Page 1

Page 2

Page 3

Copyright Information

CG Triumvirate is a trademark of Agfa Corporation.

CG Times based upon Times New Roman under license from the Monotype Corporation.

Windows is a registered trademark of the Microsoft Corporation.

All other brand and product names are trademarks, service marks, registered trademarks, or registered service marks

of their respective companies.

Limitation of Liability

In no event shall Datamax-O'Neil be liable to the purchaser for any indirect, special or consequential damages or lost

profits arising out of or relating to Datamax-O'Neil's products, or the performance or a breach thereof, even if DatamaxO'Neil has been advised of the possibility thereof. Datamax-O'Neil's liability, if any, to the purchaser or to the customer

of the purchaser hereunder shall in no event exceed the total amounts paid to Datamax-O'Neil hereunder by the

purchaser for a defective product.

In no event shall Datamax-O'Neil be liable to the purchaser for any damages resulting from or related to any failure or

delay of Datamax-O'Neil in the delivery or installation of the computer hardware, supplies or software or in the

performance of any services.

Some states do not permit the exclusion of incidental or consequential damages, and in those states the foregoing

limitations may not apply. The warranties here give you specific legal rights, and you may have other legal rights which

vary from state to state.

Firmware (Software) Agreement

The enclosed Firmware (Software) resident in the Printer is owned by Licensor or its suppliers and is licensed for used

only on a single printer in the user's Trade or Business. The User agrees not to, and not to authorize or permit any

other person or party to, duplicate or copy the Firmware or the information contained in the non-volatile or

programmable memory. The firmware (Software) is protected by applicable copyright laws and Licensor retains all

rights not expressly granted. In no event will Licensor or its suppliers be liable for any damages or loss, including

direct, incidental, economic, special, or consequential damages, arising out of the use or inability to use the Firmware

(Software).

Information in this document is subject to change without notice and does not represent a commitment on the part of

Datamax-O'Neil Corporation. No part of this manual may be reproduced or transmitted in any form or by any means,

for any purpose other than the purchaser's personal use, without the expressed written permission of Datamax-O'Neil

Corporation.

Important Safety Instructions

This printer has been carefully designed to provide many years of safe, reliable performance. As with all types of

electrical equipment, however, there are a few basic precautions you should take to avoid hurting yourself or damaging

the equipment:

- Carefully read the provided installation and operating instructions.

- Read and follow all warning instruction labels on the printer.

- Place the printer on a flat, firm, solid surface.

- Make sure all openings on the printer remain unblocked; never insert anything into the openings or ventilation slots.

- Do not place the printer near a heat source.

- Do not use your printer near water, or spill liquid into it.

- Be certain that your power source matches a listed voltage rating for the printer (if unsure, check with your dealer or local utility

company).

- Do not place the power cord where it can be stepped on; and, if the power cord becomes damaged, immediately replace it.

- If service is required, use only qualified trained technicians to repair your printer.

All rights reserved. Copyright © 2015, Datamax-O'Neil

Part Number 88-2362-01, Revision D

Page 4

Page 5

Agency Compliance

This product complies to the following:

CFR 47 Part 15, Class A Digital Device

This device complies with Part 15, Subpart B of the FCC Rules.

Operation is subject to the following two conditions: 1) This device

may not cause harmful interference, and 2) this device must

accept any interference received, including interference that may

cause undesired operation.

This Class A digital apparatus complies with Industry Canada ICS003 Class A requirements.

UL 60950-1, 2nd Edition. Safety of Information Technology

Equipment Including Electrical Business Equipment

CAN/CSA-C22.2 No.60950-1, 2nd Edition. Safety of Information

Technology Equipment Including Electrical Business Equipment

European Council Directive 2004/108/EC “EMC Directive”

EN55022, Emissions, Class A

EN55011, Emissions, Class A (p1120n only)

EN55024, Immunity

EN61000-3-2, Harmonics

EN61000-3-3, Voltage Fluctuations and Flicker

European Council Directive 2006/95/EC “Low Voltage Directive”

IEC 60950-1, 2nd Edition (CB Scheme)

Directive 2011/65/EU RoHS2 [EN5058

Customs Union – Russia, Kazakhstan, Belarus

CISPR 22 Class A Warning

Warning: This is a Class A product. In a domestic environment this

product may cause radio interference in which case the user may

be required to take adequate measures.

1 (2012)]

Page 6

CoC-MEX

ACMA – Australian Communications and Media Authority

EN55022; 2010 +AC:2011 Class A

Certificate of Compliance - Mexico

CoC-Mex-00588-UL; UL 60950-1, 2nd Edition, 2011-12-19

GB4943.1-2011; GB9254-2008 (Class A); GB17625.1-2012

Page 7

Table of Contents

Agency Compliance ....................................................... 5

1. Safety

Warnings and Cautions .................................................. 1

General Safety Information ............................................. 1

2. Overview

About the Printer .............................................................3

p1115 Standard Features ............................................... 6

p1115s Standard Features ............................................. 8

p1120n Standard Features ........................................... 10

p1125 Standard Features ............................................. 12

p1725 Standard Features ............................................. 14

Options .........................................................................16

Unpacking the Printer ...................................................16

Specifications ...............................................................17

3. Connections and Setup

Connections ..................................................................19

Media Loading ..............................................................19

Installing Ribbon ...........................................................32

Configuring Media and Ribbon Settings ....................... 37

Optional Rewinder ........................................................40

Top-of-Form Sensor ..................................................... 42

Removing Ribbon Wrinkle ............................................47

Manual Head Pressure Adjustment (p1115 only) ......... 49

Installing Cutter and Tray ............................................. 51

Upward-Facing Present Sensor ................................... 57

Print Driver Installation .................................................59

4. Menu System

Menu Overview .............................................................61

Layout of the Display ....................................................61

Three Button Panel .......................................................62

Home Screen ................................................................62

Information Button ....................................................... 63

Performance Series User’s Guide

Page 8

Table of Contents

Feed Button .................................................................. 69

Menu ............................................................................70

5. Cleaning and Maintenance

Overview .....................................................................109

Intervals ......................................................................109

Supplies ......................................................................109

Cleaning the Automatic Loading Sensor .................... 109

Cleaning the Top-of-Form Sensor .............................. 109

Cleaning the Paper Low Sensor ................................. 110

Cleaning the Printhead ...............................................110

Cleaning the Cutter ..................................................... 110

6. Maintenance

Safety Overview ......................................................... 111

Tools Needed ............................................................. 111

Replacing the Printhead ............................................. 111

Replacing the Upper Platen Roller ............................. 114

7. Troubleshooting

Errors ..........................................................................119

Warnings ....................................................................120

Troubleshooting .......................................................... 120

Troubleshooting Print Quality ..................................... 123

8. Terms and Definitions

Processing State ........................................................ 125

Printer State ................................................................125

Media Setup ............................................................... 125

Basic ...........................................................................125

Advanced ....................................................................126

Tools ...........................................................................131

Test .............................................................................132

9. Appendix A

Symbol Sets ............................................................... 133

Fonts ...........................................................................134

Barcodes ....................................................................136

Performance Series User’s Guide

Page 9

1 Safety

Warnings and Cautions

The following Warnings and Cautions are used throughout this manual:

Warning: Warnings alert you to possible safety risks.

Caution: Cautions alert you to the potential for equipment damage.

General Safety Information

Caution: This product is intended for indoor use only.

All service procedures should be done by properly trained and qualified service

personnel.

Any on-site assembly required during the installation process must be performed by

properly trained and qualified service personnel.

The product must be connected to a properly grounded and appropriately rated AC

receptacle using the supplied cord set.

Caution: This product contains sensitive electronic components that could be damaged

if exposed to excessive force.

Caution: Use only factory-approved consumables and cleaning kits. Use of any non-

approved supplies could damage the product and void the warranty.

Caution: Do not connect the wireless antenna connection to any outside plant

connection.

Figure: 1 - 1 Caution - Hot

The printhead heats during printing. Do not touch.

1 Performance Series User’s Guide

Page 10

1 | Safety

Performance Series User’s Guide 2

Page 11

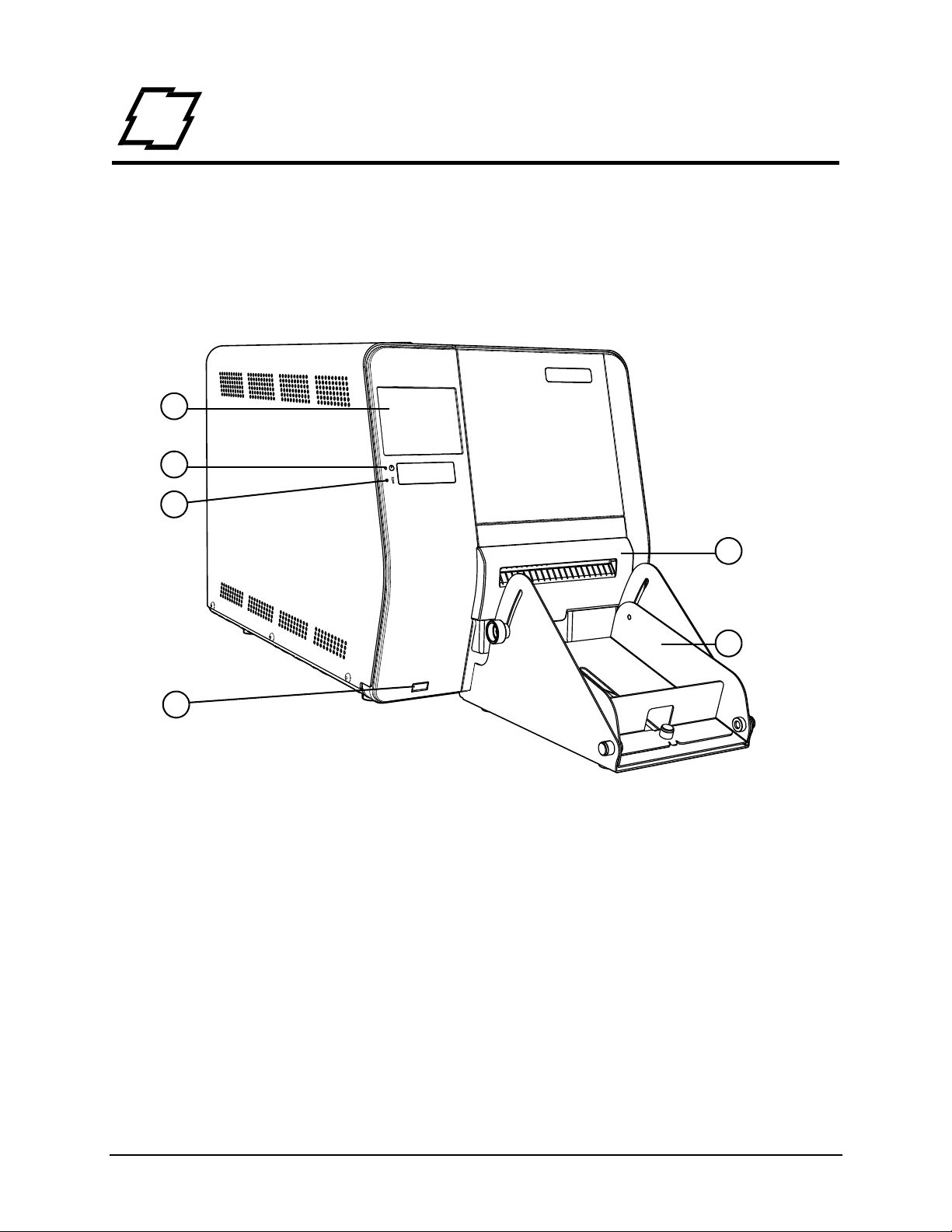

2Overview

1. Touchscreen Control Panel

2. Power LED

3. Error LED

4. Cutter (Optional)

5. Cutter Tray (Optional)

6. USB Host (Optional)

1

2

3

4

5

6

Some features and options are not available on all models.

About the Printer

Product Tour

The following illustrations show some of the features and available options for the printer.

Figure: 2 - 1 Front View

3 Performance Series User’s Guide

Page 12

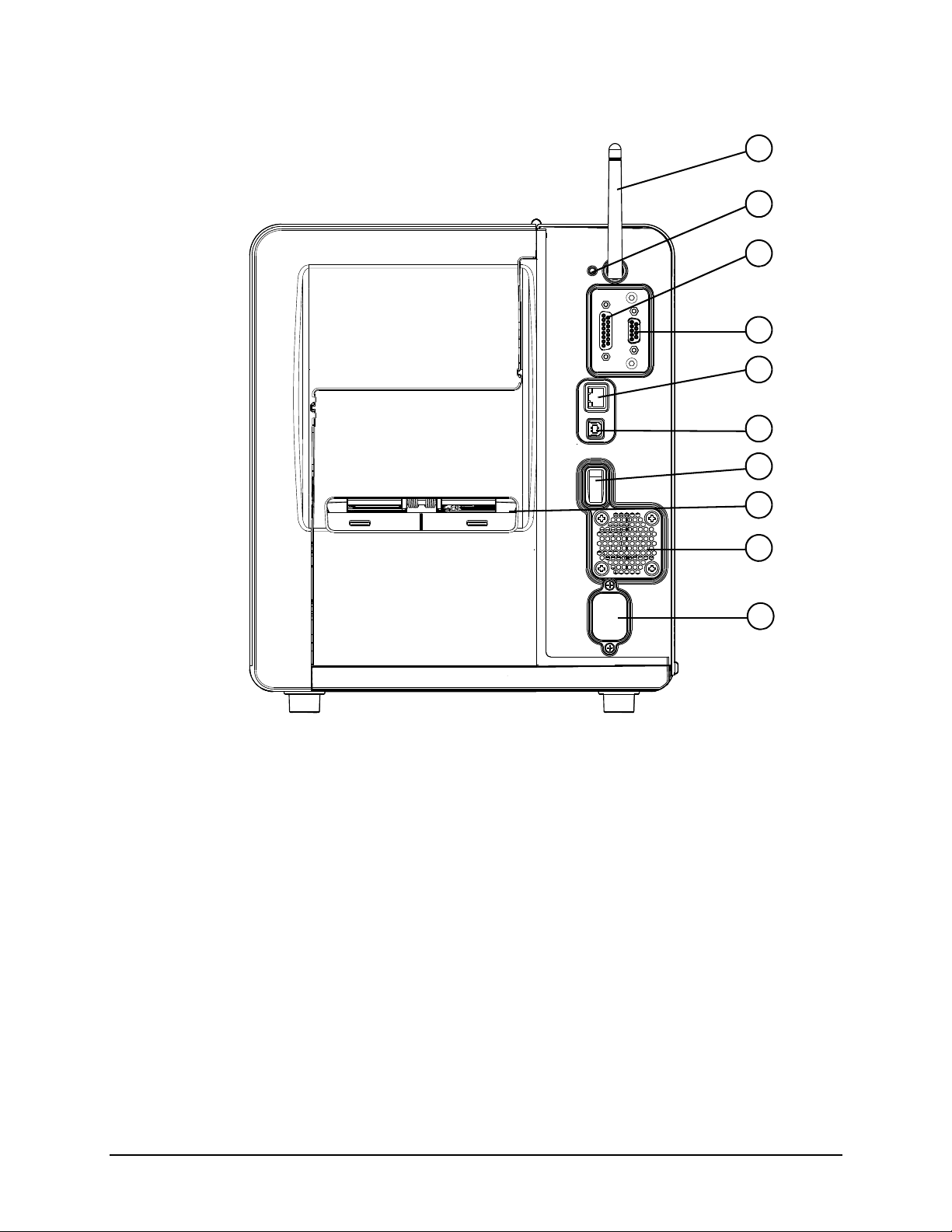

2 | Overview

1

2

3

4

5

6

7

8

9

1. Wireless Antenna (Optional)

2. Reset Switch

3. GPIO Port (Optional)

4. Serial Port (Optional)

5. Ethernet/Network Port

6. USB Port

7. Power Switch

8. Fanfold Media Slot

9. Rear Compartment Vent

10. AC Power Inlet

10

Some features and options are not available on all models.

Figure: 2 - 2 Rear View

Performance Series User’s Guide 4

Page 13

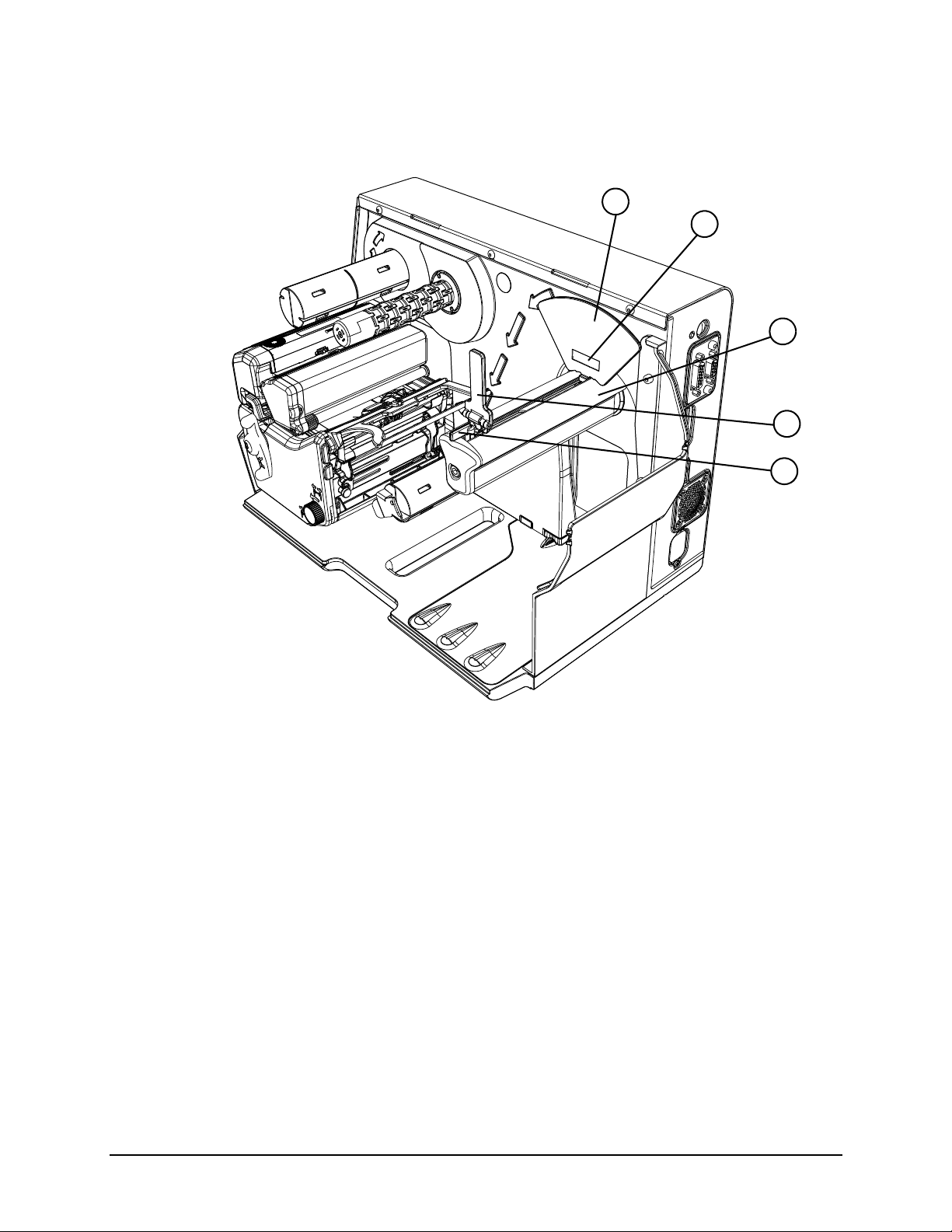

Figure: 2 - 3 Media Area

.

1. Head Pressure Adjustment Wheel (p1115 Only)

2. Power Ribbon Transport Assembly (Optional)

3. Ribbon

4. Media

5. Media Hanger

6. Printhead Carriage Assembly

7. Printhead Latch

8. Printhead Latch Lever

9. Rear Fanfold Media Access Slot

10. Platen Carriage Assembly

11. Media Width Guide Adjustment Knob

12. Bouncer

13. Lower Fanfold Media Access Slot

14. Power Media Rewinder Assembly (Optional)

123

4

5

6

7

8

9

10

11

12

13

14

Some features and options are not available on all models.

Overview | 2

5 Performance Series User’s Guide

Page 14

2 | Overview

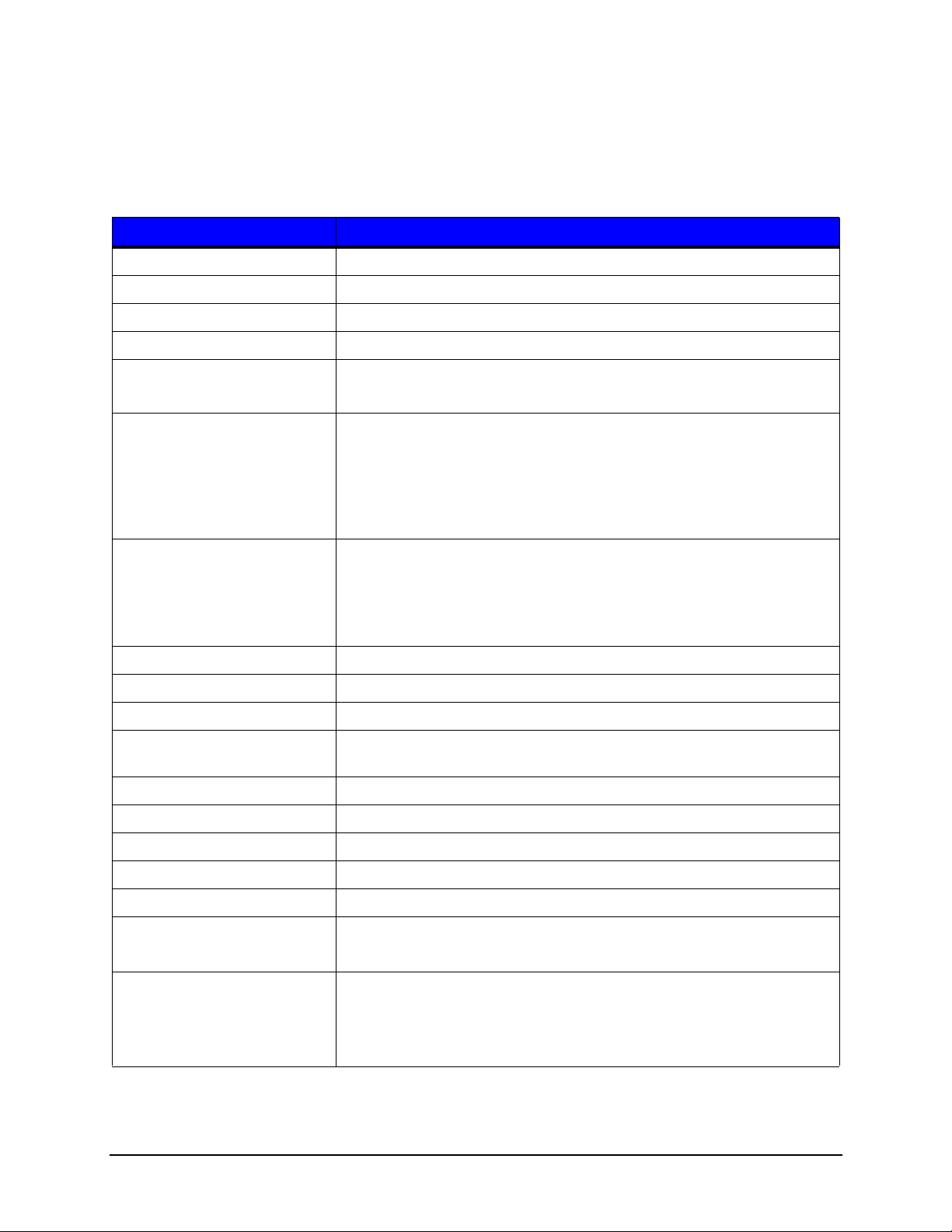

p1115 Standard Features

The p1115 thermal printer has the following standard features:

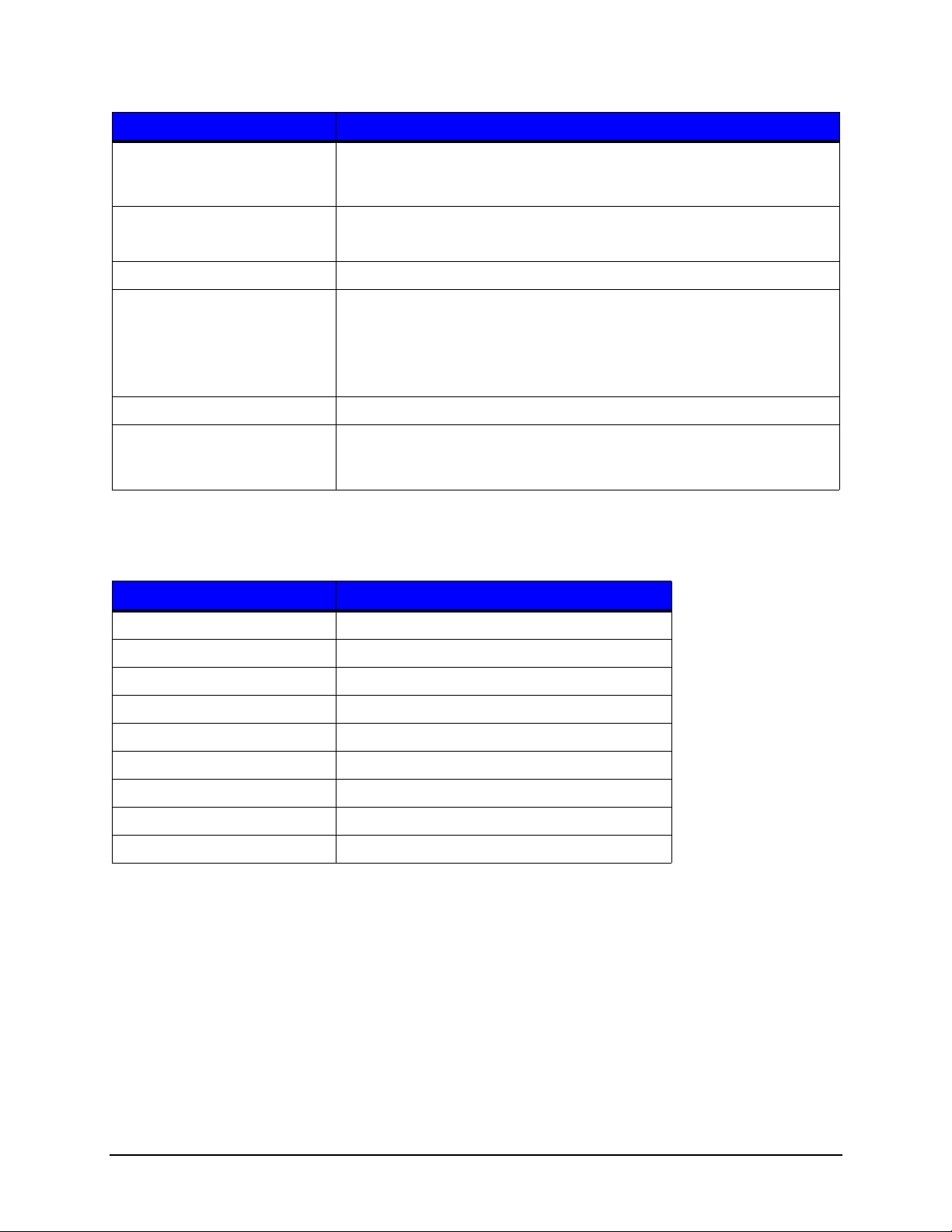

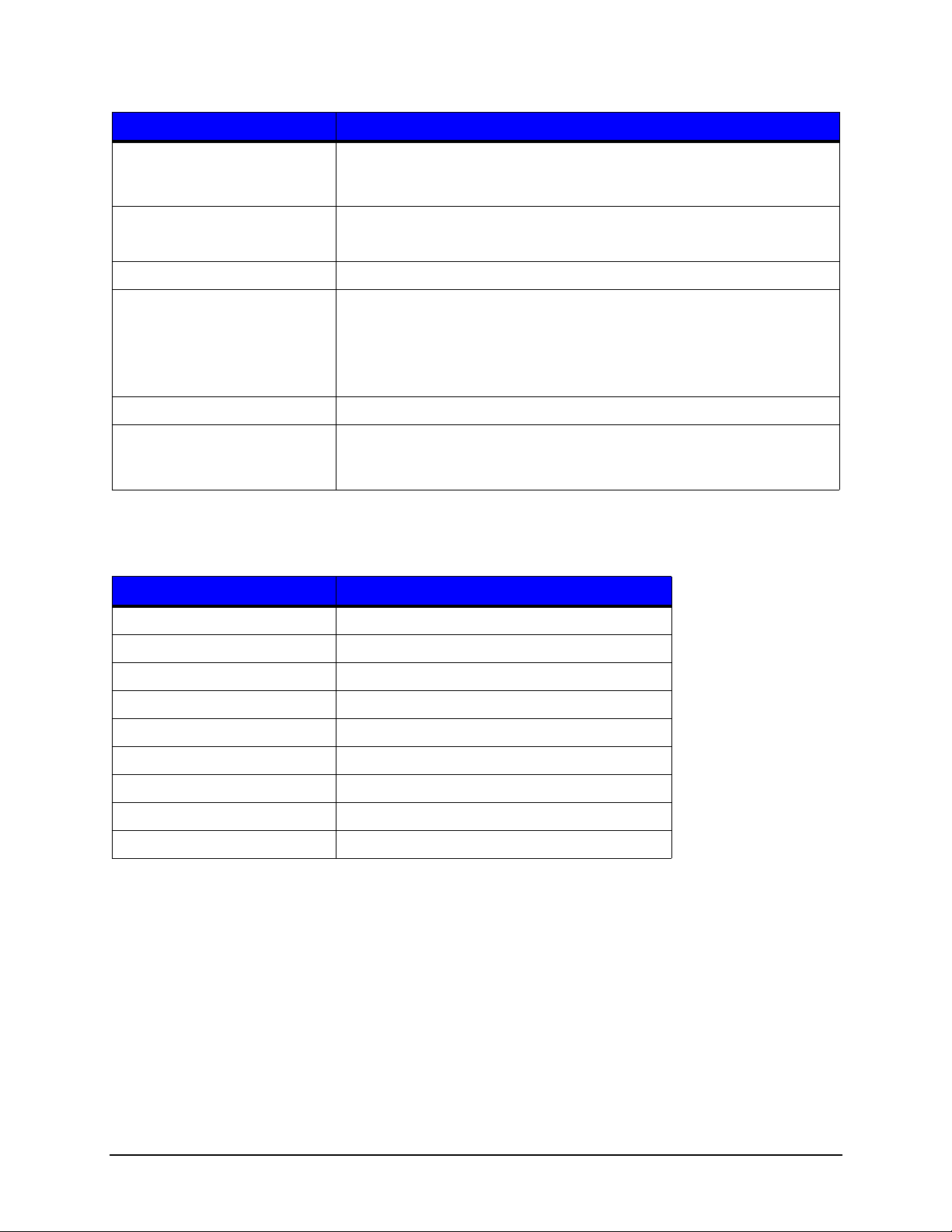

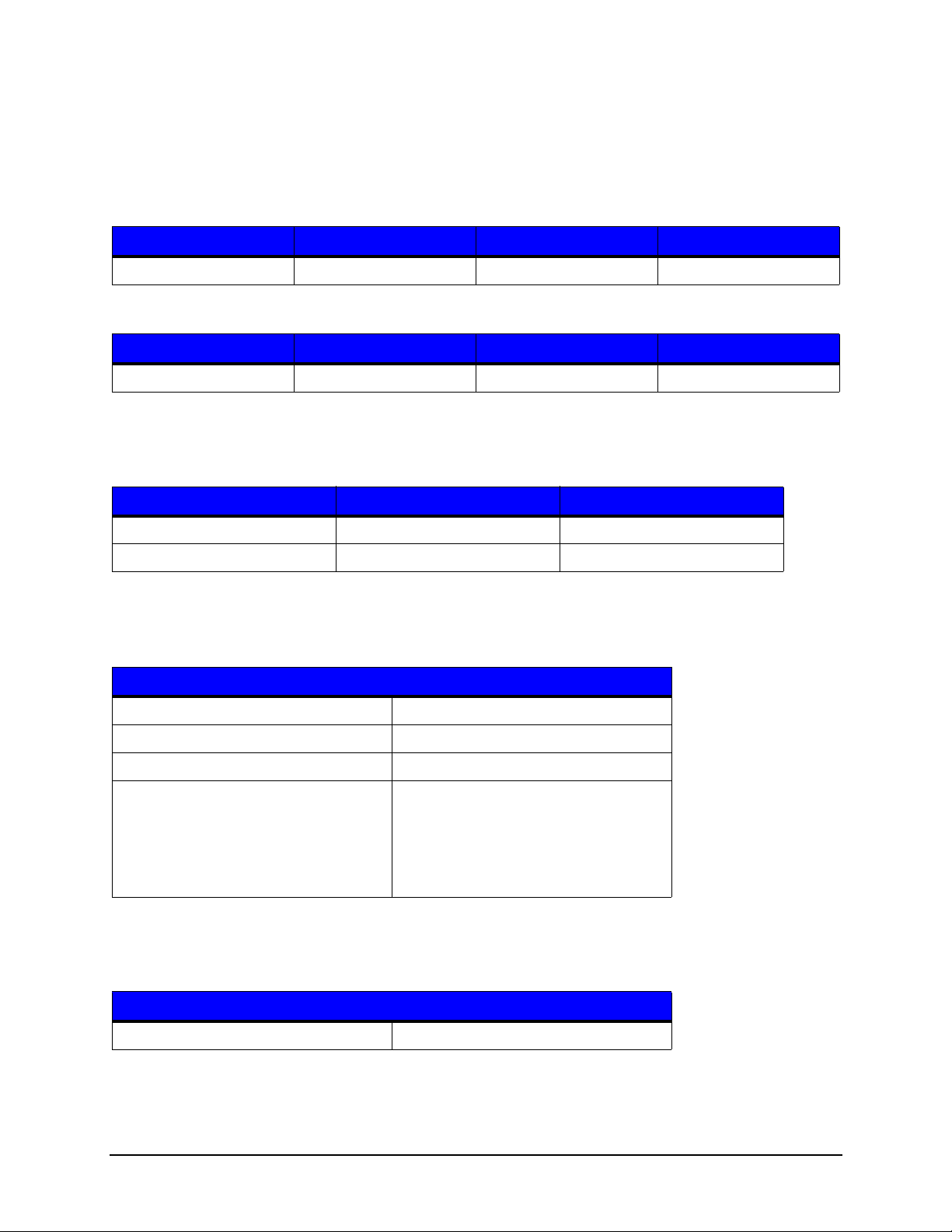

Table 1: p1115 Standard Features

Features Descriptions

Power Supply 110V to 230V

Max Print Speed 6 IPS / 152 mmps

Resolution 300 dpi / 11.8 dpmm

Memory 32 MB Flash (4MB User Space) / 64 MB DDR2 SDRAM

Printer Type • Direct Thermal

• Thermal Transfer (Optional)

Media Supply • Fan fold

• Roll-fed

• Die-cut

• Continuous Labels: perforated or continuous tag/ticket stock (8”

[203mm] roll max diameter.

Double-sided Top-of-Form

Sensor

Tea r Ba r Removable bar for tearing off gapped or continuous media.

Media Back Feed Capable of backing up at least 1.0”.

Control panel LED backlit color QVGA LCD with touchscreen.

Reset Button Inset on the rear of the unit for recovery or the resetting of the screen

LEDs Two LEDs on the front panel for Power and Error.

Power Switch Positioned on the rear of the unit.

Chassis / Media Cover Die cast construction with a clear side window.

Bar Codes See Appendix A

Fonts See Appendix A

Downloadable Font Types • True-Type Scalable

Graphics Full support of PCL5e and GL/2 graphics capability.

Adjustable position for center-biased stock:

• Label Gap

•Notch

• Reflective black mark on the bottom or the top of the form

calibration.

• PCL Bitmap

(Support for various host-based file formats [PCX, BMP] are not part of

the PCL5e standard but are supported and converted by standard

applications)

Performance Series User’s Guide 6

Page 15

Features Descriptions

Overview | 2

Industry Standard Printer

Language

Interfaces • USB 2.0 Device

Real Time Clock User replaceable battery

Printer Driver Supported

O

perating Systems

Operating Temperature 32°F (0°C) to 104°F (40°C)

Supported Languages in the

isplay

D

HP PJL, HP PCL5e, HP GL/2 and HP XL, printer languages with autolanguage select and extensions for barcode capabilities. Bi-directional

communications capability is also supported.

LAN 10/100

•

• Windows XP

• Windows Vista

• Windows 7

• Windows 8

Front panel languages are configurable via translation files which may

be loaded on the printer. Check with your sales representative for the

most recent list of available translations.

Print Characteristics

Table 2: Print Characteristics

Variable Specifications

Print Resolution 300 dpi (11.8 dpmm)

Max Print Width 4.16” (105.7 mm)

Max Print Speed 6 IPS (152 mmps)

Max Feed Speed 8 IPS (152 mmps)

Max Back-up Speed 5 IPS (127 mmps)

Media Width Range* 1” - 4.65” (25.44 mm - 118.1 mm)

Media Thickness Range* 0.003” - 0.010” (0.076 mm - 0.254 mm)

Ribbon Width Range** 1” - 4.65” (25.44 mm - 118.1 mm)

Print Length 0.25” - 36” (6.35 mm - 915 mm)

*Media wound out.

**Coated side in (CSI) or coated side out (CSO).

7 Performance Series User’s Guide

Page 16

2 | Overview

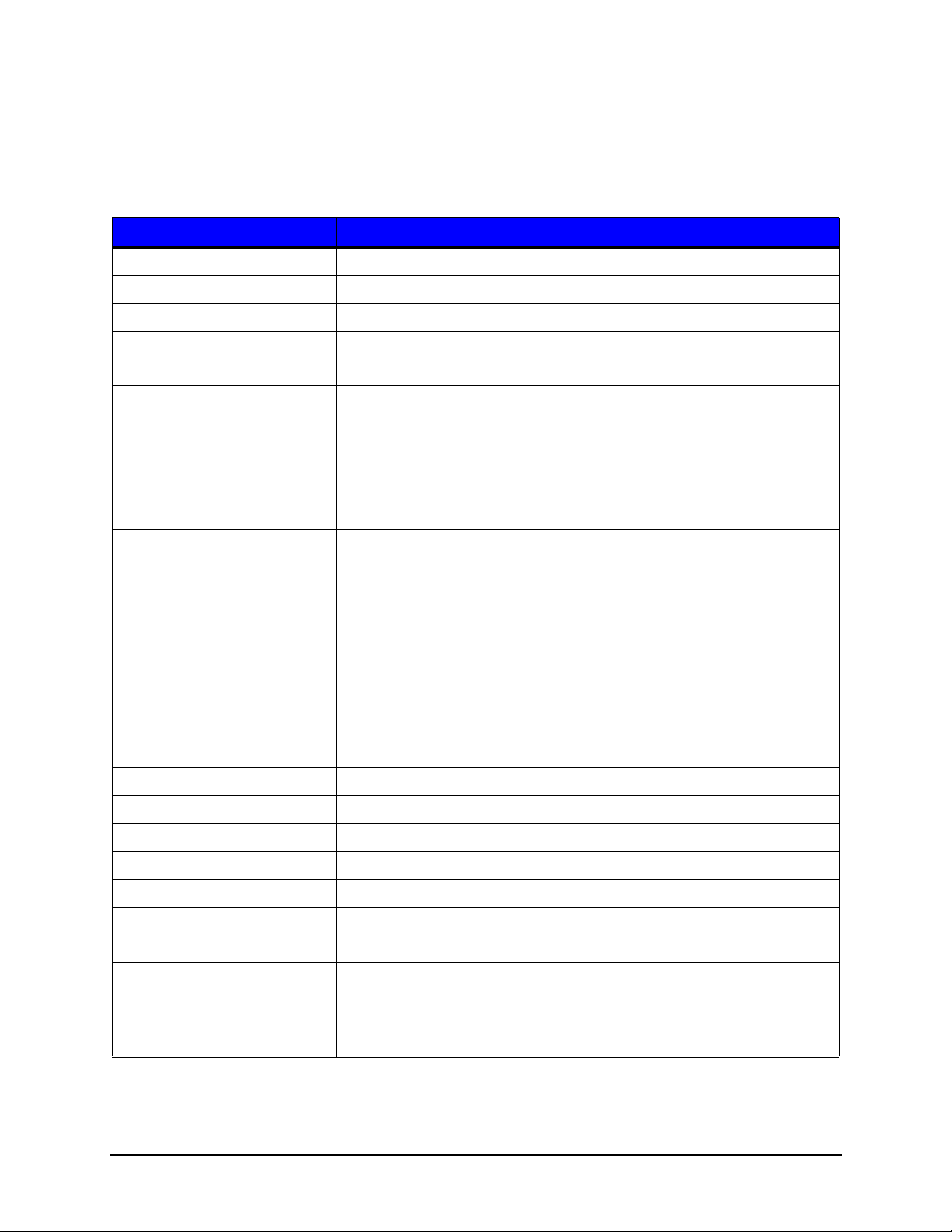

p1115s Standard Features

The p1115s thermal printer has the following standard features:

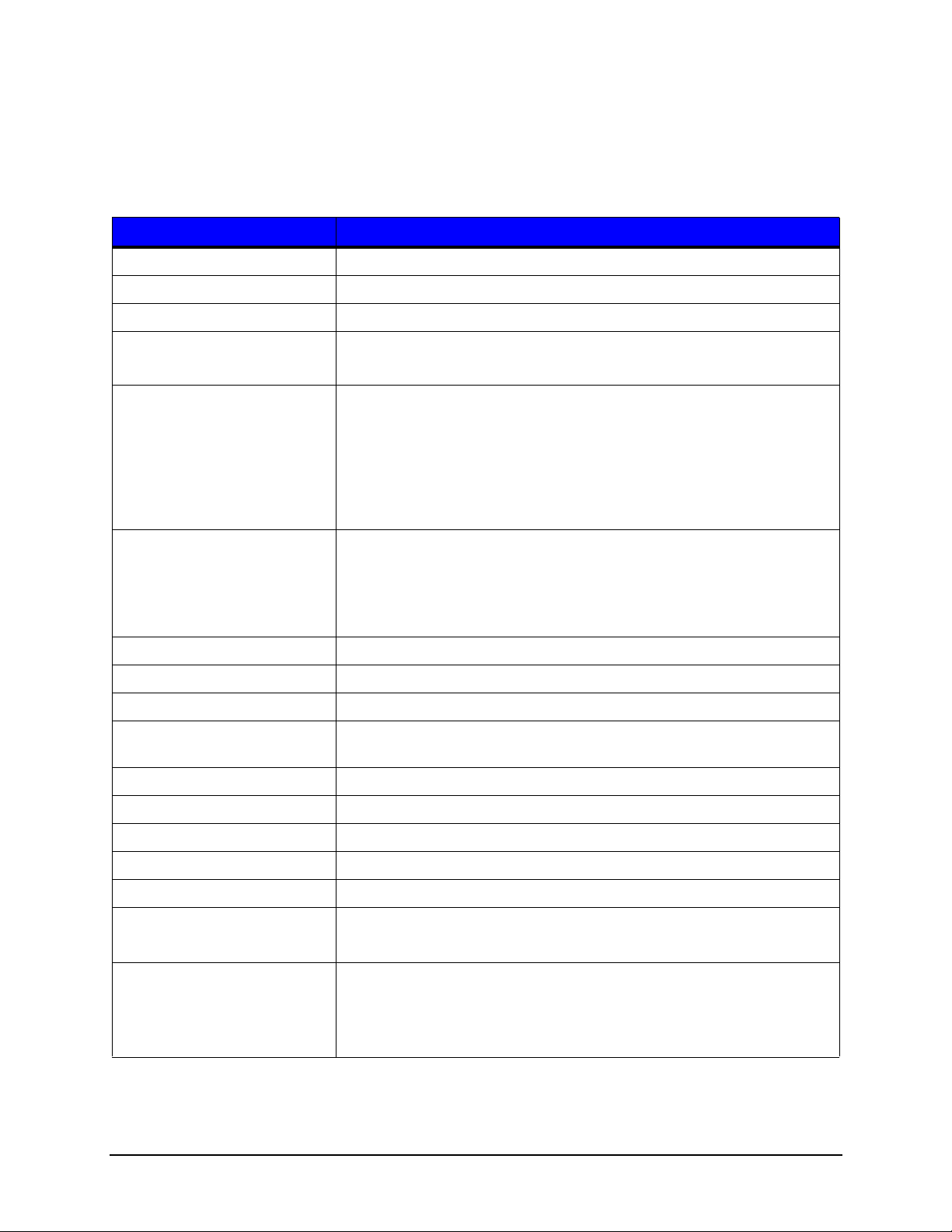

Table 3: p1115s Standard Features

Features Descriptions

Max Print Speed 6 IPS / 152 mmps

Resolution 600 dpi / 23.6 dpmm

Memory 64MB Flash (32MB User Space) / 64MB DDR2 SDRAM

Printer Type • Direct Thermal

• Thermal Transfer (Optional)

Media Supply • Fan fold

• Roll-fed

• Die-cut

• Continuous Labels: perforated or continuous tag/ticket stock (8”

[203 mm] roll max diameter on 1.0”, 1.5” or 3” [25 mm, 38 mm

or 76 mm] core).

Double-sided Top-of-Form

Sensor

Tea r Ba r Removable bar for tearing off gapped or continuous media.

Media Back Feed Capable of backing up at least 1.0”.

Control panel LED backlit color QVGA LCD with touchscreen.

Reset Button Inset on the rear of the unit for recovery or the resetting of the screen

LEDs Two LEDs on the front panel for Power and Error.

Power Switch Positioned on the rear of the unit.

Chassis / Media Cover Die-cast construction with a clear side window.

Bar Codes See Appendix A

Fonts See Appendix A

Downloadable Font Types • True-Type Scalable

Graphics Full support of PCL5e and GL/2 graphics capability.

Adjustable position for center-biased stock:

• Label Gap

•Notch

• Reflective black mark on the bottom or the top of the form

calibration.

• PCL Bitmap

(Support for various host-based file formats [PCX, BMP] are not part of

the PCL5e standard but are supported and converted by standard

applications)

Performance Series User’s Guide 8

Page 17

Features Descriptions

Overview | 2

Industry Standard Printer

Language

Interfaces • USB 2.0 Device

Real Time Clock User replaceable battery

Printer Driver Supported

O

perating Systems

Operating Temperature 32°F (0°C) to 104°F (40°C)

Supported Languages in the

isplay

D

HP PJL, HP PCL5e, HP GL/2 and HP XL, printer languages with autolanguage select and extensions for barcode capabilities. Bi-directional

communications capability is also supported.

LAN 10/100

•

• Windows XP

• Windows Vista

• Windows 7

• Windows 8

Front panel languages are configurable via translation files which may

be loaded on the printer. Check with your sales representative for the

most recent list of available translations.

Print Characteristics

Table 4: Print Characteristics

Variable Specifications

Print Resolution 600 dpi (23.6 dpmm)

Max Print Width 4.16” (105.6 mm)

Max Print Speed 6 IPS (152 mmps)

Max Feed Speed 8 IPS (152 mmps)

Max Back-up Speed 5 IPS (127 mmps)

Media Width Range* 1” - 4.65” (25.44 mm - 118.1 mm)

Media Thickness Range* 0.003” - 0.010” (0.076 mm - 0.254 mm)

Ribbon Width Range** 1” - 4.65” (25.44 mm - 118.1 mm)

Print Length 0.25” - 36” (6.35 mm - 915 mm)

*Media wound out.

**Coated side in (CSI) or coated side out (CSO).

9 Performance Series User’s Guide

Page 18

2 | Overview

p1120n Standard Features

The p1120n thermal printer has the following standard features:

Table 5: p1120n Standard Features

Features Descriptions

Max Print Speed 8 IPS / 203 mmps

Resolution 300 dpi / 11.8 dpmm

Memory 32MB Flash (4MB User Space) / 64MB DDR2 SDRAM

Printer Type • Direct Thermal

• Thermal Transfer (Optional)

Media Supply • Fan fold

• Roll-fed

• Die-cut

• Continuous Labels: perforated or continuous tag/ticket stock (8”

[203 mm] roll max diameter on 1.0”, 1.5” or 3” [25 mm, 38 mm

or 76 mm] core).

Double-sided Top-of-Form

Sensor

Tea r Ba r Removable bar for tearing off gapped or continuous media.

Media Back Feed Capable of backing up at least 1.0” (for near edge printhead).

Control panel LED backlit color QVGA LCD with touchscreen.

Reset Button Inset on the rear of the unit for recovery or the resetting of the screen

LEDs Two LEDs on the front panel for Power and Error.

Power Switch Positioned on the rear of the unit.

Chassis / Media Cover Die-cast construction with a clear side window.

Bar Codes See Appendix A

Fonts See Appendix A

Downloadable Font Types • True-Type Scalable

Graphics Full support of PCL5e and GL/2 graphics capability.

Adjustable position for center-biased stock:

• Label Gap

•Notch

• Reflective black mark on the bottom or the top of the form

calibration.

• PCL Bitmap

(Support for various host-based file formats [PCX, BMP] are not part of

the PCL5e standard but are supported and converted by standard

applications)

Performance Series User’s Guide 10

Page 19

Features Descriptions

Overview | 2

Industry Standard Printer

Language

Interfaces • USB 2.0 Device

Real Time Clock User replaceable battery

Printer Driver Supported

O

perating Systems

Operating Temperature 32°F (0°C) to 104°F (40°C)

Supported Languages in the

isplay

D

HP PJL, HP PCL5e, HP GL/2 and HP XL, printer languages with autolanguage select and extensions for barcode capabilities. Bi-directional

communications capability is also supported.

LAN 10/100

•

• Windows XP

• Windows Vista

• Windows 7

• Windows 8

Front panel languages are configurable via translation files which may

be loaded on the printer. Check with your sales representative for the

most recent list of available translations.

Print Characteristics

Table 6: Print Characteristics

4” Near Edge

Print Resolution 300 dpi (11.8 dpmm)

Max Print Width 4.27” (108.5 mm)

Max Print Speed 8 IPS (203 mmps)

Max Feed Speed 10 IPS (254 mmps)

Max Back-up Speed 5 IPS (127 mmps)

Media Width Range* 1” - 4.65” (25.44 mm - 118.1 mm)

Media Thickness Range* 0.003” - 0.020” (0.076 mm - 0.508 mm)

Ribbon Width Range** 1” - 4.65” (25.44 mm - 118.1 mm)

Print Length 0.2” - 99” (5.08 mm - 2475.6 mm)

*Media wound out.

**Coated side in (CSI) or coated side out (CSO).

11 Performance Series User’s Guide

Page 20

2 | Overview

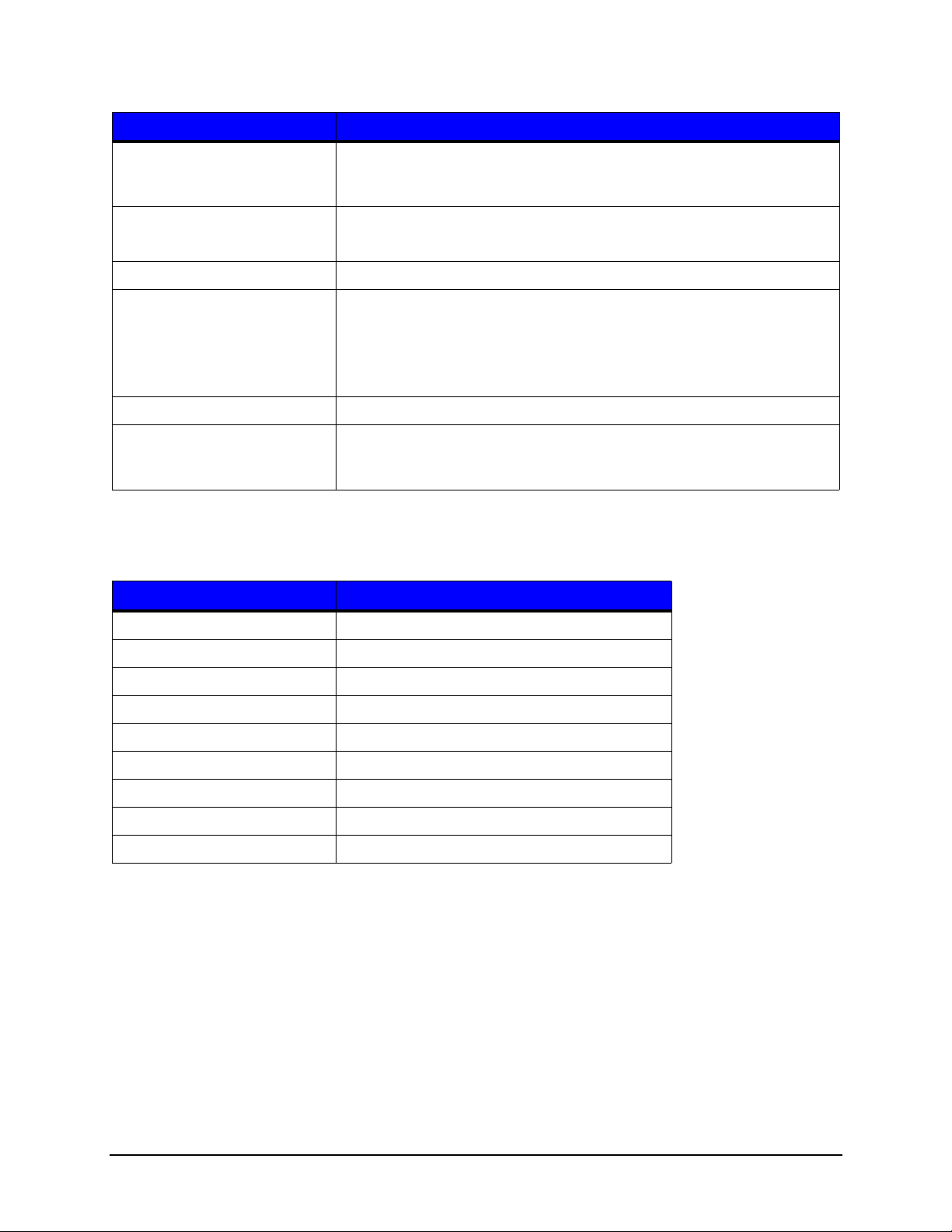

p1125 Standard Features

The p1125 thermal printer has the following standard features:

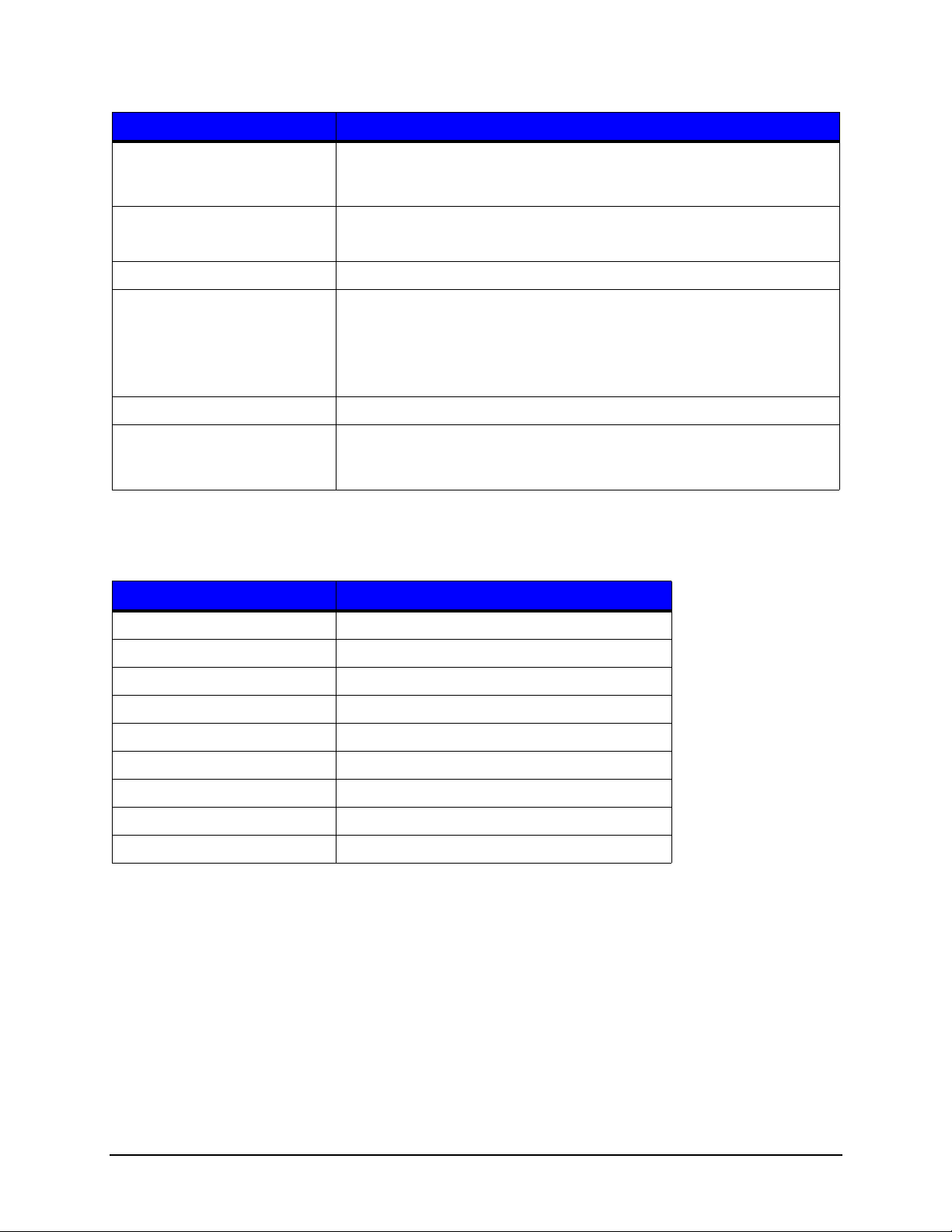

Table 7: p1125 Standard Features

Features Descriptions

Max Print Speed 10 IPS / 254 mmps

Resolution 300 dpi / 11.8 dpmm

Memory 32 MB Flash (4 MB User Space) / 64 MB DDR2 SDRAM

Printer Type • Direct Thermal

• Thermal Transfer (Optional)

Media Supply • Fan fold

• Roll-fed

• Die-cut

• Continuous Labels: perforated or continuous tag/ticket stock (8”

[203 mm] roll max diameter on 1.0”, 1.5” or 3” [25 mm, 38 mm

or 76 mm] core).

Double-sided Top-of-Form

Sensor

Tea r Ba r Removable bar for tearing off gapped or continuous media.

Media Back Feed Capable of backing up at least 1.0”.

Control panel LED backlit color QVGA LCD with touchscreen.

Reset Button Inset on the rear of the unit for recovery or the resetting of the screen

LEDs Two LEDs on the front panel for Power and Error.

Power Switch Positioned on the rear of the unit.

Chassis / Media Cover Die-cast construction with a clear side window.

Bar Codes See Appendix A

Fonts See Appendix A

Downloadable Font Types • True-Type Scalable

Graphics Full support of PCL5e and GL/2 graphics capability.

Adjustable position for center-biased stock:

• Label Gap

•Notch

• Reflective black mark on the bottom or the top of the form

calibration.

• PCL Bitmap

(Support for various host-based file formats [PCX, BMP] are not part of

the PCL5e standard but are supported and converted by standard

applications)

Performance Series User’s Guide 12

Page 21

Features Descriptions

Overview | 2

Industry Standard Printer

Language

Interfaces • USB 2.0 Device

Real Time Clock User replaceable battery

Printer Driver Supported

O

perating Systems

Operating Temperature 32°F (0°C) to 104°F (40°C)

Supported Languages in the

isplay

D

HP PJL, HP PCL5e, HP GL/2 and HP XL, printer languages with autolanguage select and extensions for barcode capabilities. Bi-directional

communications capability is also supported.

LAN 10/100

•

• Windows XP

• Windows Vista

• Windows 7

• Windows 8

Front panel languages are configurable via translation files which may

be loaded on the printer. Check with your sales representative for the

most recent list of available translations.

Print Characteristics

Table 8: Print Characteristics

Variable Specifications

Print Resolution 300 dpi (11.8 dpmm)

Max Print Width 4.27” (108.5 mm)

Max Print Speed 10 IPS (254 mmps)

Max Feed Speed 12 IPS (254 mmps)

Max Back-up Speed 5 IPS (127 mmps)

Media Width Range* 1” - 4.65” (25.44 mm - 118.1 mm)

Media Thickness Range* 0.003” - 0.010” (0.076 mm - 0.254 mm)

Ribbon Width Range** 1” - 4.65” (25.44 mm - 118.1 mm)

Print Length 0.10” - 99” (5.08 mm - 2475.6 mm)

*Media wound out.

**Coated side in (CSI) or coated side out (CSO).

13 Performance Series User’s Guide

Page 22

2 | Overview

p1725 Standard Features

The p1725 thermal printer has the following standard features:

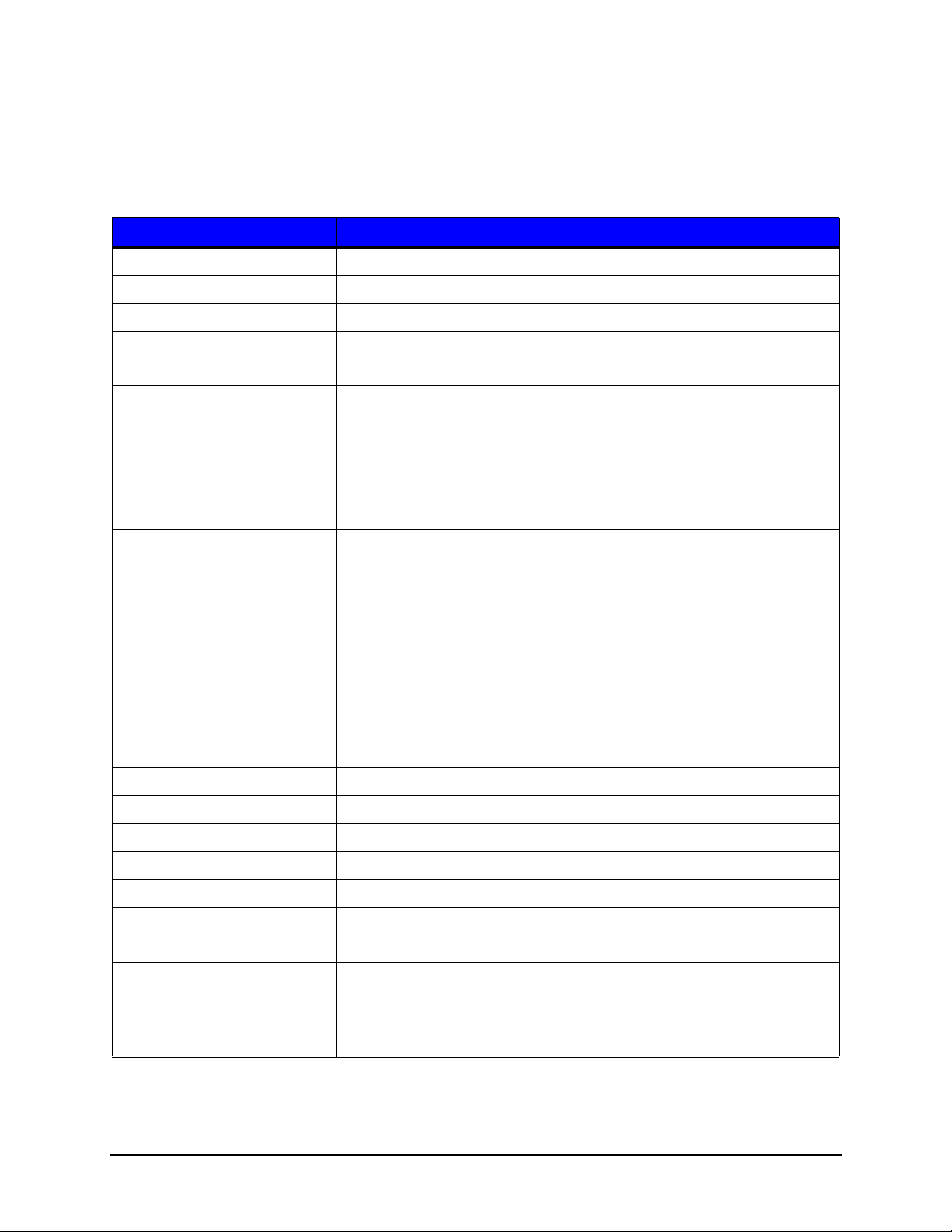

Table 9: p1725 Standard Features

Features Descriptions

Max Print Speed 10 IPS / 254 mmps

Resolution 300 dpi / 11.8 dpmm

Memory 64 MB Flash (32 MB User Space) / 64 MB DDR2 SDRAM

Printer Type • Direct Thermal

• Thermal Transfer (Optional)

Media Supply • Fan fold

• Roll-fed

• Die-cut

• Continuous Labels: perforated or continuous tag/ticket stock (8”

[203 mm] roll max diameter on 1.0”, 1.5” or 3” [25 mm, 38 mm

or 76 mm] core).

Double-sided Top-of-Form

Sensor

Tea r Ba r Removable bar for tearing off gapped or continuous media.

Media Back Feed Capable of backing up at least 1.0”.

Control panel LED backlit color QVGA LCD with touchscreen.

Reset Button Inset on the rear of the unit for recovery or the resetting of the screen

LEDs Two LEDs on the front panel for Power and Error.

Power Switch Positioned on the rear of the unit.

Chassis / Media Cover Die-cast construction with a clear side window.

Bar Codes See Appendix A

Fonts See Appendix A

Downloadable Font Types • True-Type Scalable

Adjustable position for center-biased stock:

• Label Gap

•Notch

• Reflective black mark on the bottom or the top of the form

calibration.

• Intellifont Scalable

• PCL Bitmap

Graphics Full support of PCL5e and GL/2 graphics capability.

(Support for various host-based file formats [PCX, BMP] are not part of

the PCL5e standard but are supported and converted by standard

applications)

Performance Series User’s Guide 14

Page 23

Features Descriptions

Overview | 2

Industry Standard Printer

Language

Interfaces • USB 2.0 Device

Real Time Clock User replaceable battery

Printer Driver Supported

O

perating Systems

Operating Temperature 32°F (0°C) to 104°F (40°C)

Supported Languages in the

isplay

D

HP PJL, HP PCL5e, HP GL/2 and HP XL, printer languages with autolanguage select and extensions for barcode capabilities. Bi-directional

communications capability is also supported.

LAN 10/100

•

• Windows XP

• Windows Vista

• Windows 7

• Windows 8

Front panel languages are configurable via translation files which may

be loaded on the printer. Check with your sales representative for the

most recent list of available translations.

Print Characteristics

Table 10: Print Characteristics

Variable Specifications

Print Resolution 300 dpi (11.8 dpmm)

Max Print Width 6.83” (173.5 mm)

Max Print Speed 10 IPS (254 mmps)

Max Feed Speed 12 IPS (254 mmps)

Max Back-up Speed 5 IPS (127 mmps)

Media Width Range* 2” - 7.1” (50.8 mm - 180.3 mm)

Media Thickness Range* 0.003” - 0.010” (0.076 mm - 0.254 mm)

Ribbon Width Range** 2” - 7.1” (50.8 mm - 180.3 mm)

Print Length 0.25” - 36” (6.35 mm - 915 mm)

*Media wound out.

**Coated side in (CSI) or coated side out (CSO).

15 Performance Series User’s Guide

Page 24

2 | Overview

Options

The following options are available:

• Thermal Transfer (Ribbon)

• Internal Power Rewind with Batch Rewind

• Media Present Sensor (Future option for the p1725)

• Peel and Present (Future option for the p1725)

• Media Cutter (Future option for the p1725)

• Media Cutter Tray (Future option for the p1725)

• Applicator Port (General Purpose I/O) and Serial Port (RS-232C)

• Wireless Module (not an available option for the p1115)

• USB Host Port (not an available option for the p1115)

• Audio Indicator (not an available option for the p1115)

• Media Hub with 1.0”,1.5” or 3” media hub adapters (not an available option for the

p1725)

• Non-US Power Cords

Unpacking the Printer

Upon receiving the printer, verify the box is undamaged. Carefully unpack the printer

from its packaging and visually check for any physical damage that may have occurred

during shipment.

Checking the Contents

The contents may vary depending on your configuration. It is recommended that all

packaging materials be saved if the printer is to be shipped again. If the packaging

material is discarded, new packaging material may be available from your reseller.

• Printer

• Power Cord

• Driver CD

• Product documentation not included on the CD

• Accessories/Options

Additional items that may be required include the following:

• All applicable communication cables

•Media

• Ribbon

Performance Series User’s Guide 16

Page 25

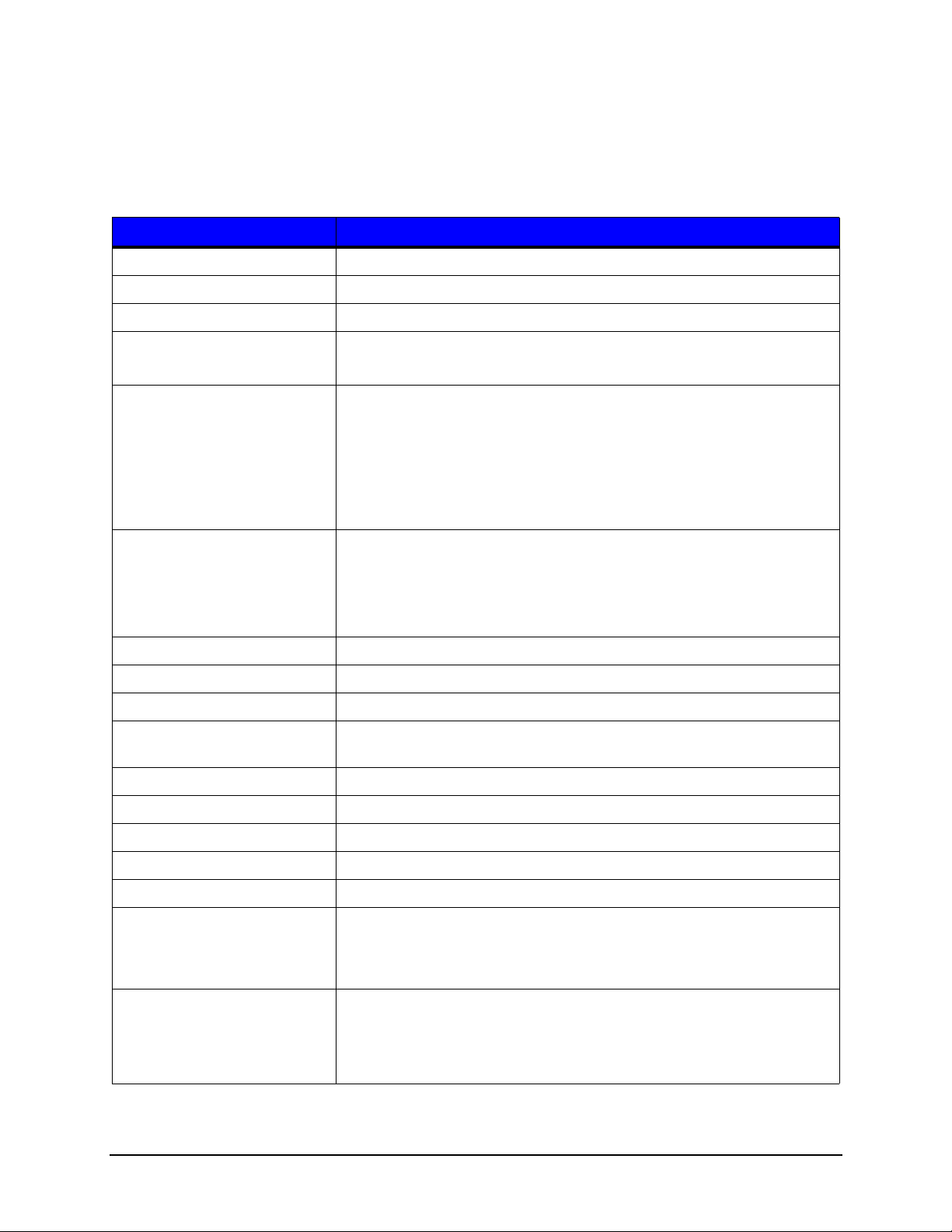

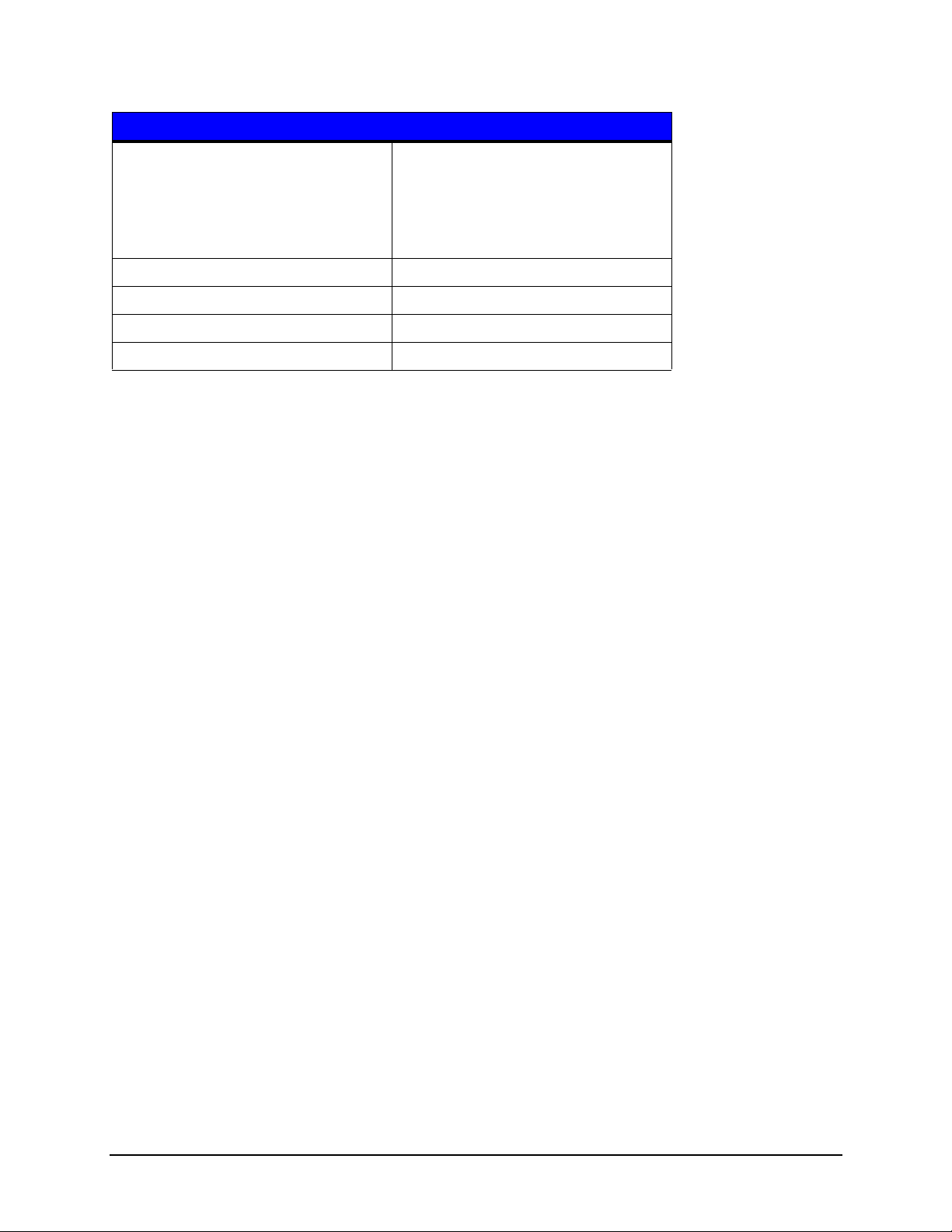

Specifications

Dimensions and Weight

Table 11: Dimensions and Specifications (p1115, p1115s, p1120n, p1125)

Height Width Depth Weight

11.9 in (30.3 cm) 10.8 in (27.4 cm) 18.7 in (47.5 cm) 41 lbs. (19 kg)

Table 12: Dimensions and Specifications (p1725)

Height Width Depth Weight

11.9 in (30.3 cm) 13.4 in (34 cm) 18.7 in (47.5 cm) 52 lbs. (24 kg)

Environmental

Table 13: Temperatu res

Temperature Humidity

Overview | 2

Operating 32°F to 104°F (0°C to 40°C) <=20% to 80%

Storage -4°F to 140°F (-20°C to 60°C) <=35%

Print Driver Requirements

Table 14: Print Driver Minimum System Requirements

Minimum System Requirements

Processor / Speed 500 MHz processor

RAM 512 MB

Hard Drive Space 6 MB

Supported Operating Systems Windows XP - x86 & x64

Windows Vista - x86 & x64

Windows 7 - x86 & x64

Windows 8

Configuration Utility

Table 15: Configuration Utility Minimum System Requirements

Minimum System Requirements

Processor / Speed 500 MHz processor

17 Performance Series User’s Guide

Page 26

2 | Overview

Minimum System Requirements

Supported Operating Systems Windows XP - x86 & x64

Windows Vista - x86 & x64

Windows 7 - x86 & x64

Windows 8

RAM 256 MB

Hard Drive Space 5 MB

Minimum Screen Resolution 800 x 600

.NET Framework 2.0

Performance Series User’s Guide 18

Page 27

3 Connections and Setup

Connections

Power

To connect the printer to a viable power source, please follow the steps below.

Caution: Ensure the printer power switch is off before connecting the AC power and

data/network connectivity cables to the printer.

Caution: Adhere to all environmental requirements when installing and using the printer.

Use of the product in an unsuitable environment may affect print quality and the

durability of the printer and may void the manufacturer’s warranty.

1. Place the printer on a suitable level surface capable of securely supporting 60lbs.

2. Connect the AC power cord to the AC power inlet on the back of the printer.

3. Connect the AC power cord to AC utility power.

Data

Printer data connectivity can be accomplished by the following standard or optional

interfaces:

•USB

• Ethernet/Network

• Serial (Optional)

• GPIO (Optional)

• Wireless (Optional)

Connect the appropriate interface cables for your network configuration.

Media Loading

The printer is designed to print on media that is center-aligned on the media hanger.

There are two different media mounts available for most models.

The standard self-centering media hanger synchronizes the adjustment to facilitate the

centering of the media. The optional self-centering media hub* allows for the use of 1”,

1.5” and 3” roll cores.(*Not available for all printer models.)

Please consult your sales representative to obtain the appropriate media.

Note: The printer should be connected to AC power and running during media loading.

19 Performance Series User’s Guide

Page 28

3 | Connections and Setup

1. Inside media adjustment lever

2. Paper low sensor (Optional)

3. Self-centering media hanger

4. Outside media adjustment lever

5. Media adjuster knob

1

2

3

4

5

Media Hanger Overview

Figure: 3 - 1 Self-Centering Media Hanger

Media Specifications

Media core size:

• 3” (76.199 mm)

Media roll diameter:

• Maximum -- 8”

Performance Series User’s Guide 20

Page 29

Connections and Setup | 3

Media roll width:

• Please refer to the model feature charts in the Overview section.

Media thickness:

• 0.003” to 0.01” (the p1120n can accept media thickness of up to 0.020”)

Media dimensions:

• Please refer to the model feature charts in the Overview section.

Note: Ensure there is no tape or adhesive residue on the media roll.

Installing Media on the Media Hanger

1. Open the media cover.

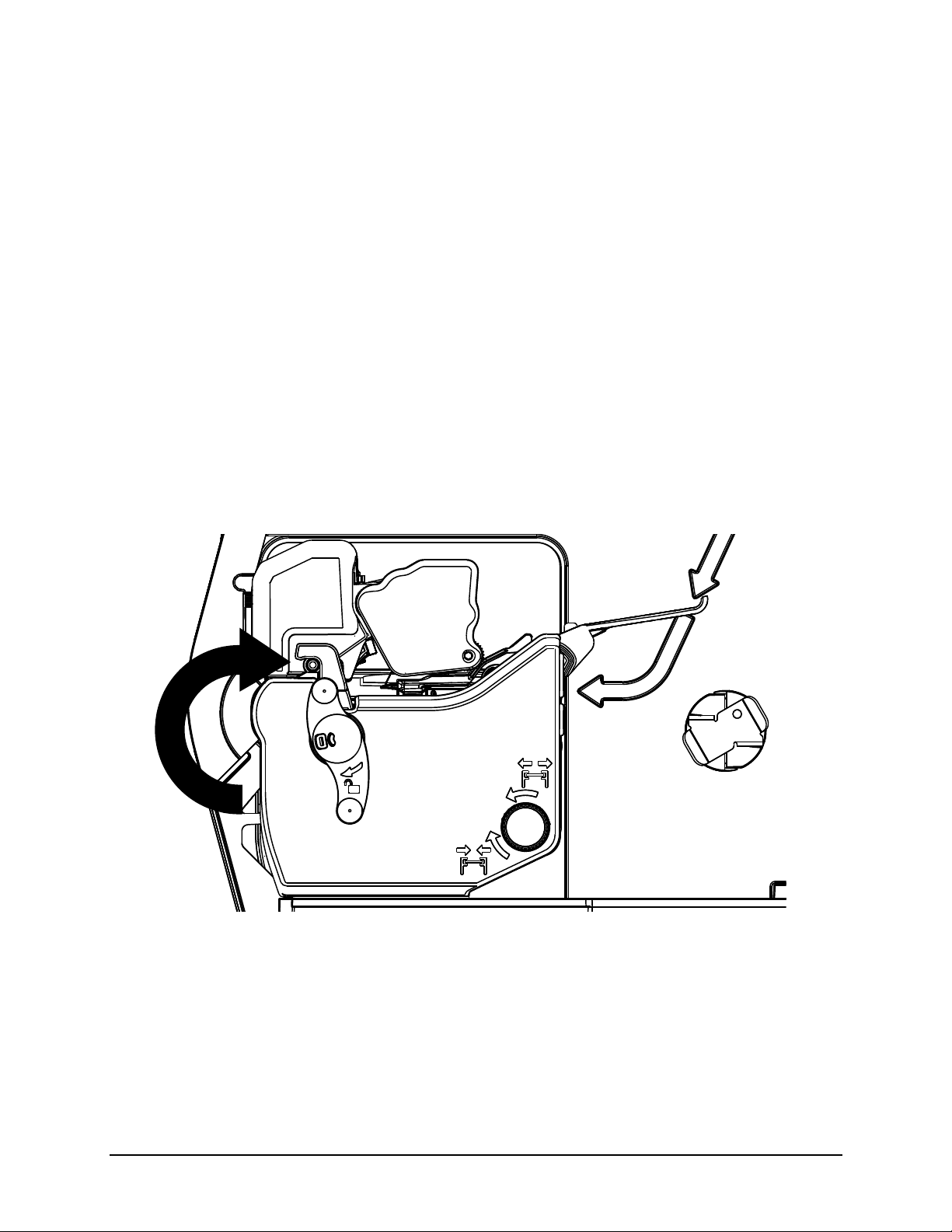

2. Unlock the printhead mechanism by turning the printhead latch lever clockwise about 190°.

Note: Do not unlatch the printhead mechanism.

Figure: 3 - 2 Unlock the Printhead Mechanism

21 Performance Series User’s Guide

Page 30

3 | Connections and Setup

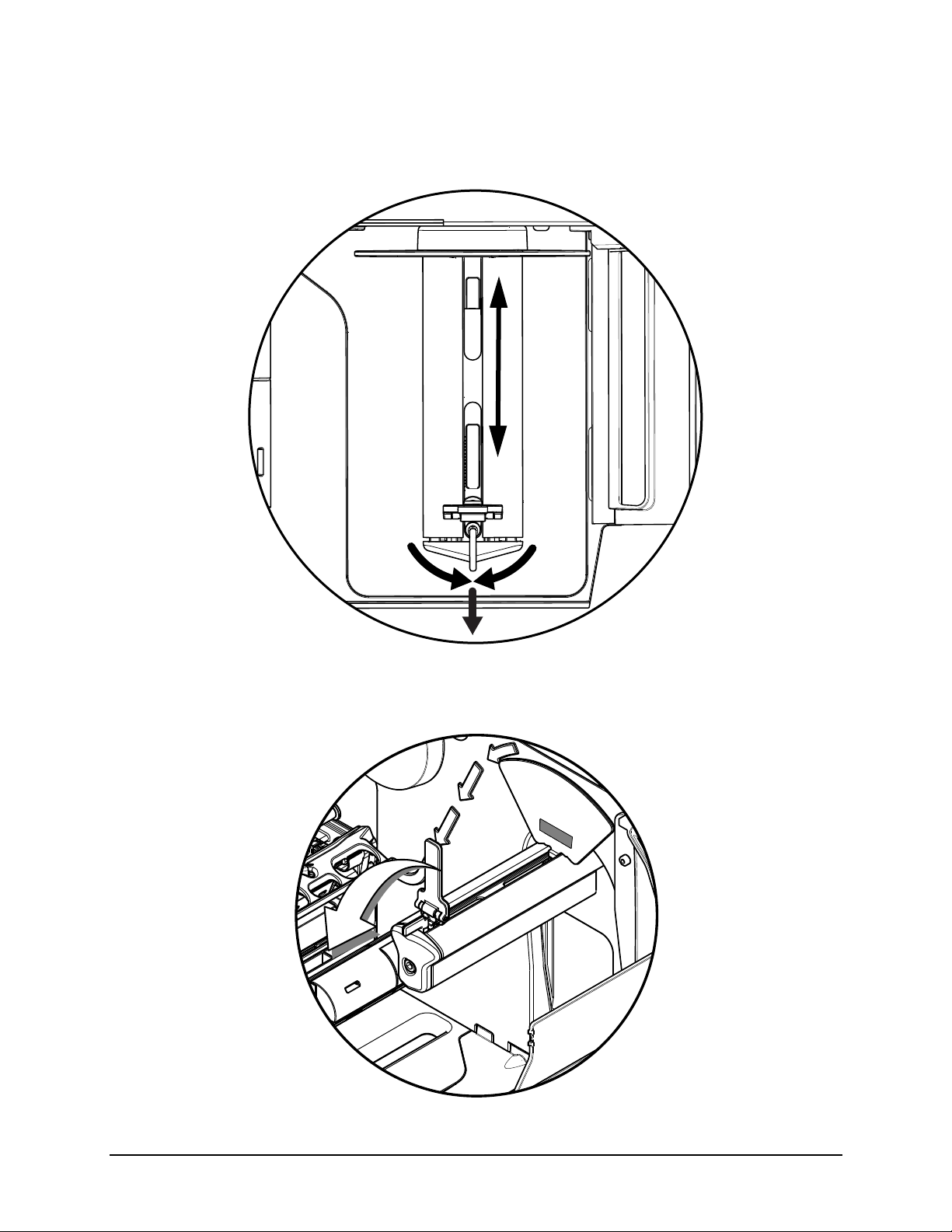

3. Center the media adjuster knob and pull it to widen the gap between the two media adjustment levers.

Figure: 3 - 3 Self-Centering Media Hanger from Top

4. Rotate the outside media adjustment lever downward.

Figure: 3 - 4 Outside Media Adjustment Lever

Performance Series User’s Guide 22

Page 31

Connections and Setup | 3

5. Gently route the media core over the outside media adjustment lever onto the media hanger.

Caution: Be careful not to damage the outside media adjustment lever.

Figure: 3 - 5 Media Installation

6. Rotate the outside media adjustment lever upward.

Figure: 3 - 6 Outside Media Adjustment Lever

7. Slide the media adjuster knob inward to center the media roll on the media hanger.

23 Performance Series User’s Guide

Page 32

3 | Connections and Setup

Media Guides

Note: Ensure the media roll turns freely. There should be 0.8 mm to 1.5 mm clearance

between the media adjustment levers and the media roll.

8. Rotate the media guide adjustment knob counter clockwise to widen the guides until they are set slightly wider than the width of the media.

Figure: 3 - 7 Media Guide Adjustment Knob

9. Route the media under the bouncer and into the media guides.

Figure: 3 - 8 Media Guides

Performance Series User’s Guide 24

Page 33

Connections and Setup | 3

Pinch Roller Knob

Pinch Roller

10.Press the pinch roller knob and slide the media 0.25 inches beyond the pinch roller.

Figure: 3 - 9 Pinch Roller

11. Rotate the media guide adjustment knob clockwise to tighten the guides.

Note: Ensure the guides are neither too tight nor too loose on the media or print quality

will be affected.

Figure: 3 - 10 Tighten Media Guide Adjustment Knob

25 Performance Series User’s Guide

Page 34

3 | Connections and Setup

12.Rotate the latch lever counter-clockwise until the printhead mechanism is locked.

Figure: 3 - 11 Lock the Printhead Mechanism

Note: If the media has been installed properly and read by the autoloading sensor, it

should automatically feed under the printhead once the printhead carriage assembly has

been latched and locked. If the media does not automatically load, unlatch the printhead

assembly and manually feed the media under the printhead. Upon locking the printhead,

it would be beneficial to both feed the media by selecting the Feed button on the main

menu to properly set the next label and perform a Paper Calibration.

13.Set the Top-of-Form sensor

Note: Refer to the section called “Top-of-Form Sensor.” Setting the top-of-form sensor to

read specific media characteristics is done in the control panel.

Performance Series User’s Guide 26

Page 35

Optional Media Hub Overview

1

2

3

4

5

1. Media hub adjustment channels

2. Media hub adjustment lever

3. Hub adjustment slots

4. Media hub

5. Core holders

Figure: 3 - 12 Media Hub Layout from Top

Connections and Setup | 3

Media Specifications

Media core size:

• 3” (76.199 mm) standard

• 1” (25.4 mm) optional

• 1.5” (38.099 mm) optional

Media roll diameter:

• Maximum - 8”

Media roll width:

• Maximum - 4.65”

Media thickness:

• 0.003” to 0.01” (the p1120n can accept media thickness of up to 0.020”)

27 Performance Series User’s Guide

Page 36

3 | Connections and Setup

Media Hub

Adjustment

Lever

Hub

Handle

Media dimensions:

• Minimum specifications - 0.5” H x 1” W

Note: Ensure there is no tape or adhesive residue on the media roll.

Installing Media on the Media Hub

1. Open the media cover.

2. Press the media hub adjustment lever and pull the media hanger outward using the handle.

Figure: 3 - 13 Media installation

3. Hold the media hub adjustment lever and place the media core on the core holders.

Performance Series User’s Guide 28

Page 37

Connections and Setup | 3

Media Guide

Bouncer

Media

Guide

4. Slide the media hub inward using the handle and release the hub adjustment lever once the media is supported.

Figure: 3 - 14 Media Installation

5. Route the media under the bouncer and into the media guides.

Figure: 3 - 15 Media Guide

29 Performance Series User’s Guide

Page 38

3 | Connections and Setup

Pinch Roller Knob

Pinch Roller

6. Press the pinch roller knob and slide the media 0.25 inches beyond the pinch roller.

Figure: 3 - 16 Pinch Roller View from Top

7. While pressing the pinch roller knob, rotate the media guide adjustment wheel until the media guide touches the media on both sides.

Caution: Ensure the media guides are neither too tight nor too loose or print quality will

be affected and feed issues may develop.

Performance Series User’s Guide 30

Page 39

Connections and Setup | 3

Note: To loosen the media guides, rotate the media guide adjustment wheel counter-

clockwise. To tighten, rotate the adjustment wheel clockwise.

Figure: 3 - 17 Media Guide Adjustment Wheel

Note: The factory default media width is set to 4 inches.

31 Performance Series User’s Guide

Page 40

3 | Connections and Setup

Installing Ribbon

For thermal transfer printing, ribbon must be installed. The ribbon should be slightly

wider than the print media being used to ensure proper coverage.

1. Open the media cover.

2. Rotate the printhead latch lever clockwise to unlock and raise the printhead carriage assembly.

Figure: 3 - 18 Printhead Latch Lever

3. Slide the ribbon core over the ribbon supply hub until the core is centered on the hub.

Performance Series User’s Guide 32

Page 41

Note: Only use ribbon with a 1” diameter core.

Ribbon Supply Hub

Figure: 3 - 19 Install Ribbon

Connections and Setup | 3

4. Route the ribbon between the ribbon cam roller and the green top-of-form adjustment lever.

Note: The printer supports both coated side in (CSI) and coated side out (CSO). Ensure

the ink side faces the media.

Note: See the Menu section for information on setting the printer to run inside or outside

ink.

33 Performance Series User’s Guide

Page 42

3 | Connections and Setup

Cam Roller

Top-of-Form

Sensor Adjustment

Inside Ink Shown

Lever

Caution: Do not route the ribbon under the top-of-form sensor.

Figure: 3 - 20 Route Ribbon (Inside ink ribbon is shown)

Performance Series User’s Guide 34

Page 43

Connections and Setup | 3

5. Route the ribbon under the printhead, over the ribbon shield and clockwise around the ribbon rewinder hub.

Figure: 3 - 21 Route to Ribbon Rewinder Hub

Note: Roll the ribbon around the ribbon rewinder hub at least five (5) times to ensure it

will stay in position.

6. Ensure the thermal transfer option is selected in the control panel.

7. Set the thermal transfer option to CSI or CSO depending on the ribbon type.

Note: See the menu section for more information about the printer settings.

35 Performance Series User’s Guide

Page 44

3 | Connections and Setup

8. Rotate the printhead carriage assembly counter-clockwise until it latches.

Figure: 3 - 22 Latch the Printhead Carriage Assembly

9. Rotate the printhead latch lever counter-clockwise to lock the printhead carriage.

Note: Ensure the printhead latch lever has locked the printhead mechanism before

printing or the printer will enter a no-print condition.

Note: When removing the ribbon from the ribbon rewinder hub, grasp the center of the

ribbon, squeeze tightly and pull outward away from the rewinder hub. The rewinder hub

will collapse slightly allowing the used ribbon to slide off.

Performance Series User’s Guide 36

Page 45

Connections and Setup | 3

Configuring Media and Ribbon Settings

Once the media and ribbon have been loaded, the print parameters should be set to

match the type of media and ribbon being used. This will ensure optimal print quality.

Once set, the parameters will not need to be set again unless the media or ribbon types

are changed.

Using Media and Ribbon IDs

Media and ribbons supplied by Datamax-O’Neil and other vendors may have up to an

eight (8) digit media ID and ribbon ID assigned. Additional codes may be created in the

Utility menu and then selected from Media menu via the printer’s front panel. All relevant

print parameters will be automatically configured.

1. Select Menu > Basic > Media > Media ID.

2. Using the up and down arrows, select the appropriate Paper ID.

3. To select the Ribbon ID, navigate to tab 2 and use the scroll arrows to highlight and select the appropriate Ribbon ID.

4. Select the Home button.

5. After selecting the Home button, select the green Accept button to again confirm your selection or the red Reject button to cancel the changes.

Note: Although using media and ribbon IDs usually produce very good results, minor

adjustments may be required. Refer to the section titled Adjusting Media and Ribbon

Settings.

Selecting Media and Ribbon Types

If media and ribbon IDs are not known, the media and ribbon types may be selected

manually.

1. Select Menu > Basic > Media > Select Type.

2. Using the up and down arrows, select your paper type.

Note: If the paper type is not known, either select Coated Direct Thermal for direct

thermal printing or select Coated Thermal Transfer for printing with a ribbon.

3. Tab to the Ribbon screen.

4. Using the up and down arrow, select your ribbon type.

Note: If the ribbon type is not known, select Wax to start. This selection can always be

changed if required.

5. Tab to the Settings screen.

37 Performance Series User’s Guide

Page 46

3 | Connections and Setup

6. Select the Paper Sensor Type button until your paper type appears. The options

are as follows:

•Gap

• Mark on Top

• Mark on Bottom

•Notch

• Continuous

Note: For more information, refer to the section “Top-of-Form Sensor.”

7. Select the Paper Sensor Side button until the correct option appears. The options

are as follows:

•Outside

• Inside

Note: For more information, refer to the section “Top-of-Form Sensor.”

8. Select the Ribbon Mode button until the correct option appears. The options are as

follows:

•None

• Coated In (CSI)

• Coated Out (CSO)

Note: For more information, refer to the section “Top-of-Form Sensor.”

Note: CSI ribbon (shiny side facing outward) should be installed where the ribbon

unwinds in a counter-clockwise direction. CSO ribbon (dull side facing outward) should

be installed where the ribbon unwinds in a clockwise direction. If these settings do not

match the ribbon type being used, the ribbon supply hub will turn in the wrong direction.

Setting the Media and Ribbon Parameters Manually (Advanced)

There are times when all print parameters must be set manually. This can happen when

a new or specialized media or ribbon are being used.

Note: Some values may be grayed-out, meaning they are automatically set by default.

To change these values, select the Auto button next to the value field and then select the

green Accept button to confirm your choice to change to manual mode.

Note: Please see the Menu section for more information.

1. Select Menu > Advanced > Media.

2. Select the Paper Sensor Type field until the correct paper type appears. The

options are as follows:

•Gap

Performance Series User’s Guide 38

Page 47

Connections and Setup | 3

• Mark on Top

• Mark on Bottom

•Notch

• Continuous

3. Select the Paper Sensor Side field until the correct option appears. The options

are as follows:

•Outside

• Inside

4. Select the Ribbon Mode field until the correct option appears. The options are as

follows:

• None - for direct thermal printing

• Coated In - for thermal transfer printing

• Coated Out - for thermal transfer printing

5. Tab to the next screen and enter values for Heat and Heat Balance.

6. Tab to the next screen and enter values for Head Pressure and Rewinder Tension.

7. Tab to the next screen and enter values for Ribbon Tension Front and Ribbon Tension Rear.

8. Tab to the next screen and enter values for Ribbon Low Diameter, Gap/Mark Offset and Gap/Mark Noise.

9. If media levels are to be tracked, tab to the next screen and enter values for Ribbon Length, Form Length and Number of Forms. These parameters are used for media tracking when Paper Change Warning is enabled.

10.Select the Home button and select the green Accept button to confirm the settings.

Load a Saved Media File

For media and ribbon settings that are frequently used, media setup files can be saved to

the printer’s internal memory for easy access. For more information on saving the user

setup files, refer to the section titled Setups from the Tools > User Files menu section.

To select an internally saved media setup file, perform the following steps:

1. Select Menu > Basic > Media > User Media.

2. Using the up and down arrows, select the appropriate Internal Media Setup File.

3. Select the green Accept button and confirm the settings.

39 Performance Series User’s Guide

Page 48

3 | Connections and Setup

Counter Clockwise

Clockwise

Metal Clasp

Optional Rewinder

The rewinder is designed to rewind in either direction but the direction must be set

through the menu.

Note: Either the peel plate or the rewinder plate must be installed.

Installation of Media

1. Route the media through the platen carriage assembly.

Note: Follow the instructions for the installed media hanger.

2. Route the media under the platen carriage and around the rewinder shaft.

3. Remove the metal clasp and wind the media around the rewinder shaft in the desired direction.

Figure: 3 - 23 Rewinder

4. Insert the edge of the media into one of the two grooves on the rewinder shaft.

Performance Series User’s Guide 40

Page 49

Connections and Setup | 3

Note: For thicker labels, remove the label from the backing and insert the backing into

the groove.

Figure: 3 - 24 Media Rewinder

Note: Be sure to center align the paper on the rewinder shaft. Otherwise, the paper will

not rewind tightly.

5. Reinstall the metal clasp into the grooves.

Perform the following steps to set the rewinder direction:

1. Select Menu > Basic > Printer Mode.

2. Select the rewinder direction.

Note: Upon exiting the utility, a prompt will ask the user to accept the changes or reject

them.

Note: If the rewinder is enabled and the Auto Present Distance is set, then the printer

present distance will be set to zero (0) to avoid unnecessary backing up.

41 Performance Series User’s Guide

Page 50

3 | Connections and Setup

Note: If the rewinder is enabled, the Auto Present Distance set, and the printer in

Prompt or Applicator mode, then the actual printer present distance will be set to work

with the peel mechanism.

Top-of-Form Sensor

This printer is designed to use several types of media. The top-of-form sensor can read

media characteristics from the center to the left inside edge (viewing from the front of the

printer). Setting the top-of-form sensor to read specific media characteristics is done in

the control panel.

Media Types Supported

There are five paper types that are supported. These include gap, mark on top, mark on

bottom, notch and continuous.

The following are illustrations of the types of supported media but not every supported

media is illustrated. Please contact your reseller for assistance in selecting the

appropriate media for the printer.

Figure: 3 - 25 Gap Example

Performance Series User’s Guide 42

Page 51

Figure: 3 - 26 Notch Example

Note: The use of Notch paper disables the Out of Paper warning.

Connections and Setup | 3

43 Performance Series User’s Guide

Page 52

3 | Connections and Setup

Figure: 3 - 27 Mark on Top Example

Figure: 3 - 28 Mark on Bottom Example

Figure: 3 - 29 None

Note: For continuous paper, excessive vertical adjustment may push the print into the

next label. This mode will create labels with a 1/8” gap between them.

Performance Series User’s Guide 44

Page 53

Connections and Setup | 3

Mark

Inside Sensor Pod

Outside Sensor Pod

Lever

Top-of-Form

Adjustment

Setting the Top of Form Sensor

The top of form sensor enables the printer to determine where the print should begin and

end. Once the appropriate media has been loaded, the media type can be entered

manually into the control panel.

1. Select Menu > Basic > Media from the control panel.

2. Select Select Type.

3. Select the paper and ribbon type.

4. Select Paper Sensor Type.

5. Select the paper sensor side, either inside or outside, that correlates with the type of media being used.

Note: For example, media types with marks in the middle of the media, select Outside.

Note: The LED of the selected sensor will illuminate.

6. Unlock and release the printhead carriage assembly allowing it to open.

7. Using the adjustment lever, slide the top-of-form sensor so the appropriate LED-lit sensor pod is centered over the mark, notch or gap that was selected.

Figure: 3 - 30 Example of Top-of-Form Sensor Adjustment on “Mark on Top” media

45 Performance Series User’s Guide

Page 54

3 | Connections and Setup

Note: For illustration purposes, the image of the printhead carriage assembly was

removed in the image above. The LED sensor pods can be viewed from the front of the

printer, under the printhead carriage assembly. The active sensor pod is lit by an LED.

Note: If the wrong pod is active for your media type, check your settings.

8. Close and lock the printhead carriage assembly.

Performance Series User’s Guide 46

Page 55

Connections and Setup | 3

Front Ribbon Shield

Ribbon Shield

Adjustment Screws

Removing Ribbon Wrinkle

1. Center the supply ribbon core so the ribbon overlaps the media equally on both sides.

2. Verify there are no folds or creases in the ribbon.

3. Adjust the front ribbon shield to the middle position of the mounting slot.

Figure: 3 - 31 Ribbon Shield

4. Set the printer to print ten (10) consecutive Quality Labels from the Test menu.

a. Select Menu > Test > Test Labels.

b. Enter 10 in the Select Count field.

5. Print the labels.

6. Check for ripples drifting left or right in the ribbon between the ribbon supply and the cam roller.

47 Performance Series User’s Guide

Page 56

3 | Connections and Setup

Cam Roller

Screw

Cam Roller

Adjuster

Note: If the ripples are vertically straight, advance to step 12 to adjust the ribbon shield.

Figure: 3 - 32 Supply Side Inspection

7. If excessive ripples exist, loosen the 3 mm cam roller hex head screw enough to allow the cam roller to spin.

Figure: 3 - 33 Cam Roller

8. Turn the cam roller adjuster until the ripples are either gone or are vertical.

Performance Series User’s Guide 48

Page 57

Connections and Setup | 3

Note: The ripples must never drift left or right.

9. Tighten the cam roller screw.

10.Print ten (10) Quality Labels from the test menu.

Note: If wrinkles still appear continue with the adjustment procedure.

11. Loosen the ribbon shield adjustment screws.

12.While printing test labels, slowly adjust the lower shield until the ribbon tension is constant from left to right and the wrinkles disappear.

Note: Adjust the ribbon shield by adding tension to the side with wrinkling or light print.

Note: Adjustment should eliminate side-to-side wrinkles.

Manual Head Pressure Adjustment (p1115 only)

The printer calculates the ribbon and media settings and then suggests the optimal

printhead pressure. If the current printhead pressure setting is different from the

suggested setting, a prompt will appear on the menu screen suggesting that the head

pressure should be adjusted.

1. Select Info > Extended Status from the home screen.

2. Rotate the printhead latch lever clockwise to unlock the printhead carriage assembly.

Note: The printhead carriage assembly should be unlocked but not released.

Figure: 3 - 34 Unlock the Printhead Carriage Assembly

49 Performance Series User’s Guide

Page 58

3 | Connections and Setup

3. Rotate the printhead pressure adjustment wheel until the head pressure is set to the appropriate setting.

Note: Rotating the wheel clockwise increases the pressure while rotating the wheel

counter-clockwise decreases the pressure.

Figure: 3 - 35 Printhead Pressure Adjustment Wheel - View from Top

4. Rotate the printhead carriage assembly counter-clockwise until it latches.

Figure: 3 - 36 Latch the Printhead Carriage Assembly

Performance Series User’s Guide 50

Page 59

Connections and Setup | 3

Installing Cutter and Tray

Warning: To prevent serious injury, never place a finger or object other than media near

the cutter mechanism.

Caution: Never cut paper or media in an area where adhesives exist. Doing so will

damage the cutter and void the manufacturer’s warranty.

Caution: The media cover will not close with both the cutter and present sensor installed

at the same time for those printers with a present sensor installed in the cover..

Caution: The printer must be powered off and disconnected from AC utility power prior

to the cutter installation.

The cutter and cutting tray are available options that must be installed after receiving the

printer.

Cutter

Perform the following procedure to install the cutter.

Note: The printer and the cutter tray must be on the same level surface.

1. Power off the printer and disconnect it from utility power.

2. Remove the lower cover from the printer.

Figure: 3 - 37 Lower Cover

Note: The printer cover can be removed by carefully pulling the bottom of the cover.

51 Performance Series User’s Guide

Page 60

3 | Connections and Setup

Power/Data

Connector

3. Loosen and remove the media plate thumbscrew and the media plate.

Figure: 3 - 38 Remove Media Plate

Note: Retain the thumbscrew for cutter installation.

4. Align the cutter with the power/data connector and install the thumbscrew to secure it to the platen carriage assembly.

Figure: 3 - 39 Cutter Installation

Performance Series User’s Guide 52

Page 61

Connections and Setup | 3

Mounting Hooks

Baseplate

Slots

5. Rotate the cutter until it magnetically locks into place.

6. Activate the cutter option in the Options menu by selecting Menu > Advanced > Printer > Options > Cutter.

Note: Feed a label through the printer and observe the cut distance to ensure it cuts on

the gap. If it cuts on the label, adjust your Cut Distance Adjust settings in the

Adjustments menu. Select Menu > Advanced > Adjustments > Cut Distance Adjust.

Note: A negative value moves the cut line toward the current label being printed. A

positive value moves the cut line toward the next label to be printed.

Cutter Tray

The cutter tray collects labels and media after they have been cut. The tray may be

installed before or after the installation of the cutter.

1. Place the tray mounting hooks into the baseplate slots.

Note: For a clearer illustration, the cutter has been removed from the illustration below.

Figure: 3 - 40 Cutter Tray Installation

53 Performance Series User’s Guide

Page 62

3 | Connections and Setup

Setting Up the Cutter Tray

The cutter tray assembly is adjustable to fit various label lengths from 2” (50.8 mm) to 6”

(152.4 mm) and widths up to 4.65” (118.1 mm) for the p1115, p1115s, p1120 and p1125.

The maximum label width for the p1725 is 7.1” (180.34 mm).

1. Loosen the tray lock thumbscrews.

Figure: 3 - 41 Tray Lock Thumbscrews

Performance Series User’s Guide 54

Page 63

2. Loosen the height adjustment thumbscrews.

Figure: 3 - 42 Height Adjustment Thumbscrews

Connections and Setup | 3

3. Rotate the tray shelf to the desired position and secure all four thumbscrews that were previously loosened.

Figure: 3 - 43 Tray Shelf Adjustment

55 Performance Series User’s Guide

Page 64

3 | Connections and Setup

4. Loosen the length guide thumbscrew.

Figure: 3 - 44 Length Guide

5. Adjust the length guide to the desired position and then secure the thumbscrew.

Figure: 3 - 45 Length Guide Adjustment

Performance Series User’s Guide 56

Page 65

Connections and Setup | 3

Upward-Facing Present Sensor

Note: The upward-facing present sensor is not an available option for the p1725

Perform the following procedure for installing the upward-facing present sensor.

1. Power off the printer and disconnect it from utility power.

2. Remove the lower cover from the printer.

Figure: 3 - 46 Lower Cover

Note: The printer cover can be removed by carefully pulling the bottom of the cover.

3. Loosen and remove the media plate thumbscrew and the media plate.

Figure: 3 - 47 Remove Media Plate

57 Performance Series User’s Guide

Page 66

3 | Connections and Setup

Captive Screw

Note: Retain the thumbscrew for future re-installation of the media plate.

4. Align the present sensor with the power/data connector and tighten the captive screw to secure it to the platen carriage assembly.

Figure: 3 - 48 Present Sensor Installation

5. Close the present sensor until it magnetically locks into place.

6. Activate the present sensor option in the Options menu by selecting Menu > Basic > Printer Mode > Present Sensor Enable.

Performance Series User’s Guide 58

Page 67

Connections and Setup | 3

Print Driver Installation

Overview

This installation should be executed only on a computer where a pw Series printer driver

is not currently installed or one that the driver have been completely removed.

The Windows driver is located on the Accessories CD-ROM included with the printer. For

the latest version please visit our web site at http://www.datamax-oneil.com

Installing the Windows Driver:

1. Place the Accessories CD-ROM included with the printer into the computers CDROM drive. Once the CD-ROM starts select your printer model then “Install Driver”

from the menu. Follow the instructions on the screen to install.

If the driver was downloaded from our website, simply double click the downloaded

“.exe” file to launch the installation.

2. Check the “Remove printer drivers” radio button then click ‘Next’. If this option is not available skip to Step 6.

3. On the next screen check the “Remove printers” radio button then click ‘Next’.

4. Browse the list of installed printers, if any “Workstation” or “Performance” printers are listed check the corresponding check boxes and click ‘Next’ to remove the installed printers.

5. The next screen will show a summary of items to be removed, click ‘Finish’ to complete the removal process. Once complete return to the main screen to install the new driver.

59 Performance Series User’s Guide

Page 68

3 | Connections and Setup

6. Check the “Install printer drivers” radio button then click ‘Next’ and follow the on-screen instructions to install the driver.

7. When prompted, select your printer from the list, (i.e., Datamax-O’Neil p1xxx). Continue to follow the on-screen instructions to install the driver.

Important Notes:

The Windows driver functions the same as any other Windows printer. While built-in help

files provide information on all settings, there are some important setting parameters that

should be observed for trouble free printing:

Page Setup Tab: Stock

It is important that the Stock setting

matches the size of the label you are

using. If you cannot find a match for your

label click New and enter the dimensions

of your label.

Options Tab: Print Speed & Printhead

Temperature

These two settings will have the greatest

effect on print quality. Some label stocks

will require more heat and slower print

speeds to generate a quality image.

The Windows application software used to create the label format will likely have a "Page

Setup" screen. This will also need to match the size of the label you are using

Performance Series User’s Guide 60

Page 69

4 Menu System

Menu Overview

The printer is designed with a touchscreen display. Functions can be enabled and

disabled and settings can be changed through the on-screen menu. Press the buttons on

the screen with the light touch of a finger. Some items may be grayed out or not visible

depending on the printer model and available options.

Caution: Do not touch the screen with excessive force or by using sharp objects. Doing

so will damage the touchscreen and may void the manufacturer’s warranty.

Layout of the Display

Navigation

The menu screens have buttons for advancing or returning to screens.

Back Button

The Back button provides the user with the option to return to a previous menu

screen.

Home Button

Selecting the Home button sends the user to the main screen.

Tabbed Browsing

Blue left and right arrow buttons are provided at the bottom right of the screen to

navigate tabbed menus. Select the right arrow to advance to the next tab or the left

arrow to return to the previous tab.

Scrolling

Some menu screens allow for scrolling. Select the appropriate up or down arrow.

Changing V alues

Numeric values can be entered or changed by selecting the field and entering the

values using the numeric keypad. They can also be increased or decreased using

the subsequent plus or minus buttons.

Other menu options are changed by pressing the button until the appropriate

selection appears.

Page Return Button

The Page Return button allows the user to return to the last setup screen that was

exited after selecting the Home button.

61 Performance Series User’s Guide

Page 70

4 | Menu System

Printer Status

Buttons

Date / Time

Operator Action

Fault Information

Model ID

Connected Devices

Area

Area

and

Mode Indicators

Three Button Panel

The printer may be placed in 3-button security mode which restricts the operator from

changing any settings or printing test labels. An administrator can access the printer

menu by pressing on the “Model ID” in the taskbar and entering the appropriate security

password. Once the password has been entered and accepted, the user will be allowed

access to the full home screen.

To return the menu to the 3-button security mode, select the “Model ID” again.

Home Screen

The home screen presents several options to the user.

Printer Status

The printer status area displays the state of the printer. These states include the

following:

Performance Series User’s Guide 62

• Rea

• Bus

dy - The printer is idle and ready to accept internal or external commands.

y - Appears when printing or feeding paper.

• Fault - The printer has paused due to a fault condition.

• Wa

rning - The printer has paused due to a warning indicator.

• Coo

• W

ling Down - The printer has paused while it is cooling down.

aiting - The printer is blocked by the optional Applicator or Present Sensor.

• Configuration - The printer is connected to the Configuration Utility

• Canceling - The printer is currently canceling a print job.

.

Page 71

Menu System | 4

Operator Action Area

Information about the current printer action will be displayed in this area. For example,

“Printing 1 of 3” might be displayed when printing the first of three labels for a print job.

Date / Time

The time and date may be toggled on by pressing the upper right corner of the display.

After pressing the blank area, the current date and time will be displayed on the screen.

Once the home button is pressed, a screen will appear asking the user if the date and

time will be displayed. Select the green Accept button to display the time or the red

Reject button to cancel.

Fault Information Area

Warnings and faults will be displayed in this area. Once the fault has been corrected, the

message will disappear.

Connected Devices

The symbol for devices connected to the USB host will be presented in this area.

Mode Indicators

The printer will display modes that have been activated. If options have been installed

but not enabled, they will not appear in this area of the display.

Information Button

By selecting the information button from the task bar, the following information can be

accessed. Select the Print button in the taskbar to print the information. Not all of the

information listed below is available for every printer.

• System Info

• Settings Report

• Network Report

• Extended Status

• Serial Report

• GPIO Report

• Printhead Info

• Fonts Report

Note: Selecting the up or down arrow will display additional information.

63 Performance Series User’s Guide

Page 72

4 | Menu System

1. System Information

The following will be displayed upon selection of the System Info button:

• Printer Model

• Printhead Model

• Firmware Version

• FPGA Version

• Ribbon Version

•Boot Version

•Board ID

•RAM Size

• Flash Size

• Printer Key

• Absolute Counter

• Printhead Counter

• Setup File

• Paper

• Ribbon

• Detected Options

2. Settings Report

The settings report provides information on the printer settings.

Media Settings

• Paper Sensor Type

• Paper Sensor Side

• Ribbon Mode

•Heat

• Heat Balance

• Head Pressure

• Rewinder Tension

• Ribbon Tension Front

• Ribbon Tension Rear

• Ribbon Low Diameter

Performance Series User’s Guide 64

Page 73

• Gap/Mark Offset

• Gap/Mark Noise

• Number of Forms

• Form Length

• Ribbon Length

Printer Settings

• Cutter Mode

• Cut by Count

• Rewinder Mode

• Present Sensor

• Print Speed

• Feed Speed

• Reverse Speed

Menu System | 4

• Present Distance

• Error Sound

• Warning Sound

• Paper Low Warning

• Paper Out Warning

• Cover Open Warning

• Paper Change Warning

• Rewinder Full Warning

• Reprint on Error

• Present Timeout

• Pause Mode

Page Defaults Settings

• Print Length

•Print Width

• Vertical Offset

• Horizontal Offset

•Orientation

• Raster Mode

• Font Name (Number)

65 Performance Series User’s Guide

Page 74

4 | Menu System

• Point Size

• Pitch Size

• Symbol Set

• Print Truncation

• Print on Gap/Mark

Auto Settings

• Auto Load

• Auto Option Detect

• Auto Calibrate

• Auto Present Distance

• Auto Tension

• Auto Pressure

• Auto Speed Adjust

• Suggested Pressure (p1115)

Adjustment Settings

• Present Distance Adjust

• Cut Distance Adjust

• Cutter Rotation Adjust

• Vertical Adjust

• Horizontal Adjust

• Head Pressure Adjust

• Rewinder Tension Adjust

• Ribbon Tension Front Adjust

• Ribbon Tension Rear Adjust

• Darkness

• Contrast

Calibration Settings

• Paper Threshold (for non-continuous sensor type)

• Gap/Mark Threshold (for non-continuous sensor type)

• TOF Gain (for non-continuous sensor type)

• Autoload Empty

Performance Series User’s Guide 66

Page 75

Menu System | 4

• Autoload Current

3. Network Report

The Network Report option provides information about the network on which the printer

resides. The following information is available:

• Ethernet IP

• Ethernet Subnet Mask

• Ethernet Gateway

• Ethernet MAC

• Ethernet DHCP

• Wireless IP*

• Wireless Subnet Mask*

• Wireless Gateway*

• Wireless SSID*

• Wireless MAC*

• Wireless DHCP*

• Hostname

• Network Time Protocol

• Webpages

•SSH

•SNMP

•SNMP Trap IP

•LPD

*Available only if the wireless option is installed.

4. Extended Status

The Extended Status option provides sensor information including:

• Head Temperature

• Head Voltage

• Head Pressure

• Paper Level

• Ribbon Level

• Rewinder Level

67 Performance Series User’s Guide

Page 76

4 | Menu System

• TOF Sensor

• Auto Load Sensor

• Session Label Count

Extended Status is also available when printing by pressing the icon in the mode

indicator area.

Note: With “Paper Change Warning” enabled, levels will be shown as percentages.

5. Serial Report

The serial report provides serial connectivity information including:

• Baud Rate

• Data Bits

•Stop Bits

•Parity

• Flow Control

6. GPIO Report

The GPIO Report provides the following information:

• GPIO Mode

• Slew Speed

• Pulse Width

• Signal 1 - I/O, Function, Type

• Signal 2 - I/O, Function, Type

• Signal 3 - I/O, Function, Type

• Signal 4 - I/O, Function, Type

• Signal 5 - I/O, Function, Type

• Signal 6 - I/O, Function, Type

• Signal 7 - I/O, Function, Type

• Signal 8 - I/O, Function, Type

7. Printhead Info

The Printhead Info report provides the following information:

• Printhead Serial Number

• Printhead Model

Performance Series User’s Guide 68

Page 77

Menu System | 4

• Printer Serial Number

• Current Firmware

• Printhead Inches

• Installation Date (Initial)

• Installation Date (Current)

• Clean Schedule

• Clean Procedures

• Clean Counter Resets

• Number of Inches

8. Fonts Report

The Fonts Report provides the font name and the font number. This includes both the

resident and user downloaded or imported fonts. It will also show a sample PCL

sequence for addressing the font using the appropriate typeface number.

Note: The resident fonts are listed in the Appendix of this manual.

Note: It is the user’s responsibility to obtain the appropriate licenses for downloaded or

imported fonts.

Feed Button

Selecting the feed button will feed the media through the print mechanism one label at a

time.

69 Performance Series User’s Guide

Page 78

4 | Menu System

Menu

The Menu button provides the user with access to the system settings and also allows

for the enabling of options. The Menu screen displays the following options:

•Basic

•User

• Advanced

• Tools

• Language

•Test

1. Basic

Selecting the Basic button allows for access to the basic settings. These include the

following:

• Printer Mode

•Media

•Print Adjust

Printer Mode

The printer is available with several options which are enabled or disabled via the Printer

screen. Three of the modes cannot happen concurrently so the highest priority mode will

take precedence. The order is as follows:

1. Pause Mode (High)

2. Present Sensor (Medium)

3. GPIO Mode (Low)

a. Cutter Mode

The cutter supports the cutting of media into separate labels.

For printers with a print media cutter inst

alled, select from the following Cutter Mode

options:

•Off

• Cut By Label

• Cut By Job

• Cut By Count

Cut By Count enables the user to specify the number of labels printed prior to being cut.

Select the Cut By Count field and enter the number of labels to be printed.

Performance Series User’s Guide 70

Page 79

Menu System | 4

b. Rewinder Mode

Rewinder Mode controls the operation of the powered internal label rewinder.

For printers with a print media rewinder installed, select from the following Rewinder

Mode options:

•Off

• Clockwise

• Counter Clockwise

c. Present Sensor

The Present Sensor option controls the on-demand dispensing of labels.

To enable or disable the installed Present Sensor option, select or deselect the

corresponding checkbox.

d. GPIO Mode

The GPIO Mode enables or disables the applicator function from the printer. For printers

with an applicator connected, select from the following settings:

•Off

•Custom