Datasheet 74HCT40105U, 74HCT40105DB, 74HCT40105D, 74HC40105U, 74HC40105PW Datasheet (Philips)

...Page 1

DATA SH EET

Product specification

Supersedes data of December 1990

File under Integrated Circuits, IC06

1998 Jan 23

INTEGRATED CIRCUITS

74HC/HCT40105

4-bit x 16-word FIFO register

For a complete data sheet, please also download:

•The IC06 74HC/HCT/HCU/HCMOS Logic Family Specifications

Page 2

1998 Jan 23 2

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

FEATURES

• Independent asynchronous inputs and outputs

• Expandable in either direction

• Reset capability

• Status indicators on inputs and outputs

• 3-state outputs

• Output capability: standard

• ICCcategory: MSI

GENERAL DESCRIPTION

The 74HC/HCT40105 are high-speed Si-gate CMOS

devices and are pin compatible with the “40105” of the

“4000B” series. They are specified in compliance with

JEDEC standard no. 7A.

The 74HC/HCT40105 are first-in/first-out (FIFO) “elastic”

storage registers that can store sixteen 4-bit words. The

“40105” is capable of handling input and output data at

different shifting rates. This feature makes it particularly

useful as a buffer between asynchronous systems. Each

word position in the register is clocked by a control flip-flop,

which stores a marker bit. A “1” signifies that the position’s

data is filled and a “0” denotes a vacancy in that position.

The control flip-flop detects the state of the preceding

flip-flop and communicates its own status to the

succeeding flip-flop. When a control flip-flop is in the “0”

state and sees a “1” in the preceding flip-flop, it generates

a clock pulse that transfers data from the preceding four

data latches into its own four data latches and resets the

preceding flip-flop to “0”. The first and last control flip-flops

have buffered outputs. Since all empty locations “bubble”

automatically to the input end, and all valid data ripples

through to the output end, the status of the first control

flip-flop (data-in ready output - DIR) indicates if the FIFO is

full, and the status of the last flip-flop (data-out ready

output - DOR) indicates if the FIFO contains data. As the

earliest data is removed from the bottom of the data stack

(output end), all data entered later will automatically ripple

toward the output.

QUICK REFERENCE DATA

GND = 0 V; T

amb

= 25 °C; tr= tf= 6 ns

Notes

1. C

PD

is used to determine the dynamic power dissipation (PDin µW):

PD= CPD× V

CC

2

× fi+∑(CL× V

CC

2

× fo) where:

fi= input frequency in MHz.

fo= output frequency in MHz.

∑ (CL× V

CC

2

× fo) = sum of outputs

CL= output load capacitance in pF

VCC= supply voltage in V

2. For HC the condition is VI= GND to V

CC

For HCT the condition is VI= GND to VCC− 1.5

SYMBOL PARAMETER CONDITIONS

TYP.

UNIT

HC HCT

t

PHL

/ t

PLH

propagation delay CL= 15 pF; VCC=5 V

MR to DIR, DOR 16 15 ns

SO to Q

n

37 35 ns

t

PHL

propagation delay

SI to DIR 16 18 ns

SO to DOR 17 18 ns

f

max

maximum clock frequency 33 31 MHz

C

I

input capacitance 3.5 3.5 pF

C

PD

power dissipation capacitance per package notes 1 and 2 134 145 pF

Page 3

1998 Jan 23 3

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

ORDERING INFORMATION

PIN DESCRIPTION

TYPE NUMBER

PACKAGE

NAME DESCRIPTION VERSION

74HC(T)40105N DIP16 plastic dual in-line package; 16 leads (300 mil); long body SOT38-1

74HC(T)40105D SO16 plastic small outline package; 16 leads; body width 3.9 mm SOT109-1

74HC(T)40105DB SSOP16 plastic shrink small outline package; 16 leads; body width 5.3 mm SOT338-1

74HC(T)40105PW TSSOP16 plastic thin shrink small outline package; 16 leads; body width 4.4 mm SOT403-1

PIN NO. SYMBOL NAME AND FUNCTION

1

OE output enable input (active LOW)

2 DIR data-in ready output

3 SI shift-in input (LOW-to-HIGH, edge-triggered)

4, 5, 6, 7 D

0

to D

3

parallel data inputs

8 GND ground (0 V)

9 MR asynchronous master reset input (active HIGH)

13, 12, 11, 10 Q

0

to Q

3

3-state data outputs

14 DOR data-out ready output

15

SO shift-out input (HIGH-to-LOW, edge-triggered)

16 V

CC

positive supply voltage

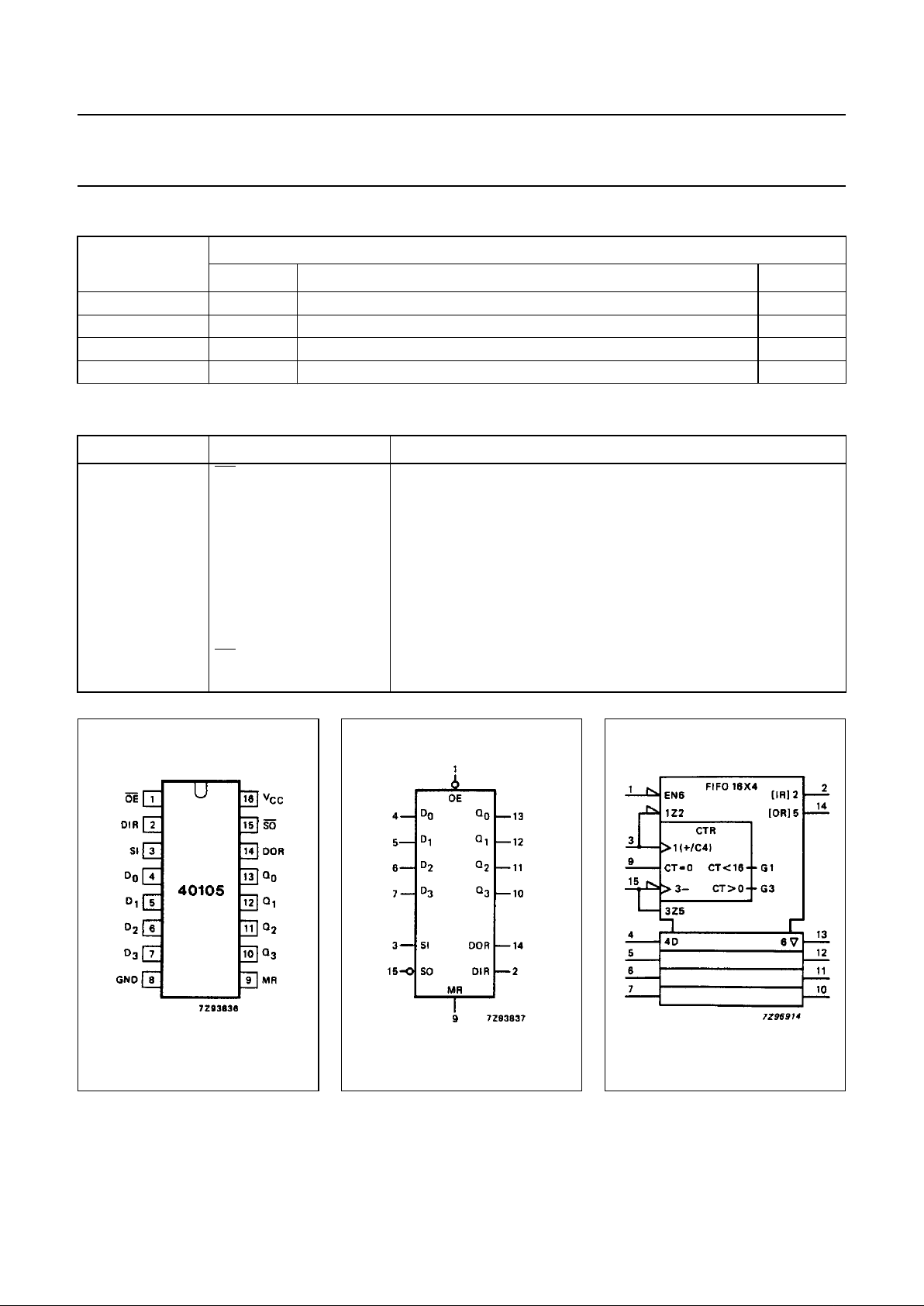

Fig.1 Pin configuration. Fig.2 Logic symbol. Fig.3 IEC logic symbol.

Page 4

1998 Jan 23 4

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

INPUT AND OUTPUTS

Data inputs (D

0

to D3)

As there is no weighting of the inputs,

any input can be assigned as the

MSB. The size of the FIFO memory

can be reduced from the 4 × 16

configuration, i.e. 3 × 16, down to

1 × 16, by tying unused data input

pins to V

CC

or GND.

Data outputs (Q

0

to Q3)

As there is no weighting of the

outputs, any output can be assigned

as the MSB. The size of the FIFO

memory can be reduced from the

4 × 16 configuration as described for

data inputs. In a reduced format, the

unused data outputs pins must be left

open circuit.

Master-reset (MR)

When MR is HIGH, the control

functions within the FIFO are cleared,

and date content is declared invalid.

The data-in ready (DIR) flag is set

HIGH and the data-out-ready (DOR)

flag is set LOW. The output stage

remains in the state of the last word

that was shifted out, or in the random

state existing at power-up.

Status flag outputs (DIR, DOR)

Indication of the status of the FIFO is

given by two status flags,

data-in-ready (DIR) and

data-out-ready (DOR):

DIR = HIGH indicates the input stage

is empty and ready to accept valid

data;

DIR = LOW indicates that the FIFO is

full or that a previous shift-in

operation is not complete (busy);

DOR = HIGH assures valid data is

present at the outputs Q

0

to Q3(does

not indicate that new data is awaiting

transfer into the output stage);

DOR = LOW indicates the output

stage is busy or there is no valid data.

Shift-in control (SI)

Data is loaded into the input stage on

a LOW-to-HIGH transition of SI.

It also triggers an automatic data

transfer process (ripple through). If SI

is held HIGH during reset, data will be

loaded at the falling edge of the MR

signal.

Shift-out control (

SO)

A HIGH-to-LOW transition of

SO causes the DOR flags to go LOW.

A HIGH-to-LOW transition of

SO causes upstream data to move

into the output stage, and empty

locations to move towards the input

stage (bubble-up).

Output enable (

OE)

The outputs Q0to Q3are enabled

when OE = LOW. When OE = HIGH

the outputs are in the high impedance

OFF-state.

FUNCTIONAL DESCRIPTION

Data input

Following power-up, the master-reset

(MR) input is pulsed HIGH to clear the

FIFO memory (see Fig.8). The

data-in-ready flag (DIR = HIGH)

indicates that the FIFO input stage is

empty and ready to receive data.

When DIR is valid (HIGH), data

present at D

0

to D3can be shifted-in

using the SI control input.

With SI = HIGH, data is shifted into

the input stage and a busy indication

is given by DIR going LOW.

The data remains at the first location

in the FIFO until DIR is set to HIGH

and data moves through the FIFO to

the output stage, or to the last empty

location. If the FIFO is not full after the

SI pulse, DIR again becomes valid

(HIGH) to indicate that space is

available in the FIFO. The DIR flag

remains LOW if the FIFO is full (see

Fig.6). The SI use must be made

LOW in order to complete the shift-in

process.

With the FIFO full, SI can be held

HIGH until a shift-out (

SO) pulse

occurs. Then, following a shift-out of

data, an empty location appears at

the FIFO input and DIR goes HIGH to

allow the next data to be shifted-in.

This remains at the first FIFO location

until SI goes LOW (see Fig.7).

Data transfer

After data has been transferred from

the input stage of the FIFO following

SI = LOW, data moves through the

FIFO asynchronously and is stacked

at the output end of the register.

Empty locations appear at the input

end of the FIFO as data moves

through the device.

Data output

The data-out-ready flag

(DOR = HIGH) indicates that there is

valid data at the output (Q

0

to Q3).

The initial master-reset at power-on

(MR = HIGH) sets DOR to LOW (see

Fig.8). After MR = LOW, data shifted

into the FIFO moves through to the

output stage causing DOR to go

HIGH.

As the DOR flag goes HIGH, data can

be shifted-out using the SO = HIGH,

data in the output stage is shifted out

and a busy indication is given by DOR

going LOW. When SO is made LOW,

data moves through the FIFO to fill

the output stage and an empty

location appears at the input stage.

When the output stage is filled DOR

goes HIGH, but if the last of the valid

data has been shifted-out leaving the

FIFO empty the DOR flag remains

LOW (see Fig.9). With the FIFO

empty, the last word that was

shifted-out is latched at the output

Q0to Q3.

With the FIFO empty, the SO input

can be held HIGH until the SI control

input is used. Following an SI pulse,

Page 5

1998 Jan 23 5

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

data moves through the FIFO to the

output stage, resulting in the DOR

flag pulsing HIGH and a shift-out of

data occurring. The SO control must

be made LOW before additional data

can be shifted-out (see Fig.10).

High-speed burst mode

If it is assumed that the

shift-in/shift-out pulses are not

applied until the respective status

flags are valid, it follows that the

shift-in/shift-out rates are determined

by the status flags. However, without

the status flags a high-speed burst

mode can be implemented. In this

mode, the burst-in/ burst-out rates are

determined by the pulse widths of the

shift-in/shift-out inputs and burst rates

of 35 MHz can be obtained. Shift

pulses can be applied without regard

to the status flags but shift-in pulses

that would overflow the storage

capacity of the FIFO are not allowed

(see Figs 11 and 12).

Expanded format

With the addition of a logic gate, the

FIFO is easily expanded to increase

word length (see Fig.17). The basic

operation and timing are identical to a

single FIFO, with the exception of an

additional gate delay on the flag

outputs. If during application, the

following occurs:

• SI is held HIGH when the FIFO is

empty, some additional logic is

required to produce a composite

DIR pulse (see Figs 7 and 18).

Due to the part-to-part spread of the

ripple through time, the SI signals of

FIFOAand FIFOBwill not always

coincide and the AND-gate will not

produce a composite flag signal. The

solution is given in Fig.18.

The “40105” is easily cascaded to

increase the word capacity and no

external components are needed. In

the cascaded configuration, all

necessary communications and

timing are performed by the FIFOs.

The intercommunication speed is

determined by the minimum flag

pulse widths and the flag delays. The

data rate of cascaded devices is

typically 25 MHz. Word-capacity can

be expanded to and beyond 32-words

× 4-bits (see Fig.19).

Page 6

1998 Jan 23 6

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

Fig.4 Functional diagram.

Fig.5 Logic diagram.

(see control flip-flops)

(1) LOW on S input of FF1, and FF5 will set Q output to HIGH independent of state on R input.

(2) LOW on R input of FF2, FF3 and FF4 will set Q output to LOW independent of state on S input.

Page 7

1998 Jan 23 7

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

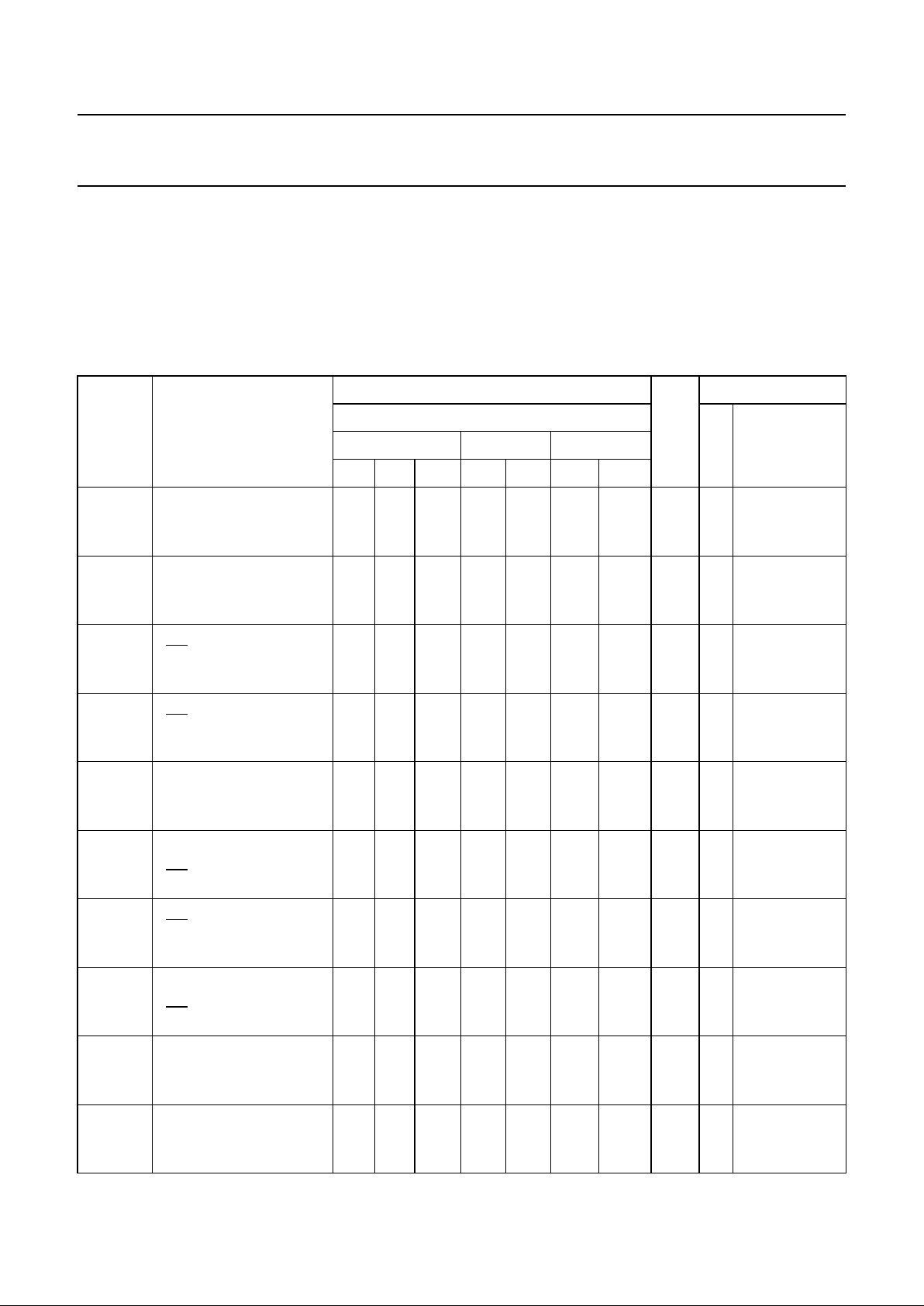

DC CHARACTERISTICS FOR 74HC

For the DC characteristics see

“74HC/HCT/HCU/HCMOS Logic Family Specifications”

.

Output capability: standard

ICCcategory: MSI

AC CHARACTERISTICS FOR 74HC

GND = 0 V; t

f

= tf= 6 ns; CL= 50 pF

SYMBOL PARAMETER

T

amb

(°C)

UNIT

TEST CONDITIONS

74HC

V

CC

(V)

WAVEFORMS

+25 −40 to +85 −40 to +125

min. typ. max. min. max. min. max.

t

PHL

/ t

PLH

propagation delay

MR to DIR, DOR

52 175 220 265 ns 2.0 Fig.8

19 35 44 53 4.5

15 30 37 45 6.0

t

PHL

propagation delay

SI to DIR

52 210 265 315 ns 2.0 Fig.6

19 42 53 63 4.5

15 36 45 54 6.0

t

PHL

propagation delay

SO to DOR

55 210 265 315 ns 2.0 Fig.9

20 42 53 63 4.5

16 36 45 54 6.0

t

PHL

/ t

PLH

propagation delay

SO to Q

n

116 400 500 600 ns 2.0 Fig.14

42 80 100 120 4.5

34 68 85 102 6.0

t

PLH

propagation delay/

ripple through delay

SI to DOR

564 2000 2500 3000 ns 2.0 Fig.10

205 400 500 600 4.5

165 340 425 510 6.0

t

PLH

propagation delay/

bubble-up delay

SO to DIR

701 2500 3125 3750 ns 2.0 Fig.7

255 500 625 750 4.5

204 425 532 638 6.0

t

PZH

/ t

PZL

3-state output enable time

OE to Q

n

41 150 190 225 ns 2.0 Fig.16

15 30 38 45 4.5

12 26 33 38 6.0

t

PHZ

/ t

PLZ

3-state output disable

time

OE to Q

n

41 140 175 210 ns 2.0 Fig.16

15 28 35 42 4.5

12 24 30 36 6.0

t

THL

/ t

TLH

output transition time 19 75 95 110 ns 2.0 Fig.14

7 15 19 22 4.5

6 13 16 19 6.0

t

W

SI pulse width

HIGH or LOW

80 19 100 120 ns 2.0 Fig.6

16 7 20 24 4.5

14 6 17 20 6.0

Page 8

1998 Jan 23 8

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

t

W

SO pulse width

HIGH or LOW

120 39 150 180 ns 2.0 Fig.9

24 14 30 36 4.5

20 11 26 31 6.0

t

W

DIR pulse width

HIGH

12 58 180 10 225 10 270 ns 2.0 Fig.7

6 21 36 5 45 5 54 4.5

5 17 31 4 38 4 46 6.0

t

W

DOR pulse width

LOW

12 55 170 10 215 10 255 ns 2.0 Fig.9

6 20 34 5 43 5 51 4.5

5 16 29 4 37 4 43 6.0

t

W

MR pulse width

HIGH

80 22 100 120 ns 2.0 Fig.8

16 8 20 24 4.5

14 6 17 20 6.0

t

rem

removal time

MR to SI

50 14 65 75 ns 2.0 Fig.15

10 5 13 15 4.5

9 4 11 13 6.0

t

su

set-up time

Dn to SI

−5 −39 −5 −5 ns 2.0 Fig.13

−5 −14 −5 −5 4.5

−5 −11 −5 −5 6.0

t

h

hold time

Dnto SI

125 44 155 190 ns 2.0 Fig.13

25 16 31 38 4.5

21 13 26 32 6.0

f

max

maximum pulse

frequency

SI, SO using flags or

burst mode

3.6 10 2.8 2.4 MHz 2.0 Fig.6, 9, 11

and 12

18 30 14 12 4.5

21 36 16 14 6.0

f

max

maximum pulse

frequency

SI, SO cascaded

3.6 10 2.8 2.4 MHz 2.0 Figs 6 and 9

18 30 14 12 4.5

21 36 16 14 6.0

SYMBOL PARAMETER

T

amb

(°C)

UNIT

TEST CONDITIONS

74HC

V

CC

(V)

WAVEFORMS

+25 −40 to +85 −40 to +125

min. typ. max. min. max. min. max.

Page 9

1998 Jan 23 9

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

DC CHARACTERISTICS FOR 74HCT

For the DC characteristics see

“74HC/HCT/HCU/HCMOS Logic Family Specifications”

.

Output capability: standard

ICCcategory: MSI

Note to HCT types

The value of additional quiescent supply current (∆I

CC

) for a unit load of 1 is given in the family specifications.

To determine ∆I

CC

per input, multiply this value by the unit load coefficient shown in the table below.

AC CHARACTERISTICS FOR 74HCT

GND = 0 V; t

f

= tf= 6 ns; CL= 50 pF

INPUT UNIT LOAD COEFFICIENT

OE 0.75

SI 0.40

D

n

0.30

MR 1.50

SO 0.40

SYMBOL PARAMETER

T

amb

(°C)

UNIT

TEST CONDITIONS

74HCT

V

CC

(V)

WAVEFORMS

+25 −40 to +85 −40 to +125

min. typ. max. min. max. min. max.

t

PHL

/ t

PLH

propagation delay

MR to DIR, DOR

18 35 44 53 ns 4.5 Fig.8

t

PHL

propagation delay

SI to DIR

21 42 53 63 ns 4.5 Fig.6

t

PHL

propagation delay

SO to DOR

20 42 53 63 ns 4.5 Fig.9

t

PHL

/ t

PLH

propagation delay

SO to Q

n

40 80 100 120 ns 4.5 Fig.14

t

PLH

propagation delay/

ripple through delay

SI to DOR

188 400 500 600 ns 4.5 Fig.10

t

PLH

propagation delay/

bubble-up delay

SO to DIR

244 500 625 750 ns 4.5 Fig.7

t

PZH

/ t

PZL

3-state output enable time

OE to Q

n

18 35 44 53 ns 4.5 Fig.16

t

PHZ

/ t

PLZ

3-state output disable

time

OE to Q

n

15 30 38 45 ns 4.5 Fig.16

t

THL

/ t

TLH

output transition time 7 15 19 22 ns 4.5 Fig.14

Page 10

1998 Jan 23 10

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

t

W

SI pulse width

HIGH or LOW

16 6 20 24 ns 4.5 Fig.6

t

W

SO pulse width

HIGH or LOW

16 7 20 24 ns 4.5 Fig.9

t

W

DIR pulse width

HIGH or LOW

6 20 34 5 43 5 51 ns 4.5 Fig.7

t

W

DOR pulse width

HIGH or LOW

6 19 34 5 43 5 51 ns 4.5 Fig.9

t

W

MR pulse width

HIGH

16 7 20 24 ns 4.5 Fig.8

t

rem

removal time

MR to SI

15 7 19 22 ns 4.5 Fig.15

t

su

set-up time

Dn to SI

−5 −14 −4 −4 ns 4.5 Fig.13

t

h

hold time

Dnto SI

27 16 34 41 ns 4.5 Fig.13

f

max

maximum pulse frequency

SI, SO using flags or

burst mode

28 12 10 MHz 4.5 Fig.6, 9, 11 and

12

f

max

maximum pulse frequency

SI, SO cascaded

28 12 10 MHz 4.5 Figs 6 and 9

SYMBOL PARAMETER

T

amb

(°C)

UNIT

TEST CONDITIONS

74HCT

V

CC

(V)

WAVEFORMS

+25 −40 to +85 −40 to +125

min. typ. max. min. max. min. max.

Page 11

1998 Jan 23 11

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

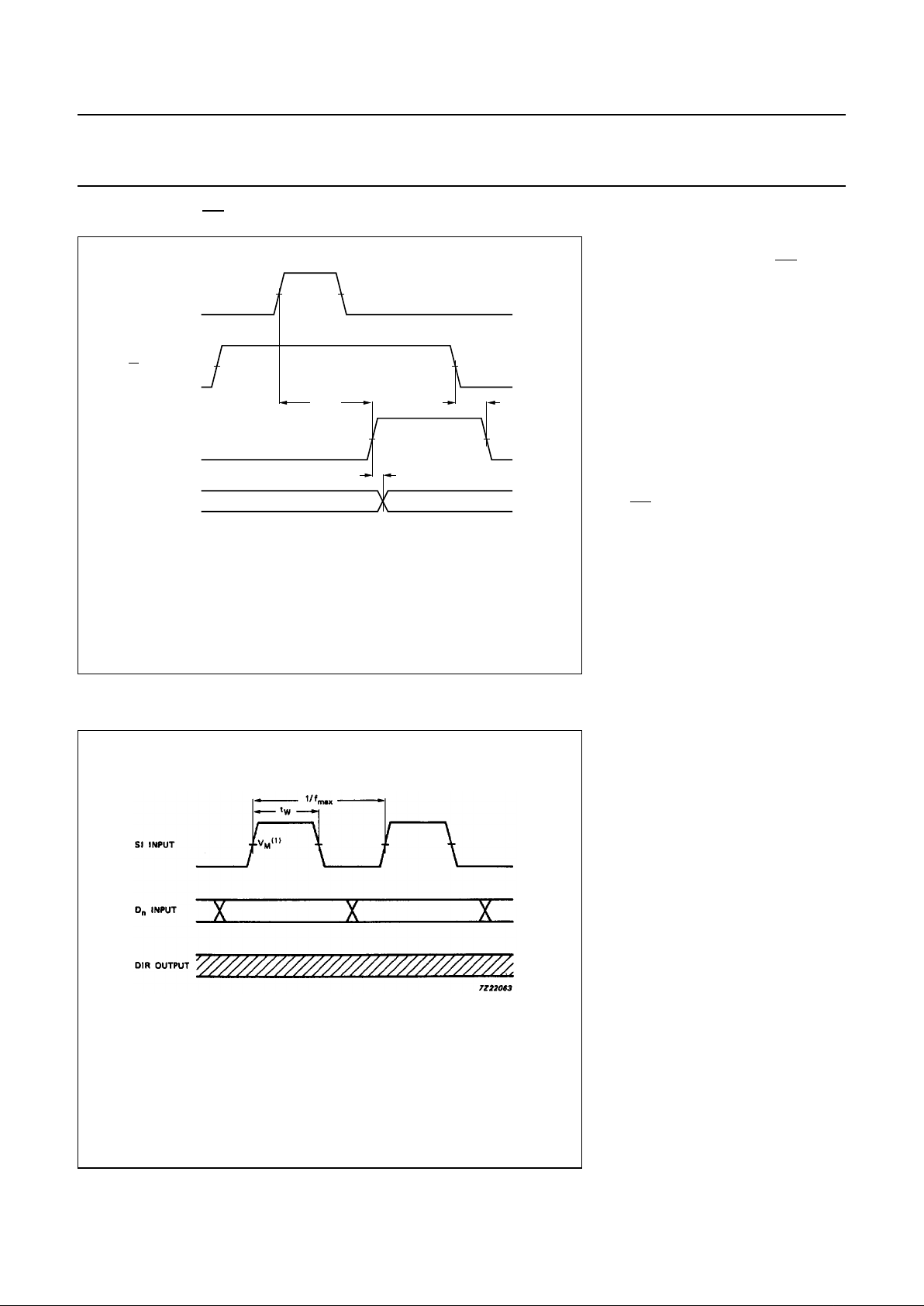

AC WAVEFORMS

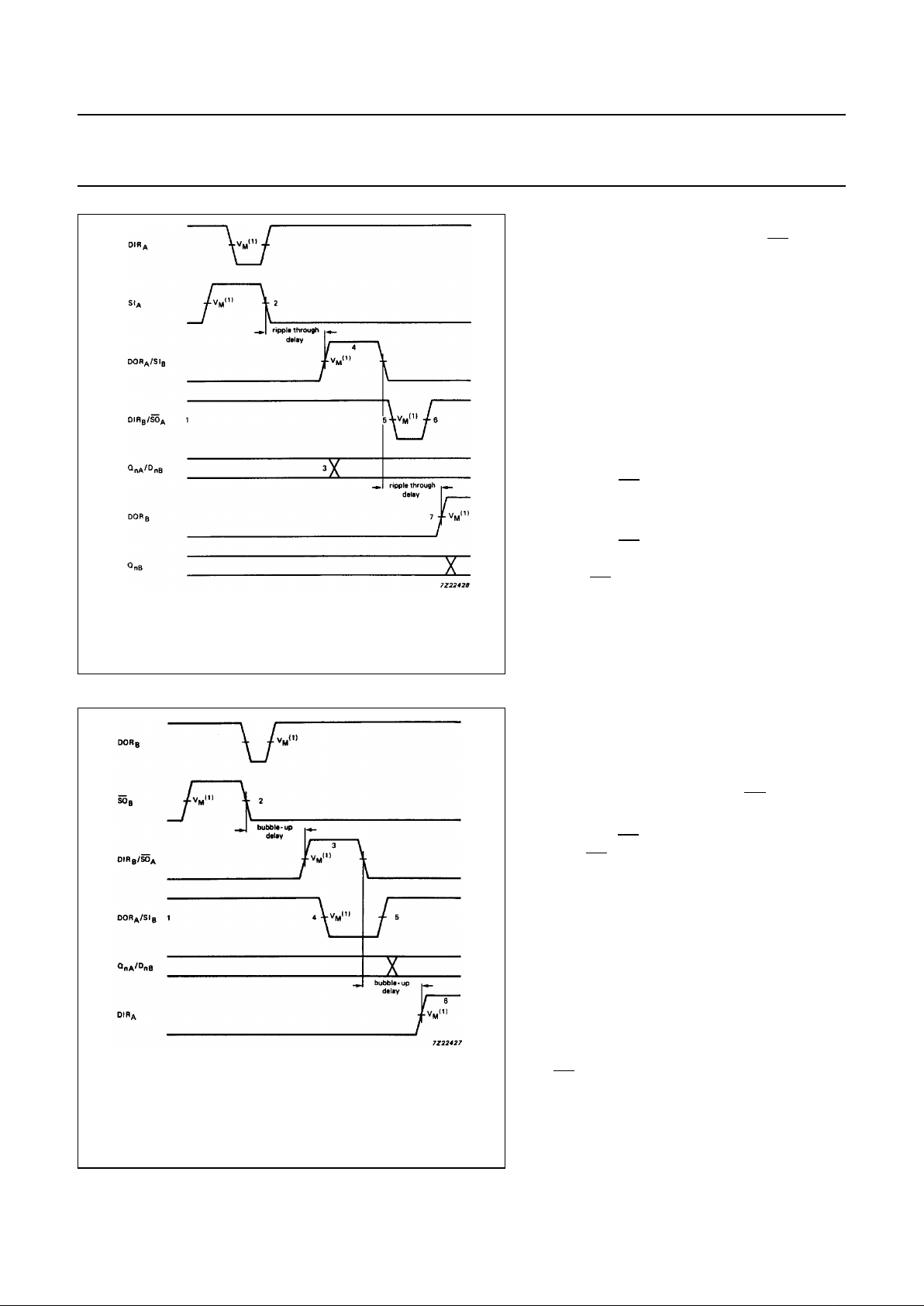

Shifting in sequence FIFO empty to FIFO full

Fig.6 Waveforms showing the SI input to DIR output propagation

delay. The SI pulse width and SI maximum pulse frequency.

(1) HC : VM= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

Notes to Fig.6

1. DIR initially HIGH; FIFO is

prepared for valid data.

2. SI set HIGH; data loaded into

input stage.

3. DIR drops LOW, input stage

“busy”.

4. DIR goes HIGH, status flag

indicates FIFO prepared for

additional data; data from first

location “ripple through”.

5. SI set LOW; necessary to

complete shift-in process.

6. Repeat process to load 2nd word

through to 16th word into FIFO.

7. DIR remains LOW: with attempt

to shift into full FIFO, no data

transfer occurs.

With FIFO full; SI held HIGH in anticipation of empty location

Fig.7 Waveforms showing bubble-up delay, SO input to DIR output

and DIR output pulse width.

(1) HC : VM= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

Notes to Fig.7

1. FIFO is initially, shift-in is held

HIGH.

2. SO pulse; data in the output

stage is unloaded, “bubble-up

process of empty locations

begins”.

3. DIR HIGH; when empty location

reached input stage, flag

indicates FIFO is prepared for

data input.

4. DIR returns to LOW; FIFO is full

again.

5. SI brought LOW; necessary to

complete whidt-in process, DIR

remains LOW, because FIFO is

full.

Page 12

1998 Jan 23 12

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

Master reset applied with FIFO full

Fig.8 Waveforms showing the MR input to DIR, DOR output

propagation delays and the MR pulse width.

(1) HC : VM= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

Notes to Fig.8

1. DIR LOW, output ready HIGH;

assume FIFO is full.

2. MR pulse HIGH; clears FIFO.

3. DIR goes HIGH; flag indicates

input prepared for valid data.

4. DOR drops LOW; flag indicates

FIFO empty.

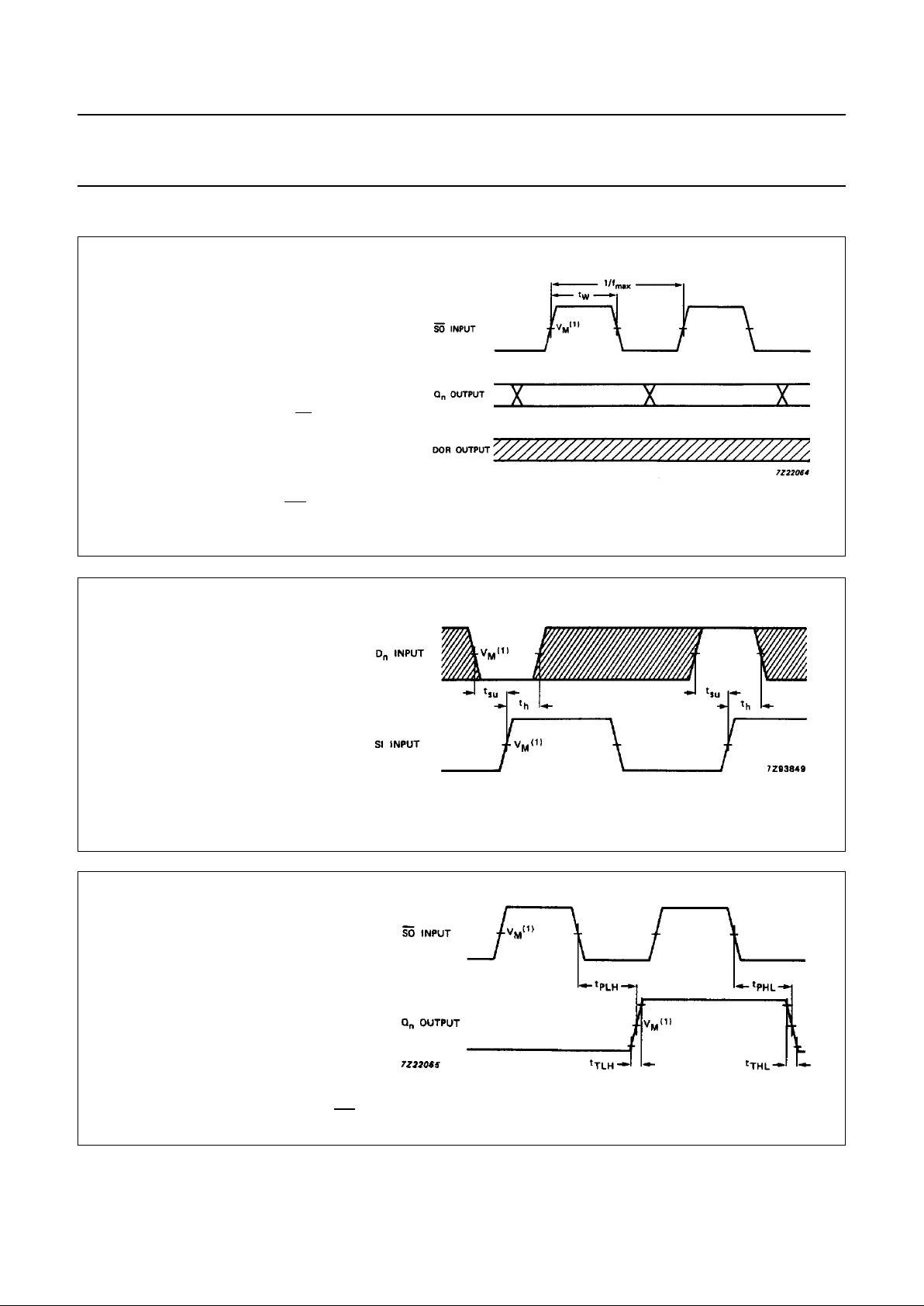

Shifting out sequence; FIFO full to FIFO empty

Fig.9 Waveforms showing the SO input to DIR output propagation

delay. The SO pulse width and SO maximum pulse frequency.

(1) HC : VM= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

Notes to Fig.9

1. DOR HIGH; no data transfer in

progress, valid data is present at

output stage.

2. SO set HIGH.

3. SO is set LOW; data in the input

stage is unloaded, and new data

replaces it as empty location

“bubbles-up” to input stage.

4. DOR drops LOW; output stage

“busy”.

5. DOR goes HIGH; transfer

process completed, valid data

present at output after the

specified propagation delay.

6. Repeat process to unloaded the

3rd through to the 16th word from

FIFO.

7. DOR remains LOW; FIFO is

empty.

Page 13

1998 Jan 23 13

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

With FIFO empty; SO is held HIGH in anticipation

Fig.10 Waveforms showing ripple through delay SI input to DOR output

and propagation delay from the DOR pulse to the Qnoutput.

(1) HC : VM= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

agewidth

MBA337

t

PHL

/ t

PLH

V

M

(1)

SI INPUT

SO INPUT

DOR OUTPUT

Q OUTPUT

n

V

M

(1)

V

M

(1)

2

1

t

PLH

ripple through

delay

4

5

6

t

PHL

3

Notes to Fig.10

1. FIFO is initially empty, SO is held

HIGH.

2. SI pulse; loads data into FIFO

and initiates ripple through

process.

3. DOR flag signals the arrival of

valid data at the output stage.

4. Output transition; data arrives at

output stage after the specified

propagation delay between the

rising edge of the DOR pulse to

the Q

n

output.

5. SO set LOW; necessary to

complete shift-out process. DOR

remains LOW, because FIFO is

empty.

6. DOR goes LOW; FIFO is empty

again.

Shift-in operation; high-speed burst mode

Fig.11 Waveforms showing SI minimum pulse width and SI maximum

pulse frequency, in high-speed shift-in burst mode.

(1) HC : VM= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

Note to Fig.11

In the high-speed mode, the burst-in

rate is determined by the minimum

shift-in HIGH and shift-in LOW

specifications. The DIR status flag is

a don’t care condition, and a shift-in

pulse can be applied regardless of the

flag. A SI pulse which would overflow

the storage capacity of the FIFO is

ignored.

Page 14

1998 Jan 23 14

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

Shift-out operation; high-speed burst mode

Fig.12 Waveforms showing SO minimum pulse width and maximum pulse frequency, in high-speed shift-out

burst mode.

In the high-speed mode, the burst-out rate is determined by the

minimum shift-out HIGH and shift-out LOW specifications. The

DOR flag is a don’t care condition and a

SO pulse can be applied

without regard to the flag.

(1) HC : V

M

= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

Fig.13 Waveforms showing hold and set up times for Dninput to SI input.

The shaded areas indicate when the input is permitted

to change for predictable output performance.

(1) HC : V

M

= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

Fig.14 Waveforms showing SO input to Qnoutput propagation delays and output transition time.

(1) HC : VM= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

Page 15

1998 Jan 23 15

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

Fig.15 Waveforms showing the MR input to SI input removal time.

(1) HC : VM= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

handbook, halfpage

MBA332

V

M

(1)

V

M

(1)

t

rem

MR INPUT

SI INPUT

Fig.16 Waveforms showing the 3-state enable and disable times for input OE.

(1) HC : VM= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

Page 16

1998 Jan 23 16

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

APPLICATION INFORMATION

Fig.17 Expanded FIFO for increased word length; 16 words × 8 bits.

The PC74HC/HCT40105 is easily expanded to

increase word length. Composite DIR and DOR

flags are formed with the addition of an AND

gate. The basic operation and timing are

identical to a single FIFO, with the exception of

an added gate delay on the flags.

Fig.18 Expanded FIFO for increased word length.

This circuit is only required if the SI input is constantly held HIGH, when the FIFO is empty and the automatic shift-in cycles are started (see Fig.7).

Page 17

1998 Jan 23 17

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

Expanded format

Fig.19 shows two cascaded FIFOs providing a capacity of 32 words × 4 bits

Fig.20 shows the signals on the nodes of both FIFOs after the application of a SI pulse, when both FIFOs are initially

empty. After a rippled through delay, date arrives at the output of FIFOA. Due to SOAbeing HIGH, a DOR pulse is

generated. The requirements of SIBand DnBare satisfied by the DORApulse width and the timing between the rising

edge of DORAand QnA. After a second ripple through delay, data arrives at the output of FIFOB.

Fig.21 shows the signals on the nodes of both FIFOs after the application of a SORpulse, when both FIFOs are initially

full. After a bubble-up delay a DIRRpulse is generated, which acts as a SOApulse for FIFOA. One word is transferred

from the output of FIFOAto the input of FIFOB. The requirements of the SOApulse for FIFOAis satisfied by the pulse

width of DORB. After a second bubble-up delay an empty space arrives at DnA, at which time DIRAgoes HIGH.

Fig.22 shows the waveforms at all external nodes of both FIFOs during a complete shift-in and shift-out sequence.

Fig.19 Cascading for increased word capacity; 32 words × 4 bits.

The PC7HC/HCT40105 is easily cascaded to increase word capacity without any external circuitry. In cascaded format, all necessary

communications are handled by the FIFOs. Figs 17 and 19 demonstrate the intercommunication timing between FIFO

A

and FIFOB. Fig.22 gives an

overview of pulse and timing of two cascaded FIFOs, when shifted full and shifted empty again.

Page 18

1998 Jan 23 18

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

Fig.20 FIFO to FIFO communication; input timing under

empty condition.

(1) HC : VM= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

Notes to Fig.20

1. FIFOAand FIFOBinitially empty, SOAheld

HIGH in anticipation of data.

2. Load one word into FIFOA; SI pulse applied,

results in DIR pulse.

3. Data outA/data inBtransition; valid data

arrives at FIFOAoutput stage after a specified

delay of the DOR flag, meeting data input

set-up requirements of FIFOB.

4. DORAand SIBpulse HIGH; (ripple through

delay after SI

A

LOW) data is unloaded from

FIFOA as a result of the data output ready

pulse, data is shifted into FIFOB.

5. DIRBand SOAgo LOW; flag indicates input

stage of FIFOBis busy, shift-out of FIFOAis

complete.

6. DIRBand SOAgo HIGH automatically; the

input stage of FIFOBis again able to receive

data, SO is held HIGH in anticipation of

additional data.

7. DORBgoes HIGH; (ripple through delay after

SIBLOW) valid data is present one

propagation delay later at the FIFOBoutput

stage.

(1) HC : VM= 50%; VI= GND to VCC.

HCT : V

M

= 1.3 V; VI= GND to 3 V.

Fig.21 FIFO to FIFO communication; output timing under

full condition.

Notes to Fig.21

1. FIFOAand FIFOBinitially empty, SIBheld

HIGH in anticipation of shifting in new data as

empty location bubbles-up.

2. Unload one word into FIFOB; SO pulse

applied, results in DOR pulse.

3. DIRB and SOApulse HIGH; (bubble-up delay

after SOBLOW) data is loaded into FIFOBas

a result of the DIR pulse, data is shifted out of

FIFOA.

4. DOR

A

and SIBgo LOW; flag indicates the

output stage of FIFOAis busy, shift-in to

FIFORis complete.

5. DORAand SIBgo HIGH; flag indicates valid

data is again available at FIFOAoutput stage,

SIBis held HIGH, awaiting bubble-up of

empty location.

6. DIRAgoes HIGH; (bubble-up delay after

SOALOW) an empty location is present at

input stage of FIFOA.

Page 19

1998 Jan 23 19

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

Fig.22 Waveforms

showing the

functionally and

intercommunication

between two

FIFOs

(refer to Fig.19).

Note to Fig.22

Sequence 1 (Both FIFOs empty, starting shift-in process):

After a MR pulse has been applied FIFOAand FIFOBare

empty. The DOR flags of FIFOAand FIFOBgo LOW due

to no valid data being present at the outputs. The DIR flags

are set HIGH due to the FIFOs being ready to accept data.

SOBis held HIGH and two SIApulses are applied (1).

These pulses allow two data words to ripple through to the

output stage of FIFOAand to the input stage of FIFOB(2).

When data arrives at the output of FIFOB, a DORBpulse is

generated (3). When

SOBgoes LOW, the first bit is shifted

out and a second bit ripples through to the output after

which DORBgoes HIGH (4).

Sequence 2 (FIFOBruns full):

After the MR pulse, a series of 16 SI pulses are applied.

When 16 words are shifted in, DIRBremains LOW due to

FIFOBbeing full (5). DORAgoes LOW due to FIFOAbeing

empty.

Sequence 3 (FIFOAruns full):

When 17 words are shifted in, DORAremains HIGH due to

valid data remaining at the output of FIFOA.QnAremains

HIGH, being the polarity of the 17th data word (6). After the

32th SI pulse, DIR remains LOW and both FIFOs are full

(7). Additional pulses have no effect.

Sequence 4 (Both FIFOs full, starting shift-out process):

SI

A

is held HIGH and two SOBpulses are applied (8).

These pulses shift out two words and thus allow empty

locations to bubble-up to the input stage of FIFOB, and

proceed to FIFOA(9). When the first empty location arrives

at the input of FIFOA, a DIRApulse is generated (10) and

a new word is shifted into FIFOA.SIAis made LOW and

now the second empty location reaches the input stage of

FIFOA, after which DIRAremains HIGH (11).

Sequence 5 (FIFOAruns empty):

At the start of sequence 5 FIFOAcontains 15 valid words

due to two words being shifted out and one word being

shifted in sequence 4. An additional series of SOBpulses

are applied. After 15SOBpulses, all words from FIFOAare

shifted into FIFOB. DORAremains LOW (12).

Sequence 6 (FIFOBruns empty):

After the next SOBpulse, DIRBremains HIGH due to the

input stage of FIFOBbeing empty (13). After another 15

SOBpulses, DORBremains LOW due to both FIFOs being

empty (14). Additional SOBpulses have no effect. The last

word remains available at the output Qn.

Page 20

1998 Jan 23 20

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

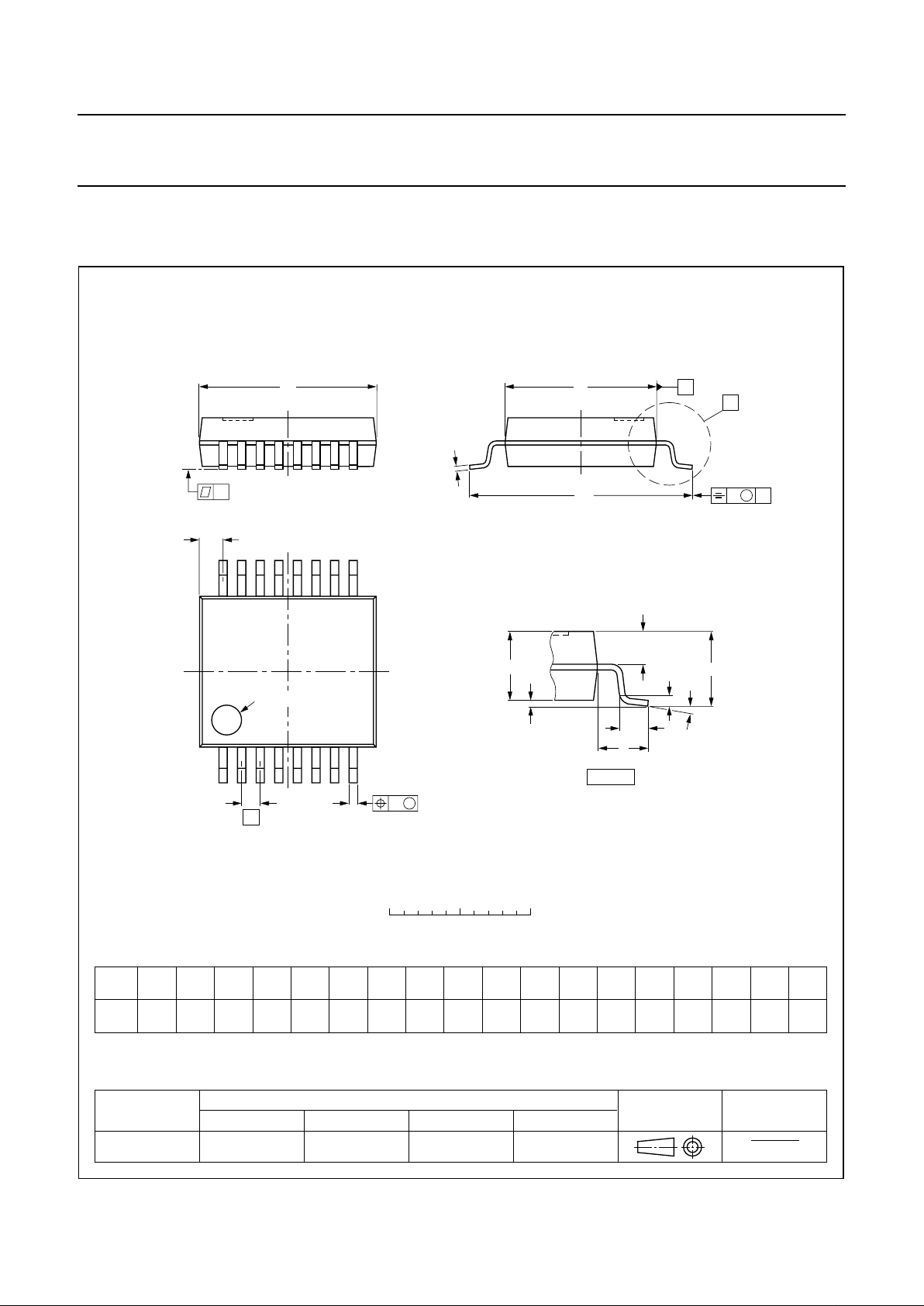

PACKAGE OUTLINES

UNIT

A

max.

1 2

b

1

cEe M

H

L

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC EIAJ

mm

inches

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

SOT38-1

92-10-02

95-01-19

A

min.

A

max.

b

max.

w

M

E

e

1

1.40

1.14

0.055

0.045

0.53

0.38

0.32

0.23

21.8

21.4

0.86

0.84

6.48

6.20

0.26

0.24

3.9

3.4

0.15

0.13

0.2542.54 7.62

0.30

8.25

7.80

0.32

0.31

9.5

8.3

0.37

0.33

2.2

0.087

4.7 0.51 3.7

0.15

0.021

0.015

0.013

0.009

0.010.100.0200.19

050G09 MO-001AE

M

H

c

(e )

1

M

E

A

L

seating plane

A

1

w M

b

1

e

D

A

2

Z

16

1

9

8

b

E

pin 1 index

0 5 10 mm

scale

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

(1) (1)

D

(1)

Z

DIP16: plastic dual in-line package; 16 leads (300 mil); long body

SOT38-1

Page 21

1998 Jan 23 21

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

X

w M

θ

A

A

1

A

2

b

p

D

H

E

L

p

Q

detail X

E

Z

e

c

L

v M

A

(A )

3

A

8

9

1

16

y

pin 1 index

UNIT

A

max.

A1A2A

3

b

p

cD

(1)E(1) (1)

eHELLpQZywv θ

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC EIAJ

mm

inches

1.75

0.25

0.10

1.45

1.25

0.25

0.49

0.36

0.25

0.19

10.0

9.8

4.0

3.8

1.27

6.2

5.8

0.7

0.6

0.7

0.3

8

0

o

o

0.25 0.1

DIMENSIONS (inch dimensions are derived from the original mm dimensions)

Note

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

1.0

0.4

SOT109-1

95-01-23

97-05-22

076E07S MS-012AC

0.069

0.010

0.004

0.057

0.049

0.01

0.019

0.014

0.0100

0.0075

0.39

0.38

0.16

0.15

0.050

1.05

0.041

0.244

0.228

0.028

0.020

0.028

0.012

0.01

0.25

0.01 0.004

0.039

0.016

0 2.5 5 mm

scale

SO16: plastic small outline package; 16 leads; body width 3.9 mm

SOT109-1

Page 22

1998 Jan 23 22

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

UNIT A1A2A

3

b

p

cD

(1)E(1)

eHELLpQZywv θ

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC EIAJ

mm

0.21

0.05

1.80

1.65

0.25

0.38

0.25

0.20

0.09

6.4

6.0

5.4

5.2

0.65 1.25

7.9

7.6

1.03

0.63

0.9

0.7

1.00

0.55

8

0

o

o

0.130.2 0.1

DIMENSIONS (mm are the original dimensions)

Note

1. Plastic or metal protrusions of 0.25 mm maximum per side are not included.

SOT338-1

94-01-14

95-02-04

(1)

w M

b

p

D

H

E

E

Z

e

c

v M

A

X

A

y

1

8

16

9

θ

A

A

1

A

2

L

p

Q

detail X

L

(A )

3

MO-150AC

pin 1 index

0 2.5 5 mm

scale

SSOP16: plastic shrink small outline package; 16 leads; body width 5.3 mm

SOT338-1

A

max.

2.0

Page 23

1998 Jan 23 23

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

UNIT A1A2A

3

b

p

cD

(1)E(2) (1)

eHELLpQZywv θ

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC JEDEC EIAJ

mm

0.15

0.05

0.95

0.80

0.30

0.19

0.2

0.1

5.1

4.9

4.5

4.3

0.65

6.6

6.2

0.4

0.3

0.40

0.06

8

0

o

o

0.13 0.10.21.0

DIMENSIONS (mm are the original dimensions)

Notes

1. Plastic or metal protrusions of 0.15 mm maximum per side are not included.

2. Plastic interlead protrusions of 0.25 mm maximum per side are not included.

0.75

0.50

SOT403-1 MO-153

94-07-12

95-04-04

w M

b

p

D

Z

e

0.25

18

16

9

θ

A

A

1

A

2

L

p

Q

detail X

L

(A )

3

H

E

E

c

v M

A

X

A

y

0 2.5 5 mm

scale

TSSOP16: plastic thin shrink small outline package; 16 leads; body width 4.4 mm

SOT403-1

A

max.

1.10

pin 1 index

Page 24

1998 Jan 23 24

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

SOLDERING

Introduction

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mounted components are mixed

on one printed-circuit board. However, wave soldering is

not always suitable for surface mounted ICs, or for

printed-circuits with high population densities. In these

situations reflow soldering is often used.

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“IC Package Databook”

(order code 9398 652 90011).

DIP

SOLDERING BY DIPPING OR BY WA VE

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joint for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (T

stg max

). If the

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

R

EPAIRING SOLDERED JOINTS

Apply a low voltage soldering iron (less than 24 V) to the

lead(s) of the package, below the seating plane or not

more than 2 mm above it. If the temperature of the

soldering iron bit is less than 300 °C it may remain in

contact for up to 10 seconds. If the bit temperature is

between 300 and 400 °C, contact may be up to 5 seconds.

SO, SSOP and TSSOP

REFLOW SOLDERING

Reflow soldering techniques are suitable for all SO, SSOP

and TSSOP packages.

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several techniques exist for reflowing; for example,

thermal conduction by heated belt. Dwell times vary

between 50 and 300 seconds depending on heating

method.

Typical reflow temperatures range from 215 to 250 °C.

Preheating is necessary to dry the paste and evaporate

the binding agent. Preheating duration: 45 minutes at

45 °C.

W

AVE SOLDERING

Wave soldering can be used for all SO packages. Wave

soldering is not recommended for SSOP and TSSOP

packages, because of the likelihood of solder bridging due

to closely-spaced leads and the possibility of incomplete

solder penetration in multi-lead devices.

If wave soldering is used - and cannot be avoided for

SSOP and TSSOP packages - the following conditions

must be observed:

• A double-wave (a turbulent wave with high upward

pressure followed by a smooth laminar wave) soldering

technique should be used.

• The longitudinal axis of the package footprint must be

parallel to the solder flow and must incorporate solder

thieves at the downstream end.

Even with these conditions:

• Only consider wave soldering SSOP packages that

have a body width of 4.4 mm, that is

SSOP16 (SOT369-1) or SSOP20 (SOT266-1).

• Do not consider wave soldering TSSOP packages

with 48 leads or more, that is TSSOP48 (SOT362-1)

and TSSOP56 (SOT364-1).

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Maximum permissible solder temperature is 260 °C, and

maximum duration of package immersion in solder is

10 seconds, if cooled to less than 150 °C within

6 seconds. Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

R

EPAIRING SOLDERED JOINTS

Fix the component by first soldering two diagonallyopposite end leads. Use only a low voltage soldering iron

(less than 24 V) applied to the flat part of the lead. Contact

time must be limited to 10 seconds at up to 300 °C. When

using a dedicated tool, all other leads can be soldered in

one operation within 2 to 5 seconds between

270 and 320 °C.

Page 25

1998 Jan 23 25

Philips Semiconductors Product specification

4-bit x 16-word FIFO register 74HC/HCT40105

DEFINITIONS

LIFE SUPPORT APPLICATIONS

These products are not designed for use in life support appliances, devices, or systems where malfunction of these

products can reasonably be expected to result in personal injury. Philips customers using or selling these products for

use in such applications do so at their own risk and agree to fully indemnify Philips for any damages resulting from such

improper use or sale.

Data sheet status

Objective specification This data sheet contains target or goal specifications for product development.

Preliminary specification This data sheet contains preliminary data; supplementary data may be published later.

Product specification This data sheet contains final product specifications.

Limiting values

Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one or

more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation

of the device at these or at any other conditions above those given in the Characteristics sections of the specification

is not implied. Exposure to limiting values for extended periods may affect device reliability.

Application information

Where application information is given, it is advisory and does not form part of the specification.

Loading...

Loading...