Page 1

Page 2

Page 3

Copyright

CG Times (based upon Times New Roman), CG Triumvirate, MicroType, and TrueType

are trademarks of the AGFA Monotype Corporation.

PCL, Intellifont, and HP Laser JetII are trademarks of the Hewlett Packard Corporation.

Macintosh is a trademark of the Apple Corporation.

Windows is a trademark of the Microsoft Corporation.

All other brand and product names are trademarks, service marks, registered

trademarks, or registered service marks of their respective companies.

Information in this manual is subject to change without notice and does not represent a

commitment on the part of Datamax-O’Neil Corporation. No part of this manual may be

reproduced or transmitted in any form or by any means, for any purpose other than the

purchaser’s personal use, without the expressed written permission of Datamax-O’Neil

Corporation..

All rights reserved

Copyright © 2014, Datamax-O’Neil

Part Number 88-2364-01

Revision B

Thermal Printer Programmer’s Guide

Page 4

Thermal Printer Programmer’s Guide

Page 5

Table of Contents

Table of Contents

1. Programmer’s Guide

Overview ...............................................................................................1

Scope ...................................................................................................1

Referenced Documents ........................................................................1

Trademark References .........................................................................1

Datamax-O'Neil Commands .................................................................3

PCL Language ......................................................................................3

PCL Command Structure ............................................................................3

Fonts and Symbol Sets Supported ..............................................................6

Printing Unicode Characters in PCL ........................................................11

Datamax-O'Neil Barcode Command Structure .........................................11

PJL (Printer Job Language) Commands ............................................22

Standard PJL Commands ..........................................................................22

PJL File System Commands .....................................................................24

User Font Download via PJL ....................................................................24

PJL FSDELETE Command ......................................................................25

PJL FSINIT Command .............................................................................25

PJL INFO Read-Back Command .............................................................26

PJL JOB Command ..................................................................................28

PJL PERFORM Command .......................................................................28

PJL Head Cleaning Procedure/Command ................................................30

PJL Cutter, Rewinder, and Ribbon Assembly Self-Test Commands .......31

PJL GPIO Self Test ..................................................................................31

PJL GPIO Wrap Test ...............................................................................32

PJL GPIO Read Test ................................................................................32

PJL GPIO Write Test ...............................................................................33

PJL CONFIG PRINTFILE .......................................................................33

PJL CONFIG Command ...........................................................................33

PJL UPGRADE Command .......................................................................34

PJL Variables ............................................................................................35

PJL Internal Variables ..............................................................................42

Defining Internal Variables ......................................................................42

PJL Increment Command .........................................................................42

PJL Date/Time Command ........................................................................43

Hex Transfer Method ................................................................................48

i Thermal Printer Programmer’s Guide

Page 6

Table of Contents

2. Appendix A

Printer Model Printable Print Widths ...................................................51

3. Appendix B

Printer Model Speed ...........................................................................53

Thermal Printer Programmer’s Guide

Page 7

1 Programmer’s Guide

Overview

This Programmer’s Guide provides information about printer specific commands that are

supported by the following printer(s):

•p1115

• p1120n

•p1125

• p1115s

• p1725

•w1110

The Datamax-O'Neil Performance & Workstation Series printers language is based on

Hewlett Packard

barcode printing, Datamax-O'Neil has extended the language by adding barcode specific

commands. Methods exist to print barcodes in a Windows® environment without using

these new commands. Examples include using commercially available barcode fonts or

label design packages.

®

PCL 5e. Because this language does not have native support for

Scope

This document describes Datamax-O'Neil PCL barcode commands, internal variable

commands and various commands specific to thermal print devices. . Knowledge of PCL

is helpful but not required. A full explanation of PCL is beyond the scope of this guide,

please refer to the reference documents listed below.

Referenced Documents

The following documents referenced herein shall apply unless otherwise superseded by

requirements specified elsewhere in this document.

• Hewlett Packard Corporation, "PCL 5 Printer Technical Reference Manual"

• Hewlett Packard Corporation, "HP PCL/PJL Technical Reference Manual"

Trademark References

CG Triumvirate is a trademark of Monotype Imaging Inc.

CG Times, a product of Monotype Imaging Inc., is based on Times New Roman, a U.S.

registered trademark of Monotype Corporation plc.

PCL is a U.S. registered trademarks of Hewlett-Packard Company.

1 Thermal Printer Programmer’s Guide

Page 8

1 | Programmer’s Guide

Microsoft, Windows, and MS-DOS are U.S. registered trademarks of Microsoft

Corporation.

TrueType is a registered trademark of Apple Computer, Inc.

Helvetica and Times Roman are trademarks of Linotype AG and its subsidiaries.

Univers is a U.S. registered trademark of Linotype AG and its subsidiaries.

Antique Olive is a trademark of Monsieur Marcel OLIVE.

Arial is a registered trademark of The Monotype Corporation plc.

Thermal Printer Programmer’s Guide 2

Page 9

Programmer’s Guide | 1

Datamax-O'Neil Commands

There are frequent references to Hewlett Packard’s (HP) PCL Technical Reference

Manual (TRM). This document can be found on HP’s website listed in the Referenced

Documents above. Datamax-O'Neil provides unique commands not within the command

set found in the HP’s PCL TRM. No command defined within this document supersedes

or negates any commands found within the PCL TRM. This does not imply that all

commands defined within the PCL TRM are implemented by the Datamax-O'Neil

Barcode Label Printers. Many commands found within the PCL TRM are irrelevant within

the context of the Barcode Label Printer. Examples of these are commands for selecting

discrete pages sizes such as Letter, Legal, A4, and Executive. Features such as

duplexing and stapling do not currently exist in D-O Barcode Printers and these

commands, if found within the data stream, are silently ignored without error.

PCL Language

PCL Command Structure

General Information

As per Hewlett Packard’s specification on the syntax of escape sequences, there are two

forms of PCL escape sequences: two-character escape sequences and parameterized

escape sequences.

Two character escape sequences have the following form:

<ESC>X

“X” is a character that defines the operation to be performed. Two examples of twocharacter escape sequences are <ESC>E and <ESC>9. The first example resets the

printer to default conditions and the second resets the left and right margins to their

default value. The value of “X” may be any character within the range 0x30 – 0x7E.

Parameterized escape sequences have the following form:

<ESC>X y z1 [+|-]#[.#] z2 [+|-]#[.#] z3 … [+|-]#[.#] Zn[data]

The following characters y, #, zi and data may be optional. The parameterized character

X is within the range of 0x21 – 0x2F. The group character “y” is within the range of 0x60

– 0x7E. Group characters specify the type of control being performed.

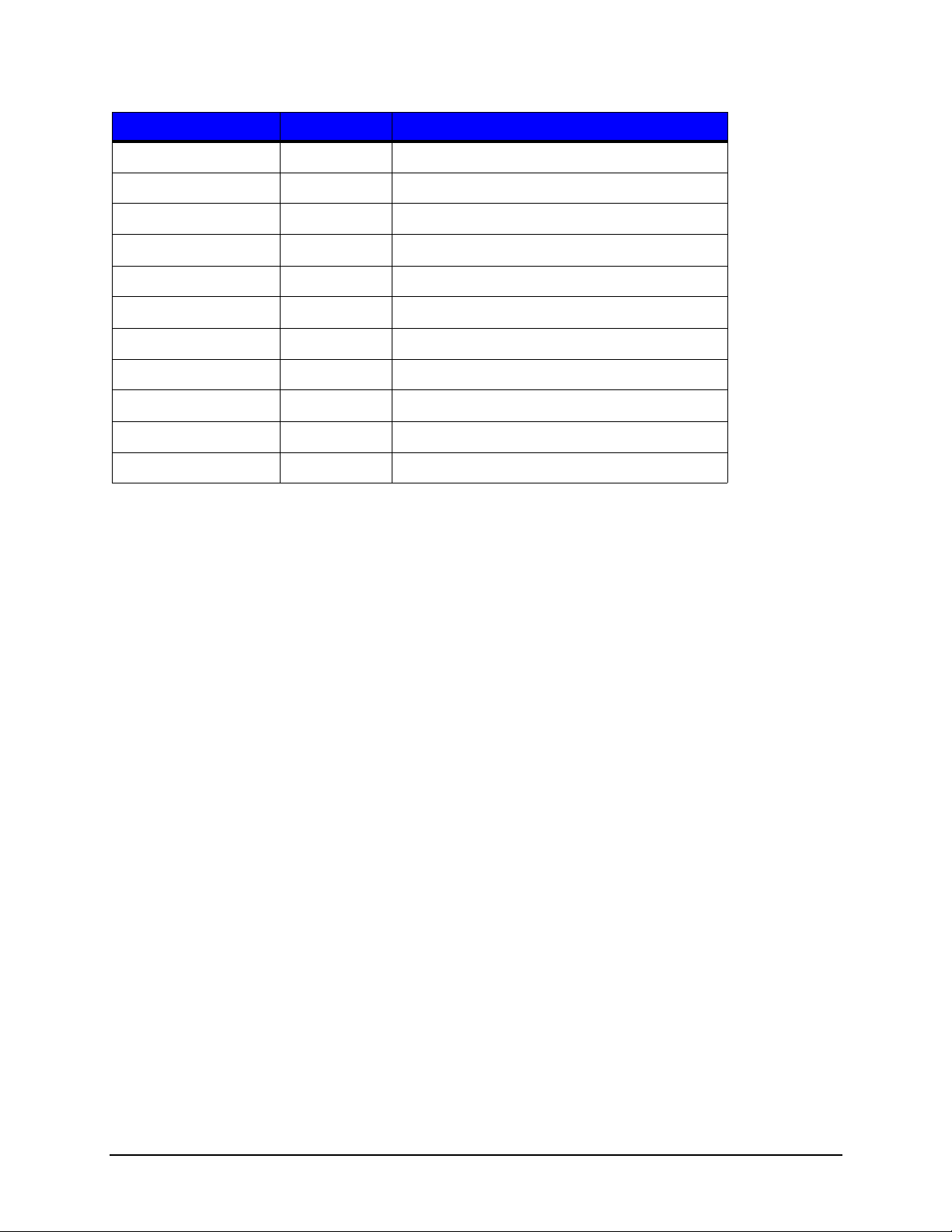

Table 1: Parameterized Character <ESC> X...

Character (X) Symbol Purpose

0x21 ! Reserved by D-O for debug firmware

0x22 “ Not Used

0x23 # Not Used

0x24 $ D-O Barcode Parameter

3 Thermal Printer Programmer’s Guide

Page 10

1 | Programmer’s Guide

Character (X) Symbol Purpose

0x25 % PCL Language Parameter

0x26 & PCL Cursor Parameter

0x27 ‘ Not Used

0x28 ( PCL Font Parameter

0x29 ) PCL Font Parameter

0x2A * PCL Graphic Parameter

0x2B + Not Used

0x2C , Not Used

0x2D - Not Used

0x2E . Not Used

0x2F / Not USed

The value field ‘#’ is a group of characters specifying a numeric value. The value is an

ASCII string of characters within the range 0x30 – 0x39. The string may be preceded

with an optional ‘+’ or ‘-‘ sign and may contain a decimal portion separated by the

decimal point. Consider the following example:

<ESC>&l5.81C

This command will set the printer to print 33 lines per label on a 4 inch high label. The

value specified is the number of 1/48 inch increments between rows (5.81 = 4/33 x 48).

The parameter character is any character from the ASCII table within the range of 0x60 –

0x7E. This character specifies the parameter to which the previous value field applies.

This character is used when combining escape sequences as described below in the

section titled “Combining Escape Sequences.”

The Termination Character is any character from the ASCII table within the range 0x40 –

0x5E. This character specifies the parameter to which the previous value field applies.

This character terminates the escape sequence.

The Binary Data is eight-bit data (for example, graphics data, downloaded fonts, etc.).

The number of bytes of binary data is specified by the value field of the escape

sequence. Binary data immediately follows the terminating character of the escape

sequence. Data that is to be encoded into barcode images will be considered as binary

data.

Combining Escape Sequences

All escape sequences that have the same first two characters AFTER the “<ESC>” (the

parameterized and group character) can be combined into a single escape sequence.

For example, the three commands (each begins with the <ESC> character) are of the

type “EC&l”.

Thermal Printer Programmer’s Guide 4

Page 11

Programmer’s Guide | 1

The following:

<ESC>&l1O<ESC>&l2A <ESC>&l5.81C

can be combined into the following single escape sequence:

<ESC>&l1o2a5.81C

In the example above, the capital ‘O’ becomes a lower case ‘o’, the ‘A’ of the second

command becomes an ‘a’ and the ‘EC&l’ are dropped from the second and third

commands. The printer commands are performed in the order they are combined, from

left to right.

Barcode Clipping

PCL normally clips print objects at the dot level on the logical page boundary. Barcodes

clipped in this manner can easily go undetected. Because of this, any portion of a

barcode that falls beyond the boundaries of the logical print area will be dropped and a

shaded rectangle will be printed, inscribing the area within the logical print page where

the barcode would have been. This will provide visual evidence to the user the barcode

has been clipped and is therefore invalid.

Barcodes that are not generated internally by the printer will not be clipped in this

manner and may not be readable by scanning devices.

Cursor Positioning Commands

The PCL cursor refers to the Current Active Position (CAP) which identifies the current

position on the label where a print command begins laying out page data. The cursor can

be moved anywhere within the logical page using a combination of the horizontal and

vertical cursor position commands and control codes. Although there are many different

ways to move the cursor, there are three types of cursor positioning units. These include

PCL Units, Decipoints, and Row/Column units.

The size of a PCL unit is determined by the value specified by the Unit of Measure

command. The format of this command is <ESC>&u#D where # is the number of units

per inch. The “units per inch” value is a discrete value from the following set of values:

{96, 100, 120, 144, 150, 160, 180, 200, 225, 240, 288, 300, 360, 400, 450, 480, 600,

720, 800, 900, 1200, 1440, 1800, 2400, 3600, and 7200}. If the Unit of Measure is not

set, the default value is 300.

A decipoint, in PCL terminology, is 1/720 inch or one-tenth of a PCL point. A PCL point is

exactly 1/72 inch as opposed to a typographic point which is approximately 1/72 inch.

Decipoints are resolution independent. Labels that are designed using units of decipoints

will be resolution independent and are therefore easily portable across PCL printers of

different resolutions. This is the preferred unit of measure in label design.

Cursor Positioning after Printing Barcode

PCL has a procedure for cursor positioning after printing a text character. Set the Current

Active Position (CAP) to the right at a distance equal to the width of that character, ready

5 Thermal Printer Programmer’s Guide

Page 12

1 | Programmer’s Guide

for the next character to be rendered. With raster images, the CAP is moved vertically to

the next dot row below the raster image previously rendered and then returned to the

horizontal start position of the raster image. The terminus CAP of the barcode is

selectable with the commands described below.

Set the Current Active Position (CAP) to the right of the last printed text character at a

distance equal to the width of that character so the next character can be rendered. With

raster images, the CAP is moved vertically to the next dot row below the previously

rendered raster image and returned to the horizontal start position of the raster image.

The terminus CAP of the barcode is selectable with the commands described below.

Orientation and the Influence on Label Dimensions

HP PCL defines the portrait orientation to be the page configuration where the X

dimension moves to the left along the short edge of the paper and the Y dimension

moves downward along the long edge of the paper. This seems perfectly reasonable

until both the label stock and the arbitrary dimensions a label may have on a given roll of

media are considered. As an example, for the common label stock size of 4” by 6”, it is

obvious the label is in the portrait orientation. For 4” by 3” label stock, HP PCL regards

this label as being in the landscape orientation and will automatically rotate the text,

images, rules, and coordinates by 90 degrees to maintain the portrait orientation with

respect to the shorter distance on the side. This may not be what an experienced user of

thermal printers would expect to see. In order for the same image to be produced on a

shorter label, the printer must be programed to produce the image in the landscape

orientation. Orientation takes precedence over label dimensions. If the printer is in the

portrait orientation, HP PCL will rotate the image to align it to the short edge of the label.

This subtle design characteristic may cause problems with users of legacy label printers

therefore we have chosen to modify this behavior to be more in-line with thermal printers.

Fonts and Symbol Sets Supported

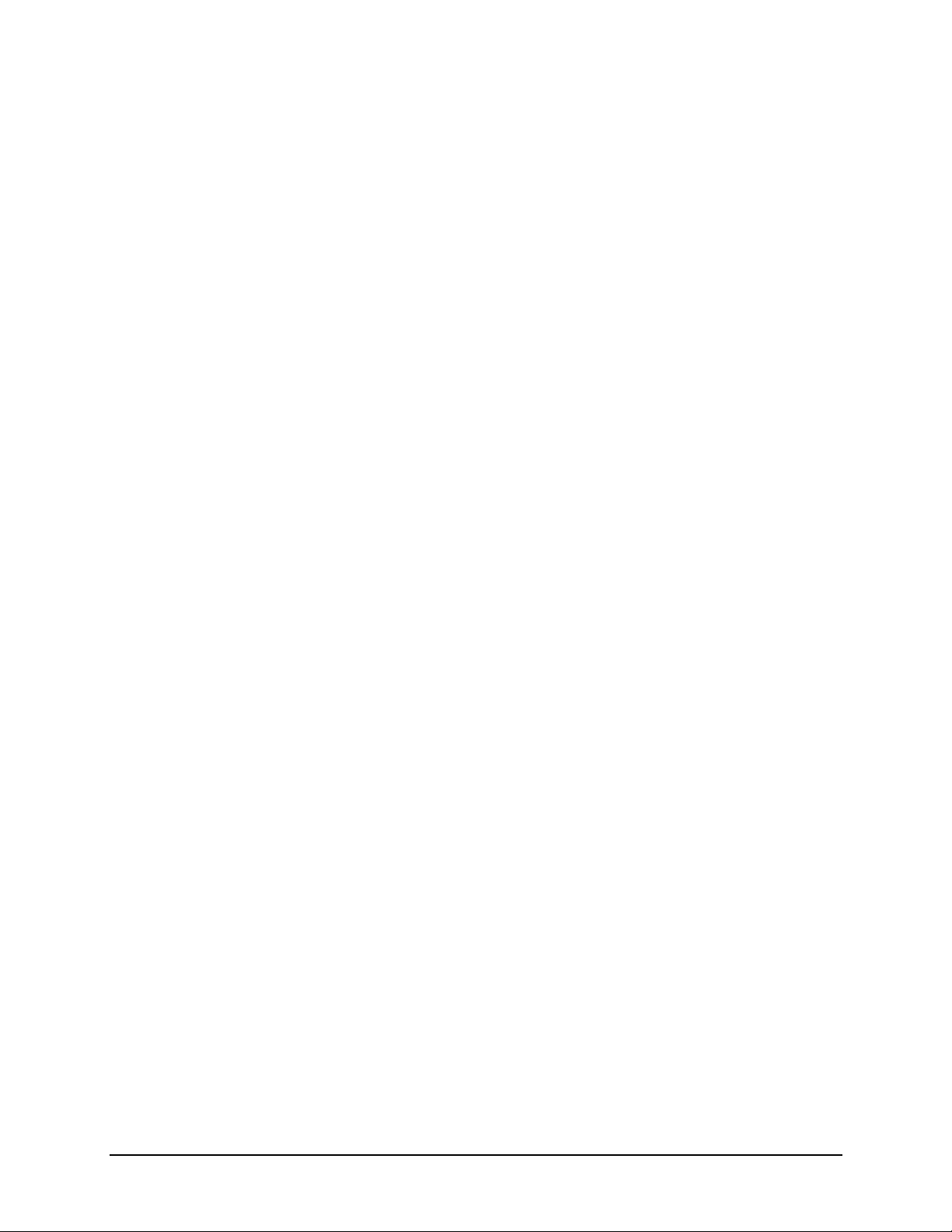

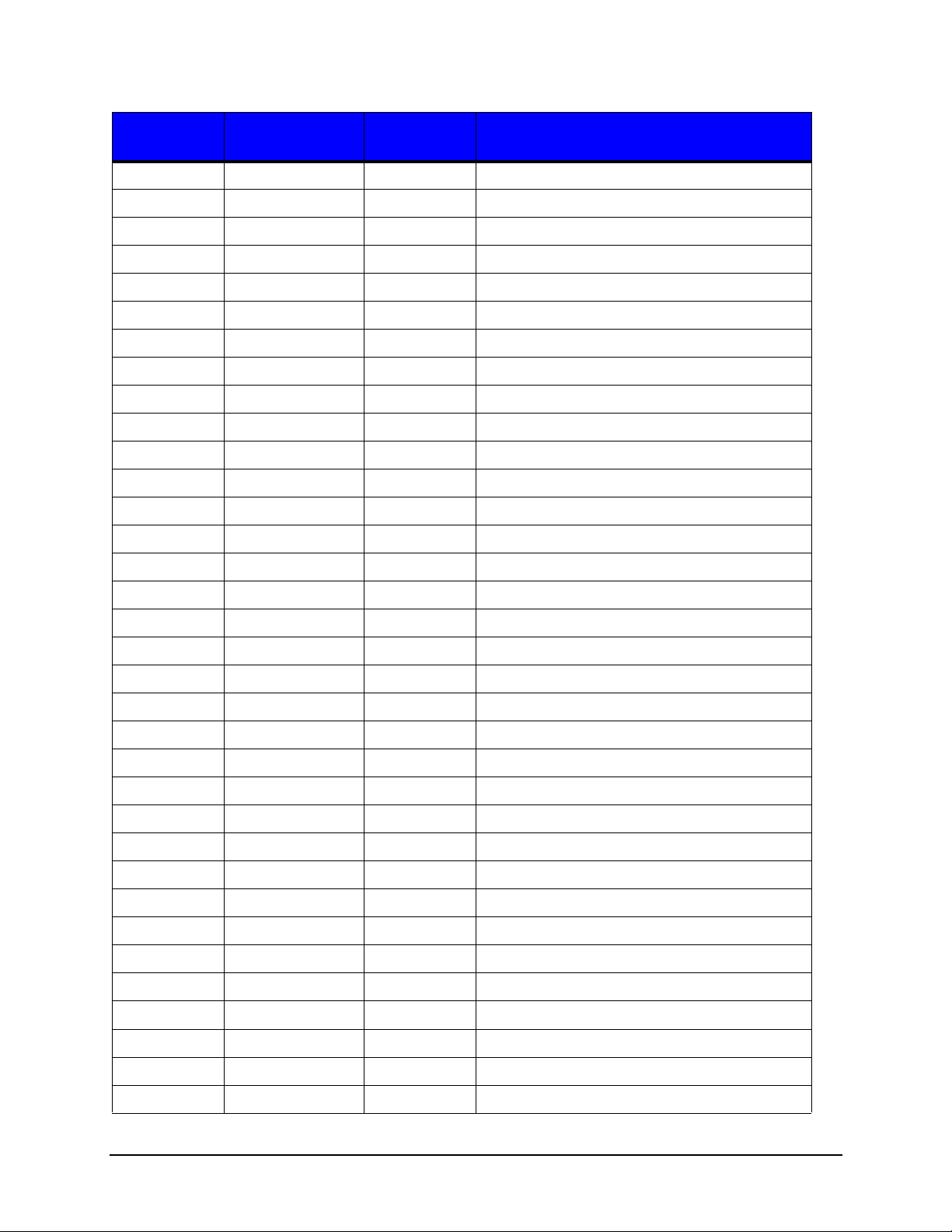

Resident Scalable Fonts

The table below provides a list of the 53 resident scalable fonts and the escape

sequence needed to select that font as the current primary font. The <ESC> tag

represents the escape character 0x1B. The <symset> tag represents the symbol set to

use with the selected font (see section 13 below). The <ptsize> tag represents the

requested point size of the font, up to two decimal places. The <pitch> tag represents

horizontal spacing of a fixed pitch font in characters per inch.

Refer to the Symbol Set Mapping Table resident symbol sets. The tags must be replaced

with their appropriate values. Developers may choose to define their own symbol sets.

Note: The resident fonts for your printer may vary in number from those listed in this

table.

Thermal Printer Programmer’s Guide 6

Page 13

Programmer’s Guide | 1

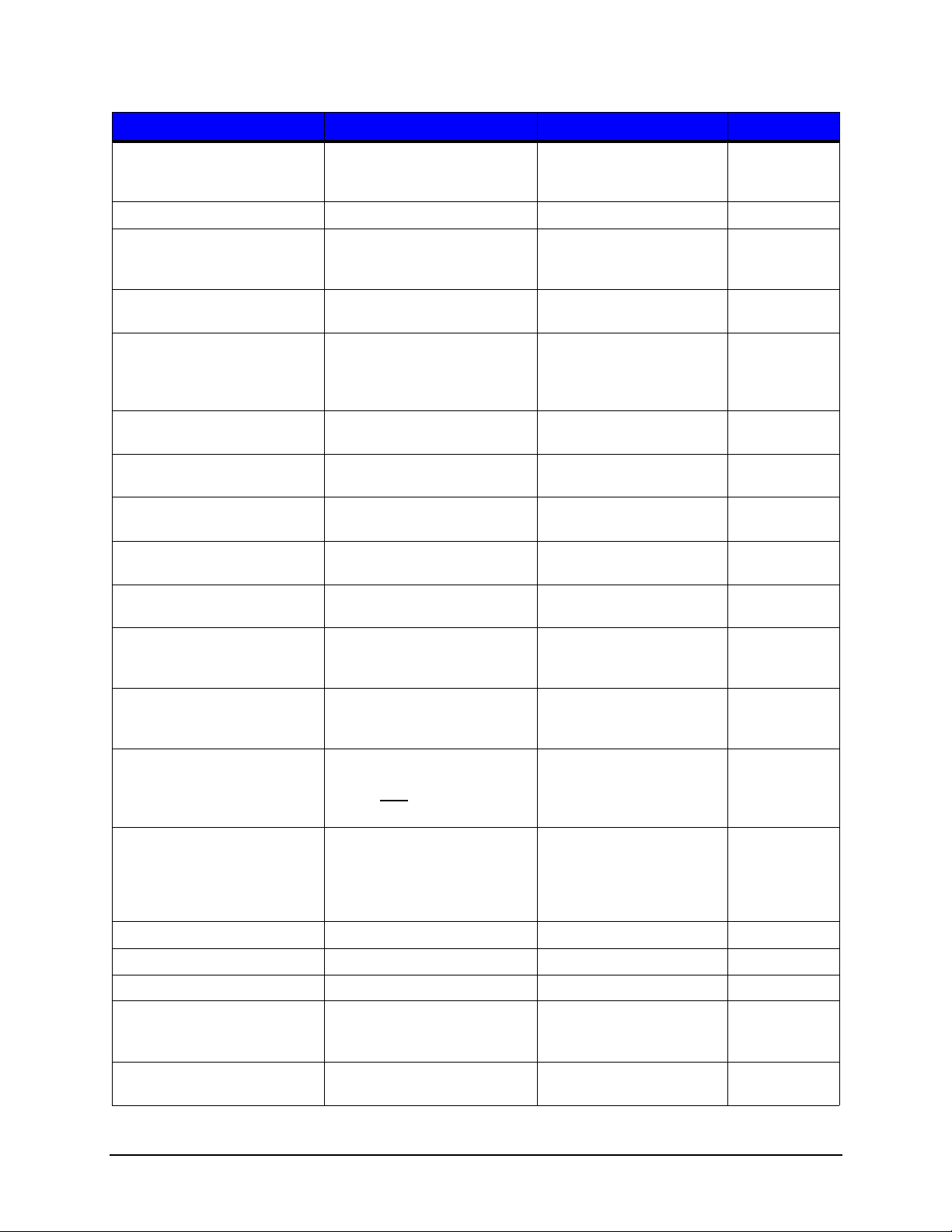

Table 2: Fonts and Escape Sequences

Font Name Escape Sequence

Albertus Medium <ESC>(<symset><ESC>(s1p<ptsize>v0s1b4362T

Albertus Extra Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s4b4362T

Antique Olive <ESC>(<symset><ESC>(s1p<ptsize>v0s0b4168T

Antique Olive Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s0b4168T

Antique Olive Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s3b4168T

Arial <ESC>(<symset><ESC>(s1p<ptsize>v0s0b16602T

Arial Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s0b16602T

Arial Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s3b16602T

Arial Bold Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s3b16602T

Clarendon Condensed Bold <ESC>(<symset><ESC>(s1p<ptsize>v4s3b4140T

Coronet <ESC>(<symset><ESC>(s1p<ptsize>v1s0b4116T

Courier <ESC>(<symset><ESC>(s0p<pitch>h0s0b4099T

Courier Italic <ESC>(<symset><ESC>(s0p<pitch>h1s0b4099T

Courier Bold <ESC>(<symset><ESC>(s0p<pitch>h0s3b4099T

Courier Bold Italic <ESC>(<symset><ESC>(s0p<pitch>h1s3b4099T

Garamond Antiqua <ESC>(<symset><ESC>(s1p<ptsize>v0s0b4197T

Garamond Kursiv <ESC>(<symset><ESC>(s1p<ptsize>v1s0b4197T

Garamond Halbfett <ESC>(<symset><ESC>(s1p<ptsize>v0s3b4197T

Garamond Kursiv Halbfett <ESC>(<symset><ESC>(s1p<ptsize>v1s3b4197T

Letter Gothic <ESC>(<symset><ESC>(s0p<pitch>h0s0b4102T

Letter Gothic Italic <ESC>(<symset><ESC>(s0p<pitch>h1s0b4102T

Letter Gothic Bold <ESC>(<symset><ESC>(s0p<pitch>h0s3b4102T

Marigold <ESC>(<symset><ESC>(s1p<ptsize>v0s0b4297T

CG Omega <ESC>(<symset><ESC>(s1p<ptsize>v0s0b4113T

CG Omega Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s0b4113T

CG Omega Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s3b4113T

CG Omega Bold Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s3b4113T

CG Times <ESC>(<symset><ESC>(s1p<ptsize>v0s0b4101T

CG Times Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s0b4101T

CG Times Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s3b4101T

CG Times Bold Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s3b4101T

Times New Roman <ESC>(<symset><ESC>(s1p<ptsize>v0s0b16901T

Times New Roman Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s0b16901T

Times New Roman Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s3b16901T

7 Thermal Printer Programmer’s Guide

Page 14

1 | Programmer’s Guide

Font Name Escape Sequence

Times New Roman Bold Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s3b16901T

Univers Medium <ESC>(<symset><ESC>(s1p<ptsize>v0s0b4148T

Univers Medium Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s0b4148T

Univers Bold <ESC>(<symset><ESC>(s1p<ptsize>v0s3b4148T

Univers Bold Italic <ESC>(<symset><ESC>(s1p<ptsize>v1s3b4148T

Univers Condensed Medium <ESC>(<symset><ESC>(s1p<ptsize>v4s0b4148T

Univers Condensed Medium Italic <ESC>(<symset><ESC>(s1p<ptsize>v5s0b4148T

Univers Condensed Bold <ESC>(<symset><ESC>(s1p<ptsize>v4s3b4148T

Univers Condensed Bold Italic <ESC>(<symset><ESC>(s1p<ptsize>v5s3b4148T

Symbol <ESC>(19M<ESC>(s1p<ptsize>v0s0b16686T

Wingdings <ESC>(579L<ESC>(s1p<ptsize>v0s0b31402T

OCR A <ESC>(<symset><ESC>(s1p<pitch>h0s0b23584T

OCR A Fixed <ESC>(<symset><ESC>(s0p<pitch>h0s0b23584T

OCR B <ESC>(<symset><ESC>(s1p<pitch>h0s0b23590T

OCR B Fixed <ESC>(<symset><ESC>(s0p<pitch>h0s0b23590T

VeraMono <ESC>(<symset><ESC>(s1p<ptsize>v3s0b23410T

CG Triumvirate <ESC>(<symset><ESC>(s1p<ptsize>v0s0b26708T

CG Triumvirate Bold Condensed <ESC>(<symset><ESC>(s1p<ptsize>v0s0b26714T

Symbol Sets

Symbol sets are used to map character codes to the associated character image. The

most familiar symbol set is the ASCII character mapping for characters occupying the

character codes ranging from 0x20, which is the space character, through 0x7E, which is

the tilde ‘~’ character. These symbol sets are used to support the internationalization of

labels.

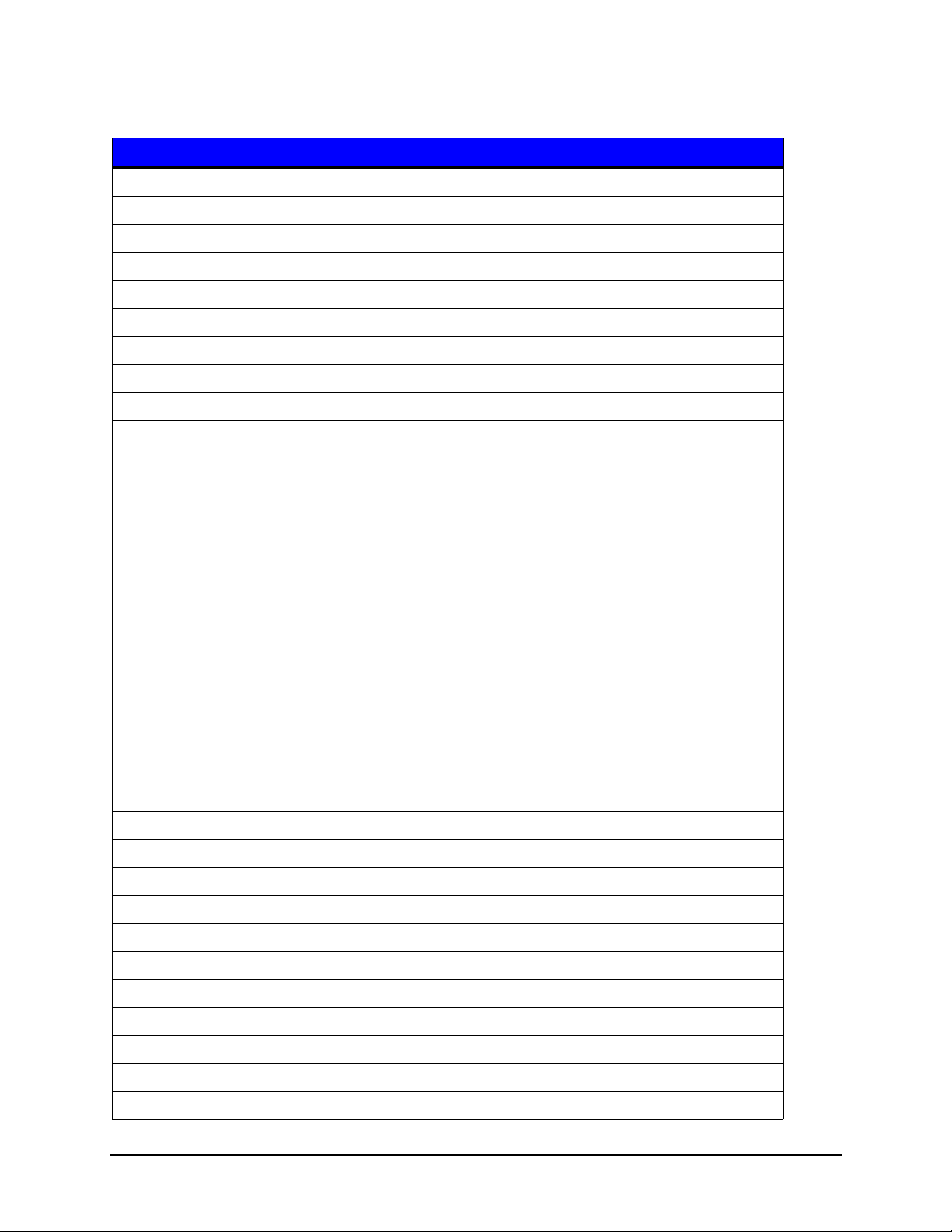

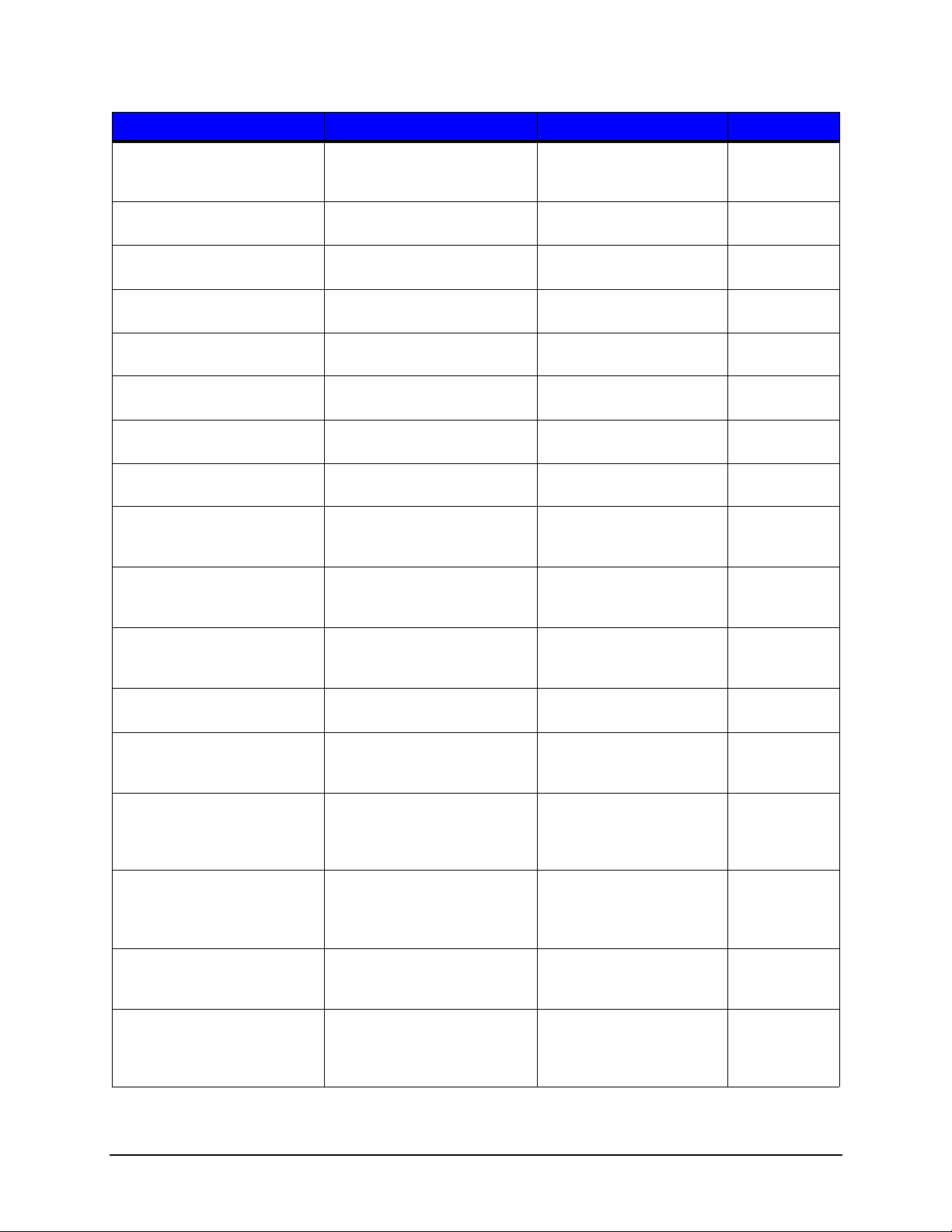

Table 3: Symbol Sets

PCL

Symbol Set

10U PC8 PC-8 PC-8

8U ROMAN8 Roman-8 Roman-8

PJL Symbol

Name

Control

Panel Name

Symbol Set Description

4U ROMAN9 Roman-9 Roman-9

0N ISOL1 ISO-L1 ISO 8859-1 Latin 1

2N ISOL2 ISO-L2 ISO 8859-2 Latin 2

4N ISOL4 ISO-L4 ISO 8859-4 Latin 4

5N ISOL5 ISO-L5 ISO 8859-9 Latin 5

Thermal Printer Programmer’s Guide 8

Page 15

Programmer’s Guide | 1

PCL

Symbol Set

6N ISOL6 ISO-L6 ISO 8859-10 Latin 6

9N ISOL9 ISO-L9 ISO 8859-15 Latin 9

26U PC775 PC-775 PC-775

5M PSMATH PS MATH PS-Math

8M MATH8 MATH-8 Math-8

15U PIFONT IP FONT Pi Font

6J MSPUBL MS PUBL Microsoft Publishing

11U PC8DN PC-8 DN PC-8 Danish/Norwegian

12U PC850 PC-850 PC-850 Multilingual

17U PC852 PC-852 PC-852

13U PC858 PC-858 PC-858 Multilingual

9T PC8TK PC-8 TK PC-Turkish

9J PC1004 PC-1004 PC-1004

19U WINL1 WIN L1 Windows CP1252 Latin 1

9E WINL2 WIN L2 Windows CP1250 Latin 2

PJL Symbol

Name

Control

Panel Name

Symbol Set Description

5T WINL5 WIN L5 Windows CP1254 Latin 5

19L WINBALT WINBALT Windows CP1257 Baltic

7J DESKTOP DESKTOP Desktop

10J PSTEXT PS TEXT PS Text

1U LEGAL LEGAL Legal

1E ISO4 ISO-4 United Kingdom Code Set

0U ISO6 ISO-6 7 Bit ASCII Code Set

0S ISO11 ISO-11 7 Bit Western Europe (Swedish)

0I ISO15 ISO-15 7 Bit Western Europe (Italian)

2S ISO17 ISO-17 7 Bit Western Europe (Spanish)

1G ISO21 ISO-21 7 Bit Western (German)

0D ISO60 ISO-60 7 Bit Western Europe (Norwegian)

1F ISO69 ISO-69 7 Bit Western Europe (French)

9U WIN30 WIN 3.0 Windows CP1252 (obsolete)

12J MCTEXT MC TEXT MC Text

18N UCS2 UCS-2 Unicode 2 Byte Encoding

0E ROMANEXT RomanExt Roman Extensions

579L WINGDINGS WindDings Wingdings Font

14L ZAPDINGBATS ZapDingBats Windows Dingbats Font

9 Thermal Printer Programmer’s Guide

Page 16

1 | Programmer’s Guide

12U

PC85

PCL

Symbol Set

19M SYMBOL Symbol Symbol Font

PJL Symbol

Name

Control

Panel Name

Symbol Set Description

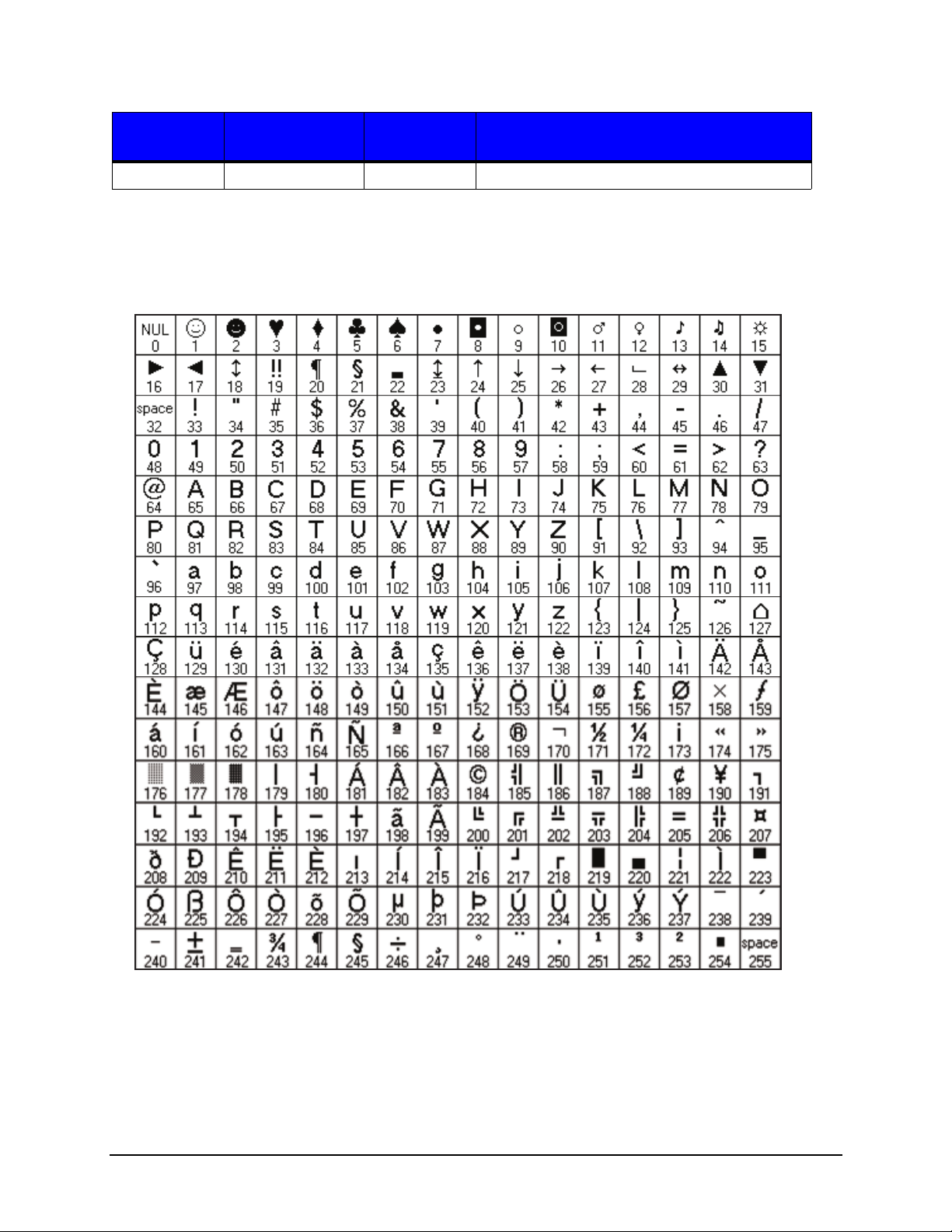

The table below (PC-850 Symbol Set) is an example of character code mapping and the

character image associated with that code.

Figure: 1 - 1 PC-850 Symbol Set

Thermal Printer Programmer’s Guide 10

Page 17

Programmer’s Guide | 1

Printing Unicode Characters in PCL

To print Unicode characters, the symbol set 18N (UCS-2) should be used to set handling

to Unicode mapping together with UTF-8 text parsing method. Refer to the following

syntax:

<ESC>&t83P<ESC>(18N<ESC>(sn1Tdata …

The 83P in <ESC>&t command signifies the UTF-8 text parsing method. The 18N in

<ESC>( command sets the Unicode mode. The n1T is used to select a font in the

<ESC>(s command where n1 is the typeface id of the font. Immediately following are the

characters to print in UTF-8 format. Refer to the example below:

<ESC>&t83P<ESC>(18N<ESC>(s1p16v0s0b9999T<D8><B6><CE><B1><E0><B

8><82><EA><B0><95><E8><90><81>

This prints the characters “ض α?강萁“ (an Arabic, Greek, Thai, Korean and Chinese

symbol) assuming the font supports all of these characters. The font selection command

parameters are “1p” for proportional spacing, “16v” for point size of 16, “0s” for no italic,

“0b” for no bold and “9999T” for typeface ID.

Datamax-O'Neil Barcode Command Structure

Command Structure Syntax

As stated earlier, printer commands are performed in the order that they are combined,

from left to right. There are several barcode parameters that are only relevant to a subset

of the total number of barcodes provided.

All Datamax-O'Neil barcodes and their support parameters will begin with the following

sequence:

<ESC>$b... 0x1b 0x24 0x62

There are several escape commands associated with barcodes. Any escape command

that modifies a property of a barcode will only affect the currently selected barcode. For a

label design with multiple barcode types, modification of one or more barcode properties

does not affect the properties of any other barcode type.

The following commands illustrate how one might handle modifying the default

parameters for multiple barcode types on a single label. Note that the examples below

have line numbers. For ease of reading each line is separated by a carriage return and

line feed. When sending this data to the printer, all the lines in the examples should NOT

have a carriage return and line feed except where you see the symbol “CRLF”. The

“CRLF” symbol indicates a carriage return/line feed combination should be inserted into

the data stream. The “<ESC>” symbol indicates the escape character (hex value 0x1B)

should be inserted into the data stream.

11 Thermal Printer Programmer’s Guide

Page 18

1 | Programmer’s Guide

Table 4: Example of Printing Barcodes (Compressed Commands)

Commands Description

<ESC>%-12345X@PJL SET RESOLUTION =

CRL

300

@PJL SET PAPERWIDTH=2880

@PJL SET PAPERLENGTH=2880

@PJL ENTER LANGUAGE = PCL

F

CRL

F

CRL

F

CRL

F

Reset the printer and enter into PJL mode, Set the

resolution to 300 DPI

Set the label width to 2880 decipoints (4 inches)

Set the label length to 2880 decipoints (4 inches)

Select the PCL emulation

<ESC>&a2160h720v270P Set the horizontal cursor position at 2160

decipoints (3 inches) and the vertical cursor

position at 720 decipoints (1 inch) and set the

writing direction at 270 degrees counter clockwise

from horizontal (down the label).

<ESC>$b1030c360h2a10W9876543210

Select barcode 1030 (Code 128 w/ Auto select).

Set the barcode height of this barcode to 360

decipoints and enable autoprint w/ checksum

(human readable). With the currently selected

barcode (1030), print the data 9876543210 (10

bytes of data)

<ESC>&a0p720h540V Set the writing direction to 0 degrees, the horizontal

cursor position at 720 decipoints horizontally (1

inch) and 540 decipoints vertically (¾ inch).

<ESC>$b1061c360h0a10W1234567890 Select barcode 1061 (Interleave 2 of 5 w/ Bearer

Bars), the height of the barcode to 360 decipoints

(1/2 inch), no autoprint and print the following 10

bytes: 1234567890

<ESC>E Reset PCL (this causes any imaged data to be

printed)

<ESC>%-12345X Reset the printer and wait for more PJL commands

Table 5: Example of printing Barcodes (Uncompressed Commands

Commands Descriptions

<ESC>%-12345X@PJL SET RESOLUTION =

CRL

300

@PJL SET PAPERWIDTH=2880

@PJL SET PAPERLENGTH=2880

@PJL ENTER LANGUAGE = PCL

F

CRL

F

CRL

F

CRL

F

<ESC>&a2160H Set the horizontal cursor position to 2160

<ESC>&720V

Reset the printer and enter PJL mode

Set the label width to 2880 decipoints (4 inches)

Set the label length to 2880 decipoints (4 inches)

Select the PCL emulation

decipoints

Set the vertical cursor position to 720 decipoints

Thermal Printer Programmer’s Guide 12

Page 19

Programmer’s Guide | 1

Commands Descriptions

<ESC>&a270P

<ESC>$b1030C Select barcode number 1030 (Code 128 /w Auto

<ESC>$b360H Set the barcode height to 360 decipoints (½ inch)

<ESC>$b2A Enable barcode autoprint with checksum

<ESC>$b10W9876543210 With the current barcode (1030) print the 10 bytes

<ESC>&0P

<ESC>&a720H Set the horizontal cursor position to 720 decipoints

<ESC>&a540V

<ESC>$b1061C

<ESC>$b360H

<ESC>$b0A

Set the writing direction to 270 degrees counter

clockwise from horizontal

select)

of data: 9876543210

Set the writing direction at 0 degrees.

Set the vertical cursor position to 1440 decipoints

Select barcode number 1061 (Interleave 2 of 5)

Set the barcode height to 180 decipoints (¼ inch)

Disable barcode autoprint for this barcode

<ESC>$b10W0123456789 With the current barcode type (1061) print data

0123456789

<ESC>E Reset PCL (print the imaged data)

<ESC>%-12345X Reset the printer and wait for more PJL commands

Comparing the two tables above there is a noticeable difference in the amount of data

saved by compressing the commands. In general, three bytes for each combined

command will be saved. This becomes significant with larger, more complex labels,

especially if the labels will be stored in the printer as macros.

Enable/Disable Barcode Autoprint

The following command will enable or disable human readable autoprint of the barcode

data:

<ESC>$b#A 0x1b 0x24 0x62 <0|1|2> 0x41

The command will affect only those barcodes with a human readable component. The

following arguments are valid:

0 – Disable human readable text

1 – Enable human readable text

2 – Enable human readable with checksum information

Note: The autoprint field is considered part of the barcode object. It is implied that when

the height of the barcode is specified, the height of the autoprint is included in that

barcode height. For example, if a Code 3 of 9 barcode is selected with autoprint in the

normal orientation and has a height of 1 inch, the height is measured from the top of the

barcode to the baseline of the autoprint text.

13 Thermal Printer Programmer’s Guide

Page 20

1 | Programmer’s Guide

Select Guard Boxes/Bars

The following will select guard boxes or bars on barcodes that support them:

<ESC>$b#B 0x1b 0x24 0x62 <value> 0x42

Select Barcode Type

The following will select the current barcode type:

<ESC>$b#C 0x1b 0x24 0x62 <value> 0x43

Note that all barcode commands below operate on the currently selected barcode. The

table below contains the list of barcodes and their numerical values.

Set Barcode Data Delimiter

The following will select the data delimiter for the currently selected barcode:

<ESC>$b#D 0x1b 0x24 0x62 <value> 0x44

The value parameter is the ASCII value of the character to be used as a delimiter. Refer

to the print barcode data below for a description of the “Print Barcode Data” command

and note how this command extends the capabilities of the “Print Barcode Data”

command. The following combined1 command will select the Code 39 barcode, set the

Data Delimiter to the tilde character ‘~’ (ASCII 127) and print the barcode with the data

‘0123456789’.

<ESC>$b1000c126d0W0123456789~

In this example the value of the width command is set to zero. This will instruct the printer

to read data after the ‘W’ command until the data delimiter (~) is found. The delimiter is

discarded and not printed. The default value for the data delimiter is the carriage return

(ASCII 13). The delimiter value must be a value not found in the data set being encoded

in the barcode.

Select Error Correction Capacity

The following will set the ECC for 2D barcodes - Datamatrix, PDF417, QR and Aztec,

where:

<ESC>$b#E 0x1b 0x24 0x62 <value> 0x45

1. See Section on Combined Escape Sequences.

Thermal Printer Programmer’s Guide 14

Page 21

Values:

Aztec (0-4) PDF 417 (0-8)

Programmer’s Guide | 1

0 - 23%

1 - 10%

2 - 23%

3 - 36%

4 - 50%

Datamaxtrix (1)

1 - ECC 200

QR Code (1-4)

1 - High Density 7%

2 - Standard Density 15%

3 - High Reliablity 25%

4 - Ultra Reliabilty 30%

For Maxicode barcodes:

<ESC>$b#E 0x1b 0x24 0x62 <value> 0x45

Where n=

2 = Structured carrier, numeric, US

3 = Structured carrier, alphanumeric, non US

4 = Standard

5 = Full ECC

6 = Reader program

0 - 2 Codewords

1 - 4 Codewords

2 - 8 Codewords

3 - 16 Codewords

4 - 32 Codewords

5 - 64 Codewords

6 - 128 Codewords

7 - 256 Codewords

8 - 512 Codewords

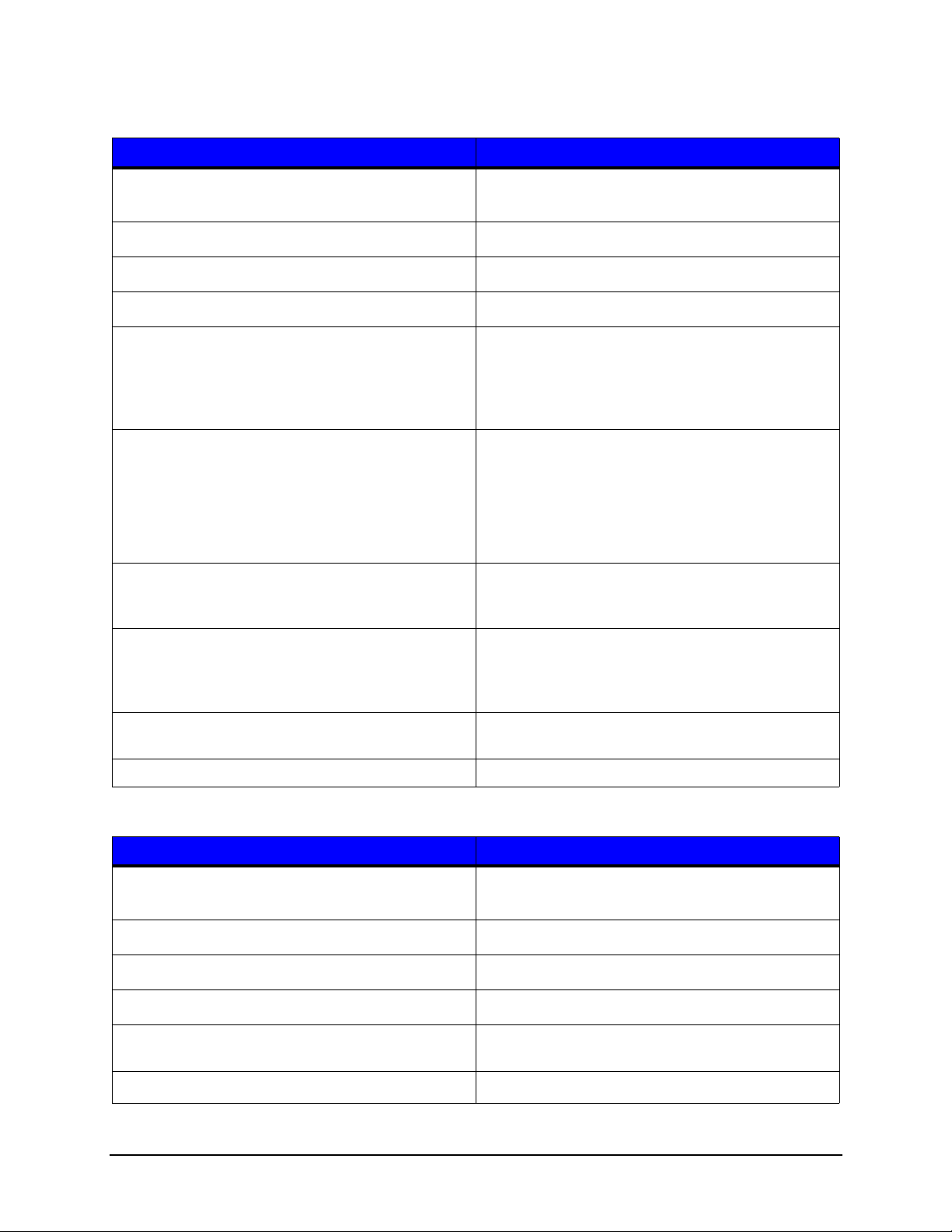

Select Barcode Terminating Current Active Position

The following will place the cursor position at the location depicted in the diagram below.

This escape sequence must be sent prior to sending any data that is to appear in the

barcode.

<ESC>$b#F 0x1b 0x24 0x62 <value> 0x46

Select Barcode Height (Decipoints)

The following will set the barcode height in decipoints with 1 decimal.

<ESC>$b#H 0x1b 0x24 0x62 <value> 0x48

If the barcode auto print is enabled prior to sending the barcode data, the height of the

barcode will include the height of any human readable text if enabled. The number of

pixels used in the barcode height will always be rounded. As an example, if the barcode

height is specified to be 97 decipoints, the number of dots used on a 300 DPI printer is

[(97 x 300)/720 = 40.417] and will round down to 40 dots. If the height is specified to be

98 [(98 x 300)/720 = 40.833] the number of dots will be 41. The default barcode height is

720 decipoints (1 inch) for linear barcodes.

Figure: 1 - 2 Terminating Current Active Position

15 Thermal Printer Programmer’s Guide

Page 22

1 | Programmer’s Guide

Select Barcode Height (PCL Units)

The following will set the barcode height in PCL units with 1 decimal. The number of

codewords per line are as follows: PDF417 (0-30), Micro PDF (0-4), QR Code (0-40). For

Datamatrix it is the symbol size value per the table below.

<ESC>$b#J 0x1b 0x24 0x62 <value> 0x48

1 - 10x10 7 - 22x22 13 - 44x44 19 - 88x88 25 - 8x18

2 -12 x12 8 - 24x24 14 - 48x48 20 - 96x96 26 - 8x32

3 - 14x14 9 - 26x26 15 - 52x52 21 - 104x104 27 - 12x26

4 - 16x16 10 - 32x32 16 - 64x64 22 - 120x120 28 - 12x36

5 - 18x18 11 - 36x36 17 - 72x72 23 - 132x132 29 - 16x36

6 - 20x20 12 - 40x40 18 - 80x80 24 - 144x144 30 - 16x48

If the barcode auto print is enabled prior to sending the barcode data, the height of the

barcode will include the height of any human readable text if enabled. The number of

pixels used in the barcode height will always be rounded. As an example, if the barcode

height is specified to be 97 decipoints, the number of dots used on a 300 DPI printer is

[(97 x 300)/720 = 40.417] and will round down to 40 dots. If the height is specified to be

98 [(98 x 300)/720 = 40.833] the number of dots will be 41. The default barcode height is

720 decipoints (1 inch) for linear barcodes.

Select Narrow Bar Width (Decipoints)

The following command will set the width of a narrow bar in Decipoints (720/inch) with

one decimal:

<ESC>$b#M 0x1b 0x24 0x62 <value> 0x4d

An example of this command might be:

<ESC>$b9.6M

This will set the width of the narrow bar to 9.6 Decipoints which is equivalent to 4 dots at

300 dpi or 8 dots at 600dpi. This command will round for example (2*300)/720 = 0.833

Thermal Printer Programmer’s Guide 16

Page 23

Programmer’s Guide | 1

and will round up to 1 dot. (3*300)/720 = 1.25 and will round down to 1 dot. (4*300)/720=

1.667 and will round up to 2 dots. The printer will not ensure that the narrow element

width is within specification for that barcode type. The default narrow element width will

be defaulted to a reasonable value for each barcode type.

Select Narrow Bar Width (Dots)

The following command, like the one above, will set the width of a narrow bar in PCL

units.

<ESC>$b#N 0x1b 0x24 0x62 <value> 0x4e

The PCL unit defaults to 300 units per inch. This may be modified with the <ESC>&u#D

command. See the PCL Technical Reference Manual for details about this command. If

the user’s environment contains printers with various print densities, refer to the section

titled “Select Barcode Width using Decipoints.”

Select Barcode Anchor

The following will select the point that will serve as the barcode anchor point that

coincides with the beginning cursor position:

<ESC>$b#O 0x1b 0x24 0x62 <value> 0x4F

The diagram below provides the value used to designate where the barcode anchor

point will be. The value may be modified at any time for any subsequent barcodes that

follow.

Many barcodes require quiet zones. A quiet zone is the area immediately surrounding

the barcode and must be free of any text or graphic images. It is the user’s responsibility

to insure no text, lines, boxes or graphic images of any kind encroach within the quiet

zone. Failure to do so could render the barcode unreadable by some barcode scanners.

Figure: 1 - 3 Barcode Anchor Point

Select Leading and Trailing Quiet Zone Size

The following command will set the quite zone size

<ESC>$b#Q 0x1b 0x24 0x62 <value> 0x51

17 Thermal Printer Programmer’s Guide

Page 24

1 | Programmer’s Guide

Select Barcode Ratio

The following command will set the wide-to-narrow bar ratio.

<ESC>$b#R 0x1b 0x24 0x62 <value> 0x52

The value of ‘#’ may be one of the following:

1 = 2:1

2 = 7:3

3 = 5:2

4 = 3:1

Any other value will default to the standard ratio of the currently selected barcode. This

command only affects Code 3 of 9 and Interleaved 2 of 5.

Print Barcode Data

The following command will use the provided data in this sequence to print the currently

selected barcode.

<ESC>$b#W 0x1b 0x24 0x62 <value> 0x57

The number of data bytes is specified in the <value> parameter field. As an example:

<ESC>$b1000C <ESC>$b10W1234567890THIS IS A BARCODE

The following condensed command is also valid:

<ESC>$b1000c10W1234567890THIS IS A BARCODE

Either command will select the Code 39 Barcode as the default barcode then send the

10 characters following the barcode selection command to the Code 39 module for

rendering at the current cursor position. It will be followed by the text “This is a Barcode”

using the currently selected font (not the autoprint typeface). A width value of zero will

trigger the data scanning process to read barcode data until the barcode data delimiter is

encountered. Refer to the section titled “Set Barcode Data Delimiter” for details of the

“Barcode Data Delimiter Command”.

Print Internal Variable Barcode Data

The following command will use data described by internal variables such as Date, Time

or Counting fields:

<ESC>$b#Y 0x1b 0x24 0x62 <value> 0x59

Since the length of the data at any given moment is unknown by the host, this provides a

means for internal data fields to be processed into barcodes. Refer to section “PJL GPIO

Write Test” for the details on usage of internal data fields and for a “<value>” parameter

to specify in the command.

Default Barcode Parameters

Several of the barcodes provided by the printer are user configurable including line

width, barcode heights and the bar/space ratio. The table above contains the default

values for the user configurable parameters. Note that every effort has been made to

Thermal Printer Programmer’s Guide 18

Page 25

Programmer’s Guide | 1

insure every resident barcode produced by Datamax-O'Neil Barcode Printers are within

industry specification. Upon deciding to modify these values, be aware that some

barcode scanners may not be able to property decode the barcode. Also note that any

modified values are not stored permanently in the printer. Once the job of labels has

completed, the default values are restored.

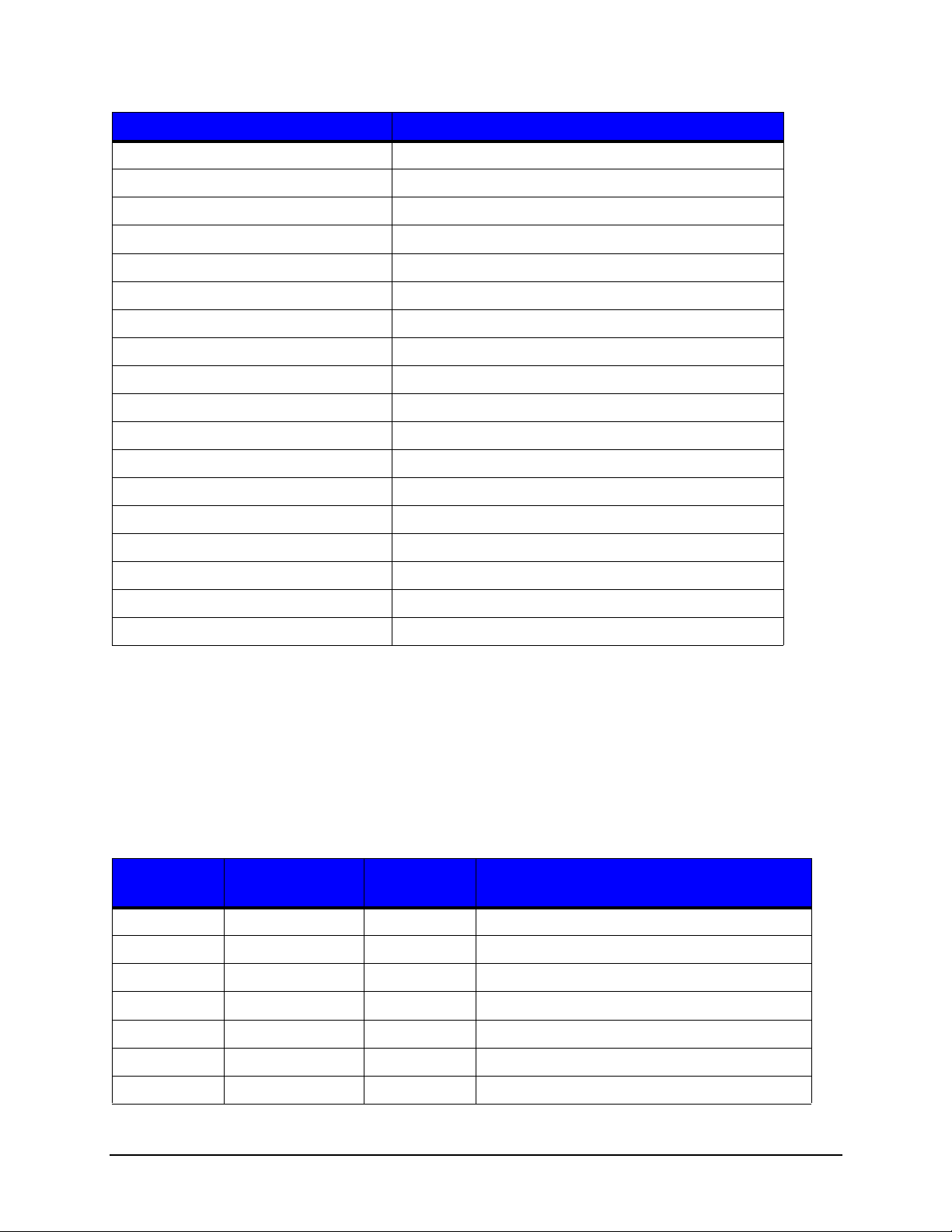

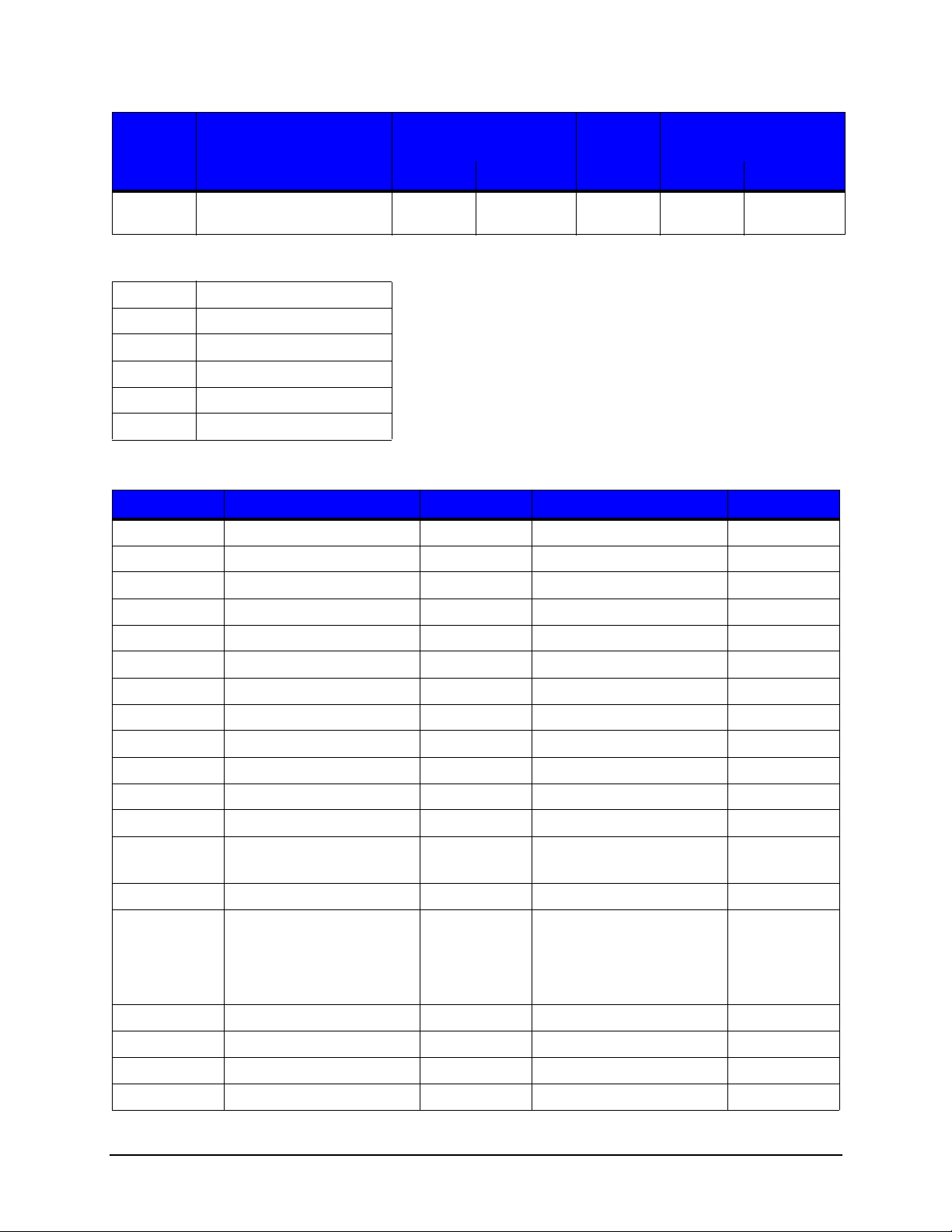

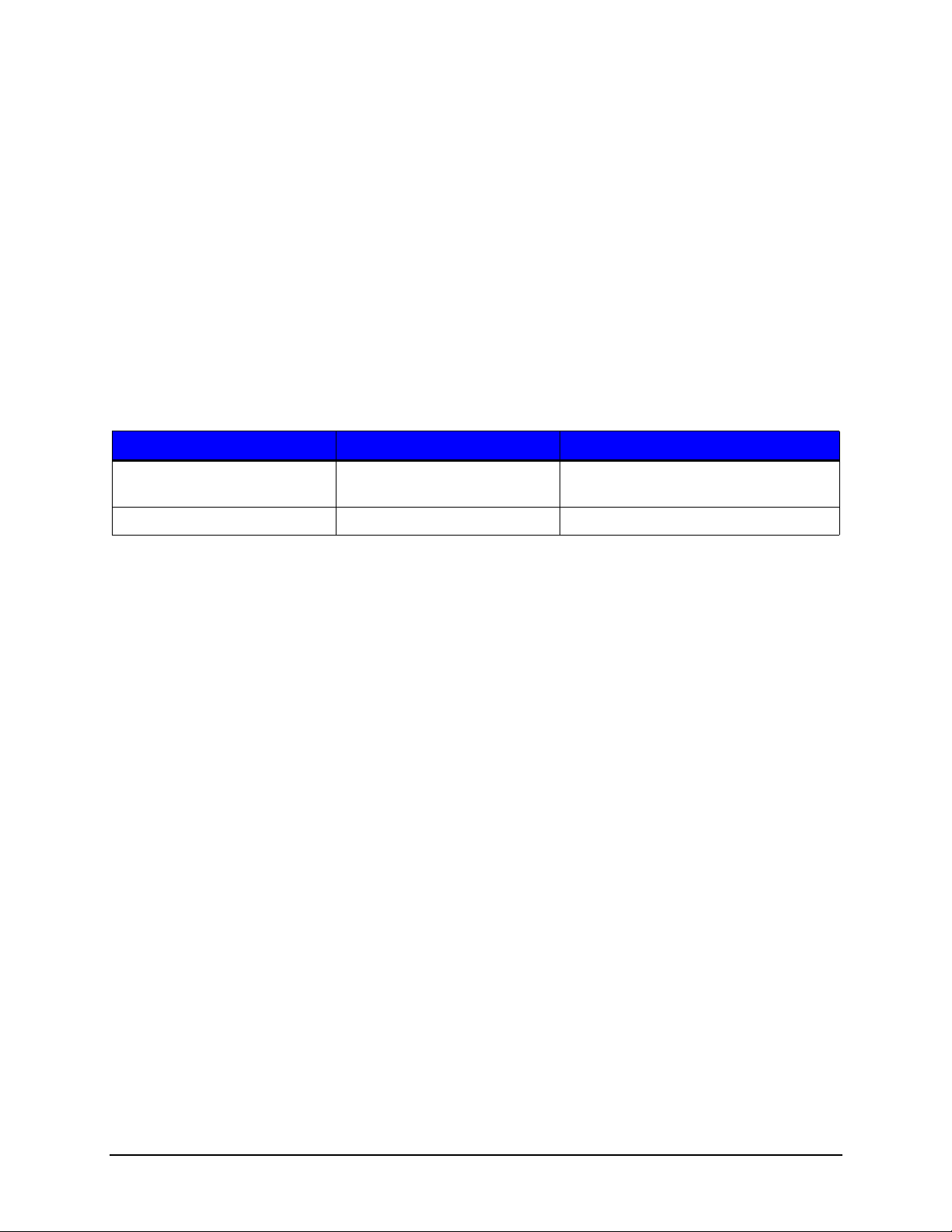

Table 6: Barcode Defaults

Barcode IDBarcode Description Narrow Element

Width

Default

Ratio

Default Height

Dots Decipoints Dots Decipoints

1000

(Default)

1001

1010 UPC A 4 9.6 N/A 300 720

1020 UPC E 4 9.6 N/A 300 720

1021 UPC/EAN Add-On 4 9.6 N/A 300 720

1030 Code 128 Auto Select 3 7.2 N/A 150 360

1031 Code 128 Set A 3 7.2 N/A 150 360

1032 Code 128 Set B 3 7.2 N/A 150 360

1033 Code 128 Set C 3 7.2 N/A 150 360

1040 EAN 8 4 9.6 N/A 240 576

1050 EAN 13 4 9.6 N/A 300 720

1060 Interleaved 2 of 5 Mod 10 3 7.2 3:1 150 360

1061 Interleaved 2 of 5 Bearer

1062 Interleaved 2 of 5 3 7.2 3:1 150 360

1070 GS1-128 4 9.6 N/A 450 1080

Code 3 of 9

Code 3 of 9 Extended

Bars

4 9.6 3:1 150 360

4 9.6 3:1 150 360

3 7.2 3:1 150 360

1080 Codabar 3 7.2 N/A 150 360

1090 UK Plessey 3 7.2 N/A 150 360

1091 MSI Plessey Mod 10 3 7.2 N/A 150 360

1100 Code 93 3 7.2 N/A 150 360

1110 HIBC Code 39 3 7.2 N/A 150 360

1111 HI B C C ode 128 3 7.2 N/ A 150 360

1120 Telepen 3 7.2 N/A 150 360

1130 GS1 Databar (linear only) 3 7.2 N/A 141 338.4

1131 GS1 Databar Expanded

(linear only)

1500 Postnet 6 14.4 N/A 38 91.2

1510 Planet 6 14.4 N/A 38 91.2

1520 FIM 9 21.6 N/A 187 448.8

3 7.2 N/A 144 345.6

19 Thermal Printer Programmer’s Guide

Page 26

1 | Programmer’s Guide

Barcode IDBarcode Description Narrow Element

Width

Default

Ratio

Default Height

Dots Decipoints Dots Decipoints

1530 USPS Intelligent Mail

(OneCode)

5 12 N/A 45 108

Table 7: 2D Barcodes

2000 QR Code Auto

2010 PDF 417

2020 Micro PDF

2030 Datamatrix

2040 UPS MaxiCode

2050 Aztec

Table 8: Valid Barcode Data

Barcode ID Barcode Description Length Valid Characters Checksum

1000 Code 3 of 9 1-75 0-9, A-Z, $,%,+,-,.,/,space No

1001 Code 3 of 9 Extended 1-66 ASCII 0-0x7F No

1010 UPC A 1-11 0-9 Yes

1020 UPC E 1-7 0-9 Yes

1021 UPC/EAN Add-On 2 or 5 0-9 Yes

1030 Code 128 Auto Select 1-79 ASCII 0-0x7F Yes

1031 Code 128 Set A 1-79 ASCII 0-0x7F Yes

1032 Code 128 Set B 1-79 ASCII 0-0x7F Yes

1033 Code 128 Set C 1-79 ASCII 0-0x7F Yes

1040 EAN 8 1-7 0-9 Yes

1050 EAN 13 1-12 0-9 Yes

1060 Interleaved 2 of 5 Mod 10 1-89 0-9 Yes

1061

1062 Interleaved 2 of 5 1-89 0-9 No

1070 GS1-128 1-79 ASCII 0x20-0x7F

1080 Codabar 1-60 0-9, A-D No

1090 UK Plessey 1-65 0-9, A-F No

1091 MSI Plessey Mod 10 1-55 0-9 Yes

Interleaved 2 of 5 Bearer

Bars

1-89 0-9 Yes

Yes

The leading AI value must be

placed in square brackets

and a trailing checksum must

be included.

1100 Code 93 1-107 ASCII 0x20-0x7F No

Thermal Printer Programmer’s Guide 20

Page 27

Programmer’s Guide | 1

Barcode ID Barcode Description Length Valid Characters Checksum

1110 HIBC Code 39 1-36 0-9, A-Z, $,%,+,-,.,/,space Yes

1111 HIBC Code 128 1-36 0-9, A-Z, $,%,+,-,.,/,space Yes

1120 Telepen 1-30 ASCII 0x20-0x7F Yes

1130 GS1 Databar (linear only) 1-13 0-9 Yes

1131 GS1 Databar Expanded

(linear only)

1500 Postnet 1-38 0-9 Yes

1510 Planet 1-38 0-9 Yes

1520 FIM 1 A-D No

1530 USPS Intelligent Mail

(OneCode)

2000 QR Code Auto 1-256 ASCII 0x20-0x7F Yes

2010 PDF 417 1-256 Full ASCII (0 – 0xFF) Yes

2020 Micro PDF 1-256 Full ASCII (0 – 0xFF) Yes

2030 Datamatrix 1-256 Full ASCII (0 – 0xFF) Yes

2040 UPS MaxiCode 1-138 Alphanumeric, ASCII 0x1E,

2050 Aztec 1-256 Full ASCII (0 – 0xFF) Yes

1-45 ASCII 0x20-0x7F Yes

20 0-9 Yes

Yes

0x1D,0x04,[,),>

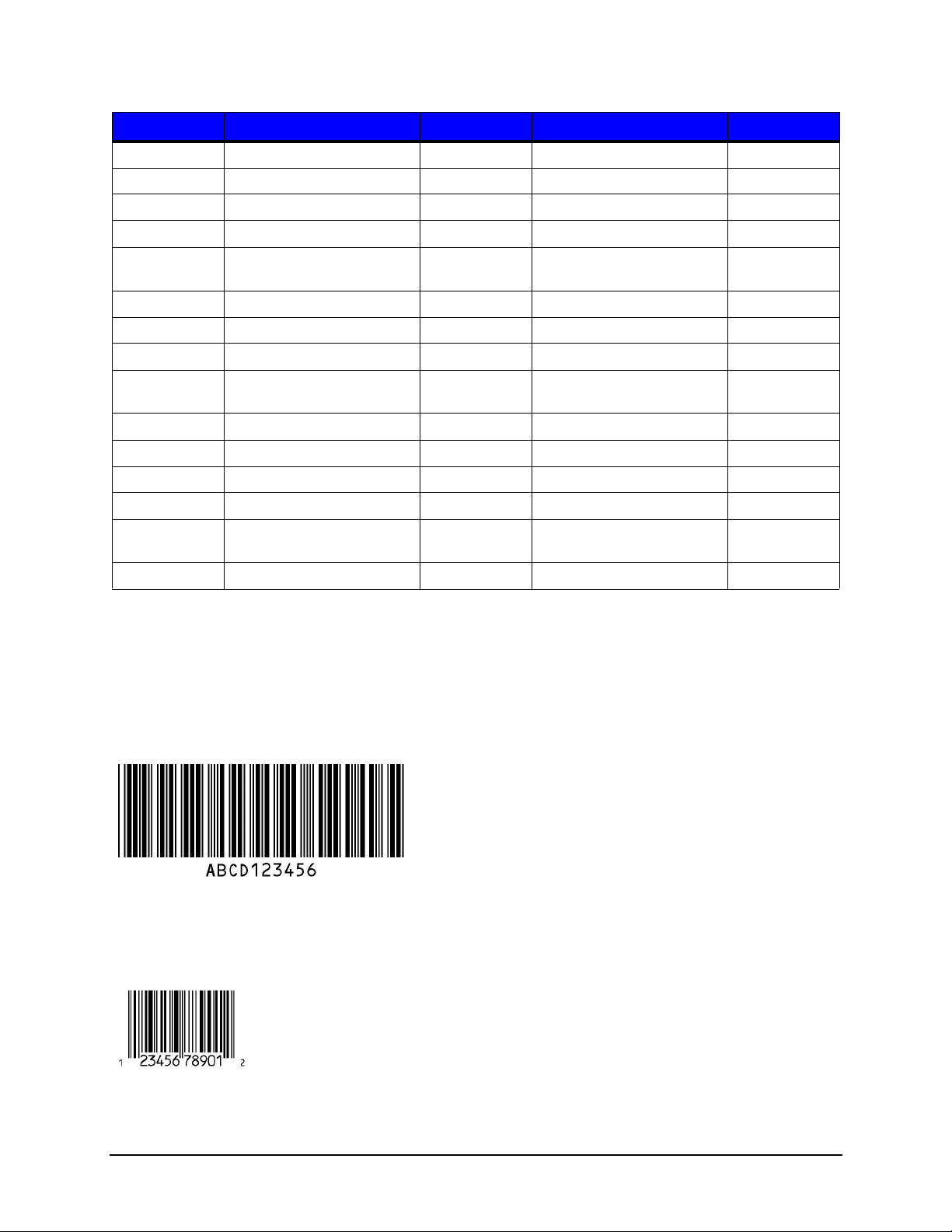

BarcodeSamples

The following sequence will print a code 3 of 9 barcode, height of 300 dots (includes

text), narrow bar width 4 dots and data “ABCD123456”.

<ESC>$b1000c300j4n10WABCD123456

The following sequence will print a UPC E barcode, human readable text, narrow bar

width 3 dots, 200 dots height and data “12345678901”

<ESC>$b1010c1a3n200j11W12345678901

21 Thermal Printer Programmer’s Guide

Page 28

1 | Programmer’s Guide

The following sequence will print a QR Code (Auto) barcode with error correction

capacity of 2, height 10 units, anchor position bottom left and data “This is a test, this is

only a test.”

<ESC>$b2000c2e10j0o36WThis is a test, this is only a test.

The following sequence will print a UPS Maxicode with anchor point top left, mode 2 structured carrier U.S. numeric. The first 15 primary characters represent a 9-digit

postcode (“328081234”), 3-digit country code (“840”) and 3-digit service code (“016”)

followed by standard secondary data.

<ESC>$b2040c3o2e102W328081234840016[)><RS>01<GS>961Z93400914<GS>UPSN<

GS>654321<GS>123<GS>SHIPPERNUM30<GS>1/1<GS>1<GS>N<GS>12345 MAIN

STREET ANYTOWN<GS>FL<RS><EOT>

Note : For UPS Maxicode modes 2 and 3 the primary data must be 15 characters long formatted as:

Characters Meaning

1-9 Postcode data which can consist of up to 9 digits (for mode 2) or

up to 6 alphanumeric characters (for mode 3). Remaining unused

characters should be filled with the SPACE character (ASCII 32).

10-12 Three digit country code according to ISO 3166.

13-15 Three digit service code. This depends on your parcel courier.

PJL (Printer Job Language) Commands

Standard PJL Commands

The following are standard PJL commands supported by Datamax-O'Neil thermal

printers with modifications listed below. Please refer to the HP PCL/PJL Technical

Reference Manual for more information on these commands.

Thermal Printer Programmer’s Guide 22

Page 29

Programmer’s Guide | 1

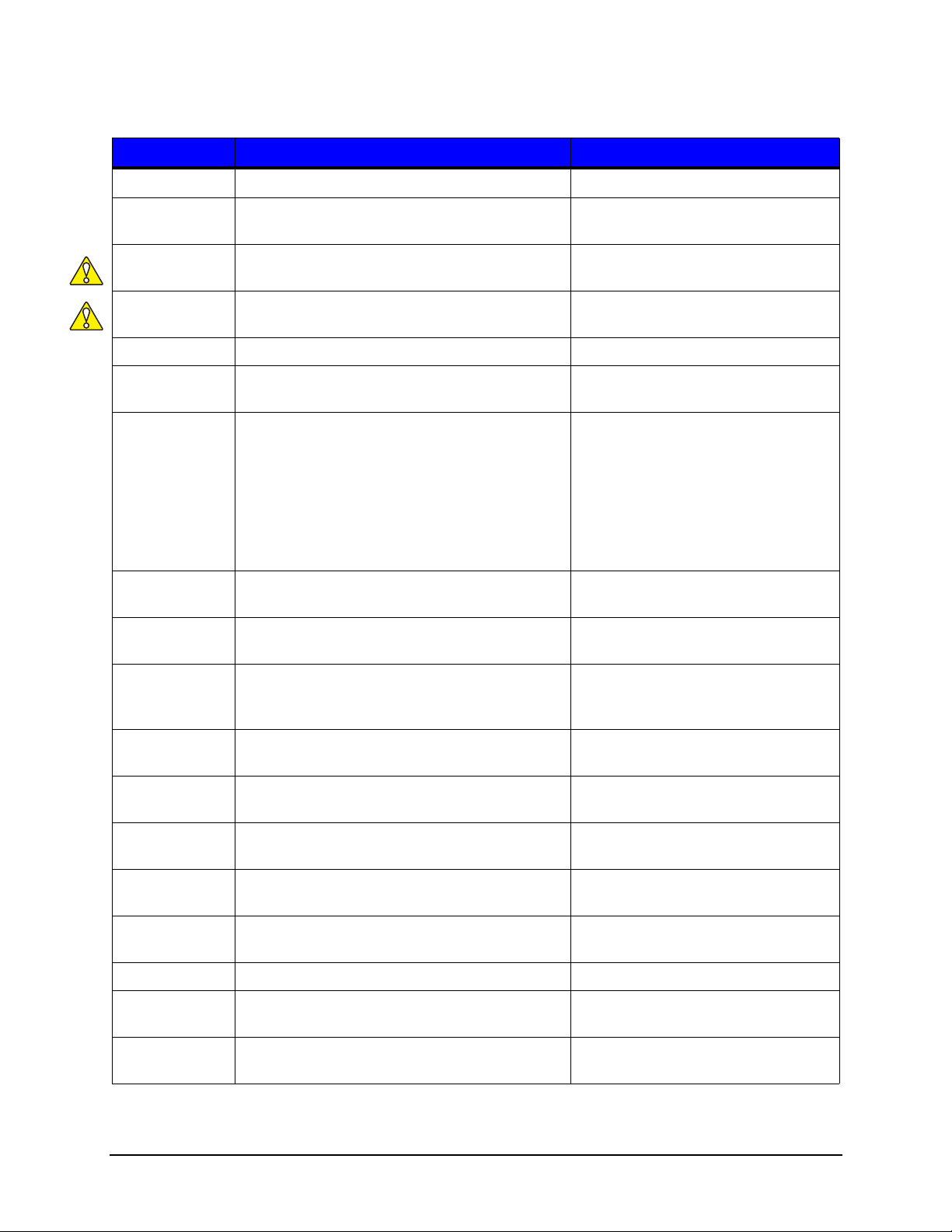

Table 9: PJL Commands

Command Description Modifications

1

FSDOWNLOAD

1

FSMKDIR

1

FSDELETE

1

FSINIT

Downloads a file to the printer file system Restrictions added (See below)

Creates the specified directory on the printer

Restrictions added (See below)

file system

Deletes files or empty directories from the

Restrictions added (See below)

printer file system

Initializes (formats) the mass storage system Clears user flash file system and

reboots (See below)

COMMENT Adds a line of information as comments

DINQUIRE Obtain the default value of a specified PJL

environment variable

DEFAULT Sets the user default environment value for the

specified environment variable. These values

are shown on front panel equipped printers.

This command should only be used with the

default configuration setting of the printer and

NOT with each print job. See the SET

command below for setting up a specific print

job.

ECHO Prompts the printer to return a specified

message to the host computer

ENTER Selected a printer language for processing the

current job

INITIALIZE Resets the PJL current environment and user

default environment variables to the factory

default values

INFO Requests a specified category of printer

information

INQUIRE Requests the current value for a specified PJL

environment variable

N/A

N/A

N/A

N/A

N/A

N/A

More categories added (See below)

N/A

RESET Resets current PJL variables to user default

values

SET Sets a current environment variable to a

Also writes flash if changes to user

default values

N/A

specified value for the duration of a PJL job

USTATUS Allows printer to send unsolicited status

N/A

messages

USTATUSOFF Turns off all unsolicited status

N/A

JOB Informs printer of the start of a print job Added additional security option (See

below)

EOJ Tells the printer the print job is complete Also writes flash if changes to user

default values

23 Thermal Printer Programmer’s Guide

Page 30

1 | Programmer’s Guide

Caution: Exercise caution when issuing these PJL Commands. They cannot be undone.

1

Use the PJL DISKLOCK variable to prevent unauthorized file system access. Refer to

the PJL Technical Reference document for more information.

PJL File System Commands

For the FSDOWNLOAD, FSMKDIR, and FSDELETE commands, the additional

parameter “TYPE” is used to restrict access to the user flash file system. Also, specific

extensions must be used on file names if they are to be accessed via front panel user file

functions. Sub folders will not be accessible from the front panel in these directories

therefore the NAME parameter should not contain directory paths. If using a filename

that already exists the new file will replace the older one.

The following is the syntax to download a file:

@PJL FSDOWNLOAD FORMAT:BINARY SIZE = nnn TYPE = n NAME = "0:filename.ext"

<LF>

Above, the size is the amount of data starting after the end of line.

Type and filename extension are as follows:

Table 10: Type and File Name Extensions

Type (n) - User File Location File Name

0 - User Labels (default) xxx.pcl

1 - User Setups xxx.stc

2 - User Media xxx.stm

3 - User Images xxx.png, xxx.jpg

4 - User Languages xxx.qm

5 - User Fonts xxx.ttf

User Font Download via PJL

To download a user font, it must be a True Type format and unbounded, meaning there

are more than 256 supported characters typically addressed via Unicode. It is the user’s

responsibility to obtain the appropriate licenses to use the fonts. There must be sufficient

space in the user flash section to download a font. Currently, there is a limit of ten (10)

downloaded fonts.

Use the PJL FSDOWNLOAD command to download a font to the printer. The syntax is

as follows:

@PJL FSDOWNLOAD FORMAT:BINARY SIZE=aaa TYPE=5

NAME=”0:FontName=bbb.ttf” <CR><LF>data…

Thermal Printer Programmer’s Guide 24

Page 31

Programmer’s Guide | 1

In this example, “aaa” is the binary size of the font to be downloaded. “FontName” is the

desired internal name of the font. The maximum length of “FontName” is 16 characters.

“bbbbb” is the desired typeface id (1-65535) used to access the font in PCL. ”data” is the

actual True Type font. Note the “TYPE” parameter must be 5 to download to the user

fonts directory in user flash. The filename should be in quotes with the leading 0: to

maintain the HP convention. The equals sign must be present as well as the lower case

ttf extension. The actual True Type font data immediately follows the <LF> terminator.

PJL FSDELETE Command

Use the PJL FSDELETE command to remove a file, command syntax is as follows:

@PJL FSDELETE TYPE=n NAME = “0:filename.ext” <LF>

PJL FSINIT Command

To format the user flash file system in case of corruption issue the following command:

<ESC>%-12345X@PJL JOB NAME = “JOB_INIT_USERFS” <LF>

@PJL FSINIT VOLUME = “0:” <LF>

@PJL EOJ <LF>

<ESC>%-12345X

This will erase the user flash system and reboot the printer. Upon restart, the empty file

system will be formatted, necessary default files copied internally, and the printer will be

reset to factory defaults. Note that the following will be deleted permanently from the

printer:

• Wired, wireless and serial communication settings

• SNMP settings

• Time zone setting

• Touch screen calibration

• Internal user setup files

• Internal user labels

• Internal user languages files (except English)

• Internal media setup files

• Downloaded fonts

After reset, the touchscreen calibration procedure will appear on the display. In addition,

the services for web pages, SSH, NTP, SNMP will revert to defaults.

25 Thermal Printer Programmer’s Guide

Page 32

1 | Programmer’s Guide

PJL INFO Read-Back Command

This command is used to read back printer information. In addiction to standard

parameters the following table are also available, where:

<ESC>%-12345X@PJL INFO xxx <LF>

@PJL EOJ <LF>

<ESC>%-12345X

“xxx” is the desired parameter as noted below:

Table 11: PJL INFO Read-Back Command Parameters

Parameter Description

DATETIME

SENSORS Returns value of system sensors.

SYSTEMSTATUS Returns system status

SYSTEMINFO Returns system info.

MEDIAFILES Returns list of internal media setup files.

SETUPFILES Returns list of internal user setup files.

LABELFILES Returns list of internal user labels files.

LANGUAGEFILES Returns list of language files.

FONTFILES Returns list of user font files.

RESIDENTFONTS Returns list of resident and downloaded fonts.

IMAGE FILES Returns list of internal images

Returns the date and time from the printer.

The following is a sample DATETIME response:

@PJL INFO DATETIME

Wed Jan 4 10:53:44 EST 2012

The following is a sample SENSORS response:

@PJL INFO SENSORS

HEADTEMP=265;

MOTORTEMP=135;

HEADVOLTAGE=271;

HEADPRESSURE=7;

RIBBONLEVEL=0;

REWINDERLEVEL=0;

HEADUP=0;

HEADUNLATCHED=0;

PRESENTSENSOR=0;

CUTTERHOME=0;

COVEROPEN=1;

HEADTEMPADC=226;

Thermal Printer Programmer’s Guide 26

Page 33

MOTORTEMPADC=215;

HEADVOLTAGEADC=211;

TOFADC=190;

PAPERLOWADC=137;

AUTOLOADADC=213;

HEADPRESSUREDECODE=2;

PAPERWIDTHDECODE=3;

PAPERWIDTHSECTIONS=6;

REWINDERCTR=0;

The following is sample SYSTEMSTATUS response:

@PJL INFO SYSTEMSTATUS

ENGINE=IDLE;

WARNING=NONE;

ERROR=NONE;

LASTSYSWARNING=0;

LASTSYSERROR=0;

ERRORCOUNT=0;

LASTLABELCOUNT=0;

LASTLABELCOPIES=0;

SESSIONLABELS=0;

EQUIPPED=0;

Programmer’s Guide | 1

The following is a sample SYSTEMINFO response:

@PJL INFO SYSTEMINFO

PRINTERMODEL=p1120n;

PRINTHEADMODEL=G5199;

SOFTWAREVERSION=12.01.04y;

FIRMWAREVERSION=0x5021;

RIBBONVERSION=0xD;

BOOTVERSION=BL12.01.03x;

BOARDID=104584-002E;

RAMSIZE=64 MB;

FLASHSIZE=32 MB;

SECURITYKEY=0x00005AC2;

PRINTERODOMETER=17162;

PRINTHEADODOMETER=4210;

DETECTEDOPTIONS= REWINDER RIBBONCONTROLLER GPIO USBHOST

AUDIOALARM;

The following is a sample MEDIAFILES response:

@PJL INFO MEDIAFILES

File1.stm

File2.stm

File3.stm

File4.stm

The following is a sample SETUPFILES response:

27 Thermal Printer Programmer’s Guide

Page 34

1 | Programmer’s Guide

@PJL INFO SETUPFILES

File1.stc

File2.stc

File3.stc

File4.stc

The PJL INFO RESIDENTFONTS command will return the list of resident fonts, the font

number and a PCL sample sequence. There are place holders for the ten allowed

download fonts named “Downloaded Font0”, “Downloaded Font1”, “Downloaded Font2”,

etc. These names will be replaced with the downloaded font name starting from Font 0.

Refer to the example below:

0, “CG Times “,”<ESC>(s1p__v0s0b4101T";

1,"CG Times It","<Esc>(s1p__v1s0b4101T";

2,"CG Times Bd","<Esc>(s1p__v0s3b4101T";

3,"CG Times BdIt","<Esc>(s1p__v1s3b4101T";

4,"Univers Md","<Esc>(s1p__v0s0b4148T";

(...)

51,"CG Triumv BdCd","<Esc>(s1p__v0s0b26714T";

52,"MyFont1 ","<Esc>(s1p__v0s0b9998T";

53,"MyFont2 ","<Esc>(s1p__v0s0b9999T";

54,"Downloaded Font2","<Esc>(s1p__v0s0b0T";

55,"Downloaded Font3","<Esc>(s1p__v0s0b0T";

PJL JOB Command

The parameter “SECURITY” is used to allow changes to defaults for printer specific

items such as adjustments and media calibration values. The value of the SECURITY

parameter must match the printer’s security key to take effect.

The following is a sample command:

<ESC>%-12345X@PJL JOB SECURITY = “0x00005AC2” <LF>

@PJL DEFAULT HEADPRESSUREADJ = 5 <LF>

@PJL EOJ <LF>

The parameter “MODEL” can be used to ensure a model match when sending a file. The value is the printer

model name in quotes, such as “p1125”. If the values do not match then a Model Mismatch warning will be displayed.

PJL PERFORM Command

The custom PJL PERFORM command is used for various functions on the printer. PJL

password security in the JOB command is used to protect against unauthorized use of

this command. Please refer to the HP PCL/PJL Technical Reference Manual for more

information on PJL security. These commands will perform an immediate action when

received and should not be part of a PCL data stream. It is recommended to send one

command at a time.

Thermal Printer Programmer’s Guide 28

Page 35

The syntax of the command is as follows:

<ESC>%-12345X@PJL JOB NAME = "JOB_NAME" <LF>

@PJL PERFORM PARAMETER [= value] <LF>

@PJL EOJ <LF>

The value is optional as noted below:

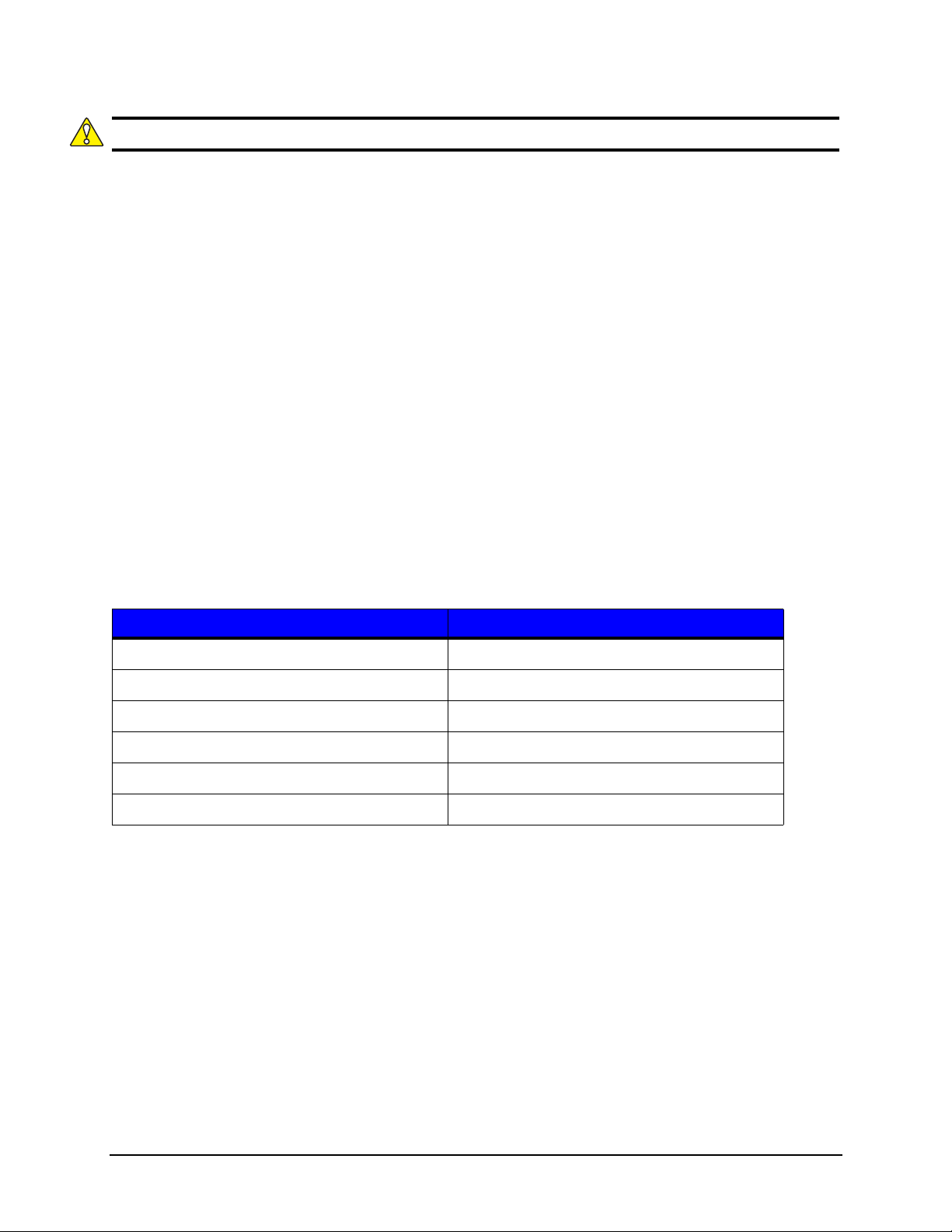

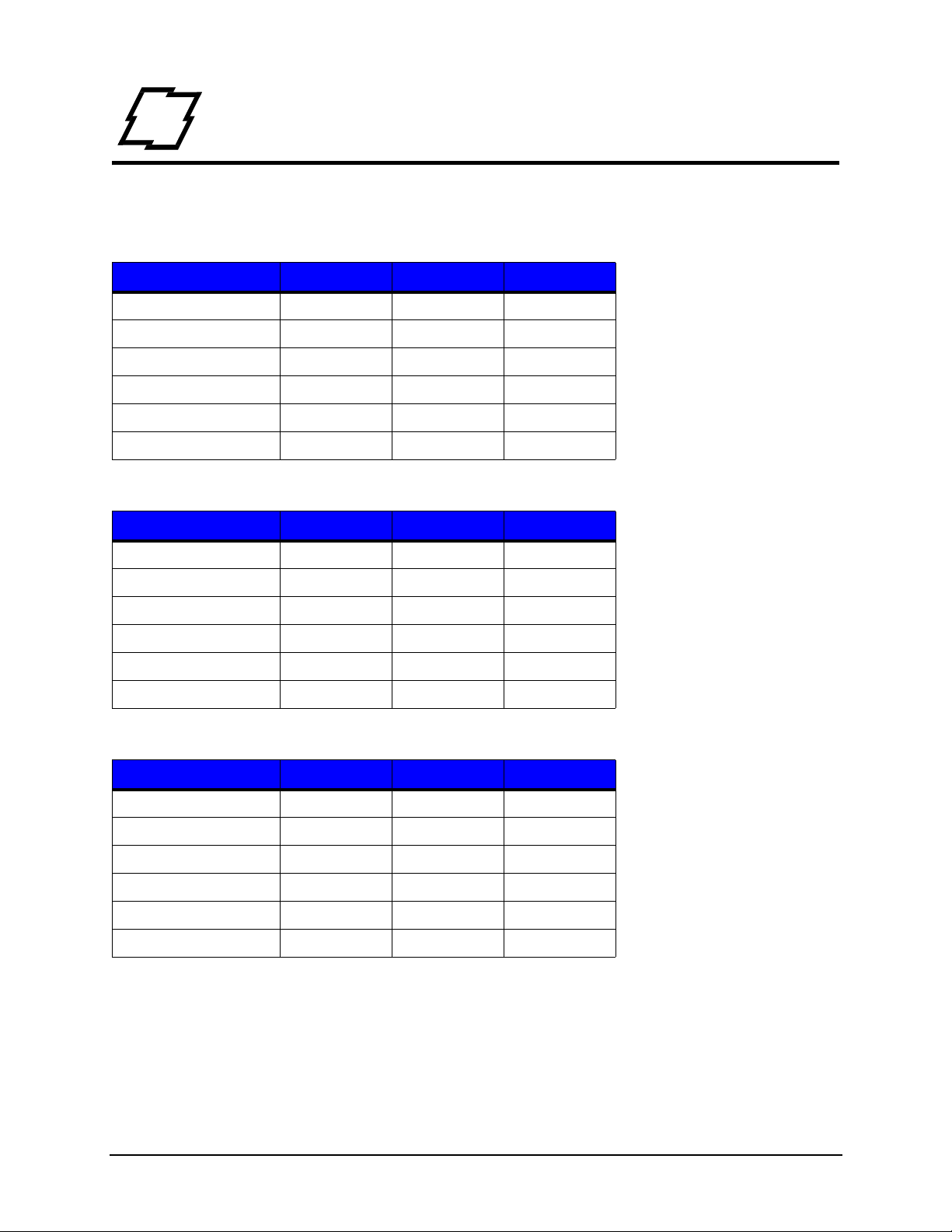

Table 12: PJL PERFORM Command

Parameter Description Value Notes

Programmer’s Guide | 1

DOTCHECK Performs a dotcheck

diagnostic on the print

head

EMPTYCAL Performs empty

calibration.

ABORTALL Abort all current functions N/A

CAL Performs paper calibration Distance in dots to

FEED Feeds media to next Top-

of-Form

STOP Pause engine

HEADCLEAN Performs head clean

RESUME Un-pauses engine

MOVE Moves media a certain

distance

CUT Engage cutter Number of cut cycles

RIBBONFRONT Performs test of front

(take-up) ribbon spindle

assembly

Number of dots to

check. 0 for all

N/A Media should be

move

N/A

N/A

N/A

N/A

Distance in dots to

move

N/A

removed prior to issue

Media should be

loaded prior to issue

Must be in head clean

mode (See below)

Must be in self test

mode (See below)

RIBBONBACK Performs test of back

(supply) ribbon spindle

assembly

REWIND Performs test of rewinder

assembly

SELFTEST Initialize self-test mode 0 for disable, 1 for

HEADCLEANMODE Initialize head clean mode 0 for disable, 1 for

GPIOSELFTEST Performs GPIO wrap test

GPIOWRITE Test of GPIO input pins Integer representing

N/A

N/A

enable, 2 for reset

counters

enable

N/A

on/off state of output

pins

29 Thermal Printer Programmer’s Guide

Must be in self test

mode (See below)

Must be in self test

mode (See below)

Must be in self test

mode (See below)

Page 36

1 | Programmer’s Guide

Parameter Description Value Notes

GPIOREAD Test of GPIO output pins

PRINTSETTINGS Print the settings report

PRINTINFO Print system info report

PRINTNETWORK Print network report

PRINTSERIAL Print serial report

PRINTGPIO Print Applicator (GPIO)

N/A

N/A

N/A

N/A

N/A

N/A

report

PRINTFONTS Print fonts report

N/A

PRINT10 Print internal 10% pattern Quantity to print

PRINT20 Print internal 20% pattern Quantity to print

PRINT50 Print internal 50% pattern Quantity to print

PRINTQL Print internal quality label Quantity to print

SETDATETIME Set data and time String “HHHH-MM-DD

hh:mm:ss”

SETTIMEZONE Set time zone String, i.e. “EST+5” for

Eastern Standard

Time

Must be in self test

mode (See below)

PRINTSYSREPORT Print abbreviated system

N/A

Workstation Series only

report

REBOOT Restart printer N/A

PRINTFILE Print user label “filename.pcl”

File must be in User

Labels. This typically has

a .pcl extension.

PJL Head Cleaning Procedure/Command

Prior to performing print head cleaning the head clean mode must be entered as follows:

<ESC>%-12345X@PJL JOB NAME = "JOB_CLEAN_INIT" <LF>

@PJL PERFORM HEADCLEANMODE = 1 <LF>

@PJL EOJ <LF>

The media should then be removed and a special cleaning card inserted. Issue the

PERFORM HEADCLEAN command:

<ESC>%-12345X@PJL JOB NAME = "JOB_CLEAN" <LF>

@PJL PERFORM HEADCLEAN <LF>

@PJL EOJ <LF>

When the cleaning is complete disable the head clean mode:

Thermal Printer Programmer’s Guide 30

Page 37

Programmer’s Guide | 1

<ESC>%-12345X@PJL JOB NAME = "JOB_CLEAN_END" <LF>

@PJL PERFORM HEADCLEANMODE = 0 <LF>

@PJL EOJ <LF>

PJL Cutter, Rewinder, and Ribbon Assembly Self-Test Commands

Prior to performing self test procedures for options, the self test mode must be entered

as the following:

<ESC>%-12345X@PJL JOB NAME = "JOB_SELFTEST_INIT" <LF>

@PJL PERFORM SELFTEST = 1 <LF>

@PJL EOJ <LF>

For rewinder or ribbon assembly tests the media should be detached from the

mechanism. To perform the rewinder test, issue the following:

<ESC>%-12345X@PJL JOB NAME = "JOB_REWIND_TEST" <LF>

@PJL PERFORM REWIND <LF>

@PJL EOJ <LF>

Ribbon front and back assemblies can be tested using the PERFORM RIBBONFRONT

or RIBBONBACK commands, respectively.

For testing the cutter, insert a value for the number of cuts as seen below.

<ESC>%-12345X@PJL JOB NAME = "JOB_REWIND_TEST" <LF>

@PJL PERFORM CUT = n <LF>

@PJL EOJ <LF>

“n” is the number of cut cycles to perform.

View test results by using the PJL INFO SYSTEMSTATUS read-back command. The

value LASTLBLCNT is the total cycles requested and ERRORCOUNT is the number that

failed.

The PERFORM ABORTALL command is used to cancel ongoing tests. To re-test and

clear counters issue PERFORM SELFTEST = 2

When the self tests are complete the command below can be used to disable the self test

mode:

<ESC>%-12345X@PJL JOB NAME = "JOB_SELFTEST_END" <LF>

@PJL PERFORM SELFTEST = 0 <LF>

@PJL EOJ <LF>

PJL GPIO Self Test

Prior to performing self test procedures for GPIO the self test mode must be entered as

follows:

31 Thermal Printer Programmer’s Guide

Page 38

1 | Programmer’s Guide

<ESC>%-12345X@PJL JOB NAME = "JOB_SELFTEST_INIT" <LF>

@PJL PERFORM SELFTEST = 1 <LF>

@PJL EOJ <LF>

When the self tests are complete the following command is used to disable the self test

mode:

<ESC>%-12345X@PJL JOB NAME = "JOB_SELFTEST_END" <LF>

@PJL PERFORM SELFTEST = 0 <LF>

@PJL EOJ <LF>

PJL GPIO Wrap Test

To run the GPIO wrap test, either the wrap connector or the GPIO test board with wrap

jumper should be connected to the printer and the following command should be issued:

<ESC>%-12345X@PJL JOB NAME = "JOB_GPIOWRAP_TEST" <LF>

@PJL PERFORM GPIOSELFTEST <LF>

@PJL EOJ <LF>

The PJL INFO SYSTEMSTATUS read back command is used to view test results. The

value LASTLBLCNT refers to the total cycles requested and ERRORCOUNT refers to

the number failed.

PJL GPIO Read Test

Prior to performing the GPIO read test, the GPIO parameters in the database should be

set accordingly using the either front panel, the PJL variables or other means. The signal

function for all pins should be “None”. The signal type for all pins should be set to “High”.

The I/O configuration should be set with an integer representing a bitwise value where

first bit is pin 1, the second bit is pin 2, etc. One is an input pin and zero is an output pin.

Bits 8 – 15 are fixed at 1. For instance if pins 1-4 are input and pins 5-8 are output this

value is 65295 (1111111100001111).

Note: Pins are coupled 1/2, 3/4, 5/6, 7/8.

To start the test, enter the following command:

<ESC>%-12345X@PJL JOB NAME = "JOB_GPIOREAD_TEST" <LF>

@PJL PERFORM GPIOREAD <LF>

@PJL EOJ <LF>

While the test is running, check the ERRORCOUNT value from the PJL INFO

SYSTEMSTATUS read back command to view the GPIO read status. Use bitwise

operand AND of this value against 0x01 for pin1, 0x02 for pin 2, 0x04 for pin 3, etc. If the

result is true then it is considered a high signal. If the result is false, it is considered a low

signal.

Note: This is only for input pins. Output pins are a “do not care”.

Thermal Printer Programmer’s Guide 32

Page 39

Programmer’s Guide | 1

PJL GPIO Write Test

Prior to performing the GPIO write test, the GPIO parameters in the database should be

set using either the front panel, PJL variables or by other means. The signal function for

all pins should be “None”. The signal type for all pins should be “High”. For pulse mode,

the “High Pulse” value should be used for output pins. The I/O configuration should be

set with an integer representing a bitwise value where first bit is pin 1, the second bit is

pin 2, etc. One is an input pin and zero is an output pin. Bits 8 – 15 are fixed at 1. For

example, if pins 1-4 are input and pins 5-8 are output, then the resulting value would be

65295 (1111111100001111).

Note: Pins are coupled 1/2, 3/4, 5/6, 7/8.

To start the test, enter the following command:

<ESC>%-12345X@PJL JOB NAME = "JOB_GPIOWRITE_TEST" <LF>

@PJL PERFORM GPIOWRITE = n <LF>

@PJL EOJ <LF>

Where “n” is an integer representing a bitwise value and when the first bit is pin 1, the

second bit will be pin2, etc. One is ON state and zero is OFF state. Only output pins are

used.

For example, if pins 1-4 are output ON and pins 5-8 are input then the resulting value

would be 15 (00001111).

Note: Pins are coupled 1/2, 3/4, 5/6, 7/8.

PJL CONFIG PRINTFILE

To print an internal user label file, issue the following command:

<ESC>%-12345X@PJL JOB NAME = "JOB_NAME" <LF>

@PJL PERFORM PRINTFILE = “0:filename.pcl” <LF>

@PJL EOJ <LF>

Note: The extension.pcl must be used in order to see the file listed under the internal

user label files on front panel-equipped printers.

PJL CONFIG Command

The custom PJL CONFIG command is used with various functions for printer

configurations. PJL password security in the JOB command protects against

unauthorized use of this command. Please refer to the HP PCL/PJL Technical Reference

Manual for more information on PJL security. These commands will perform an

immediate action when received and should not be part of a PCL print data stream.

The syntax of the command is as follows:

33 Thermal Printer Programmer’s Guide

Page 40

1 | Programmer’s Guide

<ESC>%-12345X@PJL JOB NAME = "JOB_NAME" <LF>

@PJL PERFORM CONFIG [= value] <LF>

@PJL EOJ <LF>

The value is optional as noted below.

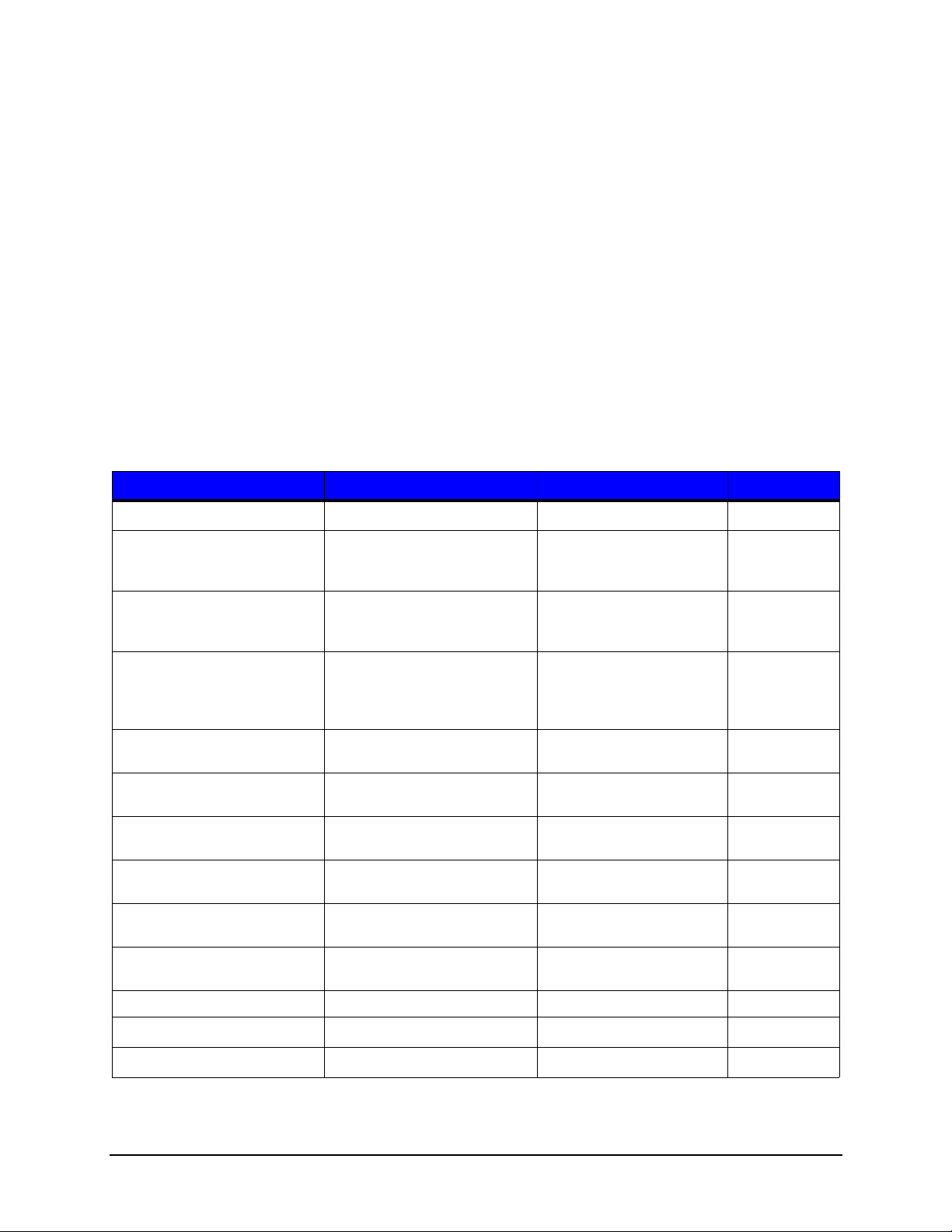

Table 13: PJL CONFIG Command

Parameter Description Value Notes

SAVEMEDIA

SAVESETUP Saves current setup settings

LOADMEDIA Loads a media configuration

LOADSETUP Loads a user setup

LOADLANGUAGE Loads a user language file

Saves current media settings

to internal media setups

to internal user setups

from internal media

configuration from internal

user setups

from internal user flash

“0:filename.stm” See below

“0:filename.stc” See below

“filename.stm” See below

“filename.stc” See below

“filename.qm” Will restart front panel

application

Saving and Loading Configuration

To capture the current printer settings to a user setup file, enter the following command:

<ESC>%-12345X@PJL JOB NAME = "JOB_NAME" <LF>

@PJL CONFIG SAVESETUP = “0:filename.stc” <LF>

@PJL EOJ <LF>

To restore the file, enter the following:

<ESC>%-12345X@PJL JOB NAME = "JOB_NAME" <LF>

@PJL CONFIG LOADSETUP = “filename.stc” <LF>

@PJL EOJ <LF>

Note: The extension, .stc must be used in order to see the file listed under the internal

user setup files on front panel equipped printers. Media setup files are performed as

similarly to the example above but using the SAVEMEDIA and LOADMEDIA CONFIG

parameters with file extension .stm instead.

PJL UPGRADE Command

The custom PJL UPGRADE command is used for printer software upgrades. PJL

password security in the JOB command protects against unauthorized use of this

command. Please refer to the HP PCL/PJL Technical Reference Manual for more

information about PJL security. The software package file with name

“SW[modelname]_SW[revision].bin” should be placed on a TFTP server. Afterward, the

following PJL command should be entered:

Thermal Printer Programmer’s Guide 34

Page 41

Programmer’s Guide | 1

<ESC>%-12345X@PJL JOB NAME = "JOB_UPGRADE" <LF>

@PJL UPGRADE SERVERIP = “xxx.xxx.xxx.xxx” FILENAME = “SW…bin” <LF>

@PJL EOJ<LF>

<ESC>%-12345X

SERVERIP is the IP address of the TFTP server and FILENAME is the software package

name.

PJL Variables

The PJL variables supported by the printer include some standard as well as custom

variables. The DEFAULT command allows the user to set a variable permanently,

however this should never appear in a configuration header for a PCL print job. Only a

few select parameters can use the SET command in a PCL print job. To see all PJL

variables use the PJL Info Variables command.

Table 14: PJL Variables

Variable Description Range Default

6, 7

HEAT

HEATBALANCE

HEADPRESSURE

PAPERSENSORTYPE

PAPERSENSORSIDE

RIBBON

RIBBONLOWDIAMETER The diameter at which a ribbon

RIBBONTENSIONF

RIBBONTENSIONR

REWINDTENSION

SETUPFILE Last loaded setup N/A “”

PAPERID

RIBBONID

6

6, 7

6

6

6

6

6

6

6

6

Controls the heat energy 1 – 30 4

Controls the energy of the

leading edges of the printed

image

Adjusts the printer head

pressure to enhance the quality

of print

Specifies the type of mark used

to indicate the top of a label.

NONE implies continuous.

Specifies which media sensor to

use

Specifies thermal transfer (TT)

or direct thermal (DT)

low warning will be triggered

This sets tension of the front

ribbon motor

This sets tension of the rear

ribbon motor

This sets tension of the rewinder

motor

Paper ID code N/A "X640"

Ribbon ID code N/A "Y520"

1 – 10 7

1 - 10 7

NONE, GAP,

MARKTOPSIDE,

MARKUNDERSIDE,

NOTCH

INSIDE, OUTSIDE OUTSIDE

NONE, INSIDE, OUTSIDE INSIDE

100 - 2000 (1/1000") 1380

1 - 30 20

1 - 20 15

1 - 20 11

GAP

35 Thermal Printer Programmer’s Guide

Page 42

1 | Programmer’s Guide

Variable Description Range Default

KEYPROMPT Informs the user interface to

OFF, ON OFF

prompt the user for the next

label

PAUSEMODE Same as KEYPROMPT OFF, ON OFF

CUTTER

7

When a cutter is installed, this

OFF, ON, PERLABEL OFF

controls the cutting action for the

media

CUTBYCOUNT

10

The number of labels to print

0-32767 1

before cutting

REWINDER When the rewinder is installed,

this controls the operation and

OFF, CLOCKWISE,

COUNTERCLOCKWISE

OFF

direction of the powered internal

label rewinder

PRESENTSENSOR This controls the "on-demand"

OFF, ON OFF

dispensing of labels

ERRORBUZZER Used to select the buzzer sound

for an error

WARNINGBUZZER Used to select the buzzer sound

for a warning

PRINTSPEED

6, 7, 9

Sets the print speed of the

DISABLE, SOUND1,

DISABLE

SOUND2

DISABLE, SOUND1,

DISABLE

SOUND2

20 – 80 (1/10 IPS) 60

printer

FEEDSPEED

9

Sets the feed speed of the

0 – 120 (1/10 IPS) 0 (auto)

printer

REVERSESPEED

9

Sets the speed at which the

0 – 50 (1/10 IPS) 0 (auto)

label will be retracted into the

printer

RETRACTTIMEOUT The length of time before the

0 – 1000 (sec) 0

presented label is retracted to

the next top of label

RETRACTDELAY The length of time before the

10 – 1000 (ms) 70

label is retracted at the next top

of label after

the label has been

removed

LABELPRESENTDIST The distance, beyond the

0 - 2880 (decipoints) 0 (auto)

bottom edge of the label, that

the label will be presented to the

user for removal. This is

measured in decipoints.

PAPERLOWWARNING Show paper low warning OFF, ON OFF

PAPEROUTWARNING Show paper out warning OFF, ON ON

COVEROPENWARNING Show cover open warning OFF, ON ON

AUTOLOAD Sensors will trigger the

OFF, ON ON

automatic load process when

paper is detected

AUTOOPTIONDETECT Controls the hardware

OFF, ON ON

automatic detection

Thermal Printer Programmer’s Guide 36

Page 43

Programmer’s Guide | 1

Variable Description Range Default

AUTOCALIBRATE Automatically calibrates the

paper out sensors after loading

the paper

AUTOPRESENTDIST Enables the automatic setting of

the present distance

AUTOTENSION

6

Enables the automatic setting of

tension

AUTOPRESSURE

6

Enables the automatic setting of

pressure

AUTOMEDIAGLOBAL

6

Enables the automatic setting of

media parameters

AUTOSPEEDADJUST Enables the automatic speed

adjust

PAPERLENGTH

7

Sets the print length of the label

in decipoints (1/720th of an inch)

PAPERWIDTH

7, 8, 11

Sets the print width of the label

in decipoints (1/720th of an inch)

HORIZONTALOFFSET

7

Shifts the print area of the

logical page to the left or right on

the physical page in decipoints

VERTICALOFFSET

7

Shifts the print area of the

logical page up or down on the

physical page in decipoints

ORIENTATION

7

Controls the orientation of the

logical page on the physical

page

RASTERMODE

7

This controls how overlapping

images are placed on the paper

FONTNUMBER

1

This is the typeface number the

printer uses if none is specified

in the command stream

PITCH

1

This specifies the default

character pitch in characters per

inch. The default font must be a

fixed pitch font.

PTSIZE

1

This specifies the default point

size of the default font. The

default font must be scalable for

this to be effective.

SYMSET

1

This specifies the default

symbol set. The symbol set

must be resident in the printer.

PRINTTRUNCATION

7

This clips the print image at the

MARK or GAP. If the

PAPERTOFTYPE is "NONE"

then clip at PAPERLENGTH.

OFF, ON ON

OFF, ON ON

OFF, ON ON

OFF, ON ON

OFF, ON ON

OFF, ON ON

72 - 71280 (decipoints) 2880

72 - 3074 (decipoints) 2880

0 - 2800 (decipoints) 0

0 - 7200 (decipoints) 0

PORTRAIT, LANDSCAPE,

PORTRAIT

RPORTRAIT,

RLANDSCAPE

TRANSPARENT,

OPAQUE

TRANSPAREN

T

0 – 62 23

0.44 - 99.99 10.00

4.00 - 999.75 12.00

PJL sym set name3 PC8

OFF, ON ON

37 Thermal Printer Programmer’s Guide

Page 44

1 | Programmer’s Guide

Variable Description Range Default

PRINTONGAP Sets the printer to print on gap/

OFF, ON OFF

mark or not

DARKNESS

7

This allows for the adjustment of

± 20 0