Datasheet 28LV010RT4FS25, 28LV010RT4FS20, 28LV010RT4FI25, 28LV010RT4FI20, 28LV010RT4FE25 Datasheet (MAXWELL)

...Page 1

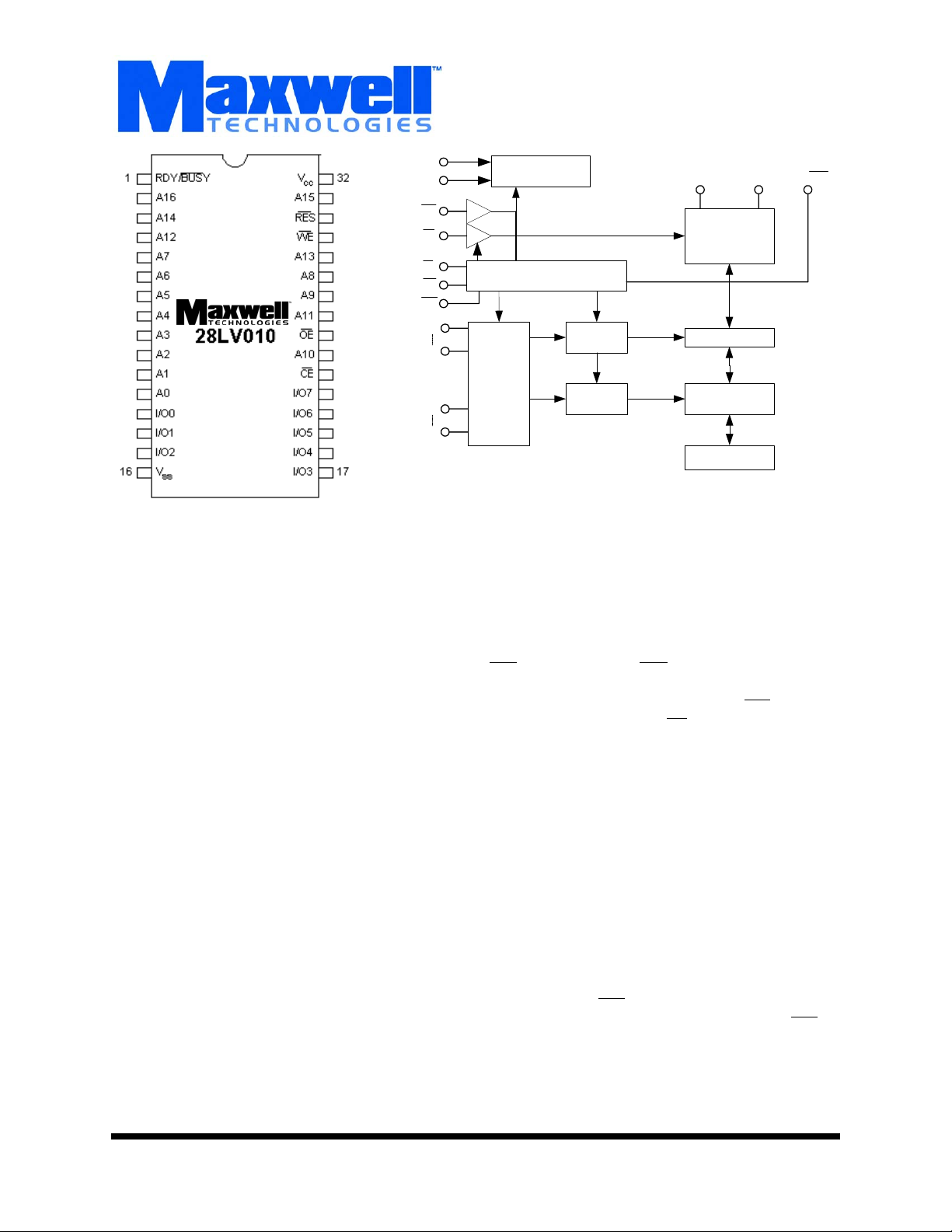

28LV010

3.3V 1 Megabit (128K x 8-Bit)

EEPROM

FEATURES:

• 3.3V low voltage operation 128K x 8 Bit EEPROM

•R

AD-PAK® radiation-hardened against natural space

radiation

• Total dose hardness:

- > 100 krad (Si), depending upon space mission

• Excellent Single Event Effects:

- SEL

> 84 MeV/mg/cm

TH

- SEUTH > 37 Mev/mg/cm2 (read mode)

-SEU saturated cross section = 3E-6 cm

- SEU

= 11.4 Mev/mg/cm2 (write mode)

TH

-SEU saturated cross section = 5E-3 cm

hard errors

• Package:

- 32 Pin R

- 32 Pin R

AD-PAK® flat pack

AD-PAK® DIP

- JEDEC-approved byte-wide pinout

• Address Access Time:

- 200, 250 ns maximum access times available

• High endurance:

- 10,000 erase/write (in Page Mode), 10-year data

retention

• Page write mode:

- 1 to 128 bytes

• Automatic programming

- 10 ms automatic page/byte write

• Low power dissipation

- 20 mW/MHz active current (typ.)

- 72 µW standby (maximum)

2

2

(read mode)

2

(write mode) with

V

CC

V

SS

RES

OE

CE

WE

RES

A0

A6

A7

A16

High Voltage

Generator

Control Logic Timing

Address

Buffer and

Latch

Y Decoder

X Decoder

I/O0 I/O7 RDY/Busy

I/O Buffer and

Input Latch

Y Gating

Memory Array

Data Latch

Logic Diagram

DESCRIPTION:

Maxwell Technologies’ 28LV010 high density, 3.3V, 1 Megabit

EEPROM microcircuit features a greater than 100 krad (Si)

total dose tolerance, depending upon space mission. The

28LV010 is capable of in-system electrical Byte and Page programmability. It has a 128-Byte Page Programming function to

make its erase and write operations faster. It also features

Data

Polling and a Ready/Busy signal to indicate the completion of erase and programming operations. In the 28LV010,

hardware data protection is provided with the RES

tion to noise protection on the WE

signal and write inhibit on

power on and off. Meanwhile, software data protection is

implemented using the JEDEC-optional Standard algorithm.

The 28LV010 is designed for high reliability in the most

demanding space applications.

Maxwell Technologies' patented R

AD-PAK® packaging technol-

ogy incorporates radiation shielding in the microcircuit package. It eliminates the need for box shielding while providing

the required radiation shielding for a lifetime in orbit or space

mission. In a GEO orbit, R

AD-PAK provides greater than 100

krad (Si) radiation dose tolerance. This product is available

with screening up to Class S.

Note:The recommended form of data protection during power

on/off is to hold the RES

pin to VSS during power up and power

down. This may be accompanied by connecting the RES

to the CPU reset line. Failure to provide adequate protection

during power on/off may result in lost or modified data.

pin, in addi-

Memory

pin

1000579

(858) 503-3300 - Fax: (858) 503-3301- www.maxwell.com

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

1

Page 2

3.3V 1 Megabit (128K x 8-Bit) EEPROM

TABLE 1. 28LV010 PINOUT DESCRIPTION

PIN SYMBOL DESCRIPTION

28LV010

12-5, 27, 26, 23, 25,

4, 28, 3, 31, 2

13-15, 17-21 I/O0 - I/O7 Input/Output

24

22

29

32 V

16 V

1 RDY/BUSY

30

A0-A16 Address

OE Output Enable

CE Chip Enable

WE Write Enable

CC

SS

RES Reset

TABLE 2. 28LV010 ABSOLUTE MAXIMUM RATINGS

PARAMETER SYMBOL MIN MAX UNIT

Supply Voltage (Relative to Vss) V

Input Voltage (Relative to Vss) V

Operating Temperature Range T

Storage Temperature Range T

Power Supply

Ground

Ready/Busy

CC

IN

OPR

STG

-0.6 7.0 V

1

-0.5

-55 125 °C

-65 150 °C

7.0 V

Memory

1. VIN min = -3.0 V for pulse width < 50 ns.

ICC1 ±10%

I

2 ±10%

CC

I

3A ±10%

CC

I

3B ±10%

CC

1000579

TABLE 3. DELTA LIMITS

PARAMETER VARIATION

12.19.01 Rev 3

All data sheets are subject to change without notice

2

©2001 Maxwell Technologies

All rights reserved.

Page 3

3.3V 1 Megabit (128K x 8-Bit) EEPROM

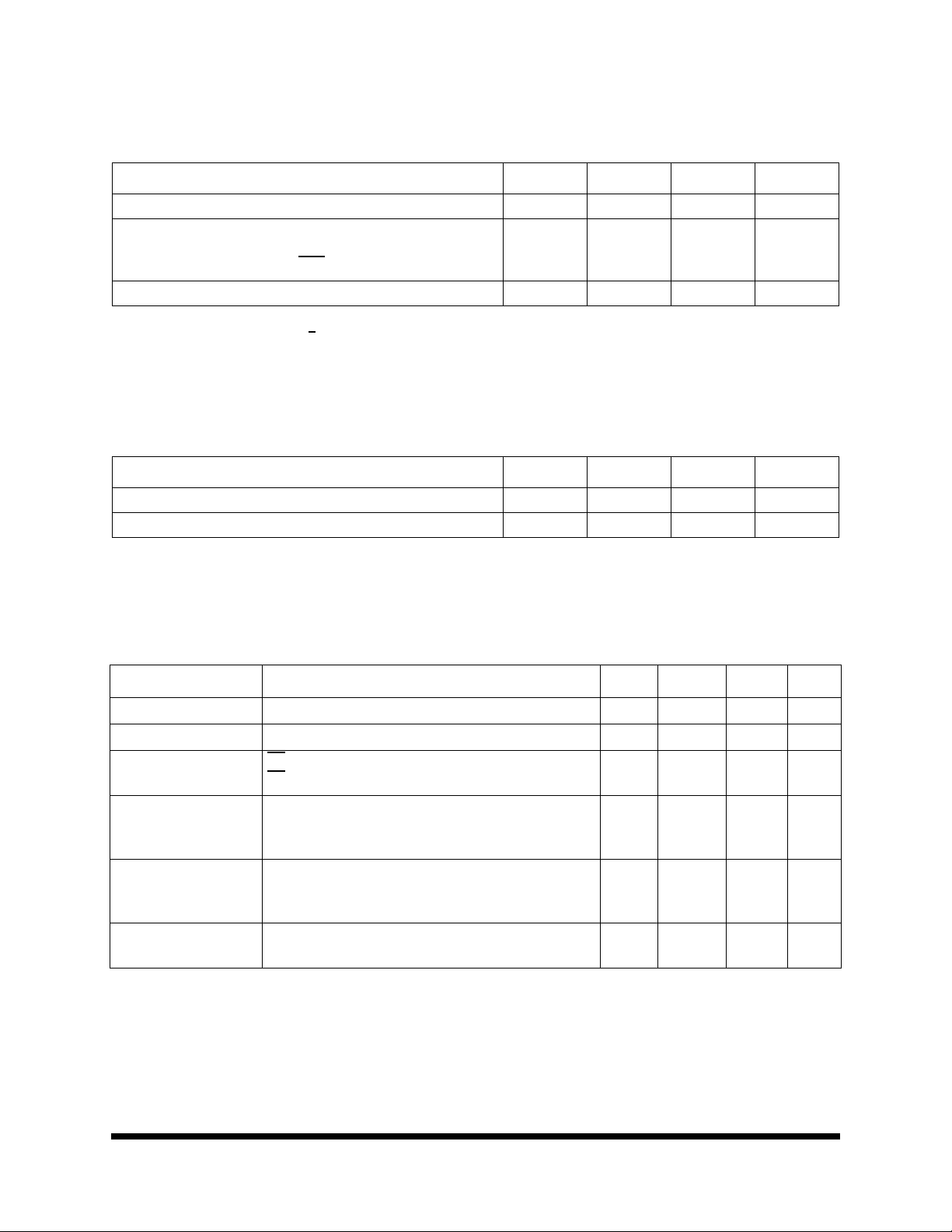

TABLE 4. 28LV010 RECOMMENDED OPERATING CONDITIONS

PARAMETER SYMBOL MIN MAX UNIT

28LV010

Supply Voltage V

Input Voltage

RES

_PIN

Operating Temperature Range T

min = -1.0 V for pulse width < 50 ns.

1. V

IL

2. V

min = 2.2 V for VCC = 3.6 V.

IH

TABLE 5. 28LV010 CAPACITANCE

(TA = 25°C, F = 1MHZ)

P

ARAMETER SYMBOL MIN MAX UNIT

OUT

1

= 0V

1

Input Capacitance: VIN = 0V

Output Capacitance: V

1. Guaranteed by design.

TABLE 6. 28LV010 DC ELECTRICAL CHARACTERISTICS

(VCC = 3.3V ± 0.3, TA = -55 TO +125°C UNLESS OTHERWISE SPECIFIED)

3.0 3.6 V

1

-0.3

2

2.0

VCC-0.5

0.8

+0.3

V

CC

V

+1

CC

-55 +125 °C

V

V

V

V

OPR

CC

IL

IH

H

Memory

C

IN

C

OUT

-- 6 pF

-- 12 pF

P

ARAMETER TEST CONDITIONS SYMBOL MIN MAX UNIT

Input Leakage Current VCC = 3.6V, VIN = 3.6V I

Output Leakage Current V

Standby V

Operating V

Current CE = V

CC

Current I

CC

= 3.6V, V

CC

CC

CE = V

IH

= 0mA, Duty = 100%, Cycle = 1 µs @ VCC = 3.3V

OUT

I

= 0mA, Duty = 100%, Cycle = 250 ns @ VCC =

OUT

= 3.6V/0.4V I

OUT

3.3V

Input Voltage V

Output Voltage I

1. V

min = 2.2V for VCC = 3.6V.

IH

1000579

= 2.1 mA

OL

I

= -400 µA

OH

12.19.01 Rev 3

All data sheets are subject to change without notice

I

I

I

V

V

CC1

CC2

CC3

V

V

LI

LO

IL

IH

H

OL

OH

-- 2 µA

-- 2 µA

--

--

--

--

--

2.0

VCC-0.5

--

V

x0.8

CC

1

20

1

6

15

0.8

--

--

0.4

--

µA

mA

mA

V

V

3

©2001 Maxwell Technologies

All rights reserved.

Page 4

3.3V 1 Megabit (128K x 8-Bit) EEPROM

28LV010

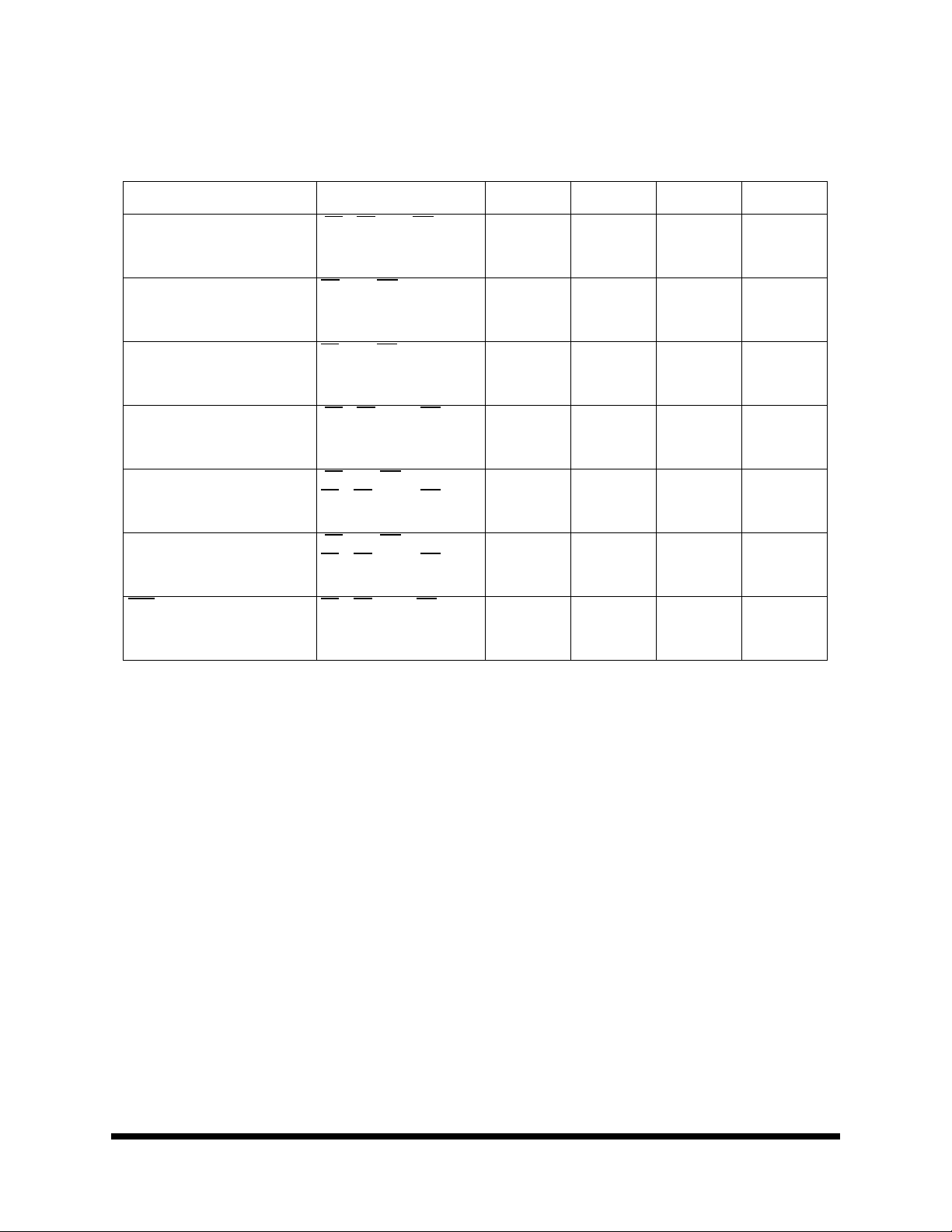

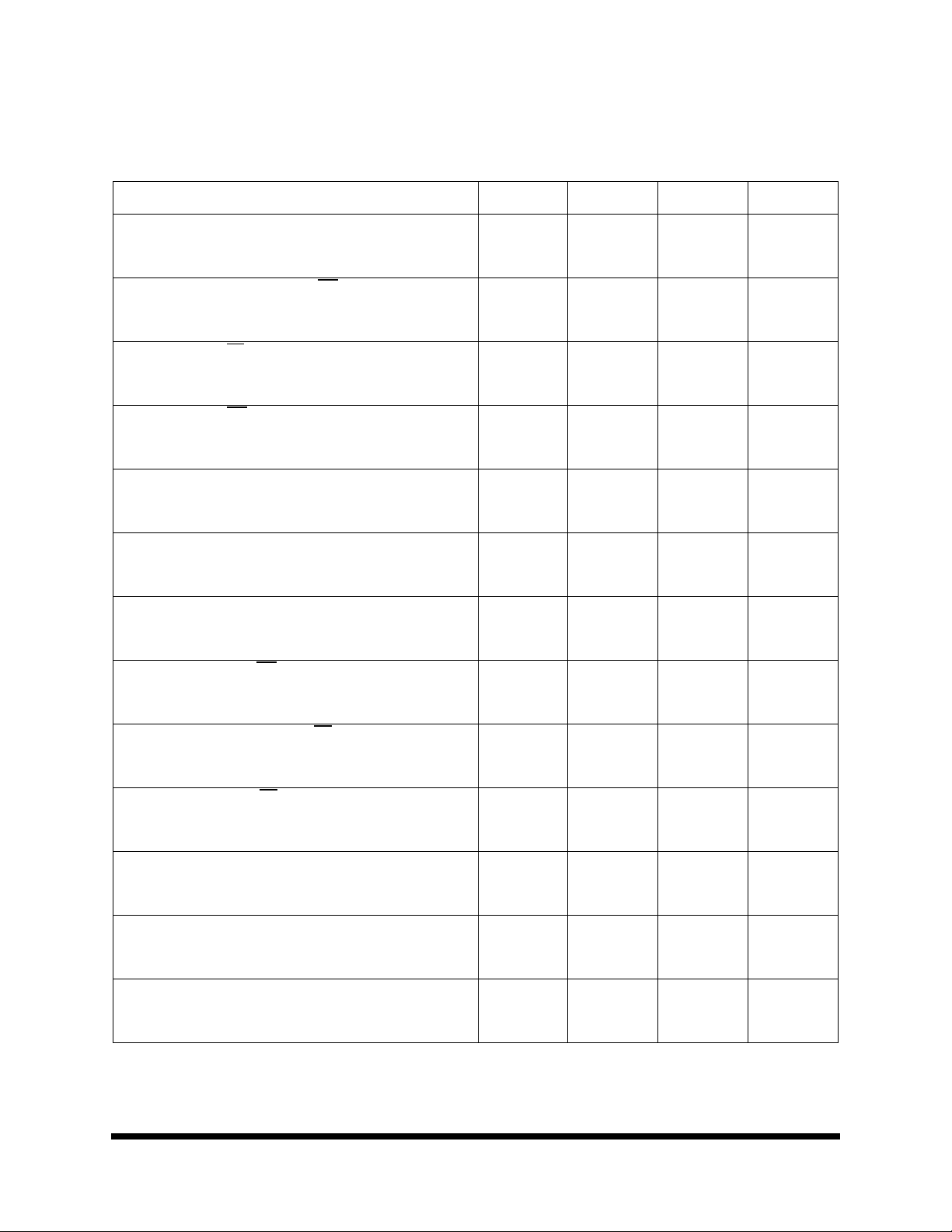

TABLE 7. 28LV010 AC CHARACTERISTICS FOR READ OPERATION

(VCC = 3.3V ± 10%, TA = -55 TO +125 °C UNLESS OTHERWISE SPECIFIED)

P

ARAMETER TEST CONDITIONS SYMBOL MIN MAX UNIT

Address Access Time

-200

-250

Chip Enable Access Time

-200

-250

Output Enable Access Time

-200

-250

Output Hold to Address Change

-200

-250

Output Disable to High-Z

-200

-250

Output Disable to High-Z

-200

-250

to Output Delay

RES

-200

-250

2

3

CE = OE = VIL, WE = V

= VIL, WE = V

OE

= VIL, WE = VIH t

CE

= OE = VIL, WE = V

CE

= VIL, WE = VIH

CE

CE

= OE = VIL, WE = V

= VIL, WE = VIH

CE

CE

= OE = VIL, WE = V

= OE = VIL WE = V

CE

IH

IH

IH

IH

IH

IH

t

t

ACC

t

CE

OE

t

OH

t

DF

DFR

t

RR

1

ns

--

--

200

250

ns

--

--

200

250

ns

0

0

110

120

ns

0

0

0

0

50

50

--

--

ns

Memory

ns

0

0

300

350

ns

0

0

525

550

1. Test conditions: Input pulse levels - 0.4V to 2.4V; input rise and fall times < 20 ns; output load - 1 TTL gate + 100 pF

(including scope and jig); reference levels for measuring timing - 0.8V/1.8V.

2. t

DF

and t

is defined as the time at which the output becomes an open circuit and data is no longer driven.

DFR

3. Guaranteed by design.

1000579

12.19.01 Rev 3

All data sheets are subject to change without notice

4

©2001 Maxwell Technologies

All rights reserved.

Page 5

3.3V 1 Megabit (128K x 8-Bit) EEPROM

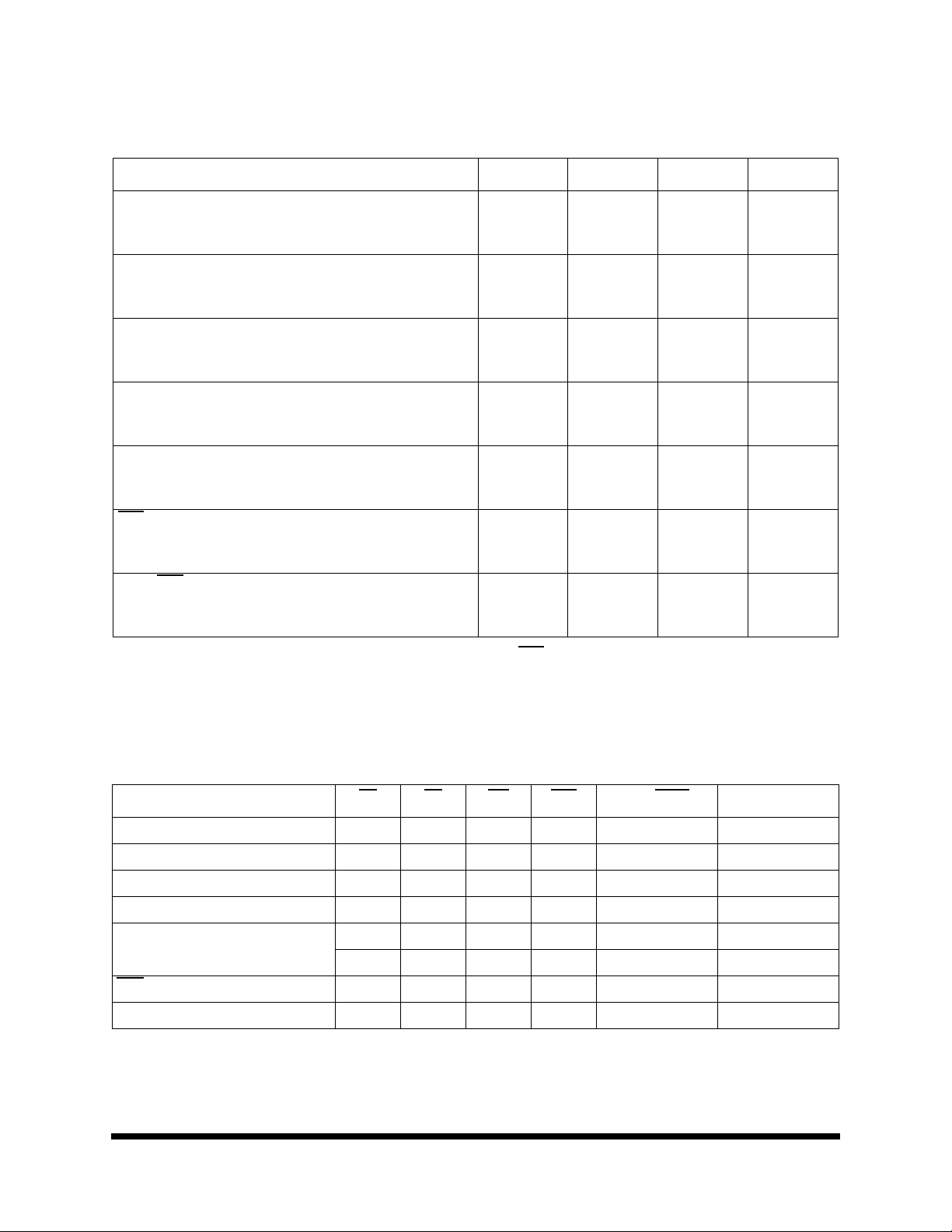

TABLE 8. 28LV010 AC ELECTRICAL CHARACTERISTICS FOR ERASE AND WRITE OPERATIONS

(VCC = 3.3V ± 10%, TA = -55 TO +125 °C UNLESS OTHERWISE SPECIFIED)

P

ARAMETER SYMBOL MIN MAX UNIT

28LV010

Address Setup Time

-200

-250

Chip Enable to Write Setup Time (WE

-200

-250

Write Pulse Width (CE

controlled)

-200

-250

Write Pulse Width (WE

controlled)

-200

-250

Address Hold Time

-200

-250

Data Setup Time

-200

-250

Data Hold Time

-200

-250

Chip Enable Hold Time (WE

controlled)

-200

-250

Write Enable to Write Setup Time (CE

-200

-250

controlled)

controlled)

t

AS

t

CS

t

CW

t

WP

t

AH

t

DS

t

DH

t

CH

t

WS

0

0

0

0

200

250

200

250

125

150

100

100

10

10

0

0

0

0

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

--

ns

ns

ns

ns

ns

ns

ns

ns

ns

Memory

Write Enable Hold Time (CE

controlled)

-200

-250

Output Enable to Write Setup Tim

-200

-250

Output Enable Hold Time

-200

-250

Write Cycle Time

1,2

-200

-250

1000579

12.19.01 Rev 3

t

WH

t

OES

t

OEH

t

WC

All data sheets are subject to change without notice

0

0

0

0

0

0

--

--

--

--

--

--

--

--

15

15

©2001 Maxwell Technologies

ns

ns

ns

ms

5

All rights reserved.

Page 6

3.3V 1 Megabit (128K x 8-Bit) EEPROM

TABLE 8. 28LV010 AC ELECTRICAL CHARACTERISTICS FOR ERASE AND WRITE OPERATIONS

(VCC = 3.3V ± 10%, TA = -55 TO +125 °C UNLESS OTHERWISE SPECIFIED)

P

ARAMETER SYMBOL MIN MAX UNIT

28LV010

Byte Load Cycle

-200

-250

Data Latch Time

2

-200

-250

Byte Load Window

-200

-250

Time to Device Busy

-200

-250

Write Start Time

-200

-250

to Write Setup Time

RES

-200

-250

to RES Setup Time

V

CC

-200

-250

t

BLC

t

DL

2

2

2

t

t

t

BL

t

DB

DW

t

RP

RES

1

1

--

--

100

100

100

120

150

150

100

100

1

1

30

30

700

750

--

--

--

--

--

--

--

--

--

--

µs

ns

µs

ns

ns

Memory

µs

µs

must be longer than this value unless polling techniques or RDY/BSY are used. This device automatically completes the

1. t

WC

internal write operation within this value.

2. Guaranteed by design.

TABLE 9. 28LV010 MODE SELECTION

1,2

MODE CE OE WE RES RDY/BUSY I/O

Read V

Standby V

Write V

Deselect V

IL

IH

IL

IL

Write Inhibit X X V

XV

Data

Polling V

IL

Program X X X V

V

IL

V

IH

V

H

High-Z D

X X X High-Z High-Z

V

IH

V

IH

IL

V

IL

V

IL

V

IH

IH

V

H

V

H

High-Z --> V

OL

High-Z High-Z

X-- --

X X -- --

V

IH

V

H

IL

V

OL

Data Out (I/O7)

High-Z High-Z

1. X = Don’t care.

2. Refer to the recommended DC operating conditions.

D

OUT

IN

1000579

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

6

Page 7

3.3V 1 Megabit (128K x 8-Bit) EEPROM

FIGURE 1. READ TIMING WAVEFORM

28LV010

Memory

1000579

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

7

Page 8

3.3V 1 Megabit (128K x 8-Bit) EEPROM

FIGURE 2. BYTE WRITE TIMING WAVEFORM(1) (WE CONTROLLED)

28LV010

Memory

1000579

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

8

Page 9

3.3V 1 Megabit (128K x 8-Bit) EEPROM

FIGURE 3. BYTE WRITE TIMING WAVEFORM (2) (CE CONTROLLED)

28LV010

Memory

1000579

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

9

Page 10

3.3V 1 Megabit (128K x 8-Bit) EEPROM

FIGURE 4. PAGE WRITE TIMING WAVEFORM(1) (WE CONTROLLED)

28LV010

Memory

1000579

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

10

Page 11

3.3V 1 Megabit (128K x 8-Bit) EEPROM

FIGURE 5. PAGE WRITE TIMING WAVEFORM(2) (CE CONTROLLED)

28LV010

Memory

1000579

IGURE 6. SOFTWARE DATA PROTECTION TIMING WAVEFORM(1) (IN PROTECTION MODE)

F

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

11

All rights reserved.

Page 12

3.3V 1 Megabit (128K x 8-Bit) EEPROM

FIGURE 7. SOFTWARE DATA PROTECTION TIMING WAVEFORM(2) (IN NON-PROTECTION MODE)

IGURE 8. DATA POLLING TIMING WAVEFORM

F

28LV010

Memory

1000579

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

12

Page 13

3.3V 1 Megabit (128K x 8-Bit) EEPROM

FIGURE 9. TOGGLE BIT WAVEFORM

28LV010

FIGURE 10. SEU SATURATED CROSS SECTION VALUES IN READ MODE

1.00E-02

1.00E-03

1.00E-04

1.00E-05

Cross-section [cm^2]

1.00E-06

Memory

28LV010 Read Mode Cross-s ection

lv1

lv2

lv5

lv6

1000579

1.00E-07

0 102030405060708090

LET [ Mev- cm^2/mg]

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

13

All rights reserved.

Page 14

3.3V 1 Megabit (128K x 8-Bit) EEPROM

FIGURE 11. SEU SATURATED CROSS SECTION VALUES IN WRITE MODE

28LV010 WRITE MODE AVERAGE CROS S-S ECTION

1.00E-01

1.00E-02

1.00E-03

28LV010

1.00E-04

CROSS-SECTION [cm^2]

1.00E-05

1.00E-06

0 102030405060708090

LET [MeV-cm^2/mg]

SL1

SL2

SL3

N4

N5

EEPROM APPLICATION NOTES

This application note describes the programming procedures for the EEPROM modules and with details of various

techniques to preserve data protection.

Automatic Page Write

Page-mode write feature allows 1 to 128 bytes of data to be written into the EEPROM in a single write cycle, and

allows the undefined data within 128 bytes to be written corresponding to the undefined address (A0 to A6). Loading

the first byte of data, the data load window opens 30 µs for the second byte. In the same manner each additional byte

of data can be loaded within 30 µs. In case CE

erase and write mode automatically and only the input data are written into the EEPROM.

and WE are kept high for 100(s after data input, EEPROM enters

Memory

WE CE Pin Operation

During a write cycle, addresses are latched by the falling edge of WE or CE, and data is latched by the rising edge of

WE

or CE.

Data Polling

Data Polling function allows the status of the EEPROM to be determined. If EEPROM is set to read mode during a

write cycle, an inversion of the last byte of data to be loaded outputs from I/O 7 to indicate that the EEPROM is performing a write operation.

1000579

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

14

Page 15

3.3V 1 Megabit (128K x 8-Bit) EEPROM

28LV010

RDY/Busy Signal

RDY/Busy signal also allows a comparison operation to determine the status of the EEPROM. The RDY/Busy signal

has high impedance except in write cycle and is lowered to V

the RDY/Busy

signal changes state to high impedance.

after the first write signal. At the-end of a write cycle,

OL

RES Signal

When RES is LOW, the EEPROM cannot be read and programmed. Therefore, data can be protected by keeping

low when VCC is switched. RES should be high during read and programming because it doesn’t provide a latch

RES

function.

Memory

Data Protection

To protect the data during operation and power on/off, the EEPROM has the internal functions described below.

1. Data Protection against Noise of Control Pins (CE, OE, WE) during Operation.

During readout or standby, noise on the control pins may act as a trigger and turn the EEPROM to programming mode by mistake. To prevent this phenomenon, the EEPROM has a noise cancellation function that cuts noise if its width is 20 ns or less in

programming mode. Be careful not to allow noise of a width of more than 20 ns on the control pins.

2. Data Protection at V

CC

on/off

1000579

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

15

Page 16

3.3V 1 Megabit (128K x 8-Bit) EEPROM

When VCC is turned on or off, noise on the control pins generated by external circuits, such as CPUs, may turn the EEPROM to

programming mode by mistake. To prevent this unintentional programming, the EEPROM must be kept in unprogrammable

state during V

RES

should be kept at VSS level when VCC is turned on or off. The EEPROM breaks off programming operation when RES

become low, programming operation doesn’t finish correctly in case that RES

should be kept high for 10 ms after the last data input.

on/off by using a CPU reset signal to RES pin.

CC

falls low during programming operation. RES

28LV010

Memory

3. Software Data Protection

The software data protection function is to prevent unintentional programming caused by noise generated by external circuits.

In software data protection mode, 3 bytes of data must be input before write data as follows. These bytes can switch the nonprotection mode to the protection mode.

Software data protection mode can be canceled by inputting the following 6 bytes. Then, the EEPROM turns to the non-protection mode and can write data normally. However, when the data is input in the canceling cycle, the data cannot be written.

1000579

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

16

Page 17

3.3V 1 Megabit (128K x 8-Bit) EEPROM

28LV010

Memory

32-PIN RAD-PAK® FLAT PACKAGE

SYMBOL DIMENSION

MIN NOM MAX

A 0.121 0.134 0.147

b 0.015 0.017 0.022

c 0.004 0.005 0.009

D -- 0.820 0.830

E 0.472 0.480 0.488

E1 -- -- 0.498

E2 0.304 0.310 --

E3 0.030 0.085 --

e 0.050BSC

L 0.355 0.365 0.375

Q 0.020 0.035 0.045

S1 0.005 0.027 --

N32

F32-10

Note: All dimensions in inches

1000579

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

17

Page 18

3.3V 1 Megabit (128K x 8-Bit) EEPROM

28LV010

Memory

32 PIN DUAL IN-LINE PACKAGE

DIMENSION

SYMBOL

MIN NOM MAX

A -- 0.152 0.225

b 0.014 0.018 0.026

b2 0.045 0.050 0.065

c 0.008 0.010 0.018

D -- 1.600 1.680

E 0.510 0.590 0.620

eA 0.600 BSC

eA/2 0.300 BSC

e 0.100 BSC

L 0.135 0.145 0.155

Q 0.015 0.037 0.070

S1 0.005 0.025 --

S2 0.005 -- --

N32

1000579

D32-02

Note: All dimensions in inches

12.19.01 Rev 3

All data sheets are subject to change without notice

18

©2001 Maxwell Technologies

All rights reserved.

Page 19

3.3V 1 Megabit (128K x 8-Bit) EEPROM

Important Notice:

These data sheets are created using the chip manufacturers published specifications. Maxwell Technologies verifies

functionality by testing key parameters either by 100% testing, sample testing or characterization.

The specifications presented within these data sheets represent the latest and most accurate information available to

date. However, these specifications are subject to change without notice and Maxwell Technologies assumes no

responsibility for the use of this information.

Maxwell Technologies’ products are not authorized for use as critical components in life support devices or systems

without express written approval from Maxwell Technologies.

Any claim against Maxwell Technologies must be made within 90 days from the date of shipment from Maxwell Technologies. Maxwell Technologies’ liability shall be limited to replacement of defective parts.

28LV010

Memory

1000579

12.19.01 Rev 3

All data sheets are subject to change without notice

©2001 Maxwell Technologies

All rights reserved.

19

Page 20

3.3V 1 Megabit (128K x 8-Bit) EEPROM

)

Product Ordering Options

Model Number

28LV010

8LV010

XX

X X

-XX

Feature

Access Time

Screening Flow

Package

Option Details

20 = 200 ns

25 = 250 ns

Monolithic

S = Maxwell Class S

B = Maxwell Class B

E = Engineering (testing @ +25°C

I = Industrial (testing @ -55°C,

+25°C, +125°C)

Memory

D = Dual In-line Package (DIP)

F = Flat Pack

1000579

Radiation Feature

Base Product

Nomenclature

12.19.01 Rev 3

RP = R

AD-PAK® package

RT1 = Guaranteed to 10 krad at

die level

RT2 = Guaranteed to 25 krad at

die level

RT4 = Guaranteed to 40 krad at

die level

3.3V 1 Megabit (128K x 8-Bit)

EEPROM

All data sheets are subject to change without notice

20

©2001 Maxwell Technologies

All rights reserved.

Loading...

Loading...