Page 1

查询3059供应商

3059

AND

3060

HALL-EFFECT

GEAR-TOOTH SENSORS

—AC COUPLED

X X

V

CC

1 432 5

FILTER

OUTPUT

SUPPLY

Pinning is shown viewed from branded side.

GROUND

FILTER

Dwg. PH-011

3059

AND

3060

HALL-EFFECT GEAR-TOOTH SENSORS

—AC COUPLED

The UGN/UGS3059KA and UGN/UGS3060KA ac-coupled Halleffect gear-tooth sensors are monolithic integrated circuits that switch

in response to changing differential magnetic fields created by moving

ferrous targets. These devices are ideal for use in non-zero-speed,

gear-tooth-based speed, position, and timing applications such as in

anti-lock braking systems, transmissions, and crankshafts.

Both devices, when coupled with a back-biasing magnet, can be

configured to turn ON or OFF with the leading or trailing edge of a

gear-tooth or slot. Changes in fields on the magnet face caused by a

moving ferrous mass are sensed by two integrated Hall transducers

and are differentially amplified by on-chip electronics. This differential

sensing design provides immunity to radial vibration within the devices’

operating air gaps. Steady-state magnet and system offsets are

eliminated using an on-chip differential band-pass filter. This filter also

provides relative immunity to interference from RF and electromagnetic sources. The on-chip temperature compensation and Schmitt

trigger circuitry minimizes shifts in effective working air gaps and

switch points over temperature, allowing operation to low frequencies

over a wide range of air gaps and temperatures.

Each Hall-effect digital Integrated circuit includes a voltage regulator, two quadratic Hall-effect sensing elements, temperature compensating circuitry, a low-level amplifier, band-pass filter, Schmitt

trigger, and an open-collector output driver. The on-board regulator

permits operation with supply voltages of 4.5 to 24 volts. The output

stage can easily switch 20 mA over the full frequency response range

of the sensor and is compatible with bipolar and MOS logic circuits.

Data Sheet

27612.20*

ABSOLUTE MAXIMUM RATINGS

at T

= +25°C

A

Supply Voltage, VCC............................. 24 V

Reverse Battery Voltage, V

Magnetic Flux Density, B............ Unlimited

Output OFF Voltage, V

Output Current, I

Package Power Dissipation,

P

............................................ 500 mW

D

Operating Temperature Range, T

Prefix ‘UGN’................. -20°C to +85°C

Prefix ‘UGS’ ............... -40

Storage Temperature Range,

T

............................... -65°C to +150°C

S

OUT

......................... 25 mA

OUT

.......... -30 V

RCC

.................... 24 V

A

°C to +125°C

The two devices provide a choice of operating temperature

ranges. Both devices are packaged in a 5-pin plastic SIP.

FEATURES

■ Senses Motion of Ferrous

Targets Such as Gears

■ Wide Operating Temperature Range

■ Operation to 30 kHz

■ Resistant to RFI, EMI

Always order by complete part number, e.g., UGS3060KA .

■ Large Effective Air Gap

■ 4.5 V to 24 V Operation

■ Output Compatible With

All Logic Families

■ Reverse Battery Protection

■ Resistant to Physical Stress

Page 2

3059

AND

3060

HALL-EFFECT

GEAR-TOOTH SENSORS

—AC COUPLED

1

SUPPLY

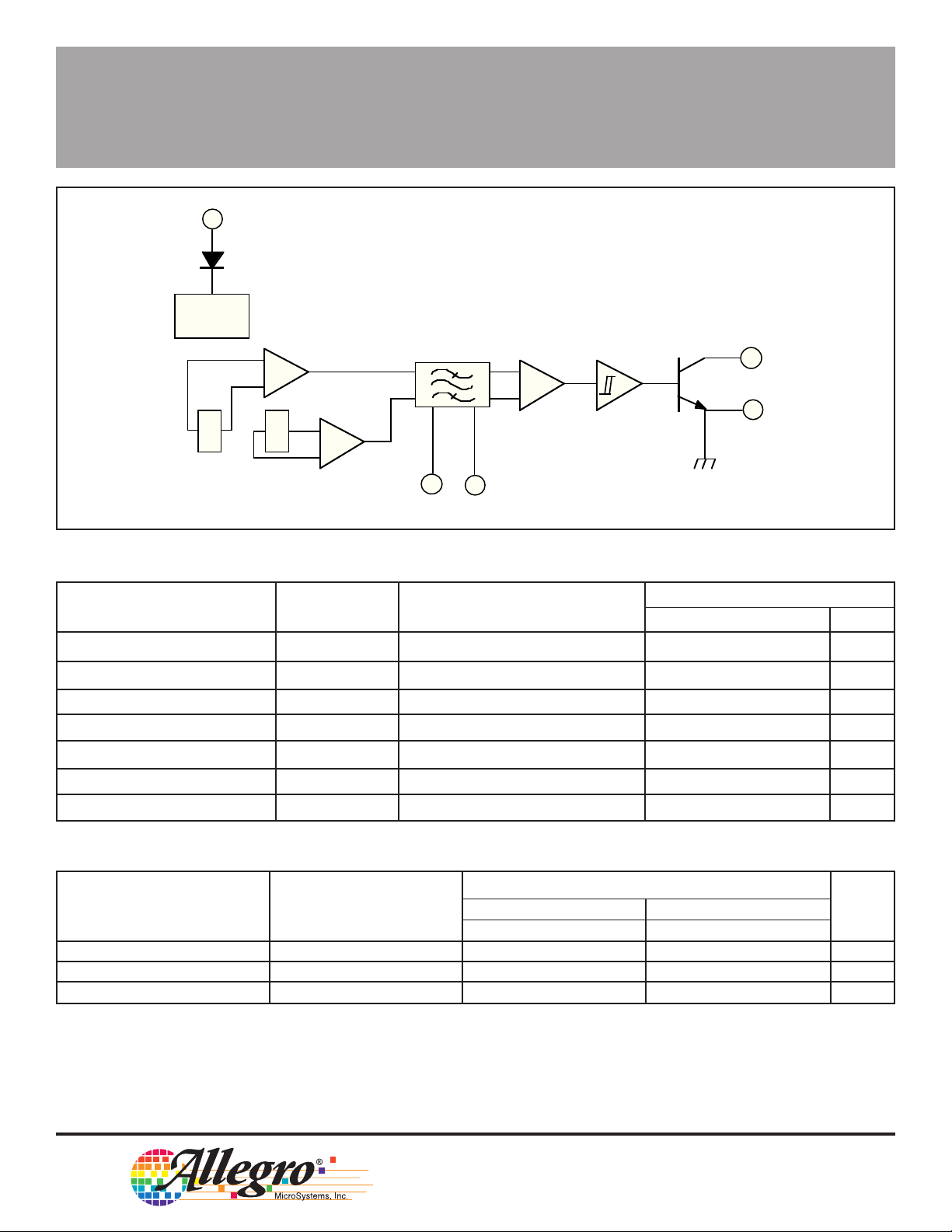

FUNCTIONAL BLOCK DIAGRAM

REG

OUTPUT

2

+

-

3

X X

4

FILTER

5

FILTER

GROUND

Dwg. FH-008

ELECTRICAL CHARACTERISTICS over operating temperature range.

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Supply Voltage V

Output Saturation Voltage V

Output Leakage Current I

Supply Current I

High-Frequency Cutoff f

Output Rise time t

Output Fall time t

OUT(SAT)

CC

OFF

CC

coh

r

f

Operating 4.5 — 24 V

I

= 20 mA, B > B

OUT

V

= 24 V, B < B

OUT

VCC = 18 V, B < B

-3 dB 30 — — kHz

V

= 12 V, RL = 820 Ω — 0.04 0.2 µs

OUT

V

= 12 V, RL = 820 Ω — 0.18 0.3 µs

OUT

OP

RP

RP

— 130 400 mV

——10µA

—1120mA

MAGNETIC CHARACTERISTICS over operating temperature and supply voltage ranges

Part Numbers*

3059 3060

Characteristic Test Conditions Min. Typ. Max. Min. Typ. Max. Units

Operate Point, B

Release Point, B

Hysteresis, B

NOTES: * Complete part number includes a prefix to identify operating temperature range (UGN or UGS) and the package suffix KA.

Magnetic switch points are specified as the difference in magnetic fields at the two Hall elements.

As used here, negative flux densities are defined as less than zero (algebraic convention).

Typical values are at TA = 25°C and VCC = 12 V.

OP

RP

hys

Output switches OFF to ON 10 65 100 5.0 15 35 G

Output switches ON to OFF -100 -65 -10 -35 -15 -5.0 G

BOP - B

RP

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

— 130 — — 30 — G

Page 3

3059

AND

3060

HALL-EFFECT

GEAR-TOOTH SENSORS

—AC COUPLED

TYPICAL OPERATING CHARACTERISTICS

SWITCH POINTS

100

50

0

-50

DIFFERENTIAL FLUX DENSITY IN GAUSS

-100

-50

-25 25 75 125

0 50 100

AMBIENT TEMPERATURE IN °C

3059

OPERATE POINT

3060

3060

RELEASE POINT

3059

OUTPUT SATURATION VOLTAGE

V = 8 V

CC

Dwg. GH-056

150

20

10

0

-10

DIFFERENTIAL FLUX DENSITY IN GAUSS

-20

0

UGN/UGS3060KA

I = 20 mA

OUT

T = +25°C

A

510152025

SUPPLY VOLTAGE IN VOLTS

OPERATE POINT

RELEASE POINT

Dwg. GH-057

300

I = 20 mA

OUT

V = 12 V

CC

200

100

SATURATION VOLTAGE IN mV

0

-50

0 25 50 75 100

AMBIENT TEMPERATURE IN °C

150-25 125

Dwg. GH-029-1

200

I = 20 mA

OUT

T = +25°C

A

150

100

SATURATION VOLTAGE IN mV

50

0

510152025

SUPPLY VOLTAGE IN VOLTS

Dwg. GH-055

Page 4

3059

AND

3060

HALL-EFFECT

GEAR-TOOTH SENSORS

—AC COUPLED

TYPICAL OPERATING CHARACTERISTICS

SUPPLY CURRENT

20

15

10

SUPPLY CURRENT IN mA

5

0

-50

0 255075100

AMBIENT TEMPERATURE IN °C

B ≤ B

13

T = +25°C

A

V = 18 V

CC

RP

125-25

150

Dwg. GH-028-1

12

11

10

SUPPLY CURRENT IN mA

9

8

0

510152025

SUPPLY VOLTAGE IN VOLTS

B < B

RP

Dwg. GH-031-1

APPLICATIONS INFORMATION

A gear-tooth sensing system consists of the sensor

IC, a back-biasing magnet, and a target. The system

requirements are usually specified in terms of the effective

working air gap between the package and the target (gear

teeth), the number of switching events per rotation of the

target, temperature and speed ranges, minimum pulse

duration or duty cycle, and switch point accuracy. Careful

choice of the sensor IC, magnet material and shape,

target material and shape, and assembly techniques

enables large working air gaps and high switch-point

accuracy over the system operating temperature range.

Naming Conventions. With a south pole in front of

the branded surface of the sensor or a north pole behind

the sensor, the field at the sensor is defined as positive.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

As used here, negative flux densities are defined as less

than zero (algebraic convention), e.g., -100 G is less than

-50 G.

Magnet Biasing. In order to sense moving non-

magnetized ferrous targets, these devices must be backbiased by mounting the unbranded side on a small

permanent magnet. Either magnetic pole (north or south)

can be used.

The devices can also be used without a back-biasing

magnet. In this configuration, the sensor can be used to

detect a rotating ring magnet such as those found in

brushless dc motors or in speed sensing applications.

Here, the sensor detects the magnetic field gradient

created by the magnetic poles.

Page 5

3059

AND

3060

HALL-EFFECT

GEAR-TOOTH SENSORS

—AC COUPLED

Figure 1

TYPICAL TRANSFER

CHARACTERISTIC

24 V

MAX

OUTPUT VOLTAGE IN VOLTS

B

RP

V

OUT(SAT)

0+B

Figure 2

LEADING

EDGE

GEAR

E2 E1

NORTH

SOUTH

B & B

E1 E2

0

-B

DIFFERENTIAL FLUX DENSITY, BE1 – B

4300 G

Sensor Operation. These sensor ICs each contain

two integrated Hall transducers (E1 and E2) that are used

to sense a magnetic field differential across the face of the

B

OP

IC (see Sensor Location drawing). Referring to Figure 1,

the trigger switches the output ON (output LOW) when

B

E1

- B

E2 < BOP

and switches the output OFF (output

HIGH) when BE1 - BE2 < BRP. The difference between B

OP

and BRP is the hysteresis of the device.

Figure 2 relates the output state of a back-biased

sensor IC, with switching characteristics shown in Figure

1, to the target gear profile and position. Assume a north

pole back-bias configuration (equivalent to a south pole at

the face of the device). The motion of the gear produces

a phase-shifted field at E1 and E2 (Figure 2(a)); internal

conditioning circuitry subtracts the fields at the two

E2

Dwg. GH-034

elements (Figure 2(b)); this differential field is band-pass

filtered to remove dc offset components and then fed into

a Schmitt trigger; the Schmitt trigger switches the output

transistor at the thresholds BOP and BRP. As shown

(Figure 2(c)), the IC output is LOW whenever sensor E1

TRAILING

EDGE

sees a (ferrous) gear tooth and sensor E2 faces air. The

output is HIGH when sensor E1 sees air and sensor E2

sees the ferrous target.

DIRECTION

OF ROTATION

AC-Coupled Operation. Steady-state magnet and

system offsets are eliminated using an on-chip differential

band-pass filter. The lower frequency cut-off of this

patented filter is set using an external capacitor the value

of which can range from 0.01 µF to 10 µF. The highfrequency cut-off of this filter is set at 30 kHz by an

(a)

internal integrated capacitor.

B – B

E1 E2

The differential structure of this filter enables the IC to

4130 G

150 G

B

OP

0 G

B

RP

-150 G

V

OUT

V

OUT(SAT)

OUTPUT DUTY CYCLE ≈ 50%

(b)

(c)

Dwg. WH-003-1

reject single-ended noise on the ground or supply line

and, hence, makes it resistant to radio-frequency and

electromagnetic interference typically seen in hostile

remote sensing environments. This filter configuration

also increases system tolerance to capacitor degradation

at high temperatures, allowing the use of an inexpensive

external ceramic capacitor.

Page 6

3059

AND

3060

HALL-EFFECT

GEAR-TOOTH SENSORS

—AC COUPLED

Low-Frequency Operation. Low-frequency operation of the sensor is set by the value of an external

capacitor. Figure 3 provides the low-frequency cut-off (-3

dB point) of the filter as a function of capacitance value.

This information should be used with care. The graph

assumes a perfect sinusoidal magnetic signal input.

In reality, when used with gear teeth, the teeth create

transitions in the magnetic field that have a much higher

frequency content than the basic rotational speed of the

target. This allows the device to sense speeds much

lower than those indicated by the graph for a given

capacitor value.

Figure 3

1 k

100

10

1.0

LOW-FREQUENCY CUTOFF IN Hz

codes Z5S, Y5S, X5S, or X7S (depending on operating

temperature range) or better are recommended. The

commonly available Z5U temperature code should not be

used in this application.

Magnet Selection. The UGx3059KA or UGx3060KA

can be used with a wide variety of commercially available

permanent magnets. The selection of the magnet depends on the operational and environmental requirements

of the sensing system. For systems that require high

accuracy and large working air gaps or

an extended temperature range, the usual magnet material of choice is rare-earth samarium cobalt (SmCo). This

magnet material has a high energy product and can

operate over an extended temperature range. For systems that require low-cost solutions for an extended

temperature range, AlNiCo 8 can be used. Due to its

relatively low energy product, smaller operational air gaps

can be expected. Neodymium iron boron (NeFeB) can be

used over moderate temperature ranges when large

working air gaps are required. Of these three magnet

materials, AlNiCo 8 is the least expensive by volume and

SmCo is the most expensive.

System Issues. Optimal performance of a gear-tooth

sensing system strongly depends on four factors: the IC

magnetic parameters, the magnet, the pole piece configuration, and the target.

0.1

0.01

0.1 1.0 10

CAPACITANCE IN µF

Dwg. GH-025

Capacitor Characteristics. The major requirement

for the external capacitor is its ability to operate in a

bipolar (non-polarized) mode. Another important requirement is the low leakage current of the capacitor (equivalent parallel resistance should be greater than 500kΩ). To

maintain proper operation with frequency, capacitor

values should be held to within ±30% over the operating

temperature range. Available non polarized capacitors

include ceramic, polyester, and some tantalum types. For

low-cost operation, ceramic capacitors with temperature

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Sensor Specifications. Shown in Figure 4 are

graphs of the differential field as a function of air gap.

A 48-tooth, 2.5” (63.5 mm) diameter, uniform target similar

to that used in ABS applications is used. The samarium

cobalt magnet is 0.32” diameter by 0.20” long

(8.13 x 5.08 mm). The maximum functioning air gap with

this typical gear/magnet combination can be determined

using the graphs and specifications for the sensor IC.

In this case, if a UGx3060KA sensor with a typical B

OP

of 15 G and a BRP of -15 G is used, the maximum allowable air gap would be approximately 0.120”. If the worst

case switch points of ±35 G for the UGx3060KA are used,

the maximum air gap is approximately 0.105”.

All system issues should be translated back to such a

profile to aid the prediction of system performance.

Page 7

3059

A

AND

3060

HALL-EFFECT

GEAR-TOOTH SENSORS

—AC COUPLED

Figure 4

DIFFERENTIAL FLUX DENSITY

2000

1500

1000

500

0

-500

-1000

-1500

DIFFERENTIAL FLUX DENSITY IN GAUSS

-2000

0

0.025 0.050 0.100 0.125

AIRGAP FROM PACKAGE FACE IN INCHES

0.075

Dwg. GH-035

Ferrous Targets. The best ferrous targets are made

of cold-rolled low-carbon steel. Sintered-metal targets are

also usable, but care must be taken to ensure uniform

material composition and density.

The teeth or slots of the target should be cut with a

slight angle so as to minimize the abruptness of transition

from metal to air as the target passes by the sensor.

Sharp transitions will result in magnetic overshoots that

can result in false triggering.

Gear teeth larger than 0.10” (2.54 mm) wide and at

least 0.10” (2.54 mm) deep provide reasonable working

air gaps and adequate change in magnetic field for

reliable switching. Generally, larger teeth and slots allow

a larger air gap. A gear tooth width approximating the

spacing between sensors (0.088” or 2.24 mm) requires

special care in the sytem design and assembly techniques.

200

150

100

50

0

-50

-100

-150

DIFFERENTIAL FLUX DENSITY IN GAUSS

-200

0.070

0.080 0.090 0.110 0.120

AIRGAP FROM PACKAGE FACE IN INCHES

Figure 5

SENSOR LOCATIONS

(±0.005” [0.13 mm] die placement)

ACTIVE AREA DEPTH

0.014"

0.37 mm

NOM

BRANDED

SURFACE

2.20 mm

E1 E2

12 4 53

0.087"

0.100

0.083"

2.10 mm

Dwg. GH-036

0.075"

1.91 mm

Dwg. MH-007D

Page 8

3059

AND

3060

HALL-EFFECT

GEAR-TOOTH SENSORS

—AC COUPLED

SEE NOTE

Dimensions in Inches

(controlling dimensions)

0.252

0.247

0.181

0.176

0.083

13452

MAX

0.600

0.560

0.016

0.050

BSC

0.063

0.059

45°

0.018

0.015

Dwg. MH-010G in

SEE NOTE

Dimensions in Millimeters

(for reference only)

6.40

6.27

4.60

4.47

2.11

13452

MAX

15.24

14.23

0.41

1.27

BSC

1.60

1.50

45°

0.46

0.38

Dwg. MH-010G mm

Surface-Mount Lead Form (Suffix -TL)

0.095

±0.005

0.002

MAX

0°–8°

0.004

MAX

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such

departures from the detail specifications as may be required to permit improvements in the design of its products.

The information included herein is believed to be accurate and reliable.

However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for

any infringements of patents or other rights of third parties which may result from

its use.

0.020

MIN

FLAT

Dwg. MH-015 in

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

2.41

±0.13

0.051

MAX

0°–8°

0.10

MAX

0.51

MIN

FLAT

Dwg. MH-015 mm

NOTES: 1. Tolerances on package height and width represent allowable

mold offsets. Dimensions given are measured at the widest

point (parting line).

2. Exact body and lead configuration at vendor’s option within

limits shown.

3. Height does not include mold gate flash.

4. Recommended minimum PWB hole diameter to clear transition

area is 0.035” (0.89 mm).

5. Where no tolerance is specified, dimension is nominal.

Loading...

Loading...