Datasheet A3054SU-30, A3054SU-29, A3054SU-28, A3054SU-27, A3054SU-26 Datasheet (Allegro)

...Page 1

3054

MULTIPLEXED

TWO-WIRE

HALL-EFFECT SENSOR ICs

The A3054KU and A3054SU Hall-effect sensors are digital magnetic sensing ICs capable of communicating over a two-wire power/

signal bus. Using a sequential addressing scheme, the device responds to a signal on the bus and returns the diagnostic status of the

IC, as well as the status of each monitored external magnetic field.

As many as 30 sensors can function on the same two-wire bus. This

IC is ideal for multiple sensor applications where minimizing the wiring

harness size is desirable or essential.

Each device consists of high-resolution bipolar Hall-effect switching circuitry, the output of which drives high-density CMOS logic

stages. The logic stages decode the address pulse and enable a

response at the appropriate address. The combination of magneticfield or switch-status sensing, low-noise amplification of the Halltransducer output, and high-density decoding and control logic is made

possible by the development of a new sensor DABiC™ (digital analog

bipolar CMOS) fabrication technology. The A3054SU is an improved

replacement for the original UGN3055U.

These unique magnetic sensing ICs are available in two temperature ranges; the A3054SU operates within specifications between

-20°C and +85°C, while the A3054KU is rated for operation between

-40°C and +125°C. Alternative magnetic and temperature specifications are available on special order. Both versions are supplied in

0.060" (1.54 mm) thick, three-pin plastic SIPs. Each device is clearly

marked with a two-digit device address (XX).

3054

MULTIPLEXED TWO-WIRE

HALL-EFFECT SENSOR ICs

FEATURES

■ Complete Multiplexed Hall-Effect ICs with

Simple Sequential Addressing Protocol

■ Allows Power and Communication Over a

Two-Wire Bus (Supply/Signal and Ground)

■ Up to 30 Hall-Effect Sensors Can Share a Bus

■ Sensor Diagnostic Capabilities

■ Magnetic-Field or Switch-Status Sensing

■ Low Power of DABiC Technology Favors

Battery-Powered and Mobile Applications

■ Ideal for Automotive, Consumer, and Industrial Applications

Always order by complete part number:

Part Number Operating Temperature Range

A3054KU-XX -40°C to +125°C

A3054SU-XX -20°C to +85°C

where XX = address (01, 02, … 29, 30).

Pinning is shown viewed from branded side.

ABSOLUTE MAXIMUM RATINGS

at T

A

= +25°C

Supply Voltage, V

BUS

. . . . . . . . . . . . . . 18 V

Magnetic Flux Density, B . . . . . . . Unlimited

Operating Temperature Range, T

A

A3054KU . . . . . . . . . . . -40°C to +125°C

A3054SU . . . . . . . . . . . . -20°C to +85°C

Storage Temperature Range,

TS. . . . . . . . . . . . . . . . . -55°C to +150°C

Package Power Dissipation,

PD. . . . . . . . . . . . . . . . . . . . . . . 635 mW

Data Sheet

27680.1

Dwg. PH-005

1

BUS

GROUND

32

SWITCH IN

X

LOGIC

Page 2

3054

MULTIPLEXED

TWO-WIRE

HALL-EFFECT SENSOR ICs

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Limits

Characteristic Symbol Test Conditions Min Typ Max Units

Power Supply Voltage V

BUS

——15 V

Signal Current I

S

DUT Addressed, B > 300 G 12 15 20 mA

Quiescent Current I

QL

V

BUS

= 6 V — 1.5 2.5 mA

I

QH

V

BUS

= 9 V — 1.4 2.5 mA

∆I

Q

I

QL

– I

QH

— 100 300 µA

Address Range Addr Factory Specified 1 — 30 —

Clock Thresholds V

CLH

LOW to HIGH — — 8.5 V

V

CHL

HIGH to LOW 6.5 — — V

V

CHYS

Hysteresis — 0.8 — V

Max. Clock Frequency* f

CLK

50% Duty Cycle 2.5 — — kHz

Address LOW Voltage V

L

V

RST

6.0 V

CHL

V

Address HIGH Voltage V

H

V

CLH

9.0 V

BUS

V

Reset Voltage V

RST

2.5 3.5 5.5 V

Propagation Delay* t

plh

LOW to HIGH 10 20 30 µs

t

phl

HIGH to LOW — 5.0 10 µs

Pin 3-2 Resistance R

SWH

DUT Addressed, B < 5 G — 50 — kΩ

R

SWL

DUT Addressed, B > 300 G — 200 — Ω

Pin 3-2 Output Voltage V

SWH

DUT Addressed, B < 5 G — 3.9 — V

V

SWL

DUT Addressed, B> 300 G — 30 — mV

MAGNETIC CHARACTERISTICS over operating temperature range.

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Magnetic Threshold† B

OP

Turn-On 50 150 300 G

B

RP

Turn-Off 5.0 100 295 G

Hysteresis B

HYS

B

OP

– B

RP

5.0 50 — G

ELECTRICAL CHARACTERISTICS over operating temperature range.

Typical Data is at TA = +25°C and is for design information only.

*This parameter, although warranteed, is not production tested.

†Alternative magnetic switch point specifications are available on special order. Please contact the factory.

W

Copyright © 1995 Allegro MicroSystems, Inc.

Page 3

3054

MULTIPLEXED

TWO-WIRE

HALL-EFFECT SENSOR ICs

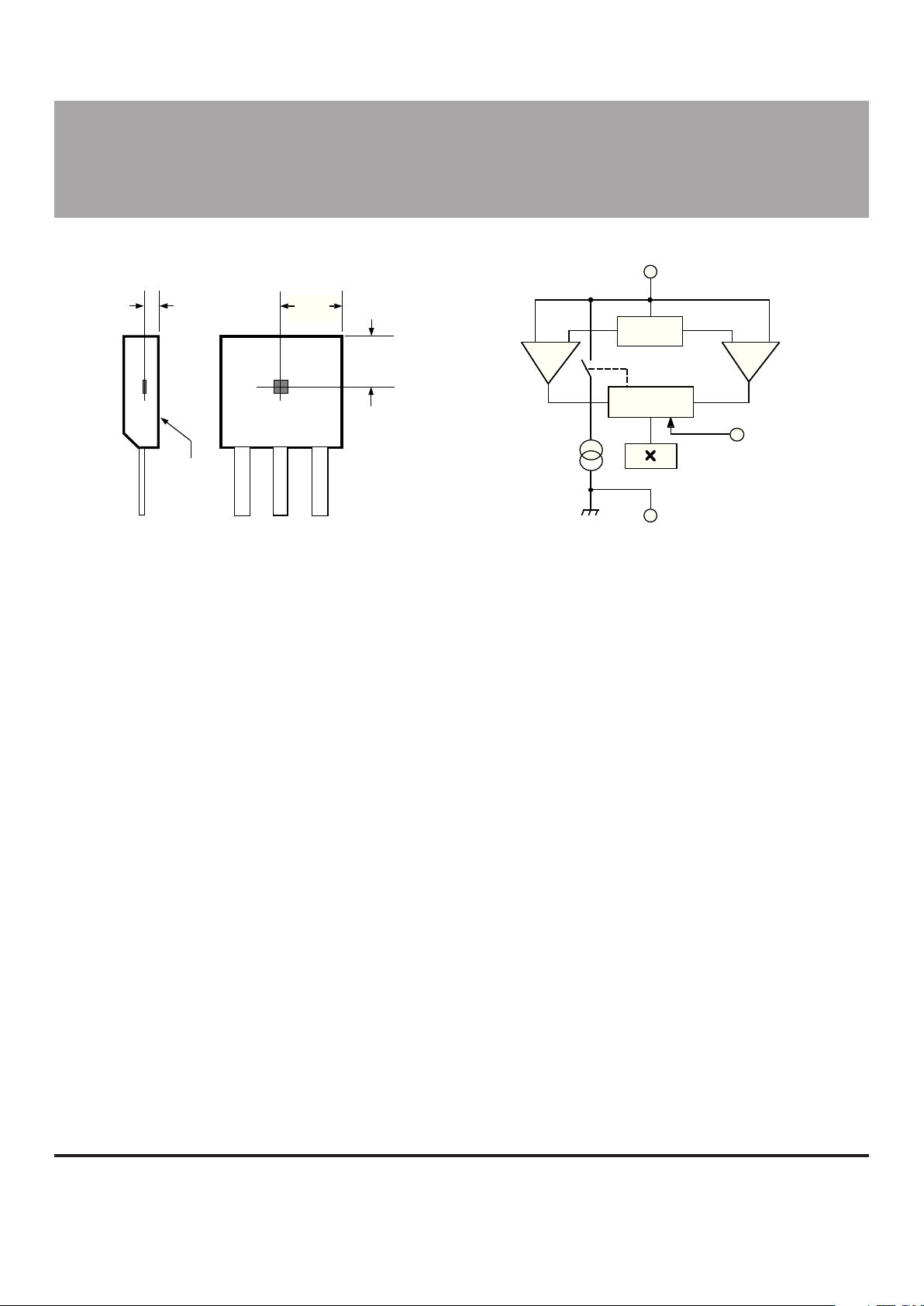

FUNCTIONAL BLOCK DIAGRAMSENSOR LOCATION

(±0.005” [0.13 mm] die placement)

CLOCK

Dwg. FH-009

BUS

SWITCH IN

(OPTIONAL)

GROUND

CMOS LOGIC

REG

COMP COMP

RESET

1

3

2

1 32

Dwg. MH-002-10A

0.015"

0.38 mm

NOM

BRANDED

SURFACE

ACTIVE AREA DEPTH

0.073"

1.85 mm

A

0.090"

2.29 mm

DEFINITION OF TERMS

Sensor Address

Each bus sensor has a factory-specified predefined

address. At present, allowable sensor addresses are

integers from 01 to 30.

LOW-to-HlGH Clock Threshold (V

CLH

)

Minimum voltage required during the positive-going

transition to increment the bus address and trigger a

diagnostic response from the bus sensors. This is also

the maximum threshold of the on-chip comparator that

monitors the supply voltage, V

BUS

.

HlGH-to-LOW Threshold (VHL)

Maximum voltage required during the negative-going

transition to trigger a

signal

current response from the bus

sensors. This is also the maximum threshold of the

on-chip comparator that monitors the supply voltage,

V

BUS

.

Bus HIGH Voltage (VH)

Bus HIGH voltage during addressing. Voltage should

be greater than V

CLH

.

Address LOW Voltage (VL)

Bus LOW voltage during addressing. Voltage should

be greater than V

RST

and less than V

CHL

.

Bus Reset Voltage (V

RST

)

Voltage level while resetting sensors.

Sensor Quiescent Current Drain (IQ)

The current drain of bus sensors when active but not

addressed. IQH is the quiescent current drain when the

sensor is not addressed and is at VH IQL is the quiescent

current drain when the sensor is not addressed and is at

VL. Note that IQL is greater than IQH.

Diagnostic Phase

Period on the bus when the address voltage is at VH.

During this period, a correctly addressed sensor responds

by increasing its current drain on the bus. This response

from the sensor is called the diagnostic response and

the bus current

increase

is called the diagnostic current.

Signal Phase

Period on the bus when the address voltage is at VL.

During this period, a correctly addressed sensor that

detects a magnetic field greater than the magnetic operate point, BOP, responds by maintaining a current drain of

IS on the bus. This response from the sensor is called the

signal response and the bus current is called the signal

current.

Sensor Address Response Current (IS)

Sensor current during the

diagnostic

and the

signal

responses of the bus sensor. This is accomplished by

enabling an internal constant-current source.

Page 4

3054

MULTIPLEXED

TWO-WIRE

HALL-EFFECT SENSOR ICs

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

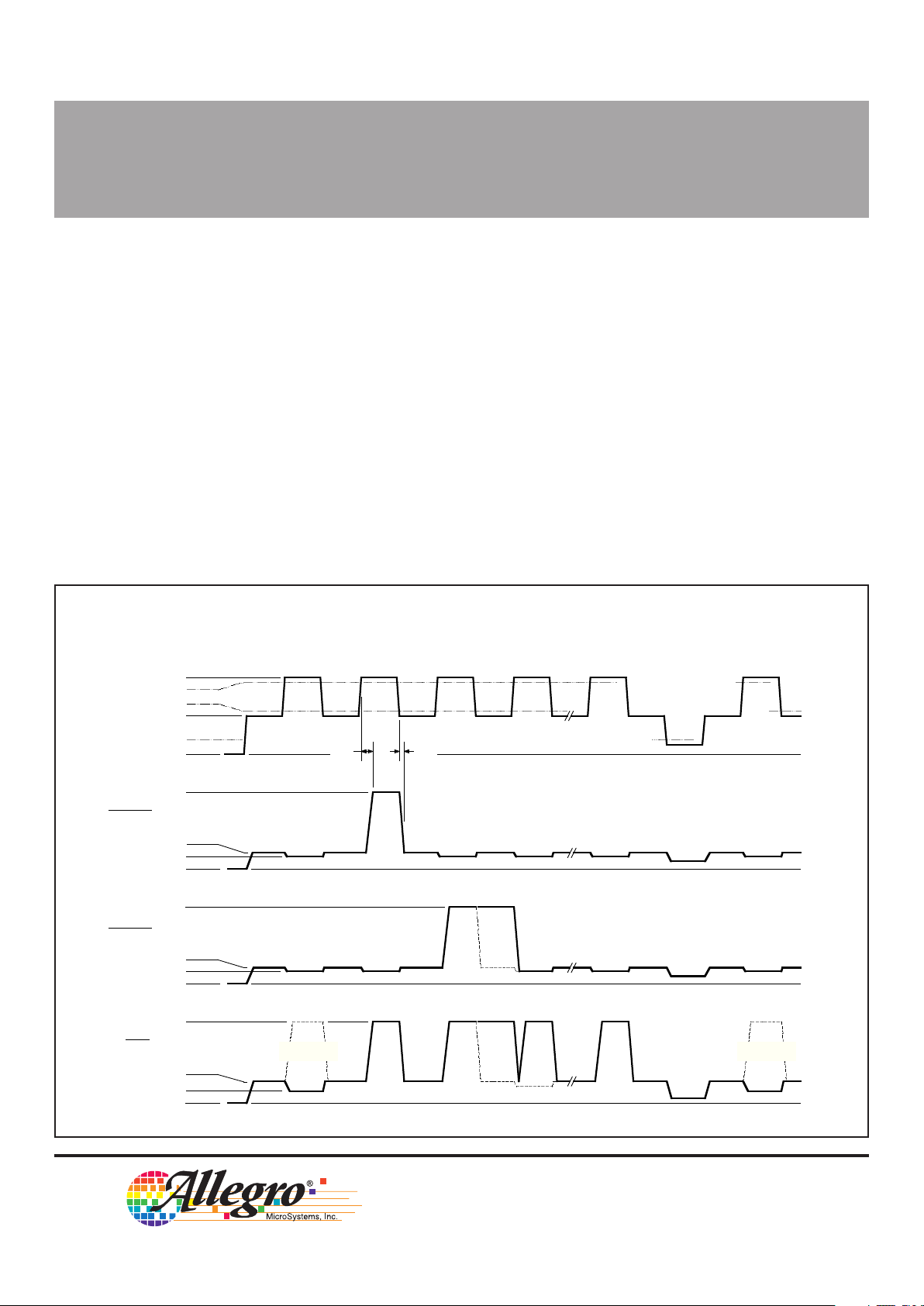

A device may be addressed by changing the supply

voltage as shown in Figure 1. A preferred addressing

protocol is as follows: the bus supply voltage is brought

low (<2.5 V) so that all devices on the bus are reset. The

voltage is then raised to the address LOW voltage (VL) and

the bus quiescent current is measured. The bus is then

toggled between VL and VH (address HIGH voltage), with

each positive transition representing an increment in the

bus address. After each voltage transition, the bus current

may be monitored to check for diagnostic and signal

responses from sensor ICs.

Sensor Addressing

When a sensor detects a bus address equal to its

factory-programmed address, it responds with an increase

in its supply current drain ( IS) during the next HIGH portion

ADDRESSING PROTOCOL

Magnetic Operate Point (BOP)

Minimum magnetic field required to switch ON the

Hall amplifier and switching circuitry of the addressed

sensor. This circuitry is only active when the sensor is

addressed.

Magnetic Release Point (BRP)

Magnetic field required to switch OFF the Hall

amplifier and switching circuitry after the output has been

switched ON. When a device is deactivated by changing

the bus address, all magnetic memory is lost.

Magnetic Hysteresis (B

HYS

)

Difference between the BOP and BRP magnetic field

thresholds.

FIGURE 1

BUS TIMING

SENSOR 03 — DIAGNOSTIC

AND SIGNAL CURRENTS

DIAGNOSTIC

ADDRESS 01

DIAGNOSTIC

ADDRESS 02

DIAGNOSTIC

ADDRESS 04

DIAGNOSTIC

ADDRESS

n

RESET

DIAGNOSTIC

ADDRESS 01

SENSOR 02 —

DIAGNOSTIC CURRENT

DIAGNOSTIC

ADDRESS 03

SENSOR 01

NOT PRESENT

V

H

V

L

V

RST

0

I

S

I

QL

I

QH

0

I

S

0

I

S

n • I

QL

n • I

QH

0

t

phl

t

plh

V

CLH

V

CHL

Dwg. WH-005

BUS

VOLTAGE

SENSOR 02

CURRENT

WITH NO

MAGNETIC

FIELD

SENSOR 03

CURRENT

WITH

MAGNETIC

FIELD

TOTAL

BUS CURRENT

WITH

MAGNETIC

FIELD AT

SENSOR 03

RESET

I

QL

I

QH

SENSOR 01

NOT PRESENT

Page 5

3054

MULTIPLEXED

TWO-WIRE

HALL-EFFECT SENSOR ICs

ofthe address cycle. This response may be

used as an indication that the sensor is "alive

and well" on the bus and is called the

diag-

nostic

response. If the sensor detects an

ambient magnetic field, it continues with I

S

during the low portion of the address cycle.

This response from the sensor is called the

signal

response. When the next positive

(address) transition is detected, the sensor

becomes disabled, and its contribution to the

bus signal current returns to IQ.

Bus Current

Figure 1 shows the addressing protocol.

The top trace represents the bus voltage

transitions as controlled by the bus driver

(see Applications Notes for an optimal bus

driver schematic). The second trace represents the bus current contribution of Sensor

02. The

diagnostic

response from the sensor

indicates that it detected its address on the

bus. However, no

signal

current is shown,

which indicates that sufficient magnetic field

is not detected at the chip surface and that

pin 3 is open circuited. The third trace

represents the current drain of Sensor 03

when a magnetic field is detected. Note both

the

diagnostic

and

signal

currents from the

sensor. The last trace represents the overall

bus current drain. When no sensors are

addressed, the net bus current is the sum of

quiescent currents of all sensors on the bus

(for 'n' sensors, the bus current drain is

n • IQ).

Bus Issues

After a reset, while at the address LOW

voltage (VL), and before the first address

pulse, bus current calibration may be performed. This feature allows for fail-safe

detection of signal current and eliminates

detection problems caused by low signal

current (IS), the operation of sensors at

various ambient temperatures, lot-to-lot

variation of quiescent current, and the

addition or replacement of sensors to the bus

while in the field. At present, a maximum of

30 active sensors can coexist on the same

bus, each with a different address. Address

TYPICAL DEVICE QUIESCENT CURRENT

FIGURE 2

SENSOR CONNECTIONS

Dwg. EH-004

1 32

1 32

NC

SWITCH

POSITIVE BUS SUPPLY

BUS RETURN

X

X

6

91215

SUPPLY VOLTAGE, V IN VOLTS

0

Dwg. GH-045

3

QUIESCENT CURRENT, I IN mA

0

0.5

1.0

1.5

2.0

T = +25°C

A

BUS

Q

Page 6

3054

MULTIPLEXED

TWO-WIRE

HALL-EFFECT SENSOR ICs

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

ADDRESS

RESET

ANALOG OUT

(POSITIVE) BUS SUPPLY

BUS RETURN

MICROPROCESSOR

INTERFACE

01 02 28 29 30

Dwg. EH-005

31 is designed to be inactive to allow for

further address expansion of the bus (to 62

maximum addresses). In order to repeat the

address cycle, the bus must be reset, as

shown in Figure 1, by bringing the supply

voltage to below V

RST

. Sensors have been

designed not to ‘wrap-around’.

Magnetic Sensing

The sensor IC has been designed to

respond to an external magnetic field whose

magnetic strength is greater than BOP. It

accomplishes this by amplifying the output of

an on-chip Hall transducer and applying it to

a threshold detector. In order that bus

current is kept to a minimum, the transducer

and amplification circuitry is kept powered

down until the sensor is addressed. Hence,

the magnetic status is evaluated only when

the sensor is addressed.

External Switch Sensing

Pin 3 of the IC may be used to detect the

status of an external switch when magnetic

field sensing is not desired (and in the

absence of a magnetic field). The allowable

states for the switch are ‘open’ or ‘closed’

(shorted to sensor ground).

APPLICATIONS NOTES

Magnetic Actuation

The left side of Figure 2 shows the wiring of an A3054KU or

A3054SU when used as a magnetic threshold detector. Pin 1 of the

sensor is wired to the positive terminal of the bus, pin 2 is connected to

the bus negative terminal, and

pin 3 has no connection.

Mechanical Actuation

The right side of Figure 2 shows the wiring of an A3054KU or

A3054SU when used to detect the status of a mechanical switch.

In this case, pin 3 is connected to the switch. The other side of the

switch is connected to the bus return (negative bus supply or ground).

When the mechanical switch is closed, and the correct bus address is

detected by the IC, the sensor responds with a signal current. If the

switch is open, only the diagnostic current is returned.

Bus Configuration

A maximum of 30 individually addresable sensors may be connected across the same two-wire bus as shown in Figure 3. It is

recommended that the sensors use a dedicated digital ground wire to

minimize the effects of changing ground potential (as in the case of

chassis ground in the automotive industry).

The bus was not designed to require two-wire twisted pair wiring to

the sensors. However, in areas of extreme electromagnetic interference, it may be advisable to install a small bypass capacitor (0.01 µF

for example) between the supply and ground terminals of each sensor

instead of using the more expensive wiring.

FIGURE 3

BUS INTERCONNECTION

Page 7

3054

MULTIPLEXED

TWO-WIRE

HALL-EFFECT SENSOR ICs

Bus Driver

It is recommended that the bus be controlled

by microprocessor-based hardware for the

following reasons:

• Sensor address information may be stored

in ROM in the form of a look-up table.

• Bus faults can be pinpointed by the

microprocessor by comparing the diagnostic response to the expected response in

the ROM look-up table.

• The microprocessor, along with an A/D

converter, can also be used to self calibrate the quiescent currents in the bus and

hence be able to easily detect a signal

response.

• The microprocessor can also be used to filter out random line noise

by digitally filtering the bus responses.

• The microprocessor can easily keep track of the signal responses

and initiate the appropriate action (e.g., light a lamp or sound an

alarm, and also pinpoint the location of the signal).

Optimally, the microprocessor is used to control bus-driving

circuitry that will accept TTL-level inputs to drive the bus and will return

an analog voltage representation of the bus current.

Interface Schematic

The bus driver is easily designed using a few operational amplifiers, resistors, and transistors. Figure 4 shows a schematic of a

recommended bus driver circuit that is capable of providing 6 V to 9 V

transitions, resetting the bus, and providing an analog measurement of

the bus current for the A/D input of the microprocessor.

FIGURE 4

BUS INTERFACE SCHEMATIC

50 kΩ

Dwg. EH-003A

1 32

1 32

+15 V

1 kΩ

10 kΩ

9 V

20 kΩ

5 kΩ

5 kΩ

ADDRESS

RESET

1 kΩ

50 Ω

50 kΩ

100 kΩ

100 kΩ

NC

SWITCH

BUS SUPPLY

BUS RETURN

X

X

ANALOG OUT

0.001

µF

R

5

R

8

R

9

R

10

R

7

R

6

Q

1

Q

2

Z

1

R

4

OP

1

OP

2

Q

3

Page 8

3054

MULTIPLEXED

TWO-WIRE

HALL-EFFECT SENSOR ICs

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

In Figure 4, the ADDRESS input provides a TTL-compatible input

to control the bus supply. A HIGH (5 V) input switches Q1 ON and sets

the bus voltage to 6 V through the resistor divider R4, R5, and Zener

Z1. A LOW input switches Q1 OFF and sets the bus voltage to 9 V

(Z1). This voltage is fed into the positive input of the operational

amplifier OP1 and is buffered and made available at BUS SUPPLY (or

sensor supply). Bus reset control is also available in the form of a TTLcompatible input. When the RESET input is HIGH, Q2 is switched ON

and the positive input of the operational amplifier is set to the saturation voltage of the transistor (approximately 0 V). This resets the bus.

A linear reading of the bus current is made possible by amplifying

the voltage generated across R6 (which is I

BUS

• R6). The amplifier,

OP2, is a standard differential amplifier of gain R9/R7 (provided that R

7

= R8, R9 = R10). The gain of the total transim-pedance amplifier is

given by:

V

OUT

= I

BUS

• R6 • R9/R

7

This voltage is available at the ANALOG OUT terminal.

Bus Control Software

The processing of the bus current (available at ANALOG OUT) is

best done by feeding it into the A/D input of a microprocessor. If the

flexibility provided by a microprocessor is not desired, this signal could

be fed into threshold detection circuitry; e.g., comparator, and the

output used to drive a display.

Related References

1. G. AVERY, “Two-Terminal Hall Sensor,”

ASSIGNEE: Sprague

Electric Company, North Adams, MA, United States. Patent number

4,374,333; Feb. 1983.

2. T. WROBLEWSKI and F. MEISTERFIELD, “Switch Status

Monitoring System, Single-Wire Bus, Smart Sensor Arrangement

There Of,”

ASSIGNEE: Chrysler Motor Corporation, Highland Park, Ml,

United States. Patent number 4,677,308; June 1987.

Page 9

3054

MULTIPLEXED

TWO-WIRE

HALL-EFFECT SENSOR ICs

Dimensions in Inches

(controlling dimensions)

Dimensions in Millimeters

(for reference only)

NOTES: 1. Tolerances on package height and width represent allowable mold offsets.

Dimensions given are measured at the widest point (parting line).

2. Exact body and lead configuration at vendor’s option within limits shown.

3. Height does not include mold gate flash.

4. Recommended minimum PWB hole diameter to clear transition area is

0.035” (0.89 mm).

5. Where no tolerance is specified, dimension is nominal.

6. Minimum lead length was 0.500” (12.70 mm). If existing product to the

original specifications is not acceptable, contact sales office before

ordering.

Dwg. MH-003D mm

1.60

1.50

0.46

0.38

0.41

1.27

1 2 3

2.54

45°

SEE NOTE

4.65

4.52

4.60

4.47

15.24

14.23

2.18

MAX

Dwg. MH-003D in

0.063

0.059

0.018

0.015

0.016

0.050

1 2 3

0.100

45°

SEE NOTE

0.183

0.178

0.181

0.176

0.600

0.560

0.086

MAX

Page 10

3054

MULTIPLEXED

TWO-WIRE

HALL-EFFECT SENSOR ICs

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

This page intentionally left blank

Page 11

3054

MULTIPLEXED

TWO-WIRE

HALL-EFFECT SENSOR ICs

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such departures from

the detail specifications as may be required to permit improvements in the design of its products.

The information included herein is believed to be accurate and reliable. However, Allegro

MicroSystems, Inc. assumes no responsibility for its use; nor for any infringements of patents or

other rights of third parties which may result from its use.

Page 12

3054

MULTIPLEXED

TWO-WIRE

HALL-EFFECT SENSOR ICs

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

HALL-EFFECT SENSORS SELECTION GUIDE

Partial Part Avail. Oper. ␣ Operate Limits Over Temp.␣

Number Temp. B

OP

max B

RP

min B

hys

min Function† Notes

3046 E/L +200 -200 15 Gear-Tooth Sensor

3054 K/S +300 +5 5.0 Unipolar Multiplex 1

3056 E/L +225 -225 15 Gear-Tooth Sensor

3058 E/L +300 -300 150 Gear-Tooth Sensor

3059 K/S +100 -100 20 AC Gear-Tooth Sensor

3060 K/S +35 -35 10 AC Gear-Tooth Sensor

3121 E/L +500 +80 60 Unipolar Switch

3122 E/L +430 +120 70 Unipolar Switch

3123 E/L +470 +160 70 Unipolar Switch

3132 K/L/S +95 -95 30 Bipolar Switch

3133 K/L/S +75 -75 30 Bipolar Switch

3134 E/L +50 -40 10 Bipolar Switch

3141 E/L +175 +10 20 Unipolar Switch

3142 E/L +245 +60 30 Unipolar Switch

3143 E/L +355 +150 30 Unipolar Switch

3144 E/L +450 +25 20 Unipolar Switch

3161 E +160 +30 5.0 2-Wire Unipolar Switch

3175 S +180 -180 80 Bipolar Latch

3177 S +150 -150 50 Bipolar Latch

3185 E/L +300 -300 280 Bipolar Latch

3187 E/L +175 -175 100 Bipolar Latch

3188 E/L +200 -200 160 Bipolar Latch

3189 E/L +250 -250 100 Bipolar Latch

3195 E/L +200 -200 110 Bipolar Latch 2, 3

3197 L +200 -200 110 Bipolar Latch 3

3235 S +200 +15 15 Unipolar Switch 4

-200 -15 15 Unipolar Switch

3275 S +250 -250 100 Bipolar Latch 5

3421 E/L +300 -300 240 Direction Detection

3422 E/L +85 -85 10 Direction Detection

3503 S Typ. 1.3 mV/G – Linear Sensor

3515 E/L Typ. 5.0 mV/G – Chopper-Stabilized Linear Sensor

3516 E/L Typ. 2.5 mV/G – Chopper-Stabilized Linear Sensor

3517 L/S Typ. 5.0 mV/G – Chopper-Stabilized Linear Sensor

3518 L/S Typ. 2.5 mV/G – Chopper-Stabilized Linear Sensor

3625 S +150 -150 200* 900 mA Bipolar Latch 3, 5, 6

3626 S +150 -150 200* 400 mA Bipolar Latch 3, 5, 6

5140 E +240 +25 20 300 mA Unipolar Switch 3, 6

Operating Temperature Ranges:

C = 0°C to +70°C, S = -20°C to +85°C, E = -40°C to +85°C, K = -40°C to +125°C, L = -40°C to +150°C

Notes 1. Multiplexed two-wire sensor; after proper address, power/signal bus current indicates magnetic field condition.

2. Active pull down.

3. Protected.

4. Output 1 switches on south pole, output 2 switches on north pole for 2-phase, bifilar-wound, unipolar-driven brushless dc motor control.

5. Complementary outputs for 2-phase bifilar-wound, unipolar-driven brushless dc motor control.

6. Power driver output.

* Typical.

† Latches will not switch on removal of magnetic field; bipolar switches may switch on removal of field but require field reversal for reliable operation

over operating temperature range.

Loading...

Loading...