Datasheet 54RHSCT630CC, 54RHSCT630CB, 54QHSCT630FS, 54QHSCT630FL, 54QHSCT630FE Datasheet (DYNEX)

...Page 1

54HSC/T630

1/10

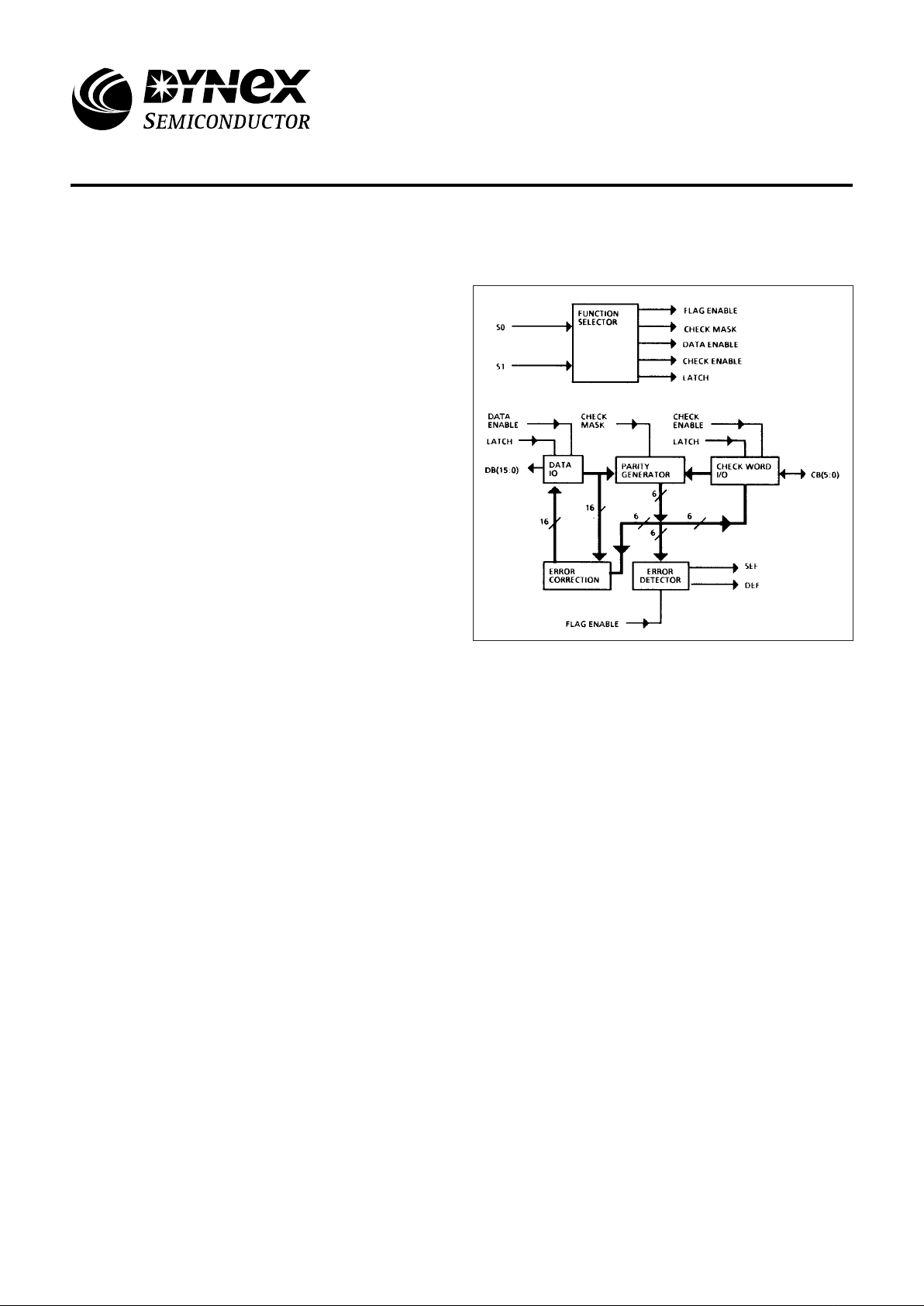

The 54HSC/T630 is a 16-bit parallel Error Detection and

Correction circuit. It uses a modified Hamming code to

generate a 6-bit check word from each 16-bit data word. The

check word is stored with the data word during a memory write

cycle. During a memory read cycle a 22-bit word is taken from

memory and checked for errors.

Single bit errors in data words are flagged and corrected.

Single bit errors in check words are flagged but not corrected.

The position of the incorrect bit is pinpointed, in both cases, by

the 6-bit error syndrome code which is output during the error

correction cycle.

Two bit errors are flagged but not corrected. Any

combination of two bit errors occurring within the 22-bit word

read from memory, (ie two errors in the 16-bit data word, two

bits in the 16-bit check word or one error in each) will be

correctly identified.

The gross errors of all bits, low or high, will be detected.

The control signals S1 and S0 select the function to be

performed by the EDAC They control the generation of check

words and the latching and correction of data (see table 1)

When errors are detected, flags are placed on outputs SEF

and DEF (see table 2).

Figure 1: Block Diagram

FEATURES

■ Radiation Hard:

Dose Rate Upset Exceeding 3x10

10

Rad(Si)/sec

Total Dose for Functionality Upto 1x106 Rad(Si)

■ High SEU Immunity, Latch Up Free

■ CMOS-SOS Technology

■ All Inputs and Outputs Fully TTL Compatible (54HST630)

or CMOS Compatible (54HSC630)

■ Low Power

■ Detects and Corrects Single-Bit Errors

■ Detects and Flags Dual-Bit Errors

■ High Speed:

Write Cycle - Generates Checkword In 40ns Typical

Read Cycle - Flags Errors In 20ns Typical

54HSC/T630

Radiation hard 16-Bit ParallelError

Detection & Correction

Replaces June 1999 version, DS3595-4.0 DS3595-5.0 January 2000

Page 2

54HSC/T630

2/10

Table 1: Control Functions

Control Error Flags

Cycle S1 S0 EDAC Function Data UO Checkword SEF DEF

WRITE Low Low Generates Checkword Input Data Output Checkword Low Low

READ Low High Read Data BCheckword Input Data Input Checkword Low Low

READ High High Latch & Flag Error Latch Data Latch Checkword Enabled Enabled

READ High Low Correct Data Word & Output Output Syndrome Bits Enabled Enabled

Generate Syndrome Bits Corrected

Data

Table 2: Error Functions

Total Number of Errors Error Flags Data Correction

16-bit Data 6-bit Checkword SEF DEF

0 0 Low Low Not Applicable

1 0 High Low Correctlon

0 1 High Low Correction

1 1 High High Interrupt

2 0 High High Interrupt

0 2 High High Interrupt

ERROR DETECTION & CORRECTION

During a memory write cycle, six check bits (CBO-CB5)

are generated by eight-input parity generators using the data

bits defined in Table 3. During a memory read cycle, the 6-bit

checkword is retrieved along with the actual data.

Error detection is accomplished as the 6-bit checkword and

the 16-bit data word from memory are applied to internal parity

generators/checkers. If the parity of all six groupings of data

and check bits are correct, it is assumed that no error has

occurred and both error flags will be low. It should be noted

that the sense of two of the check bits, bits CBO and CB1, is

inverted to ensure that the gross-error condition of all lows and

all highs is detected.

If the parity of one or more of the check groups is incorrect,

an error has occurred and the proper error flag or flags will be

set high. Any single error in the 16bit data word will change the

sense of exactly three bits of the 6-bit checkword. Any single

error in the 6bit checkword changes the sense of only that one

bit. In either case, the single error flag will be set high while the

dual error flag will remain low.

Any two-bit error will change the sense of an even number

of check bits. The two-bit error is not correctable since the

parity tree can only identify singlebit errors. Both error flags are

set high when any two-bit error is detected.

Three or more simultaneous bit errors cause the EDAC to

transmit that no error, a correctable error, or an uncorrectable

error has occurred and hence produce erroneous results in all

three cases.

Error correction is accomplished by identifying the bad bit

and inverting it. Identification of the erroneous bit is achieved

by comparing the 16-bit word and 6-bit checkword from

memory with the new checkword with one (checkword error)

or three (data word error) inverted bits.

As the corrected word is made available on the data word l/

O port, the checkword l/O port presents a 6-bit syndrome error

code. This syndrome code can be used to identify the

corrupted bit in memory (see Table 4. overleaf).

Page 3

54HSC/T630

3/10

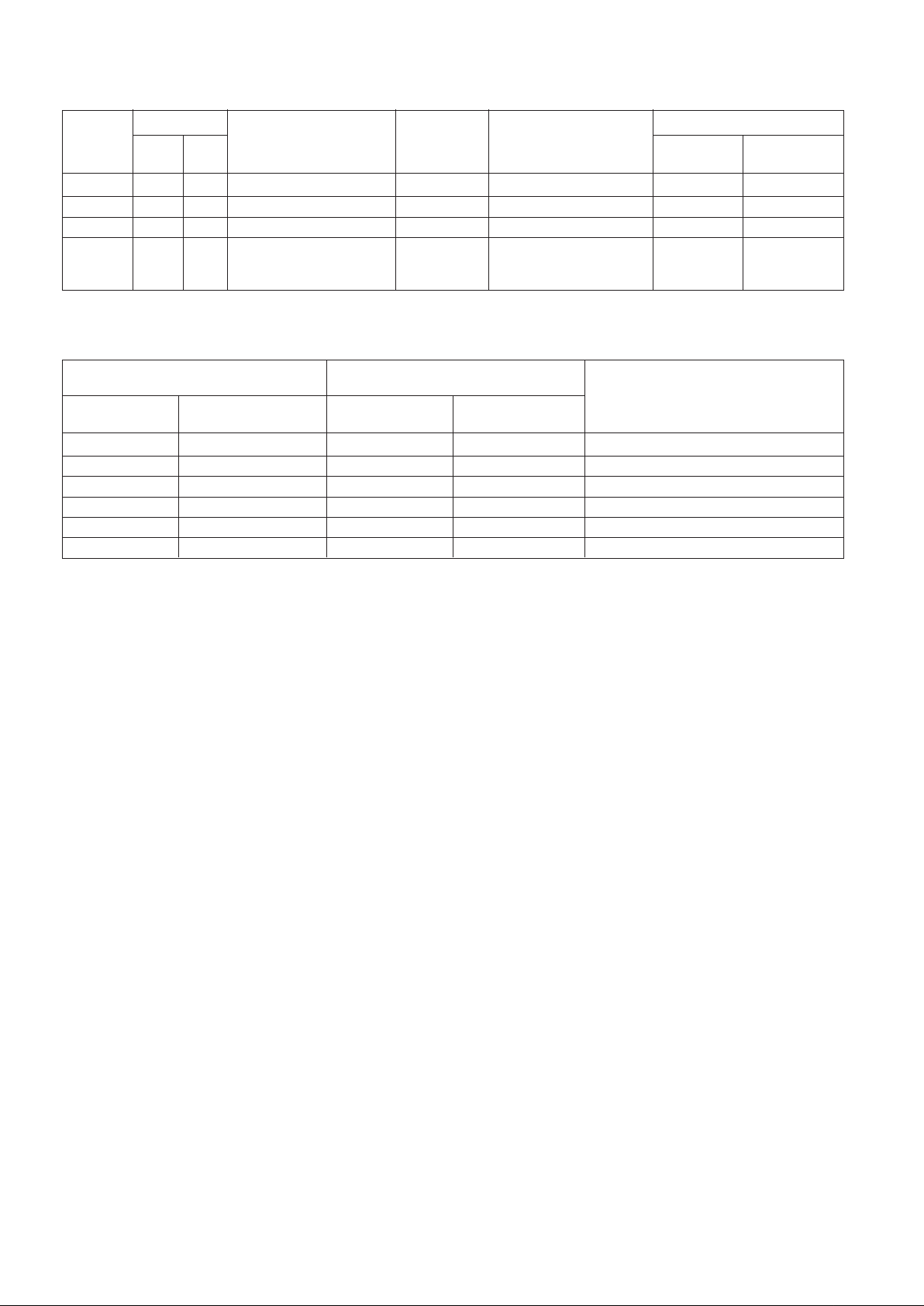

14

X

X

X

13

X

X

X

12

X

X

X

11

X

X

X

10

X

X

X

9

X

X

X

8

X

X

X

16-bit Data Word

Checkword

Bit

CB0

CB1

CB2

CB3

CB4

CB5

2

X

X

X

15

X

X

X

7

X

X

X

6

X

X

X

5

X

X

X

4

X

X

X

1

X

X

X

3

X

X

X

0

X

X

X

The six check bits are partly bits derived from the matrix of data bits as indicated by 'X' for each bit.

Table 3: Check Word Generation

Error Location

DB15

H

H

L

H

L

L

CB0

L

H

H

H

H

H

CB1

H

L

H

H

H

H

CB2

H

H

L

H

H

H

CB3

H

H

H

L

H

H

CB4

H

H

H

H

L

H

CB5

H

H

H

H

H

L

No

Error

H

H

H

H

H

H

DB0

L

L

H

L

H

H

DB1

L

H

L

L

H

H

DB2

H

L

L

L

H

H

DB3

L

L

H

H

L

H

DB4

L

H

L

H

L

H

DB5

H

L

L

H

L

H

DB6

H

L

H

L

L

H

DB7

H

H

L

L

L

H

DB8

L

L

H

H

H

L

DB9

L

H

L

H

H

L

DB10

L

H

H

L

H

L

DB11

H

L

H

L

H

L

DB12

H

H

L

L

H

L

DB13

L

H

H

H

L

L

DB14

H

L

H

H

L

L

Syndrome

Error

Code

CB0

CB1

CB2

CB3

CB4

CB5

Table 4: Error Syndrome Codes

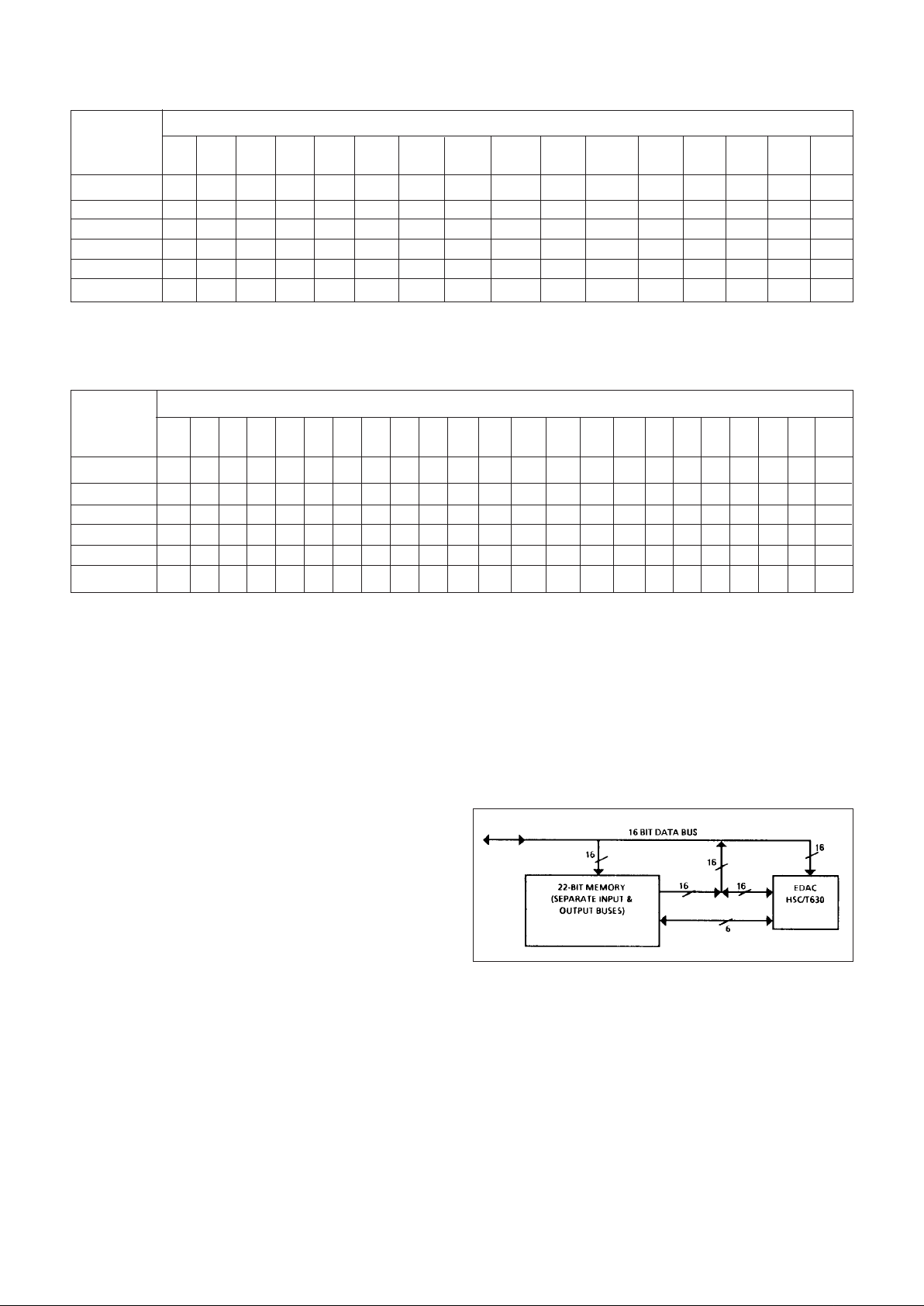

APPLICATIONS

Although many semiconductor memories have separate

input and output pins, it is possible to design the error

detection and correction function using a single EDAC. EDAC

data and check bit pins function as inputs or outputs

dependent upon the state of control signals S0 and S1. It

becomes necessary to use wired AND logic, with fairly

complex timing system, to control the EDAC and data bus.

This scheme becomes difficult to implement both in terms of

board layout and timing. System performance is also

adversely affected, See Figure 2.

Optimised systems can be implemented using two EDAC’s

in parallel, One of the units is used strictly as an encoder

during the memory write cycle. Both controls S0 and Sl are

grounded, The encoder chip will generate the 6-bit check word

for memory storage along with the 16-bit data.

The second of the two EDAC’s will be used as a decoder

during the memory read cycle. This decoder chip requires

timing pulses for correct operation. Control S1 is set low and

S0 high as the memory read cycle begins. After the memory

output data is valid, the control S1 input is moved from the low

to a high. This low-to-high transition latches the 22-bit word

from memory into internal registers of this second EDAC and

enables the two error flags. If no error occurs, the CPU can

accept the 16-bit word directly from memory. If a single error

has occurred, the CPU must move the control SO input from

the high to a low to output corrected data and the error

syndrome bits. Any dual error should be an interrupt condition.

In most applications, status registers will be used to keep

tabs on error flags and error syndrome bits. If repeated

patterns of error flags and syndrome bits occur, the CPU will

be able to recognize these symptoms as a “hard” error. The

syndrome bits can be used to pinpoint the faulty memory chip,

See Figure 3.

Figure 2: Error Detection and Correction Using a

Single EDAC Unit

Page 4

54HSC/T630

4/10

Figure 3: Error Detection and Correction Using Two EDAC Units

S1 S0 Function

L H Start READ

H H Latch data & flag errors

H L Correct data & Output syndrome bits

DC CHARACTERISTICS AND RATINGS

Parameter Min Max Units

Supply Voltage -0.5 7 V

Input Voltage V

SS

-0.3 VDD+0.3 V

Current Through Any Pin -20 +20 mA

Operating Temperature -55 125 °C

Storage Temperature -65 150 °C

Note: Stresses above those listed may cause permanent

damage to the device. This is a stress rating only and

functional operation of the device at these conditions, or at

any other condition above those indicated in the operations

section of this specification, is not implied. Exposure to

absolute maximum rating conditions for extended periods

may affect device reliability.

Table 5: Absolute Maximum Ratings

Subgroup Definition

1 Static characteristics specified in Table 6 at +25°C

2 Static characteristics specified in Table 6 at +125°C

3 Static characteristics specified in Table 6 at -55°C

9 Switching characteristics specified in Table 7 at +25°C

10 Switching characteristics specified in Table 7 at +125°C

11 Switching characteristics specified in Table 7 at -55°C

DEFINITION OF SUBGROUPS

Page 5

54HSC/T630

5/10

Total dose radiation not

exceeding 3x105 Rad(SI)

Symbol Parameter Conditions Min Typ Max Units

V

DD

Supply Voltage - 4.5 5.0 5.5 V

V

IH1

TTL Input High Voltage - 2.0 - - V

V

IL1

TTL Input Low Voltage - - - 0.8 V

V

IH2

CMOS Input High Voltage - 3.5 - - V

V

IL2

CMOS Input Low Voltage - - - 1.5 V

V

OH1

TTL Output High Voltage IOH = -4mA 2.4 - - V

V

OL1

TTL Output Low Voltage IOL = 12mA (CB or DB), - - 0.4 V

IOL = 4mA (SEF or DEF)

V

OH2

CMOS Output High Voltage IOH = -4mA VDD-0.5 - - V

V

OL2

CMOS Output Low Voltage IOL = 12mA (CB or DB), - - 0.5 V

I

OL

= 4mA (SEF or DEF)

I

1L

Input Low Current VDD = 5.5, VIN = V

SS

- - -10 µA

I

1H

Input High Current VDD = 5.5, VIN = V

DD

--50µA

I2LIO Low Current VDD = 5.5, VIN = V

SS

- - -50 µA

I

2H

IO High Current VDD = 5.5, VIN = V

DD

--50µA

IDDPower Supply Current VDD = Max, S0 & S1 at - - 1 mA

5.5V, All CB & DB pins

grounded, DEF & SEF

open

VDD = 5V±10%, over full operating temperature range.

Mil-Std-883, method 5005, subgroups 1, 2, 3

Parameters at higher radiation levels available on request.

Table 6: Electrical Characteristics

Parameter

t

PLH

Propogation delay time, low-to-high-level output (Note 4)

t

PLH

Propogation delay time, low-to-high-level output (Note 4)

t

PLH

Propogation delay time, low-to-high-level output (Note 5)

t

PLH

Propogation delay time, low-to-high-level output (Note 5)

t

PZH

Output enable time to high level (Note 6)

t

PZL

Output enable time to low level (Note 6)

t

PHZ

Output disable time to high level (Note 7)

t

PLZ

Output disable time to low level (Note 7)

tS Set-up time to S1 ›

tH Hold time after S1 ›

1. VDD = 5V ±10% and CL = 50pF, over full operating temperature and total dose = 300K Rad(Si)

2. Input Pulse VSS to 3.0 Volts.(TTL), VDD -1V (CMOS).

3. Times Measurement Reference Level 1.5 Volts.

4. These parameters describe the time intervals taken to generate the check word during the memory write cycle.

5. These parameters describe the time intervals taken to flag errors during memory read cycle.

6. These parameters describe the time intervals taken to correct and output the data word and to generate and output the syndrome error code during

the memory read cycle.

7. These parameters describe the time intervals taken to disable the CB & DB buses in preparation for a new data word during the memory read cycle.

8. Mil-Std-883, method 5005, subgroups 9, 10, 11

9.

Parameters at higher radiation levels available on request.

From

(Input)

DB

DB

S1 ⇑

S1 ⇑

S0 ⇓

S0 ⇓

S0 ⇑

S0 ⇑

CB, DB

CB, DB

To

(Output)

CB

CB

DEF

SEF

CB, DB

CB, DB

CB, DB

CB, DB

-

-

Min.

-

-

-

-

-

-

-

30

15

Max.

58

58

29

29

40

45

45

65

-

-

Units

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

Conditions (HST)

S0 = 0V, S1 = 0V

S0 = 0V, S1 = 0V

S0 = 3V

S0 = 3V

S1 = 3V (fig. 5)

S1 = 3V (fig. 4)

S1 = 3V (fig. 5)

S1 = 3V (fig. 4)

-

-

Conditions (HSC)

S0 = 0V, S1 = 0V

S0 = 0V, S1 = 0V

S0 = V

DD

-1V

S0 = VDD-1V

S1 = VDD-1V (fig. 5)

S1 = VDD-1V (fig. 4)

S1 = VDD-1V (fig. 5)

S1 = V

DD

-1V (fig. 4)

-

-

AC ELECTRICAL CHARACTERISTICS

Table 7: AC Electrical Characteristics

Page 6

54HSC/T630

6/10

Figure 4: Output Load Circuit Figure 5: Output Load Circuit

Figure 6: Read, Flag and Correct, Made Switching Waveforms

(Note 6)

(Note 6)

(Note 5)

(Note 5)

(Note 7)

(Note 7)

t

s

Page 7

54HSC/T630

7/10

PIN ASSIGNMENTS

Figure 7: 28-Lead Ceramic DIL (Solder Seal)

- Package Style C

Figure 8: 28-Lead Flatpack (Solder Seal) - Package Style F

PACKAGE OUTLINES

Figure 9: 28-Lead Ceramic DIL (Solder Seal) - Package Style C

D

W

A

e b Z

H

A

1

15°

M

E

C

e

1

Seating Plane

114

2815

Ref

Millimetres Inches

Min. Nom. Max. Min. Nom. Max.

A - - 5.715 - - 0.225

A1 0.38 - 1.53 0.015 - 0.060

b 0.35 - 0.59 0.014 - 0.023

c 0.20 - 0.36 0.008 - 0.014

D - - 36.02 - - 1.418

e - 2.54 Typ. - - 0.100 Typ. -

e1 - 15.24 Typ. - - 0.600 Typ. -

H 4.71 - 5.38 0.185 - 0.212

Me - - 15.90 - - 0.626

Z - - 1.27 - - 0.050

W - - 1.53 - - 0.060

XG404

Page 8

54HSC/T630

8/10

Ref

Millimetres Inches

Min. Nom. Max. Min. Nom. Max.

A - - 2.97 - - 0.117

b 0.38 - 0.48 0.015 - 0.019

c 0.076 - 0.152 0.003 - 0.006

D 18.08 - 18.49 0.712 - 0.728

E 12.50 - 12.90 0.492 - 0.508

E2 9.45 - 9.85 0.372 - 0.388

e 1.14 - 1.40 0.045 - 0.055

L 8.00 - 9.27 0.315 - 0.365

Q 0.66 - - 0.026 - -

S - - 1.14 - - 0.045

XG543

Figure 10: 28-Lead Ceramic Flatpack (Solder Seal) - Package Style F

E

b

e

D

L

A

Q

c

Pin 1

S

E2

Page 9

54HSC/T630

9/10

RADIATION TOLERANCE

Total Dose Radiation Testing

For product procured to guaranteed total dose radiation

levels, each wafer lot will be approved when all sample

devices from each lot pass the total dose radiation test.

The sample devices will be subjected to the total dose

radiation level (Cobalt-60 Source), defined by the ordering

code, and must continue to meet the electrical parameters

specified in the data sheet. Electrical tests, pre and post

irradiation, will be read and recorded.

GEC Plessey Semiconductors can provide radiation

testing compliant with Mil-Std-883 method 1019 Ionizing

Radiation (total dose) test.

ORDERING INFORMATION

For details of reliability, QA/QC, test and assembly

options, see ‘Manufacturing Capability and Quality

Assurance Standards’ Section 9.

Unique Circuit Designator

‘Blank’

R

Q

H *

No tolerance implied

100 kRads (Si) Guaranteed

300 kRads (Si) Guaranteed

1000 kRads (Si) Guaranteed

*HSC Onl

y

Radiation Tolerance

CFCeramic DIL (Solder Seal)

Flatpack (Solder Seal)

Package Type

QA/QCI Process

(See Section 9 Part 4)

Test Process

(See Section 9 Part 3)

Assembly Process

(See Section 9 Part 2)

L

C

D

E

B

S

Rel 0

Rel 1

Rel 2

Rel 3/4/5/STACK

Class B

Class S

Reliability Level

54xHSC/T630xxxxx

Total Dose (Function to specification)* 3x105 Rad(Si)

Transient Upset (Stored data loss) 5x1010 Rad(Si)/sec

Transient Upset (Survivability) >1x10

12

Rad(Si)/sec

Neutron Hardness (Function to specification) >1x1015 n/cm

2

Single Event Upset** <1x10

-10

Errors/bit day

Latch Up Not possible

* Other total dose radiation levels available on request

** Worst case galactic cosmic ray upset - interplanetary/high altitude orbit

Figure 11: Radiation Hardness Parameters

Page 10

54HSC/T630

10/10

CUSTOMER SERVICE CENTRES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

North America Tel: 011-800-5554-5554. Fax: 011-800-5444-5444

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

SALES OFFICES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

Germany Tel: 07351 827723

North America Tel: (613) 723-7035. Fax: (613) 723-1518. Toll Free: 1.888.33.DYNEX (39639) /

Tel: (831) 440-1988. Fax: (831) 440-1989 / Tel: (949) 733-3005. Fax: (949) 733-2986.

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

These offices are supported by Representatives and Distributors in many countries world-wide.

© Dynex Semiconductor 2000 Publication No. DSxxxx-y Issue No. x.x January 2000

TECHNICAL DOCUMENTATION – NOT FOR RESALE. PRINTED IN UNITED KINGDOM

HEADQUARTERS OPERATIONS

DYNEX SEMICONDUCTOR LTD

Doddington Road, Lincoln.

Lincolnshire. LN6 3LF. United Kingdom.

Tel: 00-44-(0)1522-500500

Fax: 00-44-(0)1522-500550

DYNEX POWER INC.

Unit 7 - 58 Antares Drive,

Nepean, Ontario, Canada K2E 7W6.

Tel: 613.723.7035

Fax: 613.723.1518

Toll Free: 1.888.33.DYNEX (39639)

This publication is issued to provide information only which (unless agreed by the Company in writing) may not be used, applied or reproduced for any purpose nor form part of any order or contract nor to be regarded

as a representation relating to the products or services concerned. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or service. The Company

reserves the right to alter without prior notice the specification, design or price of any product or service. Information concerning possible methods of use is provided as a guide only and does not constitute any

guarantee that such methods of use will be satisfactory in a specific piece of equipment. It is the user's responsibility to fully determine the performance and suitability of any equipment using such information and

to ensure that any publication or data used is up to date and has not been superseded. These products are not suitable for use in any medical products whose failure to perform may result in significant injury

or death to the user. All products and materials are sold and services provided subject to the Company's conditions of sale, which are available on request.

All brand names and product names used in this publication are trademarks, registered trademarks or trade names of their respective owners.

http://www.dynexsemi.com

e-mail: power_solutions@dynexsemi.com

Datasheet Annotations:

Dynex Semiconductor annotate datasheets in the top right hard corner of the front page, to indicate product status. The annotations are as follows:-

Target Information: This is the most tentative form of information and represents a very preliminary specification. No actual design work on the product has been started.

Preliminary Information: The product is in design and development. The datasheet represents the product as it is understood but details may change.

Advance Information: The product design is complete and final characterisation for volume production is well in hand.

No Annotation: The product parameters are fixed and the product is available to datasheet specification.

Loading...

Loading...