Page 1

Page 2

Page 3

Copyright Information

CG Triumvirate is a trademark of Agfa Corporation.

CG Times based upon Times New Roman under license from the Monotype Corporation.

Windows is a registered trademark of the Microsoft Corporation.

All other brand and product names are trademarks, service marks, registered trademarks, or registered service marks

of their respective companies.

Limitation of Liability

In no event shall Datamax-O'Neil be liable to the purchaser for any indirect, specia l or consequential damages or lost

profits arising out of or relating to Datamax-O'Neil's products, or the performance or a breach thereof, even if DatamaxO'Neil has been advised of the possibility thereof. Datamax-O'Neil's liability, if any, to the purchaser or to the customer

of the purchaser hereunder shall in no event exceed the total amounts paid to Datamax-O'Neil hereunder by the

purchaser for a defective product.

In no event shall Datamax-O'Neil be liable to the purchaser for any damages resulting from or related to any fai lure or

delay of Datamax-O'Neil in the delivery or installation of the computer hardware, supplies or software or in the

performance of any services.

Some states do not permit the exclusion of incidental or consequential damages, and in those states the foregoing

limitations may not apply. The warranties here give you sp ecific legal rights, and you may have other legal rights which

vary from state to state.

Firmware (Software) Agreement

The enclosed Firmware (Software) resident in the Printer is owned by Licensor or its suppliers and is licensed for used

only on a single printer in the user's Trade or Business. The User agrees not to, and not to authorize or permit any

other person or party to, duplicate or copy the Firmware or the information contained in the non-volatile or

programmable memory. The firmware (Software) is protected by applicable copyright laws and Licensor retains all

rights not expressly granted. In no event will Licensor or its suppliers be liable for any damages or loss, including

direct, incidental, economic, special, or consequential damages, arising out of the use or inability to use the Firmware

(Software).

Information in this document is subject to change without notice and does not represent a commitment on the part of

Datamax-O'Neil Corporation. No part of this manual may be reproduced or transmitted in a ny form or by any means,

for any purpose other than the purchaser's personal use, without the expresse d written permissio n of Datamax-O'Neil

Corporation.

Important Safety Instructions

This printer has been carefully designed to provide many years of safe, rel iable performance. As with all types of

electrical equipment, however, there are a few basic precautions you should take to avoid hurting yourself or damaging

the equipment:

- Carefully read the provided installation and operating instructions.

- Read and follow all warning instruction labels on the printer.

- Place the printer on a flat, firm, solid surface.

- Make sure all openings on the printer remain unblocked; never insert anything into the openings or ventilation slots.

- Do not place the printer near a heat source.

- Do not use your printer near water, or spill liquid into it.

- Be certain that your power source matches a listed voltage rating for the printer (if unsure, check with your dealer or local utility

company).

- Do not place the power cord where it can be stepped on; and, if the power cord becomes damaged, immediately replace it.

- If service is required, use only qualified trained technicians to repair your printer.

All rights reserved. Copyright © 2014, Datamax-O'Neil

Part Number 88-2363-01, Revision B

Workstation Series User’s Guide

Page 4

Workstation Series User’s Guide

Page 5

Agency Compliance

This product complies to the following:

CFR 47 Part 15, Class A Digital Device

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: 1) This device may not

cause harmful interference, and 2) this device must accept any

interference received, including interference that may cause

undesired operation.

This Class A digital apparatus complies with Industry Canada ICS003 class A requirements.

UL 60950-1 Safety of Information Technology Equipment Including

Electrical Business Equipment

CAN/CSA-C22.2 No.60950-1 Safety of Information Technology

Equipment Including Electrical Business Equipment

European Council Directive 2004/108/EC “EMC Directive”

EN55022, Emissions, Class A

EN55024, Immunity

EN61000-3-2, Harmonics

EN61000-3-3, Voltage Fluctuations and Flicker

European Council Directive 206/95/EC “Low Voltage Directive”

EN60950-1

IEC 60950-1 (CB Scheme)

EN45014 General Criteria for Suppliers Declaration of Conformity

Directive 93/68/EEC CE Marking

Directives 2002/95/EC RoHS and 2011/65/EU RoHS2

Page 6

Page 7

Table of Contents

Agency Compliance .............................................................................................5

1. Safety

Warnings and Cautions ........................................................................................1

General Safety Information ...................................................................................1

2. Overview

Workstation Series Overview .... ...........................................................................3

w1110 Product Tour .....................................................................................................3

Options ..........................................................................................................................6

Standard Features ................................................................................................7

Options .................................................................................................................8

Unpacking the Printer ...........................................................................................8

Checking the Contents .........................................................................................8

Specifications .......................................................................................................9

Print Characteristics ......................................................................................................9

Dimensions and Weight ................................................................................................9

Environmental ...............................................................................................................9

Print Driver Requirements ............................................................................................9

Configuration Utility ...................................................................................................10

3. Connections and Setup

Connections ........................................................................................................11

Power ..........................................................................................................................11

Data .............................................................................................................................11

Media Loading ....................................................................................................12

Media Loading - Peel and Present .....................................................................14

Control Panel ......................................................................................................17

LEDs ...........................................................................................................................17

LED Indicators ............................................................................................................17

Buttons ........................................................................................................................18

Feed .............................................................................................................................18

Test Labels ..................................................................................................................18

Calibration ..........................................................................................................18

Paper Calibration ........................................................................................................18

Sensor Calibration .......................................................................................................19

Printer Settings ...................................................................................................19

Print Driver Installation .......................................................................................20

Overview .....................................................................................................................20

Workstation Series User’s Guide

Page 8

Table of Contents

Important Notes: .........................................................................................................21

4. Operation

Printer Modes .....................................................................................................53

Tear Mode ...................................................................................................................53

Present Sensor Mode ..................................................................................................53

Pause Mode .................................................................................................................53

Reporting ............................................................................................................54

System Report .............................................................................................................54

Settings Report ............................................................................................................55

Webpages ..........................................................................................................56

5. Cleaning and Maintenance

Overview .............................................................................................................57

Intervals ..............................................................................................................57

Supplies ..............................................................................................................57

Cleaning the Top-of-Form Sensor ......................................................................57

Cleaning the Printhead .......................................................................................57

6. Troubleshooting

LED Indicators ....................................................................................................59

Errors ..................................................................................................................59

Warnings ............................................................................................................60

Troubleshooting ..................................................................................................60

Troubleshooting Print Quality .............................................................................61

Tools ...........................................................................................................................61

Preliminary Instructions ..............................................................................................61

7. Appendix A

Symbol Sets .......................................................................................................63

Fonts ...................................................................................................................64

Barcodes ............................................................................................................66

Workstation Series User’s Guide

Page 9

1 Safety

Warnings and Cautions

The following Warnings and Cautions are used throughout this manual:

Warning: W a rnings alert you to possible safety risks.

Caution: Cautions alert you to the potential for equipment damage.

General Safety Information

Caution: This product is intended for indoor use only.

All service procedures should be done by properly trained and qualified service

personnel.

Any on-site assembly required during the installation process must be performed by

properly trained and qualified service personnel.

The product must be connected to a properly grounded and appropriately rated AC

receptacle using the supplied cord set.

Caution: This product contains sensitive electronic components that could be damaged

if exposed to excessive force.

Caution: Use only factory-approved consumables and cleaning kits. Use of any non-

approved supplies could damage the product and void the warranty.

Caution: The printer must be installed on a stable, level surface.

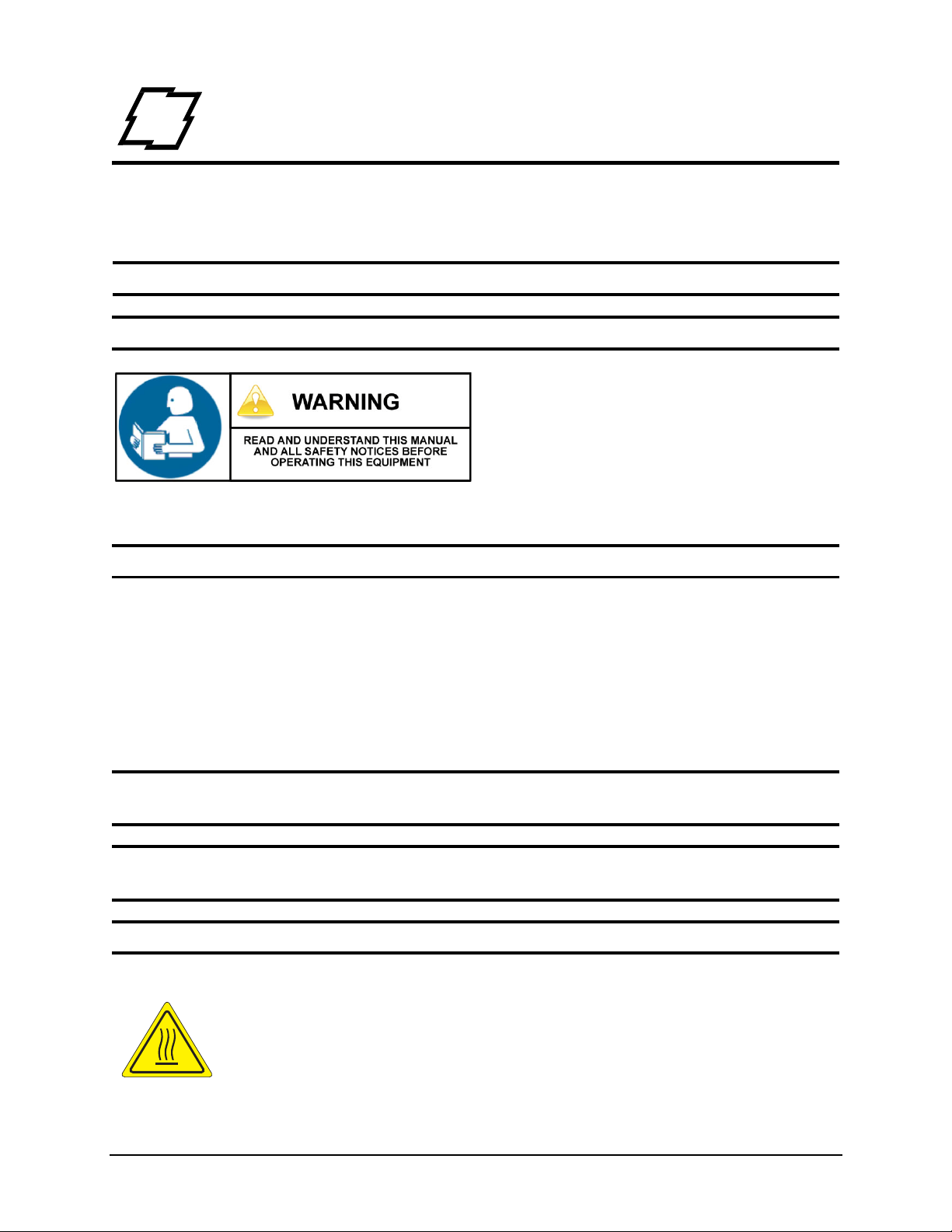

Figure: 1 - 1 Caution - Hot

1 Workstation Series User’s Guide

Page 10

1 | Safety

The printhead heats during printing. Do not touch.

Caution: Serious damage and bodily injury can result if this printer is exposed to liquids

or foreign objects.

Workstation Series User’s Guide 2

Page 11

2Overview

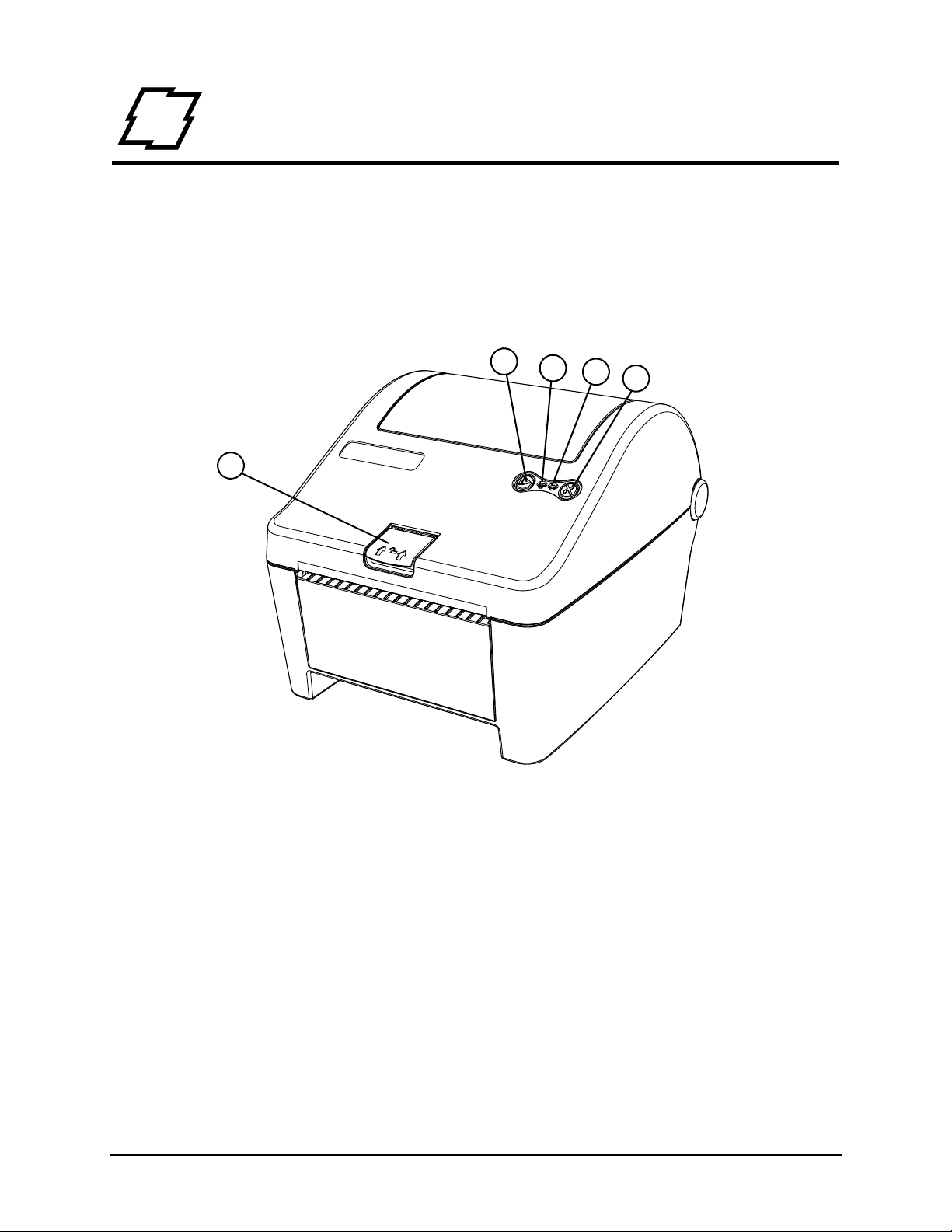

1

2

3

4

5

1. Cover Latch Release

2. Stop/Resume

3. Power LED (Green)

4. Error LED (Red)

5. Feed/Cancel

Workst ation Series Overview

w1110 Product Tour

The following illustrations show some of the features and available options for the printer.

Figure: 2 - 1 Front View - w1110

3 Workstation Series User’s Guide

Page 12

2 | Overview

1. Power Switch

2. DC Power Inlet

3. Reset Button

4. USB 2.0 Port

5. Ethernet/Network Port

1

2

3

4

5

Figure: 2 - 2 Rear View - w1110

Workstation Series User’s Guide 4

Page 13

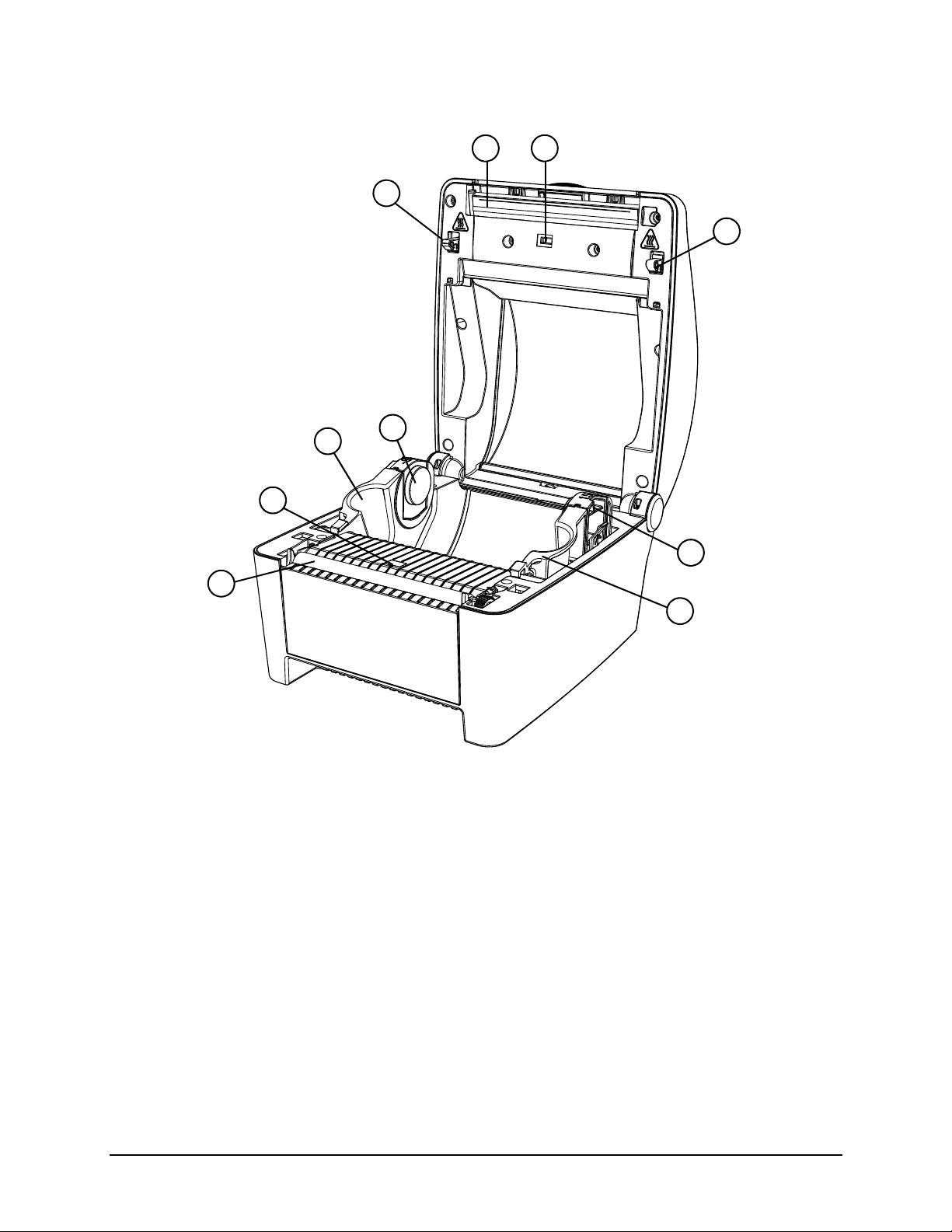

Figure: 2 - 3 Media Area

.

1. Printhead

2. Upper Top-of-Form Sensor

3. Cover Latch

4. Left Media Support Bracket

5. Left Core Adapter

6. Right Core Adapter

7. Right Media Support Bracket

8. Lower Top-of-Form Sensor

9. Platen Roller

1

2

3

4

5

6

7

8

9

3

Overview | 2

5 Workstation Series User’s Guide

Page 14

2 | Overview

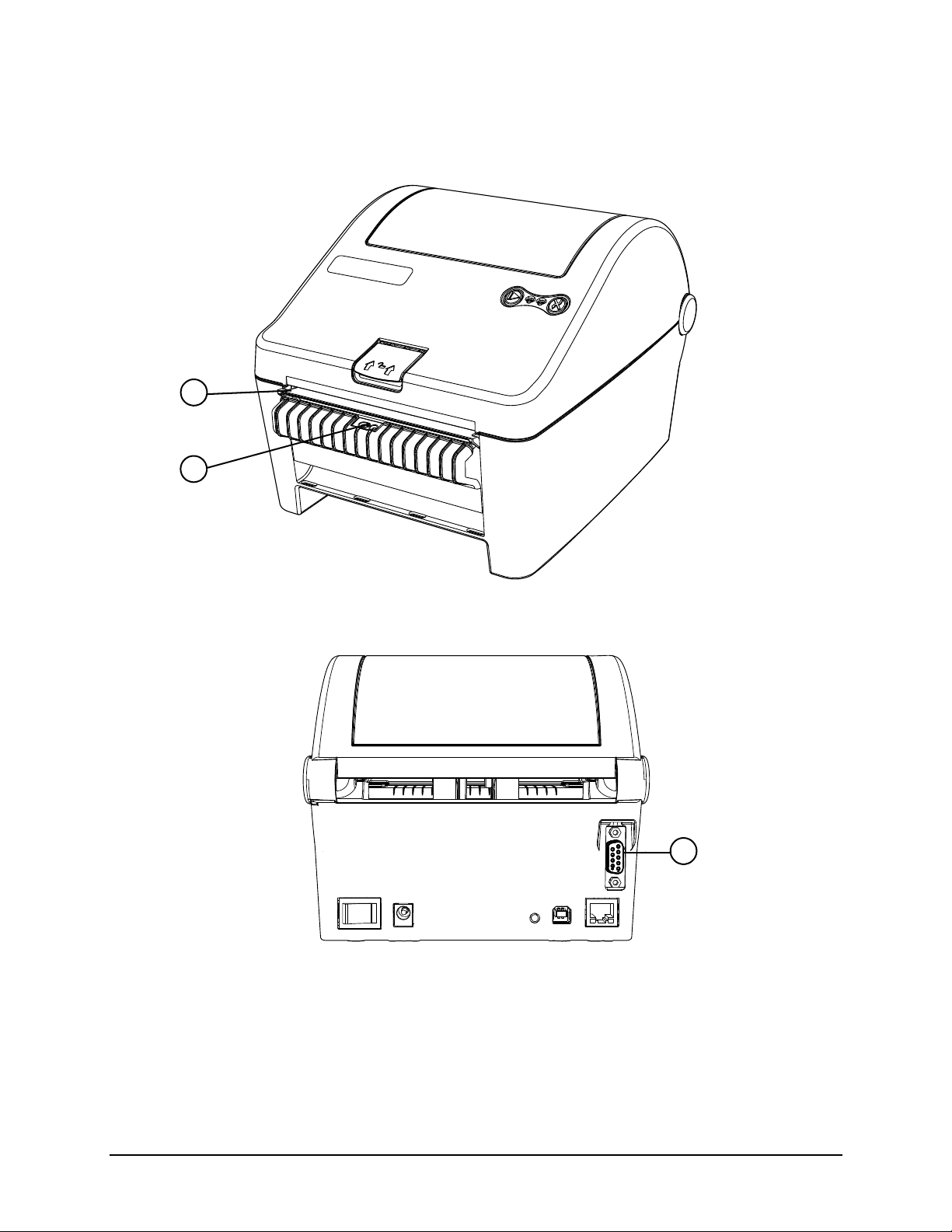

1

2

1. Peel Bar

2. Present Sensor

1

1. Serial Interface

Options

Figure: 2 - 4 Peel and Present

Figure: 2 - 5 Serial Interface

Workstation Series User’s Guide 6

Page 15

Standard Features

The thermal printer has the following standard features:

Table 1: Standard Features

Features Descriptions

Max Print Speed 4 IPS / 102 mmps

Resolution 300 dpi / 11.8 dpmm

Memory 32MB Flash (4MB User Space) / 32MB DDR2 RAM

Printer Type Direct Thermal

Media Supply • Roll-fed

• Die-cut

• Continuous Labels: (5” [127mm] roll max diameter on 1.0” and

1.5” [25.4mm and 38mm] core)

Overview | 2

Double-sided Top-of-Form

Sensor

Tear Bar Bar for tearing off gapped or continuous media

Media Back Feed Capable of backing up; max 0.5”

Control Panel Two buttons

Reset Button Inset on the rear of the unit

LEDs Two LEDs: Green - Power On, Red - Error

Power Switch Positioned on the rear of the un it

Chassis / Media Cover Plastic construction with a clear window

Bar Codes See Appendix A

Fonts See Appendix A

Downloadable Font Types • True-Type Scalable

Graphics Full support of PCL5e and GL/2 graphics capability.

Fixed position for center-biased stock:

• Label Gap

• Reflective black mark on the bottom or the top of the form

• PCL Bitmap (300 dpi)

(Support for various host-based file fomats [PCX, BMP] are not part of

the PCL5e standard but are supported and converted by standard

applications)

Industry Standard Printer

Language

Interfaces • USB 2.0 Device

HP PJL, HP PCL5e, HP GL/2 and HP XL, printer languages with autolanguage select and extensions for barcode capabilities. Bi-directional

communications capability is also supported.

• LAN 10/100

7 Workstation Series User’s Guide

Page 16

2 | Overview

Features Descriptions

Printer Driver Supported

Operating Systems

Operating Temperature 32°F (0°C) to 104°F (40°C)

• Windows XP

• Windows Vista

• Windows 7

• Windows 8

Options

The following options are available:

• Peel and Present

• Serial Interface

• Non-US Power Cords

Unpacking the Printer

Upon receiving the printer, verify the box is undamaged. Carefully unpack the printer

from its packaging and visually check for any physical damage that may have occurred

during shipment.

Checking the Contents

The contents may vary depending on your configuration. It is recommended that all

packaging materials be saved if the printer is to be shipped again. If the packaging

material is discarded, new packaging material may be available from your reseller.

• Printer

• Power Cord

• AC Adapter

• Driver CD

• Product documentation

• Accessories/Options

Additional items that may be required include the following:

• All Applicable Communication Cables

•Media

Workstation Series User’s Guide 8

Page 17

Specifications

Print Characteristics

Table 2: Print Characteristics

Variable Specifications

Print Resolution 300 dpi (11.8 dpmm)

Max Print Width 4.16” (105.7 mm)

Max Print Speed 4 ips (102 mmps)

Max Feed Speed 4 ips (102 mmps)

Max Back-up Speed 4 ips (102 mmps)

Media Width Range* 0.75” - 4.33” (19 mm - 110 mm)

Media Thickness Range* 0.003” - 0.008” (0.076 mm - 0.20 mm)

Print Length Range .25” - 30” (6.35 mm - 762 mm)

*Media wound out.

Overview | 2

Dimensions and Weight

Table 3: Dimensions and Specifications

Height Width Depth Weight

6.02 in (15.3 cm) 6.75 in (17.1 cm) 8.32 in (21.1 cm) 3.1 lbs. (1.4 kg)

Environmental

Table 4: Temperatures

Temperature Humidity

Operating 32°F to 104°F (0°C to 40°C) <=20% to 80%

Storage -4°F to 140°F (-20°C to 60°C) <=35%

Print Driver Requirements

Table 5: Print Driver Minimum System Requirements

Minimum System Requirements

Processor / Speed 500 MHz processor

RAM 512MB

Hard Drive Space 6MB

9 Workstation Series User’s Guide

Page 18

2 | Overview

Minimum System Requirements

Supported Operating Systems Windows XP - x86 & x64

Windows Vista - x86 & x64

Windows 7 - x86 & x64

Windows 8

Configuration Utility

Table 6: Configuration Utility Minimum System Requirements

Minimum System Requirements

Processor / Speed 500 MHz processor

Supported Operating Systems Windows XP - x86 & x64

Windows 7 - x86 & x64

Windows 8

RAM 256MB

Hard Drive Space 15MB

Minimum Screen Resolution 800 x 600

.NET Framework 3.5 SP1

Workstation Series User’s Guide 10

Page 19

3 Connections and Setup

Connections

Power

To connect the printer to a viable power source, please follow the steps below.

Caution: Ensure the printer power switch is off before connecting the AC power and

data/network connectivity cables to the printer.

Caution: Adhere to all environmental requirements when installing and using the printer.

Use of the product in an unsuitable environment may affect print quality and the

durability of the printer and may void the manufacturer’s warranty.

1. Place the printer on a suitable level surface capable of securely supporting 8lbs.

2. Connect the AC power cord to the power supply brick

3. Connect the AC power cord from the power supply brick to AC utility power.

4. Connect the DC power cord from the power supply brick to the printer power jack.

5. Using the power switch, turn on the printer.

During power-up, the LEDs indicate the status of the printer.

Table 1: Power-Up - LED Status

Action Green LED Red LED

Printer begins to power-up Solid Solid

Printer indicates powering up Double Blink Double Blink

Printer is online Solid Off or slow blink which

indicates cover open or an

uncalibrated condition.

Data

Printer data connectivity can be accomplished by the following standard or optional

interfaces:

•USB

• Ethernet/Network

• Serial (Optional)

Connect the appropriate interface cables for your network configuration.

11 Workstation Series User’s Guide

Page 20

3 | Connections and Setup

Locking Tabs

1.5” Media

Core Adapter

Media Loading

The w1110 printer supports either a 1” core or a 1.5” core paper roll. The core adapters

can be removed, rotated and reinstalled depending on the desired core size.

Please consult your reseller to obtain the appropriate media.

1. Lift the cover latch release and open the cover.

2. Verify the core size for the paper roll being used and select the appropriate core

adapter side.

a. To change the core adapter size, gently press the locking tabs outward and

remove the media core adapters from the media support brackets.

Note: The media core sizes are printed on the top of the core adapters.

Figure: 3 - 1 Media Core Adapters

b. Reinstall the core adapters with the corresponding number for the appropriate

core size facing upwards.

Workstation Series User’s Guide 12

Page 21

Connections and Setup | 3

Note: Ensure the core adapters have snapped into place.

3. Slide the media support brackets outward and place the paper roll between them.

Note: The paper must be wound out.

Figure: 3 - 2 Paper Roll Installation

4. Release the media support brackets ensuring the core is secured by the core

adapters.

13 Workstation Series User’s Guide

Page 22

3 | Connections and Setup

Left Guide

Right Guide

5. Route the paper under the support bracket guides.

Figure: 3 - 3 Support Bracket Guides

6. Close and latch the printer cover.

7. Feed the paper to find top-of-form.

Note: When installing new media, perform a paper calibration to ensure the printer finds

the top-of-form.

Media Loading - Peel and Present

The peel and present option allows for the media labels to peel at the peel bar while the

label backing routes away from the labels.

Workstation Series User’s Guide 14

Page 23

1. Open the peel and present sub-assembly .

a. Rotate the peel and present sub-assembly forward.

Figure: 3 - 4 Peel and Present Assembly

Connections and Setup | 3

2. Load the media into the support bracket and the core adapters.

3. Remove the enough labels to expose at least 6” of backing. Insert the backing

behind the roller of peel and present sub-assembly until it appears underneath.

15 Workstation Series User’s Guide

Page 24

3 | Connections and Setup

Label Backing

Note: Be sure there are no labels attached to the backing that is routed behind the peel

and present sub-assembly.

Figure: 3 - 5 Media Backing

4. Pull the label backing tight to ensure proper tension of the label backing.

5. Hold the backing tight and close the peel and present sensor assembly.

6. Close and latch the printer cover.

7. Feed the paper to find top-of-form.

Note: Peel and present mode is enabled through the configuration utility. If both peel

and present mode and prompt mode are enabled at the same time, only prompt mode

will be active.

Workstation Series User’s Guide 16

Page 25

Connections and Setup | 3

Control Panel

The control panel consists of the two (2) main buttons on the printer cover, two (2) LEDs

on the printer cover and the reset button on the back of the printer. All three are used to

perform certain printer functions.

LEDs

The green and red LEDs may blink during the operation of the printer. There are

functions of the printer where the blinking lights can be used to interpret the printer’s

state.

A slow blink is considered a repeating blink that lights for 0.8 seconds and then turns

off for 0.8 seconds. This sequence will repeat until the task has been completed.

A fast blink is considered a repeating blink that lights for 0.1 seconds and then turns

off for 0.1 seconds. This sequence will repeat until the task has been completed.

A double blink is considered two fast blinks with a pause in between.

More information is presented in the troubleshooting section.

LED Indicators

The LEDs are used to indicate the printer’s state.

Table 2: LED Chart

Light Printer State

Green Fast Blink - Waiting for an operator action

Slow Blink - Printer is processing data

Solid Light - Printer ready state

Fast Blink with Pause - Configuration Utility Control Mode

Red Fast Blink - Hardware Error

Slow Blink - Warning

Solid Light - Fault

Fast Blink with Pause - Maintenance Timer Expired

Green/Red

Combination

Fast Alternating Blink - Recovery Mode

Slow Alternating Blink - Upgrade in Progress

Slow Synchronized Blink - Cooling Down

Synchronized Double Blink - Power-up in Progress

17 Workstation Series User’s Guide

Page 26

3 | Connections and Setup

Buttons

The operation of the buttons consists of long or short presses depending on the

operation being performed. A button pressed for three (3) or more seconds is considered

a long press. A button pressed for less than three (3) seconds is considered a short

press.

The Stop/Resume button is positioned on the left side of the printer’s control panel and

the Feed/Cancel button is positioned on the right side. Together with the reset button on

the back of the printer, these buttons enable certain printer functions.

Note: Refer to the Operation section of this guide for more information about the

operational functionality of the buttons.

Feed

To set the top-of-form, select the Feed/Cancel (right) button once the media has been

installed.

Test Labels

To print a test label from the printer , select the Stop/Resume button and the Feed/Cancel

button together with a short press. A quality label will print. This function can also be

performed with the configuration utility.

Calibration

The printer uses upper and lower top-of-form sensors to determine top-of-form. Both

sensors are transmissive and reflective to ensure top-of-form for qualified media. There

are two (2) types of calibrations:

• Paper Calibration

• Sensor Calibration

Paper Calibration

The printer should be calibrated after a new type of media has been installed or to verify

a paper out warning. When loading the same type of media, calibration should not be

necessary unless the printer does not find top-of-form.

1. Install the paper into the printer .

2. Close and latch the printer cover.

3. Select the Stop/Resume button and the Feed/Cancel button together with long

presses until the paper begins to move.

Note: The media will advance through the printer verifying the top-of-form.

Workstation Series User’s Guide 18

Page 27

Connections and Setup | 3

Sensor Calibration

Sensor calibration is set during the manufacturing process and should only need to be

performed after upgrading the printer’s software. This is indicated by the red LED

blinking slowly after power-up.

1. Remove the paper from the printer.

2. Close and latch the printer cover.

3. Press the Reset, Stop/Resume, and the Feed/Cancel buttons together with one

short press.

Note: The green LED will have a fast blink sequence.

Printer Settings

All printer settings can be adjusted in the configuration utility or the printer’s internal web

pages. Refer to the Help section in the utility for more information.

19 Workstation Series User’s Guide

Page 28

3 | Connections and Setup

Print Driver Installation

Overview

This installation should be executed only on a computer where a pw Series printer driver

is not currently installed or one that the driver have been completely removed.

The Windows driver is located on the Accessories CD-ROM included with the printer . For

the latest version please visit our web site at http://www.datamax-oneil.com

Installing the Windows Driver:

1. Place the Accessories CD-ROM included with the printer into the computers CDROM drive. Once the CD-ROM starts select your printer model then “Install Driver”

from the menu. Follow the instructions on the screen to install.

If the driver was downloaded from our website, simply double click the downloaded

“.exe” file to launch the installation.

2. Check the “Remove printer drivers” radio button then click

‘Next’. If this option is not available skip to Step 6.

3. On the next screen check the “Remove printers” radio

button then click ‘Next’.

4. Browse the list of installed printers, if any “Workstation” or

“Performance” printers are listed check the corresponding

check boxes and click ‘Next’ to remove the installed

printers.

5. The next screen will show a summary of items to be

removed, click ‘Finish’ to complete the removal process.

Once complete return to the main screen to install the new

driver.

Workstation Series User’s Guide 20

Page 29

Connections and Setup | 3

6. Check the “Install printer drivers” radio button then click

‘Next’ and follow the on-screen instructions to install the

driver.

7. When prompted, select your printer from the list, (i.e.

Datamax-O’Neil w1110). Continue to follow the on-screen

instructions to install the driver.

Important Notes:

The Windows driver functions the same as any other Windows printer. While built-in help

files provide information on all settings, there are some important setting parameters that

should be observed for trouble free printing:

Page Setup Tab: Stock

It is important that the Stock setting

matches the size of the label you are

using. If you cannot find a match for your

label click New and enter the dimensions

of your label.

Options Tab: Print Speed & Printhead

Temperature

These two settings will have the greatest

effect on print quality. Some label stocks

will require more heat and slower print

speeds to generate a quality image.

The Windows application software used to create the label format will likely have a "Page

Setup" screen. This will also need to match the size of the label you are using.

21 Workstation Series User’s Guide

Page 30

3 | Connections and Setup

Workstation Series User’s Guide 22

Page 31

4 Operation

Printer Modes

The w1110 features three (3) modes:

• Tear Mode

• Present Sensor Mode

• Pause Mode

The modes are set in the printer’s configuration utility.

Tear Mode

Tear mode is used for most common print jobs and is the default mode for the printer.

This mode is always used when Present Sensor Mode and Prompt Mode are not

needed.

To pause a batch print job, select the Stop/Resume (left) button with a short press and

the printer will stop printing at the next label. The printer will enter the operator action

state indicated by a fast blink of the green LED.

To continue the print job, select the Stop/Resume button.

After pausing, the print job can be canceled by selecting the Feed/Cancel (right) button

with a long press. The green LED will illuminate with a solid light indicating the printer

ready state.

Present Sensor Mode

Present Sensor Mode controls the on-demand dispensing of labels. Once the mode is

enabled in the configuration utility and a print job has been sent to the printer, the paper

will stop printing after each label until the printed label has been removed. The printer will

enter the operator action state indicated by a fast blink of the green LED. Once the label

has been removed, the next label will be printed until the batch print job has been

completed.

The print job can be canceled by selecting the Feed/Cancel (right) button with a long

press. The green LED will illuminate with a solid light indicating the printer ready state.

Pause Mode

Pause mode allows the user to prompt the printer for the next label. Once a label has

been printed, the printer will pause until the user selects the Stop/Resume (left) button

directing the printer to print the next label.

The printer will enter the operator action state indicated by a fast blink of the green LED.

53 Workstation Series User’s Guide

Page 32

4 | Operation

To continue the print job, select the Stop/Resume button.

The print job can be canceled by selecting the Feed/Cancel (right) button with a long

press. The green LED will illuminate with a solid light indicating the printer ready state.

Reporting

The printer has a reporting feature that allows the user to print two different reports:

• System Report

• Settings Report

System Report

The system report contains information about the printer including the following:

System Report

• Printer Model

• Firmware Version

• FPGA Version

•Boot Version

•RAM Size

• Flash Size

• Printer Key

• Absolute Counter

• Setup File

• Paper

• Ethernet IP

• Ethernet MAC

• Ethernet DHCP

• Hostname

• Serial Port Settings

• Head Temperature

• Motor Temperature

• Head Voltage

• Session Label Count

• Printer Mode

Workstation Series User’s Guide 54

Page 33

Operation | 4

To print the System Report, select the Reset button and the Feed/Cancel (right) button

with a short press.

Settings Report

The Settings Report provides information about the print settings including:

Media Settings

• Paper Sensor Type

•Heat

• Heat Balance

Printer Settings

• Present Sensor

• Print Speed

• Feed Speed

• Reverse Speed

• Present Distance

• Reprint on Error

• Present Timeout

Page Defaults Settings

• Print Length

•Print Width

• Vertical Offset

• Horizontal Of fset

•Orientation

• Raster Mode

• Font Name

• Point Size

• Pitch Size

• Symbol Set

• Print Truncation

• Print on Gap/Mark

Auto Settings

55 Workstation Series User’s Guide

Page 34

4 | Operation

• Auto Option Detect

• Auto Present Distance

• Auto Speed Adjust

Adjustment Settings

• Present Distance Adjust

• Vertical Adjust

• Horizontal Adjust

• Darkness

• Contrast

Calibration Settings

• Paper Threshold

• Gap/Mark Threshold

• TOF Gain

To print the Settings Report, select the reset button and the Stop/Resume (left) button

together with a short press.

Webpages

Webpages provide a printer configuration interface for the user. Users can view the

printer status, set printer parameters, print test labels and perform simple actions like

printer calibration and setting defaults.

To access the printer Webpages from a computer where the printer has been installed,

type the printer’s IP address into the Web browser URL field.

Note: The printer must be connected to the Ethernet.

Note: The following Web browsers are supported:

• Internet Explorer (version 8 and higher)

• Firefox (version 13 and higher)

• Google Chrome (version 23 and higher)

Note: The printer’s IP address can be obtained by printing a System Report.

Workstation Series User’s Guide 56

Page 35

5 Cleaning and Maintenance

Overview

To maintain good print quality and increase printhead life, proper cleaning should be

routinely performed using factory-approved cleaning supplies.

Caution: A contaminated printhead can cause premature printhead failure.

Caution: Failure to clean the printhead as detailed in this manual could void the

printhead manufacturer’s warranty.

Intervals

The printhead should be cleaned whenever a roll of labels is replaced or every 650

inches printed.

Supplies

Caution: Cleaning should only be performed using factory-approved and authorized

cleaning supplies. Any use of non-authorized cleaning supplies can void the

printhead and platen roller warranties.

• Cleaning Pens

• Cleaning Cards/Film

• Can of Compressed Air

• Clean, lint-free cloth

• Isopropyl Alcohol

Cleaning the Top-of-Form Sensor

The Top of Form sensor should be cleaned whenever necessary.

1. Remove the media.

2. With a lint-free cloth, wipe both sensor covers to remove dust and debris.

3. Repeat as necessary.

Cleaning the Printhead

For optimum performance, the printhead should be routinely cleaned with factoryapproved cleaning supplies. When using the cleaning pen, follow the instructions located

on the packaging.

57 Workstation Series User’s Guide

Page 36

5 | Cleaning and Maintenance

Workstation Series User’s Guide 58

Page 37

6 Troubleshooting

LED Indicators

The printer LEDs are also used to indicate errors and warnings. Refer to the following

chart:

Table 1: LED Indicators

Action Green LED Red LED Notes

Warning Not affected by

Warning

Error Off Solid

Control Mode Short Blink with a

Pause

Data Transfer

Configuration

Hardware Failure Off Fast Blink

Cooling Slow Blink Slow Blink LEDs blink in sync

Maintenance Needed Not affected by

Label Presented Fast Blink Not affected

Solid Solid Short duration

Maintenance Needed

Slow Blink

Not affected

by Control

Mode

Short Blink

with a Pause

by Label

Presented

Only applies when printer is in

configurator session

Printer is not operational during this

time

0.1 seconds on and 2.3 seconds off

0.8 seconds on and 3.2 seconds off

Waiting for the operator to remove the

label

Errors

The following errors may occur:

Errors Description

SYSTEM ERROR Software or label format error. Communication rate too slow.

OUT OF PAPER Out of paper

PRINTHEAD HOT Printhead is too hot

FPGA HARDWARE Analog to digital converter hardware fault

NV RAM HARDWARE Non-volatile memory hardware fault

PAPER SENSOR BLOCKED Top-of-form sensor hardware fault or sensor calibration

performed with paper installed

PAPER CALIBRATION Could not calibrate media

59 Workstation Series User’s Guide

Page 38

6 | Troubleshooting

Errors Description

PRESENT SENSOR HARDWARE Present sensor hardware fault

HEAD UP Printing or feeding with the cover open

Note: To clear errors, open the printer cover fully and then close and latch it.

Warnings

Warnings Description

MAINTENANCE REMINDER Maintenance timer has expired

POWER SUPPL Y HARDWARE Printhead voltage above maximum specifications

POWER SUPPLY LOW Printhead voltage below minimum specifications

PRINTER COOLING The printer is cooling

PAPER CALIBRATION MARGINAL Paper sensor calibration marginal

PERFORM CALIBRATE SENSORS There is a need to run Sensor Calibration

COVER OPEN The printer cover is open and should be latched

PRESENT SENSOR NOT

INSTALLED

The present sensor is enabled but not installed

Troubleshooting

The following chart provides basic troubleshooting steps for diagnosing problems with

the printer. If the symptoms remain after troubleshooting, contact your technical support

representative.

Symptom Causes Solutions

System Error Incorrect label format or

communication is too slow.

Out of Paper The printer may be out of media. Install a new media roll.

The media is too transparent to be

detected.

FPGA Hardware The main controller board may be

faulty.

1. Connect to a different input port.

2. Analyze the label format.

3. Try a different label design

method.

1. Perform “Calibrate Sensors.”

2. Check the “Auto Load Sensor”

reading in the “Extended St atus”

utility.

Ensure the latest software update has

been performed.

NV RAM Hardware The main controller board may be

faulty.

Workstation Series User’s Guide 60

Contact your technical support

representative.

Page 39

Troubleshooting | 6

Symptom Causes Solutions

Paper Sensor Blocked Adhesive, dirt or remnants of a label

may be covering the sensor.

The main controller board may be

faulty.

The Top-of-Form sensor failed the

“Calibrate Sensors” calibration due to a

faulty sensor.

Paper Calibration The characteristics of the media may

not be sensed by the printer. (Ex. gap,

notch, mark)

No Top-of-Form

Found

The gap or mark was not found. 1. Ensure the Top-of-Form type has

The label image size exceeded the

maximum of 99 inches.

1. Clean the debris from the sensor.

2. Perform “Calibrate Sensors”

calibration.

Contact your technical support

representative.

Contact your technical support

representative.

1. Set the paper mode to continuous.

2. Install different media.

been set correctly.

2. Install different media.

1. Check the print mechanism for a

paper jam.

2. Calibrate the printer for the

media being used.

There may be dirt or debris obstructing

the Top-of-Form sensor.

Present Sensor

Hardware

There may be a poor connection. Contact your technical support

The Present Sensor module may be

faulty.

Troubleshooting Print Quality

Tools

• Datamax-O’Neil approved media

• Magnifying lens

• Barcode verifier and grading system

• Printhead cleaning card

• Printhead cleaning pen

1. Clean the debris from the sensors.

2. Perform “Calibrate Sensors”

calibration.

representative.

Contact your technical support

representative.

Preliminary Instructions

1. Ensure the latest software has been loaded.

61 Workstation Series User’s Guide

Page 40

6 | Troubleshooting

2. Load the media according to the instructions in the Setup section.

Note: Verify that the paper is properly exiting the printer.

3. Print a Quality Label from the configuration utility or the printer control panel

buttons.

4. Examine the print quality.

Note: Some imperfections can be caused by a contaminated printhead. Clean the

printhead and reprint the label.

Symptom Possible Solutions

No Print or Poor Print Quality Verify the proper media is being used.

Light Print on One Side Contact your technical support representative.

Print Quality Defect Clean the printhead and platen roller with factory-approved

cleaning supplies.

If there are any missing dots, the printhead should be replaced

by a certified technician.

Print Quality gets worse over time Printhead is at the end of life and should be replaced by a

certified technician.

Diminished print quality on the Quality

Label

Image size is out of the print area (off

the side or top or truncated from the

next label)

Incomplete horizontal lines requires an increase in the

sharpness setting.

For higher-grade barcodes, lighten the print by reducing the

darkness setting.

For white specks inside dark boxes, increase the darkness

setting and clean the printhead and platen roller.

If the small font is not readable, increase the darkness setting.

When dithering increments are not equal, adjust the darkn e ss

setting.

If graphics are not displayed properly, adjust the sharpness

setting.

Turn off print truncation.

Ensure the image width is the same as the print width.

Workstation Series User’s Guide 62

Page 41

7 Appendix A

Symbol Sets

The following Symbol Sets are available:

Table 1: Symbol Sets

Number Symbol Sets

0PC-8

1Roman-8

2Roman-9

3ISO-L1

4ISO-L2

5ISO-L4

6ISO-L5

7ISO-L6

8ISO-L9

9 PC-775

10 PS MATH

11 MATH-8

12 PI FONT

13 MS PUBL

14 PC-8 DN

15 PC-850

16 PC-852

17 PC-858

18 PC-8 TK

19 PC-1004

20 WIN L1

21 WIN L2

22 WIN L5

23 WINBALT

24 DESKTOP

25 PS TEXT

26 LEGAL

27 ISO-4

63 Workstation Series User’s Guide

Page 42

7 | Appendix A

Number Symbol Sets

28 ISO-6

29 ISO-11

30 ISO-15

31 ISO-17

32 ISO-21

33 ISO-60

34 ISO-69

35 WIN 3.0

36 MC TEXT

37 UCS-2

38 RomanExt

39 Wingdings

40 ZapDingBats

41 Symbol

Fonts

The following Fonts are supported:

Table 2: Fonts

Font Escape Sequence

CG Times <ESC>(<symset><ESC>(s1p<ptsize>v0s0b4101T

CG Times Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s0b4101T

CG Times Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s3b4101T

CG Times Bold Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s3b4101T

Univers Medium <ESC>(<symset><ESC>(s1p<ptsize>v0s0b4148T

Univers Medium Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s0b4148T

Univers Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s3b4148T

Univers Bold Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s3b4148T

Univers Condensed Medium <ESC>(<symset><ESC>(s1p<ptsize>v4s0b4148T

Univers Condensed Medium Italic <ESC>(<symset><ESC>(s1p<ptsize>v5s0b4148T

Univers Condensed Bold <ESC>(<symset><ESC>(s1p<ptsize>v4s3b4148T

Univers Condensed Bold Italic <ESC>(<symset><ESC>(s1p<ptsize>v5s3b4148T

Antique Olive <ESC>(<symset><ESC>(s1p<ptsize>v0s0b4168T

Antique Olive Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s0b4168T

Antique Olive Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s3b4168T

Workstation Series User’s Guide 64

Page 43

Font Escape Sequence

CG Omega <ESC>(<symset><ESC>(s1p<ptsize>v0s0b4113T

CG Omega Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s0b4113T

CG Omega Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s3b4113T

CG Omega Bold Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s3b4113T

Garamond Antiqua <ESC>(<symset><ESC>(s1p<ptsize>v0s0b4197T

Garamond Kursiv <ESC>(<symset><ESC>(s1p<ptsize>v1s0b4197T

Garamond Halbfett <ESC>(<symset><ESC>(s1p<ptsize>v0s3b4197T

Garamond Kursiv Halbfett <ESC>(<symset><ESC>(s1p<ptsize>v1s3b4197T

Courier <ESC>(<symset><ESC>(s0p<pitch>h0s0b4099T

Courier Italic <ESC>(<symset><ESC>(s0p<pitch>h1s0b4099T

Courier Bold <ESC>(<symset><ESC>(s0p<pitch>h0s3b4099T

Courier Bold Italic <ESC>(<symset><ESC>(s0p<pitch>h1s3b4099T

Letter Gothic <ESC>(<symset><ESC>(s0p<pitch>h0s0b4102T

Appendix A | 7

Letter Gothic Bold <ESC>(<symse t><ESC>(s0p<pitch>h0s3b4102T

Letter Gothic Italic <ESC>(<symset><ESC>(s0p<pitch>h1s0b4102T

Albertus Medium <ESC>(<symse t>< ESC>( s1 p< ptsize>v0 s1b 436 2 T

Albertus Extra Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s4b4362T

Clarendon Condensed Bold <ESC>(<symset><ESC>(s1p<ptsize>v4s3b4140T

Coronet <ESC>(<symset><ESC>(s1p<ptsize>v1s0b4116T

Marigold <ESC>(<symset><ESC>(s1p<ptsize>v0s0b4297T

Arial <ESC>(<symset><ESC>(s1p<ptsize>v0s0b16602T

Arial Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s0b16602T

Arial Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s3b16602T

Arial Bold Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s3b16602T

Times New Roman <ESC>(<symset><ESC>(s1p<ptsize>v0s0b16901T

Times New Roman Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s0b16901T

Times New Roman Bold <ESC>(<s ymset>< ESC>(s1p< ptsize>v0s3b16901T

Times New Roman Bold Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s3b16901T

Symbol <ESC>(19M<ESC>(s1p<ptsize>v0s0b16686T

Wingdings <ESC>(579L<ESC>(s1p<ptsize>v0s0b31402T

OCR-A Fixed <ESC>(<symset><ESC>(s0p<pitch> h0 s0 b2 358 4 T

OCR-A Mono <ESC> (<s ym set><ESC>(s1p<pitch>h0s0b23584T

OCR-B Fixed <ESC>(<symset><ESC>(s0p<pitch> h0 s0 b2 359 0 T

OCR-B Mono <ESC> (<s ym set><ESC>(s1p<pitch>h0s0b23590T

65 Workstation Series User’s Guide

Page 44

7 | Appendix A

Font Escape Sequence

Vera Regular Mono <ESC>(<symset><ESC>(s0p<pitch>h0s0b23410T

Vera Italic <ESC>(<symset><ESC>(s0p<pitch> h1s0 b2 3 410 T

Vera Bold <ESC>(<symset><ESC>(s0p<pitch>h0s3b23410T

Vera Bold Italic <ESC>(<symset><ESC>(s0p<pitch>h1s3b23410T

CG Triumvirate <ESC>(<symset><ESC>(s1p<ptsize>v0s0b92244T

CG Triumvirate Condensed Bold <ESC>(<symset><ESC>(s1p<ptsize>v4s3b92250T

LinePrinter <ESC>(<symset><ESC>(s0p16.67h8.5v0s0b0T

Barcodes

The following barcodes are supported:

Table 3: Barcodes

Barcode

ID

1000 Code 3 of 9 1-75 0-9, A-Z, $,%,+,-,.,/,space

1001 Extended Code 3 of 9 1-66 ASCII 0-0x7F

1010 UPC-A 1-11 0-9

1020 UPC-E 1-7 0-9

1021 UPC/EANAdd-On 2 or 5 0-9

1030 Code 128 Autoselect 1-79 ASCII 0-0x7F

1031 Code 128 Code Set A 1-79 ASCII 0-0x7F

1032 Code 128 Code Set B 1-79 ASCII 0-0x7F

1033 Code 128 Code Set C 1-79 ASCII 0-0x7F

1040 EAN-8 1-7 0-9

1050 EAN-13 1-12 0-9

1060 Interleaved 2 of 5 Mod 101-89 0-9

1061 Interleaved 2 of 5

bearer bars

1062 Interleaved 2 of 5 1-89 0-9

Type Length Valid ASCII Characters, decimal

value representation

1-89 0-9

1070 GS1-128 1-79 ASCII 0x20-0x7F

The leading AI value must be placed in

square brackets and a trailing

checksum must be included.

1080 Codabar 1-60

1090 UK Plessey 1-65

Workstation Series User’s Guide 66

A-D, 0-9

A-D, 0-9

Page 45

Appendix A | 7

Barcode

ID

1091 MSI Plessey Mod 10 1-55 0-9

1100 Code 93 1-107 ASCII 0x20-0x7F

1 110 HIBC Code 93 1-36 0-9, A-Z, $,%,+,-,.,/,space

1111 HIBC Code 128 1-36 0-9, A-Z, $,%,+,-,.,/,space

1120 Telepen 1-30 ASCII 0x20-0x7F

1130 GS1 Databar (RSS)

(linear only)

1131 GS1 Databar

Expanded (linear only)

1500 Postnet 1-38 0-9

1510 Planet 1-38 0-9

1520 FIM 1 A, B, C, D

1530 UPS Intelligent Mail

(OneCode)

2000 QR Code - Auto 1-256 ASCII 0x20-0x7F

2010 PDF-417 1-256 Full ASCII (0 – 0xFF)

Type Length Valid ASCII Characters, decimal

value representation

1-13

1-45 ASCII 0x20-0x7F

20

0-9

2020 MicroPDF417 1-256 Full ASCII (0 – 0xFF)

2030 DataMatrix 1-256 Full ASCII (0 – 0xFF)

2040 UPS MaxiCode 1-138 Alphanumeric, ASCII 0x1E,

0x1D,0x04,[,),>

2050 Aztec 1-256 Full ASCII (0 – 0xFF)

67 Workstation Series User’s Guide

Loading...

Loading...