Page 1

Page 2

Page 3

1 Safety

Warnings and Cautions

The following Warnings and Cautions are used throughout this manual:

Warning: Warnings alert you to possible safety risks.

Caution: Cautions alert you to the potential for equipment damage.

General Safety Information

Caution: This product is intended for indoor use only.

All service procedures should be done by properly trained and qualified service

personnel.

When operating, the product must be connected to a properly grounded and

appropriately rated AC receptacle using the supplied cord set.

Caution: This product contains sensitive electronic components that could be damaged

if exposed to excessive force.

Caution: Use only factory-approved consumables and cleaning kits. Use of any non-

approved supplies could damage the product and void the warranty.

Figure: 1 - 1 Caution - Hot

The printhead heats during printing. Do not touch.

1 Internal Rewinder Installation Guide

Page 4

1 | Safety

Internal Rewinder Installation Guide 2

Page 5

2 Internal Rewind Installation Guide

Tools Needed

• 2.5mm Hex Head Wrench

• 3mm Hex Head Wrench

• 5mm Hex Head Wrench

• 3mm Nut Driver

• 7mm Nut Driver

• #2 Phillips Screwdriver

• Small Flat Blade Screwdriver

Safety Overview

Caution: ESD protection is required when performing these steps.

Warning: The cover set may only be removed by a Datamax-O’Neil Authorized Service

Center. Unauthorized service will void the manufacturer’s warranty.

Warning: The printer must be powered off and disconnected from utility power prior to

performing these procedures. Failure to heed this warning may result in personal injury

or damage to internal components.

• Maintain complete ESD protection in a safe, clean environment at all times while

servicing this equipment.

• When handling the printhead, grasp it by its edges.

• Avoid contact between the printhead and clothing.

• Never pull on any wires to disconnect connectors. This can void the manufacturer’s warranty.

3 Internal Rewinder Installation Guide

Page 6

2 | Internal Rewind Installation Guide

Internal Rewinder Installation Procedure

Note: Retain all hardware for reassembly.

1. Open the media cover assembly.

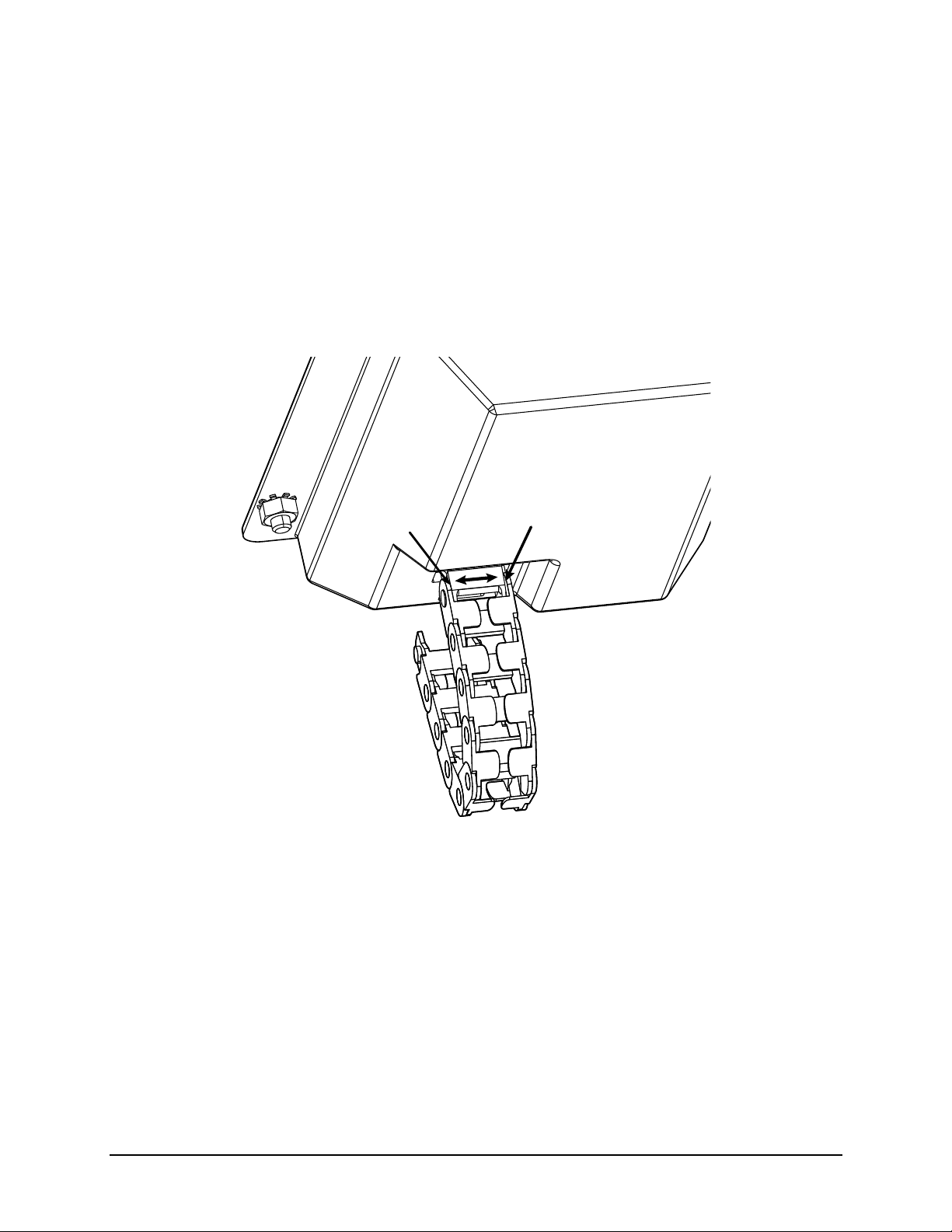

2. If the present sensor option is installed on the cover, gently pry the sides of the

cable chain outward to disconnect it from the present sensor cable connection

cover.

Note: If there is no present sensor mounted on the media cover, continue to step 5.

Figure: 2 - 1 Cable Chain Disconnect

Note: To clarify the illustration above, the cable chain is shown disconnected from the

printer chassis backbone.

Internal Rewinder Installation Guide 4

Page 7

Internal Rewind Installation Guide | 2

3. Remove all four 7mm nuts securing the present sensor cable connection cover to

the media cover.

Figure: 2 - 2 PCB Cover

4. Disconnect the present sensor cable connector and route the connector (male) out

of the opening.

5. Loosen all three (3) 2.5mm hex head screws from the upper cover mount.

Note: For an easier re-installation, loosen but do not remove the screws.

Figure: 2 - 3 Upper Screws

5 Internal Rewinder Installation Guide

Page 8

2 | Internal Rewind Installation Guide

6. Loosen and remove the three (3) 2.5mm hex head screws securing the right side

cover to the printer chassis.

Figure: 2 - 4 Right Side Screws

7. Lift and remove the cover assembly from the printer chassis.

Caution: Exercise caution when removing the cover set assembly and secure it in a safe

position where it will not be damaged.

Figure: 2 - 5 Lift Cover Assembly

Internal Rewinder Installation Guide 6

Page 9

8. Remove the frame plug from the side of the printer.

Figure: 2 - 6 Frame Plug

Internal Rewind Installation Guide | 2

9. Connect cable 105048 to the media rewinder assembly.

7 Internal Rewinder Installation Guide

Page 10

2 | Internal Rewind Installation Guide

10.Secure the media rewinder assembly to the printer frame by installing the three (3)

socket head screws included with the kit.

Figure: 2 - 7 Media Rewinder Assembly

Caution: Ensure the cables are not damaged during the installation.

11. Connect the other end of cable 105048 to junction J12 of the main PCB assembly

and route the cable so that it is free from all moving parts.

Internal Rewinder Installation Guide 8

Page 11

Internal Rewind Installation Guide | 2

12.Insert the media rewind hub through the printer frame and through the media

rewinder assembly bearing.

Figure: 2 - 8 Media Rewind Hub

9 Internal Rewinder Installation Guide

Page 12

2 | Internal Rewind Installation Guide

13.Install the supplied helical gear to the media rewind hub and secure it with the

provided e-clip.

Figure: 2 - 9 Helical Gear

Internal Rewinder Installation Guide 10

Page 13

Internal Rewind Installation Guide | 2

14.Place the rewinder assembly cover over the rewinder and secure it with the

included screws.

Figure: 2 - 10 Rewinder Cover

15.Remove the roller cover panel.

Figure: 2 - 11 Roller Cover Panel

11 Internal Rewinder Installation Guide

Page 14

2 | Internal Rewind Installation Guide

16.Insert a small, flat-blade screwdriver into the release opening, gently pry it to the left

and remove the latch handle.

Figure: 2 - 12 Latch Handle

Figure: 2 - 13 Latch Handle

Internal Rewinder Installation Guide 12

Page 15

Internal Rewind Installation Guide | 2

17.Loosen and remove the screw securing the platen cover to the platen carriage and

remove the platen cover.

Figure: 2 - 14 Platen Cover

13 Internal Rewinder Installation Guide

Page 16

2 | Internal Rewind Installation Guide

18.Insert the lower platen roller assembly through the opening in the printer chassis

and route it through the print mechanism.

Figure: 2 - 15 Platen Roller Assembly

Internal Rewinder Installation Guide 14

Page 17

19.Install the flanged bearing and secure it with the e-clip.

Figure: 2 - 16 Flanged Bearing and E-Clip

Internal Rewind Installation Guide | 2

15 Internal Rewinder Installation Guide

Page 18

2 | Internal Rewind Installation Guide

20.If applicable, loosen and remove the thumbscrew securing the tear plate to the print

mechanism and remove the tear plate.

Figure: 2 - 17 Tear Plate

21.Install either the media rewind bracket or the peel plate.

22.Reinstall all other printer components in the reverse order as they were removed.

Internal Rewinder Installation Guide 16

Loading...

Loading...