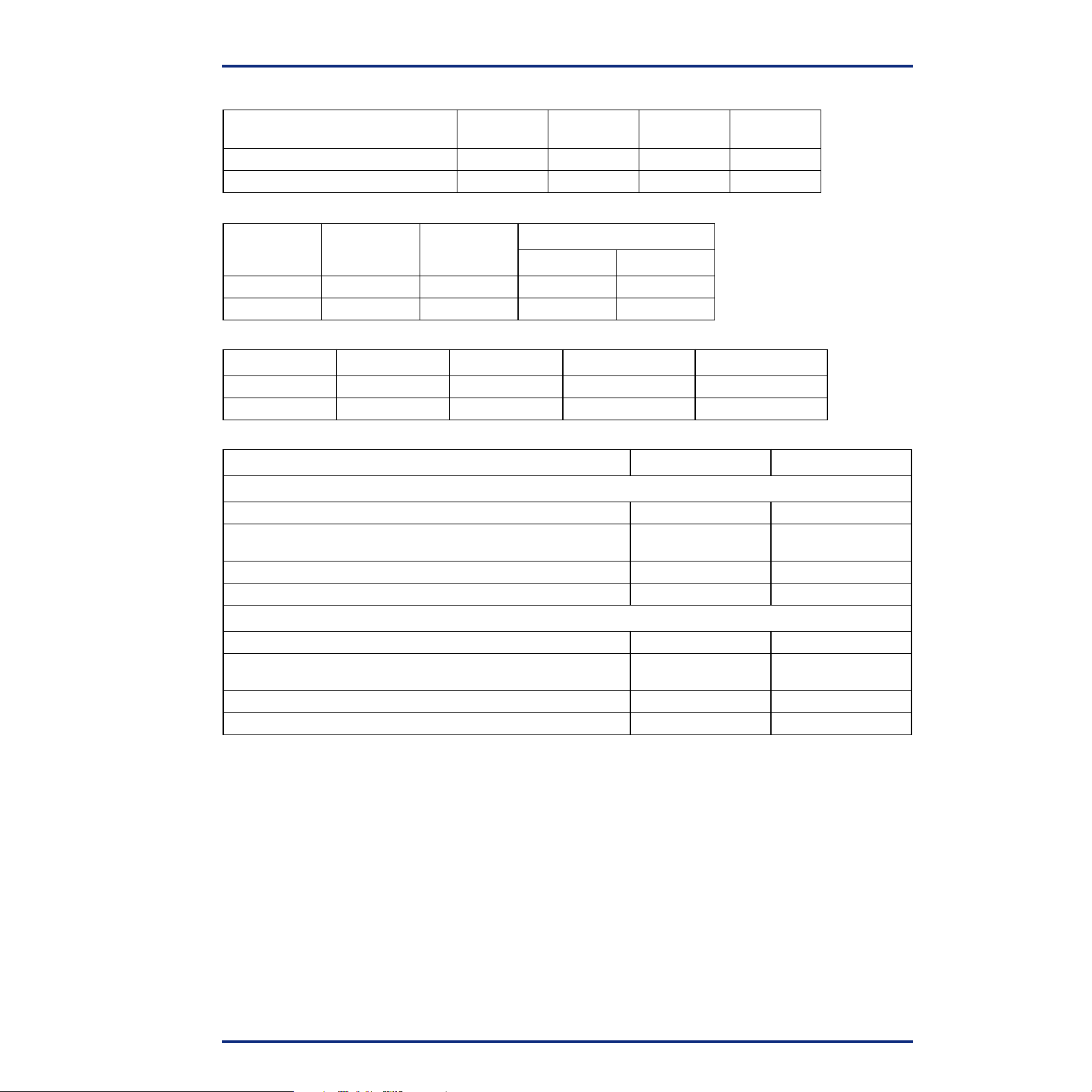

Temperature Maximums

ProASIC™ 500K Family

Parameter Min. Max. Units

Retention

Storage Temperature –65 +150 °C N/A

Storage Temperature—Programmed –65 +110 °C 20 years

Program

Programming Limits and Recommended Operating Conditions

Junction T emperature

Product Grade

Programming

Cycles

Program

Retention

Min. Max.

Commercial 500 20 years 0°C 110°C

Industrial 500 20 years –40°C 110°C

Supply Voltages

Mode V

DDL

V

DDP

V

PP

V

PN

Single V oltage 2.5V 2.5V 2.5V ≤ VPP ≤ 16.5 V –12V ≤ VPN ≤ 0V

Mixed V oltage 2.5V 3.3V 3.3V ≤ V

Recommended Operating Conditions

≤ 16.5V –12V ≤ VPN ≤ 0V

PP

Parameter Symbol Limits

Commercial

DC Supply Voltage (2.5V I/Os) V

DC Supply Voltage (3.3V, 2.5V I/Os) V

Operation Ambient Temperature Range T

Operation Junction Temperature (maximum) T

DDL

V

& V

DDP

DDL

A

J

DDP

2.3V to 2.7V

3.0V to 3.6V

2.3V to 2.7V

0°C to 70°C

≤ 110°C

Industrial

DC Supply Voltage (2.5V I/Os) V

DDL

DC Supply Voltage (2.5V, 3.3V I/Os) V

V

Operation Ambient Temperature Range T

Operation Junction Temperature (maximum) T

& V

DDP

DDL

A

J

DDP

2.3V to 2.7V

3.0V to 3.6V

2.3V to 2.7V

–40°C to 85°C

≤ 110°C

15

Page 16

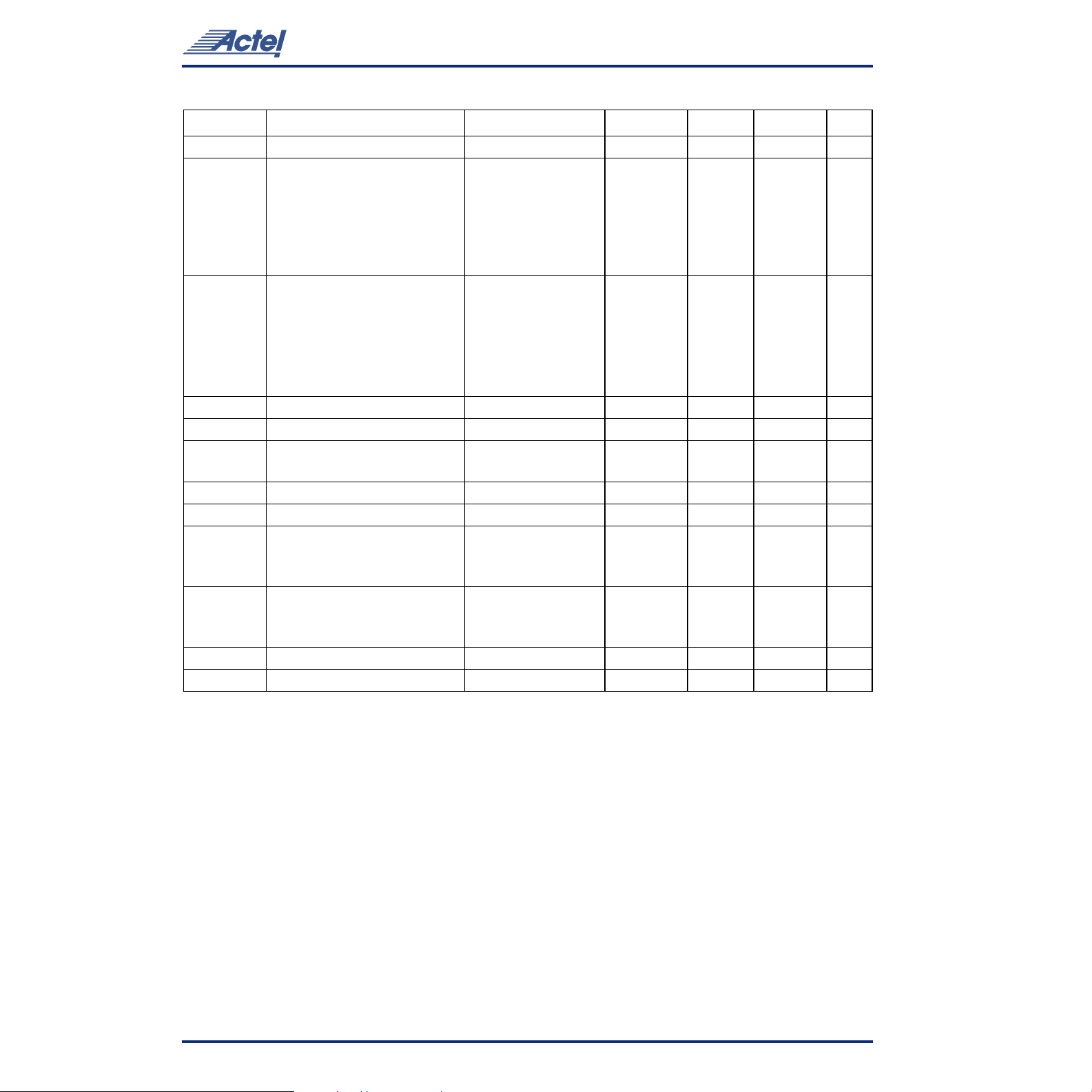

DC Electrical Specifications (V

DDP

= 2.5V)

Symbol Parameter Conditions Min. Typ. Max. Units

V

V

V

V

V

I

IN

I

DDQ

I

OZ

I

OSH

I

OSL

C

C

DDP

OH

OL

IH

IL

I/O

CLK

, V

DDL

Supply V oltage 2.3 2.7 V

Output High Voltage

High Drive

Low Drive

= –2.0 mA

I

OH

I

= –4.0 mA

OH

I

= –8.0 mA

OH

= –1.0 mA

I

OH

I

= –2.0 mA

OH

I

= –4.0 mA

OH

2.1

2.0

1.7

2.1

2.0

1.7

V

Output Low Voltage

High Drive

Low Drive

Input High Voltage 1.7 V

= 5.0 mA

I

OL

I

= 10.0 mA

OL

I

= 15.0 mA

OL

= 2.0 mA

I

OL

I

= 3.5 mA

OL

I

= 5.0 mA

OL

0.2

0.4

0.7

0.2

0.4

0.7

+ 0.3 V

DDP

V

Input Low Voltage –0.3 .7 V

Input Current

Input Current

Quiescent Supply Current VIN = V

3-State Output Leakage Current VOH = VSS or V

with pull-up

without pull-up

†

or V

SS

DDL

DDL

–20

–10

–100

10

µA

µA

1.0 10 mA

–10 +10 µA

Output Short Circuit Current High

High Drive

Low Drive

–120

–100

mA

Output Short Circuit Current Low

High Drive

Low Drive

100

30

mA

I/O Pad Capacitance 8pF

Clock Input Pad Capacitance 8 pF

Notes: All process conditions. Junction Temperature: –40 to +110°C.

† No pull-up resistor.

16

Page 17

ProASIC™ 500K Family

DC Electrical Specifications (V

= 3.3V)

DDP

Symbol Parameter Conditions Min. Typ. Max. Units

V

DDP

V

DDL

V

OH

V

OL

V

IH

V

IL

I

IN

I

DDQ

Supply V oltage 3.0 3.6 V

Supply Voltage, Logic Array 2.3 2.7 V

Output High Voltage

3.3V I/O, High Drive

3.3V I/O, Low Drive

2.5V I/O, High Drive

2.5V I/O, Low Drive

= –3.0 mA

I

OH

I

= –5.0 mA

OH

I

= –10.0 mA

OH

= –2.0 mA

I

OH

I

= –3.0 mA

OH

I

= –6.0 mA

OH

= –0.5 mA

I

OH

I

= –1.0 mA

OH

I

= –2.0 mA

OH

= –0.5 mA

I

OH

I

= –1.0 mA

OH

I

= –2.0 mA

OH

V

DDP

0.9

V

DDP

0.9

– 0.2

* VDDP

2.4

– 0.2

* VDDP

2.4

2.1

2.0

1.7

2.1

2.0

1.7

Output Low Voltage

3.3V I/O, High Drive

3.3V I/O, Low Drive

2.5V I/O, High Drive

2.5V I/O, Low Drive

= 7.5 mA

I

OL

I

= 12.0 mA

OL

I

= 15.0 mA

OL

= 2.5 mA

I

OL

I

= 4.0 mA

OL

I

= 5.0 mA

OL

= 7.5 mA

I

OL

I

= 15.0 mA

OL

I

= 24.0 mA

OL

= 2.5 mA

I

OL

I

= 5.0 mA

OL

I

= 8.0 mA

OL

0.1

0.1

0.2

* VDDP

0.4

0.2

* VDDP

0.4

0.2

0.4

0.7

0.2

0.4

0.7

Input High Voltage

LVTTL/LVCMOS

2.5V Mode

2

1.7

V

V

DDP

DDP

+ 0.3

+ 0.3

Input Low Voltage

LVTTL/LVCMOS

2.5V Mode

–0.3

–0.3

0.8

0.7

Input Current

LVTTL/LVCMOS

LVTTL/LVCMOS

Quiescent Supply Current VIN = V

with pull-up

without pull-up

†

or V

SS

DD

–40

–10

–200

10

µA

µA

1.0 10 mA

V

V

V

V

V

V

Notes: Refer to PCI Specifications Revision 2.2. for 3.3V high drive, high slew-rate output pads, and all 3.3V input/clock pads.

† No pull-up resistor.

17

Page 18

DC Electrical Specifications (V

= 3.3V) (Continued)

DDP

Symbol Parameter Conditions Min. Typ. Max. Units

I

OZ

I

OSH

I

OSL

C

C

I/O

CLK

3-State Output Leakage Current VOH = V

Output Short Circuit Current High

3.3V I/O, High Drive

3.3V I/O, Low Drive

2.5V I/O, High Drive

2.5V I/O, Low Drive

Output Short Circuit Current Low

3.3V I/O, High Drive

3.3V I/O, Low Drive

2.5V I/O, High Drive

2.5V I/O, Low Drive

I/O Pad Capacitance 8pF

Clock Input Pad Capacitance 8 pF

SS

†

or V

DD

–10 +10 µA

–200

mA

–140

–100

–100

160

mA

50

160

50

Notes: Refer to PCI Specifications Revision 2.2. for 3.3V high drive, high slew-rate output pads, and all 3.3V input/clock pads.

† No pull-up resistor.

18

Page 19

Timing Characteristics

ProASIC™ 500K Family

EN

A

PAD

OTBx

A

PAD

V

OL

50%

t

DLH

50%

V

OH

50%

t

DHL

50%

EN

PAD

50%

V

CC

t

ENZL

50%

50%

V

OL

10%

EN

PAD

GND

50%

t

ENZH

50%

V

OH

50%

90%

Figure 17 • Tri-State Buffer Delays

Table 3 • Tri-State Buffer Delays

(Worst-Case Commercial Conditions, V

DDP

= 3.0V, V

Macro T ype Description

OTB33PH 3.3V, PCI Output Current, High Slew Rate 4.41 4.28 4.40 3.71 ns

OTB33PN 3.3V, PCI Output Current, Nominal Slew Rate 4.91 6.08 4.90 5.46 ns

OTB33PL 3.3V, PCI Output Current, Low Slew Rate 5.51 7.41 5.50 6.86 ns

OTB33LH 3.3V, Low Output Current, High Slew Rate 6.23 6.90 6.24 6.09 ns

OTB33LN 3.3V, Low Output Current, Nominal Slew Rate 6.98 9.63 6.98 9.26 ns

OTB33LL 3.3V, Low Output Current, Low Slew Rate 7.80 12.56 7.80 12.28 ns

OTB25HH 2.5V, High Output Current, High Slew Rate 7.15 3.73 7.15 3.48 ns

OTB25HN 2.5V, High Output Current, Nominal Slew Rate 7.54 5.41 7.54 5.14 ns

OTB25HL 2.5V, High Output Current, Low Slew Rate 8.45 6.66 8.45 6.38 ns

OTB25LH 2.5V, Low Output Current, High Slew Rate 10.77 5.74 10.76 5.37 ns

OTB25LN 2.5V, Low Output Current, Nominal Slew Rate 11.54 8.60 11.52 8.35 ns

OTB25LL 2.5V, Low Output Current, Low Slew Rate 12.39 11.37 12.38 11.12 ns

OTB25LPHH 2.5V, Low Power, High Output Current, High Slew Rate 5.30 5.29 5.27 4.57 ns

OTB25LPHN 2.5V, Low Power, High Output Current, Nominal Slew Rate 6.27 7.99 6.24 7.46 ns

OTB25LPHL 2.5V, Low Power, High Output Current, Low Slew Rate 7.15 10.20 7.12 9.74 ns

OTB25LPLH 2.5V, Low Power, Low Output Current, High Slew Rate 7.74 9.02 7.71 8.10 ns

OTB25LPLN 2.5V, Low Power, Low Output Current, Nominal Slew Rate 8.96 13.11 8.93 12.76 ns

OTB25LPLL 2.5V, Low Power, Low Output Current, Low Slew Rate 10.24 17.72 10.21 17.38 ns

Notes:

1. t

2. t

3. t

4. t

= Data-to-Pad HIGH

DLH

= Data-to-Pad LOW

DHL

= Enable-to-Pad, Z to HIGH

ENZH

= Enable-to-Pad, Z to LOW

ENZL

= 2.3V, 35 pF load, TJ = 70°C)

DDL

Max

t

DLH

Max

t

DHL

Max

t

ENZH

Max

t

ENZL

Units

19

Page 20

A

A

PAD

PAD

V

OBx

50%

OL

t

DLH

50%

V

OH

50%

t

DHL

50%

Figure 18 • Output Buffer Delays

Table 4 • Output Buffer Delays

(Worst-Case Commercial Conditions, V

DDP

= 3.0V, V

Macro T ype Description Max. t

OB33PH 3.3V, PCI Output Current, High Slew Rate 4.41 4.28 ns

OB33PN 3.3V, PCI Output Current, Nominal Slew Rate 4.91 6.08 ns

OB33PL 3.3V, PCI Output Current, Low Slew Rate 5.51 7.41 ns

OB33LH 3.3V, Low Output Current, High Slew Rate 6.23 6.90 ns

OB33LN 3.3V, Low Output Current, Nominal Slew Rate 6.98 9.63 ns

OB33LL 3.3V, Low Output Current, Low Slew Rate 7.80 12.56 ns

OB25HH 2.5V, High Output Current, High Slew Rate 7.15 3.73 ns

OB25HN 2.5V, High Output Current, Nominal Slew Rate 7.54 5.41 ns

OB25HL 2.5V, High Output Current, Low Slew Rate 8.45 6.66 ns

OB25LH 2.5V, Low Output Current, High Slew Rate 10.77 5.74 ns

OB25LN 2.5V, Low Output Current, Nominal Slew Rate 11.54 8.60 ns

OB25LL 2.5V, Low Output Current, Low Slew Rate 12.39 11.37 ns

OB25LPHH 2.5V, Low Power, High Output Current, High Slew Rate 5.30 5.29 ns

OB25LPHN 2.5V, Low Power, High Output Current, Nominal Slew Rate 6.27 7.99 ns

OB25LPHL 2.5V, Low Power, High Output Current, Low Slew Rate 7.15 10.20 ns

OB25LPLH 2.5V, Low Power, Low Output Current, High Slew Rate 7.74 9.02 ns

OB25LPLN 2.5V, Low Power, Low Output Current, Nominal Slew Rate 8.96 13.11 ns

OB25LPLL 2.5V, Low Power, Low Output Current, Low Slew Rate 10.24 17.72 ns

Notes:

1. t

2. t

= Data-to-Pad HIGH

DLH

= Data-to-Pad LOW

DHL

= 2.3V, 35 pF load, TJ = 70°C)

DDL

DLH

Max. t

DHL

Units

20

Page 21

PAD

IBx

ProASIC™ 500K Family

V

CC

PAD

Y

Y

50%

50%

V

CC

50%

0V

50%

GND

t

INYH

t

INYL

Figure 19 • Input Buffer Delays

Table 5 • Input Buffer Delays

(Worst-Case Commercial Conditions, V

DDP

= 3.0V, V

Macro T ype Description

IB25 2.5V, CMOS Input Levels, No Pull-up Resistor 2.26 0.70 ns

IB25LP 2.5V, CMOS Input Levels, Low Power 2.25 1.51 ns

IB33 3.3V, CMOS Input Levels, No Pull-up Resistor 1.98 1.02 ns

Notes:

1. t

2. t

= Input Pad-to-Y HIGH

INYH

= Input Pad-to-Y LOW

INYL

= 2.3V, TJ = 70°C)

DDL

Max.

t

INYH

Max.

t

INYL

Units

Table 6 • Global Input Buffer Delays

(Worst-Case Commercial Conditions, V

Macro T ype Description

GL25 2.5V, CMOS Input Levels 2.17 1.74 ns

GL25LP 2.5V, CMOS Input Levels 2.38 2.37 ns

GL33 3.3V, CMOS Input Levels 3.97 1.17 ns

GL25U 2.5V, CMOS Input Levels, with Pull-up Resistor 2.17 1.74 ns

GL25LPU 2.5V, CMOS Input Levels, Low Power, with Pull-up Resistor 2.38 2.37 ns

GL33U 3.3V, CMOS Input Levels, with Pull-up Resistor 3.97 1.17 ns

DDP

= 3.0V, V

= 2.3V, TJ = 70°C)

DDL

Max.

t

INYH

Max.

t

INYL

Units

Table 7 • Predicted Global Routing Delay*

(Worst-Case Commercial Conditions, V

Parameter Description Max. Units

t

RCKH

t

RCKL

t

RCKH

t

RCKL

* The timing delay difference between tile locations is less than 15ps.

Input Low to High (fully loaded row—32 inputs) 1.19 ns

Input High to Low (fully loaded row—32 inputs) 1.1 ns

Input Low to High (minimally loaded row—1 input) 0.89 ns

Input High to Low (minimally loaded row—1 input) 0.85 ns

DDP

= 3.0V, V

= 2.3V, TJ = 70°C)

DDL

Table 8 • Global Routing Skew

(Worst-Case Commercial Conditions, V

Parameter Description Max. Units

t

RCKSWH

t

RCKSHH

Maximum Skew Low to High 0.30 ns

Maximum Skew High to Low 0.26 ns

DDP

= 3.0V, V

= 2.3V, TJ = 70°C)

DDL

21

Page 22

A

B

Y

C

A

B

C

50%Y50%

50%

t

DALH

t

DAHL

50% 50%

t

DBLH

50%

t

DBHL

50% 50%

50%50%

t

DCLH

50%

t

DCHL

50%

Figure 20 • Module Delays

Table 9 • Sample Macrocell Library Listing

(Worst-Case Commercial Conditions, V

Cell Name Description

NAND2 2-Input NAND 0.42 ns

AND2 2-Input AND 0.40 ns

NOR3 3-Input NOR 0.42 ns

MUX2L 2-1 Mux with Active Low Select 0.42 ns

OA21 2-Input OR into a 2-Input AND 0.40 ns

XOR2 2-Input Exclusive OR 0.34 ns

LDL Active Low Latch (LH/HL) D: 0.26/0.21 t

DFFL Negative Edge-Triggered D-type Flip-Flop (LH/HL) CLK-Q:

Note: Assumes fanout of two.

= 2.3V, TJ = 70º C)

DDL

Maximum

Intrinsic Delay

0.42/0.37

Minimum

Setup/Hold Units

0.54

setup

t

0.20

hold

0.43

t

setup

t

0.20

hold

ns

ns

22

Page 23

Embedded Memory Specifications

This section focuses on the embedded memory of the

ProASIC 500K family. It describes the SRAM and FIFO

interface signals and includes timing diagrams that show the

relationships of signals as they pertain to single embedded

memory blocks (Table 10). Refer to Table 2 on page 9 for

basic RAM configurations.

Enclosed Timing Diagrams—SRAM Mode:

• Asynchronous RAM Read, Address Controlled, RDB=0

• Asynchronous RAM Read, RDB Controlled

• Asynchronous RAM Write

• Synchronous RAM Read, Access Timed Output Strobe

(Synchronous Transparent)

• Synchronous RAM Read, Pipeline Mode Outputs

(Synchronous Pipelined)

• Synchronous RAM Write

• Synchronous Write & Read to the Same Location

• Asynchronous Write & Synchronous Read to the Same

Location

• Asynchronous Write & Read to the Same Location

• Synchronous Write & Asynchronous Read to the Same

Location

ProASIC™ 500K Family

Note: The difference between synchronous transparent

and pipeline modes is the timing of all the output

signals from the memory. In transparent mode

the outputs will change within the same clock

cycle to reflect the data requested by the currently

valid access to the memory. However, if clock

cycles are short (high clock speed) the data

requires most of the clock cycle to change to valid

values (stable signals). This makes processing of

this data in the same clock cycle nearly

impossible. Most designers solve this problem by

adding registers at all outputs of the memory to

push the data processing into the next clock cycle.

In this setup, the whole cycle time can be used to

process the data. To simplify the use of this kind

of memory setup these registers have been

implemented as part of the memory primitive

and are available to the user in the synchronous

pipeline mode. In this mode the output signals

will change shortly after the second rising edge

following the initiation of the read access.

Table 10 • Memory Block SRAM Interface Signals

SRAM Signal Bits In/Out Description

WCLKS 1 IN Write clock used on synchronization on write side

RCLKS 1 IN Read clock used on synchronization on read side

RADDR<0:7> 8 IN Read address

RBLKB 1 IN Negative true read block select

RDB 1 IN Negative true read pulse

WADDR<0:7> 8 IN Write address

WBLKB 1 IN Negative true write block select

DI<0:8> 9 IN Input data bits <0:8>, <8> will be generated if PARGEN is true

WRB 1 IN Negative true write pulse

DO<0:8> 9 OUT Output data bits <0:8>

RPE 1 OUT Read parity error

WPE 1 OUT Write parity error

PARODD 1 IN Selects odd parity generation/detect when high, even when low

Notes: Not all signals shown are used in all modes.

23

Page 24

Synchronous RAM Read, Access Timed Output Strobe (Synchronous Transparent)

RCLK

RB=(RBD+RBLKB)

RADDR

RDATA

RPE

t

RACS

t

RDCS

Old Data Out

t

RDCH

t

RACH

New Valid

Address

t

OCH

t

RPCH

Cycle Start

t

CMH

t

OCA

t

RPC

t

CCYC

New Valid Data Out

t

CM

T

= 0°C to 110°C; V

J

Symbol t

Description Min. Max. Units Notes

xxx

= 2.3V to 2.7V

DDL

CCYC Cycle time 7.5 ns

CMH Clock high phase 3.0 ns

CML Clock low phase 3.0 ns

OCA New RDATA access from RCLK ↑ 7.5 ns

OCH Old RDATA valid from RCLK ↑ 3.0 ns

RACH RADDR hold from RCLK ↑ 0.5 ns

RACS RADDR setup to RCLK ↑ 1.0 ns

RDCH RDB hold from RCLK ↑ 0.5 ns

RDCS RDB setup to RCLK ↑ 1.0 ns

RPCA New RPE access from RCLK ↑ 9.5 ns

RPCH Old RPE valid from RCLK ↑ 3.0 ns

24

Page 25

Synchronous RAM Read, Pipeline Mode Outputs (Synchronous Pipelined)

ProASIC™ 500K Family

RCLK

RB=(RDB+RBLKB)

RADDR

RDATA

RPE

t

RACS

t

RACH

t

RDCH

t

RDCS

New Valid

Address

Cycle Start

t

CMH

Old Data Out

New Valid Data Out

Old RPE Out New RPE Out

t

t

t

OCH

t

RPCA

t

CML

t

CCYC

OCA

RPCH

T

= 0°C to 110°C; V

J

Symbol t

CCYC Cycle time 7.5 ns

CMH Clock high phase 3.0 ns

CML Clock low phase 3.0 ns

OCA New RDATA access from RCLK ↑ 2.0 ns

OCH Old RDATA valid from RCLK ↑ .75 ns

RACH RADDR hold from RCLK ↑ 0.5 ns

RACS RADDR setup to RCLK ↑ 1.0 ns

RDCH RDB hold from RCLK ↑ 0.5 ns

RDCS RDB setup to RCLK ↑ 1.0 ns

RPCA New RPE access from RCLK ↑ 4.0 ns

RPCH Old RPE valid from RCLK ↑ 1.0 ns

Description Min. Max. Units Notes

xxx

= 2.3V to 2.7V

DDL

25

Page 26

Asynchronous RAM Write

WB=(WRB+WBLKB)

WADDR

WDATA

WPE

= 0°C to 110°C; V

T

J

Symbol t

Description Min. Max. Units Notes

xxx

t

AWRS

t

WPDA

= 2.3V to 2.7V

DDL

t

t

WRML

DWRS

t

WRCYC

t

WRMH

t

AWRH

t

DWRH

t

WPDH

AWRH WADDR hold from WB ↑ 1.0 ns

AWRS WADDR setup to WB ↓ 0.5 ns

DWRH WDATA hold from WB ↑ 1.5 ns

DWRS WDATA setup to WB ↑ 0.5 ns PARGEN is inactive

DWRS WDATA setup to WB ↑ 2.5 ns PARGEN is active

WPDA WPE access from WDATA 3.0 ns WPE is invalid while

WPDH WPE hold from WDATA 1.0 ns PARGEN is active

WRCYC Cycle time 7.5 ns

WRMH WB high phase 3.0 ns Inactive

WRML WB low phase 3.0 ns Active

26

Page 27

Asynchronous RAM Read, Address Controlled, RDB=0

RADDR

RDATA

RPE

t

OAH

t

RPAH

t

OAA

t

RPAA

t

ACYC

ProASIC™ 500K Family

= 0°C to 110°C; V

T

J

Symbol t

Description Min. Max. Units Notes

xxx

= 2.3V to 2.7V

DDL

ACYC Read cycle time 7.5 ns

OAA New RDATA access from RADDR stable 7.5 ns

OAH Old RDATA hold from RADDR stable 3.0 ns

RPAA New RPE access from RADDR stable 10.0 ns

RPAH Old RPE hold from RADDR stable 3.0 ns

27

Page 28

Asynchronous RAM Read, RDB Controlled

RB=(RDB+RBLKB)

RDATA

RPE

t

ORDH

t

RPRDH

t

ORDA

t

RPRDA

t

RDML

t

RDCYC

t

RDMH

= 0°C to 110°C; V

T

J

Symbol t

Description Min. Max. Units Notes

xxx

= 2.3V to 2.7V

DDL

ORDA New RDATA access from RB ↓ 7.5 ns

ORDH Old RDATA valid from RB ↓ 3.0 ns

RDCYC Read cycle time 7.5 ns

RDMH RB high phase 3.0 ns Inactive setup to new cycle

RDML RB low phase 3.0 ns Active

RPRDA New RPE access from RB ↓ 9.5 ns

RPRDH Old RPE valid from RB ↓ 3.0 ns

28

Page 29

Synchronous RAM Write

ProASIC™ 500K Family

WCLK

WRB, WBLKB

WADDR, WDATA

WPE

t

WRCH, tWBCH

t

WRCS, tWBCS

t

DCS, tWDCS

t

DCH, tWACH

t

WPCH

Cycle Start

t

WPCA

t

CMH

t

CCYC

t

CML

T

= 0°C to 110°C; V

J

Symbol t

Description Min. Max. Units Notes

xxx

= 2.3V to 2.7V

DDL

CCYC Cycle time 7.5 ns

CMH Clock high phase 3.0 ns

CML Clock low phase 3.0 ns

DCH WDATA hold from WCLK ↑ 0.5 ns

DCS WDATA setup to WCLK ↑ 1.0 ns

WACH WADDR hold from WCLK ↑ 0.5 ns

WACS WADDR setup to WCLK ↑ 1.0 ns

WPCA New WPE access from WCLK ↑ 3.0 ns WPE is invalid while

WPCH Old WPE valid from WCLK ↑ 0.5 ns

WRCH,

WRB & WBLKB hold from WCLK ↑ 0.5 ns

PARGEN is active

WBCH

WRCS,

WRB & WBLKB setup to WCLK ↑ 1.0 ns

WBCS

Note: On simultaneous read and write accesses to the same location WDATA is output to RDATA.

29

Page 30

Synchronous Write & Read to the Same Location

RCLK

RDATA

Last Cycle Data

New Data*

WCLK

t

WCLKRCLKH

t

WCLKRCLKS

t

OCH

t

OCA

* New data is read if WCLK ↑ occurs before setup time.

The data stored is read if WCLK ↑ occurs after hold time.

= 0°C to 110°C; V

T

J

Symbol t

xxx

Description Min. Max. Units Notes

= 2.3V to 2.7V

DDL

CCYC Cycle time 7.5 ns

CMH Clock high phase 3.0 ns

CML Clock low phase 3.0 ns

WCLKRCLKS WCLK ↑ to RCLK ↑ setup time – 0.1 ns

WCLKRCLKH WCLK ↑ to RCLK ↑ hold time 7.0 ns

OCH Old RDATA valid from RCLK ↑ 3.0 ns

OCA New RDATA valid from RCLK ↑ 7.5 ns

OCA/OCH displayed for

Access Timed Output

Notes:

1. This behavior is valid for Access Timed Output and Pipelined Mode Output. Shown are the timings of an access timed output.

2. During synchronous write and synchronous read access to the same location, the new write data will be read out if the active write clock

edge occurs before or at the same time as the active read clock edge. The negative setup time insures this behavior for WCLK and RCLK

driven by the same design signal.

3. If WCLK changes after the hold time, the data will be read.

4. A setup or hold time violation will result in unknown output data.

30

Page 31

Asynchronous Write & Synchronous Read to the Same Location

RCLK

ProASIC™ 500K Family

RDATA

Last Cycle Data

New Data*

WB = {WRB + WBLKB}

WDATA

t

WCLKRCLKS

t

WCLKRCLKH

t

OCH

t

OCA

t

DWRRCLKS

t

DWRH

* New data is read if WB ↓ occurs before setup time.

The stored data is read if WB ↓ occurs after hold time.

= 0°C to 110°C; V

T

J

Symbol t

xxx

Description Min. Max. Units Notes

= 2.3V to 2.7V

DDL

CCYC Cycle time 7.5 ns

CMH Clock high phase 3.0 ns

CML Clock low phase 3.0 ns

WBRCLKS WB ↓ to RCLK ↑ setup time –0.1 ns

WBRCLKH WB ↓ to RCLK ↑ hold time 7.0 ns

OCH Old RDATA valid from RCLK ↑ 3.0 ns

OCA New RDATA valid from RCLK ↑ 7.5 ns

OCA/OCH displayed for

Access Timed Output

DWRRCLKS WDATA to RCLK ↑ setup time 0 ns

DWRH WDATA to WB ↑ hold time 1.5 ns

Notes:

1. This behavior is valid for Access Timed Output and Pipelined Mode Output. Shown are the timings of an access timed output.

2. In asynchronous write and synchronous read access to the same location, the new write data will be read out if the active write signal edge

occurs before or at the same time as the active read clock edge. If WB changes to low after hold time, the data will be read.

3. A setup or hold time violation will result in unknown output data.

31

Page 32

Asynchronous Write & Read to the Same Location

RB, RADDR

RDATA

OLD

NEWERNEW

WB = {WRB+WBLKB}

0°C to 110°C; V

T

J =

Symbol t

xxx

t

ORDA

t

ORDH

t

RAWRS

= 2.3V to 2.7V

DDL

t

OWRA

t

OWRH

Description Min. Max. Units Notes

t

RAWRH

ORDA New RDATA access from RB ↓ 7.5 ns

ORDH Old RDATA valid from RB ↓ 3.0 ns

OWRA New RDATA access from WB ↑ 3.0 ns

OWRH Old RDATA valid from WB ↑ 0.5 ns

RAWRS RB ↓ or RADDR from WB ↓ 5.0 ns

RAWRH RB ↑ or RADDR from WB ↑ 5.0 ns

Notes:

1. During an asynchronous read cycle, each write operation (sync. or async.) to the same location will automatically trigger a read

operation which updates the read data.

2. Violation or RAWRS will disturb access to the OLD data.

3. Violation of RAWRH will disturb access to the NEWER data.

32

Page 33

Synchronous Write & Asynchronous Read to the Same Location

RB, RADDR

ProASIC™ 500K Family

RDATA

OLD

NEW NEWER

WCLK

t

RAWCLKS

T

= 0°C to 110°C; V

J

Symbol t

xxx

t

ORDA

t

ORDH

t

OWRA

t

OWRH

= 2.3V to 2.7V

DDL

Description Min. Max. Units Notes

t

RAWCLKH

ORDA New RDATA access from RB ↓ 7.5 ns

ORDH Old RDATA valid from RB ↓ 3.0 ns

OWRA New RDATA access from WCLK ↓ 3.0 ns

OWRH Old RDATA valid from WCLK ↓ 0.5 ns

RAWCLKS RB ↓ or RADDR from WCLK ↑ 5.0 ns

RAWCLKH RB ↑ or RADDR from WCLK ↓ 5.0 ns

Notes:

1. During an asynchronous read cycle, each write operation (sync. or async.) to the same location will automatically trigger a read

operation which updates the read data.

2. Violation of RAWCLKS will disturb access to OLD data.

3. Violation of RAWCLKH will disturb access to NEWER data.

33

Page 34

Asynchronous FIFO Full and Empty Transitions

The asynchronous FIFO accepts writes and reads while not

full or not empty, respectively. When the FIFO is full, all

writes are inhibited. Conversely, when the FIFO is empty, all

reads are inhibited. A problem is created if the FIFO is

written during the transition out of full to not full or read

during the transition out of empty to not empty. The exact

time at which the write (read) operation changes from

inhibited to accepted after the read (write) signal which

causes the transition from full (empty) to not full (empty) is

indeterminate. This indeterminate period starts 1 ns after the

RB (WB) transition which deactivates full (not empty) and

ends 3 ns after the RB (WB) transition, for slow cycles. For

fast cycles, the indeterminate period ends 3 ns (7.5 ns – RDL

(WRL)) after the RB (WB) transition, whichever is later.

The timing diagram for write is shown in Figure 21 on page

35. The timing diagram for read is shown in Figure 22 on page

35. For basic RAM configurations, see Table 2 on page 9.

Enclosed Timing Diagrams—FIFO Mode:

• Asynchronous FIFO Read

• Asynchronous FIFO Write

• Synchronous FIFO Read, Access Timed Output

Strobe (Synchronous Transparent)

• Synchronous FIFO Read, Pipeline Mode Outputs

(Synchronous Pipelined)

• Synchronous FIFO Write

• FIFO Reset

Table 11 • Memory Block FIFO Interface Signals

FIFO Signal Bits In/Out Description

WCLK 1 IN Write clock used on synchronization on write side

RCLK 1 IN Read clock used on synchronization on read side

LEVEL <0:7> 8 IN Direct configuration implements static flag logic.

RBLKB 1 IN Negative true read block select.

RDB 1 IN Negative true read pulse.

RESET 1 IN Negative true reset for FIFO pointers.

WBLKB 1 IN Negative true write block select.

DI<0:8> 9 IN Input data bits <0:8>, <8> will be generated if PARGEN is true.

WRB 1 IN Negative true write pulse.

FULL, EMPTY 2 OUT FIFO flags. FULL prevents write and EMPTY prevents read.

EQTH, GEQTH 2 OUT

DO<0:8> 9 OUT Output data bits <0:8>

RPE 1 OUT Read parity error.

WPE 1 OUT Write parity error.

LGDEP <0:2> 3 IN Configures DEPTH of the FIFO to 2

PARODD 1 IN Selects odd parity generation/detect when high, even when low.

EQTH is true when the FIFO holds (LEVEL) words. GEQTH is true when the

FIFO holds (LEVEL) words or more.

(LGDEP+1)

34

Page 35

FULL

RB

ProASIC™ 500K Family

Write

cycle

WB

Figure 21 • Write Timing Diagram

EMPTY

WB

Read

cycle

Write acceptedWrite inhibited

1ns

3ns

Read acceptedRead inhibited

1ns

RB

Figure 22 • Read Timing Diagram

3ns

35

Page 36

Asynchronous FIFO Read

RB=(RDB+RBLKB)

RDATA

RPE

WB

EMPTY

FULL

EQTH, GETH

t

RDWRS

t

ORDH

t

RPRDH

Cycle Start

t

ORDA

t

RPRDA

t

RDL

t

RDCYC

t

THRDH

t

THRDA

t

RDH

(Empty inhibits read)

t

, t

ERDH

FRDH

t

, t

ERDA

FRDA

T

= 0°C to 110°C; V

J

Symbol t

ERDH,

FRDH,

Description Min. Max. Units Notes

xxx

Old EMPTY, FULL, EQTH, & GETH valid

hold time from RB ↑

THRDH

ERDA New EMPTY access from RB ↑ 3.0

FRDA FULL↓ access from RB ↑ 3.0

= 2.3V to 2.7V

DDL

0.5 ns Empty/full/thresh are invalid

from the end of hold until the

new access is complete

1

1

ns

ns

ORDA New RDATA access from RB ↓ 7.5 ns

ORDH Old RDATA valid from RB ↓ 3.0 ns

RDCYC Read cycle time 7.5 ns

RDWRS WB ↑, clearing EMPTY, setup to

RB ↓

3.0

2

ns Enabling the read operation

1.0 ns Inhibiting the read operation

RDH RB high phase 3.0 ns Inactive

RDL RB low phase 3.0 ns Active

RPRDA New RPE access from RB ↓ 9.5 ns

RPRDH Old RPE valid from RB ↓ 4.0 ns

THRDA EQTH or GETH access from RB↑ 4.5 ns

Notes:

1. At fast cycles, ERDA & FRDA = MAX (7.5 ns – RDL), 3.0 ns

2. At fast cycles, RDWRS (for enabling read) = MAX (7.5 ns – WRL), 3.0 ns

36

Page 37

Asynchronous FIFO Write

ProASIC™ 500K Family

WB=(WRB+WBLKB)

WDATA

WPE

RB

FULL

EMPTY

EQTH, GETH

t

WRRDS

t

WPDA

t

DWRS

t

EWRH

t

EWRA

Cycle Start

, t

FWRH

, t

FWRA

t

WRL

t

WRCYC

t

THWRH

t

THWRA

t

WRH

(Full inhibits write)

t

DWRH

t

WPDH

T

= 0°C to 110°C; V

J

Symbol t

Description Min. Max. Units Notes

xxx

= 2.3V to 2.7V

DDL

DWRH WDATA hold from WB ↑ 1.5 ns

DWRS WDATA setup to WB ↑ 0.5 ns PARGEN is inactive.

DWRS WDATA setup to WB ↑ 2.5 ns PARGEN is active.

EWRH,

FWRH,

THWRH

EWRA EMPTY ↓ access from WB ↑ 3.0

FWRA New FULL access from WB ↑ 3.0

Old EMPTY, FULL, EQTH, & GETH valid

hold time after WB ↑

0.5 ns Empty/full/thresh are invalid

from the end of hold until the

new access is complete.

1

1

ns

ns

THWRA EQTH or GETH access from WB ↑ 4.5 ns

WPDA WPE access from WDATA 3.0 ns

WPDH WPE hold from WDATA 1.0 ns

WPE is invalid while

PARGEN is active.

WRCYC Cycle time 7.5 ns

WRRDS RB ↑, clearing FULL, setup to

WB ↓

3.0

2

ns Enabling the write operation.

1.0 Inhibiting the write operation.

WRH WB high phase 3.0 ns Inactive

WRL WB low phase 3.0 ns Active

Notes:

1. At fast cycles, EWRA, FWRA = MAX (7.5 ns – WRL), 3.0 ns

2. At fast cycles, WRRDS (for enabling write) = MAX (7.5 ns – RDL), 3.0 ns

37

Page 38

Synchronous FIFO Read, Access Timed Output Strobe (Synchronous Transparent)

RCLK

RDB

RDATA

RPE

EMPTY

FULL

EQTH, GETH

Cycle Start

Old Data Out New Valid Data Out (Empty Inhibits Read)

t

RDCS

t

RDCH

t

OCH

t

RPCH

t

OCA

t

RPCA

t

CMH

t

CCYC

t

THCBH

t

THCB

t

CML

t

ECBH

t

ECBA

, t

, t

FCBH

FCBA

T

= 0°C to 110°C; V

J

Symbol t

Description Min. Max. Units Notes

xxx

= 2.3V to 2.7V

DDL

CCYC Cycle time 7.5 ns

CMH Clock high phase 3.0 ns

CML Clock low phase 3.0 ns

ECBA New EMPTY access from RCLK ↓ 3.0

FCBA FULL ↓ access from RCLK ↓ 3.0

ECBH,

FCBH,

Old EMPTY, FULL, EQTH, & GETH valid

hold time from RCLK ↓ 1.0 ns

1

1

THCBH

OCA New RDATA access from RCLK ↑ 7.5 ns

OCH Old RDATA valid from RCLK ↑ 3.0 ns

RDCH RDB hold from RCLK ↑ 0.5 ns

RDCS RDB setup to RCLK ↑ 1.0 ns

RPCA New RPE access from RCLK ↑ 9.5 ns

RPCH Old RPE valid from RCLK ↑ 3.0 ns

THCBA EQTH or GETH access from RCLK ↓ 4.5 ns

Note:

1. At fast cycles, ECBA & FCBA = MAX (7.5 .ns – CMH), 3.0 ns

ns

ns

Empty/full/thresh are invalid

from the end of hold until the

new access is complete

38

Page 39

Synchronous FIFO Read, Pipeline Mode Outputs (Synchronous Pipelined)

ProASIC™ 500K Family

RCLK

RDB

RDATA

RPE

EMPTY

FULL

EQTH, GETH

t

RDCS

t

RDCH

Cycle Start

t

ECBH

t

CMH

Old Data Out New Valid Data Out

Old RPE Out New RPE Out

, t

FCBH

t

THCBH

t

THCB

t

RPCA

t

CML

t

CCYC

t

OCA

t

ECBA

t

RPCH

t

OCH

, t

FCBA

T

= 0°C to 110°C; V

J

Symbol t

Description Min. Max. Units Notes

xxx

= 2.3V to 2.7V

DDL

CCYC Cycle time 7.5 ns

CMH Clock high phase 3.0 ns

CML Clock low phase 3.0 ns

ECBA New EMPTY access from RCLK ↓ 3.0

FCBA FULL ↓ access from RCLK ↓ 3.0

ECBH,

FCBH,

Old EMPTY, FULL, EQTH, & GETH valid

hold time from RCLK ↓

1

1

1.0 ns Empty/full/thresh are invalid

THCBH

OCA New RDATA access from RCLK ↑ 2.0 ns

OCH Old RDATA valid from RCLK ↑ 0.75 ns

RDCH RDB hold from RCLK ↑ 0.5 ns

RDCS RDB setup to RCLK ↑ 1.0 ns

RPCA New RPE access from RCLK ↑ 4.0 ns

RPCH Old RPE valid from RCLK ↑ 1.0 ns

THCBA EQTH or GETH access from RCLK ↓ 4.5 ns

Note:

1. At fast cycles, ECBA & FCBA = MAX (7.5 ns – CMS), 3.0 ns

ns

ns

from the end of hold until the

new access is complete

39

Page 40

Synchronous FIFO Write

WCLK

WRB, WBLKB

WDATA

WPE

FULL

EMPTY

EQTH, GETH

t

, t

WRCH

WBCH

t

, t

WRCS

WBCS

t

DCS

t

WPCH

t

DCS

Cycle Start

t

WPCA

t

CMH

t

CCYC

t

THCBH

t

CLM

(Full Inhibits Write)

t

, t

ECBH

FCBH

t

, t

ECBA

FCBA

t

, t

ECBH

FCBH

= 0°C to 110°C; V

T

J

Symbol t

xxx

= 2.3V to 2.7V

DDL

Description Min. Max. Units Notes

CCYC Cycle time 7.5 ns

CMH Clock high phase 3.0 ns

CML Clock low phase 3.0 ns

DCH WDATA hold from WCLK ↑ 0.5 ns

DCS WDATA setup to WCLK ↑ 1.0 ns

FCBA New FULL access from WCLK ↓ 3.0

ECBA EMPTY↓ access from WCLK ↓ 3.0

ECBH,

FCBH,

Old EMPTY, FULL, EQTH, & GETH valid

hold time from WCLK ↓

1

1

1.0 ns Empty/full/thresh are invalid

THCBH

THCBA EQTH or GETH access from WCLK ↓ 4.5 ns

WPCA New WPE access from WCLK ↑ 3.0 ns

WPCH Old WPE valid from WCLK ↑ 0.5 ns

WRCH,

WRB & WBLKB hold from WCLK ↑ 0.5 ns

WBCH

WRCS,

WRB & WBLKB setup to WCLK ↑ 1.0 ns

WBCS

Note:

1. At fast cycles, ECBA & FCBA = MAX (7.5 ns – CMH), 3.0 ns

ns

ns

from the end of hold until the

new access is complete

WPE is invalid while

PARGEN is active

40

Page 41

FIFO Reset

ProASIC™ 500K Family

RESETB

t

WBRSS

Cycle Start

Cycle Start

t

t

WBRSH

CBRSH

WB*

WCLK, RCLK

FULL

EMPTY

EQTH, GETH

t

, t

ERSA

FRSA

t

THRSA

t

CBRSS

t

RSL

*WB = WRB + WBLRB

= 0°C to 110°C; V

T

J

Symbol t

Description Min. Max. Units Notes

xxx

= 2.3V to 2.7V

DDL

CBRSH WCLK or RCLK ↑ hold from RESETB ↑ 1.5 ns Synchronous mode only

CBRSS WCLK or RCLK ↓ setup to RESETB ↑ 1.5 ns Synchronous mode only

ERSA New EMPTY ↑ access from RESETB ↓ 3.0 ns

FRSA FULL ↓ access from RESETB ↓ 3.0 ns

RSL RESETB low phase 7.5 ns

THRSA EQTH or GETH access from RESETB ↓ 4.5 ns

WBRSH WB ↓ hold from RESETB ↑ 1.5 ns Asynchronous mode only

WBRSS WB ↑ setup to RESETB ↑ 1.5 ns Asynchronous mode only

41

Page 42

Pin Description

I/O User Input/Output

The I/O pin functions as an input, output, three-state, or

bi-directional buffer. Input and output signal levels are

compatible with standard LVTTL and LVCMOS specifications.

Unused I/O pins are configured as inputs with pull-up resistor.

N/C No Connect

To maintain compatibility with future Actel ProASIC products

it is recommended that this pin not be connected to the

circuitry on the board.

GL Global Input Pin

Low skew input pin for clock or other global signals. Input

only. This pin can be configured with a pull-up resistor.

GND Ground

Common ground supply voltage.

V

DDL

Logic Array Power Supply Pin

2.5V supply voltage.

V

I/O Pad Power Supply Pin

DDP

2.5V or 3.3V supply voltage.

V

PP

This pin must be connected to V

Programming Supply Pin

during normal operation,

DDP

or it can remain at 16.5V in an ISP application. This pin must

not float.

V

PN

Programming Supply Pin

This pin must be connected to GND during normal operation,

or it can remain at –12V in an ISP application. This pin must

not float.

TMS Test Mode Select

The TMS pin controls the use of JTAG circuitry.

TCK Test Clock

Clock input pin for JTAG.

TDI Test Data In

Serial input for JTAG.

TDO Test Data Out

Serial output for JTAG.

TRST Test Reset Input

An optimal JTAG reset pin.

RCK Running Clock

A free running clock is needed during programming if the

programmer cannot guarantee that TCK will be

uninterrupted.

42

Page 43

Package Pin Assignments

208-Pin PQFP

208

1

ProASIC™ 500K Family

208-Pin PQFP

43

Page 44

208-Pin PQFP

Pin

Number

A500K050

Function

A500K130

Function

A500K180

Function

A500K270

Function

Pin

Number

A500K050

Function

1 GND GND GND GND 53 V

DDP

A500K130

Function

V

DDP

A500K180

Function

V

DDP

2 I/O I/O I/O I/O 54 I/O I/O I/O I/O

3 I/O I/O I/O I/O 55 I/O I/O I/O I/O

4 I/O I/O I/O I/O 56 I/O I/O I/O I/O

5 I/O I/O I/O I/O 57 I/O I/O I/O I/O

6 I/O I/O I/O I/O 58 I/O I/O I/O I/O

7 I/O I/O I/O I/O 59 I/O I/O I/O I/O

8 I/O I/O I/O I/O 60 I/O I/O I/O I/O

9 I/O I/O I/O I/O 61 I/O I/O I/O I/O

10 I/O I/O I/O I/O 62 I/O I/O I/O I/O

11 I/O I/O I/O I/O 63 I/O I/O I/O I/O

12 I/O I/O I/O I/O 64 I/O I/O I/O I/O

13 I/O I/O I/O I/O 65 GND GND GND GND

14 I/O I/O I/O I/O 66 I/O I/O I/O I/O

15 I/O I/O I/O I/O 67 I/O I/O I/O I/O

16 V

DDL

V

DDL

V

DDL

V

DDL

68 I/O I/O I/O I/O

17 GND GND GND GND 69 I/O I/O I/O I/O

18 I/O I/O I/O I/O 70 I/O I/O I/O I/O

19 I/O I/O I/O I/O 71 V

20 I/O I/O I/O I/O 72 V

DDL

DDP

V

V

DDL

DDP

V

DDL

V

DDP

21 I/O I/O I/O I/O 73 I/O I/O I/O I/O

22 V

DDP

V

DDP

V

DDP

V

DDP

74 I/O I/O I/O I/O

23 I/O I/O I/O I/O 75 I/O I/O I/O I/O

24 I/O I/O I/O I/O 76 I/O I/O I/O I/O

25 GL GL GL GL 77 I/O I/O I/O I/O

26 GL GL GL GL 78 I/O I/O I/O I/O

27 I/O I/O I/O I/O 79 I/O I/O I/O I/O

28 I/O I/O I/O I/O 80 I/O I/O I/O I/O

29 GND GND GND GND 81 GND GND GND GND

30 I/O I/O I/O I/O 82 I/O I/O I/O I/O

31 I/O I/O I/O I/O 83 I/O I/O I/O I/O

32 I/O I/O I/O I/O 84 I/O I/O I/O I/O

33 I/O I/O I/O I/O 85 I/O I/O I/O I/O

34 I/O I/O I/O I/O 86 I/O I/O I/O I/O

35 I/O I/O I/O I/O 87 I/O I/O I/O I/O

36 V

DDL

V

DDL

37 I/O I/O I/O I/O 89 V

V

DDL

V

DDL

88 V

DDL

DDP

V

V

DDL

DDP

V

DDL

V

DDP

38 I/O I/O I/O I/O 90 I/O I/O I/O I/O

39 I/O I/O I/O I/O 91 I/O I/O I/O I/O

40 V

DDP

V

DDP

V

DDP

V

DDP

92 I/O I/O I/O I/O

41 GND GND GND GND 93 I/O I/O I/O I/O

42 I/O I/O I/O I/O 94 I/O I/O I/O I/O

43 I/O I/O I/O I/O 95 I/O I/O I/O I/O

44 I/O I/O I/O I/O 96 I/O I/O I/O I/O

45 I/O I/O I/O I/O 97 GND GND GND GND

46 I/O I/O I/O I/O 98 I/O I/O I/O I/O

47 I/O I/O I/O I/O 99 I/O I/O I/O I/O

48 I/O I/O I/O I/O 100 I/O I/O I/O I/O

49 I/O I/O I/O I/O 101 TCK, I/O TCK, I/O TCK, I/O TCK, I/O

50 I/O I/O I/O I/O 102 TDI, I/O TDI, I/O TDI, I/O TDI, I/O

51 I/O I/O I/O I/O 103 TMS, I/O TMS, I/O TMS, I/O TMS, I/O

52 GND GND GND GND 104 V

DDP

V

DDP

V

DDP

A500K270

Function

V

DDP

V

DDL

V

DDP

V

DDL

V

DDP

V

DDP

44

Page 45

ProASIC™ 500K Family

208-Pin PQFP (Continued)

Pin

Number

105 GND GND GND GND 157 V

106 V

107 V

A500K050

Function

PP

PN

A500K130

Function

V

PP

V

PN

A500K180

Function

V

PP

V

PN

A500K270

Function

V

PP

V

PN

Pin

Number

A500K050

Function

DDP

A500K130

Function

V

DDP

A500K180

Function

V

DDP

158 I/O I/O I/O I/O

159 I/O I/O I/O I/O

108 TDO, I/O TDO, I/O TDO, I/O TDO, I/O 160 I/O I/O I/O I/O

109 TRST, I/O TRST, I/O TRST, I/O TRST, I/O 161 I/O I/O I/O I/O