Page 1

74F402

Serial Data Polynomial Generator/Checker

74F402 Serial Data Polynomial Generator/Checker

April 1988

Revised August 1999

General Description

The 74F402 expandable Serial Data Polynomial generator/

checker is an expandable versio n of the 74F401. It provides an advanced tool for th e implem entation of th e most

widely used error detection scheme in serial dig ital handling systems. A 4-bit control input sel ects one-of-six generator polynomials. The list of polynomials includes CRC16, CRC-CCITT and Ethernet, as well as three other

standard polynomials (56

Individual clear and pre set inputs are provided for floppy

disk and other applications. The Error output indicates

whether or not a transmission error has occurred. The

CWG Control input inhibits feedback during check word

transmission. The 74F402 is compatible with FAST

devices and with all TTL families.

th

order, 48th order, 32nd order).

Features

■ Guaranteed 30 MHz data rate

■ Six selectable polynomials

■ Other polynomials available

■ Separate preset and clear controls

■ Expandable

■ Automatic right justification

■ Error output open collector

■ Typical applications: Floppy and othe r disk stora ge sys-

tems Digital cassette and cartridge systems Data communication systems

Ordering Code:

Order Number Package Number Package Description

74F402PC N16E 16-Lead Plastic Dual-In-Line Package (PDIP), JEDEC MS-001, 0.300 Wide

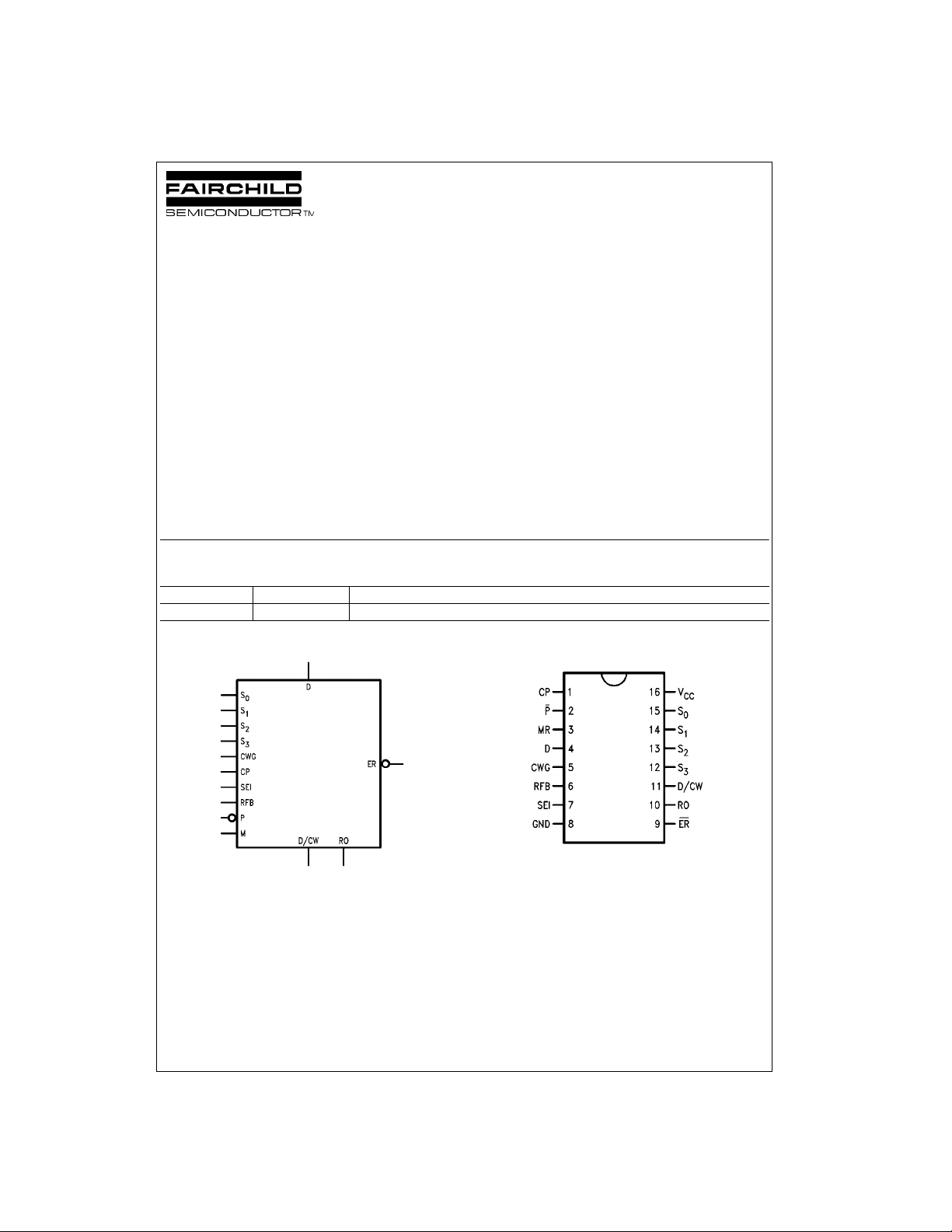

Logic Symbol Connection Diagram

FAST is a regist ered trademark of Fair c hild Semiconductor Corporation.

Ethernet is a registe red trademark of Xerox C orporation.

© 1999 Fairchild Semiconductor Corporation DS009535 www.fairchildsemi.com

Page 2

Unit Loading/Fan Out

74F402

Note 1: Open Collector

Pin Names Description

S0–S

CWG Check Word Generate Input 1.0/0.67 20 µA/−0.4 mA

D/CW Serial Data/Check Word 285(100)/13.3(6.7) −5.7 mA(−2 mA)/8 mA (4 mA)

D Data Input 1.0/0.67 20 µA/−0.4 mA

ER

RO Register Output 285(100)/13.3(6.7) −5.7 mA(−2 mA)/8 mA (4 mA)

CP Clock Pulse 1.0/0.67 20 µA/−0.4 mA

SEI Serial Expansion Input 1.0/0.67 20 µA/−0.4 mA

RFB Register Feedback 1.0/0.67 20 µA/−0.4 mA

MR Master Reset 1.0/0.67 20 µA/−0.4 mA

P

Polynomial Select Inputs 1.0/0.67 20 µA/−0.4 mA

3

Error Output (Note 1) /26.7(13.3) (Note 1) /16 mA (8 mA)

Preset 1.0/0.67 20 µA/−0.4 mA

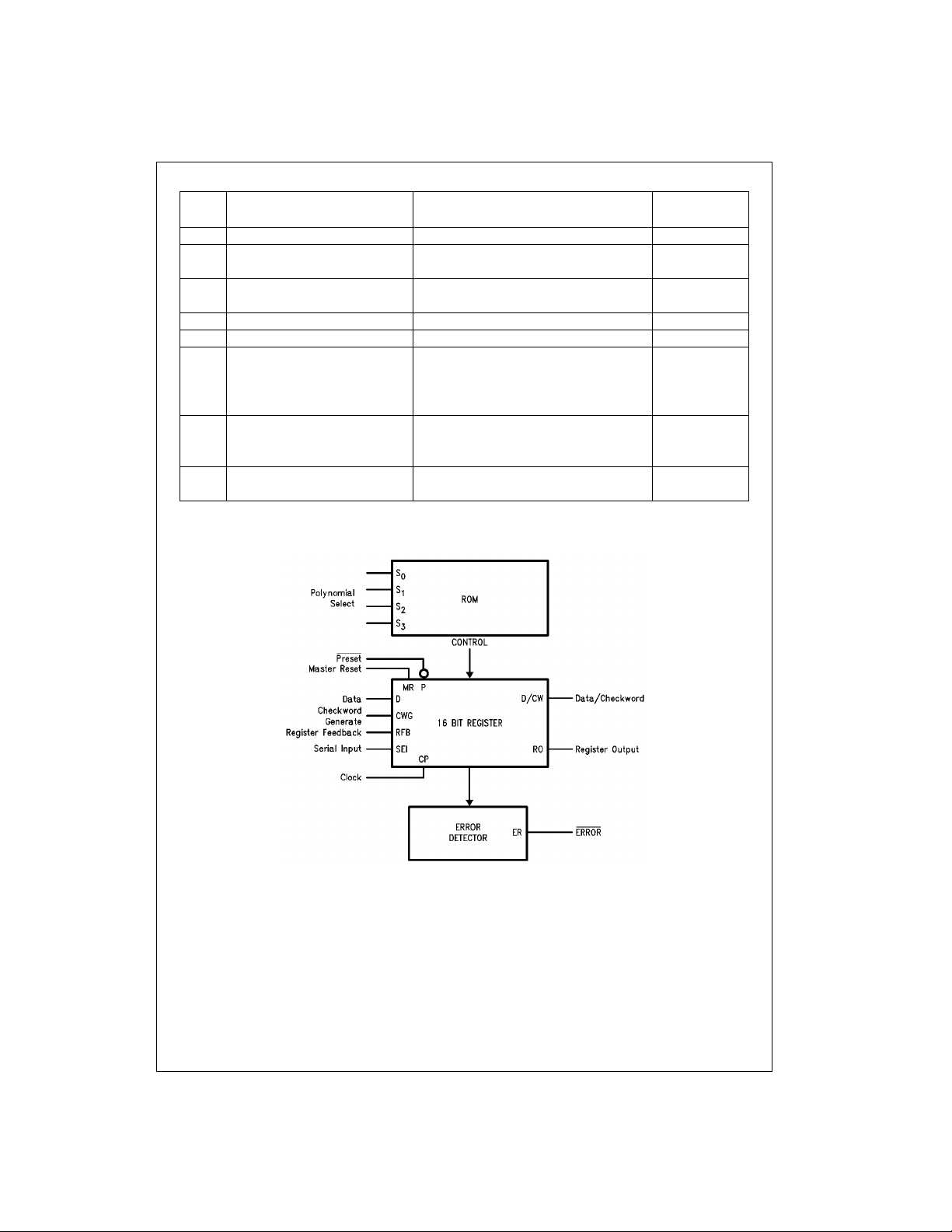

Functional Description

The 74F402 Serial Data Polynomial Generato r/Checker is

an expandable 16-bit programmable device which operates on serial data streams and provides a means of

detecting transmission er rors. Cyclic encod ing and decoding schemes for err or detection are based on poly nomial

manipulation in m odulo arithmetic . For encoding , the data

stream (message polynomial) is divided by a selected polynomial. This division results in a remainder (or residue)

which is appended t o th e m essa ge a s che ck bi t s. Fo r e rro r

checking, the bit st ream containing both data and check

bits is d ivided by the same selected polynomial. If there are

no detectable errors, th is division results in a zero remain der. Although it is possible to choose many generating

polynomials of a given de gre e, stan dar ds exist tha t spe cify

a small number of usefu l polynomials. The 7 4F402 implements the polynomials listed in Table 1 by applying the

appropriate logic levels to the select pins S

The 74F402 consists of a 16-bit register, a Read Only

Memory (ROM) and associated control circuitry as show n

in the Block Diagram. The polynomial control code presented at inputs S

selecting the desir ed polynom ial o r part of a p olyno mia l by

establishing shift mode operation on the register with

Exclusive OR (XOR) gates at appropriate inputs. To generate the check bits, the data stre am is entered via the Data

Inputs (D), using the LOW-to-HIGH transit ion of the Clock

Input (CP). This data is gated with the most significant

Register Output (RO) via the Register Feedback Input

(RFB), and controls the XOR gates. The Check Word Gen-

, S1, S2 and S3 is decoded by the ROM,

0

, S1, S2 and S3.

0

U.L.

HIGH/LOW

erate (CWG) mu st be held HIGH while t he data is being

entered. After the last data bit is entered, the CWG is

brought LOW and the check b its are shift ed ou t of the register(s) and appended to the data bits (no external gating is

needed).

To check an incoming messa ge for errors, both the data

and check bits are enter ed through the D Input with the

CWG Input held HIGH. The Error Output becom es valid

after the last check bit has been entered into the ’F402 by a

LOW-to-HIGH transition of CP, with the exception of the

Ethernet polynomial (see Applications paragraph). If no

detectable errors ha ve occurred during the data transmission, the resultant internal register bits are all LOW and the

Error Output (ER

occurred, ER

to-HIGH transition o f CP or until th e device has b een preset or reset.

A HIGH on the Master Reset Input (MR) asynchronous ly

clears the entire register. A LOW on the Preset Input (P

asynchronously sets the enti re register with the exception

of:

1. The Ethernet residue se lection, in which the regist ers

containing the non-zero res idue are cleared;

2. The 56th order polynomial, in which the 8 least significant register bits of the least significant device are

cleared; and,

3. Register S = 0, in which all bits are cleared.

) is HIGH. If a detectable error has

is LOW. ER remains valid until the next LOW-

Input I

Output I

IH/IIL

OH/IOL

)

www.fairchildsemi.com 2

Page 3

TABLE 1.

Hex

S

3

Select Code

S

S

2

S

1

0

Polynomial Remarks

0LLLL0 S = 0

CHHLLX

DHHLHX

EHHHLX

FHHHHX

7LHHHX

BHLHHX

3LLHHX

2LLHLX

4LHLLX

8HLLLX

5LHLHX

32+X26+X23+X22+X16

12+X11+X10+X8+X7+X5+X4+X2

32+X31+X27+X26+X25+X19+X16

15+X13+X12+X11+X9+X7+X6+X5+X4+X2

16+X15+X2

16+X12+X5

56+X55+X49+X45+X41

39+X38+X37+X36+X31

22+X19+X17+X16+X15+X14+X12+X11+X9

5

+X+1

48+X36+X35+

+1 CRC-16

+1 CRC-CCITT

+ Ethernet

+X+1 Polynomial

+ Ethernet

+

+ 56th

9HLLHX23+X21+ 48th

1LLLHX

6LHHLX

AHLHLX

15+X13+X8+X2

32+X23+X21

11+X2

+1Order

+ 32nd

+1Order

Block Diagram

74F402

+X+1 Residue

+ Order

3 www.fairchildsemi.com

Page 4

P

74F402

Select Code

0 0000100S = 0

P

3

2

C 1111101Ethernet

D 1111101Polynomial

E 0000000Ethernet

F 0000010Residue

7 1111100CRC-16

B 1111100CRC-CCITT

3 1111100

2 111110056th

4 1111100Order

8 0011100

5 111110048th

9 1111100Order

1 1111100

6 111110032nd

A 1111100Order

Applications

In addition to polynomial selection there are four other

capabilities provided for in the 74F402 ROM. The first is set

or clear selectability. The sixteen internal registers have the

capability to be either set or cleared when P

LOW. This set or clear capability is done in four groups of 4

(see Table 2, P

). The second ROM capability (C0) is in

0–P3

determining the po larity of the check word. A s is the case

with the Ethernet polynomial the check word can be

inverted when it is appended to the data stream or as is the

case with the other polynom ials, the residue is appended

with no inversion. Thirdly, the ROM contains a bit (C

which is used to select th e RFB input instead of the SEI

input to be fed into the LSB. This is used whe n th e p ol yno mial selected is actually a residu e (least signific ant) stored

in the ROM which indicates whether the selected locatio n

is a polynomia l o r a re si due . If the l a tter, then it in hi bits th e

RFB input.

As mentioned previously, upon a successful data transmission, the CRC register has a zero residue. There is an

exception to this, however, with respect to the Ethernet

polynomial. This polynom ial, upo n a successful dat a transmission, has a non-zero residue in the CRC register (C7 04

DD 7B)

. In order to provide a no-error indication, two

16

ROM locations have b een preloaded with the residue so

that by selecting these loca tions and clocking the device

one additional time, after the last check bit has been

entered, will result in zeroing the CRC register. In this manner a no-error indication is achieved.

With the present mix of polynomials, the largest is 56

order requiring four device s while the smallest is 16th order

requiring just one de vice. In order to acc ommodate multiplexing between h igh orde r pol ynomi als (X 16

lower order polynomials, a location of all zeros is provided.

is brought

th

order) and

P

1

TABLE 2.

P

C

C

C

0

2

1

0

Polynomial

This allows the user to choose a lower or der polynomial

even if the system is configured for a higher order one.

The 74F402 expandable CRC generator checker contains

6 popular CRC polynomials, 2-16

th

Order and 1-56th Order. The application diagram

48

shows the 74F402 connecte d for a 56

th

Order, 2-32nd Order, 1-

th

Order polynomial.

Also shown are the inp ut patterns for other polynomials.

When the 74F402 is used with a gated clock, d isablin g the

clock in a HIGH state will ensure no errone ous clocking

occurs when the clock is re-enabl ed. Preset and Master

)

1

Reset are asynchronou s inputs p resettin g the re giste r to S

or clearing to 1s re spectively (note Ethernet resi due and

th

Order select code 8, LSB, are exceptions to th is).

56

To generate a CRC, the pattern for the selected polynomial

is applied to the S inputs, t he register is preset or cleared

as required, clock is enabled, CW G is set HIGH, data is

applied to D input, output data is on D/CW. When the last

data bit has been enter ed, CWG is set L O W an d th e re gi ster is clocked for n bits (where n is the ord er of the polyn omial). The clock may now be stopped if desired (holding

CWG LOW and clocki ng t he re gi ste r w ill ou tpu t ze ros from

D/CW after the residue has been shifted out).

To check a CRC, the pattern for the selected polynomial is

applied to the S inputs, the re gister is preset or cleared as

required, clock is enabled, CWG is set HIGH, the data

stream including the CRC is applied to D input. When the

last bit of the CRC has been entered, the ER

checked: HIGH = error free data , LOW = cor rupt data. T he

th

clock may now be stopped if desired.

To implement polynomials of lower order than 56

the number of packa ges required for the order of pol ynomial and apply the pattern for the selected polynomial to

the S inputs (0000 on S inputs disab les the pac kage from

the feedback chain).

output is

th

, select

www.fairchildsemi.com 4

Page 5

74F402

5 www.fairchildsemi.com

Page 6

Absolute Maximum Ratings(Note 2) Recommended Operating

Storage Temperature −65°C to +150°C

74F402

Ambient Temperature under Bias −55°C to +125°C

Junction Temperature under Bias −55°C to +150°C

Pin Potential to Ground Pin −0.5V to +7.0V

V

CC

Input Voltage (Note 3) −0.5V to +7.0V

Input Current (Note 3) −30 mA to +5.0 mA

Voltage Applied to Output

in HIGH State (with V

CC

= 0V)

Standard Output −0.5V to V

3-STATE Output −0.5V to +5.5V

Current Applied to Output

in LOW State (Max) twice the rated I

OL

Conditions

Free Air Ambient Temperature 0°C to +70°C

Supply Voltage +4.5V to +5.5V

Note 2: Absolute maximum ratings are values beyond which the device

may be damaged or have its useful life impaired. Functional operation

CC

under these conditi ons is not implied.

Note 3: Either voltage limit or curren t limit is sufficient to protect in put s .

(mA)

DC Electrical Characteristics

Symbol Parameter Min Typ Max Units

V

V

V

V

V

I

I

I

V

I

I

I

I

I

IH

IL

CD

OH

OL

IH

BVI

CEX

ID

OD

IL

OS

OHC

CC

Input HIGH Voltage 2.0 V Recognized as a HIGH Signal

Input LOW Voltage 0.8 V Recognized as a LOW Signal

Input Clamp Diode Voltage −1.2 V Min IIN = −18 mA

Output HIGH 10% V

Voltage 5% V

Output LOW 10% V

Voltage 10% V

Input HIGH

Current

Input HIGH Current

Breakdown Test

Output HIGH

Leakage Current

Input Leakage

Test All Other Pins Grounded

Output Leakage

Circuit Current All Other Pins Grounded

Input LOW Current −0.4 mA Max VIN = 0.5V

Output Short-Circuit Current −20 −130 mA Max V

Open Collector, Output

OFF Leakage Test

Power Supply Current 110 165 mA Max

2.4

CC

2.7 IOH = −5.7 mA (RO, D/CW)

CC

CC

CC

4.75 V 0.0

0.5

0.5 IOL = 8 mA (D/CW, RO)

5.0 µAMaxVIN = 2.7V

7.0 µAMaxVIN = 7.0V

50 µAMaxV

3.75 µA0.0

250 µAMin

V

CC

VMin

IOH = −5.7 mA (RO, D/CW)

IOL = 16 mA (ER)

IID = 1.9 µA

V

V

Conditions

= V

OUT

CC

= 150 mV

IOD

= 0V (D/CW, RO)

OUT

= VCC (ER)

OUT

www.fairchildsemi.com 6

Page 7

AC Electrical Characteristics

Symbol Parameter

f

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

MAX

PLH

PHL

PLH

PHL

PLH

PHL

PLH

PHL

PLH

PLH

PLH

PHL

PHL

PLH

PLH

PHL

PLH

PHL

PLH

PHL

Maximum Clock Frequency 30 45 30 30 MHz

Propagation Delay 8.5 15.0 19.0 7.5 26.5 7.5 21.0

CP to D/CW 10.5 18.0 23.0 9.5 26.5 9.5 25.0

Propagation Delay 8.0 13.5 17.0 7.0 26.0 7.0 19.0

CP to RO 8.0 14.0 18.0 7.0 22.5 7.0 20.0

Propagation Delay 15.5 26.0 33.0 14.0 38.5 14.0 35.0

CP to ER

Propagation Delay 11.0 18.5 23.5 10.0 31.0 10.0 25.5

P to D/CW 11.5 19.5 24.5 10.5 32.0 10.5 26.5

Propagation Delay

P to RO

Propagation Delay

P to ER

Propagation Delay 10.5 18.0 23.0 9.5 29.0 9.5 25.5

MR to D/CW 11.0 19.0 24.0 10.0 28.5 10.0 26.0

Propagation Delay

MR to RO

Propagation Delay

MR to ER

Propagation Delay 6.0 10.5 13.5 5.0 19.5 5.0 15.0

D to D/CW 7.5 12.0 16.0 6.5 20.0 6.5 18.0

Propagation Delay 6.5 11.0 14.0 5.5 21.5 5.5 15.5

CWG to D/CW 7.0 12.0 15.5 6.0 21.5 6.0 17.5

Propagation Delay 11.5 19.5 24.5 9.0 29.0 10.5 26.5

Sn to D/CW 9.5 16.0 20.0 8 .5 25.0 8.5 22.0

TA = +25°CT

VCC = +5.0V VCC = +5.0V VCC = +5.0V

CL = 50 pF CL = 50 pF CL = 50 pF

= −55°C to +125°CTA = 0°C to +70°C

A

Units

Min Typ Max Min Max Min Max

8.5 14.5 18.5 7.5 23.5 7.5 20.5

9.5 16.0 20.5 8.5 31.5 8.5 22.5 ns

10.0 17.0 21.5 9.0 26.0 9.0 23.5 ns

9.0 15.5 19.5 8.0 23.5 8.0 21.5 ns

16.5 28.0 35.5 14.5 39.0 14.5 37.5 ns

74F402

ns

ns

ns

ns

ns

ns

ns

ns

7 www.fairchildsemi.com

Page 8

AC Operating Requirements

74F402

Symbol Parameter

tS(H) Setup Time, HIGH or LOW 4.5 6.0 5.0

tS(L) SEI to CP 4.5 6.0 5.0

tH(H) Hold Time, HIGH or LOW 0 1.0 0

tH(L) SEI to CP 0 1.0 0

tS(H) Setup Time, HIGH or LOW 11.0 14.0 12.5

tS(L) RFB to CP 11.0 14.0 12.5

tH(H) Hold Time, HIGH or LOW 0 0 0

tH(L) RFB to CP 0 0 0

tS(H) Setup Time, HIGH or LOW 13.5 16.0 15.0

tS(L) S1 to CP 13.0 15.5 14.5

tH(H) Hold Time, HIGH or LOW 0 0 0

tH(L) S1 to CP 0 0 0

tS(H) Setup Time, HIGH or LOW 9.0 11.5 10.0

tS(L) D to CP 9.0 11.5 10.0

tH(H) Hold Time, HIGH or LOW 0 0 0

tH(L) D to CP 0 0 0

tS(H) Setup Time, HIGH or LOW 7.0 9.0 8.0

tS(L) CWG to CP 5.5 8.0 6.5

tH(H) Hold Time, HIGH or LOW 0 0 0

tH(L) CWG to CP 0 0 0

tW(H) Clock Pulse Width 4.0 7.0 4.5

tW(L) HIGH or LOW 4.0 5.0 4.5

tW(H) MR Pulse Width, HIGH 4.0 7.0 4.5 ns

tW(L) P Pulse Width, LOW 4.0 5.0 4.5 ns

t

t

REC

REC

Recovery Time

MR to CP

Recovery Time

P to CP

TA = +25°CTA = −55°C to +125°CTA = 0°C to +70°C

Min Max Min Max Min Max

3.0 4.0 3.5

5.0 6.5 6.0

UnitsVCC = +5.0V VCC = +5.0V VCC = +5.0V

ns

ns

ns

ns

ns

ns

ns

www.fairchildsemi.com 8

Page 9

Physical Dimensions inches (millimeters) unless otherwise noted

74F402 Serial Data Polynomial Generator/Checker

16-Lead Plastic Dual-In-Line Package (PDIP), JEDEC MS-001, 0.300 Wide

Fairchild does not assume any responsibility for use of any circuitry described, no circuit patent license s are implied and

Fairchild reserves the right at any time without notice to change said circuitry and specifications.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or systems

which, (a) are intended for surgical implant into the

body, or (b) support or sustain life, and (c) whose failure

to perform when properly used in accordance with

instructions for use provide d in the labe l ing, can be re asonably expected to result in a significant injury to the

user.

Package Number N16E

2. A critical componen t in any com ponen t of a life s upport

device or system whose failu re to perform can b e reasonably expected to cause the failure of the life support

device or system, or to affect its safety or effectiveness.

www.fairchildsemi.com

9 www.fairchildsemi.com

Loading...

Loading...