Datasensor SCS1 User Manual

Smart Camera Sensor

QUICK OPERATION

DATASENSOR S.p.A. Via Lavino 265

40050 Monte S. Pietro - Bolo gna - Italy

Tel: +39 051 6765611 Fax: +39 051 6759324

http://www.datasensor.com e-mail: info@datasensor.com

DATASENSOR S.p.A. cares for the environment: 100% recycled paper.

DATASENSOR S.p.A. reserves the right to make mo difications and improvements without prior notification.

830000015 rev.G

SCS1 Series Quick Operation

GENERAL INFORMATION

SCS1 is a smart camera sensor suitable to many industrial automation applications, including process

and quality inspection, mechanical part verification, measurement and positioning, as well as filling and

labelling control.

The sensor can be set either as stand-alone using the Teach-in function, or via PC graphic interface

through the Ethernet port and thus fully exploiting the device’s most advanced functions. During sensor

configuration, 2 digital PNP outputs can be activated according to the required inspection.

SCS1 presents a standard M12 8-pole connector for power supply, switching outputs, hardware trigger,

configurable I/O, RS485 or RS232, as well as a M8 4-pole connector for external illuminator control.

Standard CS-mounting optics, available as accessories, provide flexibility in terms of operating distance

and field of view, while integrated or external illuminators particularly suit all application lighting

requirements. The installation of the compact 100x75x40 mm sturdy metal housing is easy and rapid,

thanks to specifically designed fixing brackets that guarantee precise mounting.

This guide provides basic information necessary to power up the device and configure an inspection. It

is a simple overview that does not provide the complete details of the all functions and options available.

Please refer to the SCS1 instruction manual for further information.

AVAILABLE MODELS

SCS1 with integrated illuminator SCS1 without integrated illuminator

1) with RS232 serial protocol

2) with RS485 serial protocol

3) with two supplementary digital inputs for

inspection selection

4) with RS232 serial protocol

5) with RS485 serial protocol

6) with two supplementary digital inputs

for inspection selection

1

Quick Operation SCS1 Series

/

(p

)

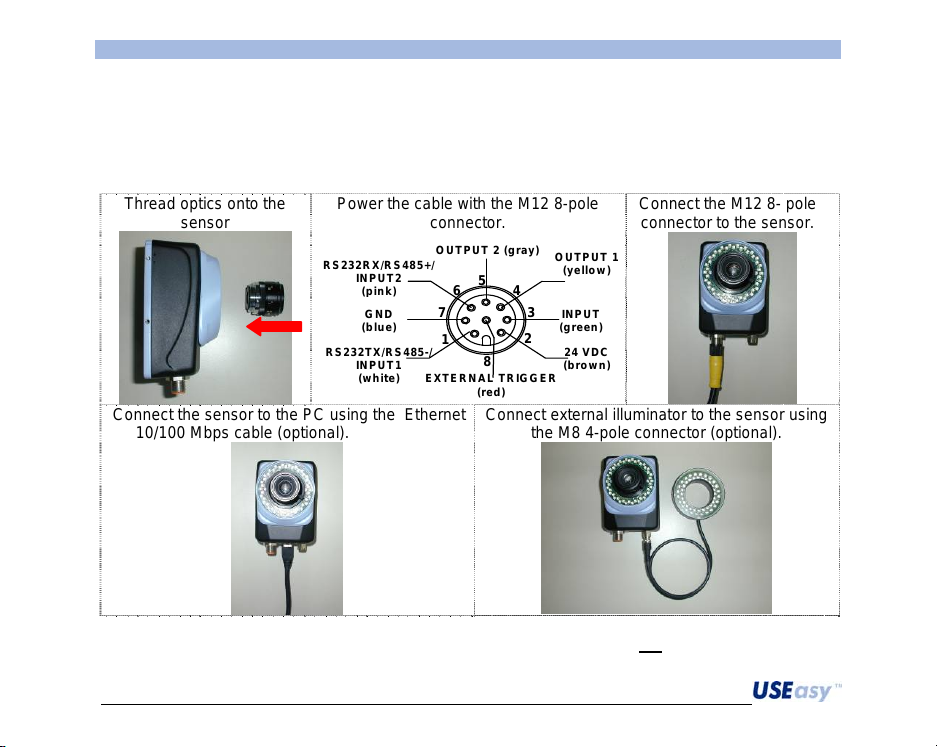

INSTALLATION

Check the following necessary components: SCS1 sensor, 16mm C-mount lens and adapter compatible

with the sensor’s CS-mount or alternatively any optics with CS mounting or C mounting with adapter,

cable with M12 8-pole connector, 24 Vdc power supply, cable with M8 4-pole connector (if an external

illuminator is used), Ethernet 10/100 Mbps cable (if the SCS1 graphic interface via PC is used).

Thread optics onto the

sensor

Connect the sensor to the PC using the Ethernet

10/100 Mbps cable (optional).

Power the cable with the M12 8-pole

connector.

RS232R X/RS 485+/

RS232TX/RS485-

INP U T2

ink

GND

(blue)

INP U T1

(white)

OUTPUT 2 (gray)

5

6

7

1

8

EXTERNAL TRIGG ER

(red)

Connect external illuminator to the sensor using

Connect the M12 8- pole

connector to the sensor.

OUTPUT 1

(yello w)

4

3

INP U T

(green )

2

24 VDC

(brown)

the M8 4-pole connector (optional).

At powering, the device initialisation process lasts approximately 30 sec during which the “SCS1” text is

visualised. During the initialisation the General Purpose Input (pin 3) must not

be active, otherwise the

push-buttons will be locked. In this case, re-boot the sensor.

2

SCS1 Series Quick Operation

y

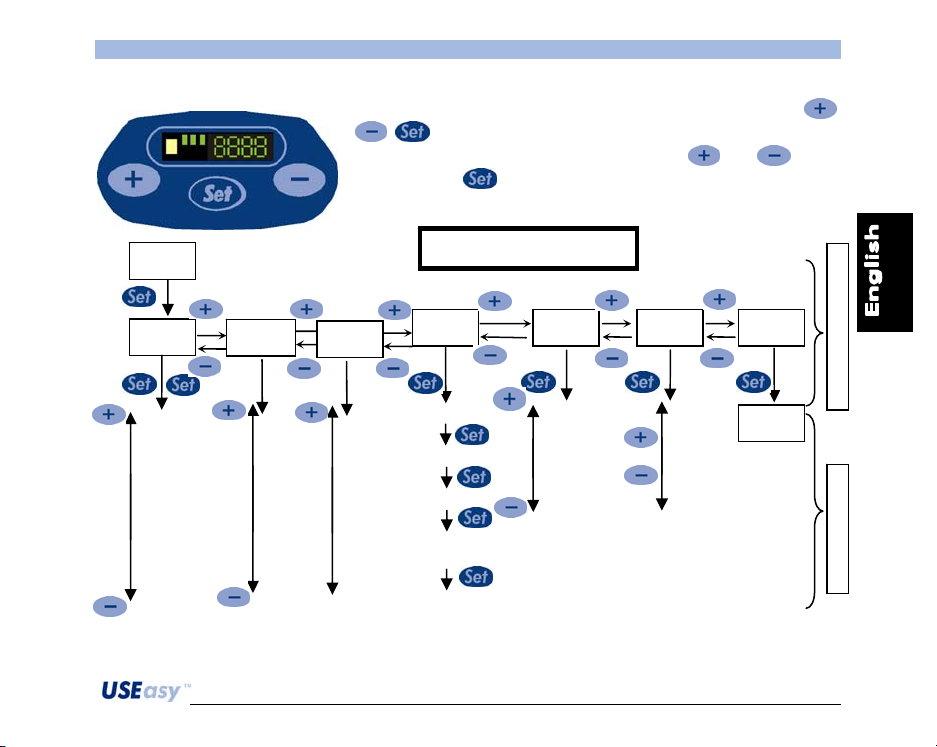

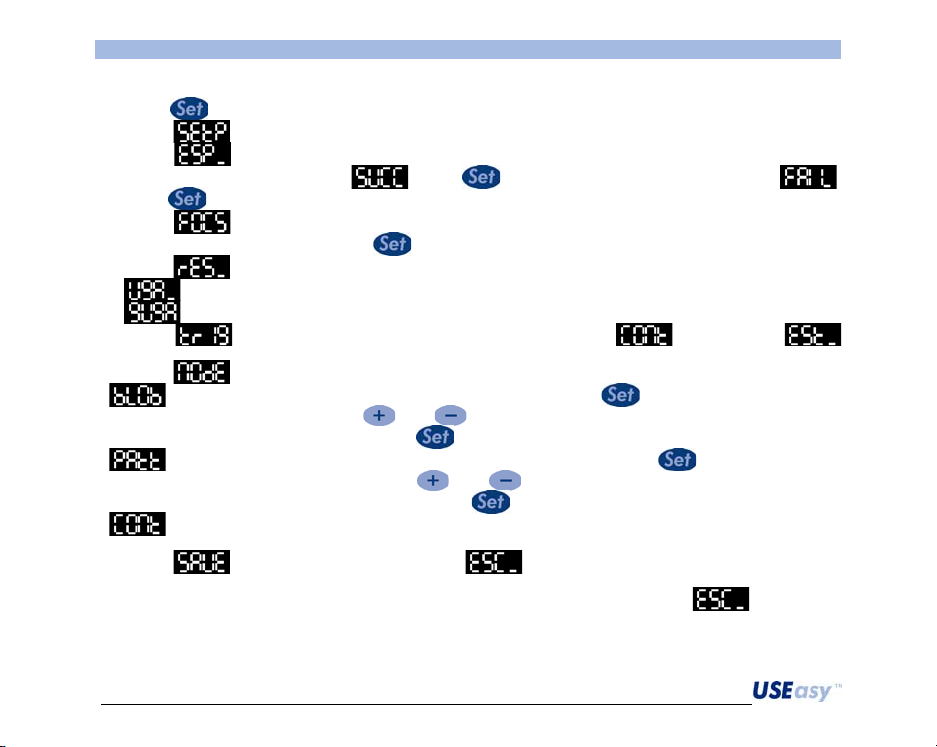

SENSOR INTEGRATED USER INTERFACE

The sensor integrated interface consists in 3 push-buttons

, and a 4-digit display presenting 4 LEDs.

The menu options can be visualised using the

buttons. Press

to select an option and the relative submenu is

and push-

opened.

Status

Sensor configuration menu

Setup

Registers

Insp.

Teach-in

Network

S.IN Displa

- Light

- Autoexposure

- Focus

- Resolution

- Trigger

- Mode

- Output

- Save

- Esc

- r0

- r1

- …

- r15

- s0

- …

- s7

- Save

- Esc

- Insp1

- Insp2

- Insp3

- Insp4

- Insp10

- Insp11

- Insp12

Background acq

Target acq.

Pass / Fail

Threshold

tuning

Sequence

confirmation

- Ip Address

- Net Mask

- Save

- Esc

- Direct

- Inverse

- Esc

Run

M

A

N

M

E

N

U

S

U

B

M

E

N

U

,

I

3

Quick Operation SCS1 Series

Step 1 - Set the inspection parameters

1) Press

2) Select

3) Select

of view. If the display visualises

press

4) Select

that appears on the display. Press

5) Select

6) Select

external.

7) Select

display that can be changed using

that can be found during inspection. Press

on the display that can be changed using

objects that can be found during inspection. Press

characteristics.

8. Select

Note: the user can exit from all submensu without saving the changing by selecting

to access the main menu.

to enter the Setup submenu.

to begin the autoexposure process, assuring that the target-object is inside the field

, press and continue. If the display visualises ,

to return to the Setup submenu and retry.

to focus the image. The user has to act on the sensor optics to increase the number

to continue.

to choose the necessary resolution. Two options are available:

full VGA (640x480 pixels);

¼ VGA (320x240 pixels).

to choose the Trigger mode. The possible modes: continuous or

to choose inspection method. The possibilities are given below:

Blob count: counts blobs inside a specific area. Pressing , a number appears on the

and . The number corresponds to the number of objects

to continue.

Pattern match: counts the objects inside a specific area. Pressing , a number appears

and . The number corresponds to the number of

to continue.

Contour match: compares the template with the target-object according to the contour

to save present configuration or to exit without saving.

.

4

Loading...

Loading...