DATASENSOR AS1 Instruction Manual

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

AS1 SERIES

OUT LED on receiver (RX)

The yellow LED ON indicates the presence of the object into controlled area.

POWER ON LED on receiver (RX)

The green LED ON indicates the optimal device functioning.

The fast blinking of the green LED indicates a critical device alignment.

Please refer to “DIAGNOSTICS” paragraph for other indications.

POWER ON LED on emitter (TX)

The green LED ON indicates the correct device functioning.

Please refer to “DIAGNOSTICS” paragraph for other indications.

General information on device positioning

• Align the two receiver (RX) and emitter (TX) units, verifying that their distance is inside

the device operating distance, in a parallel manner placing the sensitive sides one in

front of the other, with the connectors oriented on the same side. The critical alignment

of the unit will be signalled by the fast blinking of the green receiver LED.

• Mount the two receiver and emitter units on rigid supports which are not subject to

strong vibrations, using specific fixing brackets and /or the holes present on the device

lids.

Precautions to respect when choosing and installing the device

• Choose the device according to the minimum object to detect and the maximum

controlled area requested.

• In agro-industrial applications, the compatibility of light grid housing material and any

chemical agents used in the production process has to be verified with the assistance

of the DATASENSOR technical sales support department.

• The AREAscan

the safety control of the machines where installed.

Moreover the following points have to be considered:

- Avoid installation near very intense and / or blinking light sources, in particular near to

the receiver unit.

- The presence of strong electromagnetic disturbances can jeopardise the correct

functioning of the device. This condition has to be carefully evaluated and checked with

the DATASENSOR technical sales support department;

- The presence of smoke, fog and suspended dust in the working environment can

reduce the device’s operating distance.

- Strong and frequent temperature variations, with very low peak temperatures, can

generate a thin condensation layer on the optics surfaces, compromising the correct

functioning of the device.

- Reflecting surfaces near the luminous beam of the AREAscan

or lateral) can cause passive reflections able to compromise object detection inside the

controlled area.

- if different devices have to be installed in adjacent areas, the emitter of one unit must

not interfere with the receiver of the other unit.

General information relative to object detection and measurement

• For a correct object detection and / or measurement, the object has to pass completely

through the controlled area. Testing the correct detection before beginning the process

is suggested. The resolution is non uniform inside the entire controlled area. For

example the resolution in the AS1-HR model depends on the scanning program

chosen.

INSTRUCTION MANUAL

CONTROLS

INSTALLATION MODE

TM

light grids are NOT safety devices, and so MUST NOT be used in

TM

device (above, under

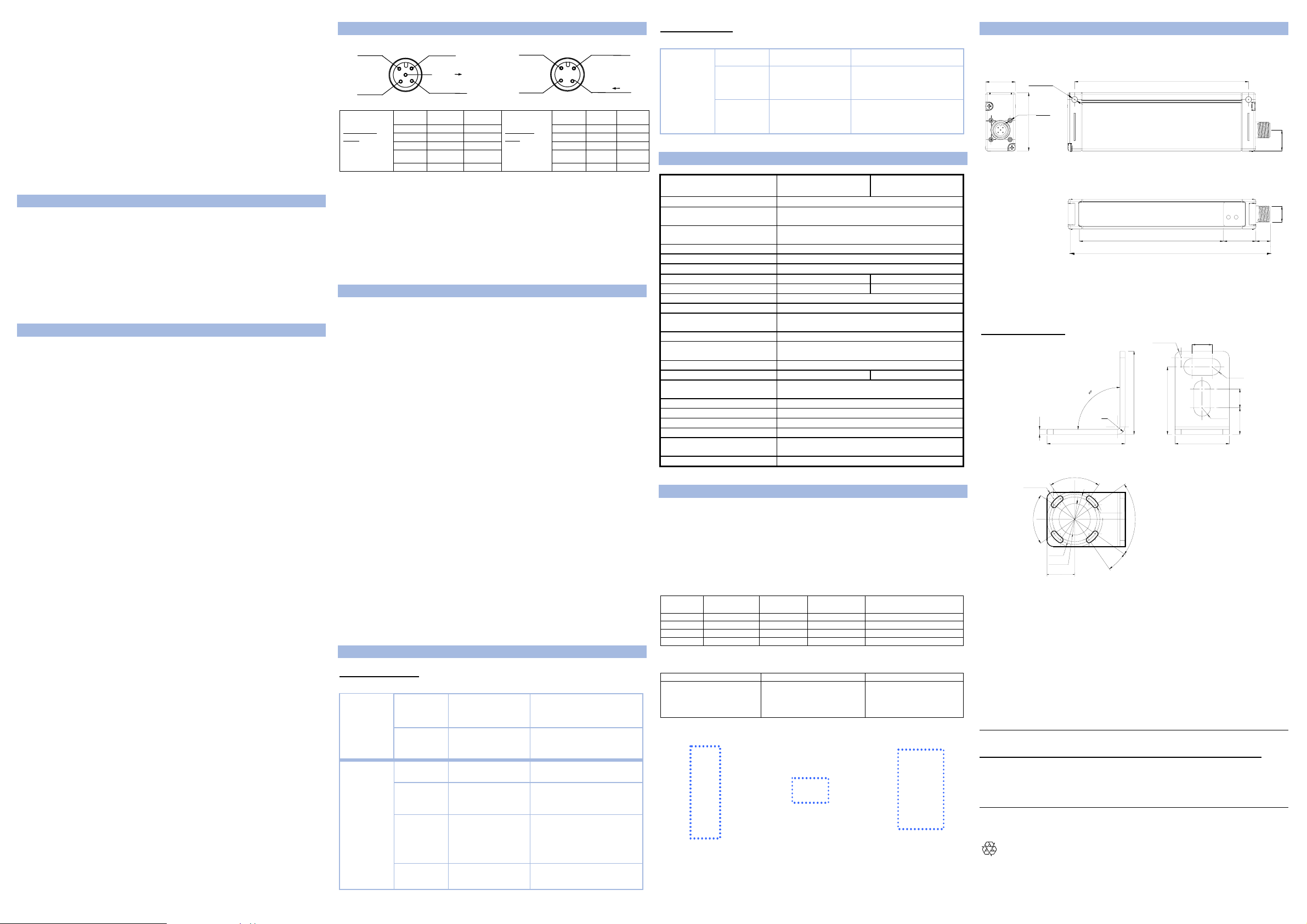

SEL_RX

RECEIVER

(RX):

M12 5-pole

connector

Shielded cables are not foreseen in the

2

1

5

3

0 V

1 – brown: +24 VDC +24 VDC 1 – brown: +24 VDC +24 VDC

2 – white: SEL_RX Not used 2 – white: SEL_TX Not used

3 – blue: 0 V 0 V 3 – blue: 0 V 0 V

4 – black:

5 – grey: SYNC SYNC

CONNECTIONS

SEL_TX

+24 VDC

SYNC ( TX)

4

SWITCHING

OUTPUT

AS1-HR AS1-SR AS1-HR AS1-SR

Switching

output

Switching

output

EMITTER

(TX):

M12 4-pole

connector

2

0 V

3

4 – black: SYNC SYNC

+24 VDC

1

SYNC ( RX)

4

standard connection.

Ground connection of the two units is not

necessary. If desired, this connection can be

obtained replacing the screw provided in the

packaging with the one indicated in the

drawing, which blocks the lid of the connector

side of each unit.

The respect of the connection shown in the

drawing, is necessary if ground connection of

the entire system is requested.

FUNCTIONING AND PERFORMANCES

The beam interruption due to the passage of an object inside the controlled area causes

the closing of the switching output and the variation of the device analogue output signal.

Small objects can be detected (reaching dimensions of only 0.5 mm) and with a reduced

surface area.

In particular:

The switching output is always activated when at least one beam is obscured.

The status variation is signalled by the yellow receiver LED that turns on.

The device presents inputs (both on TX and Rx units) that consent the selection of the

resolution and response time.

Low response times correspond to worser resolutions and viceversa.

The device does not require calibration; periodical checks of the resolution and / or

measurement are however suggested.

The blinking of the green receiver LED (stability function) signals the critical alignment of

the units and / or the functioning outside or near the maximum operating distance. In

optimal conditions the LED remains on continuously.

The two units are synchronised via cable (SYNC wire).

Precarious connections or induced disturbances on the synchronism line can cause

device malfunctioning or a temporary blocking.

RECEIVER UNIT:

Segnal Status Cause Action

OUT LED

POWER ON

LED

ON

OFF

ON

Fast blinking

Slow blinking

OFF

DIAGNOSTICS

Switching output.

Presence of the object in

the controlled area.

Switching output.

Controlled area free of

objects.

Optimal functioning.

Critical alignment of the

unit or/and functioning

closed to maximum

operating distance.

Wrong connections

and/or malfunctioning.

Device is not powered. - Verify the connections.

- Verify the output connections

and any short-circuits.

- Switch OFF and switch ON the

device.

- If condition persists, contact

Datasensor.

- If condition persists, contact

Datasensor.

EMITTER UNIT:

Segnal Status Cause Action

POWER ON

LED

ON

Blinking

OFF

Normal functioning of

emission unit.

Unit malfunctioning. - Switch OFF and switch ON the

Absence of power and/or

synchronism with

receiver

device.

- If condition persists, contact

Datasensor.

- Verify the connections and right

value of power supply.

- If condition persists, contact

Datasensor.

22

Ø4.5 N°2

M2 N°4

43.2

TECHNICAL DATA

Power supply:

Consumption on emitter unit

(TX):

Consumption on receiver unit

(RX):

AS1-LD-HR-010-xx

AS1-HD-HR-010-xx

24 Vdc ± 15%

150 mA max.

40 mA max, load excluded

AS1-LD-SR-010-xx

AS1-HD-SR-010-xx

Switching output: 1 PNP output

Switching output current: 100 mA; short-circuit protection

Output saturation voltage:

≤ 1.5 V at T=25 °C

Resolution: up to 0.5 mm up to 5 mm

Response time: 2.75 – 8 ms 1.75 ms

Operating temperature: 0…+ 50 °C

Storage temperature: -25…+ 70 °C

Operating distance

(typical values):

Emission type: INFRARED (880 nm)

Indicators:

0.3 - 2.1 m (AS1-LD) / 0.8…3 m (AS1-HD)

RX: OUT LED (yellow) / POWER ON LED (green)

FIXING BRACKET

TX: POWER ON LED (green)

Controlled height: 100 mm

N° beams: 16 6

Vibrations: 0.5 mm amplitude, 10 … 55 Hz frequency,

for every axis (EN60068-2-6)

Shock resistance: 11 ms (30 G) 6 shock for every axis (EN60068-2-27)

Housing material: Black electro-painted aluminium

Lens material: PMMA

Mechanical protection: IP65 (EN 60529)

Connections: M12 4-pole connector for TX

M12 5-pole connector for RX

Weight: 300 g.

R2.5 N°2

SCANNING PROGRAMS (only for AS1- HR)

The AS1-HR model presents inputs for the selection of the scanning program (SEL_RX ;

SEL_TX).

The selection is made connecting the input to +24Vdc.

The scanning program is activated only after input selection and device re-powering.

A different scanning program cannot be activated during device functioning.

According to the combination of the inputs selected, the response time or resolution can

be preferred, as described in the following table. The standard configuration (SEL_XX

floating inputs) corresponds to the lower resolution and highest response time .

PROG. N° SEL_RX SEL_TX RESOLUTION RESPONSE TIME (msec )

1 0V or FLOAT 0V or FLOAT LOW 2.75

2 0V or FLOAT +24Vdc M/L 3

3 +24Vdc 0V or FLOAT M/H 7.75

4 +24Vdc +24Vdc HIGH 8

Resolution figure: the box indicated the area with highest resolution

PROGRAM 1 PROGRAM 2 PROGRAM 3 - 4

Ideal for fast detection

on entire controlled area,

with low resolution.

Ideal for fast detection

on entire contolled area,

with constant resolution on

limited area.

Ideal for detection with

high resolution on entire

controlled area.

DECLARATION OF CONFORMITY

We DATASENSOR S.p.A. declare under our sole responsibility that these products are conform to the

2004/108/CE, 2006/95/CE Directives and successive amendments.

WARRANTY

DATASENSOR S.p.A. warrants its products to be free from defects.

DATASENSOR S.p.A. will repair or replace, free of charge, any product found to be defective during the

warranty period of 36 months from the manufacturing date.

This warranty does not cover damage or liability deriving from the improper application of

DATASENSOR products.

DATASENSOR S.p.A. Via Lavino 265

40050 Monte S. Pietro - Bologna - Italy

Tel: +39 051 6765611 Fax: +39 051 6759324

http://www.datasensor.com e-mail: info@datasensor.com

70°

DATASENSOR S.p.A. cares for the environment: 100% recycled paper.

DATASENSOR S.p.A. reserves the right to make modifications and improvements without prior

notification.

DIMENSIONS

129.1

15.5

mm

M12

107 10.8

150.1

24

R2.5 N°2

R3

R1.1 N°8

20°

33

4

°

N

26.8

70°

90

2

31

70°

Ø20

Ø12.5

11

826003121 Rev.B

8

R3.3

7.5

R3.3

10.5

21.6

Loading...

Loading...