Page 1

Data Sheet

March 2001

A370-Type Analog

Uncooled Laser Module

Applications

■

Narrowband video

■

Downstream telephony and data

■

Return path systems

■

Analog and digital modulation systems

■

Telecommunications

The low-profile A370-Type Analog Laser Module is ideally

suited for CATV applications, particularly in systems where

long spans and superior reliability are the critical considerations

.

Features

■

Eight-pin package suitable for CATV

applications

Frequency range up to 1.0 GHz

■

MQW F-P 1.3 µ m laser with single-mode fiber

■

pigtail

■

Wide operating temperature range:

–40 ° C to +85 ° C

No TEC required

■

High output power: typically 1.0 mW power cou-

■

pled into single-mode fiber

■

Hermetically sealed active components

Internal back-facet monitor

■

Qualification program:

■

TA-983

Telcordia Technologies

*

Benefits

■

Easily board mounted

■

Requires no lead bending

■

No additional heat sinks required

■

Pin compatible with industry-standard, 14-pin

laser module

■

High output power allows for longer system spans ,

more fiber splits, and greater tolerance of fiber and

connector quality

*

T elcordia T echnologies

Inc.

is a trademark of Telcordia Technologies,

Page 2

±

°

°

A370-Type Analog Data Sheet

Uncooled Laser Module March 2001

Description

The A370-Type Uncooled Laser Module consists of a

laser diode coupled to a single-mode fiber pigtail. The

device is available in a standard, 8-pin configuration

(see Figure 1 and/or Table 1) and is ideal for CATV

applications.

The module includes a multiquantum-well Fabry-Perot

(MQW F-P) laser and an InGaAs PIN photodiode backfacet monitor in an epoxy-free, hermetically sealed

package.

The device characteristics listed in this document are

met at 1.0 mW output power. Higher- or lower-power

operation is possible. Under conditions of a fixed photodiode current, the change in optical output is typically

0.5 dB over an operating temperature range of –40 ° C

to +85 ° C.

This device incorporates the new Laser 2000 manufac-

turing process from the Optoelectronics unit of Lucent

Technologies Microelectronics Group. Laser 2000 is a

low-cost platform that targets high-volume manufacturing and tight product distributions on all optical subassemblies. This platform incorporates an advanced

optical design that is produced on the Optoelectronic

unit’s highly automated production lines. The Laser

2000 platform is qualified for the central office and

uncontrolled environments, and can be used for applications requiring high performance and low cost.

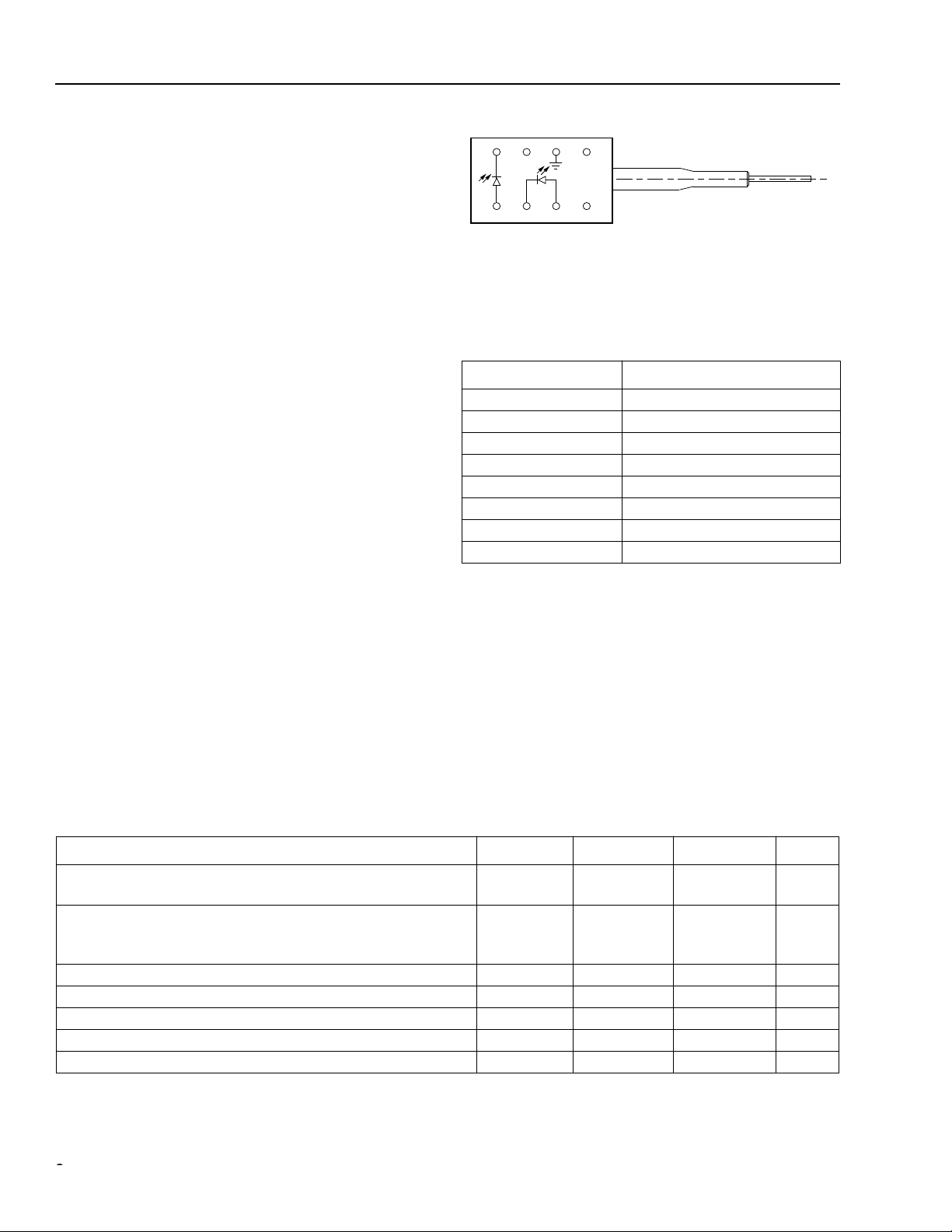

43 12

56 87

Figure 1. A370-Type Analog Uncooled Laser

Module Schematic, Top View

Table 1. Pin Descriptions

Pin Number Connection

1NC

2 Case ground

3NC

4 Photodiode cathode

5 Photodiode anode

6 Laser diode cathode

7 Laser diode anode

8NC

1-900 (C)

Absolute Maximum Ratings

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device. These are absolute stress ratings only. Functional operation of the device is not implied at these or any other conditions in excess

of those given in the operations sections of the data sheet. Exposure to absolute maximum ratings for extended

periods can adversely affect device reliability.

Parameter Symbol Min Max Unit

Maximum Peak Laser Drive Current or

Maximum Fiber Power*

Peak Reverse Laser Voltage:

Laser

Monitor

Monitor Forward Current I

Operating Case Temperature Range T

Storage Case Temperature Range T

Lead Soldering Temperature/Time — — 260/10 ° C/s

Relative Humidity (noncondensing) RH — 85 %

* Rating varies with temperature.

22

OP

I

MAX

P

RL

V

RD

V

FD

C

stg

—

—

—

—

150

10

2

20

mA

mW

V

V

—2mA

–40 85

–40 85

C

C

Lucent Technologies Inc.

Page 3

°

∆λ

±

Ω

µ

Data Sheet A370-Type Analog

March 2001 Uncooled Laser Module

Handling Precautions

Caution: This device is susceptible to dama ge as a result of electrostatic disc harge (ESD). T ake pr oper pre-

cautions during both handling and testing. Follow guidelines such as JEDEC Publication No.

108-A (Dec. 1988).

Although protection circuitry is designed into the device, take proper precautions to avoid exposure to ESD.

Electro/Optical Characteristics

Table 2. Electro/Optical Characteristics (over operating temperature range unless otherwise noted)

Parameter Symbol Test Conditions Min Typ Max Unit

Operating Temperature

Range

Optical Output Power* P

Threshold Current I

Drive Current Above

Threshold

Slope Efficiency SE CW, P

Center Wav elength

RMS Spectral Width

Tracking Error TE I

Forward Voltage V

Input Impedance R — 3 — 8

Monitor Current I

Monitor Dark Current I

Wavelength Temperature

Coefficient

* See Table 5 for more information.

† V

= reverse voltage.

R

T — –40 — 85

CW, nominal — 1 — mW

T = 25 ° C

T = full range

F

= 1.0 mW, T = 25 ° C

MON

CW, I

= constant,

4.5

1

20

15

9

—

30

—

TH

MOD

I

F

CW, P

15

45

40

70

C

mA

mA

mA

mA

T = full range

λ

C

F

MON

D

= 1.0 mW, T = 25 ° C25—50

F

P

= 1.0 mW, CW 1270 — 1350 nm

F

P

= 1.0 mW — 2 3 nm

F

= constant, CW — 0.5

MON

CW — 1.1 1.6 V

†

V

= 5 V 400 — 1200

R

†

V

= 5 V — 10 200 nA

R

µ

W/mA

1dB

— — — 0.4 0.5 nm/ ° C

A

Lucent Technologies Inc.

3

Page 4

A370-Type Analog Data Sheet

Uncooled Laser Module March 2001

Electro/Optical Characteristics

(continued)

Analog Operation

The A370 Series Laser Module has the capability of being used in a wide variety of analog operations. These may

include several channels of pure video signals , or a mix of video signals with digital data channels riding on analog

carriers. It is difficult to prepare a single battery of testing conditions that will satisfy all applications. The following

table contains a set of testing conditions that Lucent believes will give a broad indication of the performance of the

A370 Series Laser Module. Please contact your local Field Application Engineer if different testing conditions and

parametric limits are required.

The distortion characteristics are measured using a two-tone test. The frequencies are 13 MHz and 19 MHz. The

second-order distortion components are measured at f1 + f2 = 32 MHz and f1 – f2 = 6 MHz. All third-order distortion components are measured in the frequency range of 5 MHz—200 MHz, and they meet the required level. All

measurements are made with SC-SPC connectors on the laser module pigtails.

Table 3. Analog Characteristics

Parameter Symbol Test Conditions Min Typ Max Unit

Output Power* P

Relative Intensity Noise RIN CW,

Modulation Bandwidth BW –3 dB,

Second-order Distortions — T = 25 ° C, OMI = 0.2;

Third-order Distortions — T = 25 ° C, OMI = 0.2;

RF Bandpass Flatness B

Spurious Noise N

Spurious Noise (carrier off) N'

* See Table 5 for more information.

†Premium performance.

O

CW, T = –40 ° C to +85 ° C — 1.0 — mW

— –140 –130 dB/Hz

Freq. = 5 MHz to 300 MHz;

no fiber loss, T = –40 ° C to +85 ° C

1.0 — — GHz

T = –40 ° C to +85 ° C

Two-tone test: f1 = 13 MHz,

— –48

–50

–40

†

–45

†

f2 = 19 MHz; 20 km of fiber,

(7 dB loss) plus connector loss,

f1 ± f2

Two-tone test: f1 = 13 MHz,

— –60

–60

–50

†

–50

†

f2 = 19 MHz; 20 km of fiber

(7 dB loss), plus connector loss,

all peaks from 5 MHz—50 MHz

meet this level

F Peak to valley: 5 MHz to 200 MHz — — 1.0 dB

P

SP

T = 25 ° C, OMI = 0.2;

ref. to one-tone: 5 MHz to 50 MHz,

— –58

–58

–54

†

–54

†

20 km of fiber, (7 dB loss) plus

connector loss

SP

T = 25 ° C — –45

–45

–37

†

–40

†

dBc

dBc

dBc

dBc

dBc

dBc

dBc

dBc

4

Lucent Technologies Inc.

Page 5

(

)

Data Sheet A370-Type Analog

March 2001 Uncooled Laser Module

Outline Diagram

Dimensions are in inches and (millimeters).

TRADEMARK, CODE, LASER SERIAL NUMBER,

AND/OR DATE CODE IN APPROXIMATE AREA SHOWN

3

4

5678

21

0.52 (13.2)

1.06 (27.0)

MIN

39.37 (1000) MIN

PIGTAIL LENGTH

0.20 (5.00)

0.165 (4.20)

0.100 (2.54)

0.300

(7.62)

0.045 (1.143)

0.016 (0.410)

0.110 (2.79)

0.010

(0.254)

0.29

(7.37)

0.17

(4.32)

0.30

7.62

0.085

(2.16)

1-899.f

Lucent Technologies Inc.

5

Page 6

A370-Type Analog Data Sheet

Uncooled Laser Module March 2001

Qualification Information

The A370-Type Laser Module has passed the following qualification tests and meets the intent of

nologies

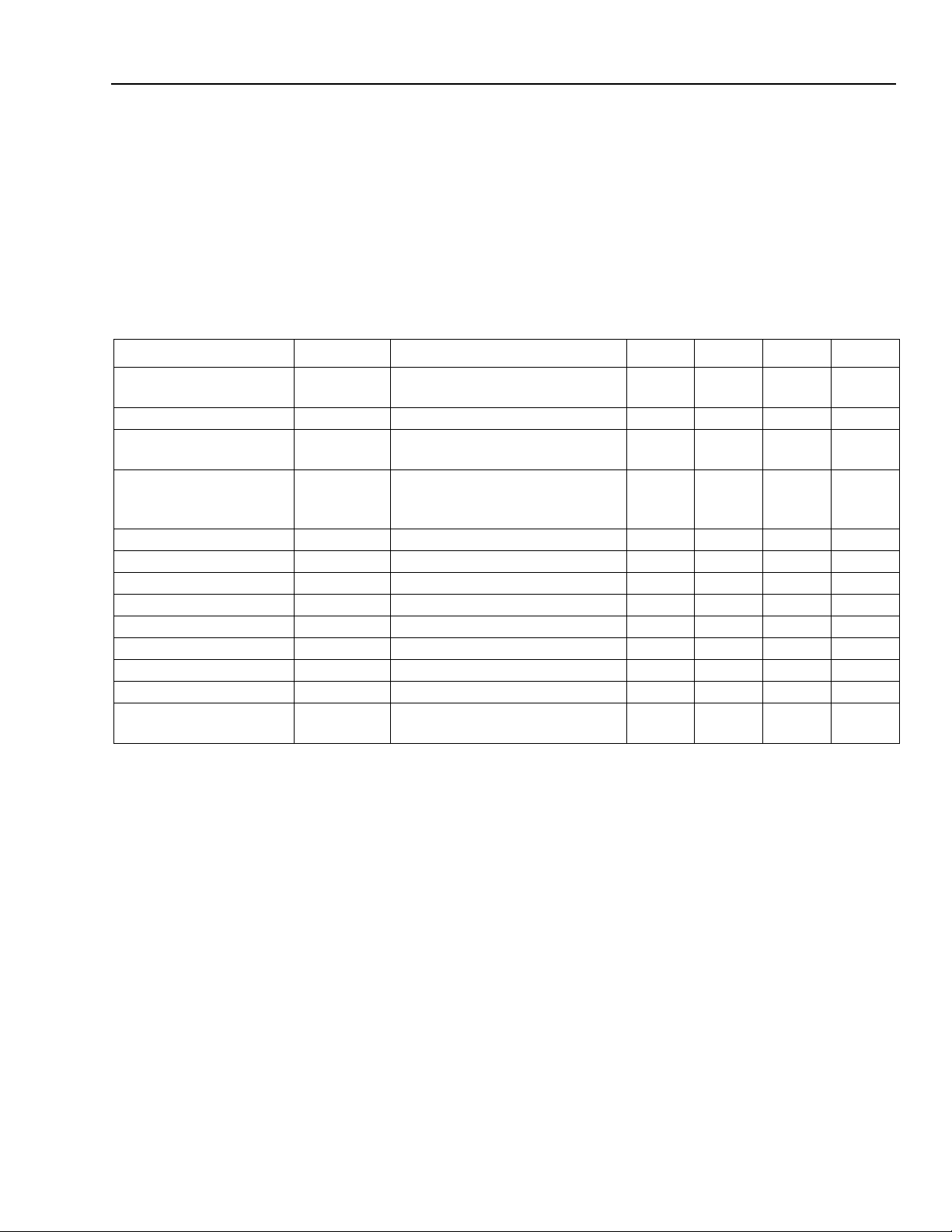

Table 4. A371-Type Laser Module Qualification Test Plan

Mechanical Shock

Vibration

Solderability

Thermal Shock

Fiber Pull

Accelerated (Biased) Aging

High-temperature Storage

Temperature Cycling

Cyclic Moisture Resistance

Damp Heat

Internal Moisture

Flammability

ESD Threshold

TR-NWT-000468 for interoffice environments and TA-TSY-000983 for outside plant environments.

Qualification Test Conditions Sample Size Reference

500 G

20 g, 20 Hz—2,000 Hz

—

Delta T = 100 ° C

1 kg; 3 times

85 °C, 5,000 hrs.

85 °C, 2,000 hrs.

500 cycles

10 cycles

40 °C, 95% RH,

1,344 hrs.

<5,000 ppm water vapor

—

—

11 MIL-STD-883

Method 2002

11 MIL-STD-883

Method 2007

11 MIL-STD-883

Method 2007

11 MIL-STD-883

Method 2003

11

25

11

11

11

11 MIL-STD-202

11 MIL-STD-883

— TR357

6

Telcordia Technologies

Telcordia Technologies

Section 5.18

Telcordia Technologies

Telcordia Technologies

Section 5.20

Telcordia Technologies

Section 5.23

Method 103

Method 1018

Sec. 4.4.2.5

Telcordia Technologies

Section 5.22

Telcordia Tech-

983

983

983

983

983

983

6

Lucent Technologies Inc.

Page 7

Data Sheet A370-Type Analog

March 2001 Uncooled Laser Module

Laser Safety Information

Class IIIb Laser Product

FDA/CDRH Class IIIb laser product. All versions are Class IIIb laser products per CDRH, 21 CFR 1040 Laser

Safety requirements. All versions are Class 3B laser products per

fied with the FDA under accession number 8720010.

This product complies with 21 CFR 1040.10 and 1040.11.

8.3 µm single-mode pigtail or connector

Wavelength = 1.3 µm

Maximum power = 10 mW

Because of size constraints, laser safety labeling is not affixed to the module but attached to the outside of the

shipping carton.

Product is not shipped with power supply.

Caution: Use of controls, adjustments, and procedures other than those specified herein may result in

hazardous laser radiation exposure.

IEC

* 60825-1:1993. The device has been classi-

DANGER

INVISIBLE LASER RADIATION

IS EMITTED FROM THE END

OF FIBER OR CONNECTOR

Avoid direct exposure to beam

Do not view beam directly with

optical instruments

INVISIBLE LASER RADIATION EMITTED FROM END OF FIBER OR CONNECTOR

Avoid exposure to beam

Class 3B Laser Product IEC-60825M 1993 Max. Output: 10 mW Wavelength: 1.3 µm

*

IEC

is a registered trademark of The International Electrotechnical Commission.

Lucent Technologies Inc.

7

Page 8

A370-Type Analog Data Sheet

Uncooled Laser Module March 2001

Ordering Information

Table 5. Ordering Information

Code Comcode Pfiber Connector

Performance

Option

A370-10A 108009150 1.0 mW SC-PC Standard

A370-10F 108013954 1.0 mW FC-PC Standard

A370-10B 108024183 1.0 mW SC-APC Standard

A370-10G 108061839 1.0 mW FC-APC Standard

A370-10N 108013962 1.0 mW none Standard

A370-11A 108225384 1.0 mW SC-PC Premium

A370-11F 108225392 1.0 mW FC-PC Premium

For additional information, contact your Microelectronics Group Account Manager or the following:

INTERNET: http://www.lucent.com/micro, or for Optoelectronics information, http://www.lucent.com/micro/opto

E-MAIL: docmaster@micro.lucent.com

N. AMERICA: Microelectronics Group, Lucent Technologies Inc., 555 Union Boulevard, Room 30L-15P-BA, Allentown, PA 18109-3286

ASIA PACIFIC: Microelectronics Group, Lucent Technologies Singapore Pte. Ltd., 77 Science Park Drive, #03-18 Cintech III, Singapore 118256

CHINA: Microelectronics Group, Lucent Technologies (China) Co., Ltd., A-F2, 23/F, Zao Fong Universe Building, 1800 Zhong Shan Xi Road,

JAPAN: Microelectronics Group, Lucent Technologies Japan Ltd., 7-18, Higashi-Gotanda 2-chome, Shinagawa-ku, Tokyo 141, Japan

EUROPE: Data Requests: MICROELECTRONICS GROUP DATALINE: Tel. (44) 7000 582 368, FAX (44) 1189 328 148

Lucent Technologies Inc. reserves the right to make changes to the product(s) or information contained herein without notice. No liability is assumed as a result of their use or application. No

rights under any patent accompany the sale of any such product(s) or information.

Copyright © 2001 Lucent Technologies Inc.

All Rights Reserved

March 2001

DS99-034LWP-1 (Replaces DS99-034LWP)

1-800-372-2447, FAX 610-712-4106 (In CANADA: 1-800-553-2448, FAX 610-712-4106)

Tel. (65) 778 8833, FAX (65) 777 7495

Shanghai 200233 P. R. China

Tel. (81) 3 5421 1600, FAX (81) 3 5421 1700

Technical Inquiries: OPTOELECTRONICS MARKETING: (44) 1344 865 900 (Ascot UK)

Tel. (86) 21 6440 0468, ext. 325, FAX (86) 21 6440 0652

Loading...

Loading...