Page 1

The A3260-- Hall-effect bipolar switch is an extremely

temperature-stable and stress-resistant sensor especially suited for

operation over extended temperature ranges to +150°C. Superior

high-temperature performance is made possible through dynamic

offset cancellation, which reduces the residual offset voltage normally

caused by device overmolding, temperature dependencies, and thermal

stress.

The device includes on a single silicon chip a voltage regulator,

Hall-voltage generator, small-signal amplifier, chopper stabilization,

Schmitt trigger, and a constant-current open-collector output. A south

pole of sufficient strength will turn the output OFF. An on-board

regulator permits operation with supply voltages of 3.5 to 24 volts.

Noise radiation is limited by control of the output current slew rate.

The first character of the part number suffix determines the device

operating temperature range; suffix ‘E–’ is -40°C to +85°C and ‘L–’ is

-40°C to +150°C. Three package styles provide a magnetically optimized package for most applications. Suffix ‘–LH’ is a miniature lowprofile surface-mount package, ‘–LT’ is a miniature SOT-89/TO243AA transistor package for surface-mount applications; while suffix

‘–UA’ is a three-lead ultra-mini-SIP for through-hole mounting.

Data Sheet

27631.50

FEATURES

■ Internal Current Regulator for 2-Wire Operation

■ Output Slew Rate Controlled

■ Resistant to Physical Stress

■ Superior Temperature Stability

■ Operation From Unregulated Supply

■ Reverse Battery Protection

■ Solid-State Reliability

■ Small Size

Always order by complete part number: the prefix 'A' + the basic four-digit

part number + a suffix to indicate operating temperature range +

a suffix to indicate package style, e.g., A3260ELH .

3260

2-WIRE, CHOPPER-STABILIZED,

PRECISION HALL-EFFECT BIPOLAR SWITCH

Suffix Code 'LH' Pinning

Supply Voltage, VCC........................... 27 V

Reverse Battery Voltage, V

RCC

.......... -16 V

Magnetic Flux Density, B ........... Unlimited

Package Power Dissipation, PD. See Graph

Junction Temperature, TJ............... +170°C

Operating Temperature Range, T

A

Suffix ‘E–’ .................. -40°C to +85°C

Suffix ‘L–’ ................ -40°C to +150°C

Storage Temperature Range,

TS.............................. -65°C to +170°C

ABSOLUTE MAXIMUM RATINGS

at TA=+25°C

ADVANCE INFORMATION

(subject to change without notice)

June 30, 2000

NC

X

SUPPLY

GROUND

12

3

Dwg. PH-003-5

NO (INTERNAL)

CONNECTION

Pinning is shown viewed from branded side.

Page 2

3260

2-WIRE, CHOPPER-STABILIZED,

PRECISION HALL-EFFECT

BIPOLAR SWITCH

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

2

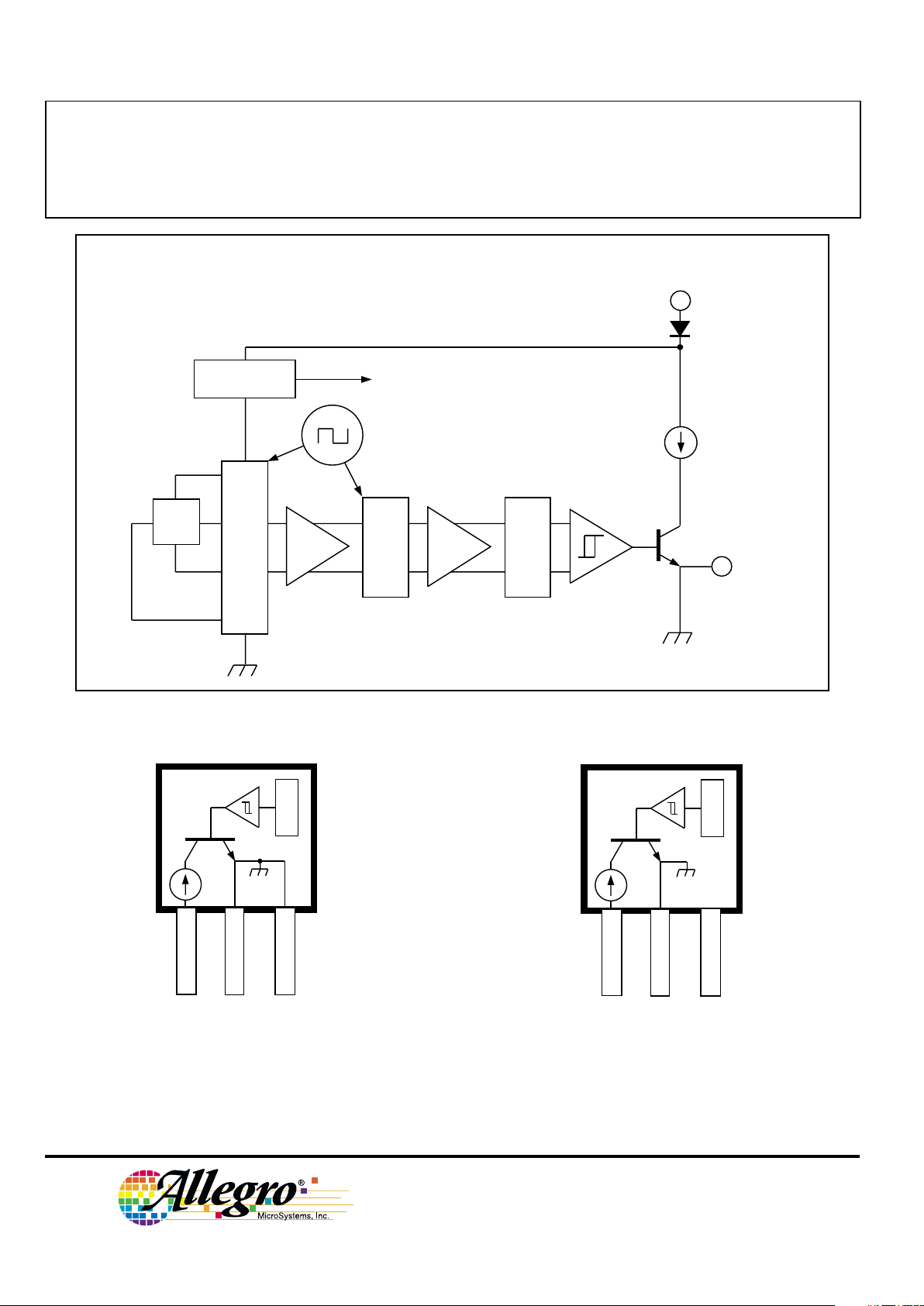

FUNCTIONAL BLOCK DIAGRAM

W

Copyright © 2000, Allegro MicroSystems, Inc.

Dwg. FH-020-4

X

DYNAMIC

OFFSET CANCELLATION

SUPPLY

REG.

SAMPLE

& HOLD

LOW-PASS

FILTER

TO ALL

SUBCIRCUITS

GROUND

Pinning is shown viewed from branded side.

Suffix Code 'UA' Pinning

(SIP)

Suffix Code 'LT' Pinning

(SOT-89/TO-243AA)

X

Dwg. PH-003-7A

1

SUPPLY

GROUND

32

GROUND

X

Dwg. PH-003-6

1

SUPPLY

GROUND

32

NO (INTERNAL)

CONNECTION

NC

Page 3

3260

2-WIRE, CHOPPER-STABILIZED,

PRECISION HALL-EFFECT

BIPOLAR SWITCH

www.allegromicro.com

3

ELECTRICAL CHARACTERISTICS over operating temperature range.

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Supply Voltage V

CC

Operating 3.5 12 24 V

Output Current I

GND(L)

B > B

OP

-4.0 -6.5 -8.0 mA

I

GND(H)

B < B

RP

-11 -14.5 -18 mA

Chopping Frequency f

C

– 340 – kHz

Output Slew Rate di/dt CL = 20 pF 0.5 — 2.0 mA/µs

Output Settling Time t

sd

CL = 20 pF — — 20 µs

Reverse Battery Current I

CC

V

RCC

= -16 V – – -15 mA

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Operate Point B

OP

–1030 G

Release Point B

RP

-30 -10 – G

Hysteresis B

hys

BOP - B

RP

–20– G

MAGNETIC CHARACTERISTICS over operating supply voltage and temperature ranges.

NOTE — Typical Data is at TA = +25°C and VCC = 12 V and is for design information only.

NOTES:1. . BOP = operate point (output turns OFF); BRP = release point (output turns ON).

2. Typical Data is at TA = +25°C and VCC = 12 V and is for design information only.

Page 4

3260

2-WIRE, CHOPPER-STABILIZED,

PRECISION HALL-EFFECT

BIPOLAR SWITCH

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

4

This page intentionally left blank

Page 5

3260

2-WIRE, CHOPPER-STABILIZED,

PRECISION HALL-EFFECT

BIPOLAR SWITCH

www.allegromicro.com

5

SENSOR LOCATIONS

(±0.005” [0.13 mm] die placement)

Package Designator “LH”

Package Designators “UA” and "UA-TL"

Although sensor location is accurate to three sigma for a

particular design, product improvements may result in small

changes to sensor location.

0.038"

0.96 mm

1 2

Dwg. MH-025

0.011"

0.28 mm

NOM

ACTIVE AREA DEPTH

0.059"

1.49 mm

A

3

0.045"

1.14 mm

1 32

Dwg. MH-008-8

0.030"

0.76 mm

NOM

ACTIVE AREA DEPTH

0.088"

2.24 mm

A

1 32

Dwg. MH-011-9A

0.018"

0.46 mm

NOM

BRANDED

SURFACE

ACTIVE AREA DEPTH

0.080"

2.04 mm

0.056"

1.44 mm

A

Package Designator “LT”

600

400

200

20 60 100 140

0

AMBIENT TEMPERATURE in °C

ALLOWABLE PACKAGE POWER DISSIPATION in MILLIWATTS

Dwg. GH-046-2C

Suffix "–UA"

R

θJA

= 206°C/W

40 80 120 180

700

500

300

100

160

Suffix "–LT"

R

θJA

= 258°C/W

Suffix "–LH"

R

θJA

= 248°C/W

Suffix "E–"

Suffix "L–"

Allegro

Page 6

3260

2-WIRE, CHOPPER-STABILIZED,

PRECISION HALL-EFFECT

BIPOLAR SWITCH

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

6

All Allegro sensors are subjected to stringent qualification requirements prior to being released to production.

To become qualified, except for the destructive ESD tests, no failures are permitted.

CRITERIA FOR DEVICE QUALIFICATION

Qualification Test Test Method and Test Conditions Test Length Samples Comments

Biased Humidity (HAST) TA = 130°C, RH = 85% 50 hrs 77 VCC = V

OUT

= 5 V

High-Temperature JESD22-A108, 408 hrs 77 V

CC

= 24 V,

Operating Life (HTOL) TA = 150°C, TJ ≤ 165°CV

OUT

= 20 V

Accelerated HTOL TA = 175°C, TJ = 190°C 504 hrs 77 VCC = 24 V,

V

OUT

= 20 V

Autoclave, Unbiased JESD22-A102, Condition C, 96 hrs 77

TA = 121°C, 15 psig

High-Temperature MIL-STD-883, Method 1008, 1000 hrs 77

(Bake) Storage Life TA = 170°C

Temperature Cycle MIL-STD-883, Method 1010, 500 cycles 77

-65°C to +150°C

Latch-Up — Pre/Post 6

Reading

Electro-Thermally — Pre/Post 6

Induced Gate Leakage Reading

ESD, CDF-AEC-Q100-002 Pre/Post x per Test to failure,

Human Body Model Reading test All leads > TBD

Electrical Distributions Per Specification — 30

Page 7

3260

2-WIRE, CHOPPER-STABILIZED,

PRECISION HALL-EFFECT

BIPOLAR SWITCH

www.allegromicro.com

7

FUNCTIONAL DESCRIPTION

Chopper-Stabilized Technique. These devices use a

proprietary dynamic offset cancellation technique, with an

internal high-frequency clock to reduce the residual offset

voltage of the Hall element that is normally caused by device

overmolding, temperature dependencies, and thermal stress.

This technique produces devices that have an extremely stable

quiescent Hall output voltage, are immune to thermal stress, and

have precise recoverability after temperature cycling. This

technique will also slightly degrade the device output repeatability.

The Hall element can be considered as a resistor array

similar to a Wheatstone bridge. A large portion of the offset is

a result of the mismatching of these resistors. The chopperstabilizing technique cancels the mismatching of the resistors by

changing the direction of the current flowing through the Hall

plate and Hall voltage measurement taps, while maintaining the

Hall-voltage signal that is induced by the external magnetic

flux. The signal is, then, captured by a sample-and-hold circuit.

Operation. The output of these devices turns ON when a

magnetic field (north pole) perpendicular to the Hall sensor

exceeds the release point threshold (BRP). After turn-ON, the

output will source current equal to the device operating current

plus a current source (I

GND(H)

). When the magnetic field is

increased (south pole) above the operate point (BOP), the output

will source current equal to the Hall-effect sensor operating

current with the current source turned OFF (I

GND(L)

). The

difference in the magnetic operate and release points is the

hysteresis (B

hys

) of the device. The hysteresis allows clean

switching of the output even in the presence of external mechanical vibration or electrical noise.

Applications. It is strongly recommended that an external

bypass capacitor be connected (in close proximity to the Hall

sensor) between the supply and ground of the device to reduce

both external noise and noise generated by the chopperstabilization technique.

Extensive applications information on magnets and Halleffect sensors is also available in the Allegro Electronic Data

Book AMS-702 or Application Note 27701.

Dwg. EH-012

REG

SAMPLE

& HOLD

X

+V

HALL

VOLTAGE

B

+

—

Dwg. AH-011-2

0 +B

0

OUTPUT CURRENT

FLUX DENSITY

Dwg. GH-034-6

-B

+I

I

OUT

+ I

CC

B

RP

B

OP

I

CC

100 Ω

Dwg. EH-011-2A

0.1 µF

SUPPLY

X

1

3

2

'UA' PACKAGE

0.95 V

–

+

Page 8

3260

2-WIRE, CHOPPER-STABILIZED,

PRECISION HALL-EFFECT

BIPOLAR SWITCH

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

8

PACKAGE DESIGNATOR 'LH'

(fits SC-74A solder-pad layout)

Dwg. MA-010-3B mm

12

0.15

0.00

0.20

0.127

3.10

2.90

2.10

1.85

3.00

2.70

0.95

BSC

0.55

REF

0.50

0.30

3

0° TO 8°

0.25

MIN

1.10

0.90

1.25

0.90

NOTES: 1. Tolerances on package height and width represent allowable mold offsets. Dimensions given are measured at the widest point (parting line).

2. Exact body and lead configuration at vendor’s option within limits shown.

3. Height does not include mold gate flash.

4. Where no tolerance is specified, dimension is nominal.

Dwg. MA-011-3 mm

12

1.00

2.40

0.95

0.70

3

Dwg. MA-010-3B in

12

0.006

0.000

0.0079

0.0050

0.122

0.114

0.083

0.073

0.118

0.106

0.037

BSC

0.022

REF

0.020

0.012

3

0° TO 8°

0.020

MIN

0.043

0.035

0.049

0.035

Dwg. MA-011-3 in

12

0.039

0.094

0.03

7

0.028

3

Dimensions in Inches

(for reference only)

Dimensions in Millimeters

(controlling dimensions)

Page 9

3260

2-WIRE, CHOPPER-STABILIZED,

PRECISION HALL-EFFECT

BIPOLAR SWITCH

www.allegromicro.com

9

Dwg. MA-009-3A in

1

23

0.072

0.064

0.167

0.155

0.059

BSC

0.0189

0.0142

0.047

0.035

0.102

0.090

0.063

0.055

0.0173

0.0138

0.090

0.084

0.0221

0.0173

0.118

BSC

0.181

0.173

Dwg. MA-009-3A mm

1

23

4.60

4.40

1.83

1.62

4.25

3.94

1.50

BSC

0.48

0.36

1.20

0.89

2.60

2.29

1.60

1.40

0.44

0.35

2.29

2.13

0.56

0.44

3.00

BSC

PACKAGE DESIGNATOR 'LT'

(SOT-89/TO-243AA)

Dimensions in Inches

(for reference only)

Dimensions in Millimeters

(controlling dimensions)

13

B

2.5

0.8

2.6

1.2

4.6

2.0

Dwg. MA-012-3 mm

Pads 1, 2, 3, and A — Standard SOT-89 Layout

Pads 1, 2, 3, and B — Low-Stress Version

Pads 1, 2, and 3 only — Lowest Stress, But Not Self Aligning

2

0.7

TYP

0.8

TYP

A

NOTE: Exact body and lead configuration at vendor’s option within limits shown.

1

B

0.098

0.031

0.102

0.047

0.181

0.079

Dwg. MA-012-3 in

Pads 1, 2, 3, and A — Standard SOT-89 Layout

Pads 1, 2, 3, and B — Low-Stress Version

Pads 1, 2, and 3 only — Lowest Stress, But Not Self Aligning

2

0.028

TYP

0.031

TYP

A

3

Page 10

3260

2-WIRE, CHOPPER-STABILIZED,

PRECISION HALL-EFFECT

BIPOLAR SWITCH

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

10

Surface-Mount Lead Form (Suffix '-TL')

Dimensions in Inches

(controlling dimensions)

Dimensions in Millimeters

(for reference only)

PACKAGE DESIGNATOR 'UA'

0.095

±0.005

0.020

MIN

FLAT

Dwg. MH-015 in

0.004

MAX

0.002

MAX

0°–8°

2.41

±0.13

0.51

MIN

FLAT

Dwg. MH-015 mm

0.10

MAX

0.051

MAX

0°–8°

Dwg. MH-014E mm

4.17

4.04

1.57

1.47

0.44

0.35

1.27

BSC

45°

16.26

15.24

0.48

0.36

2.16

MAX

45°

0.79

123

3.10

2.97

SEE NOTE

Dwg. MH-014E in

0.164

0.159

0.062

0.058

0.0173

0.0138

0.050

BSC

45°

0.640

0.600

0.0189

0.0142

0.085

MAX

45°

0.031

123

0.122

0.117

SEE NOTE

NOTES: 1. Tolerances on package height and width represent allowable mold offsets. Dimensions given are measured at the widest point (parting line).

2. Exact body and lead configuration at vendor’s option within limits shown.

3. Height does not include mold gate flash.

4. Recommended minimum PWB hole diameter to clear transition area is 0.035” (0.89 mm).

5. Where no tolerance is specified, dimension is nominal.

Page 11

3260

2-WIRE, CHOPPER-STABILIZED,

PRECISION HALL-EFFECT

BIPOLAR SWITCH

www.allegromicro.com

11

The products described herein are manufactured under one or

more of the following U.S. patents: 5,045,920; 5,264,783; 5,442,283;

5,389,889; 5,581,179; 5,517,112; 5,619,137; 5,621,319; 5,650,719;

5,686,894; 5,694,038; 5,729,130; 5,917,320; and other patents

pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such departures from the detail specifications as may be

required to permit improvements in the performance, reliability, or

manufacturability of its products. Before placing an order, the user is

cautioned to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components

in life-support appliances, devices, or systems without express written

approval.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for any infringements of patents or other rights

of third parties that may result from its use.

Page 12

3260

2-WIRE, CHOPPER-STABILIZED,

PRECISION HALL-EFFECT

BIPOLAR SWITCH

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

12

HALL-EFFECT SENSORS

Partial Part Avail. Oper. Characteristics at TA = +25°C

Number Temp. B

OP(max)BRP(min)

B

hys(typ)

Features Notes

HALL-EFFECT UNIPOLAR SWITCHES in order of B

OP

and B

hys

3240 E/L +50 +5.0 10 chopper stabilized 1

3209 E ±60 ±5.0 7.7 400 µW, chopper stabilized

3210 E ±60 ±5.0 7.7 25 µW, chopper stabilized

3361 E +55* +110‡ 5.0* 2-wire, chopper stabilized

3362 E +110 +55 5.0* 2-wire, chopper stabilized

3161 E +160 +30 20 2-wire

3141 E/L +160 +10 55

3235 S +175 +25 15* output 1 2

-25 -175 15* output 2 2

5140 E +200 +50 55 300 mA output 1, 3

3142 E/L +230 +75 55

3143 E/L +340 +165 55

3144 E/L +350 +50 55

3122 E/L +400 +140 105

3123 E/L +440 +180 105

3121 E/L +450 +125 105

3150 J +40 to +850 – 20

programmable, chopper stabilized

1

HALL-EFFECT LATCHES & BIPOLAR SWITCHES† in order of B

OP

and B

hys

3260 E/L +30 -30 20 bipolar, chopper stabilized

3280 E/L +40 -40 45 chopper stabilized

3134 E/L +50 -50 27 bipolar switch

3133 K/L/S +75 -75 52 bipolar switch

3281 E/L +90 -90 100 chopper stabilized

3132 K/L/S +95 -95 52 bipolar switch

3187 E/L +150 -150 100*

3177 S +150 -150 200

3625 S +150 -150 200 900 mA outputs 1, 3, 5

3626 S +150 -150 200 400 mA outputs 1, 3, 5

3195 E/L +160 -160 220 1, 4

3197 L +160 -160 230 1

3175 S +170 -170 200

3188 E/L +180 -180 200*

3283 E/L +180 -180 300 chopper stabilized

3189 E/L +230 -230 100*

3275 S +250 -250 100* 5

3185 E/L +270 -270 340*

Operating Temperature Ranges:

S = -20°C to +85°C, E = -40°C to +85°C, J = -40°C to +115°C, K = -40°C to +125°C, L = -40°C to +150°C

Notes 1. Protected.

2. Output 1 switches on south pole, output 2 switches on north pole for 2-phase, bifilar-wound, unipolar-driven brushless dc

motor control.

3. Power driver output.

4. Active pull down.

5. Complementary outputs for 2-phase bifilar-wound, unipolar-driven brushless dc motor control.

* Minimum. ‡ Maximum

† Latches will not switch on removal of magnetic field; bipolar switches may switch on removal of field but require field reversal

for reliable operation over operating temperature range.

Loading...

Loading...