DATASENSOR S62 Instruction Manual

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

S62…B

Polarised retroreflex

INSTRUCTION MANUAL

CONTROLS

OUTPUT LED (yellow)

The yellow LED ON indicates the following output

status: N.O. closed and N.C. open.

STABILITY LED (green)

The green LED permantely ON indicates a stable

operating condition, where the signal received has a

safety margin higher than 30% respect to the output

switching value. The sensor is ready to function

correctly.

SENSITIVITY TRIMMER (ADJ.)

A mono-turn trimmer adjusts the sensitivity and the

sensor operating distance.

See the “SETTING” paragraph for the functioning

mode.

NOTE

: the maximum trimmer mechanical rotating

range is equal to 240°. Do not force over the maximum

e minimum positions.

INSTALLATION

The sensor can be

positioned by means of

the three housing’s

holes using two screws

(M4x25 or longer, 1.5

Nm maximum tightening

torque) with washers.

Various orientable fixing

brackets to ease the sensor positioning are available

(please refer to the accessories listed in the

catalogue).

The operating distance is measured from the front

surface of the sensor optics.

The M12 connector can be oriented at two different

positions using the specific fastening spring and

rotating the block of 180°.

TECHNICAL DATA

Power supply: 10 … 30 Vdc (limit values)

Ripple: 2 Vpp max.

Current consumption

(output current excluded):

Outputs: PNP or NPN N.O. / N.C.; 30 Vdc max. (short-circuit protection)

Output current: 100 mA max (overload and overvoltage protection)

Output saturation voltage:

Response time:

Switching frequency: 1 kHz

Indicators: OUTPUT LED (YELLOW) / STABILITY LED (GREEN)

Setting: mono-turn sensitivity adjustment trimmer

Operating temperature: -10 … 55 °C

Storage temperature: -20 … 70 °C

Dielectric strength: 500 Vac / 1 min. between electronic parts and housing

Insulation resistance:

Operating distance (typical values): 0.1…8 m su R2 (EG = 2)

Emission type: RED (640 nm)

Ambient light rejection: according to EN 60947-5-2

Vibrations: 0.5 mm amplitude, 10 … 55 Hz frequency, for each axis (EN60068-2-6)

Shock resistance: 11 ms (30 G) 6 shocks for each axis (EN60068-2-27)

Housing material: ABS

Lens material: window in PMMA, lenses in polycarbonate

Mechanical protection: IP67

Connections:

Weight: 90 g. max. (cable version) / 40 g. max. (connector version)

>20 MΩ / 500 Vdc, between electronic parts and housing

2 m ∅ 4 mm cable / M12 4-pole connector

< 30 mA

≤ 2 V

500 µs max.

CONNECTIONS

SETTING

Alignement:

- Align sensor and reflector on opposite sides at the necessary

distance.

- Rotate in the clockwise direction the sensitivity adjustment

trimmer (ADJ.) to maximum level.

- Moving the sensor vertically and horizontally, establish the

powering and turning off of the yellow LED (OUT) and fix the

sensor at in the middle. The best alignment is obtained in the

following condition: yellow LED permanently OFF and green

LED permanently ON.

Control

:

- Place the target between the

sensor and the reflector. Control

that the yellow LED turns ON.

- Remove the target and control

that the yellow LED turns OFF again.

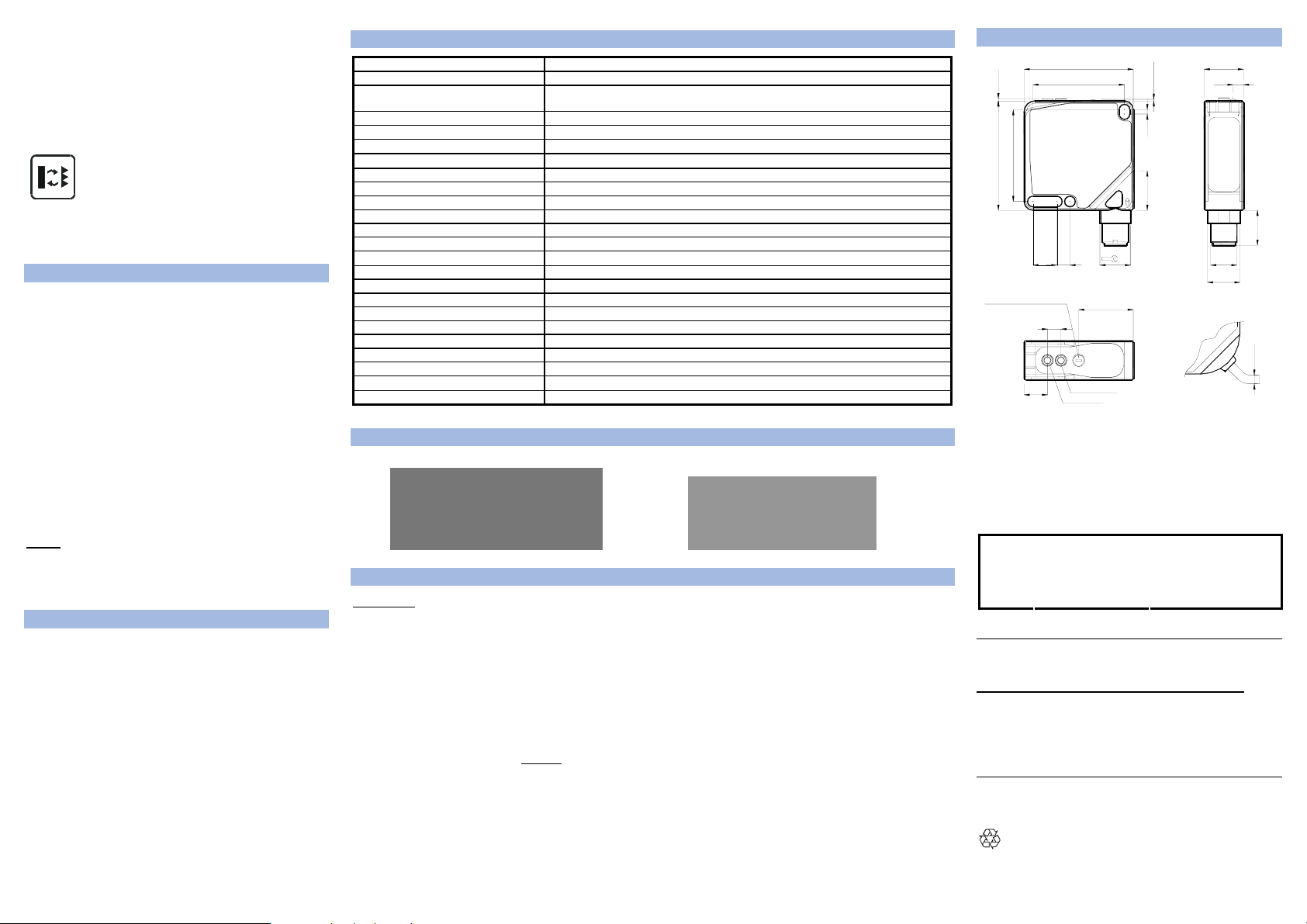

DIMENSIONS

50

1.1

42

50

SENSITIVITY TRIMMER

10.7

DECLARATION OF CONFORMITY

We DATASENSOR S.p.A. declare under our sole responsibility that

these products are conform to the 2004/108 CEE, 73/23 CEE Directives

and successive amendments.

WARRANTY

DATASENSOR S.p.A. warrants its products to be free from defects.

DATASENSOR S.p.A. will repair or replace, free of charge, any product

found to be defective during the warranty period of 36 months from the

manufacturing date.

This warranty does not cover damage or liability deriving from the

improper application of DATASENSOR products.

DATASENSOR S.p.A. Via Lavino 265

40050 Monte S. Pietro - Bologna - Italy

Tel: +39 051 6765611 Fax: +39 051 6759324

http://www.datasensor.com e- mail: info@datasensor.com

DATASENSOR S.p.A. cares for the environment: 100% recycled

paper.

DATASENSOR S.p.A. reserves the right to make modifications

and improvements without prior notification.

42

6

11

25

6.18

STABILITY LED

OUTPUT LED

EX-II-3D T6

Temperature class:

Max. Power consumpti 540 mW at 30 Vdc

Max. Internal capacitan100 nF

Internal inductance: negligible

0.75

2

18x45°

14

T6 (<85°C)

826003020 Rev.00

18

4.7

16

M12

Ø15

CABLE VERSION

Ø4

mm

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

S62…M

Background suppression

INSTRUCTION MANUAL

CONTROLS

OUTPUT LED (yellow)

The yellow LED ON indicates that the N.O. output is closed and the N.C.

output is open.

STABILITY LED (green)

When permanently ON, the green LED indicates a normal operating condition

where the received signal has a safety margin superior to 30% respect to the

output switching value. The sensor is ready to function correctly (stability

condition).

DISTANCE ADJUSTMENT TRIMMER (ADJ.)

A 6-turn trimmer allows the background suppression distance adjustment

through a mechanical variation of the optic triangulation angle.

The operating distance increases, rotating the screws in a clockwise direction.

Please refer to the “SETTING” paragraph for acquisition or setup procedure

indications.

POSITION INDICATOR

This indicator presents a scale numbered from 1 to 6 that allows a precise

adjustment of the suppression distance in the entire operating range.

Please refer to the “SETTING” paragraph for use indications.

TIMER ADJUSTMENT TRIMMER (only. M05/M15/M25/M35 vers.)

This control allows to vary the output delay deactivation from 0 to 1 sec.

Please refer to “TIMER FUNCTIONS” paragraph for use indications.

INSTALLATION

The sensor can be positioned by means

of the three housing’s holes using two

screws (M4x25 or longer, 1.5Nm max.

tightening torque) with washers.

Various orientable fixing brackets to

ease the sensor positioning are

available (please refer to the general

catalogue).

The operating distance is measured

from the front surface of the sensor optics.

The M12 connector can be oriented at two different positions using the

specific fastening spring and rotating the block of 180°.

CONNECTIONS

M12 connector

TECHNICAL DATA

Power supply: 10 … 30 VDC

Ripple: 2 Vpp max.

Consumption

(output current excluded):

Outputs: PNP or NPN N.O./N.C.; 30 Vdc max. (short-circuit protection)

Output current: 100 mA (overload and overvoltage protection)

Output saturation voltage:

Response time:

Switching frequency: 1 kHz 500 Hz 330 Hz

Emission type: RED (660 nm) INFRARED (880 nm)

Spot dimension: 6x6 mm (at 200 mm) 15x15 mm (at 400 mm) 200x200 mm (at 2000 mm)

Operating distance (typical values):

Adjustment: Multiturn distance adjustment trimmer / Timer adjustment trimmer (only M05/M15/M25/M35 vers.)

Difference (90% white / 4% black): < 8 % < 12 % < 25 % < 30 %

Hysteresis (90% white): < 5 % < 20 %

Indicators: OUTPUT LED (YELLOW) / STABILITY LED (GREEN)

Operating temperature: -10 … 55 °C

Storage temperature: -20 … 70 °C

Dielectric strength: 500 Vac 1 min., between electronics and housing

Insulating resistance:

Ambient light rejection: According to EN 60947-5-2

Vibrations: 0.5 mm amplitude, 10 … 55 Hz frequency, for each axis (EN60068-2-6)

Shock resistance: 11 ms (30 G) 6 shock for each axis (EN60068-2-27)

Housing material: ABS

Lens material: PMMA window; PC lens

Mechanical protection: IP67

Connections:

Weight: 90 g. max. cable vers. / 40 g. max. connector vers.

S62-M0… S62-M1… S62-M2… S62-M3…

40 mA max.

≤ 2 V

500 μs

30…300 mm 60…600 mm 60…1200 mm

>20 MΩ 500 Vdc, between electronics and housing

2 m cable ∅ 4 mm / M12 4-pole connector

1 ms 1,5 ms

200…2000 mm

(recommended target 400x400mm)

SETTING

Suppression distance setting

1. Object detection

Position object to detect in front of the sensor at the distance required.

Turn distance adjustment trimmer (ADJ) to minimum: yellow LED OFF and

green LED ON.

Rotate trimmer in an anticlockwise direction until yellow LED turns OFF

and green LED ON: condition where background is outside operating

range (C status of position indicator).

Rotate trimmer in a clockwise direction until the yellow LED and green LED

turn ON. Object detection condition (A status of position indicator)

A

2. Background suppression

C

3. Setting and control

Rotate trimmer in an anticlockwise direction until the indicator reaches

an intermediate point between position A and C.

If position A and C are close to each other, leave trimmer on position C.

The sensor is now ready to function correctly and in stable conditions:

Remove object and ensure that the background is in front of the sensor:

yellow LED OFF and green LED ON.

DIAGRAMMA DI RILEVAZIONE

Rotate trimmer in a clockwise direction until the yellow LED and green LED

turn ON: background detection condition (B status of position indicator).

B

The trimmer reaches maximum level with yellow LED OFF if the background

is outside the operating range.

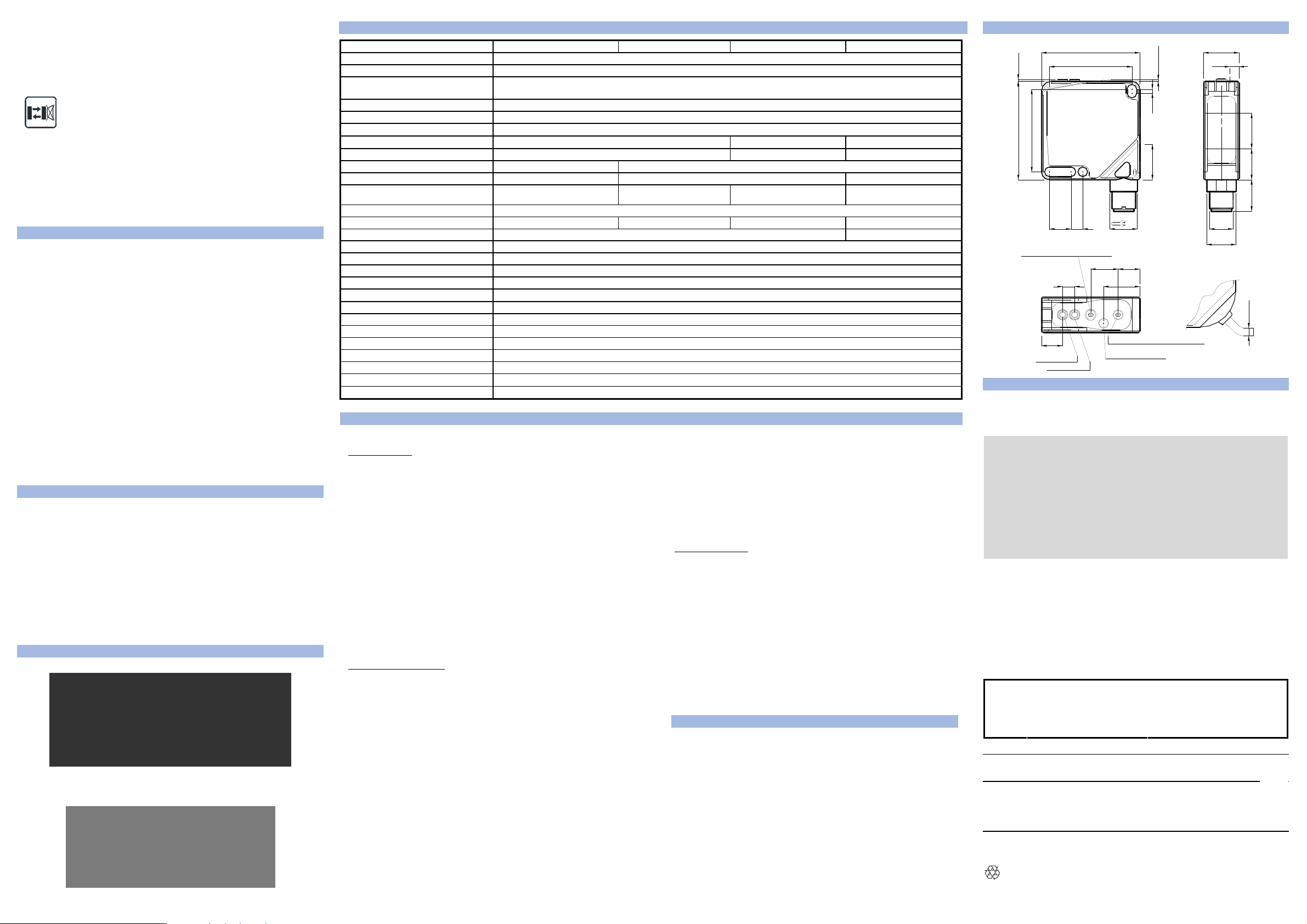

DIMENSIONS

50

11

42

6

1.1

42

50

TIMER ADJUSTMENT

TRIMMER (mod.M05/M15/M25/M35)

6.18

10.7

OUTPUT LED

STABILITY LED

0.75

2

RECEIVER

EMITTER

18x45°

14

1114

CABLE VERSION

18.4

DISTANCE ADJUSTMENT TRIMMER

POSITION INDICATOR

18

4.7

18.215.5

16

M12

Ø15

Ø4

mm

TIMER FUNCTION (S62…M05/M15/M25)

The timer function allows to adjust the output deactivation delay when the

object is outside the detection area. The delay extends the output activation

allowing the slower interface systems to detect shorter pulses.

The delay adjustment is carried-out manually using the Timer adjustment

trimmer. Clockwise rotation increase the delay from 0 to a max. 1 sec. value.

EX-II-3-D T6

Temperature class:

Max. Power consumption: 1260 mW at 30 Vdc

Max. Internal capacitance: 130 nF

T6 (<85°C)

Internal inductance: negligible

DECLARATION OF CONFORMITY

We DATASENSOR S.p.A. declare under our sole responsibility that these products are conform to the

2004/108/CE, 2006/95/CE Directives and successive amendments.

WARRANTY

DATASENSOR S.p.A. warrants its products to be free from defects.

DATASENSOR S.p.A. will repair or replace, free of charge, any product found to be defective during the

warranty period of 36 months from the manufacturing date.

This warranty does not cover damage or liability deriving from the improper application of

DATASENSOR products.

DATASENSOR S.p.A. Via Lavino 265

40050 Monte S. Pietro - Bologna - Italy

Tel: +39 051 6765611 Fax: +39 051 6759324

http://www.datasensor.com e-mail: info@datasensor.com

DATASENSOR S.p.A. cares for the environment: 100% recycled paper.

DATASENSOR S.p.A. reserves the right to make modifications and improvements without

prior notification.

826002872 Rev.D

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

S62-PL…B Laser

Polarised retroreflex

INSTRUCTION MANUAL

CONTROLS

OUTPUT LED (yellow)

The yellow LED ON indicates the following output status: N.O.

closed and N.C. open.

POWER ON LED (green)

The green LED ON indicates the sensor powering status and

laser emission presence.

SENSITIVITY TRIMMER (ADJ.)

Monoturn trimmer that adjusts the sensitivity and thus the

sensor operating distance.

Please refer to “SETTING” paragraph for the correct use

procedure.

WARNING

equal to 240°. Do not apply excessive torque over the

maximum and minimum positions.

The sensor can be positioned by

means of the three housing’s

holes using two screws (M4x25

or longer, 1.5 Nm maximum

tightening torque) with washers.

Various orientable fixing brackets

to ease the sensor positioning

are available (please refer to the accessories listed in the

general catalogue).The operating distance is measured from

the front surface of the sensor optics.

The M12 connector can be oriented at two different positions

using the specific fastening spring and rotating the block to

180°.

M12 connector

: the maximum mechanical trimmer rotation is

INSTALLATION

CONNESSIONS

TECHNICAL DATA

Power supply: 10 … 30 Vcc

Ripple: 2 Vpp max.

Consumption

(output current excluded):

30 mA max

Outputs: PNP or NPN N.O. / N.C.; 30 Vdc max. (short-circuit protection)

Output current: 100 mA max (overload and overvoltage protection)

Output saturation voltage:

Response time:

≤ 2 V

200 µs

Switching frequency: 2.5 kHz

Emission type:

RED LASER (λ = 645…665 nm): Class 2 EN 60825-1 (1994), Class II CDRH 21

CFR PART 1040.10

Pulsed emission: pot. max ≤ 5 mW; pulse duration = 5 µs;

frequency max = 32 KHz

Operating distance (typical values): refer to TAB.1

Min. detectable object dimension: 0.5 mm at 0.5m (minimum spot)

Indicators: OUTPUT LED (YELLOW) / POWER ON LED (GREEN)

Setting: Monoturn sensitivity adjustment trimmer

Functioning temperature: -10 … 55 °C

Storage temperature: -20 … 70 °C

Dielectric strength: 500 Vac 1 min., between electronics and housing

Insulating resistance:

>20 MΩ 500 Vdc, between electronics and housing

Ambient light rejection: according to EN 60947-5-2

Vibrations: 0.5 mm amplitude, 10 … 55 Hz frequency, for every axis (EN60068-2-6)

Shock resistance: 11 ms (30 G) 6 shock for every axis (EN60068-2-27)

Housing material: ABS

Lens material: PMMA window, polycarbonate lenses

Mechanical protection: IP67

Connections: M12 4-pole connector

Weight: 40 g. max.

SETTING

Alignment:

- Position the sensor and reflector aligned on opposite sides at the

desired distance.

- Turn to maximum the sensitivity adjustment trimmer (ADJ.)

(clockwise).

- Determine the powering on and powering off points of the yellow LED

(OUT) by moving vertically and horizontally the sensor and mount the

sensor in the middle of the points found.

Control:

- Enter laterally the object inside the

operating field and control that the

yellow LED turns on.

- Remove the object and check that

the yellow LED turns off immediately

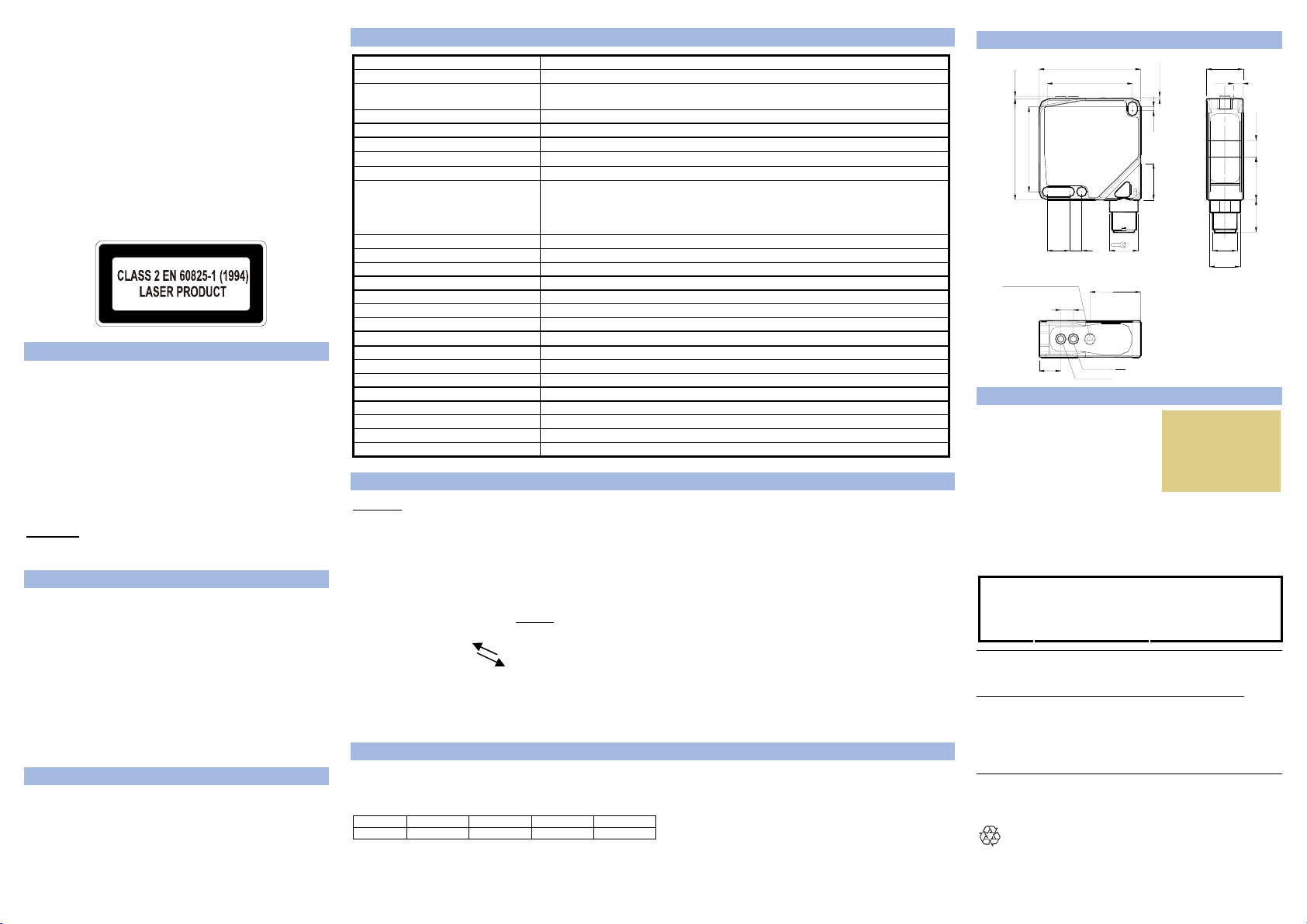

PERFORMANCES

TAB.1: Operating distances (m)

R1 R2 R6 R7 /R20 R8

0.3 … 16 0.3 … 20 0.4 … 22 0.3 … 22 0.2 … 2

Note: The use of the RT 3970 reflecting tape is not suggested.

REFLECTOR

spot diameter (mm)

distance (mm)

DIMENSIONS

SENSITIVITY TRIMMER

50

10.7

11

6.18

42

6

POWER ON LED

OUTPUT LED

25

1.1

42

50

0.75

2

18x45°

14

18

4.7

RECEIVER

EMITTER

21.5 8.5

16

M12

Ø15

mm

SAFETY PRECAUTIONS

All the electric and mechanical

safety regulations have to be

respected during sensor

functioning.

The sensor has to be protected

against mechanical damage.

Apply the labels supplied in a

visible position near the laser emission beam.

Do not stare directly into the laser beam!

Do not point the laser beam towards people!

Eye irradiation superior to 0.25 seconds is dangerous.

Please refer to the Class 2 Standard (EN60825-1).

These sensors can not be used for safety applications!

EX-II-3D T6

Temperature class:

Max. Power consumption: 800 mW at 30 Vdc

Max. Internal capacitance: 100 nF

DECLARATION OF CONFORMITY

We DATASENSOR S.p.A. declare under our sole responsibility that

these products are conform to the 2004/108/CE, 2006/95/CE Directives

and successive amendments.

WARRANTY

DATASENSOR S.p.A. warrants its products to be free from defects.

DATASENSOR S.p.A. will repair or replace, free of charge, any product

found to be defective during the warranty period of 36 months from the

manufacturing date.

This warranty does not cover damage or liability deriving from the

improper application of DATASENSOR products.

DATASENSOR S.p.A. Via Lavino 265

40050 Monte S. Pietro - Bologna - Italy

Tel: +39 051 6765611 Fax: +39 051 6759324

http://www.datasensor.com e- mail: info@datasensor.com

Internal inductance: negligible

DATASENSOR S.p.A. cares for the environment: 100% recycled

paper.

DATASENSOR S.p.A. reserves the right to make modifications

and improvements without prior notification.

826003251 Rev.B

T6 (<85°C)

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

S62-PL…M Laser

Background suppression

INSTRUCTION MANUAL

CONTROLS

OUTPUT LED (yellow)

The yellow LED ON indicates the output status: N.O. closed and N.C. open.

POWER ON LED (green)

The green LED ON indicates the sensor powering status and laser emission

presence.

DISTANCE ADJUSTMENT TRIMMER (ADJ.)

The multiturn trimmer with clutch (6 turn) adjusts the suppression distance

through the mechanical variation of the optic triangulation angle.

The operating distance increases rotation the trimmer shaft in a clockwise

direction.

Please refer to “SETTING” paragraph for the correct use procedure.

POSITION INDICATOR

This indicator has a scale numbered from 1 to 6 that allows the precise

adjustment of the suppression distance on the entire operating range.

Please refer to “SETTING” paragraph for the correct use procedure.

INSTALLATION

The sensor can be positioned by means

of the three housing’s holes using two

screws (M4x25 or longer, 1.5 Nm

maximum tightening torque) with

washers.

Various orientable fixing brackets to

ease the sensor positioning are

available (please refer to the

accessories listed in the general

catalogue).

The operating distance is measured from the front surface of the sensor

optics.

The M12 connector can be oriented at two different positions using the

specific fastening spring and rotating the block to 180°.

CONNECTIONS

M12 connector

TECHNICAL DATA

Power supply: 10 … 30 VDC

Ripple: 2 Vpp max.

Consumption

(output current excluded):

Outputs: PNP or NPN N.O. / N.C.; 30 VDC max. (short-circuit protection)

Output current: 100 mA (overload and overvoltage protection)

Output saturation voltage:

Response time:

Switching frequency: 3.5 kHz 2.5 kHz

Emission type:

Focalisation point : 60 mm 150 mm

Spot dimension: < 0.2 mm (at 60 mm) < 0.4 mm (at 150 mm)

Operating distance (typical values): 30…150 mm 50…350 mm

Adjustment: 4-turn distance adjustment trimmer 6-turn distance adjustment trimmer

Difference (90% white/ 4% black): < 4 % (see DETECTION DIAGRAM)

Hysteresis (90% white): < 1 %

Indicators: OUTPUT LED (YELLOW) / POWER ON LED (GREEN)

Functioning temperature: -10 … 55 °C

Storage temperature: -20 … 70 °C

Dielectric strength: 500 Vac 1 min., between electronics and housing

Insulating resistance:

Ambient light rejection: According to EN 60947-5-2

Vibrations: 0.5 mm amplitude, 10 … 55 Hz frequency, for each axis (EN60068-2-6)

Shock resistance: 11 ms (30 G) 6 shock for each axis (EN60068-2-27)

Housing material: ABS

Lens material: PMMA window; PC lens

Mechanical protection: IP67

Connections: M12 4-pole connector

Weight: 40 g. max.

RED LASER (λ = 645…665nm): Class 2 EN 60825-1 (1994), Class II CDRH 21 CFR PART 1040.10

Pulsed emission: pot. max ≤ 5mW; pulse duration = 5μs; frequency = 14KHz (mod. M01) / 10KHz (mod. M11)

S62-PL-M01… S62-PL-M11…

30 mA max

≤ 2 V

140 μs 200 μs

>20 MΩ 500 Vdc, between electronics and housing

SETTING

Suppression distance setting

1. Object detection

Position object to detect in front of the sensor at the distance required.

Turn distance adjustment trimmer (ADJ) to minimum: yellow LED OFF and

green LED ON.

Rotate trimmer in an anticlockwise direction until yellow LED turns OFF

and green LED ON: condition where background is outside operating

range (C status of position indicator).

Rotate trimmer in a clockwise direction until the yellow LED and green LED

turn ON. Object detection condition (A status of position indicator).

C

3. Setting and control

Rotate trimmer in an anticlockwise direction until the indicator reaches

an intermediate point between position A and C.

A

2. Background suppression

Remove object and ensure that the background is in front of the sensor:

yellow LED OFF and green LED ON.

If position A and C are close to each other, leave trimmer on position C.

The sensor is now ready to function correctly and in stable conditions.

DETECTION DIAGRAM

Rotate trimmer in a clockwise direction until the yellow LED and green LED

turn ON: background detection condition (B status of position indicator).

B

The trimmer reaches maximum level with yellow LED OFF if the background

is outside the operating range.

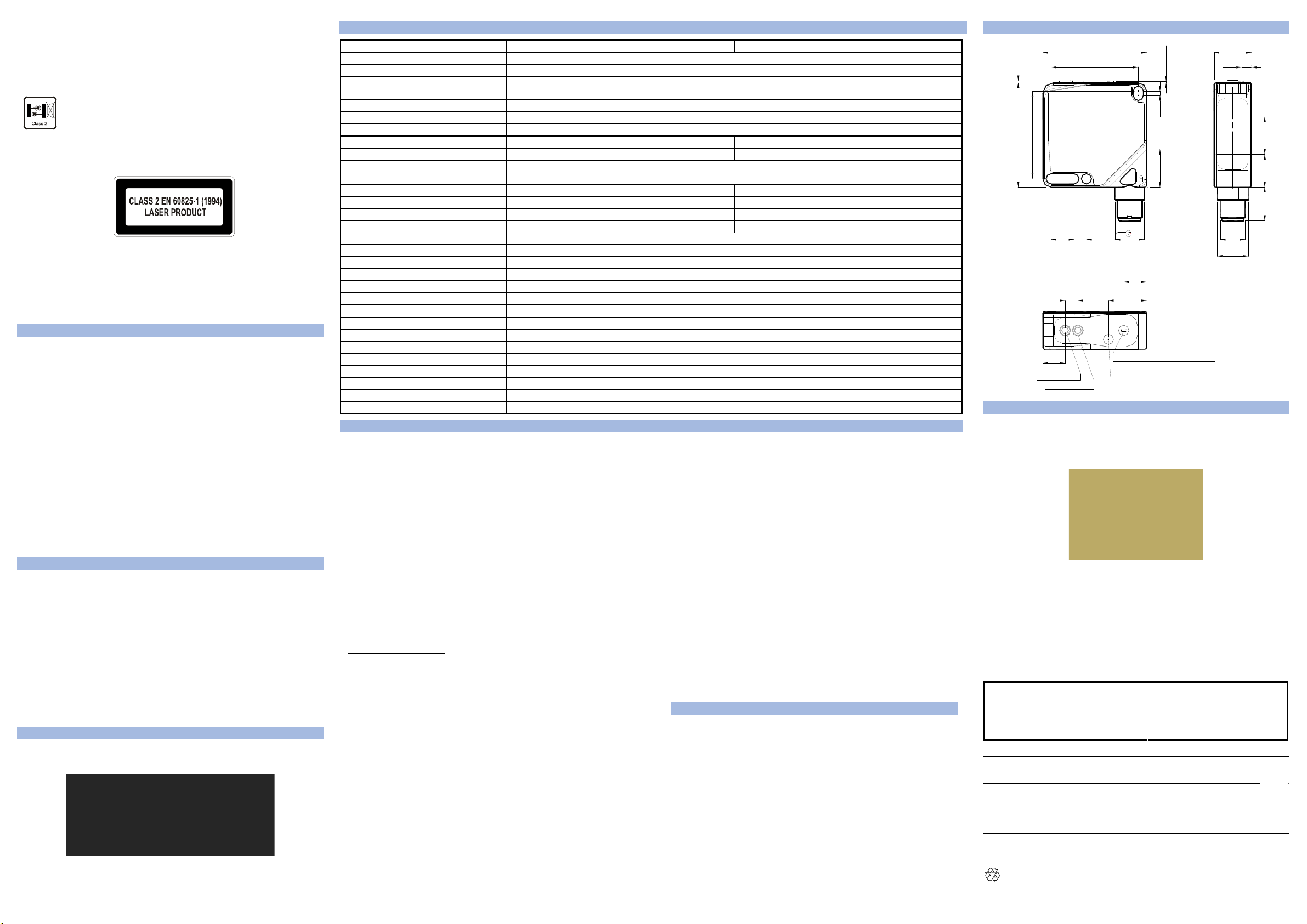

DIMENSIONS

50

1.1

50

42

42

2

0.75

RECEIVER

EMITTER

18x45°

6

11

14

11

6.18

10.7

OUTPUT LED

POWER ON LED

18.4

DISTANCE ADJUSTMENT TRIMMER

POSITION INDICATOR

18

4.7

18.215.5

16

M12

Ø15

mm

SAFETY PRECAUTIONS

All the electric and mechanical safety regulations have to be respected during

sensor functioning.

The sensor has to be protected against mechanical damage.

Apply the labels supplied in a visible position near the laser emission beam.

Do not stare directly into the laser beam!

Do not point the laser beam towards people!

Eye irradiation superior to 0.25 seconds is dangerous. Please refer to the

Class 2 Standard (EN60825-1).

These sensors can not be used for safety applications!

EX-II-3-D T6

Temperature class:

T6 (<85°C)

Max. Power consumption: 800 mW at 30 Vdc

Max. Internal capacitance: 100 pF

Internal inductance: negligible

DECLARATION OF CONFORMITY

We DATASENSOR S.p.A. declare under our sole responsibility that these products are conform to the

2004/108/CE, 2006/95/CE Directives and successive amendments.

WARRANTY

DATASENSOR S.p.A. warrants its products to be free from defects.

DATASENSOR S.p.A. will repair or replace, free of charge, any product found to be defective during the

warranty period of 36 months from the manufacturing date.

This warranty does not cover damage or liability deriving from the improper application of

DATASENSOR products.

DATASENSOR S.p.A. Via Lavino 265

40050 Monte S. Pietro - Bologna - Italy

Tel: +39 051 6765611 Fax: +39 051 6759324

http://www.datasensor.com e-mail: info@datasensor.com

DATASENSOR S.p.A. cares for the environment: 100% recycled paper.

DATASENSOR S.p.A. reserves the right to make modifications and improvements without

prior notification.

826003241 Rev.B

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

S62…Y

Micrometric Distance Meter

INSTRUCTION MANUAL

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

We

Y

Y

T

T

I

I

declare under our sole responsibility that the product(s)

M

M

R

R

S62-PX-X-XXX-XX, PHOTOELECTRIC SENSOR AND ALL ITS MODELS

O

O

To which this declaration relates in conformity with the following

standard(s) or other normative document(s)

F

F

60947-5-2, OCTOBER 1998:

EN

N

N

L

OW-VOLTAGE SWITCHGEAR AND CONTROLGEAR. PART 5: CONTROL CIRCUIT

O

O

C

C

F

F

O

O

N

N

O

O

I

I

T

T

A

A

DEVICES AND SWITCHING

CEI EN 60947-5-2/A1, JUNE 2000

CEI EN 60947-5-2/A2, JULY 2005

IEC 61000-6-2, JANUARY 1999:

ELECTROMAGNETIC COMPATIBILITY (EMC).

PART 6-2: GENERIC STANDARDS – IMMUNITY FOR INDUSTR IAL EVIRONMENTS

EN 55011, MAY 1998:

INDUSTRIAL, SCIENTIFIC AND MEDICAL (ISM) RADIO-FREQUENCY EQUIPMENT

RADIO DISTURBANCE CHARACTERISTICS

IMITS AND METHODS OF MEASUREMENT

L

Following the provision of the Directive(s):

DATASENSOR S.p.A.

Via Lavino, 265

40050 Monte San Pietro

Bologna - Italy

. SECTION 2: PROXIMITY SWITCHES

R

R

A

A

L

L

C

C

E

E

D

D

2004/108

93/68 CEE.

Monte San Pietro 24/11/2006

Giuseppe De Maria

Quality Assurance

CEE (EMC), 73/23 CEE (LV) AND SUCCESSIVE AMENDMENTS,

UNI EN ISO 14001

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

S62…Y Series Instruction Manual

TABLE OF CONTENTS

1. GENERAL INFORMATION...................................................................................................................1

1.1. General description......................................................................................................................1

1.2. Key features.................................................................................................................................1

1.3. Operating principle.......................................................................................................................1

1.4. S62Y Manager.............................................................................................................................2

2. DIRECTIONS FOR INSTALLATION.....................................................................................................3

2.1. Set-up and alignment...................................................................................................................3

2.2. Positioning the sensor with respect to the target object..............................................................3

3. DIRECTIONS FOR ELECTRICAL INSTALLATION.............................................................................4

4. USER INTERFACE ...............................................................................................................................5

4.1. General meaning of LED status during operation.......................................................................5

4.1.1. SET....................................................................................................................................6

4.1.2. SEL....................................................................................................................................6

4.1.3. SET+ SEL (adj.) ................................................................................................................8

5. STAND-ALONE MASTER/SLAVE FUNCTIONING.............................................................................9

5.1. Installation....................................................................................................................................9

5.2. Notes..........................................................................................................................................10

6. FUNCTIONS ACCESSIBLE VIA RS485.............................................................................................11

6.1. Protocol definition......................................................................................................................11

6.2. Commands ................................................................................................................................12

6.2.1. On-demand measurement reading .................................................................................12

6.2.2. Changing device address................................................................................................13

6.2.3. Changing device transmission delay...............................................................................14

6.2.4. Output smoothing (averaging).........................................................................................15

6.2.5. Continuous transmission mode on RS485......................................................................16

6.2.6. Changing analogue output gradient................................................................................17

6.2.7. Management of internal buffer memory ..........................................................................18

7. TROUBLESHOOTING ........................................................................................................................20

8. OVERVIEW OF PRODUCT FEATURES............................................................................................22

8.1. Optic specifications....................................................................................................................22

8.2. Electrical specifications..............................................................................................................22

8.3. Mechanical specifications..........................................................................................................22

8.4. Risoluzione del sistema.............................................................................................................23

8.5. Overall dimensions....................................................................................................................24

9. SAFETY PRECAUTIONS....................................................................................................................25

10. ACCESSORIES...................................................................................................................................26

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Instruction Manual S62…Y Series

1. GENERAL INFORMATION

1.1. General description

S62Y is a red laser light emitting optic sensor for contactless distance measurement.

It is equipped with analogue outputs (0..10 V voltage outputs or 4..20 mA current outputs, depending

on the model), one digital output, one alarm output and a half-duplex RS485 interface.

Two S62…Y sensors may be combined to achieve differential direct detection, for such applications

as thickness determination.

The RS485 interface supports up to eight S62…Y sensors connected to a single half-duplex

RS485, which may be controlled like common addressable peripherals.

1.2. Key features

• Operating range: 40…120 mm

• Two digital outputs (Output and Alarm)

• 4..20 mA analogue output for S62-PL-5-Y03-PIZ version

• 0..10 V voltage output for S62-PL-5-Y03-PVZ version

• User interface with two buttons and three LEDs

• Overall dimensions 50x50x18 mm

• Resolution lower than 50 µm throughout the measurement range

• Half-duplex RS485 interface capable of managing several bus sensors (max. 8)

• Programmable serial transmission baud rate and time delays

1.3. Operating principle

The S62…Y sensor uses optical triangulation to determine the position of the target object: when the

laser beam is reflected from the object to the receiver, spot position is digitally processed to calculate

object position.

Fig. 1

1

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

S62…Y Series Instruction Manual

1.4. S62Y Manager

Developed alongside the product to ensure intuitive, fast operation, the S62…Y Manager control

interface enables even less expert users to set up complex applications using one or more S62…Y

sensors, making use of the advanced features available through the serial interface.

The software is available on the CD-ROM enclosed with the product and includes exhaustive on-line

help.

It operates in the Windows 2000/XP/Vista environment.

Special features:

• Manages several sensors at the same time

• Measurement indicator with figures and graphic display

• Differential detection/reading comparison between pairs of sensors

• Data plotting to time vs. distance XY graph

(graph display may be turned on/off by user)

• Graph windows may be saved in image format

• Acquired data may be saved in ASCII format

• Data may be saved to a binary meta-format file

• Event management and ASCII LOG file (alarms)

• The graphic structure makes the software easy to control through a touch-screen display.

2

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Instruction Manual S62…Y Series

2. DIRECTIONS FOR INSTALLATION

The S62…Y sensor must be installed using suitable anti-vibration mounts to ensure the greatest

possible measurement accuracy.

2.1. Set-up and alignment

Rotate the mobile connector into the ideal position for installation; the cable should be free and not

stretched taut. Use the suitable brackets (see paragraph 8 “Accessories”) to fix the sensor. The

angles specified in the following paragraph must be observed.

Use the pre-drilled mounting holes only

2.2. Positioning the sensor with respect to the target object

The (actual or tangent) measurement plane of the object must always be kept the most

perpendicular possible to the optical axis of sensor S62…Y as shown in Fig.2:

NO YES NO YES

Fig. 2

Rotary movement

Linear movement

Sensor S62…Y is now ready to operate.

3

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

S62…Y Series Instruction Manual

3. DIRECTIONS FOR ELECTRICAL INSTALLATION

Warning: Pins 1 and 6 are not short-circuit protected, do not connect them to power supply.

Sensor S62Y is equipped with an 8-pole M12 connector: Plug in the female connector making sure to

match the key and then tighten the ring nut firmly.

Description of connections (for colours, please refer to the DATASENSOR cable).

Connection Colour Purpose Notes

1 White RS485 (TXB/-) Not protected

2 Brown +VDC 18..30VDC

3 Green Analogue out 0..10V (PVZ)

4..20mA (PIZ)

4 Yellow Digital output Short-circuit

protected

5 Grey Alarm Short-circuit

protected

6 Pink RS485 (TXA/+) Not protected

7 Blue GND 8 Red Remote Input, 0..30VDC

Once powered, the sensor runs a set-up routine that takes about one second and then starts taking

measurements.

The 4..20 mA current analogue output meets industry-standard load requirements and

is rated for 0 to 500 Ω loads. For the 0..10V voltage analogue output, we recommend

using high-impedance load (e.g. 470 kΩ).

4

Loading...

Loading...