Page 1

ELECTRONIC SCALE

DSP 500

USER MANUAL - v. 4.0

UV119UE

Doc-a-Ware 960510

Page 2

Page 3

UV119UE - DSP 500 : USER MANUAL - v. 4.0 PAGE i

WARNING

This manual makes reference to scale model ASR (type approval no. I95-004), manufactured by

DATAPROCESS S.P.A. and commercialised as DSP500 Scale.

All the information and instructions that must be observed in order to obtain the functionality

declared by the Manufacturer are included in this manual.

The scale hereby described complies with the current security rules.

The direct access to its inner parts and/or the insertion of any object or liquid into the scale is

forbidden.

Any action on the scale which is not within those expressly described in this manual must be

performed by our authorised agents.

The installation must be performed following the safety regulations in force as well as any further

procedures reported by this manual.

The manufacturer declines all responsibilities for:

• damages caused by improper installation, use and maintenance

• income loss due to possible failure

• incorrect use of the equipment

• damages caused by non-authorised technical service and/or by the use of non original

replacement parts

The information contained in this manual is subject to change without notice, and it represents no

commitment by the Manufacturer.

Page 4

PAGE ii UV119UE - DSP 500 : USER MANUAL - v. 4.0

Page 5

UV119UE - DSP 500 : USER MANUAL - v. 4.0 PAGE iii

TABLE OF CONTENTS

?

SECTION INDEX ..................................................... page 1

FEATURES.............................................................. page 2

SPECIFICATIONS ................................................... page 3

DISPLAY.................................................................. page 4

KEYBOARD............................................................. page 5

PRESENTATION

SECTION INDEX ..................................................... page 7

SWITCHING ON ...................................................... page 8

DISTINCTIVE FEATURES....................................... page 9

OPERATIONAL SEQUENCE.................................. page 10

TARE ....................................................................... page 11

RESET TO ZERO .................................................... page 11

PLU RECALL........................................................... page 12

PRICE VIA KEYBOARD ......................................... page 13

PRINT LABEL ......................................................... page 14

LABEL LAYOUT...................................................... page 15

RECEIPT TRANSACTIONS .................................... page 16

VOID ........................................................................ page 16

RETURNS................................................................ page 17

SUB-TOTAL AND DISCOUNTS.............................. page 17

PRINT RECEIPT...................................................... page 18

CORRECTING RECEIPTS ...................................... page 18

RECEIPT LAYOUT.................................................. page 19

PAPER REPLACEMENT......................................... page 20

PAPER-CASSETTE PREPARATION ..................... page 21

DAILY USE

SECTION INDEX ..................................................... page 23

CLEANING............................................................... page 24

ERROR MESSAGES ............................................... page 25

PROBLEM SOLVING .............................................. page 26

MAINTENANCE AND

PROBLEM SOLVING

SECTION INDEX ..................................................... page 27

CONFIGURATIONS, PAPER ROLLS ..................... page 28

INSTALLATION....................................................... page 29

NETWORK INSTALLATION, START, ACTIVITY ... page 30

CONNECTING TO PC ............................................. page 31

CONFIGURATIONS

AND

INSTALLATION

SECTION INDEX ..................................................... page 33

INTRODUCTION TO PROGRAMMING................... page 35

ACCESS BY KEY-CODE......................................... page 36

LEVELS AND GROUPS .......................................... page 37

SELECTION AND EDITING .................................... page 38

FUNCTION CODES................................................. page 39

GROUP 0: GENERAL PROGRAMMING ................ page 41

GROUP 1: PLU PROGRAMMING........................... page 53

GROUP 2: SETTINGS............................................. page 61

GROUP 3: RECEIPT PROGRAMMING .................. page 69

GROUP 4: LABEL PROGRAMMING...................... page 75

GROUP 5: NETWORKING AND INTERFACES ..... page 83

GROUP 7: REPORTS.............................................. page 91

GROUP 8 & 9: TOTALS & GRAND TOTALS......... page 95

PROGRAMMING

Page 6

PAGE iv UV119UE - DSP 500 : USER MANUAL - v. 4.0

Page 7

UV119UE - DSP 500 : USER MANUAL - v. 4.0 PAGE 1

PRESENTATION

FEATURES ..............................................................page 2

SPECIFICATIONS.................................................... page 3

DISPLAY .................................................................. page 4

KEYBOARD ............................................................. page 5

PRESENTATION

?

Page 8

PAGE 2 UV119UE - DSP 500 : USER MANUAL - v. 4.0

?

FEATURES

The scale Model DSP500 is a high performance cell-load type machine.

Complete in-built printer (for labels or receipts) with removable paper cassette, it answers a wide

range of different requirements - used as a stand-along unit or connected on -line with others

scales.

• programmable use for:

10 sales departments

20 operators, programmable: ON SERVICE

IN TRAINING

• 2 selectable price modes:

PLU (programmed), with temporary price revision option

(special price SP)

Random price without code (RP Random Price)

• 3 price basis available:

Liras/kg

Liras/100g

non weighted

• 4 printout options:

automatic or manual label

pre-pack label

receipt

single-item receipt

• 20 label layouts:

10 pre-set layouts

10 user-programmable layouts

• 2 load capacities and

divisions:

6 kg load capacity / 2 g per division

15 kg load capacity / 5 g per division

• 2 tare settings:

pre-set tare in PLU (only for pre-packed items)

weighed tare (fixed tare selectable)

• 5 types of sales totals:

per operator

per department

per item (PLU)

per hour

per scale

• 3 grand totals:

X totals

Z totals

ZZ totals

(daily grand totals)

(longer time period totals)

(test totals, for technical service only)

• advertising text on display:

scrolling, at programmable speed rate

by overwriting

• 4 levels of key access to

programming

Level 4 only for technical service

• external connections:

connection to PC via RS232c serial interface port

scale network, for max. no. 10 scales on-line (optional)

connection to remote PC (via optional RS422 interface)

Page 9

UV119UE - DSP 500 : USER MANUAL - v. 4.0 PAGE 3

?

SPECIFICATIONS

The DSP 500 Scale can be supplied for two different load capacities and divisions:

6kg/2g (11 lb - 1/16 oz)

15kg/5g (22 lb - 1/8 oz)

It is supplied equipped with:

- no. 1 RS232 serial interface, 256 kB Eprom, 256 kB RAM already

installed

- 1 paper cassette, inserted

- User Kit including: - User Manual, 1 copy

- 1 thermal paper roll

- 1 sheet of labels for cassette customisation

- 1 power cable (for Italian version only)

- 1 pin for small-size core paper roller

OPTIONS available on customer request:

- Extension Card for DPnet local network + 1 line RS422

Serial Interface

- additional paper cassettes

- PCMCIA memory card adapter (for use only with

optional extension card)

• Printing: labels or continuous paper rolls (self-adhesive or plain) with automatic detection

of paper cassette and printed paper counter, by km.

Print speed: 90 mm/sec - 1,5 sec/label.

Paper roll cassette easily accessible and removable for a quick paper replacement;

programmable for receipts, labels or continuous self-adhesive paper rolls.

• Label layouts: programmable for each PLU to be selected within 20 label layouts (10 label layouts

pre-set by manufacturer + other 10 layouts, user-programmable for size, type, data position).

• Receipts: 6 line programmable message to be freely positioned as header or at receipt end.

Enable print of: date and time, product description, bar-code, change, coupon.

Voids on one or more transactions on current receipt.

• PLU dynamic storage. Storage capacity: max. 3250 PLU without text or over 450 PLU of

350 characters each.

20 characters available for item description of each PLU plus 375 character for ingredients.

7-digits code and programmable number of digits to enter for PLU recall.

• Extended keyboard layout base configuration including: 99 PLU direct keys, 13 function

keys and 10 numerical keys, fully programmable.

Software key with 4 levels programming access (4th level for technical service only) , to

ensure data security and easy programming.

• Wide screen display: 2 lines of 20 alpha-numeric digits each (readable from two-sides).

Advertising text of 200 characters to be programmed: by scrolling or overlapping on display.

• Optional scale connection to DPNet network: up to 10 scales can be linked in one

a single

network.

Connection to PC: uploading/downloading of PLU and sales totals reading, scale

programming. 2 or more networks connectable to one single PC.

Connector for opening cash-drawer.

Page 10

PAGE 4 UV119UE - DSP 500 : USER MANUAL - v. 4.0

?

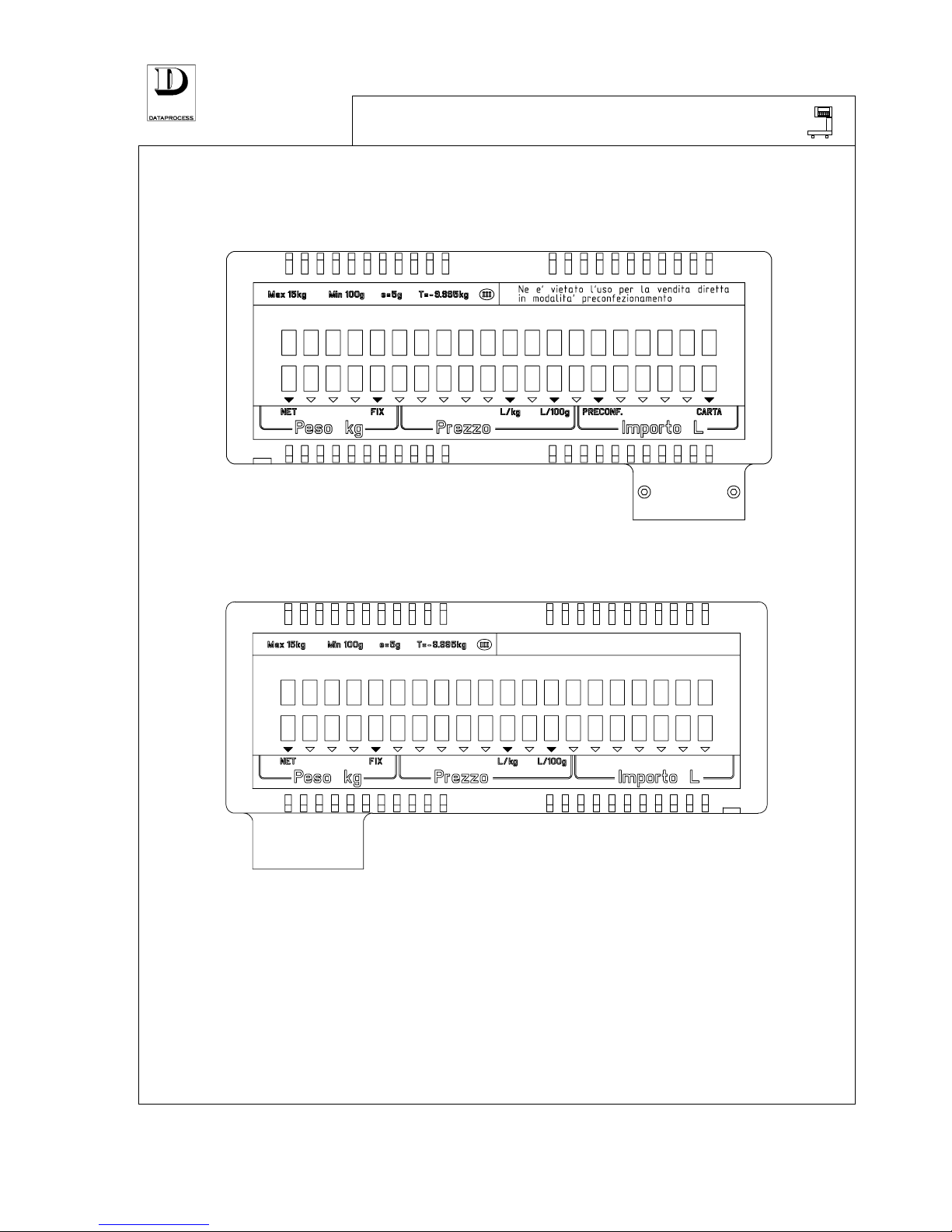

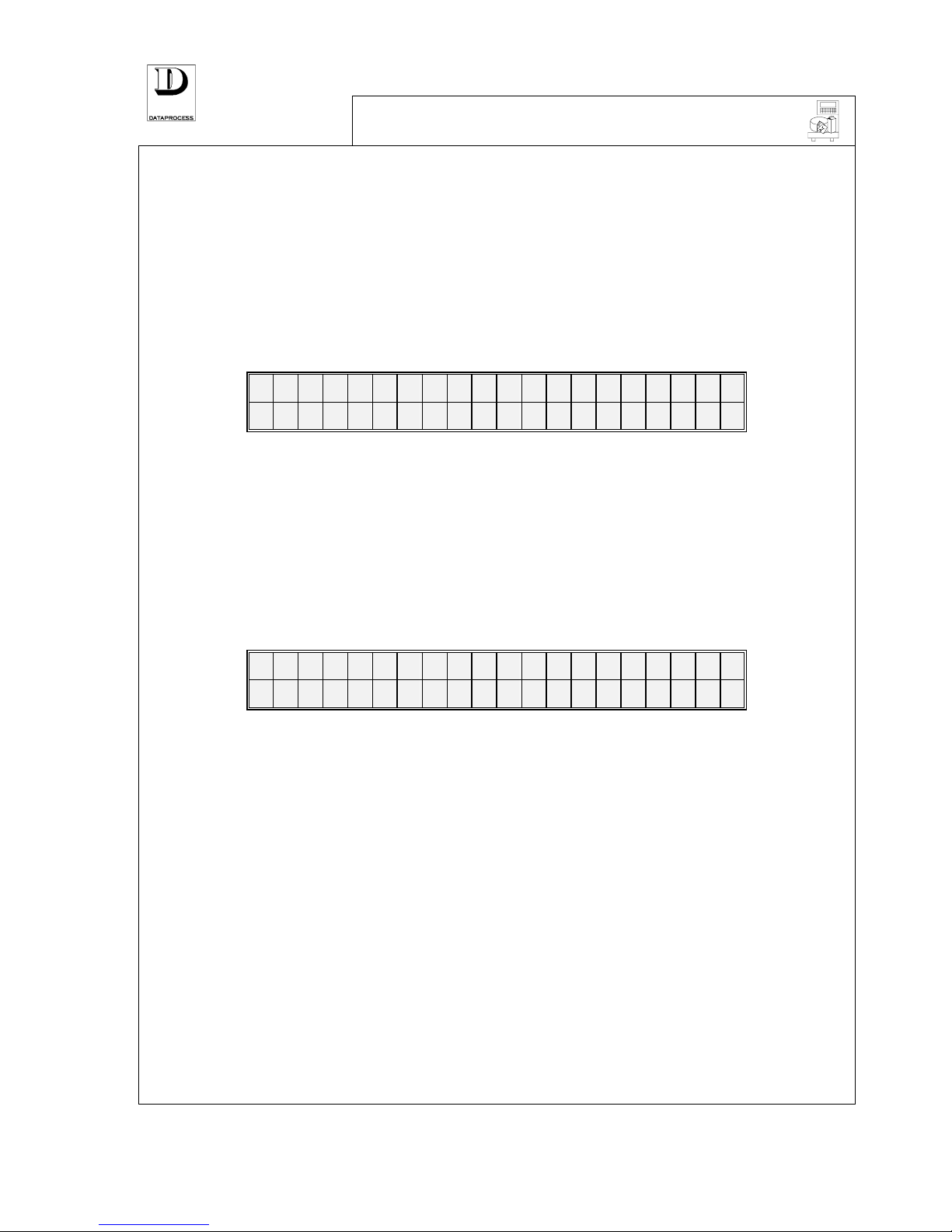

DISPLAY

The scale display is a 2-side type (for customer and for operator), each side with 2 lines of 20

characters each and one set of LED lamps.

Display: operator side

AREA DESTINATA AL LOGO COMMERCIALE

Display: customer side

On the first line the item description or scale messages are visualised, whilst the second one is for

prices and weight values.

The LED signalling lights indicate the price calculation and other values, as reported hereunder

NET

: net weight

FIX

: fixed tare

L/kg

: price per kg

L/100g

: price per 100g

PRE-PACK

: pre-packed label

PAPER

: label roll nearly out

Page 11

UV119UE - DSP 500 : USER MANUAL - v. 4.0 PAGE 5

?

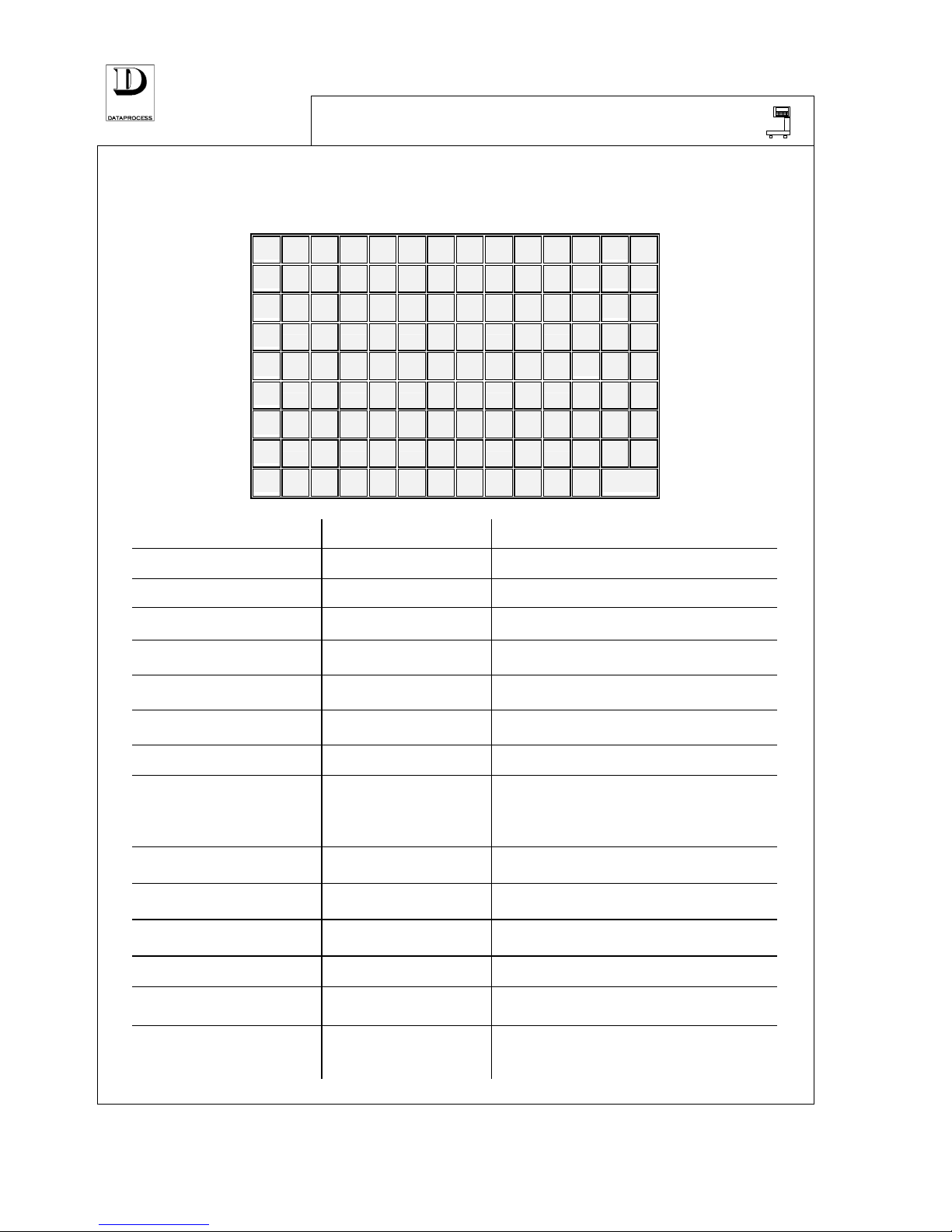

KEYBOARD

The keyboard has a rubber transparent cover with contoured relieves. The key functions are shown

on a pre-printed card placed under the keyboard cover. Further notes can be hand-written by the

operator (e.g.: PLU description). The key function card can be easily replaced.

1 10 19 28 37 46 55 64 73 82 91

F

ZER

↑↑↑↑

2 11 20 29 38 47 56 65 74 83 92

R S P

3 12 21 30 39 48 57 66 75 84 93

FIX VOI

C

4 13 22 31 40 49 58 67 76 85 94

T X

PLU

5 14 23 32 41 50 59 68 77 86 95

6 15 24 33 42 51 60 69 78 87 96

7 8 9

7 16 25 34 43 52 61 70 79 88 97

4 5 6

8 17 26 35 44 53 62 71 80 89 98

1 2 3

9 18 27 36 45 54 63 72 81 90 99

0

PRINT

1 ÷ 99

PLU / operator

direct recalling PLU or operators

F

function

<F> + key code

for accessing programming mode

ZERO

zero-setting

direct loaded weight is considered as 0

paper feed

direct feeds paper; positions label

RP

random price

<RP> + nnn

selects item price without PLU

SP

special price

PLU + <SP> + nnn

modifies PLU programmed price

PB

price basis

<RP> + <PB> + nnn

select random price into L/kg or L/100g

FIX

fixed tare

<T> + <FIX>

fix value of weighed tare

VOID

void

<VOID> + op + <> +

PRINT>

<VOID> + <PRINT>

enter void on one or more receipt items

enter void for last label (subtracted from

totals)

C

cancel

direct delete the last entered data

T

weighed tare

direct current weight is considered as tare

X

multiply

price + <X> + nnn

input the no. of items after price

PLU

PLU code

nnn + <PLU>

closes PLU code entry

0 ÷ 9

numerical keys

nnn

enter a number, of meaning according to

above mentioned keys

PRINT

print and total

direct

<

PRINT> + operator

print label, or

print receipt

Page 12

PAGE 6 UV119UE - DSP 500 : USER MANUAL - v. 4.0

Page 13

PAGE 6 UV119UE - DSP 500 : USER MANUAL- v. 4.0

DISCARD THIS PAGE

(USED ONLY FOR PAGE NUMBERING ALIGNMENT)

Page 14

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 7

DAILY USE

SWITCHING ON....................................................... page 8

DISTINCTIVE FEATURES....................................... page 9

OPERATIONAL SEQUENCE...................................page 10

TARE........................................................................page 11

RESET TO ZERO..................................................... page 11

PLU RECALL...........................................................page 12

PRICE VIA KEYBOARD ...................................page 13

PRINT LABEL..........................................................page 14

LABEL LAYOUT......................................................page 15

RECEIPT TRANSACTIONS..................................... page 16

VOID.........................................................................page 16

RETURNS ................................................................ page 17

SUBTOTAL AND DISCOUNTS ...............................page 17

PRINT RECEIPT ......................................................page 18

CORRECTING RECEIPTS.......................................page 18

RECEIPT LAYOUT ..................................................page 19

PAPER REPLACEMENT.................................... page 20

PAPER-CASSETTES.............................................page 21

DAILY USE

Page 15

PAGE 8 UV119UE - DSP 500 : USER MANUAL- v. 4.0

SWITCHING ON

For switching-on the scale, put to on position the switch which is placed at the scale left side,

under the bottom plate.

After switching on, the scale carries out an automatic routine test cycle; the digits from 0 to 9, with

comma and LED lights are represented on the display, then the display switches off for a few

seconds.

After the test cycle is over (in 15 seconds approx.) if the scale detects no anomalies, the weight is

reset to “0” and then the scale is ready to be used.

The zeros, corresponding to weight, price and total can be visualised on the display as follows:

0, 0 0 0 0 0

Networked scales

If the scale is to be used on-line with other scales, a test of network connection is carried out as it

is switched-on, after the routine test cycle. The message LOOKING FOR SCALES is represented

on the display. If all the scales pre-programmed to work on-line turn out to be actually linked, the

scale exits the search condition and can work regularly.

Contrarily, the message continues being displayed and the addresses of the scales which, although

programmed in network configuration, result to be disconnected, are visualised by pressing <C>:

S C A L E S M I S S I N G

n n n n n n n n n n n

where:

n = network address of absent scales

By pressing <PRINT> the current network configuration is accepted and the scale is enabled to

normal work. The pressure of any other key reactivates the search of the network-linked scales.

Weight different from zero

If, during the test cycle, the scale detects a floating weight (for example caused by an accidental

bump into the platter) the message CHECK CONVERTER is displayed. When the weight

stabilises, then the scale returns to its original condition. If the weight cannot stabilise call for

technical service.

If during the test cycle a weight lower than “0” is found, the message ZERO SETTING will be

displayed and the scale remains on a standby state until reset to zero is carried out. The occurrence

may be caused by the weighing platter badly positioned, or missing.

When the weight automatic reset procedure is completed, and the scale is ready to start working,

the zeros for weight, price and total are visualised on the display. Now, weight is correctly

indicated as any item is put on the platter.

Page 16

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 9

DISTINCTIVE FEATURES

The DSP500 scale has a set of 3 special features which the user should be immediately aware of:

MAPPING OPERATOR KEYS (and other “optional” keys)

Only the standard set of keys have a pre-defined lay-out on the keyboard, although modifiable. The

operator keys are, for instance, not mapped into any default position. So one or more operator keys

(up to 20) must be mapped onto the keyboard to be able to work (unless working with labels or

single-item receipts and only a single pre-set operator id.).

Programming function 07 KEYBOARD FUNCTIONS (see chapter on PROGRAMMING)

accomplishes this task. To any of the available key-functions a function-code is associated (e.g.

<OP. KEY 1> = code 131, <OP. KEY 2> = code 132. etc.) and this code is mappable to any of the

actual keyboard keys. The same mechanism is used to map to the keyboard a set of “optional”

keys, as <RETURNS>, <DISCOUNT>, <RECEIPT CORRECTION>, and payment mode keys <CASH>, <CHEQUE>, etc.-.

Operator and “optional” keys are normally mapped to any of 99 generic white keys available. The

same applies for the PLU hot-shot keys. However there is no constraint on key mapping, and also

the pre-set coloured keys can be re-mapped.

PRINTING MODES

There are a number of print modes available (receipt, labels, etc.). Some functions may be

enabled/disabled according to the current mode selected and also the way to accomplish some

tasks may vary accordingly. Here is a list of the print modes available:

1. RECEIPT: a receipt lists all the items sold (possibly returned) to a customer. In this mode a set

of functions are enabled: sub-total, change computation, free rate discount, payment mode

(cash, credit card, cheque, coupon, etc.) and receipt correction after issuing.

2. SINGLE-ITEM RECEIPT: every single-item receipt carries a single item sold. It is very much

like a label in scope, but prints on the same paper-roll used for receipts.

3. LABEL: again single item sales but printed in the typical sticky label paper. In addition the

graphical lay-out is completely programmable: text, bars and boxes positionable and

dimensionable at will.

4. AUTOMATIC LABEL: just like a normal label but printing is obtained simply by putting items

on the print plate, non need to press any key.

5. PRE-PACK LABEL: pre-pack labels are automatic labels to which pre-set tares can be applied

(for pre-packing purposes).

The DSP500 scale can switch between the print modes automatically, recognising up to 3 pre-set

printing modes/paper formats according to a set of identifier marks on the paper cartridges.

“PREFERRED” PRICE SOURCE

The DSP500 scale may operate in “PLU-prone” mode, i.e. optimised for PLU entering (and only

spare use of random-price entries), or in “Random Price prone” mode, i.e. optimised for hand

entering of unit prices (and only spare use of PLU entries).

In “PLU-prone” mode any digit entered on the numeric keypad is by default interpreted as part of a

PLU code. To type in a “random price” the <RP> key must be hit before.

In “Random Price prone” mode any digit entered on the numeric keypad is by default interpreted

as part of a unit price. To type in a PLU code the <PLU> key must be hit before.

The choice between the 2 modes can be set in programming mode to fit the user needs. Hot-shot PLU

keys, if programmed, can be used in both modes.

Page 17

PAGE 10 UV119UE - DSP 500 : USER MANUAL- v. 4.0

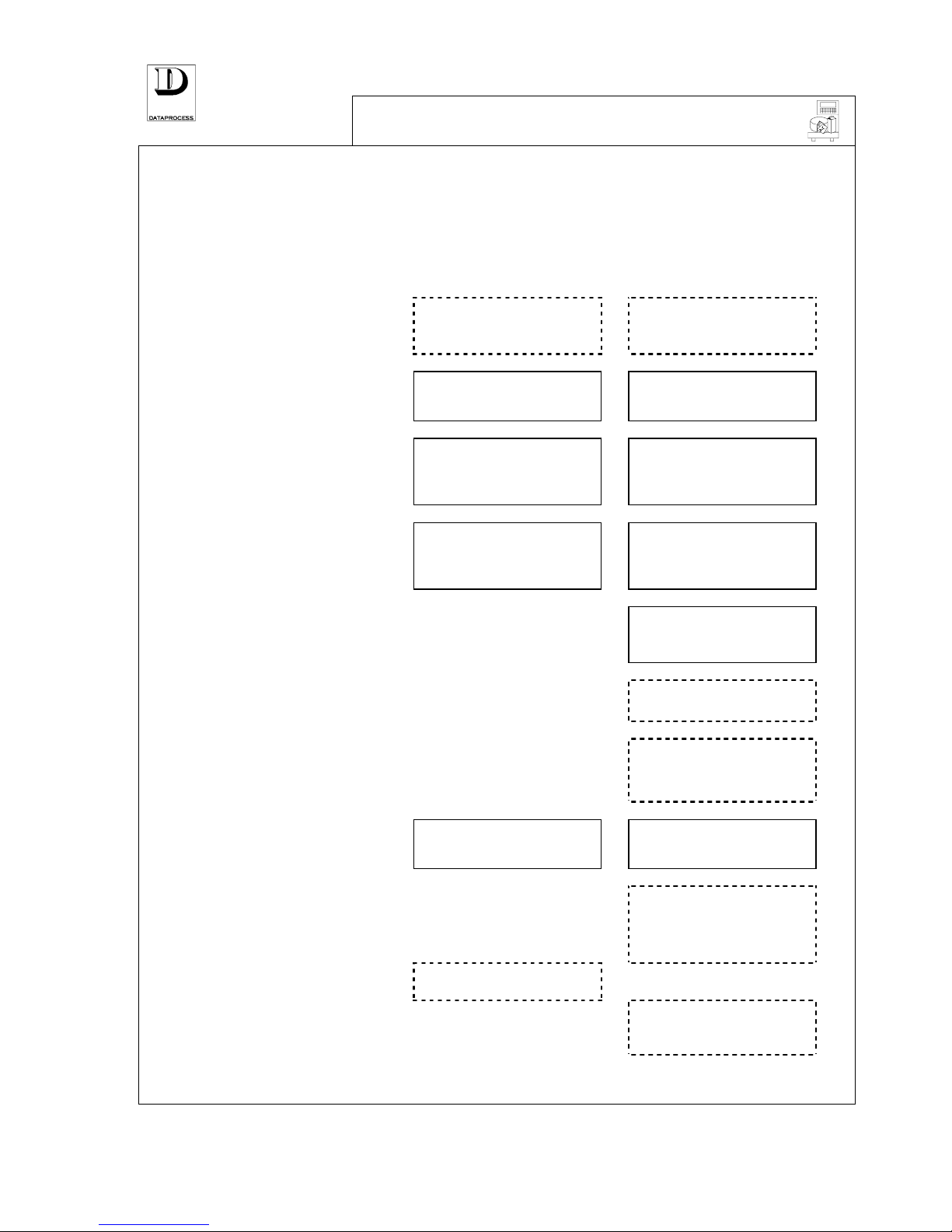

OPERATIONAL SEQUENCE

The operational sequences are different for the scale being set for working with labels or with

receipts as shown hereunder:

SEQUENCE FOR

Refer to the bracketed pages:

LABELS

RECEIPTS

TARE (page 11)

ZERO SETTING (page 11)

tare or zero reset

(when required)

tare or zero reset

(when required)

position product

on scale platter

position product

on scale platter

PLU RECALL (page 12)

PRICE VIA KEYBOARD (page 13)

price selection

by entering PLU recall code

or random price

price selection

by entering PLU recall code

or random price

total computed

by weighing,

or by entering no. of items

total computed

by weighing,

or by entering no. of items

RECEIPT TRANSACTIONS (page 16)

RETURNS (page 17)

record transaction

(assigning it to operator)

VOID ON RECEIPT (page 16)

void (if required)

SUB-TOTAL AND DISCOUNT (page 17)

sub-total and discount

(if required)

PRINT LABEL (page 14)

PRINT RECEIPT (page 18)

transaction closing

with label printout

transaction closing

with receipt printout

PRINT RECEIPT (page 18)

change computed and

printed on receipt

(if required)

VOID ON LABEL (page 16)

void (if required)

CORRECTING RECEIPTS (page 18)

corrections to receipt

(if required)

Page 18

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 11

TARE

T

Tare

Put the container or paper sheet on the scale platter and then press <T> to

subtract tare weight.

The subtracted value is transferred to tare and is no longer displayed. The LED

light NET on signals that the tare is activated.

With automatic weighed tare activated, when the scale platter is unloaded, the

tare weight, preceded by a minus (-) is visualised by the weight display.

FIX

Fixed tare

To store or ‘fix’ the same tare for a number of weighings, press the key <FIX>

that fixes the entered tare. By pressing <FIX> once again, the stored tare is

cleared.

The LED light FIX on signals that the fixed tare is activated.

Clearing tare:

An entered tare value can be cleared by one of the following ways:

• By unloading the goods from platter after the transaction has been printed.

• By loading the platter and then unloading it after that the weight stabilises.

• By pressing the key <T> with gross weight set to zero.

PRE-SET TARE (on Pre-pack only)

A pre-set tare can be assigned to the PLU ,either by entering the tare value through the keyboard

numerical keys (see progr. function 04 MANUAL TARE) or automatically, by weighing the

container (see progr. function 05 WEIGHED TARE).

When the scale is on pre-pack mode, if a PLU with its assigned tare is entered, PT followed by the

tare value expressed in kg. (i.e.: 0.938 kg) is visualised on the display. After a few seconds the

PLU description and the net weight will also be displayed, and the label is printed.

RESET TO ZERO

ZERO

By pressing <ZERO> with the empty platter, the weight is set to zero - provided

that the difference in positive as compared with the weight resulting at switchingon is less that 2 % of the scale max. load capacity (it will be 120 g for the scale

supplied for 6 kg., and 300 g for the scale supplied for 15 kg.). If higher

differences result, switch-off the scale and then switch-on again.

HALF-AUTOMATIC RESET

If the scale detects a weight lower than zero ( initially set, or set later on) , on the display the

weight signalling lights off and just one zero for price remains alighted. If the negative weight is

stable, after some seconds the scale proceeds to automatic weight reset. Even in this case, the

difference compared with the weight resulting at switching-on must be less that 2 % of the scale

max. load capacity (that is:

120 g for the scale supplied for 6 kg., and 300 g for the scale supplied

for

15 kg.). If higher differences result, recalibrate the scale by switching it off and then switching

it on again.

Page 19

PAGE 12 UV119UE - DSP 500 : USER MANUAL- v. 4.0

PLU RECALL

The daily use of the DSP 500 Scale is based on the PLU, that is on pre-programmed prices.

Each PLU is marked by a numeric code, 1 up to 7 digits long (see function 23 PLU CODE LENGTH).

Up to 3045 PLU can be stored without text (see progr. function 10 PLU EDIT ). If some text for

product description and, where needed, for ingredients is to be added, then the maximum number

of programmable PLU decreases. For example: using 350 characters for item description and

ingredients, the max. number of PLU lower to approximately 450.

Some of these PLU can be associated to the 99 direct recall keys available on the keyboard (see

progr. function 00 DIRECT PLU ).

Attention:

the code number and the dedicated key number are NOT the same (Code

no. 59238 may correspond to key no. 27).

Note that codes 1 and 2 are used by the Random Price functions, and

therefore they cannot be used for PLU.

PLU can be recalled by the two ways reported hereunder:

• directly, by pressing one of the 99 hot-shot keys (fast PLU recall) on the keyboard, if

programmed (see prog. funct. 00 HOT-SHOT KEYS).

• by using the numerical keys + the key <PLU> to confirm the entry. In PLU RECALL

priority the confirmation may also be given without <PLU> key on time-out basis (see

progr. function 22 PLU TIME LIMIT). Remember that codes 1 and 2 cannot be used.

With non-weighed item PLUs just enter the quantity by the numerical keys (if quantity is greater than

1).

When trying a recall for a non-programmed PLU, the message NON AVAILABLE is displayed.

Abort the request and press <C> to continue.

VARIATION OF PLU PRICE

Although making use of all the pre-set codes, the DSP 500 scale offers the possibility to enter a

temporary price variation and keep the PLU description and information at the same time.

SP

SPECIAL PRICE

To change a price associated to a PLU press <SP> (Special Price). The new

price must be higher or equal to the minimum price programmed for that PLU.

Attention! The above function can be selected provided that the

following conditions are present:

• It has been enabled by progr. function 25 OPERATION SETTINGS

• The function “price revision” was enabled when programming the

recalled PLU (see progr. funct. 10 PLU EDIT).

DISCOUNTS

pre-set by quantity

pre-set on single PLUs

free on total amounts

In addition to Special Prices, a PLU unit price can be set to 3 different

amounts, with each amount being automatically used if weight of

quantity is above one of the two thresholds, thus providing

“weight/quantity-based” discount capabilities. The thresholds for

automatic discounts can be specified for each PLU (see funct. 10 PLU

EDIT

).

Discounts can also be provided on a fixed base for each PLU (see funct.

10 PLU EDIT) or freely on the total amount of a receipt (see SUBTOTAL AND DISCOUNTS

).

Page 20

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 13

PRICE VIA KEYBOARD

By this function, the DSP 500 scale offer the possibility to enter non-programmed prices.

The procedures to be followed are slightly different according to the priority that was pre-set

during programming: PLU RECALL or SELECT PRICE (see progr. function 27 OPERATION

MODE

).

SCALE PRE-SET WITH

PLU RECALL PRIORITY SELECT PRICE PRIORITY

RP

(Random Price)

The message

WEIGHED RANDOM

PRICE

is displayed as

key <RP> is pressed.

ENTER PRICE

If the scale was pre-set to work

on SELECT PRICE priority,

enter directly the price you need

by the numerical keys. The

message WEIGHED RANDOM

PRICE

.

Attention: For using this function with

the scale set with PLU RECALL priority, the

possibility to select random prices must have

been expressly programmed (see progr.

function 25 OPERATION SETTINGS). If

after having pressed the key <RP> the

message NOT AVAILABLE is displayed, that

means that the option above was not enabled.

Press <C> to cancel the request.

TIME LIMIT !

A time limit can be programmed between one

entered digit and the successive one (see progr.

function 21 NUMERICAL KEY TIME LIMIT).

Once elapsed that time limit, the entered digit shall

be considered as the beginning of a new price.

HOW TO SELECT PRICE

WEIGHED

RANDOM PRICE

If the item being considered is priced by weight, now enter it.

You can choose the price basis, before entering it, by pressing <PB> to

select between price per kg. or per 100 g., as signalled by the LED lights on

the display (L/kg or L/100g).

Note:

PB

The <PB> is activated only when selecting a random price

(RP), and it must be pressed before entering the price. If you

try setting a price per 100g. after the price has already been

entered, the error signalling SEQUENCE ERROR is

displayed. Press <C> to cancel and then repeat again the

procedure in the correct sequential order, as follows:

<RP> key + <PB> key + price.

NON-WEIGHED

RANDOM PRICE

X

If the item is non-weighed, press<X> after entering the price. The message

NONWEIGH. RAN. PRICE is represented on the display. At the weight

position on the display, the symbol @ lights up, followed by the number 1.

If the quantity of items is more than 1, type in the requested quantity.

Page 21

PAGE 14 UV119UE - DSP 500 : USER MANUAL- v. 4.0

PRINT LABEL

Three different printing modes are available for labels: “Label” mode, “Automatic Label” mode

and “Pre-pack Label” mode.

The selection of the label printing mode is made during the scale programming phase (see progr:

function 20 RECEIPT / LABEL).

Each PLU includes information on the graphic format of its label (see at the next page). The preset format no. 5 is reported in the example shown herebelow:

ITEM DESCRIPTION →→→→

Smoked Ham

PACKING DATE →→→→

PACKED ON 13-09-95 EAT W ITHIN 18-09-95

←←←← EXPIRY DATE

NET W. PRICE TOTAL

Kg L/Kg Liras

NET WEIGHT AND PRICE →→→→

0,152 21500 3270

←←←← TOTAL PRICE

TARE VALUE →→→→

TARE

Kg

0,020

←←←← BAR CODE

For label printing, follow the instructions given in the following lines:

LABEL

PRINT

If the scale is set on “Label” printing mode: press the key <PRINT> after having

recalled the PLU you need or having selected Random Price.

The total price is also summed (in the general totals) to the sales attributed to the

operator which has been associated to the paper-cassette in use (see function 20

RECEIPT/LABEL

).

By hitting instead <OP 1> key (up to <OP 20> key, if all 20 operators have been

mapped to some keys in the keyboard) the sale is attributed to the specified operator.

AUTOMATIC

LABEL

In the “Automatic Label” printing mode: labels are printed automatically (without

pressing any key) at each weight variation. No pre-set tare can be used in this

case.

PRE-PACK

LABEL

Also in the “

Pre-pack label” mode labels are printed automatically at each weight

variation.

If a tare value is associated to a recalled PLU, it will replace the existing one and

is visualised for approx. 4 seconds on the display top screen.

The recalled PLU for label issue is deleted each time the scale platter is unloaded ( at each weight

re-zeroing), or by pressing <C>.

Attention:

The label prints only provided that all the following conditions are met:

1. the scale is neither below zero weight nor beyond full scale

2. the computed amount is different from zero and not exceeding the max.

pre-set limit (999.999)

3. the weight is stable and net weight is higher than 0 (for weighed prices)

4. if after the previous printed label there has been a weight variation, or

the scale platter has been unloaded (for weighed prices)

OP 1

Page 22

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 15

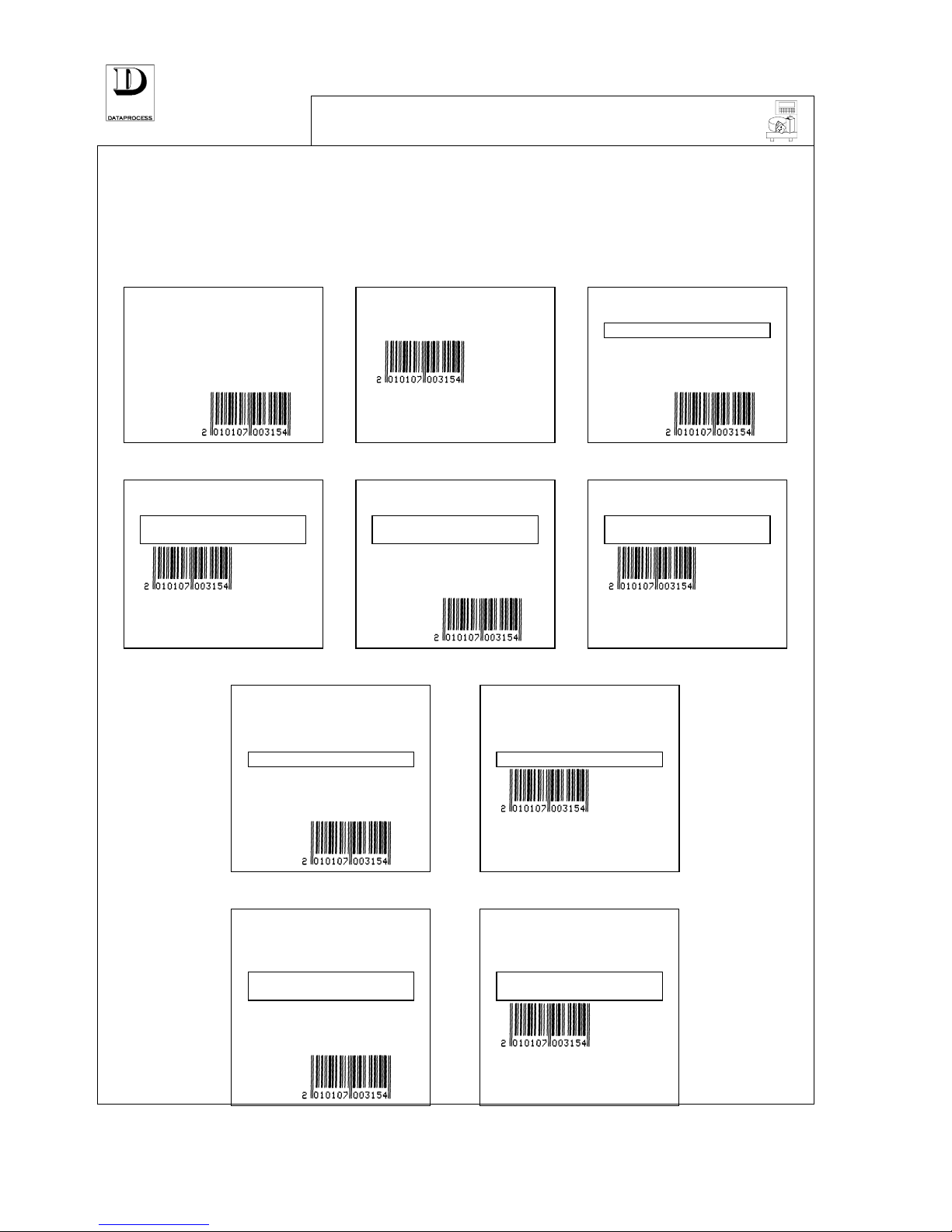

LABEL LAYOUT

The choice of label format is effected by each PLU when programming it (see funct. 10 PLU

EDIT

).

20 Label layouts are available: 10 pre-set layouts, shown on this page, and other 10 userprogrammable layouts. The even layouts shown are for non-weighted items, whilst the odd ones are for

weighted items.

Layout n° 1 Layout n° 2 Layout n° 3

Smoked Ham

Smoked Ham

Smoked Ham

EAT WITHIN 27-09-96

NET W.

Kg

0,152

PRICE

L/Kg

21500

TOTAL

Liras

3270

TOTAL

Liras

3270

NET W.

Kg

0,152

PRICE

L/Kg

21500

TOTAL

Liras

3270

TARE

Kg

0,020

TARE

Kg

0,020

Layout n° 4 Layout n° 5 Layout n° 6

Smoked Ham

Smoked Ham

Smoked Ham

EAT WITHIN 27-09-96 PACKED 17-09-96 EAT W. 27-09-

96

PACKED 17-09-96 EAT W. 27-09-

96

TOTAL

Liras

3270

NET W.

Kg

0,152

PRICE

L/Kg

21500

TOTAL

Liras

3270

TOTAL

Liras

3270

TARE

Kg

0,020

Layout n° 7 Layout n° 8

Smoked Ham

Smoked Ham

Fresh quality from the country Fresh quality from the country

EAT WITHIN 27-09-96 EAT WITHIN 27-09-96

NET W.

Kg

0,152

PRICE

L/Kg

21500

TOTAL

Liras

3270

TOTAL

Liras

3270

TARE

Kg

0,020

Layout n° 9 Layout n° 10

Smoked Ham

Smoked Ham

Fresh quality from the country Fresh quality from the country

PACKED 17-09-96 EAT W. 27-09-

96

PACKED 17-09-96 EAT W. 27-09-

96

NET W.

Kg

0,152

PRICE

L/Kg

21500

TOTAL

Liras

3270

TOTAL

Liras

3270

TARE

Kg

0,020

Page 23

PAGE 16 UV119UE - DSP 500 : USER MANUAL- v. 4.0

RECEIPT TRANSACTIONS

In “Receipt” mode each amount computed by the scale (transaction) must be

stored and assigned to a specific operator.

In case of scales working in network, an amount computed on one scale can be

assigned to any of the link-connected operators.

With the amount displayed on the scale display, press the <OP 1> key, or any

other appropriate operator key (up to <OP 20> key, if all 20 possible operators

have been mapped into the keyboard - see Attention note on operator keys).

The scale confirms by two “beeps” (in addition to the key ‘beep’ signal given out if the function 26

KEYBOARD BUZZER

is enabled) and by briefly showing the message * STORING * on the display.

Attention:

The DSP500 Scale, for printing receipts, requires at least one operator has

been enabled. To enable one or more operators (up to 20 max. ) just assign

the operator identifier to one of the 99 direct keys during programming

(see progr. function 07 KEYBOARD FUNCTIONS).

SUB TOTALS

By pressing the direct key assigned to an operator with no transaction on course, the sub-total of

the current receipt can be visualised on the display. If no receipt is being issued, zero is displayed.

VOID

If the function VOID was enabled during programming (see progr. function 25 OPERATION

SETTINGS

), a sub-total can be subtracted from a receipt on course, or the amount of the last label been

issued can be subtracted.

VOID FOR RECEIPT ON ISSUE

VOID

...

PRINT

VOID

As the key <VOID> is pressed the message ENTER OPERATOR is displayed.

Press the operator key, and the latest transaction is displayed, or the message

NO

TRANSACTION

if no receipt results on issue.

For scrolling through all the transactions of the receipt, press the key <↑↑↑↑> and,

once reached the sale to be subtracted, enter the void by pressing <PRINT>. The

message

ENTERED VOID will be visualised on the display. Press <↑

↑↑

↑> to scroll

throughout the remaining transaction if additional voids must be entered.

Press <VOID> again to confirm the entry and return to normal working condition.

VOID FOR LAST LABEL

VOID

PRINT

VOID

By pressing <VOID>,the total of the last issued label can be subtracted from total

counters. The weight, price and amount of the last label will be represented on the

display (or: price, no. of items and total for non-weighed sales).

The void can be entered by pressing <PRINT>, and a minus (“-”) sign will be

visualised on the display before the weigh and total values. The void is annulled

by pressing <PRINT> once again (figures return positive, on the display).

Confirm the void by pressing <VOID> again to return to normal working

condition.

OP 1

Page 24

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 17

RETURNS

RP

-

To enter negative amounts on receipts, for instance to take into account returns,

the RETURNS function key can be used.

The return key is not mapped in the pre-set keyboard layout, so check that this

operation has been performed in order to use it (see progr. function 07

KEYBOARD FUNCTIONS

).

Press the <RP> key, followed by unit price for the item returned and by the <->

key (the RETURNS function key).

To specify quantities of equal-priced items returned just type in the quantity after

the <-> key.

End the sequence by the appropriate operator key <OP n> (n being the operator

involved), thus specifying to which operator receipt the returns must be applied

to.

SUBTOTAL AND DISCOUNTS

SUB TOTALS

By pressing the direct key assigned to an operator with no transaction on course,

the sub-total of the current receipt can be visualised on the display.

A message OPERATOR TOTAL n (n being the operator involved) is issued on

display and the line below shows the no. of item recorded in the operator receipt,

followed by the corresponding total amount.

If no receipt is being issued, zero is displayed.

DISCOUNTS

DISCOUNT

DISCOUNT %

PRINT

Free percentage discounts can be applied by pressing the DISCOUNT function key

just after a sub-total is invoked.

The discount key is not mapped in the pre-set keyboard layout, so check that this

operation has been performed in order to use it (see progr. function

07

KEYBOARD FUNCTIONS

).

Press the desired operator key <OP n> with no transaction on course to obtain a

sub-total, then press the <DISCOUNT> key followed by the % discount wanted.

The display shows the message DISCOUNT % followed by the percentage

entered.

Then close the sale (by pressing <PRINT> or other possibly enabled receiptclosing keys - e.g. <CHEQUE>, <CASH>, ...-, see PRINT RECEIPT on next page

for details).

Discounts can also be provided either on a fixed % base for each PLU (see funct. 10 PLU EDIT), or

using Special Prices (see

PLU RECALL) or even on a 3-range weight/quantity base for each PLU

(see funct.

10 PLU EDIT).

OP 1

OP 1

OP 1

Page 25

PAGE 18 UV119UE - DSP 500 : USER MANUAL- v. 4.0

PRINT RECEIPT

PRINT

After transactions are completed, the receipt can be outprinted. Press <PRINT> and

the message ENTER OPERATOR is visualised on the display. After pressing the

operator key, the display visualises the message OPERATOR TOTAL followed by

the corresponding sale total, and the receipt is immediately printed. (If no receipt

is on issue, the display visualises the message NO TRANSACTION).

The total is displayed until a subsequent operation is started, either

loading/unloading the plate or touching the keyboard. Alternatively the scale can

be programmed so to exit the total-display status on subsequent keyboard

operation only (see progr. 34 EXIT FROM TOTAL).

CASH

CHEQUE

CREDIT CARD

COUPON

To better qualify the payment mode, for accounting purposes, a set of

function keys can be used instead of the generic <PRINT> key.

These keys are <CASH>, <CHEQUE> , <CREDIT CARD>, <COUPON>, and

by using them the amounts are totalised separately and thus can be

separately reported in total reports.

None of these keys is mapped in the pre-set keyboard layout, so check

that this operation has been performed in order to use them (see progr.

function 07 KEYBOARD FUNCTIONS).

Use these keys just as the <PRINT> key. A specific payment mode

message will be issued on the display and will be printed on the receipt.

CHANGE CALCULATION

At the end of the printed receipt, before entering any other operation, the change calculation can be added.

F

As the key <F> is pressed, the query CASH is visualised on the display. Now, type

in the amount by the numerical keys and then, when pressing <PRINT> the

computed change is displayed and then printed at the very end of the receipt (if

the “change print” function was enabled during programming as explained in the

progr. function 31 RECEIPT OPTIONS).

RECEIPT REPRINT

PRINT

Pressing <PRINT> once again prints another copy of the receipt.

A second short summarised receipt for accounting can be automatically printed , only with date,

time, amount ,operator and scale id., receipt number (see progr. 33 ACCOUNT RECEIPT).

CORRECTING RECEIPTS

RE-OPEN

Each of the operator can, if needed, re-open its last issued receipt to correct it.

Press the <RE-OPEN> key followed by the appropriate operator key <OP n>,

as queried by the message ENTER OPERATOR displayed.

The total amount of the re-opened receipt is shown on display, together with

the items sold. Now any operation on a open receipt can be performed

(adding new transactions, voiding previous transactions, etc.).

The <RE-OPEN> key is not mapped in the pre-set keyboard layout. This operation

must be performed to use it (see progr. function 07 KEYBOARD FUNCTIONS).

OP n

Page 26

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 19

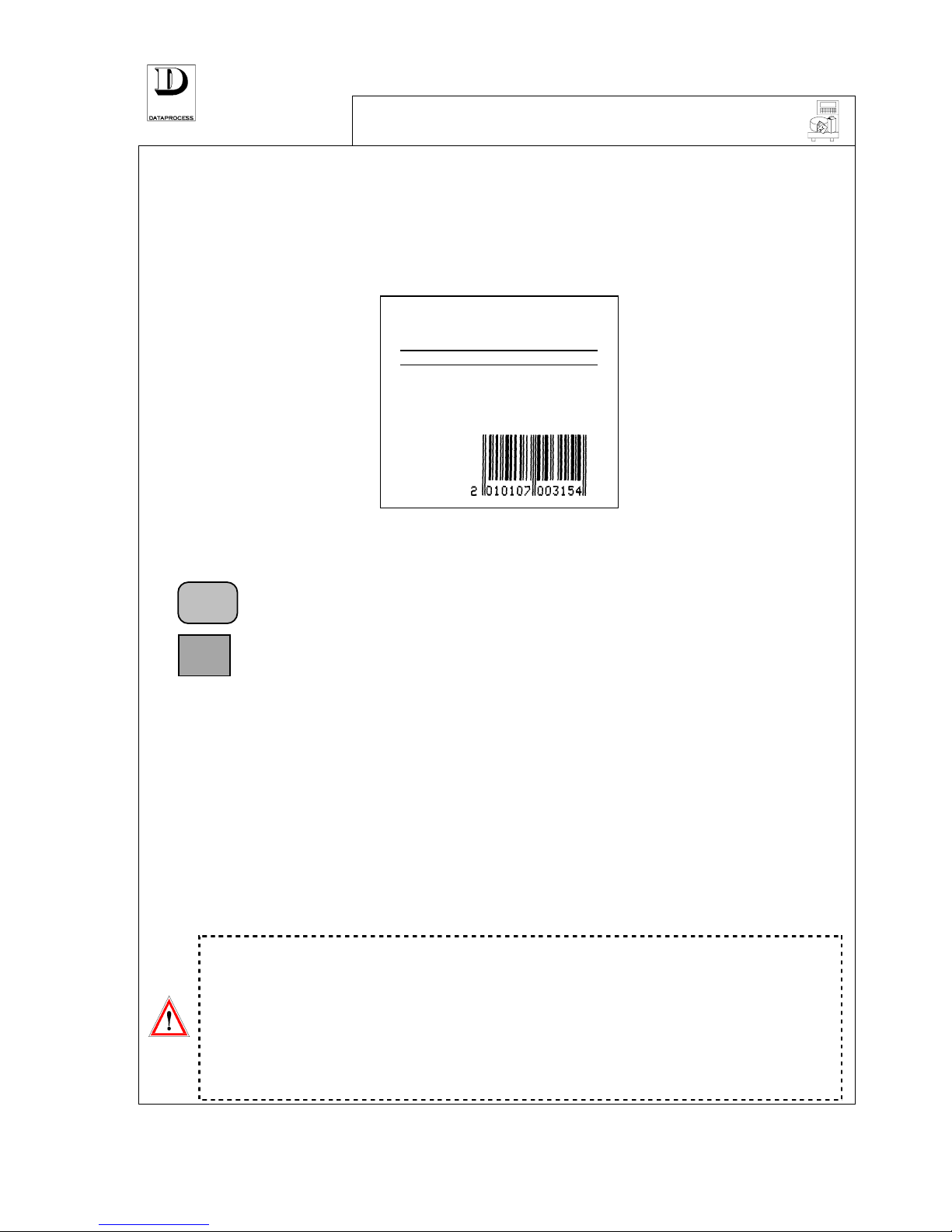

RECEIPT LAYOUT

Here is the layout of a typical receipt issued by the DSP500 scale.

Refer to the programming functions specified in brackets in the comment area for details.

PROGRAMMABLE →→→→

COMMERCIAL

MESSAGE

(30)

McPherson Butcher’s Shop

77, Redford Street

Newport, UK - EU

DATE AND TIME (31, 01) →→→→

13-09-95 14:03

kg £

PLU DESCRIPTION (31) →→→→

Smoked ham

0.152 21.50 £/kg 3.27+

←←←← WEIGHED PLU ITEM

NON-WEIGHED RANDOM PRICE

2 NP 1.75 3.50+

←←←← NON-WEIGHED RANDOM PRICE

WEIGHED RANDOM PRICE

0.255 18.00 £/kg 4.59+

←←←← WEIGHED RANDOM PRICE

NO. OF ITEMS SOLD →→→→

item 4 TOTAL 11.36

←←←← TOTAL PRICE

PAYMENT MODE (if any) →→→→

CHEQUE

OPERATOR AND →→→→

SCALE IDENTIFIER

V. 3

J. MOORE

SCA. 1 N.R. 2

←←←← RECEIPT NO.

Thanks for calling in !

←←←← PROGRAMMABLE

BAR-CODE (32) →→→→

COMMERCIAL

MESSAGE (30)

CASH

20000+

TOTAL

11360+

CHANGE

8640+

←←←← CHANGE DUE (31)

The information reported on this example can be included on the receipt printout or not, according

to the parameters entered on the programming phase (see progr. function

30 to 33).

Other receipt options, i.e. VAT printing and second short-account receipt print, have not been

included in the example to help in readability. Refer to progr. function 31 and 33, respectively, for

details.

Page 27

PAGE 20 UV119UE - DSP 500 : USER MANUAL- v. 4.0

PAPER REPLACEMENT

The paper cassette has to be replaced when one of the following messages is represented by the

display:

PAPER OUT ERROR

It is displayed when the paper is completely out. Before this occurs,

the LED signal PAPER lights up on the display.

REPLACE CASSETTE

This message is displayed when the paper cassette is not compliant

with the operational mode on use.(For example: the scale is on

“Receipt” mode, and the paper cassette is that for labels).

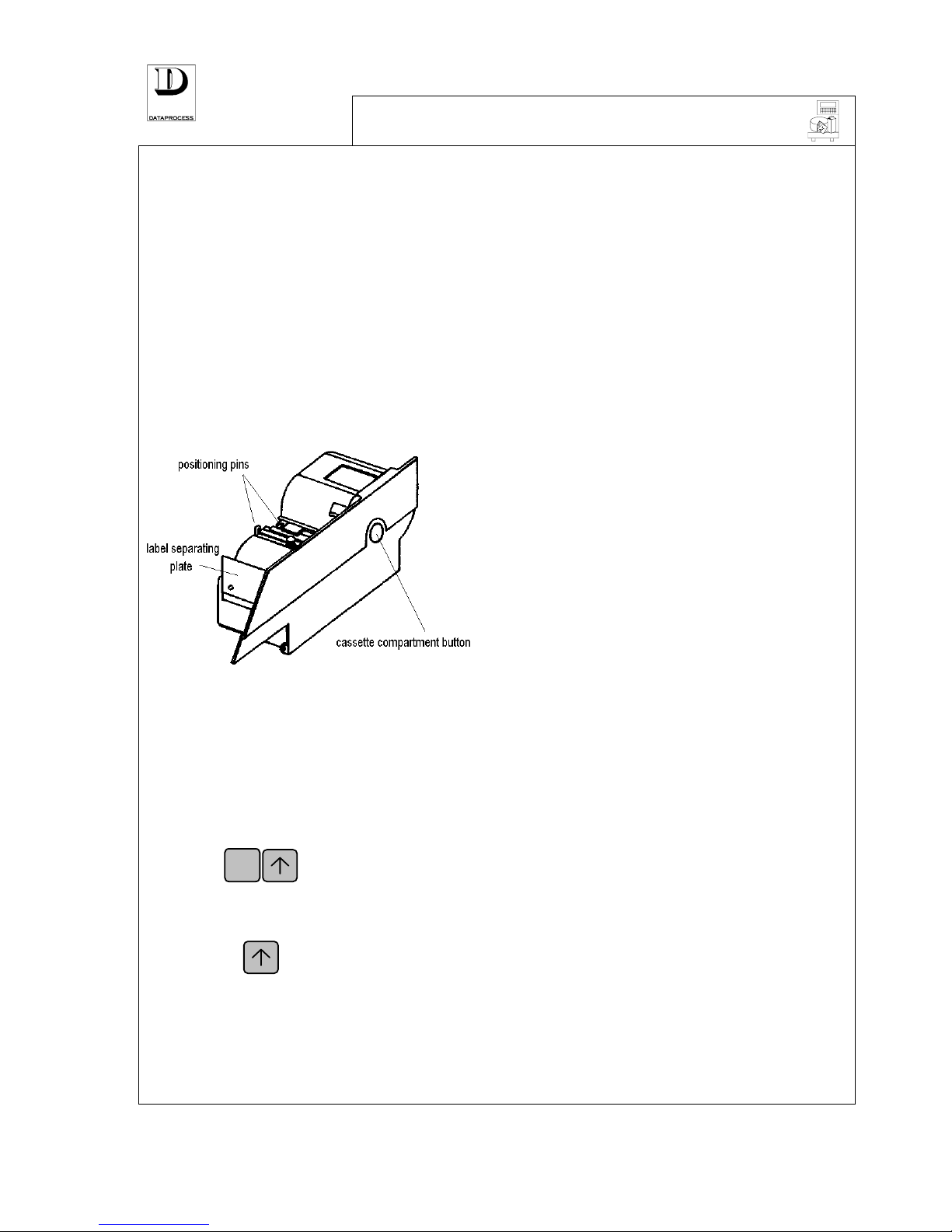

To replace the paper cassette, push the button placed on the right side of the scale (as shown by the

following figure). The cassette is pulled out for some mm. and the message

NO PAPER CASSETTE can be visualised on the display. Now the cassette can be completely

taken out.

Check that the paper is placed between the two

positioning pins, at the new paper cassette.

If it is a cassette for labels, just check that paper

is positioned correctly.

If it is a cassette for receipts then open the paper

slot on the scale front and check that 1 cm. paper

end comes out from the label separating plate.

When mounting the cassette, keep the paper end

attached to the separating plate, so that it can

slide below the printer head.

Slip in the cassette (until it clinks), re-close the paper slot so the paper can come out freely.

PAPER POSITIONING AND FEED

Position the labels correctly before restarting to use the scale. During the paper replacement or

during the scale regular use, it may be useful to have the receipt paper fed out.

F

label positioning

For positioning correctly labels, press the key <F> and then the

key <↑↑↑↑>. The printer advances the paper roll and the first label is

ejected, ready for print.

paper / label feed

If only key <↑↑↑↑> is pressed, the paper (or label) advances as long

as it is being pressed.

Page 28

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 21

PAPER-CASSETTES

The DSP 500 scale is designed to identify no. 3 different paper cassette versions for continuous

paper (receipts and single-items) and for labels. Only two label formats (with different label

lengths) can be used for the scale to automatically detects the selected type of paper and label

format. Each cassette can be associated with a specific print mode and with a default operator id.

(that can be in any case overridden by specifying any other operator when assigning each amount

in a receipt of label). See (see progr. function 20 PAPER CASSETTES).

To obtain a correct handling of the label formats A and B, enter the suitable calibrations for the

two label formats to be used on programming mode (see progr. function 50 CALIBRATION).

Attention:

When passing to a new label format (paper label of new size, spacing, etc.)

remember to re-calibrate the scale. In fact the scale does not detect the paper

directly but the cassette version to be used (see progr. function 50

CALIBRATION).

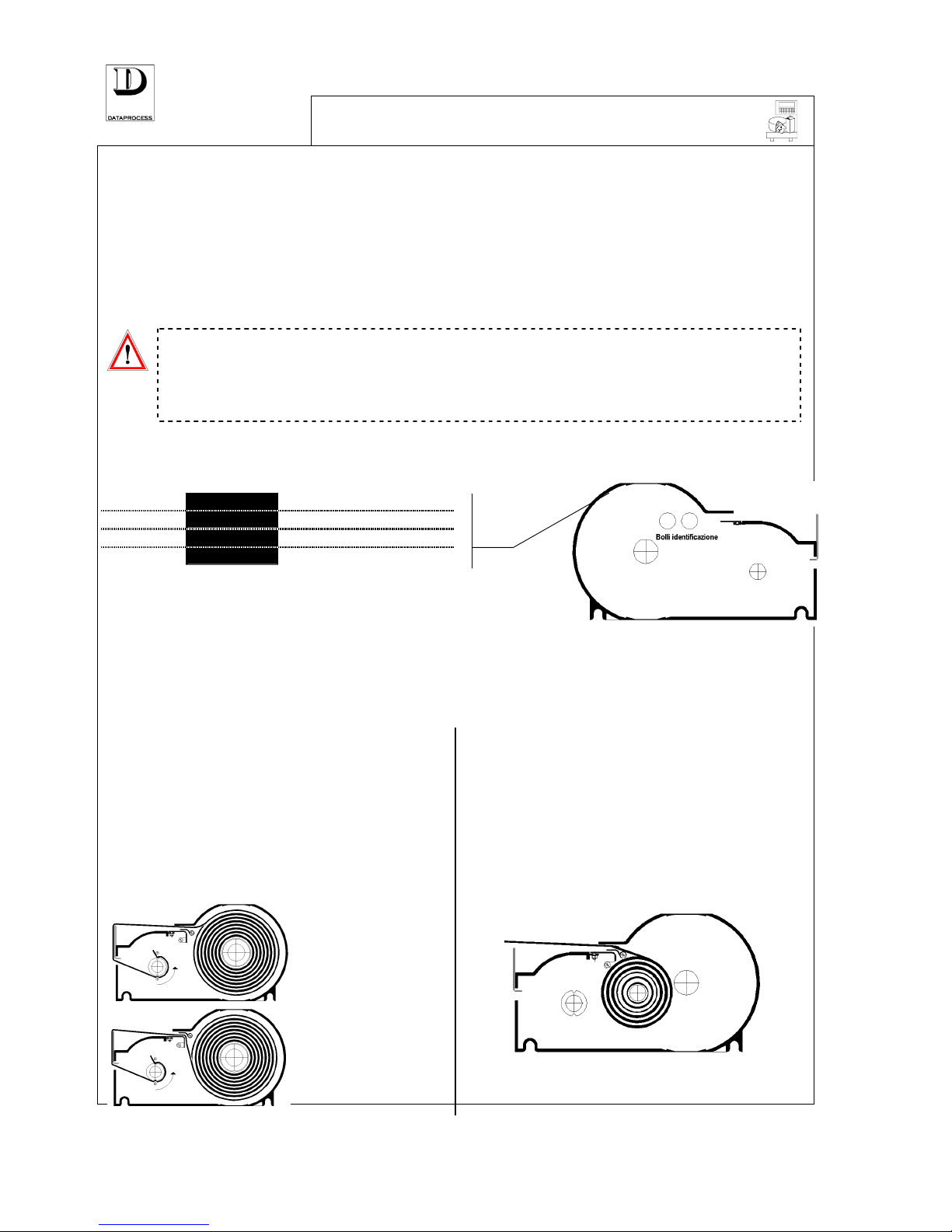

The scale detects the paper cassette thanks to an optical reader, which read the white stamps placed

inside the cassette according to the diagram reported

herebelow:

= no cassette

= cassette 1

= cassette 2

= cassette 3

After the cassette is taken out, by pressing the cassette

compartment button, lift up the cassette cover hook (on top

side) to access the cassette inside.

Inside the cassette there are two side pins and one centre pin (in the continuous paper cassette

only). This centre pin is the only difference existing between the two types of cassette. Therefore,

just remove this centre pin if you want to use the continuous paper cassette as cassette labels (and

change the white stamps positioning).

LOADING LABEL PAPER ROLLER

The roller for labels has to be inserted on the

cassette right-side pin. The strip, with labels

top side upwards must be fixed to the left-side

pin. The figure hereunder clearly shows how to

slip in the label strip, with a roller clockwise or

anti-clockwise oriented.

LOADING CONTINUOUS PAPER ROLLER

The continuous paper roller has to be inserted on

the cassette centre pin. If the centre pin is not

already mounted, screw it in.

The paper is passed over the centre metal strip

and then advances freely on the label separating

plate.

Page 29

PAGE 22 UV119UE - DSP 500 : USER MANUAL- v. 4.0

Page 30

PAGE 38 UV119UE - DSP 500 : USER MANUAL - v. 4.0

DISCARD THIS PAGE

(USED ONLY FOR PAGE NUMBERING ALIGNMENT)

Page 31

UV119UE - DSP 500 : USER MANUAL - v. 4.0 PAGE 23

MAINTENANCE AND

PROBLEM SOLVING

CLEANING...............................................................page 24

ERROR SIGNALLING..............................................page 25

PROBLEM SOLVING...............................................page 26

MAINTENANCE

AND

PROBLEM SOLVING

Page 32

PAGE 24 UV119UE - DSP 500 : USER MANUAL - v. 4.0

CLEANING

ALCOOL

ALCOHOL

ALCOOL

ALCOHOL

Switch off and disconnect the scale from mains before cleaning.

A periodical cleaning of the scale surfaces may be scheduled once per week.

For cleaning the keyboard and the display area avoid the use of alcoholic

solutions or other solvents, that may damage key labelling.

Make use of a static resistant liquid to reduce the dust.

Clean all the other external surfaces of scale using a cloth moistened with

alcohol. Remove the weighing platter for a better cleaning.

11.200

TOT.

The printer thermal head can be cleaned in two ways: by printing on

special abrasive-free forms or, with the scale switched off, by wiping the

printing head area (the dark line at the printer top edge) by means of a

stick soaked with alcohol and then drying it by a dry stick.

Clean the printer rubber pressing roller by a clean cloth. Avoid to use

tools for cleaning this roller, as rubber is soft and can easily be cut or

damaged.

Do no use detergents, solvents and clothes soaked in water.

Spray products must not be used directly on the scale. Spray on the cloth

used for cleaning instead.

Page 33

UV119UE - DSP 500 : USER MANUAL - v. 4.0 PAGE 25

ERROR SIGNALLING

ERROR MESSAGE MEANING

CALIBRATION ERROR

Error made on calibration------------ - CALL FOR TECHNICAL SERVICE -

CHANGE CASSETTE

Incorrect paper cassette selected

CLOSE RECEIPT

No more memory available for transactions

COLLECT LABEL

Draw printed label

CONVERTER CHECK

Problem with weight converter ------ - CALL FOR TECHNICAL SERVICE -

DATE ERROR

Incorrect data entry

EAROM WEIGHT ERROR

Earom weight writing error---------- - CALL FOR TECHNICAL SERVICE -

EXCEEDING WEIGHT

Weight exceeding the max. programmed value

EXISTING DATA

Data already stored

INCONSISTENT TARE

Tare value inconsistent with weight

INPUT ENABLE

Overwrite attempt on end text character

INVALID AMOUNT

Transaction with invalid amount

KEY ERROR

Incorrect key in a given function

LIMIT EXCEEDED

Signalling that pre-set limits have been exceeded

NETWORK ERROR

Signalling network error

NETWORK ERROR

Error during network transmission/reception

NO CASSETTE

Paper cassette is out of its position

NO JUMPER

Jumper not placed when calibrating scale- CALL FOR TECHNICAL SERVICE

NO TRANSACTION

No transaction recorded by selected operator

NO WEIGHT VARIATION

Transaction performed without changing weight

NOT ALLOWED

Tempted procedure not allowed

NOT ALLOWED NOW

Tempted procedure currently not allowed

NOT AVAILABLE

Procedure or data not available

NOT ENABLED

Programming enabled at higher level

OPERATOR ACTIVE

Programming not allowed with operator on service

OUT OF MEMORY

No more memory available

PAPER OUT ERROR

Signalling that paper is out

PRINT HEAD ERROR

Printer head error---------------------- - CALL FOR TECHNICAL SERVICE -

RAM WEIGHT ERROR

RAM weight error -------------------- - CALL FOR TECHNICAL SERVICE -

ROM WEIGHT ERROR

ROM weight error -------------------- - CALL FOR TECHNICAL SERVICE -

SEARCH ZERO WEIGHT

Weight reset to zero in progress

SEQUENCE ERROR

Incorrect operational sequence

TEMPERATURE ERROR

Printer head overheated beyond specified limits

TOO LOW PRICE

Price lower to the pre-set minimum value

TOO LOW WEIGHT

Weight below the minimum programmed value

UNKNOWN DATA

When selecting non-existing data (e.g.: a PLU not programmed)

VALUE ERROR

Incorrect value entered

VALUE EXCEEDED

Signalling that pre-set values have been exceeded

WEIGHT REC. ERROR

Weight received incorrectly

Page 34

PAGE 26 UV119UE - DSP 500 : USER MANUAL - v. 4.0

PROBLEM SOLVING

PROBLEM POSSIBLE CAUSE REMEDY

After switching on the

External fuse blown Replace the faulty fuse with new of

same type

scale both displays

remain OFF

Failure of display card Call for technical service

The scale switches on

but then it blocks and

the message

There is a weight on

scale platter

Take off the weight. Switch off and

then on again.

SEARCH ZERO

WEIGHT

is displayed

Problem with load cell

or with AC/DC

converter

Call for technical service

The scale switches on

but then it blocks and

the message

Platter is not placed on

scale

Place the platter on the scale. Switch

off and then on again

TOO LOW WEIGHT is

displayed

Problem with load cell

or with AC/DC

converter

Call for technical service

The scale switches on

but then it blocks and

the message

FIND SCALES is

displayed

Defective connection

with one or more scales

Press key <C> and check if the message

SCALE ABSENT is displayed. Switch

on and/or connect the scales resulting

absent. Press <PRINT>

The scale cannot detect

the paper

White stamps missing

on paper-cassette

Remove the paper cassette and check

that white stamps are present

Photocell sensor failure Call for technical service

The scale cannot detect

correctly different paper

cassettes types

White stamps

positioned incorrectly

on the paper-cassette

Remove cassette and check stamps

position. If needed, put stamps

correctly.

Photocell sensor failure Call for technical service

Page 35

PAGE 66 UV119UE - DSP 500 : USER MANUAL- v. 4.0

DISCARD THIS PAGE

(USED ONLY FOR PAGE NUMBERING ALIGNMENT)

Page 36

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 27

CONFIGURATIONS AND

INSTALLATION

CONFIGURATIONS................................................. page 28

PAPER ROLLS ........................................................ page 28

INSTALLATION .......................................................page 29

NETWORK: INSTALLATION. ....................page 30

NETWORK: ACTIVATION....................................... page 30

NETWORK: COMMUNICATIONS..........page 31

CONNECTING TO A PC.......................................... page 32

CONFIGURATIONS AND

INSTALLATION

Page 37

PAGE 28 UV119UE - DSP 500 : USER MANUAL- v. 4.0

CONFIGURATIONS

Scale available for 2 capacity and divisions: 6kg/2g

15kg/5g

equipped with no. 1 RS232 serial interface,

256 kB Eprom, 256 kB RAM

DSP500 Scale is supplied packed and complete with:

- 1 paper roll cassette, mounted

- sheet for keyboard customisation

- User kit consisting of: - User Manual, 1 copy

- 1 thermal paper roll

- 1 set of stamps for paper-cassette

marking

- 1 power cable

- 1 pin for small-size core paper roller

OPTIONS available on customer request: - Extension Card for local network + 1 line RS422

Serial Interface

- memory card adapter (for use only with optional

extension card)

- additional paper cassettes

PAPER ROLLS

The following types of paper and label rolls can be used with the DSP500 Scale:

1) self-adhesive Label Roll - thermal paper. Dimensions:

• roll ext. diameter: 130 mm max.

• roll int. diameter: 38 / 41 mm

• label width: 42.5 ÷ 62.5 mm

• label length: 30 ÷ 85 mm

2) self-adhesive, thermal paper roll. Dimensions:

• roll ext. diameter: 130 mm max.

• roll int. diameter: 38 / 41 mm

• label width: 42.5 ÷ 62.5 mm

3) non-adhesive, thermal paper roll. Dimensions:

• roll ext. diameter: 130 mm max.

• roll int. diameter: 38 / 41 mm

• label width: 42.5 ÷ 62.5 mm

or

• roll ext. diameter: 75 mm max.

• roll int. diameter: 11 mm

• label width: 42.5 ÷ 62.5 mm

Page 38

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 29

INSTALLATION

NO YES

The scale must be installed on a perfectly level, stable surface for proper

operation.

It is equipped with a spirit-level to assist levelling.

Adjust the 4 threaded feet of the scale until the bubble in centred in the

reference circle of the spirit level. Fasten the legs using the safety locks.

The scale must be connected to a 220 V., 50 Hz single-phase power

supply in compliance with the rules in force. The electric plant to which

the scale has to be connected should also follow the current safety

standards. The socket chosen for connecting the scale shall:

• be suitable for use with the scale plug

• ensure good grounding; the ground connection shall not have

adaptors or extensions

• be on a dedicated line. In cases where it is not possible, be sure that

the scale is not connected to lines powering other high input devices

(such as: refrigerators, motor-driven equipment)

Attention:

it is most important that the connection of the scale to the electric mains be

made correctly, for ensuring the scale good operation and for safety

reasons. The manufacturer disclaims all responsibilities for scales installed

without observing the instructions and the rules into force.

Page 39

PAGE 30 UV119UE - DSP 500 : USER MANUAL- v. 4.0

NETWORK:

INSTALLATION

Check the following before connecting scales in a network configuration:

a) each scale to be link-connected must be equipped with a serial Interface Module (supplied as an

optional item, see section CONFIGURATION)

b) when installing the scales, they must be connected by a special network cable, normally

supplied with the network module

Once that all the scales have been connected for network operation, proceed with programming

each scale as described herebelow:

c) use the function

54 NETWORK ADDRESS to set for each scale its unique network address. ( 1

through 10, a different address to be used for each scale)

d) by the function

55 LOCAL/NETWORK, enable network operation on each connected scale

Once that scales have duly been set, the network connection must be activated as follows:

e) use the function 57 FIND SCALES on one of the linked scales. This function allows to

automatically start network configuration and to check that all scales are present.

When the above procedure is completed, the network is activated. Exit from programming and

proceed with the scales normal operation.

NETWORK: ACTIVATION

When switching on any of the link-connected scales, an automatic search of the scales currently

connected is performed and the following message is represented on the display:

F I N D I N G S C A L E S

If all the scales pre-set for network operation result to be duly linked, the scale goes out of the

“search” status and return to its regular operation.

Contrarily, the message remains displayed. By pressing <C> the addresses of the scales that,

although programmed to work on network, result disconnected.

M I S S I N G S C A L E S

n n n n n n n n n n n

where:

n = network address of the absent scales

The current network configuration is accepted by pressing the key <PRINT> and the scale is set to

normal operation. The pressure of any other key reactivates the search of the link-connected scales.

In a network system already activated, the switching on of a scale which was pre-programmed for

network operation, causes the network automatic reconfiguration with addition of the scale just

been switched on.

Page 40

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 31

NETWORK:

COMMUNICATIONS

DIALOGUE BETWEEN SCALES

If, during a dialogue one scale does not answer as it is disconnected or switched off, the following

message is represented on the calling scale:

S C A L E n n N O R E S P O N S E

C = O K , P R I N T = R E T R Y

where:

nn = address of the scale not responding

By pressing <C> the current network configuration, excluding the scales not responding, will be

accepted and the scale will resume normal operation.

Press <PRINT> to try dialoguing again with the non-answering scale.

NETWORK BROADCAST PROGRAMMING

The programming functions that, when carried out by any network linked scale, automatically

update the data on all the other linked scales are listed herebelow:

01 DATE AND TIME date and time setting

10 PLU EDIT PLU information (item description, price, label, etc.)

11 PLU COPY copy PLU with a new code

12 PLU DELETE delete PLU

NETWORK TOTALS REPORTS

The totals shown on the printed reports listed hereunder are the sum of the transactions effected by

each link-connected scale:

80 OPERATOR TOTALS printout of sales totals subdivided by operator

81 DEPARTMENT TOTALS printout of sales totals subdivided by department

82 TOTALS BY VAT printout of sales totals subdivided by VAT rate

83 PLU TOTALS printout of sales totals subdivided by PLU

84 TOTALS BY HOUR printout of sales totals subdivided by hour

85 SCALE TOTALS printout of sales totals subdivided by scale

86 X GRAND TOTAL printout of sales grand totals on daily basis (1st level)

87 X GR. TOTAL RESET printout and reset of daily grand totals (1st level)

88 BEST PLUs best sold PLUs, in sale-descending order

89 BEST OPERATORS best operators, in descending sale-amount order

90 Z GRAND TOTAL printout of longer time period totals (2nd level)

91 Z GR. TOTAL RESET printout and reset of daily and longer time period totals (2nd

level)

Page 41

PAGE 32 UV119UE - DSP 500 : USER MANUAL- v. 4.0

CONNECTING TO A PC

PLU

DSP500 Scale can be connected to a personal computer through RS232c serial interface; it can

also be prepared to deliver an output signal for controlling the opening of a cash-register (where

allowed by regulations), by means of another connector.

All programming (with the exception of label formats programming) can be handled by the PC,

and be then downloaded to the scale.

In the same way, all programming entered by a scale can be uploaded from the scale into the PC.

All connectors are placed at the scale base plate. The RS232c serial connector to PC is a DB9 (9

pole) socket. The connector for drawer control is mini-jack type. Contact your dealer for correct

cables supply. Fasten the plugs securely by their screws, where needed.

Contact your dealer for getting the documentation on cables and connectors, on the functions

selectable by PC and on software supporting communication.

Page 42

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 33

PROGRAMMING

SECTION INDEX.........................................................................page 35

ACCESS BY KEY-CODE............................................................page 36

LEVELS AND GROUPS..............................................................page 37

SELECTION AND EDITING........................................................page 38

FUNCTION CODES ....................................................................page 39

INTRODUCTION TO

PROGRAMMING

0

GENERAL PROGRAMMING .....................................................page 41

(direct PLU, date and time, advertising text, operators, manual

tare, weighed tare, access key codes, keyboard functions,

departments and VAT rates)

GENERAL PROGR. GROUP

1

PLU PROGRAMMING ................................................................page 53

(PLU edit, copy, delete and test)

PLU PROGR. GROUP

2

SETTINGS...................................................................................page 61

(receipt/label, num. key time-out, auto PLU time-out, PLU preset digits, label bar-code, enable/disable random price, special

price, void, returns, discount on subtotal, keyboard buzzer,

operational mode)

SETTINGS GROUP

3

RECEIPT PROGRAMMING........................................................page 69

(shop name, print date, time, PLU description, change, print

bar-code & customisation, print double total, exit from totals)

RECEIPT PROG. GROUP

4

LABEL PROGRAMMING............................................................page 75

(label layout, layout copy and delete, fixed text, pre-set labels)

LABEL PROG. GROUP

5

NETWORKING AND INTERFACES ...........................................page 83

(label calibration, printer setting, serial channels A and B

programming, network enabling and addressing, TX communication

programming, find scales, Memory Card handling)

NETWORKING AND INTERFACES

GROUP

7

REPORTS ...................................................................................page 91

(hot-shot report, PLU report, PLU bar-code report, general

report, random prices used)

REPORTS GROUP

8 / 9

SUB-TOTAL AND TOTAL REPORTS - 1st LEVEL ...................page 95

(totals by operator, by department, by PLU, by hour, by scale,

by VAT rates, list of best PLUs and operators,and 1st level

printed reports and reset)

TOTAL REPORTS - 2nd LEVEL ................................................page 102

(2nd level printed total reports and reset)

1st-2nd-LEVEL TOTALS GROUP

Page 43

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 1

INTRODUCTION TO

PROGRAMMING

ACCESS BY KEY-CODE.......................page 2

LEVELS AND GROUPS...........................................page 3

SELECTION AND EDITING............................ page 4

FUNCTION CODES .................................................page 5

INTRODUCTION TO

PROGRAMMING

Page 44

PAGE 2 UV119UE - DSP 500 : USER MANUAL- v. 4.0

ACCESS BY KEY-

CODE

F

As key <F> is pressed, the display shows the query KEY CODE. Enter the right

access code, so that the programming possibilities of the operator can be identified.

There are 4 different codes corresponding to 4 access “levels” (as detailed on next page).

After that a code has been entered, the scale passes to the “Programming” mode.

The keyboard control keys change their functions, as shown herebelow.

C

EXIT

F

5x7 5x12 5x18 7x18 7x23

SEL

CLEA

CENT

MESS

START

MESS

PAGE CHARCHARPAGE

END

MESS INS CANC

! + “ - £ . $ , % : / ; ( ‘ ) * = > ?

<

7 8 9

Q W E R T Y U I O P

4 5 6

A S D F G H J K L

1 2 3

SPACE

Z X C V B N M

CR SHIFT

0

ENTER

Remove the rubber protective cover from the keyboard and turn the pre-printed sheet to the rear

side, where the key functions in “Programming” mode are given.

EXIT

To exit “Programming” and get the scale back to weighing (scale status), just press

<EXIT> key (which is in the same position as <ZERO> in keyboard normal operation).

Page 45

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 3

LEVELS AND GROUPS

ACCESS LEVELS

No. 4 access levels to programming are available, each of them having a specific key code, as

follows:

LEVEL 1

LEVEL 2

LEVEL 3

LEVEL 4

(operator Level)

(department foreman Level)

(Shop manager Level)

(for technical service)

pre-set key code:......................1111

pre-set key code:......................2222

pre-set key code:......................3333

Each level has different programming possibilities, more extended for higher levels.

All functions are always shown. When you try, however, to access a function which is assigned to

higher levels only, the message

NOT ENABLED shall be displayed, and the system shall not allow

it. Then press key <C> to release.

GROUPS OF PROGRAMMING FUNCTIONS

In “Programming” mode up to 10 groups of functions, numbered from 0 through 9 are available.

Each group of functions can be assigned with up to 10 functions max., for no. 100 functions as a

total numbered from 0 up to 99:

0123456789-

general programming

PLU programming

settings

receipt programming

label programming

interface programming

printer settings

reports

X totals

Z totals

When entering the “

Programming” mode, the system automatically positions to group “0”.

DESCRIPTION OF FUNCTIONS

A detailed description of the main programming functions is given in the next sections, subdivided

by function groups.

Page 46

PAGE 4 UV119UE - DSP 500 : USER MANUAL- v. 4.0

SELECTION AND EDITING

HOW TO SELECT A FUNCTION

Use the following procedure to move within the main function groups, from 0 to 9:

<> and <> Shifts from one group to another.

<ENTER>

Selects the specific group to be accessed and positions at the first function.

After the desired group has been accessed, follow the procedure indicated hereunder for selecting

the proper function you want:

<> and <> For scrolling through the available group functions.

<ENTER>

Selects the required function.

F

+ ...

Any of the no. 100 functions can be selected directly by pressing key <F> followed by

the numerical code identifying the function (of no. 2 figures).

HOW TO MOVE WITHIN A FUNCTION

Use the same procedure as detailed hereunder to move within a function:

<> and <> For scrolling through function fields.

<SEL>

To select the required option.

<ENTER>

To acknowledge the selected option and go to the next field.

EXIT

After programming a function, press <EXIT> to return to function selection.

By pressing <EXIT> sequentially, you return to the previous situations until exiting the

“Programming” mode.

HOW TO INPUT TEXT MESSAGES

<CLEAR MESS>

<CLEAR MESS> Clears a text. When pressed, the message ENTER TO

CONFIRM

is displayed, then press the key <ENTER> to delete. By

pressing any other key the deletion is aborted.

<CENT MESS>

Centres the entered text, with no confirmation.

<START MESS>

Moves the cursor to the beginning of the entered text.

<

PAGE> < PAGE>

Moves the cursor to the next/last page (20 characters page).

<

CHAR> < CHAR>

Moves the cursor to the next/last character.

<END MESS>

Moves the cursor to the end of the entered text.

<INS>

Switches from edit (EDIT) to overwrite (OVW) mode and viceversa. The active

mode is signalled at the bottom right side of the display, by the corresponding

abbreviation.

<CANC>

Deletes the character where the cursor is positioned.

<SPACE>

Inserts a blank space.

<CR>

To go to a new line.

<SHIFT>

Changes from capital letters, set as default, to lowercase letters and from the

punctuation marks put on the bottom line to the upper line. The abbreviation ins (or

scc) identifies the lowercase letter mode, and INS (or SCC) the capital letter mode.

Page 47

UV119UE - DSP 500 : USER MANUAL- v. 4.0 PAGE 5

FUNCTION CODES

Function Name Description ACCESS FROM LEVELS:

1 2 3 4

00 HOT-SHOT PLU KEYS assigning PLU codes to direct keys o o o o

01 DATE AND TIME setting date and time o o o

02 ADVERTISING TEXT advertising text to be displayed o o o

03 OPERATORS setting operator qualification o o o

04 MANUAL TARE manual tare (for pre-pack labels only) o o o

05 WEIGHED TARE pre-set tare (for pre-pack labels only) o o o

06 ACCESS KEY CODE setting access keys for level 1, 2 and 3 o o

07 KEYBOARD FUNCTIONS setting key functions (operator keys, direct keys, etc.) o o

08 VAT / DEPARTMENTS associating VAT rates to departments o o o

09 VAT RATES setting the VAT rates o o o

10 PLU EDIT setting PLU(description, unit price, label format, etc.) o o o

11 PLU COPY copy PLU with a new code o o o

12 PLU DELETE deleting PLU o o o

13 PLU TEST testing the number of stored PLU and the available PLU o o o

20 PAPER CASSETTE selecting type of print for each cassette and association labels/ default operator o o o

21 NUM. KEY TIME-OUT setting time limit for num. key entry o o o

22 PLU TIME-OUT setting time limit for PLU entry o o o

23 PLU PRE-SET DIGITS setting pre-set of digits for PLU code o o o

24 LABEL BAR-CODE setting composition of bar-code on labels and single-item receipts o o o

25 OPERATION SETTINGS enable/disable a set of scale operation options o o o

26 KEYBOARD BUZZER enable/disable keyboard buzzer o o o

27 OPERATIONAL MODE select operational mode (PLU recall/random price) o o o

30 SHOP NAME selecting shop name (and commercial text) to be printed on receipt o o o

31 RECEIPT OPTIONS enable/disable a set of optional fields to printed on the receipt o o o

32 PRINT BAR-CODE enable/disable bar-code printout on receipt o o o

33 PRINT DOUBLE TOTAL enable/disable double print of total, date end time o o o

34 EXIT FROM TOTALS selecting exit mode from totals o o o

40 LABEL LAYOUT setting user-programmable label layouts (11 up to 20) o o o

41 LAYOUT COPY copying label layout o o o

42 LAYOUT DELETE deleting label layout o o o

43 FIXED TEXTS programming fixed texts for labels o o o

50 CALIBRATION printer automatic detection of label formats o o o

51 PRINTER SETTING setting printer parameters (label feed, printing intensity) o o o

52 SERIAL CHANNEL A setting serial channel A parameters (baud rate, parity bit, etc.) o o o

53 SERIAL CHANNEL B setting serial channel B parameters (baud rate, parity bit, etc.) o o o

54 NETWORK ADDRESS addressing scale to network o o o

55 LOCAL/NETWORK selecting local/network mode o o o

56 TX PROGRAMMING programming TX communication o o o

57 FIND SCALES checking the network linked scales o o

58 MEMORY CARD PLU read/write on memory card o o o

70 HOT-SHOT REPORT printing list of direct keys and corresponding PLU codes o o o

71 PLU REPORT printing list of stored PLU o o o

72 PLU/BAR-CODE REPORT printing list of stored PLU and bar-codes o o o