Page 1

4N51, 4N52

67023

4N53, 4N54

HERMETIC , NUMERIC AND HEXADECIMAL

DISPLAYS

OPTOELECTRONIC PRODUCTS

Mii

DIVISION

Features:

Applications:

• Conforms to MIL-PRF-87157

Three character options

•

Numeric, Hexidecimal or Over range

4 X 7 dot matrix character

•

Memory latch/decoder/driver is TTL compatible

•

Available in Red or Green

•

Categorized for luminous intensity

•

High reliability systems

•

• Instrumentation panels

Communication equipment

•

Medical equipment

•

Harsh environments

•

IR blocking filter available

•

DESCRIPTION

The

4N51-4N54

an on-board decoder/driver and memory (except 4N53). These displays are hermetically sealed and conform to MIL-PRF-87157, the

general specification for light emitting diode displays. The character height is 7.4mm (.29”). The green LED version conforms to

MIL-D-87157 with exception of color.

The 4N51 is a numeric display which decodes positive BCD logic into the numbers “0-9”, a “-” sign, a right-hand decimal point, and a

test pattern (all LED’s on).

series are solid state numeric and hexidecimal displays for use in high reliability applications. The displays feature

The 4N52 is the same as the 4N51, but the decimal point is located on the left side of the device.

The 4N53 is an over range device which displays “+1” and a right-hand decimal point. This display is typically driven using external

switching transistors.

The 4N54 is a hexidecimal display which decodes positive BCD logic into 16 characters “0-9, A-F”. An input is provided to blank the

display (all LED’s off) without losing the contents of the memory.

ABSOLUTE MAXIMUM RATINGS

Storage Temperature..........................................................................................................................................-65°C to +125°C

Operating Free-Air Temperature Range. ...........................................................................................................-55°C to +100°C

Lead Solder Temperature (1/16” [1.6mm] below seating plane for 10s) ........................................................................... 260°C

Supply Voltage, V

Voltage Applied to Input Logic, DP and Enable Pins ............................................................................................... . -0.5V to 7V

Voltage Applied to Blanking Input (4N54 only)........................................................................................................... -0.5V to 7V

Forward Current, Each LED (4N53 only) ............................................................................................................................10mA

Reverse Voltage, Each LED (4N53 only).................................................................................................................................4V

(4N51, 4N52, 4N54)................................................................................................................. .-0.5V to 7V

CC

MICROPAC INDUSTRIES, INC. OPTOELECTRONIC PRODUCTS DIVISION • 725 E. Walnut St., Garland, TX 75040 • (972) 272-3571 • Fax (972) 487-6918

www.micropac.com

E-MAIL:

optosales@micropac.com

2 - 4

Page 2

4N51, 4N52,

67023

4N53, 4N54

*

HERMETIC, NUMERIC AND HEXIDECIMAL DISPLAYS

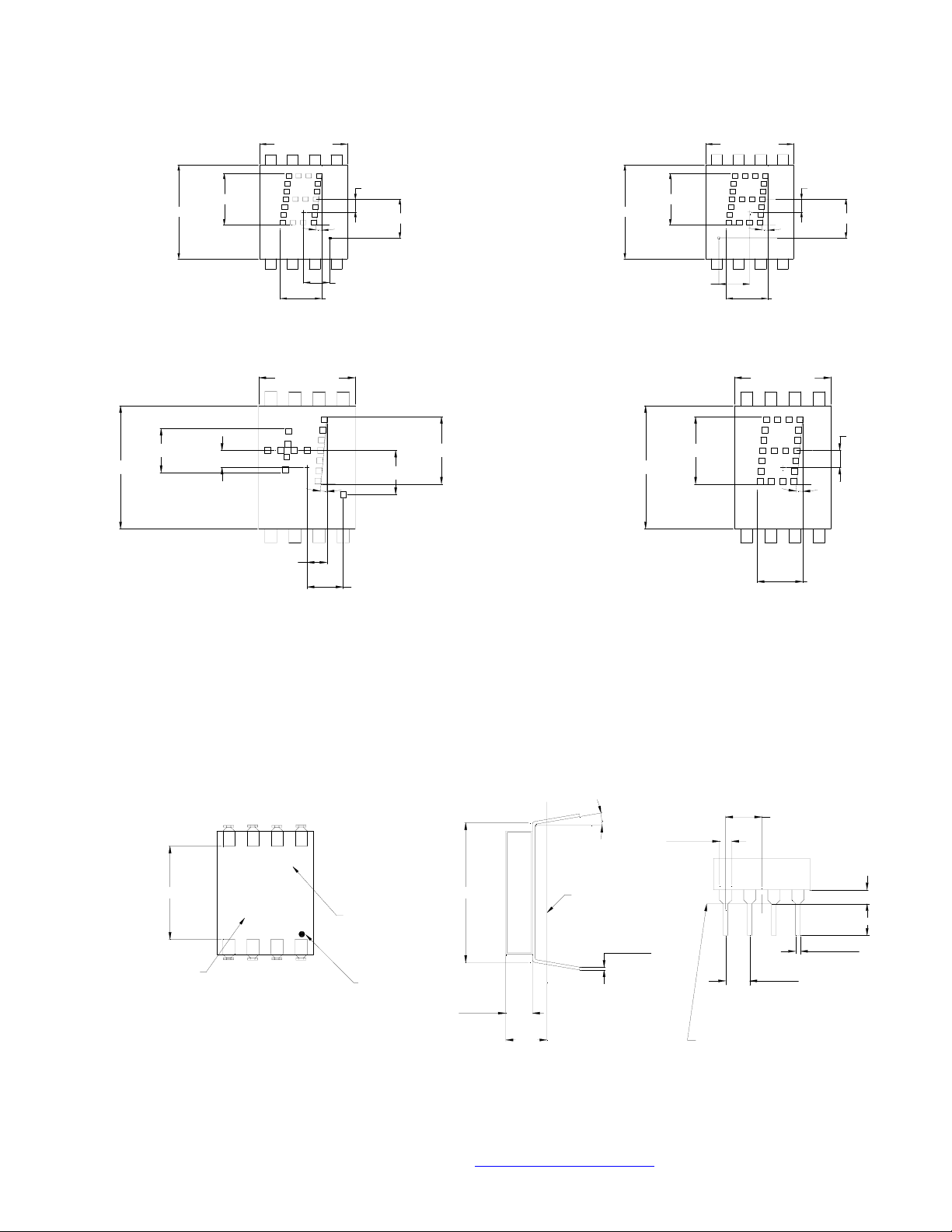

0.190 [4.83]

0.530 [13.46]

0.530 [13.46]

0.290 [7.37]

0.072 [1.84]

0.400 [10.16]

4N51

0.400 [10.16]

5°

0.083 [2.11]

5°

0.120 [3.04]

0.190 [4.83]

0.150 [3.81]

0.0 73 [1 .84]

0.220 [5.59]

0.190 [4.83]

0.290 [7.36]

0.530 [13.46]

0.530 [13.46]

0.290 [7.37]

0.140 [3.56]

0.290 [7.37]

0.400 [10.16]

5°

0.190 [4.83]

4N52

0.400 [10.16]

0.073 [1.84]

0.220 [5.59]

0.073 [1.84]

5°

0.190 [4.83]

0.400 [10.16]

DATE CODE

*JEDEC Registered Data

4N53

REAR VIEW

6

5

X

Mii

XXX

YYWW

4N54

SIDE VIEW

87

LUMINOUS

INTENSITY

CATEGORY

1234

PIN 1 KEY

0.600 [15.24]

0.110

[2.79]

0.170

[4.32]

10°

SEATING PLANE

.012±.003

[0.3±0.08]

TYP

0.050

[1.27]

END VIEW

0.100±.005

[2.5±0.13]

SEATING PLANE

0.150 [3.81]

TYP

0.060 [1.52]

0.136 [3.45]

.020±.003

[0.5±0.08]

TYP

MICROPAC INDUSTRIES, INC. OPTOELECTRONIC PRODUCTS DIVISION • 725 E. Walnut St., Garland, TX 75040 • (972) 272-3571 • Fax (972) 487-6918

www.micropac.com

E-MAIL:

optosales@micropac.com

2 - 5

Page 3

4N51, 4N52,

67023

4N53, 4N54

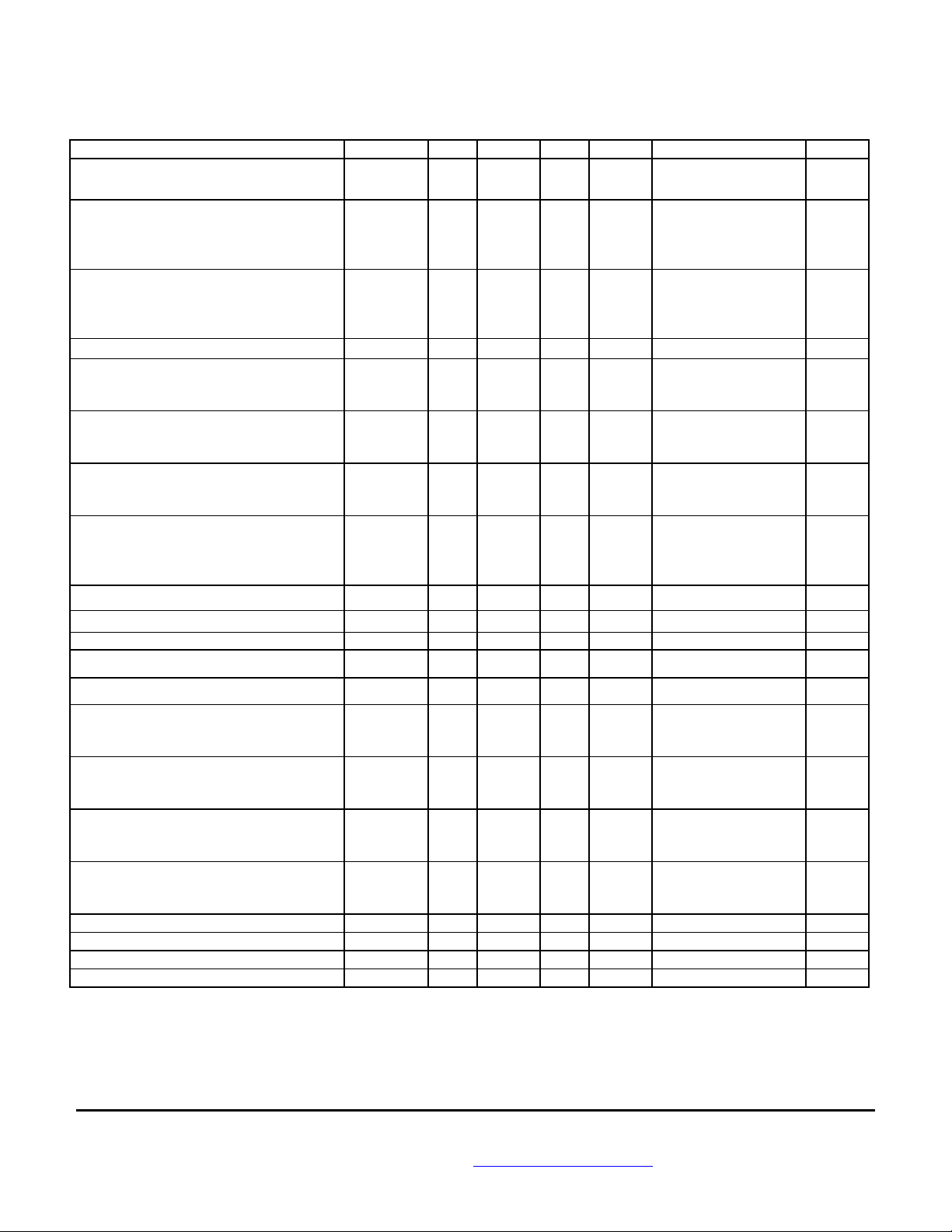

*ELECTRICAL OPTICAL CHARACTERISTICS

TA = -55°C to +100°C unless otherwise specified.

PARAMETER SYMBOL MIN TYP MAX UNITS TEST CONDITIONS NOTE

Supply Current 4N51

Power Dissipation 4N51

4N53

4N54

Luminous Intensity per LED 4N51

4N52

4N53

4N54

Forward Voltage per LED 4N53 V

Logic Low-Level Input Voltage 4N51

4N52

4N54

Logic Low-Level Input Voltage 4N51

4N52

4N54

Enable Low-Voltage; Data Being Entered 4N51

4N52

4N54

Enable High-Voltage; data not being

entered 4N51

4N52

4N54

Blanking Low-Voltage display not blanked 4N54

Blanking High-Voltage display blanked 4N54

Leak Rate ALL 5x10

Blanking Low-Level Input Current 4N54 I

Blanking High-Level Input Current 4N54 I

Logic Low-Level Input Current 4N51

4N52

4N54

Logic High-Level Input Current 4N51

4N52

4N54

Enable Low-Level Input Current 4N51

4N52

4N54

Enable High-Level Input Current 4N51

4N52

4N54

Wavelength at Peak Emission ALL

Dominant Wavelength ALL d 640 t

Forward Voltage per LED 4N53 V

Weight ALL 1 gm

NOTES:

1. All typical values at VCC = 5.0 volts, t

2. Luminous intensity for a specific temperature may be calculated with the following relationship: I

3. The dominant wavelength ,

λ

d

diagram.

For 4N53 test conditions, I

4.

*JEDEC Registered Data

= 10mA, all diodes lit.

F

4N52

4N54

4N52

= 25°C.

A

is a single wavelength that defines the saturated color of monochromatic light, as derived from the CIE chromaticity

I

CC

P

T

I

V

F

V

IL

V

IH

V

EL

V

EH

V

BL

V

BH

BL

BH

I

IL

I

IH

I

EL

I

EH

λ

P

F

HERMETIC, NUMERIC AND HEXIDECIMAL DISPLAYS

112

112

112

560

560

280

560

40

40

45

40

85

85

85

85

1.6 2.0 V I

2

2

2

2

2

2

3.5 V

655 nm t

1.6 2.0 V IF = 10mA

170

170

mA

170

935

935

mW V

320

935

µ

cd

0.8

0.8

VV

0.8

VV

0.8

0.8

VV

0.8

VV

0.8 V

-8

50 mA V

1.0 mA V

-1.6 mA V

+100

µ

AV

-1.6 mA V

+130

µ

AV

(tA) = I

V

V

(25°C) (.985) [t

Numeral 5 and DP lighted

Numeral 5 and DP lighted

V

CC

V

CC

I

F

V

CC

CC

CC

CC

CC

CC

CC

V

= 5.5V

CC

= 5.5V

CC

= 5V, T

= 5V, T

= 10mA,

= 5V, A = 25°C

= 10mA

F

= 4.5V

CC

= 4.5V

CC

= 4.5V

CC

= 4.5V

CC

V

= 4.5V

CC

V

= 4.5V

CC

A

A

A

= 25°C

= 25°C

= 25°C

1

1,4

2

cc/sec

= 5.5V, VBL = 0.8V

= 5.5V, VBH = 4.5V

= 5.5V, VIL = 0.4V

= 5.5V, VIH = 2.4V

= 5.5V, V

= 5.5V, V

= 0.4V

EL

= 2.4V

EH

= 25°C

A

= 25°C3

A

- 25°C].

A

MICROPAC INDUSTRIES, INC. OPTOELECTRONIC PRODUCTS DIVISION • 725 E. Walnut St., Garland, TX 75040 • (972) 272-3571 • Fax (972) 487-6918

www.micropac.com

E-MAIL:

optosales@micropac.com

2 - 6

Page 4

67023

4N51, 4N52,

4N53, 4N54

Supply Voltage 4N51

4N52

4N53

4N54

Operating Temperature ALL t

Enable Pulse Width 4N51

4N52

4N54

Time data must be held before positive 4N51

transition of enable line 4N52

4N54

Time data must be held after positive 4N51

transition of enable line 4N52

4N54

Enable pulse rise time 4N51

4N52

4N54

Forward Current 4N53 I

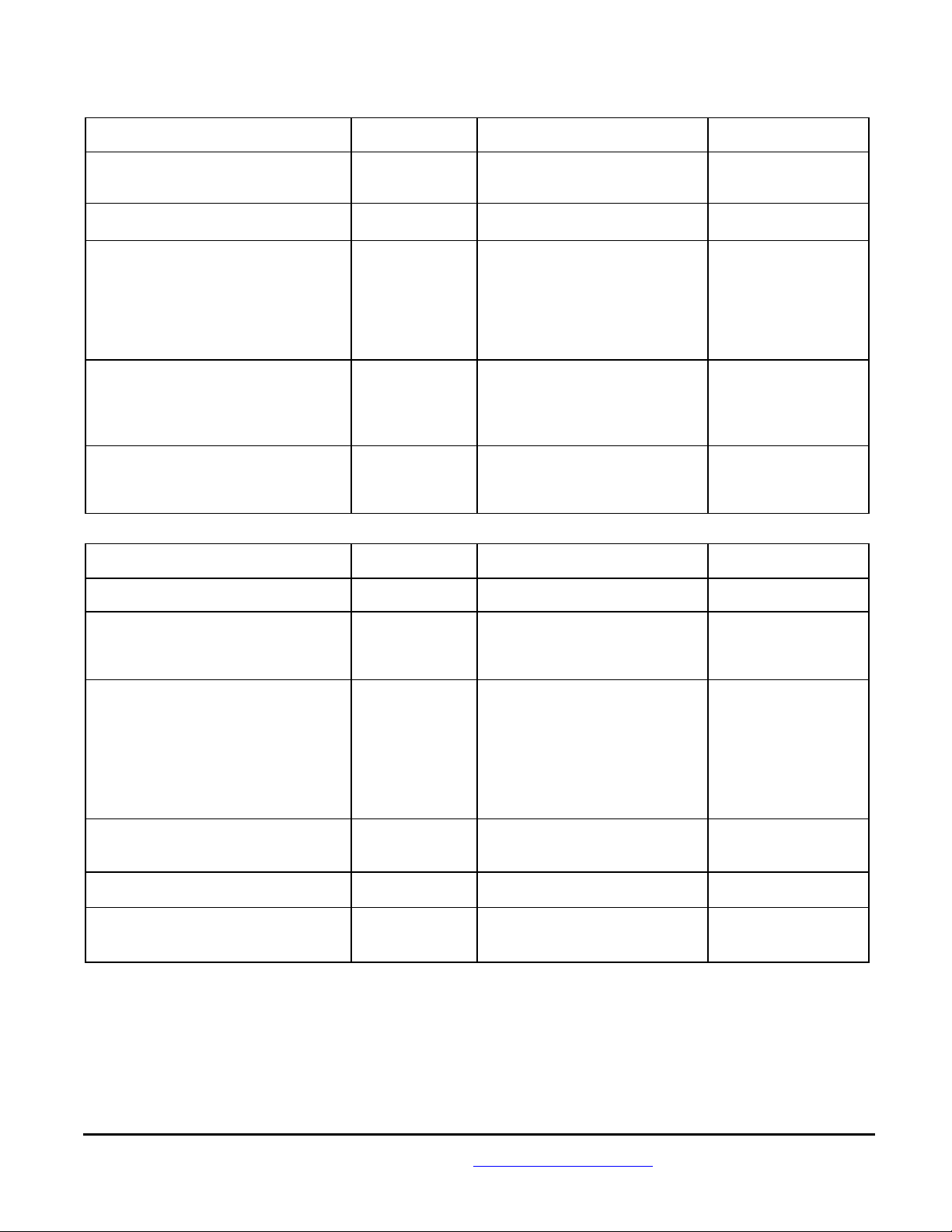

*RECOMMENDED OPERATING CONDITIONS:

PARAMETER SYMBOL MIN MAX UNITS

HERMETIC, NUMERIC AND HEXIDECIMAL DISPLAYS

V

CC

A

t

W

t

SETUP

t

HOLD

t

TLH

F

4.5

4.5

NA

4.5

-55 100

100 ns

50 ns

50 ns

510m

5.5

5.5

NA

5.5

200 ns

NA

V

V

V

°

C

67023-001

67023-101

67023-101C

67023-002

67023-102

67023-102C

67023-003

67023-103

67023-103C

67023-004

67023-104

67023-104C

67023-034

67023-315

NOTES:

1. When ordering DSCC part numbers, you may order by the MII part number or the DSCC part number.

2. The first X at the end of M87157/0010XA[X]X designates lead finish. In place of the X use A for hot solder dip

or C for gold finish.

3. Second X at the end of the M87157/0010XAX[X] designates luminous intensity code. In place of the X use C

thru K to indicate desired intensity level.

4N51 Commercial (0

4N51 Screened to TXV level (-55° to +100°C) with 100% screening.

4N51 marked with DSCC P/N JM87157/00101AXX (-55° to +100°C) with 100% screening.

4N52 Commercial (0

4N52 Screened to TXV level (-55

4N52 marked with DSCC P/N JM87157/00102AXX (-55° to +100°C) with 100% screening.

4N53 Commercial (0

4N53 Screened to TXV level (-55° to +100°C) with 100% screening.

4N53 marked with DSCC P/N JM87157/00103AXX (-55° to +100°C) with 100% screening.

4N54 Commercial (0

4N54 Screened to TXV level (-55° to +100°C) with 100% screening.

4N54 marked with DSCC P/N JM87157/00104AXX (-55° to +100°C) with 100% screening.

4N54, green commercial (0

4N54, green Mil-Temp (-55° to +100°C) with 100% screening.

°

to

70°C)

°

to

70°C)

°

to

70°C)

°

to

70°C)

°

SELECTION GUIDE

°

to +100°C) with 100% screening.

to

70°C)

*JEDEC Registered Data

MICROPAC INDUSTRIES, INC. OPTOELECTRONIC PRODUCTS DIVISION • 725 E. Walnut St., Garland, TX 75040 • (972) 272-3571 • Fax (972) 487-6918

www.micropac.com

E-MAIL:

optosales@micropac.com

2 - 7

Page 5

67023

4N51, 4N52,

4N53, 4N54

4N51, 4N52, 4N54 Logic

HERMETIC, NUMERIC AND HEXIDECIMAL DISPLAYS

1.5V

t

90%

t

HOLD

1.5V

1.5V

LH

LED MATRIX

MATRIX

DECODER

t

PIN NO.

7

5

8

1

2

3

4

CONTROL

4

6

1.5V

SETUP

1.5V

1.5V

DC1

DC2

DC4

DC8

DP

10%

t

W

LATCH

MEMORY

DP

LED MATRIX

DRIVER

DATA INPUT

(LOW LEVEL DATA)

DATA INPUT

(HIGH LEVEL DATA)

ENABLE

INPUT

FIGURE 1 Timing Diagram of 4N51, 4N52 and 4N54 Series Logic

Vcc

ENABLE

LOGIC

INPUT

DP (2)

BLANKING (3)

GROUND

FIGURE 2 Block Diagram of 4N51, 4N52 and 4N54 Series Logic

TRUTH TABLE

(1)

X

1

4N51/4N52

X

2

4

4N54

X

8

BCD DATA

X

LLLL

HLLL

LHLL

HHLL

LLHL

HLHL

LHHL

HHHL

LLLH

HLLH

LHLH

(BLANK)

HHLH

(BLANK)

LLHH

.....

HLHH

(BLANK)

(2)

LHHH

ON

OFF

LOAD DATA

LATCH DATA

DISPLAY ON

DISPLAY OFF

V

DP

V

DP

V

E

V

E

V

B

V

HHHH

DECIMAL PT.

(1)

ENABLE

BLANKING

NOTES:

1. H = Logic High: L = Logic Low. With the

enable input at logic high changes in BCD

input levels or D.P. input have no effect

upon display memory, displayed character,

or D.P.

2. The decmal point, DP, pertains only to

the 4n51 and 4n52 displays.

3. The blanking control, B, pertains only

to the 4n54 hexadecimal display.

Blanking input has no effect upon memory.

(3)

00

11

22

33

44

55

66

77

88

99

A

B

C

D

E

F(BLANK)

=L

=H

=L

=H

=L

=H

B

4N53 Over Range Character

7

Vcc

dp

4

MINUS PLUS

8 1

PIN

1

2

3

4

5

6

7

8

FUNCTION

Plus

Numeral One

Numeral One

DP

Open

Open

Vcc

Minus/Plus

NUMERAL ONE

32

580 100

FIGURE 3

TYPICAL DRIVING CIRCUIT

MICROPAC INDUSTRIES, INC. OPTOELECTRONIC PRODUCTS DIVISION • 725 E. Walnut St., Garland, TX 75040 • (972) 272-3571 • Fax (972) 487-6918

www.micropac.com

E-MAIL:

PLUS

150580 150

TRUTH TABLE FOR TYPICAL DRIVING CIRCUIT

optosales@micropac.com

2 - 8

CHARACTER

+

-

1

DECIMAL POINT

BLANK

PIN

1

2,3X4

H

X

L

X

XX

HX

HXX

LLL

NOTES:

L: Line switching transistor in figure 3 cutoff.

H: Line transistor in figure 3 satuated

X: Don't Care.

8

H

H

X

X

L

Page 6

67023

4N51, 4N52,

4N53, 4N54

HERMETIC, NUMERIC AND HEXIDECIMAL DISPLAYS

PART MARKING SYSTEM

PREFERRED PART NUMBER SYSTEM MII PART NUMBERS

Standard Product With Tables I, II, III and IV Quality Level A TXV

Tables I, II

4N51 M87157/00101XXX 67023-201

67023-101 67023-001

4N52 M87157/00102XXX 67023-202 67023-102 67023-002

4N53 M87157/00103XXX 67023-203 67023-103 67023-003

4N54 M87157/00104XXX 67023-204 67023-104 67023-004

TABLE I

100% SCREENING – CLASS A OF MIL-PRF-87157

Test Screen MIL-PRF-750

Method Conditions

1. Precap Visual 2072

Commercial

Table II, Subgroups I, VII

2. High Temperature Storage 1032

TA = 125°C, Time = 24 hours

3. Temperature Cycling 1051 Condition B, 10 Cycles, 15 Min. Dwell

4. Constant Acceleration 2006

10,000 G’s at Y1 orientation

5. Fine Leak 1071 Condition H

6. Gross Leak 1071 Condition C

7. Interim Electrical / Optical Tests

8. Burn-In

(1,3)

(2)

------

1015

IV, ICC, IBL, IBH, IEL, IEH, IIL, and I

IH

TA = 25°C

Condition B at VCC = 5V and cycle through

logic at 1 character per second.

T

= 100°C, t = 160 hours

A

∆IV = 20%, ∆ICC = ±10 mA, ∆IIH = ±10 µA

and ∆IEH = ±13µA

9. Final Electrical Test

(2)

------ Same as Step 7

10. Delta Determinations ------

11. External Visual

(1)

2009

TABLE II

GROUP A ELECTRICAL TEST – CLASS A OF MIL-PRF-87157

Test Parameters LTPD

Subgroup 1

DC Electrical Test at 25°C

(2)

IV, ICC, IBL, IBH, IEL, IEH, IIL, and IIH and

5

visual function, TA = 25°C

Subgroup 2

DC Electrical Tests at High

Temperature

(2)

Same as Subgroup 1, except delete IV and visual

function. TA = +100°C

7

Subgroup 3

DC Electrical Tests at Low

Temperature

(2)

Same as Subgroup 1, except delete IV and visual

function. TA = -55°C

7

Subgroup 4, 5 and 6 not tested

Subgroup 7

Optical and Functional Tests

Satisfied by Subgroup 1 5

at 25°C.

Subgroup 8

External Visual 7

MICROPAC INDUSTRIES, INC. OPTOELECTRONIC PRODUCTS DIVISION • 725 E. Walnut St., Garland, TX 75040 • (972) 272-3571 • Fax (972) 487-6918

www.micropac.com

E-MAIL:

optosales@micropac.com

2 - 9

Page 7

4N51, 4N52,

67023 4N53, 4N54 HERMETIC, NUMERIC AND HEXIDECIMAL DISPLAYS

GROUP B, CLASS A AND B OF MIL-PRF-87157

Test MIL-PRF-750

Method

Subgroup 1

Resistance to Solvents 1022 4 Devices / 0 Failures

Internal Visual and Mechanical

Subgroup 2

(1,2)

(10)

2075 1 Device / 0 Failures

Solderability 2026

Subgroup 3

Thermal Shock (Temp. Cycle) 1051 Condition B1, 15 Min. Dwell LTPD = 15

Moisture Resistance

(3)

1021

Fine Leak 1071 Condition H

Gross Leak 1071 Condition C

Electrical / Optical Endpoints

Subgroup 4

Operating Life Test (340 hrs.)

Electrical / Optical Endpoints

(4)

(5)

(4)

------

1027

------ Same as Subgroup 3

Subgroup 5

Non-operating (Storage) Life

Test (340 hrs.)

Electrical / Optical Endpoints

(4)

GROUP C, CLASS A AND B OF MIL-PRF-87157

1032

------ Same as Subgroup 3

Test MIL-PRF-750

Method

Subgroup 1

Physical Dimensions 2066 2 Devices / 0 Failures

Subgroup 2

(2, 10)

Lead Integrity 2004 Condition B2

Fine Leak 1071 Condition H

Gross Leak 1071 Condition C

Subgroup 3

Shock 2016 1500G, Time = 0.5 ms, 5 blows in

Vibration, Variable Frequency 2056

Constant Acceleration 2006

External Visual

Electrical / Optical Endpoints

Subgroup 4

Salt Atmosphere 1041 LTPD = 15

External Visual

Subgroup 5

Bond Strength

Subgroup 6 LTPD = 10

Operating Life Test

Electrical / Optical Endpoints

NOTES: 1. Whenever electrical/optical tests are not required as endpoints, electrical rejects may be used.

2. The LTPD applies to the number of leads inspected, except in no case shall less than 3 displays be used to provide the number of leads required.

3. Initial conditioning should be a 15” bend inward one cycle.

4. Limits and conditions are per the electrical/optical characteristics.

5. Burn-in for the over range shall use Condition B at a nominal I

6. Solderability samples shall not be used.

7. Visual requirements shall be as specified in MIL-PRF-883, Methods 1010 or 1011.

8. Displays may be selected prior to seal.

9. If a given inspection lot, undergoing Group B inspection, has been selected to satisfy the Group C inspection requirements, the 340 hour life tests may

be continued on test to 1000 hours in order to satisfy the Group C Life Test requirements. In such cases, either the 340 hour endpoint measurements

shall be made a basis for Group B lot acceptance or the 1000 hour endpoint measurement shall be used as the basis for both Group B and Group C

acceptance.

10. MIL-PRF-883 test method applies.

MICROPAC INDUSTRIES, INC. OPTOELECTRONIC PRODUCTS DIVISION • 725 E. Walnut St., Garland, TX 75040 • (972) 272-3571 • Fax (972) 487-6918

(1,6)

(7)

(4)

(7)

(8)

(9)

(4)

www.micropac.com

1010 or 1011

------

1010 or 1011

2037 Condition A LTPD = 20 (c = 0)

1026

------ Same as Subgroup 3

TABLE III

Conditions Sample Size

TA = 245°C for 5 seconds

IV, ICC, IBL, IBH, IEL, IEH, IIL, I

visual function. TA = 25°C

TA = 100°C, at VCC = 5.0V and

cycling through logic at 1 character

per second.

TA = 125°C

TABLE IV

Conditions Sample Size

each orientation X

10,000G at Y1 orientation

IV, ICC, IBL, IBH, IEL, IEH, IIL, I

visual function. TA = 25°C

TA = +100°C 1000 HRS

= 8 mA with “+1” illuminated for t=340 hours.

F

E-MAIL:

optosales@micropac.com

, Y1, Z

1

LTPD = 15

and

IH

LTPD = 10

LTPD = 10

LTPD = 15

LTPD = 15

1

and

IH

2 - 10

Loading...

Loading...