Page 1

2N6027, 2N6028

Preferred Device

Programmable

Unijunction Transistor

Programmable Unijunction

Transistor Triggers

Designed to enable the engineer to “program’’ unijunction

characteristics such as RBB, η, IV, and IP by merely selecting two

resistor values. Application includes thyristor–trigger, oscillator , pulse

and timing circuits. These devices may also be used in special thyristor

applications due to the availability of an anode gate. Supplied in an

inexpensive TO–92 plastic package for high–volume requirements,

this package is readily adaptable for use in automatic insertion

equipment.

• Programmable — R

• Low On–State Voltage — 1.5 Volts Maximum @ I

• Low Gate to Anode Leakage Current — 10 nA Maximum

• High Peak Output Voltage — 11 Volts Typical

• Low Offset Voltage — 0.35 Volt Typical (R

• Device Marking: Logo, Device T ype, e.g., 2N6027, Date Code

, η, IV and I

BB

P

= 50 mA

F

= 10 k ohms)

G

http://onsemi.com

PUTs

40 VOLTS

300 mW

G

A

K

MAXIMUM RATINGS (T

Rating Symbol Value Unit

*Power Dissipation

Derate Above 25°C

*DC Forward Anode Current

Derate Above 25°C

*DC Gate Current I

Repetitive Peak Forward Current

µs Pulse Width, 1% Duty Cycle

100

µs Pulse Width, 1% Duty Cycle

*20

Non–Repetitive Peak Forward Current

µs Pulse Width

10

*Gate to Cathode Forward Voltage V

*Gate to Cathode Reverse Voltage V

*Gate to Anode Reverse Voltage V

*Anode to Cathode Voltage

Operating Junction Temperature Range T

*Storage Temperature Range T

*Indicates JEDEC Registered Data

(1) Anode positive, RGA = 1000 ohms

Anode negative, RGA = open

= 25°C unless otherwise noted)

J

(1)

P

1/θ

I

I

TRM

I

TSM

GKF

GKR

GAR

V

AK

stg

1

F

JA

T

G

J

300

4.0

150

2.67

"

50 mA

1.0

2.0

5.0 Amps

40 Volts

*

5.0 Volts

40 Volts

"

40 Volts

–50 to

+100

–55 to

+150

mW

mW/°C

mA

mA/°C

Amps

°C

°C

1

2

3

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 7 of this data sheet.

Preferred devices are recommended choices for future use

and best overall value.

2

3

TO–92 (TO–226AA)

CASE 029

STYLE 16

PIN ASSIGNMENT

Anode

Gate

Cathode

Semiconductor Components Industries, LLC, 2000

May, 2000 – Rev. 2

1 Publication Order Number:

2N6027/D

Page 2

2N6027, 2N6028

THERMAL CHARACTERISTICS

Characteristic Symbol Max Unit

Thermal Resistance, Junction to Case R

Thermal Resistance, Junction to Ambient R

Maximum Lead Temperature for Soldering Purposes

(t1/16″ from case, 10 secs max)

θJC

θJA

T

L

75 °C/W

200 °C/W

260 °C

ELECTRICAL CHARACTERISTICS (T

Characteristic

*Peak Current

(VS = 10 Vdc, RG = 1 MΩ) 2N6027

(VS = 10 Vdc, RG = 10 k ohms) 2N6027

*Offset Voltage

(VS = 10 Vdc, RG = 1 MΩ) 2N6027

(VS = 10 Vdc, RG = 10 k ohms) (Both Types)

*Valley Current

(VS = 10 Vdc, RG = 1 MΩ) 2N6027

(VS = 10 Vdc, RG = 10 k ohms) 2N6027

(VS = 10 Vdc, RG = 200 ohms) 2N6027

*Gate to Anode Leakage Current

(VS = 40 Vdc, TA = 25°C, Cathode Open)

(VS = 40 Vdc, TA = 75°C, Cathode Open)

Gate to Cathode Leakage Current

(VS = 40 Vdc, Anode to Cathode Shorted)

*Forward Voltage (IF = 50 mA Peak)

*Peak Output Voltage

(VG = 20 Vdc, CC = 0.2 µF)

Pulse Voltage Rise T ime

(VB = 20 Vdc, CC = 0.2 µF)

*Indicates JEDEC Registered Data

(1) Pulse Test: Pulse Width ≤ 300 µsec, Duty Cycle ≤ 2%.

= 25°C unless otherwise noted.)

C

2N6028

2N6028

2N6028

2N6028

2N6028

2N6028

(1)

Fig. No. Symbol Min Typ Max Unit

2,9,11 I

1 V

1,4,5 I

— I

— I

1,6 V

3,7 V

3 t

P

T

V

GAO

GKS

F

o

r

—

—

—

—

0.2

0.2

0.2

—

—

70

25

1.5

1.0

—

—

— 5.0 50 nAdc

— 0.8 1.5 Volts

6.0 11 — Volt

— 40 80 ns

1.25

0.08

4.0

0.70

0.70

0.50

0.35

18

18

150

150

—

—

1.0

3.0

2.0

0.15

5.0

1.0

1.6

0.6

0.6

50

25

—

—

—

—

10

—

µA

Volts

µA

mA

nAdc

http://onsemi.com

2

Page 3

2N6027, 2N6028

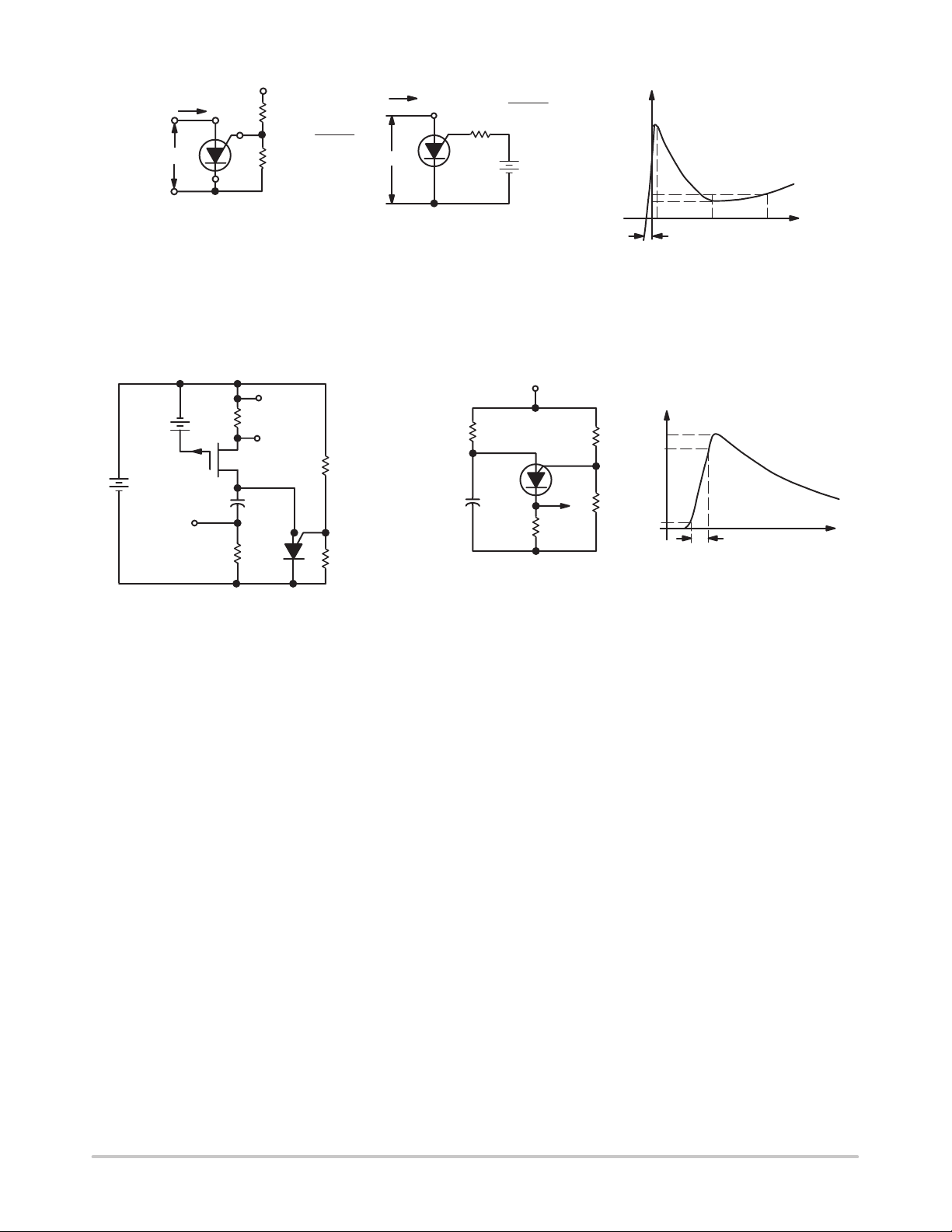

Adjust

for

Turn–on

Threshold

V

B

Scope

I

A

V

AK

1A –

Programmable Unijunction

with “Program” Resistors

R1 and R2

+V

A

G

K

100k

1.0%

2N5270

20

B

R2

– VS =

R1

–

IP (SENSE)

100 µV = 1.0 nA

+

0.01 µF

Put

Under

Test

I

R1

R1 + R2

A

+

V

B

V

AK

1B –

Equivalent Test Circuit for

Figure 1A used for electrical

characteristics testing

(also see Figure 2)

R

RG =

G

Figure 1. Electrical Characterization

510k

R

RG = R/2

VS = V

B/2

(See Figure 1)

R

C

C

R1 R2

R1 + R2

V

S

+V

20 Ω

V

A

–V

P

V

S

V

F

V

V

I

GAO

B

16k

27k

v

o

0.6 V

VT = VP – V

I

P

IC – Electrical Characteristics

+V

V

o

6 V

t

S

I

V

f

I

I

A

F

t

Figure 2. Peak Current (IP) Test Circuit Figure 3. Vo and tr Test Circuit

http://onsemi.com

3

Page 4

2N6027, 2N6028

TYPICAL V ALLEY CURRENT BEHAVIOR

µ

V

I , VALLEY CURRENT ( A)

1000

100

10

10

5.0

2.0

1.0

0.5

500

RG = 10 kΩ

100 kΩ

1 MΩ

1051520

VS, SUPPLY VOLTAGE (VOLTS) TA, AMBIENT TEMPERATURE (°C)

µ

100

V

I , VALLEY CURRENT ( A)

10

5

–25 +25 +75

0–50 +50 +100

RG = 10 kΩ

Figure 4. Effect of Supply Voltage Figure 5. Effect of Temperature

25

TA = 25°C

TA = 25°C

(SEE FIGURE 3)

20

15

100 kΩ

1 MΩ

CC = 0.2 µF

F

V , PEAK FORWARD VOLTAGE (VOLTS)

0.2

0.1

0.05

0.02

0.01

10

5.0

o

V , PEAK OUTPUT VOLTAGE (VOLTS)

0

0.020.01 0.05 0.1

IF, PEAK FORWARD CURRENT (AMP) VS, SUPPLY VOLTAGE (VOLTS)

0.2 2.00.5 1.0 5.0 35 40

5.0 15 25

1002030

Figure 6. Forward Voltage Figure 7. Peak Output Voltage

B2

R

R

2

R

B1

η =

1

RBB = R1 + R2

R1

R1 + R2

G

T

G

A

C

C

K

Typical Application

A

K

Circuit Symbol

A

E

G

P

N

P

N

K

Equivalent Circuit

with External “Program”

Resistors R1 and R2

1000 pF

+

R

2

R

1

Figure 8. Programmable Unijunction

http://onsemi.com

4

Page 5

2N6027, 2N6028

TYPICAL PEAK CURRENT BEHAVIOR

2N6027

10

5.0

µ

3.0

2.0

1.0

RG = 10 kΩ

0.5

P

I , PEAK CURRENT ( A)

0.3

0.2

0.1

100 kΩ

1.0 MΩ

105.0 15 20

VS, SUPPLY VOLTAGE (VOLTS) TA, AMBIENT TEMPERATURE (°C)

(SEE FIGURE 2)

Figure 9. Effect of Supply Voltage and R

1.0

0.7

0.5

µ

0.3

0.2

0.1

0.07

0.05

P

I , PEAK CURRENT ( A)

0.03

0.02

0.01

RG = 10 kΩ

100 kΩ

1.0 MΩ

(SEE FIGURE 2)

105.0 15 20

TA = 25°C

TA = 25°C

G

2N6028

µ

I , PEAK CURRENT ( A)

100

µ

P

I , PEAK CURRENT ( A)

P

0.05

0.02

0.01

50

20

10

5.0

2.0

1.0

0.5

0.2

0.1

10

5.0

2.0

1.0

0.5

0.2

0.1

VS = 10 VOLTS

(SEE FIGURE 2)

RG = 10 kΩ

100 kΩ

1.0 MΩ

–25 +25 +75

0–50 +50 +100

Figure 10. Effect of T emperature and R

VS = 10 VOLTS

(SEE FIGURE 2)

RG = 10 kΩ

100 kΩ

1.0 MΩ

–25 +25 +75

0–50 +50 +100

G

VS, SUPPLY VOLTAGE (VOLTS) TA, AMBIENT TEMPERATURE (°C)

Figure 11. Effect of Supply Voltage and R

http://onsemi.com

G

5

Figure 12. Effect of T emperature and R

G

Page 6

2N6027, 2N6028

TO–92 EIA RADIAL TAPE IN FAN FOLD BOX OR ON REEL

H2A H2A

H

W2

H4

H5

L1

H1

W1

W

F1

F2

P2 P2

P1

P

L

D

H2B H2B

T1

T

T2

Figure 13. Device Positioning on T ape

Specification

Inches Millimeter

Symbol Item

D

D2

F1, F2

H

H1

H2A

H2B

H4

H5

L

L1

P

P1

P2

T

T1

T2

W

W1

W2

Tape Feedhole Diameter

Component Lead Thickness Dimension

Component Lead Pitch

Bottom of Component to Seating Plane

Feedhole Location

Deflection Left or Right

Deflection Front or Rear

Feedhole to Bottom of Component

Feedhole to Seating Plane

Defective Unit Clipped Dimension

Lead Wire Enclosure

Feedhole Pitch

Feedhole Center to Center Lead

First Lead Spacing Dimension

Adhesive Tape Thickness

Overall Taped Package Thickness

Carrier Strip Thickness

Carrier Strip Width

Adhesive Tape Width

Adhesive Tape Position

NOTES:

1. Maximum alignment deviation between leads not to be greater than 0.2 mm.

2. Defective components shall be clipped from the carrier tape such that the remaining protrusion (L) does not exceed a maximum of 11 mm.

3. Component lead to tape adhesion must meet the pull test requirements.

4. Maximum non–cumulative variation between tape feed holes shall not exceed 1 mm in 20 pitches.

5. Holddown tape not to extend beyond the edge(s) of carrier tape and there shall be no exposure of adhesive.

6. No more than 1 consecutive missing component is permitted.

7. A tape trailer and leader, having at least three feed holes is required before the first and after the last component.

8. Splices will not interfere with the sprocket feed holes.

Min Max Min Max

0.1496 0.1653 3.8 4.2

0.015 0.020 0.38 0.51

0.0945 0.110 2.4 2.8

.059 .156 1.5 4.0

0.3346 0.3741 8.5 9.5

0 0.039 0 1.0

0 0.051 0 1.0

0.7086 0.768 18 19.5

0.610 0.649 15.5 16.5

0.3346 0.433 8.5 11

0.09842 — 2.5 —

0.4921 0.5079 12.5 12.9

0.2342 0.2658 5.95 6.75

0.1397 0.1556 3.55 3.95

0.06 0.08 0.15 0.20

— 0.0567 — 1.44

0.014 0.027 0.35 0.65

0.6889 0.7481 17.5 19

0.2165 0.2841 5.5 6.3

.0059 0.01968 .15 0.5

http://onsemi.com

6

Page 7

2N6027, 2N6028

ORDERING & SHIPPING INFORMATION: 2N6027 and 2N6028 packaging options, Device Suffix

Europe

U.S.

2N6027, 2N6028

2N6027, 2N6028RLRA

2N6028RLRM

2N6028RLRP

Equivalent

2N6027RL1

Shipping Description of TO92 Tape Orientation

Bulk in Box (5K/Box)

Radial Tape and Reel (2K/Reel)

Radial Tape and Reel (2K/Reel)

Radial Tape and Fan Fold Box (2K/Box)

Radial Tape and Fan Fold Box (2K/Box)

P ACKAGE DIMENSIONS

TO–92 (TO–226AA)

CASE 029–1 1

ISSUE AJ

N/A, Bulk

Round side of TO92 and adhesive tape visible

Flat side of TO92 and adhesive tape visible

Flat side of TO92 and adhesive tape visible

Round side of TO92 and adhesive tape visible

SEATING

PLANE

A

B

R

P

L

K

XX

1

G

H

V

C

N

D

J

SECTION X–X

N

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. CONTOUR OF PACKAGE BEYOND DIMENSION R

IS UNCONTROLLED.

4. LEAD DIMENSION IS UNCONTROLLED IN P AND

BEYOND DIMENSION K MINIMUM.

DIM MIN MAX MIN MAX

A 0.175 0.205 4.45 5.20

B 0.170 0.210 4.32 5.33

C 0.125 0.165 3.18 4.19

D 0.016 0.021 0.407 0.533

G 0.045 0.055 1.15 1.39

H 0.095 0.105 2.42 2.66

J 0.015 0.020 0.39 0.50

K 0.500 ––– 12.70 –––

L 0.250 ––– 6.35 –––

N 0.080 0.105 2.04 2.66

P ––– 0.100 ––– 2.54

R 0.115 ––– 2.93 –––

V 0.135 ––– 3.43 –––

STYLE 16:

PIN 1. ANODE

2. GATE

3. CATHODE

MILLIMETERSINCHES

http://onsemi.com

7

Page 8

2N6027, 2N6028

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 T oll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone: (+1) 303–308–7140 (M–F 1:00pm to 5:00pm Munich Time)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (M–F 1:00pm to 5:00pm Toulouse T ime)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (M–F 12:00pm to 5:00pm UK Time)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, England, Ireland

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

ASIA/PACIFIC : LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

T oll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–8549

Phone: 81–3–5740–2745

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

http://onsemi.com

8

2N6027/D

Loading...

Loading...