Page 1

3971

Data Sheet

29319.32

ADVANCE INFORMATION

(Subject to change without notice)

May 2, 2000

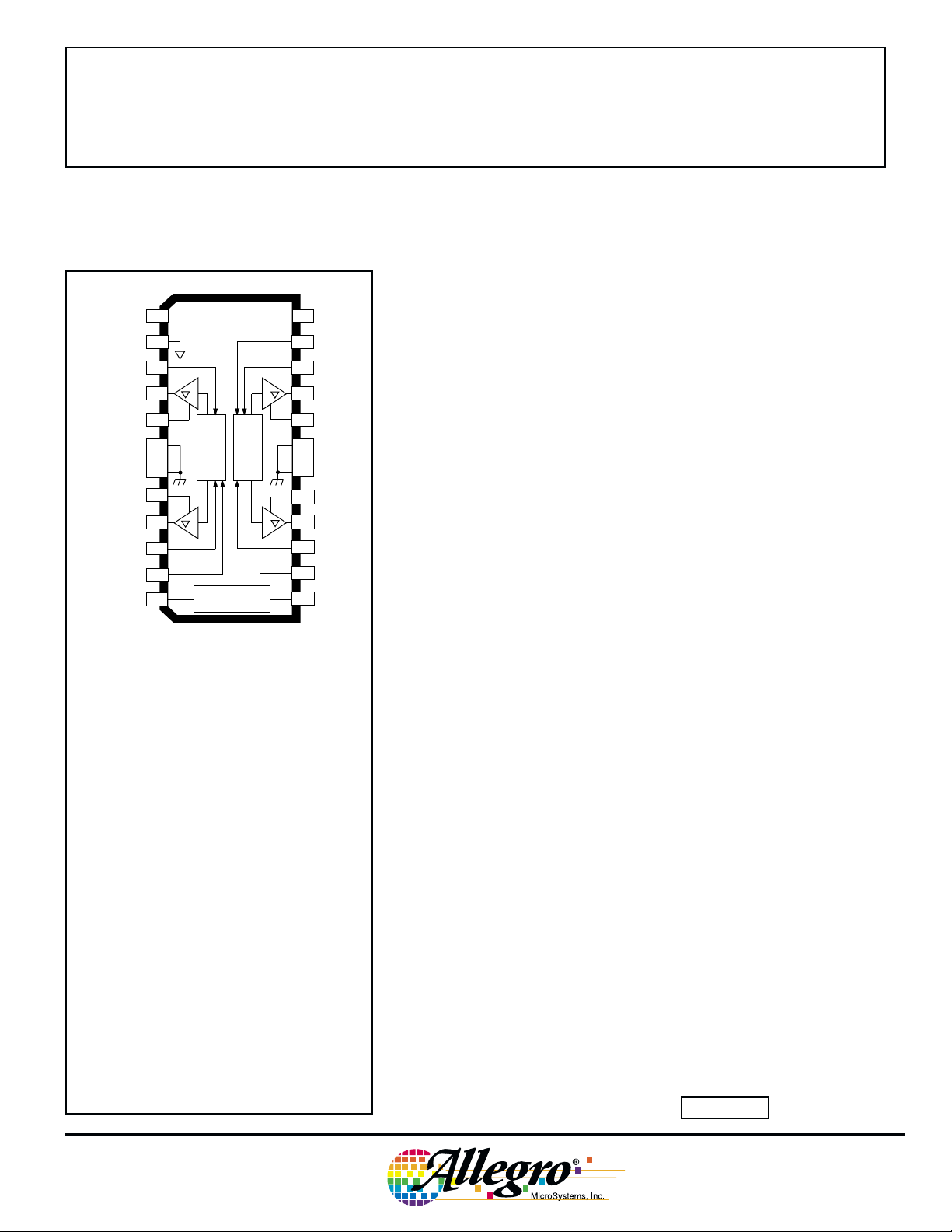

CONNECTION

LOGIC

GROUND

OUT

LOAD

SUPPLY

GROUND

GROUND

SENSE

OUT

PWM

NO

S

S

CP1

1

NC

2

10

3

4

1A

5

1

V

BB1

6

7

1

8

9

1B

9

10

11

11

1

12

LOGIC

CHARGE PUMP

LOGIC

24

DD

V

23

22

21

20

V

BB2

19

18

17

16

15

14

13

LOGIC

SUPPLY

2

PWM

S

20

OUT

2A

LOAD

SUPPLY

GROUND

GROUND

SENSE

OUT

2B

S

21

V

CP

CP2

Dwg. PP-069-2

DUAL DMOS

FULL-BRIDGE DRIVER

Designed to interface between external PWM control logic and

inductive loads such as relays, solenoids, dc motors, or stepper motors,

each full bridge can operate with output currents to ±2.5 A and operating

voltages to 50 V.

Low r

during PWM operation. Internal charge pump circuitry is used to create

a boosted voltage to fully enhance the high-side DMOS switches.

2

Three TTL-compatible logic-input terminals per bridge allow flexibility in configuring PWM control.

2

Internal circuit protection includes thermal shutdown with hysteresis,

and crossover-current protection. Special power -up sequencing is not

required.

The A3971SLB is supplied in a 24-lead plastic SOIC with a copper

batwing tab. The power tab is at ground potential and needs no electrical isolation.

DMOS output drivers provide low power dissipation

DS(on)

ABSOLUTE MAXIMUM RATINGS

at TA = +25°C

Load Supply Voltage, VBB................ 50 V

Output Current, I

Transient (<500 ns) ................... ±5 A

Logic Supply Voltage,

VDD............................................ 7.0 V

Sense Voltage, V

Logic Input Voltage Range,

VIN.................. -0.3 V to V

High-Side Gate Voltage ........... V

Package Power Dissipation,

PD............................................. 2.2 W

Operating Temperature Range,

TA............................. -20°C to +85°C

Junction Temperature, TJ............. +150°C

Storage Temperature Range,

TS........................... -55°C to +150°C

Output duty cycle, ambient temperature, and

heat sinking may limit current rating. Under

any set of conditions, do not exceed the

specified current rating or a junction temperature of 150 °C.

OUT

...................... 0.5 V

SENSE

DD

BB

+ 0.3 V

+ 8 V

FEATURES

■ ±2.5 A Load Current Capability per Bridge

■ Parallel Outputs for 5 A Load-Current Capability

■ Low r

Typically 325 mΩ source, 175 mΩ sink

■ Synchronous Rectification via Control Logic

■ Internal Undervoltage Monitor

■ Crossover-Current Protection

■ Source Connections for External Current Sensing

■ Thermal Shutdown Circuitry

Always order by complete part number: A3971SLB .

DS(on)

Outputs

Page 2

3971

DUAL DMOS

FULL-BRIDGE DRIVER

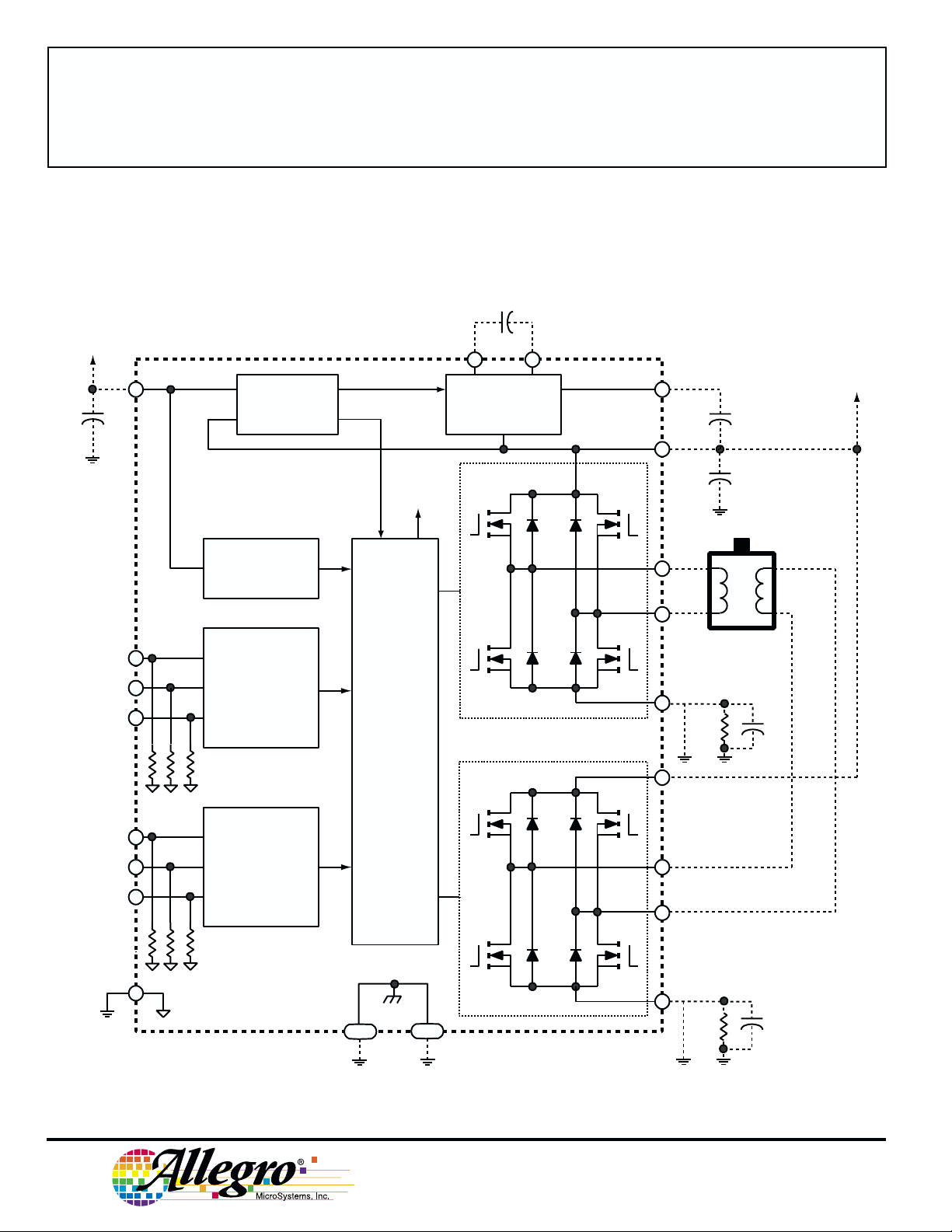

LOGIC

SUPPLY

V

DD

24

VOLTAGE

REFERENCE

FUNCTIONAL BLOCK DIAGRAM

0.22 µF/100 V

CP1CP2

12

V

REF

LOW SIDE SUPPLY

V

CP

13

CHARGE PUMP

DMOS H-BRIDGE

V

CP

14

V

BB2

20

0.22 µF

50 V

LOAD

SUPPLY

S

S

PWM

PWM

LGND

UVLO &

THERMAL

OUT

2A

21

SHUTDOWN

OUT

2B

16

3

10

10

11

11

1

BRIDGE 1

CONTROL

LOGIC

GATE

17

SENSE

(OPTIONAL)

2

RS, C

S

DRIVE

DMOS H-BRIDGE

22

S

20

15

S

21

23

2

2

BRIDGE 2

CONTROL

LOGIC

5

V

OUT

4

OUT

9

SENSE

8

BB1

1A

1B

(OPTIONAL)

1

R

,

C

S

S

GROUND

6

7

18

19

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2000, Allegro MicroSystems, Inc.

Dwg. FP-050

Page 3

3971

DUAL DMOS

FULL-BRIDGE DRIVER

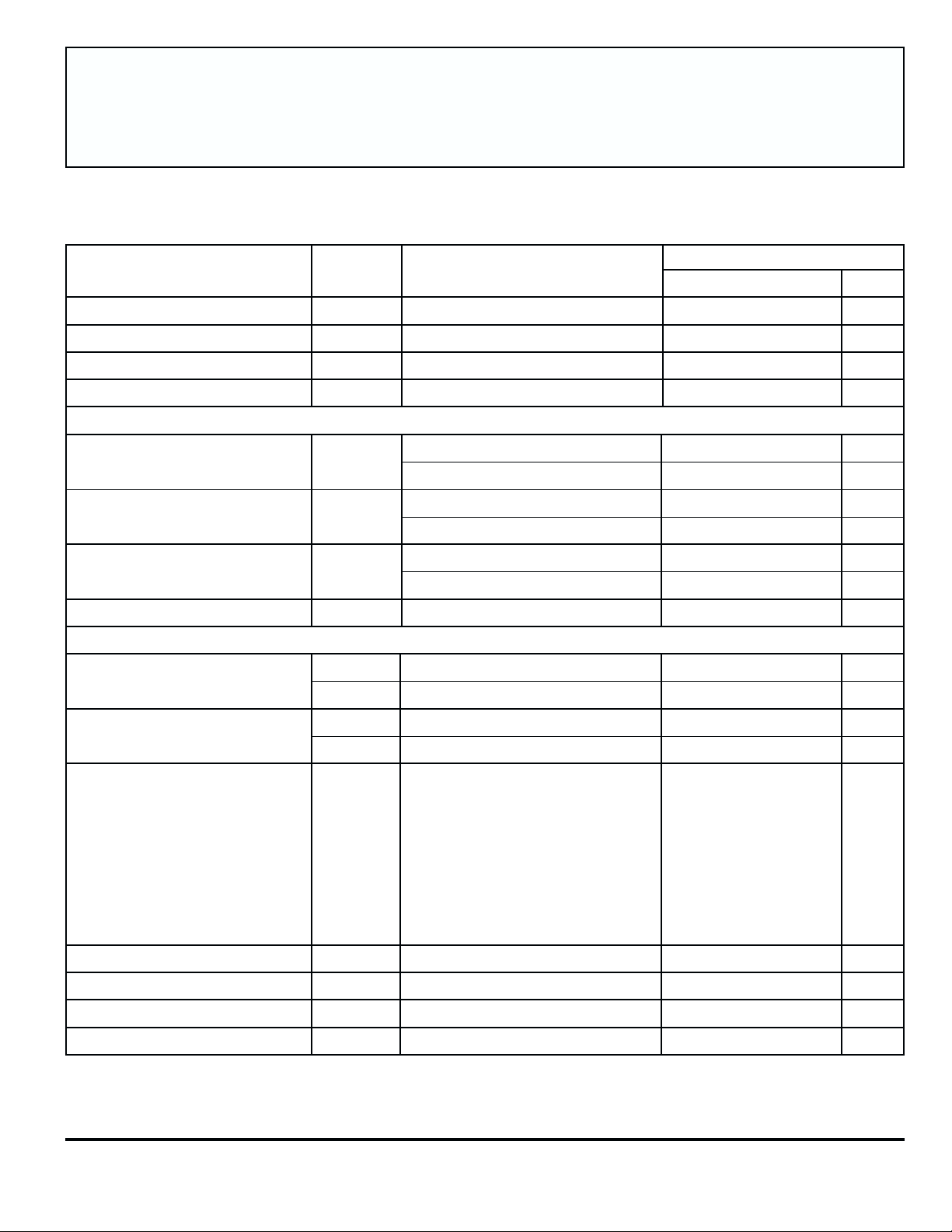

ELECTRICAL CHARACTERISTICS at TA = +25°C, VBB = 50 V, VDD = 5.0 V (unless otherwise noted).

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Load Supply Voltage Range V

Logic Supply Voltage Range V

Load Supply Current I

Logic Supply Current I

Output Drivers

Output Leakage Current I

Output ON Resistance r

DS(on)

Body Diode Forward Voltage V

High-Side Gate Voltage V

Control Logic

Logic Input Voltage V

V

Logic Input Current I

I

Propagation Delay Time t

BB

DD

BB

DD

DSS

F

CP

IN(0)

IN(1)

IN(0)

IN(1)

PD

Operating 10 — 50 V

Operating 4.5 5.0 5.5 V

Operating, each supply, no load — — 3.0 mA

Operating — — 5.0 mA

V

= V

OUT

V

OUT

High-side switch, I

Low-side switch, I

BB

= 0 V — <-1.0 -20 mA

= -2.5 A — 325 375 mΩ

OUT

= 2.5 A — 175 200 mΩ

OUT

— <1.0 20 µA

Source diode, IF = 2.5 A — 1.2 — V

Sink diode, IF = 2.5 A — 1.0 — V

C = 0.22 µF, reference V

BB

6.0 6.5 7.0 V

——0.8V

2.0 — — V

VIN = 0 V — <1.0 -5.0 µA

VIN = 5.0 V — 20 50 µA

50% to 90%:

PWM change to source off — 50 — ns

PWM change to sink off — 60 — ns

PWM change to source on — 565 — ns

PWM change to sink on — 665 — ns

Disable to source on — 150 — ns

Disable to sink on — 250 — ns

Thermal Shutdown Temperature T

Thermal Shutdown Hysteresis ∆T

UVLO Threshold V

UVLO Hysteresis ∆V

J

J

UVLO

UVLO

Increasing V

NOTES: 1. Typical Data is for design information only.

2. Negative current is defined as coming out of (sourcing) the specified device terminal.

www.allegromicro.com

DD

— 165 — °C

—15—°C

3.9 4.15 4.4 V

—0.15— V

Page 4

3971

DUAL DMOS

FULL-BRIDGE DRIVER

Logic Truth Table

PWM

x

S

x0

S

x1

OUT

xA

OUT

xB

Function

X 0 0 Z Z Disable

001LH Forward

0 1 0 H L Reverse

011LLSynchronous

101LLRectification/

111LLSlow Decay

110LL Chop

Terminal List

Terminal Name Description

1 NC No (Internal) connection

2 LGND Logic ground

3S10Control input, bridge 1

4 OUT

5V

1A

BB1

6, 7 GND Ground

8 SENSE

9 OUT

10 S

11 PWM

1

1B

11

1

12 CP1 Charge-pump capacitor

13 CP2 Charge-pump capacitor

14 V

15 S

16 OUT

17 SENSE

CP

21

2B

2

18, 19 GND Ground

20 V

21 OUT

22 S

23 PWM

24 V

BB2

2A

20

2

DD

Output A, bridge 1

Load supply voltage, bridge 1

Sense resistor, bridge 1

Output B, bridge 1

Control input, bridge 1

Control input, bridge 1

Reservoir capacitor

Control input, bridge 2

Output B, bridge 2

Sense resistor, bridge 2

Load supply voltage, bridge 2

Output A, bridge 2

Control input, bridge 2

Control input, bridge 2

Logic supply voltage

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 5

Functional Description

3971

DUAL DMOS

FULL-BRIDGE DRIVER

Charge Pump. The DMOS output stage requires a

charge pump to bring the high-side gate-source voltage

approximately 8 V above the V

supply. Two external

BB

components are required, a pumping capacitor connected

between CP1 and CP2 and a reservoir capacitor connected

between V

and VCP. Ceramic 0.22 µF capacitors are

BB

recommended.

Control Logic. Each bridge is controlled by three TTLcompatible inputs. The inputs are resistively pulled to

ground (via 250 kΩ). A crossover-delay circuit protects

the outputs from a shoot-thru condition when going from a

forward or reverse on state to synchronous rectification/

slow decay chop (both sink drivers on). If the logic is in

the DISABLE state and changes to an on state the 415 ns

crossover delay does not occur.

Protection Circuitry. In the event of a fault due to

excessive junction temperature, or low voltage on V

CP

or

VDD, the outputs of the device are disabled until the fault

condition is removed.

Current Sensing. If external current-sensing circuitry

is used, the sense resistor should have an independent

ground return to the ground terminal of the device. Due to

current transients during switching, a 0.1 µF capacitor

should be connected from the sense terminal to the

batwing tab connection of the package. This capacitor

reduces voltage swings at the terminal due to the fast di/dt,

which in turn ensures that the sink driver gate-source

voltage stays within the safe operating area. Allegro

MicroSystems recommends a value of R

R

S

= 0.5/I

TRIP

max.

given by:

S

Thermal protection. Circuitry turns off all drivers

when the junction temperature reaches 165°C, typically.

It is intended only to protect the device from failures due

to excessive junction temperatures and should not imply

that output short circuits are permitted. Thermal shutdown has a hysteresis of approximately 15°C.

Layout. The printed wiring board should use a heavy

ground plane. For optimum electrical and thermal performance, the driver should be soldered directly onto the

board. If external current sensing is used, the ground side

should have an individual path to the ground

of R

S

terminal(s) of the device. This path should be as short as

is possible physically and should not have any other

components connected to it. The load supply terminal

should be decoupled with an electrolytic capacitor

( >47 µF is recommended) placed as close to the device as

is possible.

Parallel Operation. For high-power applications, the

two DMOS full bridges in the A3971 may be connected in

parallel as shown below. The current will be shared

equally in each full bridge due to the positive temperature

coefficient of the DMOS

PWM

CONTROL

15–50 V

+

47 µF

0.22 µF

1

2

3

4

5

6

7

8

9

9

10

11

12

r

NC

V

BB1

CHARGE PUMP

DS(on)

LOGIC

.

LOGIC

24

V

DD

23

22

21

20

V

BB2

19

18

17

16

15

14

13

+5 V

15–50 V

+

47 µF

0.22 µF

www.allegromicro.com

Dwg. EP-069

Page 6

3971

DUAL DMOS

FULL-BRIDGE DRIVER

Dimensions in Inches

(for reference only)

0.2992

0.2914

0.020

0.013

0.0926

0.1043

24 13

1 2

0.0040

3

0.6141

0.5985

MIN.

0.050

BSC

0.0125

0.0091

0.419

0.394

0.050

0.016

0° TO 8°

Dwg. MA-008-24A in

NOTES:1. Exact body and lead configuration at vendor’s option within limits shown.

2. Lead spacing tolerance is non-cumulative

3. Webbed lead frame. Leads 6, 7, 18, and 19 are internally one piece.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 7

Dimensions in Millimeters

(controlling dimensions)

3971

DUAL DMOS

FULL-BRIDGE DRIVER

7.60

7.40

0.51

0.33

2.65

2.35

24

1

0.10

2

MIN.

13

10.65

10.00

3

15.60

15.20

1.27

BSC

0° TO 8°

0.32

0.23

1.27

0.40

Dwg. MA-008-24A mm

NOTES:1. Exact body and lead configuration at vendor’s option within limits shown.

2. Lead spacing tolerance is non-cumulative

3. Webbed lead frame. Leads 6, 7, 18, and 19 are internally one piece.

www.allegromicro.com

Page 8

3971

DUAL DMOS

FULL-BRIDGE DRIVER

The products described here are manufactured under one or more

U.S. patents or U.S. patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such departures from the detail specifications as may be

required to permit improvements in the performance, reliability, or

manufacturability of its products. Before placing an order, the user is

cautioned to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components

in life-support devices or systems without express written approval.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for any infringement of patents or other rights of

third parties which may result from its use.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...