Datasheet 48IMS6-1515-9, 48IMS6-15-9, 48IMS6-1212-9, 48IMS6-12-9, 48IMS6-0505-9 Datasheet (Power-one)

...Page 1

Industrial Environment DC/DC Converters < 40W IMS6 Series

6 Watt SMD and through hole IMS 6 Series

DC/DC converters

Input to output electric strength test up to 2 kV DC

Input voltage ranges:

18...36 and 36...75 V DC

Single and dual outputs of 5, 12, 15 V DC

• Wide input voltage ranges

• Electrical isolation, single and dual outputs

• Immunity to IEC/EN 61000-4-2, -3, -4, -5 and -6

• High efficiency (typ. 82%)

• Flex power: flexible load distribution

• No load and short-circuit proof

• High reliability and no derating

• Operating ambient temperature –40...+ 71 C

• Industrial, alternative and SMD pinout

• DIL 24 case with 9.0 mm profile

Safety approvals pending to IEC/EN 60950, UL 1950

LGA

C

o

Summary

The IMS 6 series of board mountable 6 W DC-DC converters has been designed according to the latest industry requirements and standards. The converters are particularly

suitable for use in mobile or stationary applications in transport, industry or telecommunications where variable input

voltages or high transient voltages are prevalent.

Covering a total input voltage range from 18 V DC up to

75 V DC.

The converters are designed and built according to the

international safety standards IEC/EN 60950, UL 1950,

CAN/CSA C22.2 No.950-95 and are LGA and UL marked.

A special feature is their small case size, DIL 24 with only

9.0 mm profile. The circuit comprises integrated planar

magnetics and all components are automatically assembled and solidly soldered onto a single PCB without any

wire connections. Thanks to the rigid mechanical design the

units withstand an extremely high level of shock and vibrations. Careful considerations of possible thermal stresses

ensure the absence of hot spots providing long life in environments where temperature cycles are a reality. The thermal design allows operation at full load up to an ambient

temperature of 71C in free air without using any potting

material.

Options : SMD pinout or K-pinout, an alternative to the

standard industrial pinout, provide a high level of application specific engineering and design-in flexibility.

Table of Contents Page

Summary .......................................................................... 1

Type Survey and Key Data .............................................. 2

Type Key .......................................................................... 2

Functional Description...................................................... 3

Electrical Input Data ......................................................... 4

Electrical Output Data ...................................................... 6

Page

Electromagnetic Compatibility (EMC) .............................. 8

Mechanical Data .............................................................. 9

Immunity to Environmental Conditions........................... 10

Safety and Installation Instructions ................................ 11

Description of Options .................................................... 13

Edition 1 06.00

Page 2

Industrial Environment DC/DC Converters < 40W IMS6 Series

Type Survey and Key Data

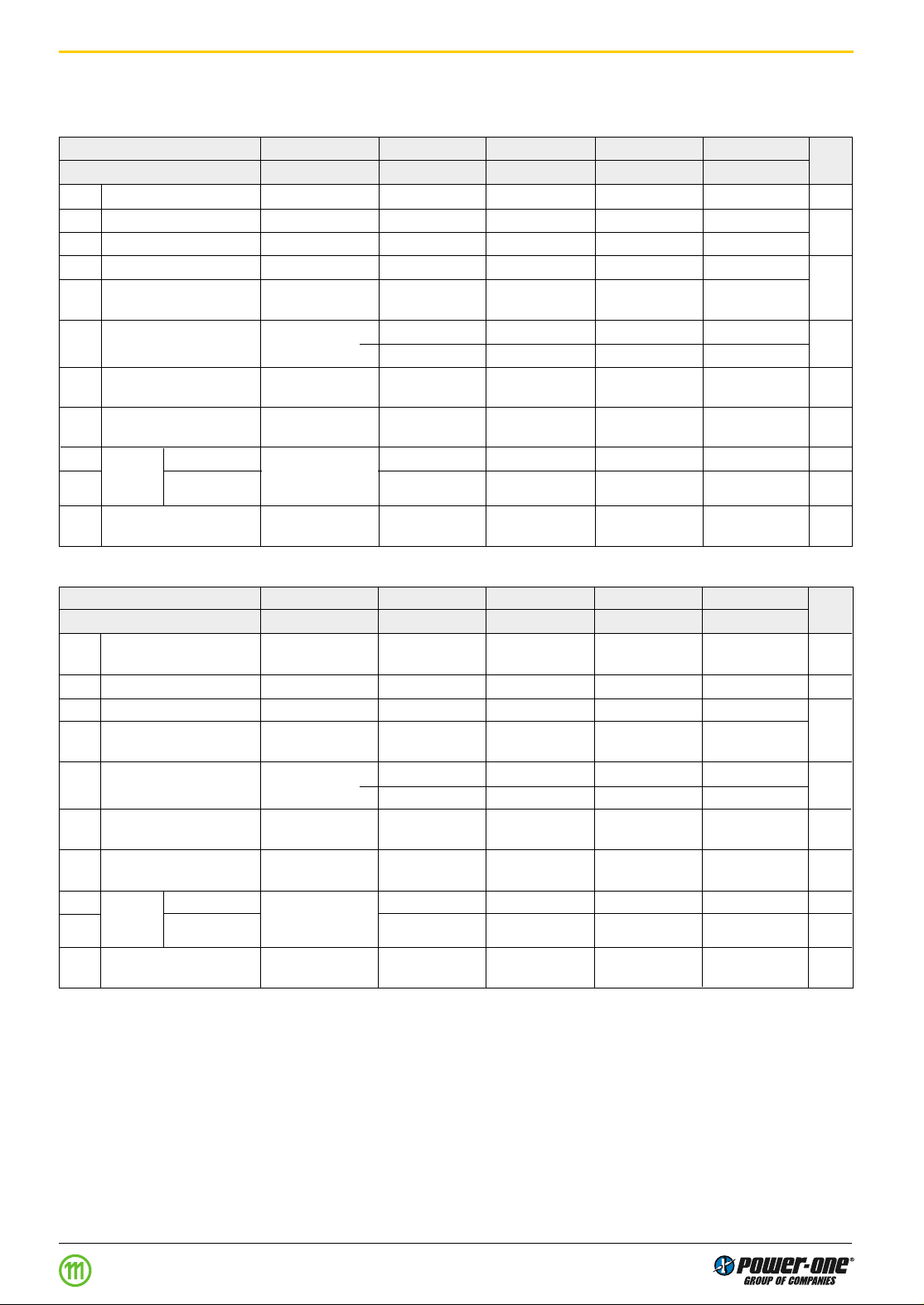

Table 1: Type survey

Output 1 Output 2 Output Power Input voltage Efficiency Type Options

U

o1 nomIo1 nomUo2 nomIo2 nom

[V DC] [A] 1[V DC] [A]

5 1000 - - 5.0

5 1000 - - 5.0 36...75 82 48IMS6-05-9

12 500 - - 6.0 18...36 83 24IMS6-12-9

12 500 - - 6.0 36...75 83 48IMS6-12-9

15 400 - - 6.0 18...36 84 24IMS6-15-9

15 400 - - 6.0 36...75 84 48IMS6-15-9

5 500 5 500 6.0 18...36 82 24IMS6-0505-9

5 500 5 500 6.0 36...75 82 48IMS6-0505-9

12 250 12 250 6.0 18...36 83 24IMS6-1212-9

12 250 12 250 6.0 36...75 83 48IMS6-1212-9

15 200 15 200 6.0 18...36 84 24IMS6-1515-9

15 200 15 200 6.0 36...75 84 48IMS6-1515-9

1

Flexible load distribution on double outputs possible to 75% , 25% asymetric loading.

1

P

o nom

[W] [V DC] [%]

range

18...36

typ

82 24IMS6-05-9

designation

M, K, Z

M, K, Z

M, K, Z

M, K, Z

M, K, Z

M, K, Z

M, K, Z

M, K, Z

M, K, Z

M, K, Z

M, K, Z

M, K, Z

Type Key

48 IMS 6 - 05 05 -9 K M Z

Input voltage range

U

i

16...36 V DC ............................................. 24

36...75 V DC ........................................... 48

Series ........................................................................IMS 6

Output voltage type for output 1 .................... ..... 05, 12, 15

Output voltage type for output 2 ......................... 05, 12, 15

Operating ambient temperature range

T

A

–40...71C .................................................. -9

Options: Alternative pinout ......................................... K

SMD-pinout

Open frame

1

Option M excludes option K and vice versa

.................................................

.................................................

2

For delivery lead times contact factory

1 2

1 2

1 2

M

Z

. Some types require a minimum order quantity

.

Edition 1 06.00

Page 3

Industrial Environment DC/DC Converters < 40W IMS6 Series

Functional Description

The IMS 6 DC-DC modules are feedback controlled flyback

converters using current mode PWM (Pulse Width Modulation).

The converter input is protected against transients by

means of a suppressor diode.

The output voltage is monitored by a separate transformer

winding close to the secondary windings and fed back to

the control circuit.

03044

Vi+

Vi–

22

23

PWM

2

3

14

16

10

Current limitation is provided by the primary circuit, thus

limiting the total output current (

I

+

I

o1 nom

for the dual output types).

o2 nom

I

for the single and

o nom

The close magnetic coupling provided by the planar construction ensures very good regulation and allows for flexible load distribution on dual output types.

22

Vo+

Vo–

Vi+

Vi–

23

2

3

PWM

03045

14

Vo+

16

Go

11

Vo–

Fig. 1

Block diagram for single output types.

Standard industrial pinout.

1

Vi+

2

n.c.

PWM

24

Vi–

Fig. 3

Block diagram for single output types.

Special pinout (Option K).

22

Vi+

23

Vi–

1

24

3

2

PWM

Fig. 5

Block diagram for single output types.

SMD pinout (Option M).

03046

03048

Fig. 2

Block diagram for dual output types.

Standard industrial pinout.

03047

1

13

Vo+

Vi+

15

Vo+

PWM

10

Go

12

Vo–

24

Vi–

11

13

Vo–

Fig. 4

Block diagram for dual output types.

Special pinout (Option K).

03049

13

14

Vo+

15

11

12

Vo–

16

10

n.c.

n.c.

9

Vi+

Vi–

22

23

1

24

3

2

PWM

14

Vo+

15

n.c.

9

10

Go

16

13

12

Vo–

11

Fig. 6

Block diagram for dual output types.

SMD pinout (Option M).

Edition 1 06.00

Page 4

Industrial Environment DC/DC Converters < 40W IMS6 Series

Electrical Input Data

General conditions:

Table 2: Input Data

Input 24 IMS 6 48 IMS 6

Characteristics Conditions

U

U

U

t

start up

t

rise

I

i o

C

I

inr p

f

s

I

i rr

u

1

Measured with a resistive or max. admissible capacitive load. (See fig.:

2

External filter required. (See:

3

Source impedance according to prETS 300132-2, version 4.3.

Input voltage range

i

Nominal input voltage

i nom

Repetitive surge voltage abs. max input (3 s) 40 100

i sur

Converter start-up time

Rise time

No load input current

Input capacitance for surge calculation 0.54 0.3

i

Inrush peak current

Switching frequency

Reflected ripple current

Input RFI level EN 55022

i RFI

conducted and radiated

T

= 25C, unless

A

1

Filter recommendations for compliance with EN 55022

T

is specified.

C

min typ

T

...

T

C min

= 0...

o

and full load

i min

i nom

o nom

= 0,

U

o

=

U

i

i nom

...

U

i min

= 0...

o

C max

I

o nom

resistive load 5 5 ms

capacitive load 12 12

...

U

i min

i max

3

,

I

= 0...

i max

o

I

o nom

2

I

1

Worst case condition at 0.25 0.5 0.25 0.5 s

U

U

I

I

U

U

I

18 36 36 75 V DC

24

15

I

o nom

approx. 400 approx. 400 kHz

1

B

Converter start-up and rise time

max min typ

48

20 mA

5 10

3.7 4.2 A

30 30 mA

1

B

)

)

max

Unit

uF

pp

Edition 1 06.00

Page 5

Industrial Environment DC/DC Converters < 40W IMS6 Series

04008

t

U

U

o nom

o

t

start up

t

rise

Fig. 7

Converter start-up and rise time

Inrush Current

The inrush current has been kept as low as possible by

choosing a very small input capacitance. A series resistor

may be inserted in the input line to limit this current further.

1 A/Div.

4

3

2

1

0

04034

Reverse Polarity Protection at Input

The suppressor diode on the input also provides for reverse

polarity protection by conducting current in the reverse direction, thus protecting the unit. An external fuse is required

to limit this current:

– For 24 IMS 6 a fast 0.63 A (F0.63A) fuse is recommended

– For 48 IMS 6 a fast 0.35 A (F035A) fuse is recommended

Filter recommendations for compliance with EN 55022

Electromagnetic emission requirements according to table

Input data

can be achieved by adding an external capacitor

as close as possible to the input terminals.

Vi+

C

i

Vi–

04035

Fig. 9

Input filter arrangement

Table 3: Input filter components (EN 55022)

Ref. 24 IMS 6 48 IMS 6

C

1 ,

2.2 F, 100 V, 2.2 F, 150 V,

Fig. 8

Typical inrush current at U

i nom

, P

o nom

5 s/Div.

versus time

(48 IMS6 ) measured according to prETS 300132-2,

version 4.3.

Type ceramic or film

Edition 1 06.00

Page 6

Industrial Environment DC/DC Converters < 40W IMS6 Series

Electrical Output Data

General conditions:

Table 6a: Output data for single output units

Output

Characteristics Conditions min typ max min typ max min typ max Unit

U

Output voltage

o

I

Output current

o nom

I

Current limit

o L

U

Line regulation

o U

U

Load regulation

u

Output voltage noise

o1, 2

U

Output overvoltage Min. load 1% 130 130 130 %

o clp

limitation

C

Admissible 680 150 100

o ext

capacitive load

u

Dynamic Voltage deviat.

o d

load

t

d

regulat.

Temperature coefficient

Uo

U

/

o

T

2

Recovery time

T

C

= 25 C, unless

A

U

i nom, Io

U

i min

U

i nom

U

i min

U

i nom

I

= (0.1...1)

o

U

i min

I

=

o

3

U

i nom

I

o nom

U

i min

I

= 0...

o

T

is specified.

C

U

o nom

= 0.5

I

o nom

...

U

i max

,

T

= 25 C 1400 700 600

C

...

U

,

I

i max

o nom

N/A

5.0 V 12.0 V 15.0 V

4.96 5.04 11.90 12.10 14.88 15.12 VDC

1000 500 400 mA

1 1 1%

3 3 3

I

o nom

i max

/2

i max

Io nom

5

6

80 120 150 mV

20 40 40 60 50 75

250 250 250 mV

11ms

0.02 0.02 0.02 %/K

...

I

o nom

...

U

1

U

I

o nom

uF

pp

Table 6b: Output data for dual output units

Output

U

o nom

5 V 12 V 15 V

Characteristics Conditions min typ max min typ max min typ max Unit

U

Output voltage

o1

U

o2

I

Output current

o nom

U

Line regulation

o U

U

Load regulation

u

Output voltage noise

o1, 2

U

Output overvoltage Min. load 1% 130 130 130 %

o clp

1

4

U

i nom

I

=

I

= 0.5

o1

o2

U

...

U

i min

U

...

U

i min

U

i nom

I

= (0.1...1)

o

U

...

U

i min

I

=

I

o

o nom

4.96 5.04 11.90 12.10 14.88 15.12 VDC

I

4.95 5.05 11.88 12.12 14.85 15.15

o nom

i max

,

I

i max

o nom

x

2 500 2 350 2 200 mA

1 1 1

x

x

3 3.5 3

I

o nom

i max

5

6

100 140 150 mV

40 60 45 70 50 75

limitation

C

Admissible 680 150 100

o ext

capacitive load

u

Dynamic Voltage deviat.

o d

load

t

d

regulat.

Temperature coefficient

Uo

U

/

T

o

1

Each output capable of delivering full output power.

2

The current limit is primary side controlled.

3

Sum of both outputs.

4

Conditions for specified output. Other output loaded with constant current

5

BW = 20 MHz

6

Measured with a probe according to EN 61204.

3

Recovery time

C

U

i nom

I

o nom

U

i min

I

= 0...

o

1

/2

Io nom

...

U

i max

I

o nom

250 600 750 mV

111 ms

0.02 0.02 0.02 %/K

I

= 0.5

I

o nom

.

o

N/A

%

pp

uF

Edition 1 06.00

Page 7

Industrial Environment DC/DC Converters < 40W IMS6 Series

Thermal Considerations

If a converter, mounted on a PCB, is located in free, quasistationary air (convection cooling) at the indicated maximum ambient temperature

specifications)

and is operated at its nominal input voltage

and output power, the case temperature

the:

Measuring point of case temperature TC

chanical Data

) will approach the indicated value

T

A max

(see table:

T

C

Temperature

measured at

(see:

Me-

T

af-

C max

ter the warm-up phase. However, the relationship between

T

and

T

A

depends heavily on the conditions of operation

C

and integration into a system. The thermal conditions are

influenced by input voltage, output current, airflow, temperature of surrounding components and surfaces and the

properties of the printed circuit board.

T

A max

is therefore

only an indicative value and under practical operating conditions, the ambient temperature

T

may be higher or lower

A

than this value.

Caution: The case temperature

Measuring point of case temperature TC

cal Data

) may under no circumstances exceed the speci-

T

measured at the

C

(see:

Mechani-

fied maximum value. The installer must ensure that under all operating conditions

stated in the table

Temperature specifications.

T

remains within the limits

C

Short Circuit Behaviour

The current limit characteristic shuts down the converter

whenever a short circuit is applied to its output. It acts selfprotecting and automatically recovers after removal of the

overload condition.

Output overvoltage protection

The outputs of the IMS 6 converters are protected against

overvoltages by Zener diodes. In the event of an overvoltage on the output, the unit will shut-down and attempt to

restart automatically. The main purpose of this feature is to

protect against possible overvoltages which could occur

due to a failure in the feedback control circuit. The units are

not designed to withstand external overvoltages applied to

the outputs.

Connection in series

The outputs of single or dual output units can be connected

in series without any precautions, taking into consideration

that the highest output voltage should remain below 60 V for

SELV operation.

Connection in parallel

The outputs of several units with equal nominal output voltage can be connected in parallel. Approximate current

sharing between 2 or several units is ensured by their load

dependent output characteristic.

Typical Performance Curves

[V]

U

5.25

5.0

4.75

4.5

4.25

4.0

o

0

0.5

05056

1.0

Fig. 12

U

versus Io (typ) of single output units (example for

o

48IMS6-05-9

Uo1 [V]

233

05058

I

16.5

16

15.5

15

14.5

14

0

Io2 = 14 mA

33 66

Io2 = 140 mA

100

33

66

200

Fig. 14

Cross load regulation of dual output units. Uo1 versus

Io1 (typ) for various Io2 (48IMS6-1515-9).

o1

[A]

I

o

[mA]

U

Uo2 [V]

+

o1

31.5

31

30.5

30

29.5

29

28.5

0

33 66

100

133

166

200

233

05057

I

o

Fig. 13

Uo versus Io (typ) of dual output units (15 V), with 30 V

load connected to Vo+ and Vo–.

Uo1, U

12.8

12.4

12

11.6

11.2

[V]

o2

0

150

300

05059

U

U

I

I

o1 no

o2

o1

o1

Fig. 15

Flexible load distribution on dual outputs (2

load variation from 0...150% of P

Output 2 loaded with 25% of P

o1 nom

o2 nom

x

12 V) with

on output 1.

.

[mA]

[%]

Edition 1 06.00

Page 8

Industrial Environment DC/DC Converters < 40W IMS6 Series

05060

U

100

o

[%]

overload short circuit condition

switch-off

05041

70

8.5

t

[ms]

60.5

60.5

Fig. 16

Overload switch-off (hiccup mode).

Frequency of pulses: 16.5 Hz, puls duration: 8.5 ms.

[%]

90

80

70

60

50

40

25

50

75

Fig. 17

Efficiency versus input voltage and load.

Typical values (48IMS6 -1212-9)

100

[%]

U

U

U

P

i nom

i max

i min

o

nom

Edition 1 06.00

Page 9

0

0

0

Industrial Environment DC/DC Converters < 40W IMS6 Series

Electromagnetic Emission

Conducted RFI noise at input according to EN 55022

[dB V]

90

07033

Radiated RFI noise according to EN 55022.

[dB V/m]

50

07034

80

70

60

50

40

30

20

10

0

.02

.01

.05

0.1

0.5

1

Fig. 18

Typical disturbance voltage (quasi-peak) at the input according to CISPR 11/EN 55011 and CISPR 22/EN 55022,

measured at U

i nom

and I

. Output leads 0.1 m, twisted.

o nom

2

EN 55022 A

EN 55022 B

5

10

20

MHz

30

40

30

20

10

Fig. 19

Typical radio frequency interference voltage at U

I

o nom

leads 0.1 m, twisted (48 IMS6-1515-9).

External capacitor at the input required (see: Recommendations for compliance with EN 55022). (48 IMS6-1515-9)

Mechanical Data

Dimensions in mm. Tolerances 0.3 mm unless otherwise indicated.

EN 55022 B

0

30

50

100

200

Frequency [MHz]

500

i nom

,

, measured with an antenna (distance 10 m). Output

1000

min. 3

15.24

Measuring point of

case temperature

T

Fig. 20

Case DIL 24, for IMS6

Weight: <10 g

33

11 x 2.54 = 27.94

09042

13

24

European

Projection

20

12

C

1

8.5

0.5

Edition 1 06.00

Page 10

Industrial Environment DC/DC Converters < 40W IMS6 Series

Immunity to Environmental Conditions

Table 8: Mechanical stress

Test Method Standard Test Conditions Status

2

Ca Damp heat IEC/DIN IEC 60068-2-3 Temperature: 40

steady state MIL-STD-810D section 507.2 Relative humidity: 93

Duration: 56 days

Ea Shock IEC/EN/DIN EN 60068-2-27 Acceleration amplitude: 100 gn = 981 m/s

(half-sinusoidal) MIL-STD-810D section 516.3 Bump duration: 6 ms operating

Number of bumps: 18 (3 each direction)

Eb Bump IEC/EN/DIN EN 60068-2-29 Acceleration amplitude: 40 gn = 392 m/s

(half-sinusoidal) MIL-STD-810D section 516.3 Bump duration: 6 ms operating

Number of bumps: 6000 (1000 each direction)

Fc Vibration IEC/EN/DIN EN 60068-2-6 Acceleration amplitude: 0.35 mm (10...60 Hz) Unit

(sinusoidal) MIL-STD-810D section 514.3 5 g

Frequency (1 Oct/min): 10...2000 Hz

Test duration: 7.5 h (2.5 h each axis)

Fda Random vibration IEC 60068-2-35 Acceleration spectral density: 0.05 g

wide band Frequency band: 10...500 Hz operating

reproducibility Acceleration magnitude: 4.9 g

high Test duration: 3 h (1 h each axis)

Kb Salt mist, cyclic IEC/EN/DIN IEC 60068-2-52 Concentration: 5% (30C) Unit not

(sodium chloride Duration: 2 h per cycle operating

NaCl solution) Storage: 40 C, 93% rel. humidity

Storage duration: 22 h per cycle

Number of cycles: 3

C Unit not

+2/-3

% operating

2

2

= 49 m/s2 (60...2000 Hz) operating

n

2

/Hz Unit

n

n rms

Unit

Unit

Table 9: Temperature specifications, valid for air pressure of 800...1200 hPa (800...1200 mbar)

Temperature Standard -9

Characteristics Conditions min max Unit

T

Ambient temperature

A

T

Case temperature –40 100

C

T

Storage temperature

S

1

MIL-STD-810D section 501.2 and 502.2

2

See

Thermal Considerations

1

Operational

1

Non operational –40 100

2

–40 71 C

Table 10: MTBF and device hours

MTBF Ground Benign Ground Fixed Ground Mobile Device Hours

MTBF acc. to MIL-HDBK-217F

48IMS6-05-9 2'651'000 h 349'000 h 124'000 h 119'000 h

1

Statistical values, based on an average of 4300 working hours per year and in general field use

T

= 40 C

C

T

= 40 C

C

T

= 70 C

C

T

= 50 C

C

1

Edition 1 06.00

Page 11

Industrial Environment DC/DC Converters < 40W IMS6 Series

Safety and Installation Instructions

Installation Instruction

Installation of the DC-DC converters must strictly follow the

national safety regulations in compliance with the enclosure, mounting, creepage, clearance, casualty, markings

and segregation requirements of the end-use application.

Connection to the system shall be made via a printed circuit

board according to:

Mechanical Data

.

The units should be connected to a secondary circuit.

Check for hazardous voltages before altering any connec-

tions.

Do not open the module.

Ensure that a unit failure (e.g. by an internal short-circuit)

does not result in a hazardous condition. See also:

Safety

of operator accessible output circuit.

Table 11: Pin allocation for standard industrial pinout

Pin Single output units Dual output units

2Vi– Vi–

3Vi– Vi–

10 n.c. 11 - Vo–

14 Vo+ Vo+

16 Vo– Go

22 Vi+ Vi+

23 Vi+ Vi+

10013

13

Bottom view

12

24

1

Fig. 22

Pin numbering

Table 12: Pin allocation for K pinout (option K)

Pin Single output units Dual output units

1 Vi+ Vi+

2 n.c. 10 - Go

11 - Go

12 Vo– 13 Vo+ Vo–

15 - Vo+

24 Vi– Vi–

Table 13: Pin allocation for SMD pinout (option M)

Pin Single output units Dual output units

1 Vi+ Vi+

2Vi– Vi–

3Vi– Vi–

9 n.c. n.c.

10 n.c. Go

11 Vo– Vo –

12 Vo– Vo –

13 Vo+ Vo–

14 Vo+ Vo+

15 Vo+ Vo+

16 Vo– Go

22 Vi+ Vi+

23 Vi+ Vi+

24 Vi- Vi+

Input Fuse

To prevent excessive current flowing through the input supply line in case of a short-circuit across the converter input

an external fuse should be installed in a non earthed input

supply line. We recommend a fast acting fuse F0.5A

for 24 IMS 6 and F0.315A

for 48 IMS 6 types.

Standards and approvals

All DC-DC converters are UL recognized according to UL

1950, UL recognized for Canada to CAN/CSA C22.2 No.

950-95 and LGA approved to IEC/EN 60950 standards.

The units have been evaluated for:

• Building in

• Supplementary insulation input to output, based on their

maximum input voltage

• The use in a pollution degree 2 environment

• Connecting the input to a secondary circuit which is subject to a maximum transient rating of 1500 V.

The DC-DC converters are subject to manufacturing surveillance in accordance with the above mentioned UL,

CSA, EN and ISO 9001 standards.

Edition 1 06.00

Safety of operator accessible output circuits

If the output circuit of a DC-DC converter is operator accessible, it shall be an SELV circuit according to IEC/EN 60950

related safety standards

The insulation concept table below shows some possible

installation configurations, compliance with which causes

the output circuit of the DC-DC converter to be an SELV circuit according to IEC/EN 60950 up to a configured output

voltage (sum of nominal voltages if in series or +/– configuration) of 46 V.

However, it is the sole responsibility of the installer to ensure the compliance with the relevant and applicable safety

regulations. More information is given in:

mation: Safety

.

Technical Infor-

Page 12

Industrial Environment DC/DC Converters < 40W IMS6 Series

Cleaning Agents

In order to avoid possible damage, any penetration of

cleaning fluids has to be prevented, since the power supplies are not hermetically sealed.

Protection Degree

The protection degree of the DC-DC converters is IP 30.

Isolation

The electric strength test is performed as factory test in accordance with IEC/EN 60950 and UL 1950 and should not

be repeated in the field. Melcher will not honour any guarantee claims resulting from electric strength field tests.

Table 14: Electric strength test voltages

Characteristic Input - Output Unit

24/48 IMS 6

Electric strength 1.2 kV

test voltage 1 s

Coupling 1.2 nF

capacitance

Insulation resist. >100 M

at 500 V DC

Partial discharge Consult factory kV

extinction voltage

1.5 kV DC

Table 15: Insulation concept leading to an SELV output circuit

Conditions Front end DC-DC converter Result

Supply Minimum required grade Maximum Minimum required safety Measures to achieve the Safety status of

voltage of isolation, to be provided DC output status of the front end specified safety status of the the DC-DC

Mains Basic 60 V Earthed SELV circuit

250 V AC vided by the DC-DC converter

by the AC-DC front end, voltage output circuit output circuit converter output

including mains supplied from the circuit

battery charger front end

>60 V Hazardous voltage

Double or reinforced 60 V SELV circuit Operational insulation, pro- SELV circuit

1

2

Operational insulation, pro- SELV circuit

ELV circuit Input fuse 3 output suppressor Earthed SELV

secondary circuit

diodes 4, and earthed circuit

output circuit

vided by the DC-DC converter

2

rms

1

The front end output voltage should match the specified input voltage range of the DC-DC converter.

2

The earth connection has to be provided by the installer according to the relevant safety standard, e.g. IEC/EN 60950.

3

The installer shall provide an approved fuse (type with the lowest rating suitable for the application) in a non-earthed input line directly

at the input of the DC-DC converter (see fig.:

Input Fuse

4

Each suppressor diode should be dimensioned in such a way, that in the case of an insulation fault the diode is able to limit the output

voltage to SELV (<60 V) until the input fuse blows (see fig.:

5

Has to be insulated from earth by double or reinforced insulation according to the relevant safety standard, based on the maximum

output voltage from the front end.

~

Mains

~

.

AC-DC

front

end

Earth

connection

Fuse

Battery

DC-DC

con-

verter

Schematic safety concept

Schematic safety concept

10004

Suppressor

diode

Earth

connection

SELV

). For UL’s purpose, the fuse needs to be UL-listed. See also:

).

+

–

Fig. 23

Schematic safety concept. Use fuse, suppressor diode

and earth connection as per table:

to an SELV output circuit

.

Safety concept leading

Edition 1 06.00

Page 13

26.6

2.5

2

27.94 ( 11 x 2.54)

1

12

24

13

110 52

26.6

2.5

2

27.94 ( 11 x 2.54)

1

12

24

13

110 52

Industrial Environment DC/DC Converters < 40W IMS6 Series

Description of Options

Table 16: Survey of options

Option Function of option Characteristic

Z Available in 'open frame' version without case

M Surface mount version, SMD Not available for 5 IMX 4 and 70 IMX 4 types

K Alternative pinout Not available for 5 IMX 4 and 70 IMX 4 types as well as all types

Bare board construction without case. Consult factory.

with 3.3 V or 24 V outputs

Option M

Surface mount version.

Note: Precautions should be taken when reflow soldering

the SMD version, option M. The reflow soldering instructions below should be strictly adhered to. An inadequate

soldering process may permanently damage the converter

or degrade its performance and Melcher will not honour any

guarantee/warranty claims resulting from damage caused

by ignoring the soldering instructions.

Infrared soldering is not permitted.

The surface mountable version of this product is assembled with high melting point solder (227 C) to ensure that

the solder joints of of the internal components do not degrade in the end users SMD soldering process.

This product is only specified for "Forced Convection

Reflow Soldering" (Hot Air). Any conventional soldering

profile is acceptable provided that the restriction curve below is not exceeded at any time during the reflow process.

T

[ C]

240

235

230

225

220

peak

11051

Option K

Alternative pinout.

This option defines an alternative pinout.

Option K excludes option M and vice versa.

Fig. 25

Proposed solder lands.

215

210

205

0

10

20

30

40

Fig. 24

Forced convection reflow soldering restriction curve

measured on pin 2

t

[s]

50

Edition 1 06.00

Loading...

Loading...