Page 1

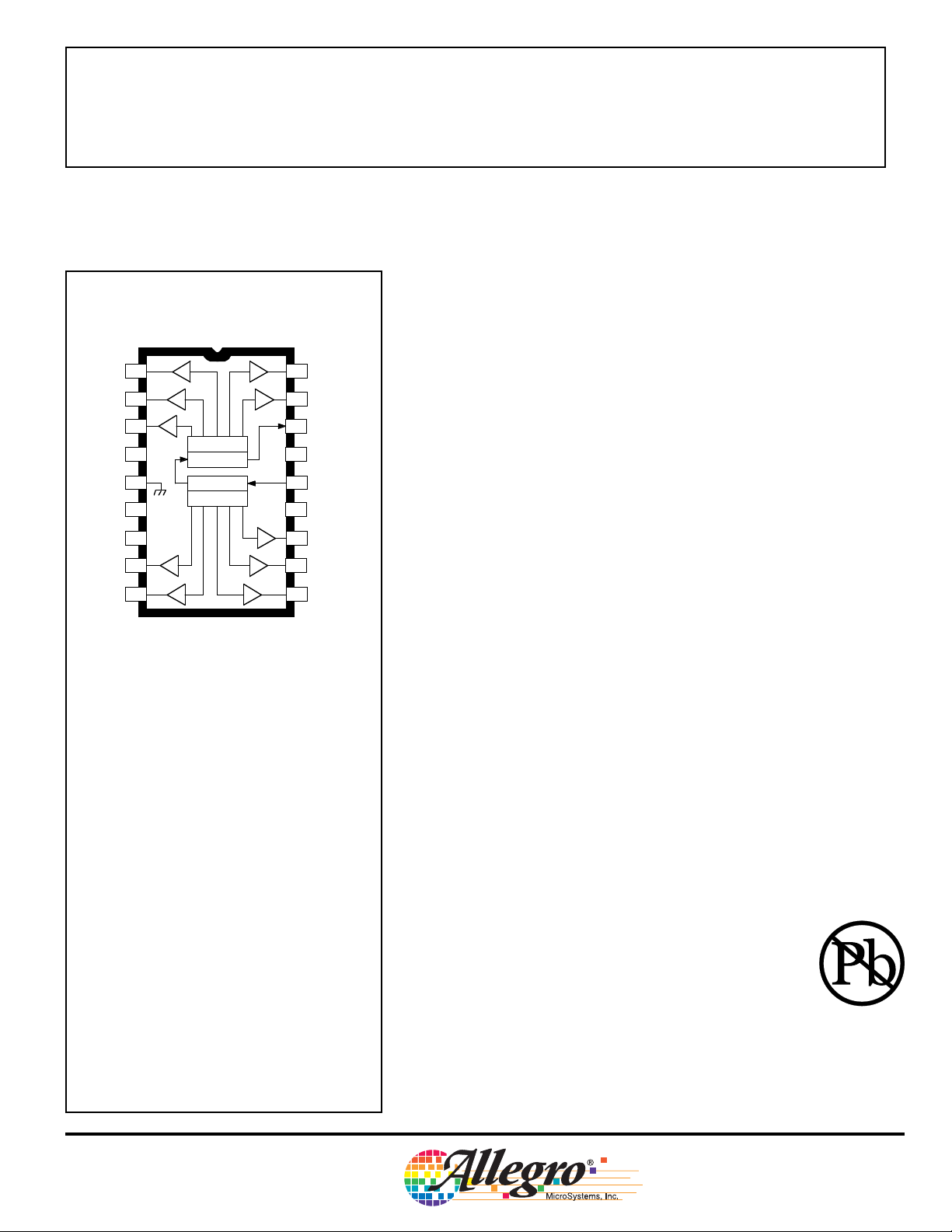

A6810xA

OUT

1

OUT

8

2

OUT

7

3

OUT

CLOCK

GROUND

LOGIC

SUPPLY

STROBE

OUT

OUT

6

CLK

4

5

6

V

7

ST

8

5

4

LATCHES

REGISTER

REGISTER

LATCHES

DD

ABSOLUTE MAXIMUM RATINGS

at TA = 25°C

Logic Supply Voltage, V

Driver Supply Voltage, V

Continuous Output Current Range,

I

........................ -40 mA to +15 mA

OUT

Input Voltage Range,

V

....................... -0.3 V to V

IN

Package Power Dissipation,

P

....................................... See Graph

D

Operating Temperature Range, T

(Suffi x ‘E–’) ................... -40°C to +85°C

(Suffi x ‘K–’) ................. -40°C to +125°C

(Suffi x ‘S–’) ................... -20°C to +85°C

Storage Temperature Range,

T

............................... -55°C to +125°C

S

Caution: These CMOS devices have input

static protection (Class 2) but are still susceptible to damage if exposed to extremely

high static electrical charges.

DD

BB

18

9

17

OUT

10

SERIAL

16

DATA OUT

LOAD

V

15

BB

SUPPLY

SERIAL

14

DATA IN

13

12

11

019

BLANKING

OUT

1

OUT

2

OUT

3

Dwg. PP-029

BLNK

.................. 7.0 V

................... 60 V

+ 0.3 V

DD

A

26182.124E

Data Sheet

6810

DABiC-IV, 10-BIT SERIAL-INPUT,

LATCHED SOURCE DRIVER

The A6810– devices combine 10-bit CMOS shift registers, ac com pa ny ing data latches and control cir cuit ry with bipolar sourcing out puts

and pnp active pull downs. De signed pri mar ily to drive vacuum-fl u o -

res cent displays, the 60 V and -40 mA output ratings also allow these

devices to be used in many other peripheral power driver ap pli ca tions.

The A6810– feature an increased data input rate (com pared with the

older UCN/UCQ5810-F) and a con trolled output slew rate.

The CMOS shift register and latches allow direct interfacing with

microprocessor-based systems. With a 3.3 V or 5 V logic supply, serialdata input rates of at least 10 MHz .

A CMOS serial data output permits cascade con nec tions in ap pli ca tions re quir ing additional drive lines. Similar devices are available as

the A6812– (20 bits) and A6818– (32 bits).

The A6810– output source drivers are npn Dar ling tons, capable of

sourcing up to 40 mA. The controlled output slew rate reduces elec tro mag net ic noise, which is an important consideration in systems that include telecommunications and/or microprocessors and to meet government emissions regulations. For inter-digit blanking, all output drivers

can be dis abled and all sink drivers turned on with a BLANK ING input

high. The pnp active pull-downs will sink at least

2.5 mA.

The A6810– are available in three temperature ranges for op ti mum

per for mance in commercial (suffi x S-), industrial (suffi x E-), or au-

tomtoive (suffi x K–) ap pli ca tions. They are provided in two package

styles for through-hole DIP (suffi x -A) or minimum-area surface-mount

SOIC (suffi x -LW). Copper lead frames, low logic-power dis si pa tion,

and low output-saturation voltages allow all devices to source 25 mA

from all outputs continuously over the max i mum operating tem pera ture

range.

The lead (Pb) free versions are provided with 100% matte tin

leadframe plating.

FEATURES

■ Controlled Output Slew Rate

■ High-Speed Data Storage

■ 60 V Minimum Output Breakdown

■ High Data Input Rate

■ PNP Active Pull-Downs

■ Low Output-Saturation Voltages

■ Low-Power CMOS Logic and Latches

■ Improved Replacements for TL4810–, UCN5810–, and UCQ5810–

Page 2

6810

10-BIT SERIAL-INPUT,

LATCHED SOURCE DRIVER

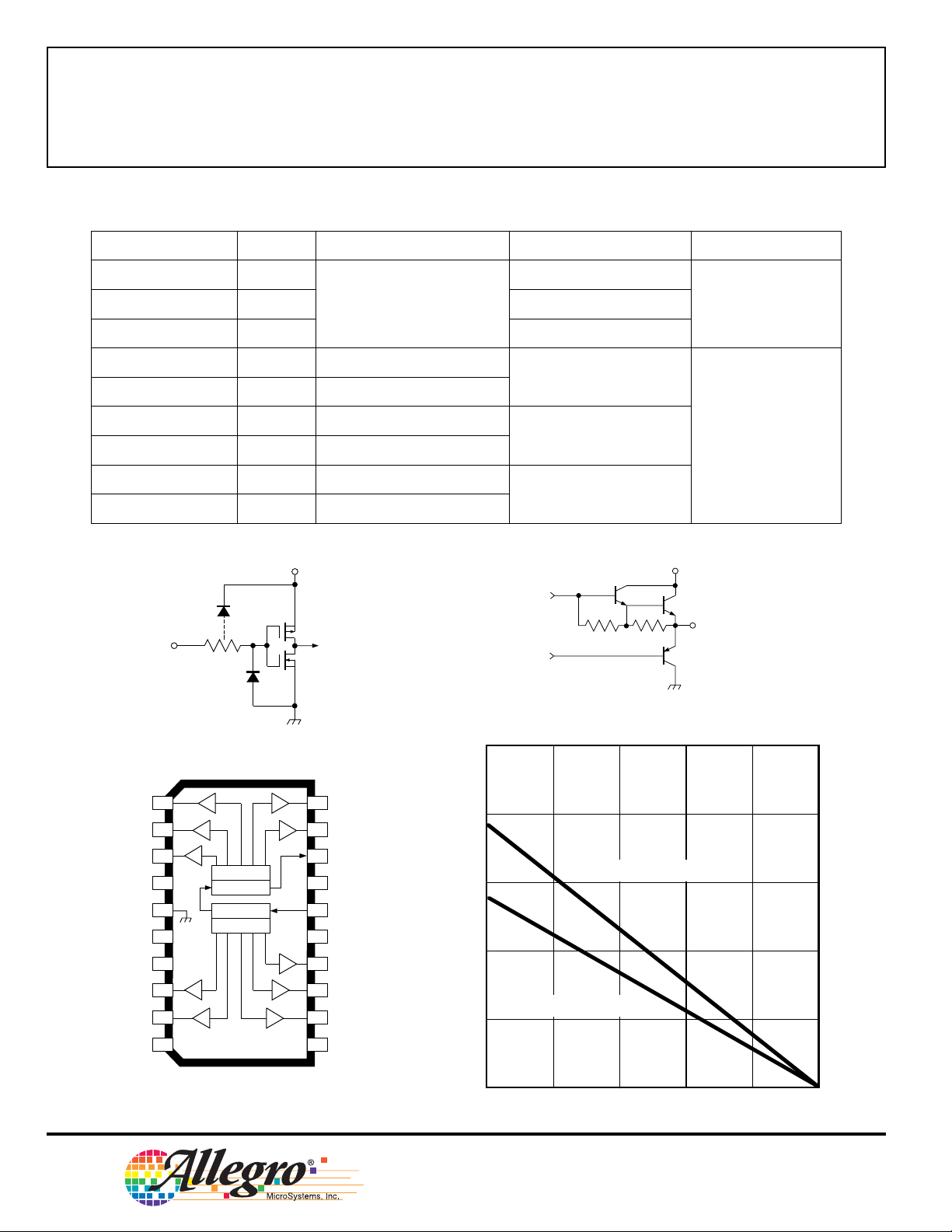

PRODUCT SELECTION GUIDE

Part Number Pb-free Packing

A6810SA

A6810SA-T

A6810EA

A6810EA-T

A6810KA

A6810KA-T

A6810SLW

A6810SLW-T

A6810SLWTR

A6810SLWTR-T

A6810ELW

A6810ELW-T

A6810ELWTR

A6810ELWTR-T

A6810KLW

A6810KLW-T

A6810KLWTR

A6810KLWTR-T

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

–

–

–

–

–

1000 pieces/13-in. reel

–

–

1000 pieces/13-in. reel

–

–

1000 pieces/13-in. reel

TIUCRICTUPNILACIPYT

V

DD

IN

21 pieces/tube

37 pieces/tube

37 pieces/tube

37 pieces/tube

Ambient Temperature, T

(°C)

–20 to 85

–40 to 85

–40 to 125

–20 to 85

–40 to 85

–40 to 125

Dwg. EP-021-19

A

Package

18-pin DIP

20-pin SOIC-W

REVIRDTUPTUOLACIPYT

V

BB

OUT

N

OUT

OUT

OUT

CLOCK

GROUND

LOGIC SUPPLY

STROBE

OUT

OUT

CONNECTION

NO

Dwg. EP-010-5

A6810xLW

1

8

2

7

3

6

4

5

6

7

8

5

9

4

10

CLK

V

ST

NC

LATCHES

REGISTER

REGISTER

LATCHES

DD

V

BLNK

NC

BB

20

OUT

19

OUT

SERIAL

18

DATA OUT

17

LOAD SUPPLY

SERIAL

16

DATA IN

15

BLANKING

14

OUT

13

OUT

12

OUT

NO

11

CONNECTION

9

10

1

2

3

Dwg. PP-029-2

2.5

2.0

SUFFIX 'A', R

QJA

= 65oC/W

1.5

1.0

SUFFIX 'LW', R

QJA

= 90oC/W

0.5

0

25

ALLOWABLE PACKAGE POWER DISSIPATION IN WATTS

50 75 100 125 150

AMBIENT TEMPERATURE IN ooooC

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1998, 2003 Allegro MicroSystems, Inc.

Page 3

LATCHED SOURCE DRIVER

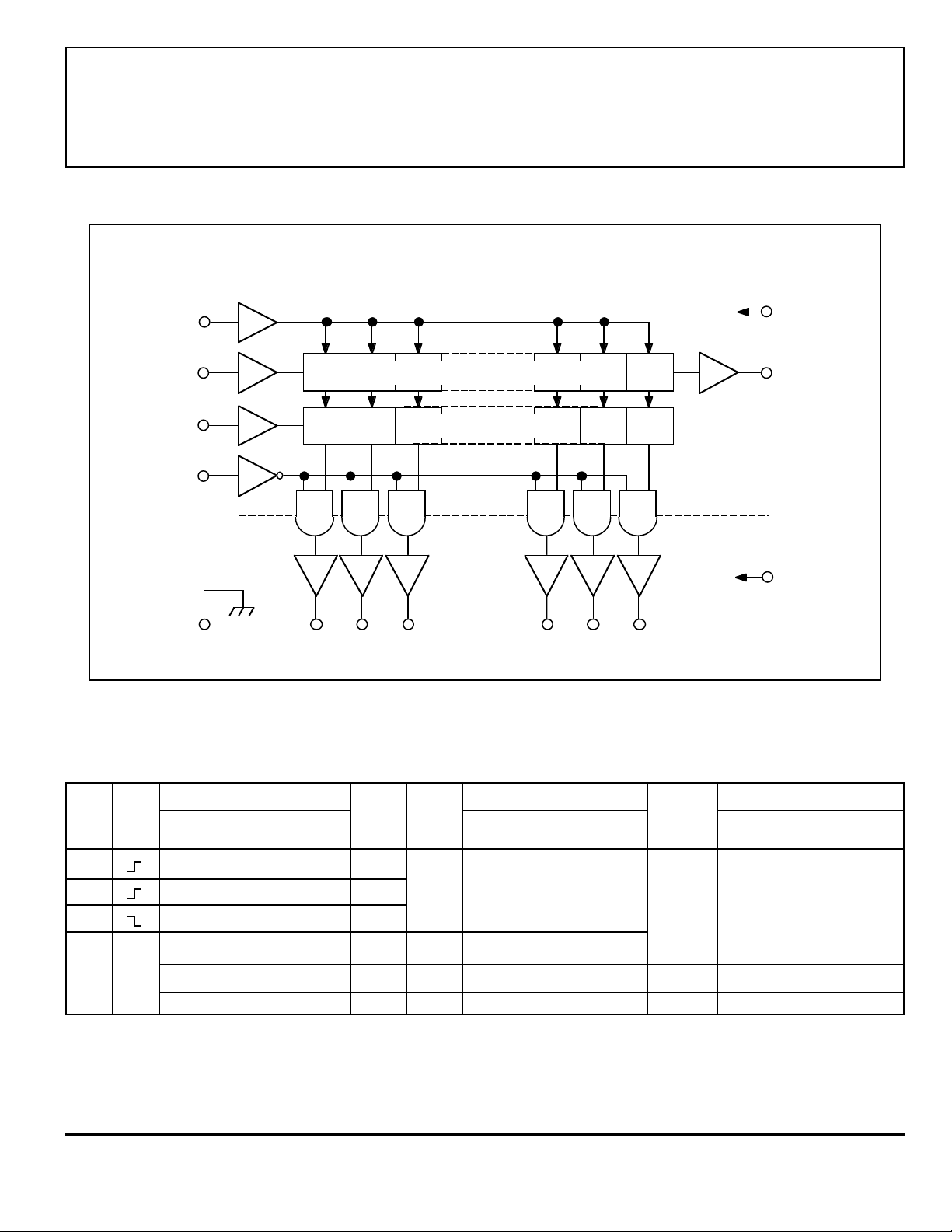

FUNCTIONAL BLOCK DIAGRAM

6810

10-BIT SERIAL-INPUT,

CLOCK

SERIAL

DATA IN

STROBE

BLANKING

GROUND

OUT1OUT

SERIAL-PARALLEL SHIFT REGISTER

LATCHES

OUT

2

3

OUT

N

V

DD

MOS

BIPOLAR

V

BB

LOGIC

SUPPLY

SERIAL

DATA OUT

LOAD

SUPPLY

Dwg. FP-013-1

TRUTH TABLE

Serial Shift Register Contents Serial Latch Contents Output Contents

Data Clock Data Strobe

Input Input I

1I2I3

HHR

LLR

XR

1R2R3

XXX...X X X L R1R2R3... R

P1P2P3... P

L = Low Logic Level H = High Logic Level X = Irrelevant P = Present State R = Previous State

www.allegromicro.com

1R2

1R2

... I

... R

... R

... R

N-1IN

N-2RN-1

N-2RN-1

N-1RN

N-1PN

Output Input I1I2I3... I

R

N-1

R

N-1

R

N

P

N

HP1P2P3... P

X X X ... X X H L L L ... L L

N-1IN

N-1 RN

N-1 PN

Blanklng I1I2I3... I

LP1P2P3... P

N-1

N-1 PN

I

N

Page 4

6810

10-BIT SERIAL-INPUT,

LATCHED SOURCE DRIVER

ELECTRICAL CHARACTERISTICS at T

= +25°C (A6810S-) or over operating temperature

A

range (A6810E-), VBB = 60 V unless otherwise noted.

Limits @ VDD = 3.3 V Limits @ VDD = 5 V

Characteristic Symbol Test Conditions Mln. Typ. Max. Min. Typ. Max. Units

V

Output Leakage Current I

Output Voltage V

Output Pull-Down Current I

OUT(1)IOUT

V

OUT(0)IOUT

OUT(0)

Input Voltage V

V

Input Current I

I

Input Clamp Voltage V

Serial Data Output Voltage V

OUT(1)IOUT

V

OUT(0)IOUT

Maximum Clock Frequency f

Logic Supply Current I

Load Supply Current I

-to-

Blanking

Strobe

Output Delay t

-to-

Output Delay t

DD(1)

I

DD(0)

BB(1)

I

BB(0)

dis(BQ)

t

en(BQ)

p(STH-QL)RL

t

p(STH-QH)RL

Output Fall Time t

Output Rise Time t

CEX

IN(1)

IN(0)

IN(1)

IN(0)

IK

c

f

r

= 0 V — <-0.1 -15 — <-0.1 -15 µA

OUT

= -25 mA 57.5 58.3 — 57.5 58.3 — V

= 1 mA — 1.0 1.5 — 1.0 1.5 V

V

= 5 V to V

OUT

BB

2.5 5.0 — 2.5 5.0 — mA

2.2 — — 3.3 — — V

— — 1.1 — — 1.7 V

VIN = V

DD

— <0.01 1.0 — <0.01 1.0 µA

VIN = 0 V — <-0.01 -1.0 — <-0.01 -1.0 µA

IIN = -200 µA — -0.8 -1.5 — -0.8 -1.5 V

= -200 µA 2.8 3.05 — 4.5 4.75 — V

= 200 µA — 0.15 0.3 — 0.15 0.3 V

10* — — 10* — — MHz

All Outputs High — 0.25 0.75 — 0.3 1.0 mA

All Outputs Low — 0.25 0.75 — 0.3 1.0 mA

All Outputs High, No Load — 1.5 3.0 — 1.5 3.0 mA

All Outputs Low — 0.2 20 — 0.2 20 µA

CL = 30 pF, 50% to 50% — 0.7 2.0 — 0.7 2.0 µs

CL = 30 pF, 50% to 50% — 1.8 3.0 — 1.8 3.0 µs

= 2.3 kΩ, CL ≤ 30 pF — 0.7 2.0 — 0.7 2.0 µs

= 2.3 kΩ, CL ≤ 30 pF — 1.8 3.0 — 1.8 3.0 µs

RL = 2.3 kΩ, CL ≤ 30 pF 2.4 — 12 2.4 — 12 µs

RL = 2.3 kΩ, CL ≤ 30 pF 2.4 — 12 2.4 — 12 µs

Output Slew Rate dV/dt RL = 2.3 kΩ, CL ≤ 30 pF 4.0 — 20 4.0 — 20 V/µs

Clock

-to-

Serial Data Out Delay t

Negative current is defined as coming out of (sourcing) the specified device terminal.

Typical data is is for design information only and is at TA = +25°C.

*Operation at a clock frequency greater than the specified minimum value is possible but not warranteed.

p(CH-SQX)IOUT

= ±200 µA — 50 — — 50 — ns

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Page 5

10-BIT SERIAL-INPUT,

LATCHED SOURCE DRIVER

TIMING REQUIREMENTS and SPECIFICATIONS

(Logic Levels are VDD and Ground)

C

6810

CLOCK

SERIAL

DATA IN

SERIAL

DATA OUT

STROBE

BLANKING

OUT

BLANKING

OUT

50%

A B

DATA

N

N

50%

t

p(CH-SQX)

t

p(STH-QH)

t

p(STH-QL)

10%

DATA

90%

t

dis(BQ)

50%

D E

50%

LOW = ALL OUTPUTS ENABLED

HIGH = ALL OUTPUTS BLANKED (DISABLED)

50%

t

en(BQ)

t

r

DATA

10%

DATA

Dwg. WP-029

t

f

90%

50%

A. Data Active Time Before Clock Pulse

(Data Set-Up Time), t

......................................... 25 ns

su(D)

B. Data Active Time After Clock Pulse

(Data Hold Time), t

C. Clock Pulse Width, t

D. Time Between Clock Activation and Strobe, t

E. Strobe Pulse Width, t

............................................... 25 ns

h(D)

............................................... 50 ns

w(CH)

....... 100 ns

su(C)

............................................. 50 ns

w(STH)

NOTE – Timing is representative of a 10 MHz clock. Higher

speeds may be attainable; operation at high temperatures will

reduce the specified maximum clock frequency.

Serial Data present at the input is transferred to the shift

register on the logic “0” to logic “1” transition of the CLOCK

input pulse. On succeeding CLOCK pulses, the registers shift

data information towards the SERIAL DATA OUTPUT. The

www.allegromicro.com

Dwg. WP-030A

SERIAL DATA must appear at the input prior to the rising edge

of the CLOCK input waveform.

Information present at any register is transferred to the

respective latch when the STROBE is high (serial-to-parallel

conversion). The latches will continue to accept new data as

long as the STROBE is held high. Applications where the

latches are bypassed (STROBE tied high) will require that the

BLANKING input be high during serial data entry.

When the BLANKING input is high, the output source

drivers are disabled (OFF); the pnp active pull-down sink

drivers are ON. The information stored in the latches is not

affected by the BLANKING input. With the BLANKING input

low, the outputs are controlled by the state of their respective

latches.

Page 6

6810

10-BIT SERIAL-INPUT,

LATCHED SOURCE DRIVER

18

0.280

0.240

A6810EA & A6810SA

Dimensions in Inches

(controlling dimensions)

10

0.014

0.008

0.300

BSC

0.430

MAX

0.210

MAX

7.11

6.10

0.015

MIN

18

1

0.070

0.045

0.022

0.014

0.920

0.880

0.100

BSC

9

0.005

MIN

0.150

0.115

Dwg. MA-001-18A in

Dimensions in Millimeters

(for reference only)

0.355

10

1

1.77

1.15

23.37

22.35

2.54

BSC

9

0.13

MIN

0.204

7.62

BSC

10.92

MAX

5.33

MAX

0.39

MIN

0.558

0.356

3.81

2.93

NOTES: 1. Exact body and lead configuration at vendor’s option within limits shown.

2. Lead spacing tolerance is non-cumulative.

3. Lead thickness is measured at seating plane or below.

4. Supplied in standard sticks/tubes of 21 devices.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Dwg. MA-001-18A mm

Page 7

A6810ELW & A6810SLW

Dimensions in Inches

(for reference only)

20 11

6810

10-BIT SERIAL-INPUT,

LATCHED SOURCE DRIVER

0.0125

0.0091

0.2992

0.2914

0.020

0.013

0.0926

0.1043

7.60

7.40

1 2

0.0040

20

MIN.

3

0.5118

0.4961

0.050

Dimensions in Millimeters

(controlling dimensions)

11

BSC

0.419

0.394

0.050

0.016

0° TO 8°

Dwg. MA-008-20 in

0.32

0.23

10.65

10.00

0.51

0.33

2.65

2.35

1

0.10

2

MIN.

3

13.00

12.60

1.27

BSC

NOTES: 1. Exact body and lead configuration at vendor’s option within limits shown.

2. Lead spacing tolerance is non-cumulative.

3. Supplied in standard sticks/tubes of 37 devices or add “TR” to part number for tape and reel.

www.allegromicro.com

1.27

0.40

0° TO 8°

Dwg. MA-008-20 mm

Page 8

6810

10-BIT SERIAL-INPUT,

LATCHED SOURCE DRIVER

The products described here are manufactured under one or more

U.S. patents or U.S. patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such departures from the detail specifications as may be

required to permit improvements in the performance, reliability, or

manufacturability of its products. Before placing an order, the user is

cautioned to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components

in life-support devices or systems without express written approval.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for any infringement of patents or other rights of

third parties which may result from its use.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...