ST 230

USER

MANUAL

DATAPROCESS EUROPE S.p.A.

20082 Binasco (MI)

Viale dell'Artigianato, 19

Tel. 02 900221

Fax. 02 90091353

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

1

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

2

CONTENTS:

1 INTRODUCTION................................................................................................................4

2 PRODUCT DESCRIPTION................................................................................................5

3 TECHNICAL SPECIFICATIONS........................................................................................7

4 UNPACKING AND INSPECTION......................................................................................8

5 STORAGE AND TRANSPORT..........................................................................................9

5.1 TRANSPORT................................................................................................................9

6 WORKING PLACE..............................................................................................................9

7 ELECTRICAL CONNECTIONS .......................................................................................10

7.1 NOTICE FOR CUSTOMERS IN THE UNITED KINGDOM.........................................10

7.2 REAR PANEL, CONNECTION ....................................................................................11

8 BEFORE USE OPERATI ONS.........................................................................................12

9 THERMAL TRANSFER RIBBON LOADING PROCEDURE.........................................14

10 LABEL ROLL LOADING PROCEDURE......................................................................17

10.1 STRIP MODE LABEL ROLL LOADING......................................................................19

10.2 DISPENSING MODE LABEL ROLL LOADING...........................................................20

11 FINAL OPERATIONS....................................................................................................22

12 USE OF THE PRINTE R................................................................................................24

13 USE OF THE PRINTE R FRONT PANEL....................................................................26

13.1 OPERATIONS FROM FRONT PANEL.......................................................................29

13.2 ON LINE.......................................................................................................................29

13.3 PRINTING PHASE STOP AND RESTART.................................................................29

13.4 OFF-LINE PHASE.......................................................................................................30

13.5 PRINTING INTERRUPTION........................................................................................31

13.6 DEMO TEXTS.............................................................................................................31

13.7 MACRO SELECTION..................................................................................................32

13.8 SET- UP OR CONFIGURATION MODE.....................................................................32

13.9 BAUD RATE SELECTION ...........................................................................................33

13.10 CHARACTER FONTS MAP SELECTION...............................................................34

13.11 PRINT MARGINS SELECTION................................................................................34

13.12 PRINTING SPEED SELECTION.............................................................................35

13.13 PRINTHEAD TEMPERATURE ADJUSTMENT .......................................................35

13.14 LABEL CALIBRATION ..............................................................................................36

13.15 OPERATION MODE SELECTION..........................................................................37

13.15.1 Label mode/paper mode....................................................................................37

13.15.2 Ribbon Economizer enable/disable...................................................................37

13.15.3 Thermal Transfer and Direct Thermal selection...............................................37

13.15.4 Enable/Disable of the photodispenser sensor (optional)..................................38

13.16 PARAMETER RESET..............................................................................................38

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

3

14 MAINTENANCE.............................................................................................................40

14.1 PRINTHEAD CLEANING.............................................................................................41

14.2 RUBBER ROLLS CLEANING.....................................................................................42

14.3 PAPER GUIDES METALLIC SHAFTS CLEANING....................................................42

15 TROUBLE SHOOTING ................................................................................................43

16 APPENDIX A..................................................................................................................46

16.1 SERIAL CABLE PINOUT.............................................................................................46

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

4

1 INTRODUCTION

The present manual contains information and advice that has to be followed in order to

ensure a safety use of the printer.

It is recommended to proceed with periodical maintenance and, if necessary, to send faulty

parts back to our distributor, as they are equipped with appropriate tools and specialised

personnel able to operate following the instructions of the manufacturer specialists.

ST 230 has to be installed following the here below instructions.

In case of mal - function contact the authorised distributor directly.

DATAPROCESS EUROPE S.p.A. is not responsible in case of maintenance carried out by

non authorised personnel or if the instructions in the present manual are not correctly

followed.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

5

2 PRODUCT DESCRIPTION

ST 230 is a label and slip overprinter to be used either in thermal transfer or direct thermal

mode.

The printer has been designed and

manufactured for use in industrial

applications where structure solidity is

essential for high-volume production.

Installation does not require special

technical knowledge and/or special

tools, please follow carefully

instructions in paragraph 7 of the

present manual.

Picture 1

Mechanical regulations are not required. Follow the instructions (see paragraph 13.14) for

automatic calibration of label photosensor.

The only operation before use is the label and ink ribbon roll loading (see relative paragraph).

ST 230 is available with a range of accessories that give more flexibility (see table page 4).

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

6

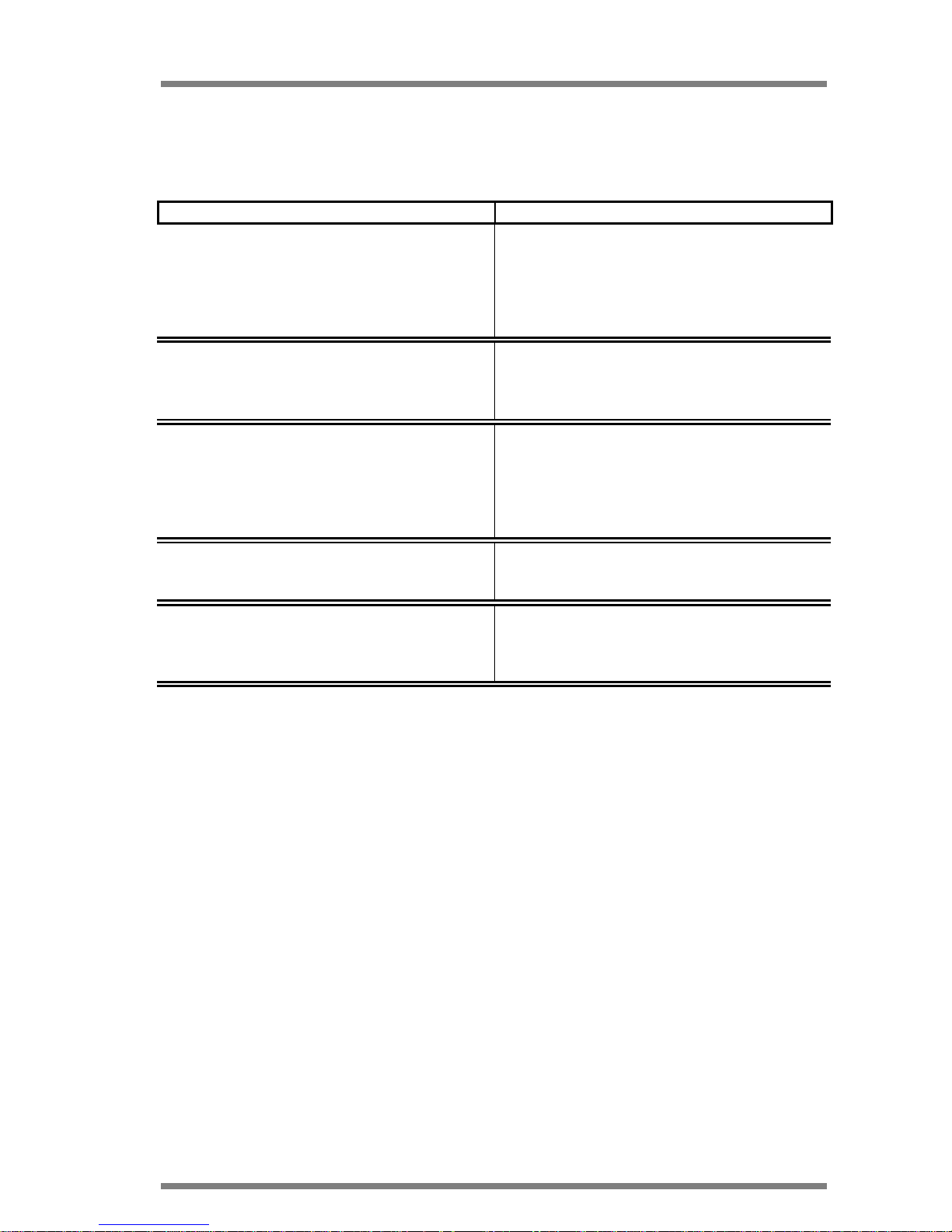

ST 230 ACCESSORIES TABLE

ACCESSORY DESCRIPTION

SOFTWARE LW230

PC graphics software MS DOS, it allows to

create and print the label.

CUTTER

Allow to produce tags and tickets from

continuous paper roll.

UNWINDER/REWINDER

Allow to unwind labels roll up to 250 mm of

diameter. A motor driven front rewinder

designed to rewind labels roll up to 250 mm of

diameter.

WINDOWS DRIVER

WinLW

PC graphics software Windows98, it allows to

create and print the label.

For further details see the Instructions of the accessories.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

7

3 TECHNICAL SPECIFICATIONS

PRINT MODE: Thermal transfer and direct thermal on thermal paper

PRINTING RESOLUTION: 6 dot/mm or 8 dot/mm

PRINT AREA SIZE: Up to 105 mm (6 dot/mm)

Up to 112 mm (8 dot/mm)

LABEL SIZE:

LENGTH: From 10 to 408 mm (6dot/mm) and from 10 to 287 mm (8dot/mm)

WIDTH: From 40 to 120 mm

LABEL ROLL SIZE: 150 mm maximum outside diameter

PRINT SPEED: Up to 125 mm/s (6 dot/mm), 100 mm/s (8 dot/mm),

regardless of text complexity.

PAPER FEED: Up to 180 mm/s

FONTS: Three standard alphanumeric fonts, two graphics fonts (logos and

symbols); 5 proportionally spaced fonts expandable from 0,8 x

1,2 mm to 110 x 95 mm.

BAR-CODES: Code 39, Code 93, 2/5 interleaved, Codabar, EAN 8, EAN 13,

EAN 128, UPC A, UPC E, Code 128, ADD_ON, ITF 14, ITF 16.

PRINTING ROTATION: 0°, 90°, 180°, 270°.

INTERFACE: RS 232 C, baud rate from 300 to 38400 bauds

XON/XOFF or CTS/RTS protocol

OVERALL SIZE: 280 mm x 210 mm x 460 mm

POWER SUPPLY: 220V +10% -15% single phase 50 Hz.

110 V (60 Hz) and 240 V version on request.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

8

4 UNPACKING AND INSPECTION

Open the packaging and check the following standard components:

1. ST 230 Printing mechanism

1. ST 230 User manual

1. Power cord

1. Anti-dust cover

Components inside the printer:

• Thermal/transfer ribbon cartridge

• Thermal/transfer ribbon rewind

clamp

• Ribbon roll locking pin

• Silicon paper locking clamp on the

rewinder

Picture 2

Save the packaging units and the non-impact material, to be used in case of returning the ST

230 printer or for internal moving.

Inspect the packaging to ensure that non damage did not incur during transport, and in

particular:

• check the external part of the printer

• open the side port to verify possible internal damage.

In case of damage.

• Notify the carrier directly, giving details about the damage

• Keep the whole packaging unit available for the inspection by the transporter

• Notify the transporter in writing and send a copy to DATAPROCESS EUROPE S.p.A.

or its distributor, indicating the amount of the damage.

IMPORTANT: DATAPROCESS EUROPE S.p.A is not responsible for

damages incurred during transport and is not authorized to

replace or repair under warranty.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

9

5 STORAGE AND TRANSPORT

In case of non immediate use the ST 230 should be stored within its original

package. The environmental conditions for storage are the following:

• Temperature from 5° C to 40° C

• Humidity: 20% to 90% non condensing.

5.1 TRANSPORT

In order to provide a safe moving of the printer follow the below instructions:

• Disconnect the printer from

the power supply (see

paragraph 7)

• Disconnect the data cable

from the serial port of the

printer

• Verify that both side and front

cover are closed.

Pack the printer as indicated in

picture 3 on your left.

Picture 3

6 WORKING PLACE

ST 230 can be installed on any flat surface able to support the weight of 17 Kg and of

dimensions to adequately locate the printer and its accessories as

indicated in picture 4 on your left.

It is recommended to leave an area around the unit sufficient to

warranty enough to maintain the working temperature within

specification.

Picture 4

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

10

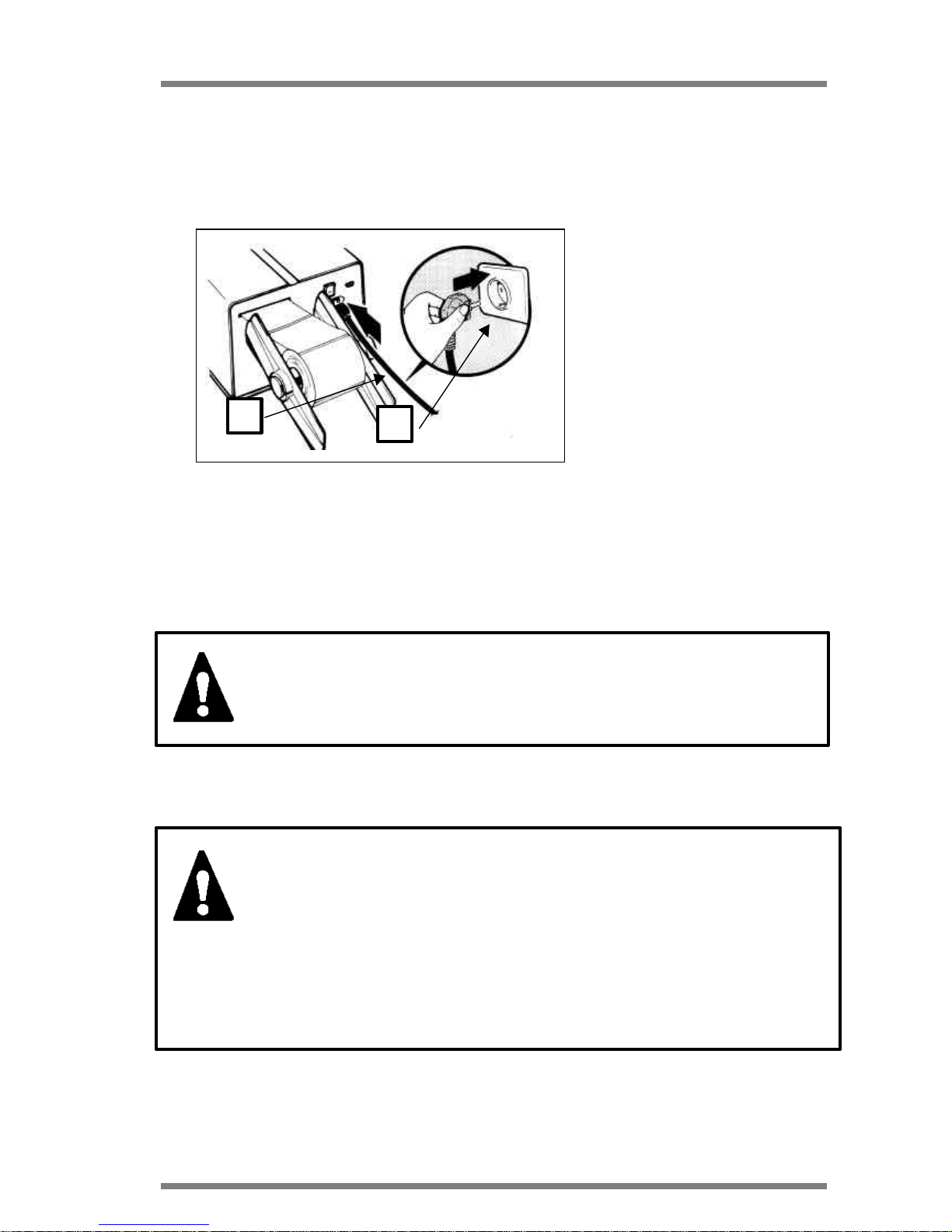

7 ELECTRICAL CONNECTIONS

The power cable of the printer has a female connector on one side and on the opposite pole

a spindle type "SCHUKO".

To provide a correct and safe

connection to the electrical network

follow the here below instructions,

as indicated on picture 5 on your

left:

1. Insert the female connector into

the proper plug mounted on the

rear panel of the printer.

Picture 5

2. Connect the spindle "SCHUKO" to an appropriate socket outlet with following voltage:

220 VAC +10% - 15% - 50/60 Hz.

The following voltages : 110 VAC and 240 VAC 50/60 Hz as per required

WARNING: Be sure that the power cord is connected to an electri-

cal installation with proper earthing.

Such electrical installation as per CEE safety rules.

7.1 NOTICE FOR CUSTOMERS IN THE UNITED KINGDOM

WARNING: If the plug supplied is not suitable for the socket outlets

in your factories, it should be cut off and an appropriate

plug fitted in accordance with the following instruction:

IMPORTANT: The wires in these mains lead are coloured in accor-

dance with the following code:

• GREEN and YELLOW : EARTH

• BLUE : NEUTRAL

• BROWN : LIVE

1

2

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

11

As the colours of the cores in the mains lead of this equipment may not correspond

with the coloured marking identifying the terminals in your plug, proceed as follows:

• The core which is coloured green and yellow must be connected to the terminal in

the plug which is marked with letter "E" or by the earth symbol

, or coloured green and yellow.

• The core that is coloured blue must be connected to the terminal that is marked

with letter "N" or coloured black.

• The core that is coloured brown must be connected to the terminal that is marked

with letter "L" or coloured red.

7.2 REAR PANEL, CONNECTION

Connect the printer with the

standard supplying cable, fol-lowing

instructions in para-graph 7.

To interface the printer to an

external driving device (PC, etc.)

use a serial cable with connector

(type D, 9 pin male). See appendix

A for the pin number of the serial

cable.

Before switching the device ON

press the switch button (when

Picture 6

off it shows one red "O"), verify that the cable is correctly

inserted as described on paragraph 7.

Picture 6 shows the rear panel and its connections.

POWER SWITCH

SERIAL CABLE

POWER CORD

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

12

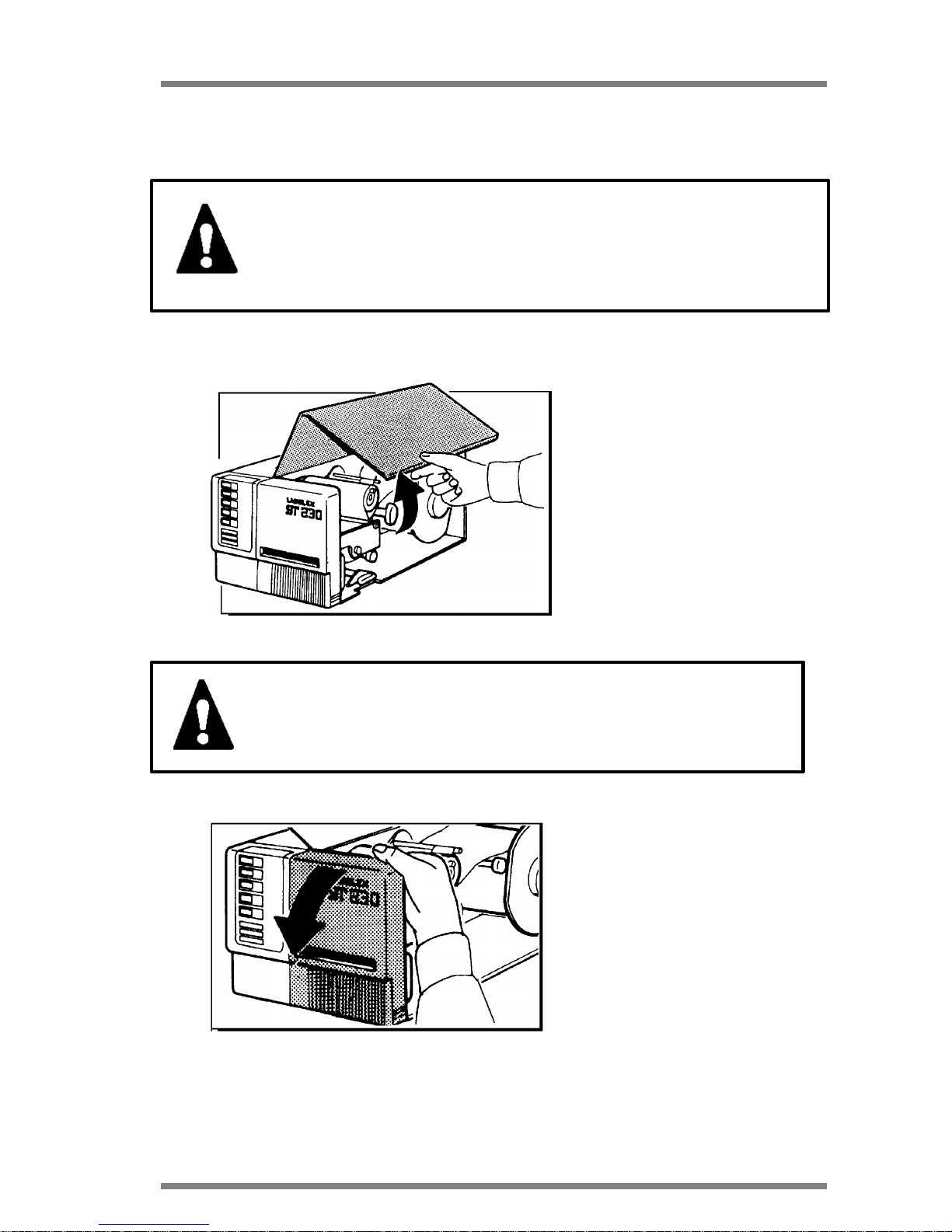

8 BEFORE USE OPERATIONS

WARNING: Before proceeding with the here bel ow instructions,

switch off the printer by pressing the power switch

(indicated on paragraph 7.2) and disconnect the spindle SCHUKO of the power cable from the plug (as in-

dicated in paragraph 7 point 2).

Open the lateral cover as indicated in the picture below.

Picture 7

WARNING : Before working inside the printer be sure that the

cover is completely open.

Then, open the plastic grey front

cover rotating it downward, as

indicated in picture 8 on your left.

Picture 8

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

13

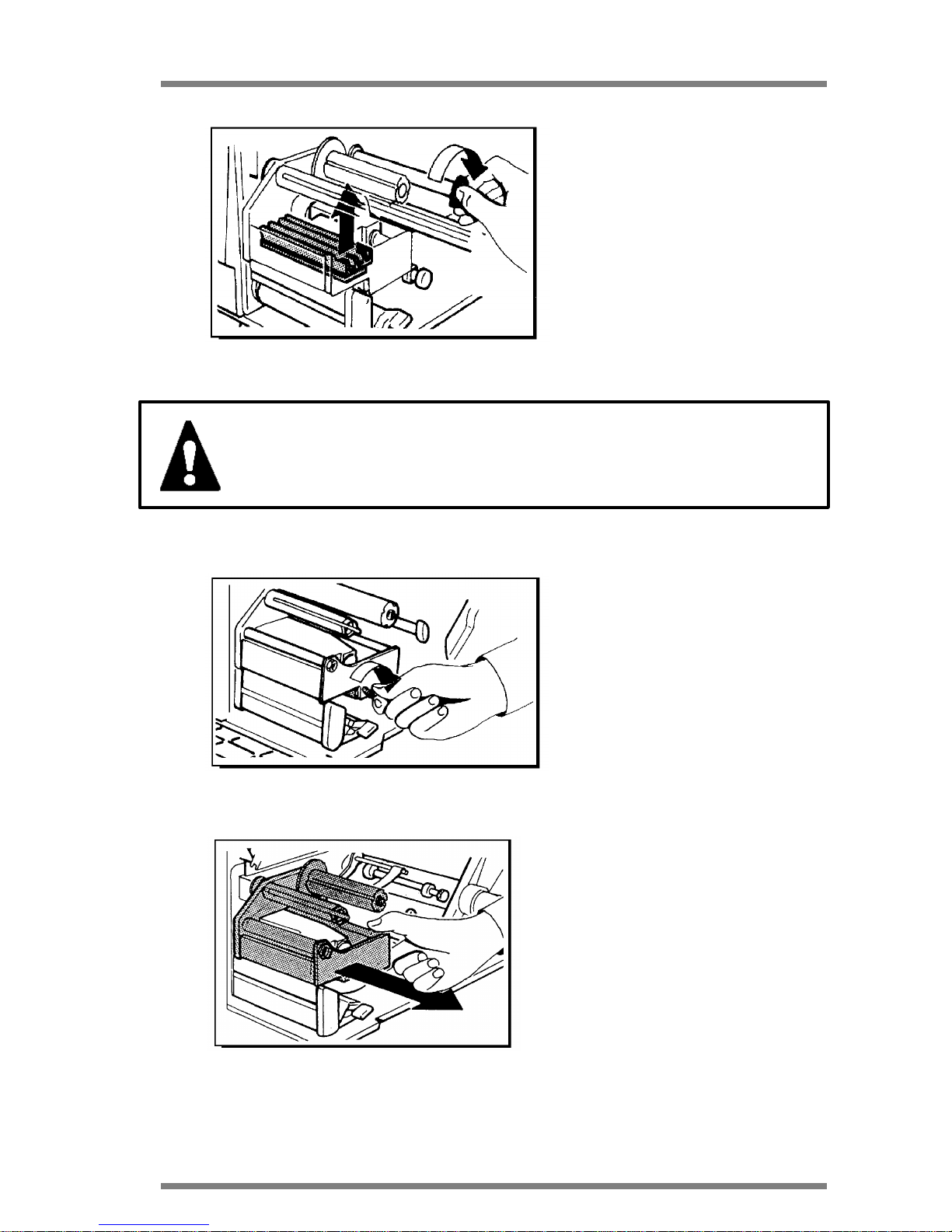

Now lift up the printhead from the

printing position rotating the black

knob half way as indicated in picture

9 on your left.

Picture 9

WARNING: Be careful not to put fingers between printhead and

rubber roll.

On the side of the reloadable

cartridge there is a knurled knob,

unlock and turn it completely in order

to unlock the cartridge, as indicated in

picture 10 on your left.

Picture 10

Take away the cartridge from its housing

pulling it out from the printer as indicated

in picture 11 on your left, and put it on the

work table.

Picture 11

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

14

9 THERMAL TRANSFER RIBBON LOADING PROCEDURE

WARNING: The cartridge is a very delicate mechanical component

and it is therefore advisable to treat it with great care

in order not to incur damage of the components.

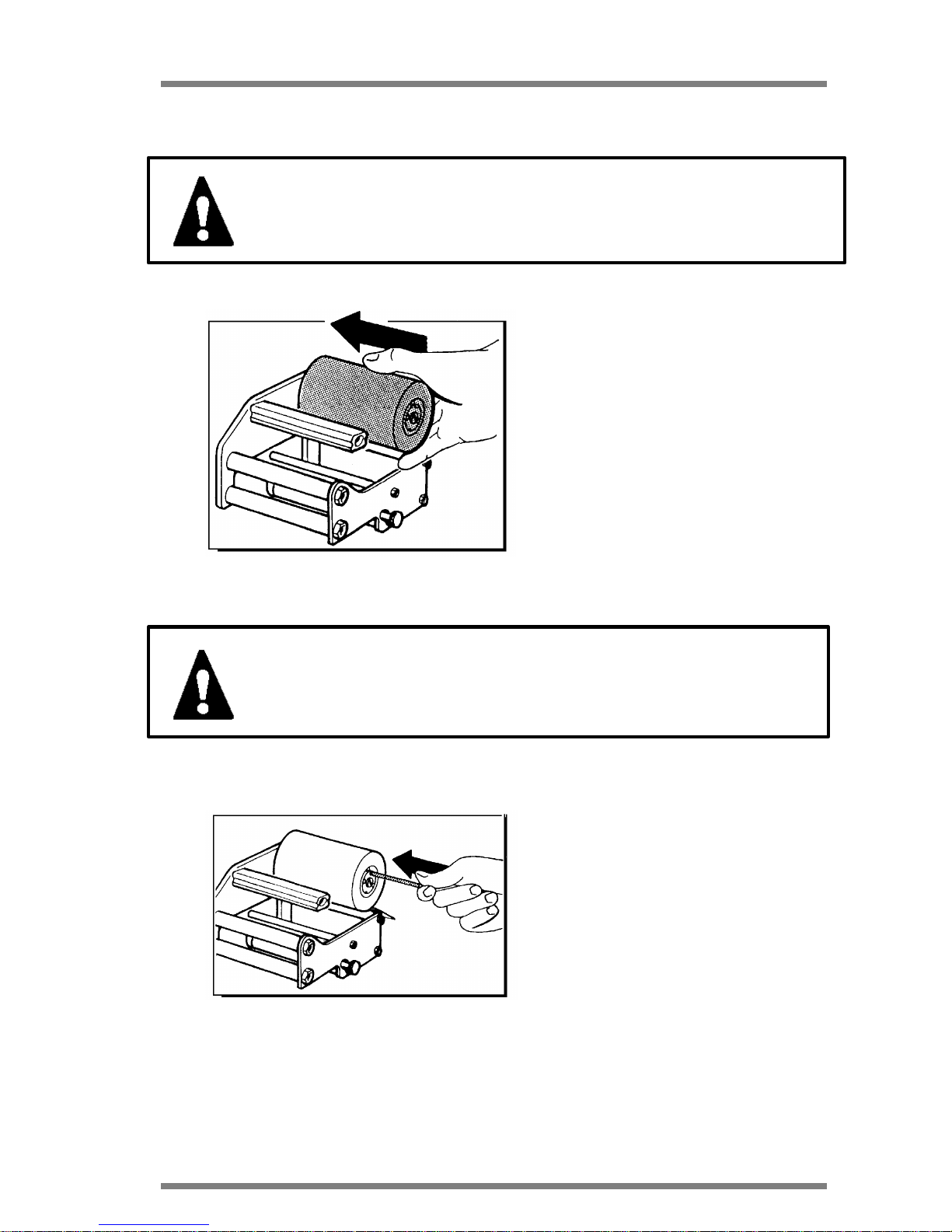

Take one roll of thermal transfer ribbon

"FOIL" and insert it on support holder

as indicated in picture 12 on your left.

Picture 12

IMPORTANT: Small dimension foil should be centered on the

cartridge and also remember that the foil is anti clockwise wound.

Fasten the steady pin to one of the four

holes on the supporting axis, choosing

the hole that permits a better blocking

of the ribbon, as indi-cated in picture 13

on your left .

If the ribbon is not perfectly fixed on the

supporting axis, the print quality may

be altered.

Picture 13

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

15

Take the starting part of the ribbon,

generally a transparent strip, and pass

it over the cartridge so that it passes all

the aluminium pivots externally, and

between the metallic blade fixed to the

knurled knob and the pivot as indicated

in picture 14.

Picture 14

Wind the ribbon for two or three cycles

around the rewinding shaft as

indicated in picture 15 on your left. The

arrow shows the direction of ribbon

rewinding.

Picture 15

Insert the appropriate blocking ribbon in

its housing as indicated in picture 16 on

your left.

Picture 16

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

16

Wind the ribbon for some turns around

the rewinding shaft till the transparent

strip is completely rewound and the

inked part is

present as indicated in picture 17 on

your left.

Picture 17

See paragraph 11 for loading the cartridge in the machine.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

17

10 LABEL ROLL LOADING PROCEDURE

Open the covers, lift the printhead and take off the printhead following the instructions in

paragraph 8.

Take the black flange away from the roll

holder as indicated in picture 18 on

your left.

Picture 18

Insert the labels roll on the roll holder,

as indicated in picture 19 on your left.

Picture 19

Take the strip of labels and let it pass

through under the black magnet brake

and adjust the width of the paper guide

to adapt it to the label width, turning the

knurled knob clockwise or

anticlockwise to widen or stretch the

device as indicated in picture 20 on

your left.

Picture 20

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

18

Adjust the width of the low paper

guide following the above - mentioned instructions and be sure that

the paper passes inside the

photosensor located on the low

paper guide as indicated in the

square reported on picture 21 on

your left.

Picture 21

Pay attention not to tighten the

paper guides too much as indicated in picture 22 on your left.

Picture 22

Insert the flange on the roll holder

as indicated in picture 23 on your

left.

Picture 23

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

19

After the above - mentioned preliminary phases, go through the procedures to insert the

paper to operate in one of the following printing modes:

• STRIP MODE

• DISPENSING MODE

10.1 STRIP MODE LABEL ROLL LOADING

This operating mode is generally

used when it is not required to print

a large quantity of labels and

therefore the printed labels can fall

down.

After the paper has passed

through the paper guides it has to

pass between the printhead and the

rubber roll as indicated in picture

24 on your left.

Picture 24

It is advisable to open the blocking

mechanism by turning the red knob

located under the printhead

clockwise as indicated in picture 25

on your left.

Picture 25

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

20

10.2 DISPENSING MODE LABEL ROLL LOADING

This operating mode is generally used when it is required to dispense the labels (that is

detaching from silicon paper) after the printout in order to stick them manually on the

object to be labelled as indicated

in the picture on your left. In this

case the printer has to be

equipped with a label

photosensor. After the paper has

passed through the paper guides

it has to pass between the

printhead and the rubber roll as

indicated in

picture 26 on your left.

Picture 26

Take away the labels from about

400 mm of material and detach all

the labels located on the strip, as

indicated in picture 27 on your left.

Picture 27

Pass the silicon paper only under

the rubber roll as indicated in

picture 28 on your left.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

21

Picture 28

Attach the silicon paper to the

rewinder shaft by winding it

approximately two or three turns as

indicated in picture 29 on your left.

Picture 29

Lock the paper on the rewinder

with the paper clamp as indicated

in picture 30 on your left.

Picture 30

Turn the red paper locking mechanism knob completely clockwise as indicated in picture 31 on

your left.

Picture 31

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

22

11 FINAL OPERATIONS

After installing the labels following

one of the above - mentioned

modes or a new thermal transfer

ribbon the operator has to reinstall

the cartridge (in case it has been

taken off, only for inked ribbon

installing), being careful to insert all

the three guides on the appropriate

housings as indicated in picture 32

on your left.

Turn the knurled knob anticlockwise to lock on its housing.

Picture 32

Lower the printhead and reposition it in printing position, turning

the black knob anti-clockwise as

indicated in picture 33 on your left.

Picture 33

WARNING: Be careful not to put fingers between printhead and

rubber roll.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

23

Close the covers of the printer,

starting from the front one paying

attention to insert the labels in the

appropriate slot and than lower the

side cover as indicated in picture

34 on your left.

Picture 34

WARNING: During closing procedure the side cover has to be

helped.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

24

12 USE OF THE PRINTER

After switching on, the printer will proceed with a self test procedure that takes some

seconds: all the leds of the front panel will turn on and then off (with exception of the red one

indicating printer on), after the printhead is lifted up and lowered, then one test label is printed

as indicated in the picture below.

If the above - mentioned procedure is well executed, the ON LINE led will light up and the

printer is ready to execute the commands received by the driving device through serial line.

The test label (printed when the printer is on) contains the following information:

LABEL TEST

ST 230 B5.3.

KIND OF PRINTHEAD AND TEMPERATURE OF THE PRINTHEAD IN

DEGREES CENTIGRADE

TEST TO VERIFY THE

FUNCTION AND

ALIGNMENT OF THE

PRINTHEAD COMPOSED

OF A BLACK AREA, ONE

GREY AREA AND

VERTICAL AND

HORIZONTAL LINES.

$&%0000000000000000

K1001J1806V05065730

P098H0039G00360000

N00000000 BR=2 CM= 7 NA=00

where:

$&% - abled functions

K - operating mode

J - printing speed and aspect ratio

V - Paper feed speed and printhead energy

P - Label photosensor sensitivity

H - Label positioning with respect of printhead

G - Printout area

N - Cutter and applicator parameters

BR - Baud rate (serial line speed communication)

CM - Fonts map

NA - Network address

6 dots/mm 29° C

PRINTER MODEL AND FIRMWARE VERSION

CURRENT VALUE OF THE PARAMETERS ON THE

NON VOLATILE MEMORY

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

25

The format used to represent values $&%, K, J, V, H, G, N is the same used by the

corresponding commands that can be sent from the external driving device, while

parameters BR, CM, NA are settable only by front panel in configuration mode.

The complete description of the commands reported on the test label as indicated in the

"PROGRAMMING GUIDE".

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

26

13 USE OF THE PRINTER FRONT PANEL

Printer ST 230 is equipped with a command front panel, composed of a serie of buttons

and leds that permit the printer parameters to be programmed.

Examining in detail the front panel

there are four keys:

ON LINE

THERM/TRANSF

HEAD LIFT

RIBBON/ECONOM

Each equipped with green LED

One key (FEED) key without LED

Three green LEDS

END PAPER/RIB.

PAPER MODE

PHOTO ON

And a red led (ON), indicating the status of the printer:

RED LED ON = PRINTER SWITCHED ON

RED LED OFF = PRINTER SWITCHED OFF

In the following pages there is a map of the light leds showing the different functions:

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

27

LIGHT LEDS TABLE

LIGHT LED STATUS MEANING

ON

OFF

FLASH

The printer in ON LINE status and is ready to

execute the commands coming from serial line.

The printer can be both in printing status or in

OFF LINE. It is not possible to execute line

commands that will be stored on the buffer with

exception of those executable in real time.

The printer can be both in printing status or in

OFF LINE. It is not possible to execute line

commands that will be stored on the buffer with

the exception of those executable in real time.

ON

OFF

The printer is ready to print in thermal/transfer

mode.

The printer is ready to print in direct thermal

ON

OFF

The printhead is lifted by its motor and the

printer is ready to execute special functions.

The printhead is in contact with the paper

(normal functioning mode).

ON

OFF

The economizer device is abled.

The economizer device is disabled.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

28

LIGHT LED STATUS MEANING

ON

OFF

FLASH

End paper and/or inked ribbon, or feed error

Normal working

Temporary stop of printing due to printhead

overheating.

ON

OFF

The printer is ready to print continuously.

The printer is ready to print on labels or to

detect the tag in order to maintain the printing

feed.

ON

OFF

FLASH

The label's photosensor (optional) is abled.

The label's photosensor (optional) is disabled.

During the print out the machine is waiting for

the printed label to be removed in order to print

the next one (only if the label photosensor is

abled).

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

29

13.1 OPERATIONS FROM FRONT PANEL

The operations from front panel can be divided in three phases:

• ON LINE

• OFF LINE

• SET UP or configuration

13.2 ON LINE

The printer is in ON LINE after switching on phase, as per instructions in paragraph

12 and the light leds on the front panel will show information on the status of the

printer (see instruction on LED TABLE on page 25 and 26).

The only key abled during this phase is the ON-LINE one that when pressed the

machine is OFF-LINE (ON-LINE led off) after being

executed the print-out in course.

13.3 PRINTING PHASE STOP AND RESTART

During printing phase, pressing the ON-LINE key printing is suspended and the

printer is on OFF-LINE at the end of the current

label. By pressing the key a second time the printout

re-start from the interruption point.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

30

This is also valid when the interruption is caused by an error (once removed the

cause).

13.4 OFF-LINE PHASE

To execute the operations below it is necessary to have the printer in OFF-LINE

status (following instructions on paragraph 13.2).

The printer can pass spontaneously in OFF-LINE status during the printing in

course in case of errors (for example : end paper, end ribbon).

During this phase from front panel it is possible to select the following operations:

PRINTHEAD LIFT

It is made by pressing the HEAD LIFT key and

is an alternative to the manual lift with the

appropriate knob.

COPY LAST LABEL

It is made by pressing the FEED key, to have

a printing test or to realign the paper after

replacement.

PRINT MODE SELECTION

It is made by pressing the THERM TRANSF key

and is indicated by lighting of it's led (see

description of led function).

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

31

ECONOMIZER SELECTION

It is made by pressing the RIBBON ECONOM

key and is indicated by the light of the relative led

(see description of light led function).

13.5 PRINTING INTERRUPTION

The following procedure permits the termination of one session of printing before

the end of the number of labels ordered. By pressing ON

LINE to suspend (see paragraph 13.4), then by pressing

the HEAD LIFT,FEED, HEAD LIFT keys one after the

other, the residual number of labels is zero.

By pressing the ON LINE key again the printer is ready to

accept other commands.

13.6 DEMO TEXTS

A serie of demo texts is included in the printer program.

Texts are acceptable by command via serial line and also

by front panel following the here below procedure.

Keep the printer in OFF-LINE mode pressing the ON-

LINE key (following instruction on paragraph 13.4).

Then press the HEAD LIFT, RIBBON ECONOM keys one

after the other. The RIBBON-ECONOM key pressed once, twice,three times

permits the selection of the first, second, third etc. demo text.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

32

Once the selection is made, press the HEAD LIFT key and ON

LINE key again in order to have the elaboration and the

printout of the desired text.

13.7 MACRO SELECTION

It is possible to insert, in a proper EPROM memory, a series of further texts (up to a

maximum of 99) or, generally, command sequences (MACRO) in order to

personalise the printer to specific operations. Texts are acceptable by command

via serial line and also by front panel following the here below procedure.

Keep the printer in OFF-LINE mode pressing the ON-

LINE key (following instruction on paragraph

13.4).Then press sequentially keys HEAD LIFT,

THERM-TRANSF.

Key THERM-TRANSF pressed once, twice, three times permits the selection of

the first, second, third macro text.

Once the selection is made, press the HEAD LIFT key and ON-

LINE again sequentially in order to have the elaboration and the

printout of the desired text.

13.8 SET- UP OR CONFIGURATION MODE

It is also possible to vary the configuration of the printer from front panel following

the here below instructions.

1. Switch the printer ON following the instructions in paragraph 7.1, keeping the

ON-LINE key pressed till the printer completes the switching on phase in

paragraph 12 and release it after a few seconds when the leds are ON for the

second time. All the light leds are off (with the exception of the red one) and the

printer is in configuration mode.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

33

2. Press the ON-LINE key to and the printer is OFF-LINE.

Then press the key HEAD LIFT and then the ON-LINE key.

All the leds are off (with the exception of the red one) and the

printer is in confi-guration status and you can be selected the

parameters here below.

Not all the parameters

available are selectable in

that way, while, viceversa, some parameters (BAUD RATE, FONT MAP,

NETWORK ADDRESS) are accessible exclusively throughout panel and not from

serial line.

• Pressing the ON LINE key again the current parameter values are memorized

(all the leds are ON for some seconds). Then pressing the HEAD LIFT and ON

LINE key the printer is ready to receive other commands.

13.9 BAUD RATE SELECTION

Select the printer in configuration mode (as described in paragraph 13.8) then

press the RIBBON ECONOM key (the respective led is

turn on). Than press the FEED key.

Every time the FEED key is pressed increases the

parameter BR, starting from current value till value 7, to restart then at 0,

alternatively.

Value's BR corresponds to the following BAUD RATES:

BR BAUD RATE

0 38400

1 19200

2 9600

3 4800

4 2400

5 1200

6 600

DEFAULT BAUD RATE

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

34

7 300

Press the RIBBON ECONOM key again to complete the selection: it is printed a

test label with the updated BR value. At this moment, exit from configuration mode

(as described in paragraph 13.8) and switch the printer off so that the new BAUD

RATE is operative.

13.10 CHARACTER FONTS MAP SELECTION

Select the printer in configuration mode (as described in paragraph13.8) then press the

RIBBON ECONOM key (the respective led is turn on).

Then press the HEAD LIFT key.

Every time the HEAD LIFT key is pressed increases the

parameter CM, starting from current value till value 9, to

restart then at 0, alternatively.

Press the RIBBON ECONOM key again to complete the selection: it is printed a test

label with the updated CM value. At this moment you have to exit from configuration

mode (as described in paragraph 13.8) so that the new modifications are operative.

The font map permits to personalize the printers relating to the

language required, generally the printer is set with CM=7 to indicate that the map in use

is the IBM PC one.

13.11 PRINT MARGINS SELECTION

Select the printer in configuration mode (as described on paragraph13.8) then press the

RIBBON ECONOM key (the respective led is turn on). Now

pressing the ON LINE and THERM TRANSF keys it is

possible respectively to tighten and widen, of 1 mm step

each, the side margin of printing zone, till a correct centering

is reached, with the help of the printed liner at each pression,

the margins relating to width of the mounted label.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

35

Pressing RIBBON ECONOM again, the selection stops and a test label is printed where

the width of the central zone (black, grey and bars) it adjust to the value given to the

margins always keeping itself centered with respects to the printhead. The adjustment of

margins is of help to avoid any possible ink stains on the rubber roll in case of using

narrower labels compared to the previous label width. In case of using different label

formats it is useful to leave the printer set with margins corresponding to the narrower

one sending time by time from line the correct command on the basis to the text to be

printed. At this point exit from configuration mode (as described in paragraph 13.8) in

order to execute the modifications programmed.

13.12 PRINTING SPEED SELECTION

Select the printer in configuration mode (as described in paragraph 13.8) then

press the THERM TRANSF key (the respective led is turn

on). Then press the FEED key.

Now, each pression of the FEED key the printer chooses

in turn one of the three different pre-set speed (the speed

values are reported on parameter J and are

1204, 1806, 2709 for the 6 dots/mm and 1105, 1306

2210 for the 8 dots/mm), printing a test label each time

to certify the selection result.

Pressing RIBBON ECONOM again, the selection stops

and a test label is printed containing the values set. At this point exit from

configuration mode (as described in paragraph 13.8) in order to execute the

modifications programmed.

13.13 PRINTHEAD TEMPERATURE ADJUSTMENT

Select the printer in configuration mode (as described in paragraph 13.8) then

press the THERM TRANSF key (the respective led is turn

on).

Concerning the temperature (printhead power), the ON

LINE key permits a rough adjustment, in turn among 5 prefixed values for the 6 dots/mm printhead (4 for the 8

dots/mm printhead) while the HEAD LIFT and RIBBON ECONOM keys permit a

+ 1 mm

- 1 mm

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

36

fine adjustment, respectively to up and down of 10mW each time.

Each key pression a test label is printed that shows the variation.

It is always advisable to operate at the minimum speed in case of rough

temperature adjustments to avoid any possible burns of the ribbon during the

passage of values. Now exit to the configuration mode (as described in paragraph

13.8) in order to execute the modifications programmed.

13.14 LABEL CALIBRATION

Select the printer in configuration mode (as described in paragraph 13.8) then

press the FEED key. Two white labels are ejected and

than a test label is printed containing all the values of

parameters P and H updated referring to the kind and

length of the label correctly mounted on the printer.

Value P is proportional to the transparency of the used

material, measured before feeding paper : it is important that in case of pre-printed

labels the paper is initially positioned in the way that under the sensor is present a

light zone and that the sensor is not reading on the gap between labels. Valid

values of P are from 52 to 255 (normally from 60 to 120), whilst extreme values of

51 or 256 indicate generally a malfunctioning, due to the absence or excess of

sensored light. Values near or exceeding 200 indicate a wrong starting position of

the paper (reading on the gap between the labels) or the use of materials very

transparent that can constitute a problem for a correct step maintaining.

The value H represents the feed paper (in dots) made from when the edge of the

label has been detected by the sensor, to correctly align the label under the printhead: these value changes relating to the height of the labels in use. The printer

calculates automatically with a certain approximation (generally less) the value

adapt to start printing from the upper edge of the label.

In case the FEED key is kept pressed, after ejecting the two white labels and

before the test print-out, the paper is fed slowly, increasing the value of H and,

therefore, lowering the starting point with respect of the edge till the key is left. This

is useful to make a fine adjustment and to find the correct label stop position to

allow the easy detachment in case of dispensing mode (with silicon paper

rewinding). In case of use of different label formats with frequent passage from one

to the other it is not easy to make a new adjustment at each label format: it is

advisable in this case to take note of P and H value reached initially for each used

+ 10 mW

- 10 mW

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

37

format and than to include the set commands of the correct values sent for the

printout of each label to reach the automatic alignment of the printout.

13.15 OPERATION MODE SELECTION

Select the printer in configuration mode (as described in paragraph 13.8) then press the

HEAD LIFT key (the respective led is turn on). Now, the other

light leds of the panel indicate the operative mode selected

that can vary as follows:

13.15.1 Label mode/paper mode

Press the FEED key: light led PAPER MODE lights when in

paper mode whilst it is off in label mode.

13.15.2 Ribbon Economizer enable/disable

Press the RIBBON ECONOM key: the corresponding light

led will light when the Ribbon Economizer is abled, whilst

when it is off the economizer is disabled.

13.15.3 Thermal Transfer and Direct Thermal selection

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

38

Press the THERM TRANSF key: the corresponding led lights

in Thermal Transfer, whilst when it is off is in direct thermal.

13.15.4 Enable/Disable of the photodispenser

sensor (optional)

Press the ON LINE key: the corresponding led indicated the

status.

NOTE: that there are two different status corresponding to the photosensor abled, depending on the

further check of correct dispensing is excluded (first pression) or abled (second

pression).

Pressing HEAD LIFT key again, the selection stops and a test label is printed con-

taining the values set. At this point exit from configuration mode (as described in

paragraph 13.8) in order to execute the modifications programmed.

13.16 PARAMETER RESET

The printer parameters can be modified by the operator to adapt the printer to the

proper requirements, nevertheless in case the printer has been programmed with

the wrong parameters the operator has to follow the here below procedure to zero

them and return to standard parameters.

Select the printer in configuration mode (as described in paragraph 13.8 at point 1)

than press together the THERM TRANSF, ON LINE keys that reset the stored

parameters on the non-volatile memory of the printer.

+

The light leds will be off, than on and a test label will be printed with the standard

parameters of the printer.

Exit from configuration mode of the printer (as described in paragraph 13.8), switch

the unit off and on to execute the variation.

WARNING: Before executing the above procedure remember

to note the correct values of the printer

configuration.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

39

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

40

14 MAINTENANCE

Due to the reduced number of moving parts, the printer does not require particular

maintenance, but a simpler periodical cleaning of the parts subject to dirt, that are:

• printhead

• feeding rubber roll

• paper guide shaft

• label presence and label gap photosensors

It is advisable to fulfil the maintenance operations weekly in case of intense use of

the printer, monthly in case of irregular use.

A paint-brush or an air jet is enough to remove the dust due to the labels sliding;

pay particular attention to the photosensor holes.

As far as the printhead, rubber roll and paper guide rolls are concerned it is

advisable to use iso-propylic alcohol and a soft cloth.

WARNING: Never use any metallic or hard tool to clean the

printhead as indicated on picture 35.

Picture 35

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

41

WARNING: Switch off the printer handling on the button

mounted on the rear panel of the printer and disconnect the

spindle from the feeding plug.

As previously explained in paragraph 8, please proceed with the following operation

by keeping the printer with:

• Cover open

• Lifted printhead

• Remove the cartridge and paper not installed

The operator will then be free to execute the following operation:

14.1 PRINTHEAD CLEANING

Take a cotton swab wet with isopropylic alcohol and pass it

under the printhead to eliminate

all the carbon residuals due to

printout, as indicated in picture

36 on your left. Note that the

printing quality also depends on

a good printhead cleaning.

Picture 36

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

42

14.2 RUBBER ROLLS CLEANING

Take a soft cloth wet with isopropylic alcohol and pass it over

the rubber rolls to eliminate all

the dirt (silicon residuals and

possible inked ribbon residuals)

posed during the labels printing

as indicated on picture 37 on your

left.

Picture 37

Remember that good printing

quality also depends on the good cleaning of rubber rolls cleaning as they are mechanical

parts dedicated to the paper movement.

14.3 PAPER GUIDES METALLIC SHAFTS CLEANING

The cleaning of the shafts is made to

eliminate glue residue from the selfadhesive labels during the printing

process.

It is important to keep them clear as

the glues on the labels create a sticky

layer causing the paper to brake.

Keep a soft cloth wetted with isopropylic alcohol and pass it on the

shafts and on the inox metal strip located after the roll holder being care-ful

to clear all the glue traces from the

above-mentioned parts, as indicated in

picture 38 on your left.

When the maintenance operations are

over, re-install the labels and the cartridge (following the instructions described in the relative paragraphs),

close the covers and switch the

printer ON.

Picture 38

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

43

15 TROUBLE SHOOTING

Some small problems can be easily solved by the operator.

In case something on the ST 230 printer goes wrong please checks the following

points before calling the Technical Assistance.

SYMPTOM POSSIBLE CAUSE ACTION

NOT SWITCHING ON

(RED LED OFF)

Wrong power supply connection.

Interrupted fuse.

Internal trouble

Check the power cord

and the presence of the ope-rating

voltage.

After detaching the power

cord check if the fuse on the rear

panel is burnt.

If so replace it with one with the

same characteristics.

Contact Technical Assistance.

COMPLETELY OFF

(THE RED LED IS ON)

Internal trouble Contact Technical Assistance.

IT STARTS CORRECTLY, BUT IT

DOES NOT PRINT THE TEST

LABEL.

Paper and/or ribbon missing.

Printhead lifted.

Disabled test label

Install correctly.

Lower in printing position.

Set the printer.

IT IS NOT REACTIVE TO THE

COMMANDS SENT BY PC.

Data cable wrong, or fault or not

correctly connected.

Communication parameters not

correct.

Check and/or replace

Check that the baud rate is the

same as that of PC and

compatible with the other

parameters of the printer.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

44

SYMPTOM POSSIBLE CAUSE ACTION

THE PAPER IS FED BUT NOT

PRINTED.

Printhead lifted (printer with

rewinder).

Printhead connection (flat cable).

Faulty printhead

Improper inked ribbon or

incorrectly mounted

Internal trouble

Lower in printing position

Verify the correct insertion

of the flat cable into the connector located at the back of the

printhead.

Replace it or contact Technical

Assistance.

Replace it with a recommended

type or reinstall it correctly.

Contact Technical Assistance.

IRREGULAR PAPER FEED

Dirty rubber roll, damaged or

worn.

Paper path not correct.

Jammed labels.

Clean it with a solvent or

contact Technical Assistance.

Verify the correct installation

of the labels roll.

Remove and clean all the

glue residue with a proper

solvent.

POOR PRINT QUALITY

(UNIFORMLY)

Improper paper and or ribbon

Wrong configuration (speedtemperature).

Insufficient pressure of printhead on the paper.

Used printhead

Replace with recommended type.

Configure again using correct

parameter value.

Verify the print by pressing on the

printhead and eventually contact

Technical Assistance.

Replace it or contact Technical

Assistance.

POOR PRINT QUALITY (ONLY ON

STRIPS PARALLEL TO THE

FEEDING DIRECTION)

Dirty printhead

Used printhead

Dirty rubber roll, used or

damaged.

Clean with proper solvent

Replace it or contact Technical

Assistance.

Clean with proper solvent or

contact Technical Assistance

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

45

SYMPTOM POSSIBLE CAUSE ACTION

POOR PRINT QUALITY

(LIGHT SPOTS)

Dirty residues lift between paper

and ribbon.

Improper paper or ribbon

Dirty rubber roll, used or

damaged.

Verify the cleanliness of the

materials used.

Verify the material used and

replace with recommended type.

Clean with proper solvent or

contact Technical Assistance.

WHITE STRIPS IN THE

FEED DIRECTION.

Dirty printhead or damaged.

Internal trouble

Clean with proper solvent

and eventually replace

it or contact Assistance.

Contact Technical Assistance.

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

46

16 APPENDIX A

16.1 SERIAL CABLE PINOUT

Here below the pinout of connector CANNON 9 female located on the rear panel of the

printer:

PIN SIGNAL DESCRIPTION

2 RxD Input - received data

3 TxD Output - transmit data

5 GND Ground

7 RTS Output Request to send

8 CTS Input - Clear to send

1-4-6-9 not used

Here below the pinout of serial cable for a PC equipped with serial port with a 25 pin

CANNON connector and for a PC with a serial port with a 9 pin CANNON connector.

Cable for 25 pin connector.

PRINTER PC - 25 Pin

RxD 2 2 TxD

TxD 3 3 RxD

GND 5 7 GND

RTS 7 5 CTS

CTS 8 4 RTS

6 DSR

8 DCD

20 DTR

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

47

Cable for 9 pin connector.

PRINTER PC - 25 Pin

RxD 2 3 TxD

TxD 3 2 RxD

GND 5 5 GND

RTS 7 8 CTS

CTS 8 7 RTS

6 DSR

1 DCD

4 DTR

DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

48

Loading...

Loading...