Page 1

92-2479-01 Rev.E

Peel & Present Option

Page 2

Page 3

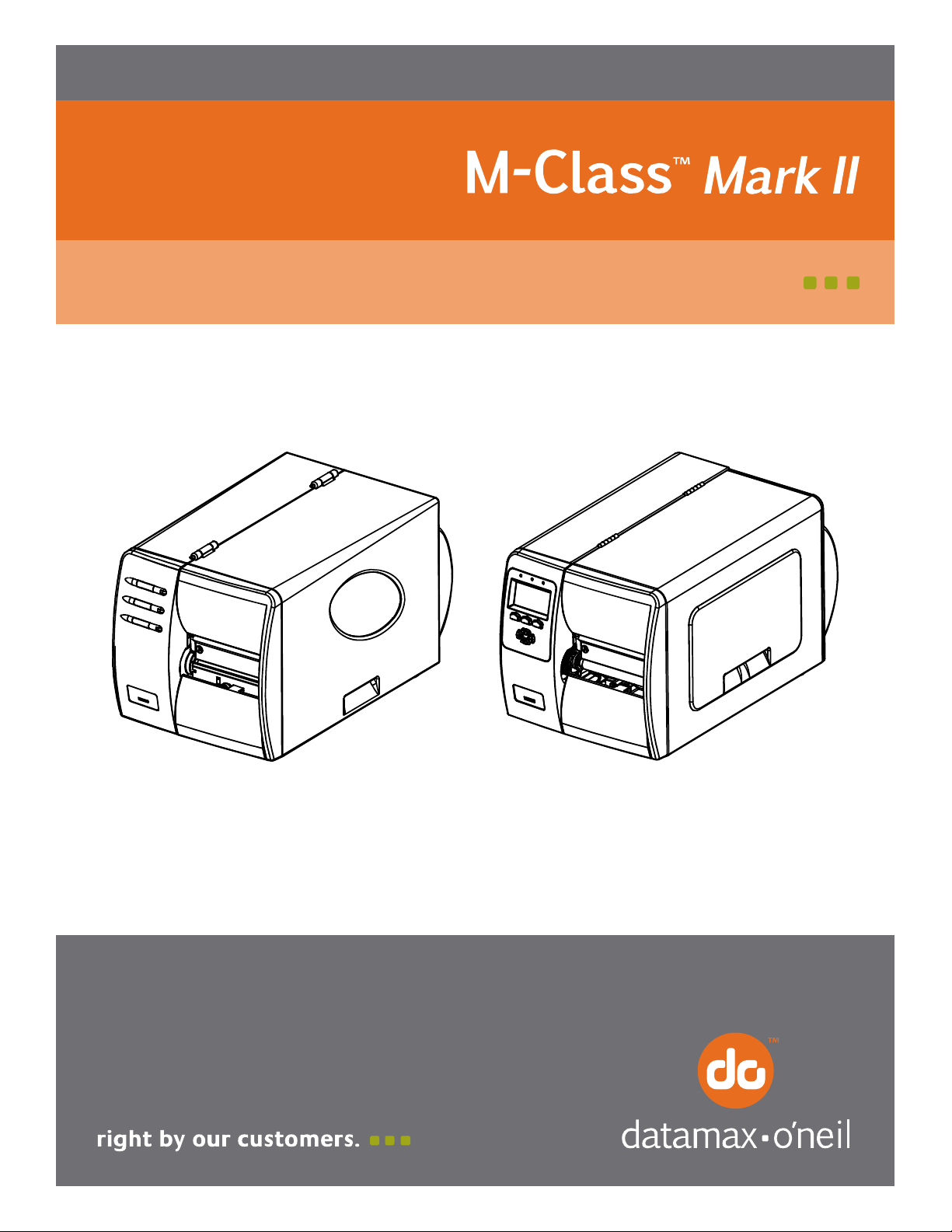

Contents of the Peel & Present Kit

This kit contains the following items:

Peel and Present Mechanism

Assist Roller and Bushing

NOTE: If this option was ordered with the printer the Assist

Roller and Bushing will already be installed in the printer.

Proceed to Step 3: Installing the Peel & Present Mechanism.

Otherwise follow the steps below to install these items into

the printer.

Other Requirements

This option requires the Internal Rewinder option. Contact your sales representative for more information.

Tools Required

To install this option you will need a #2 Flathead and a #2 Phillips head screwdriver.

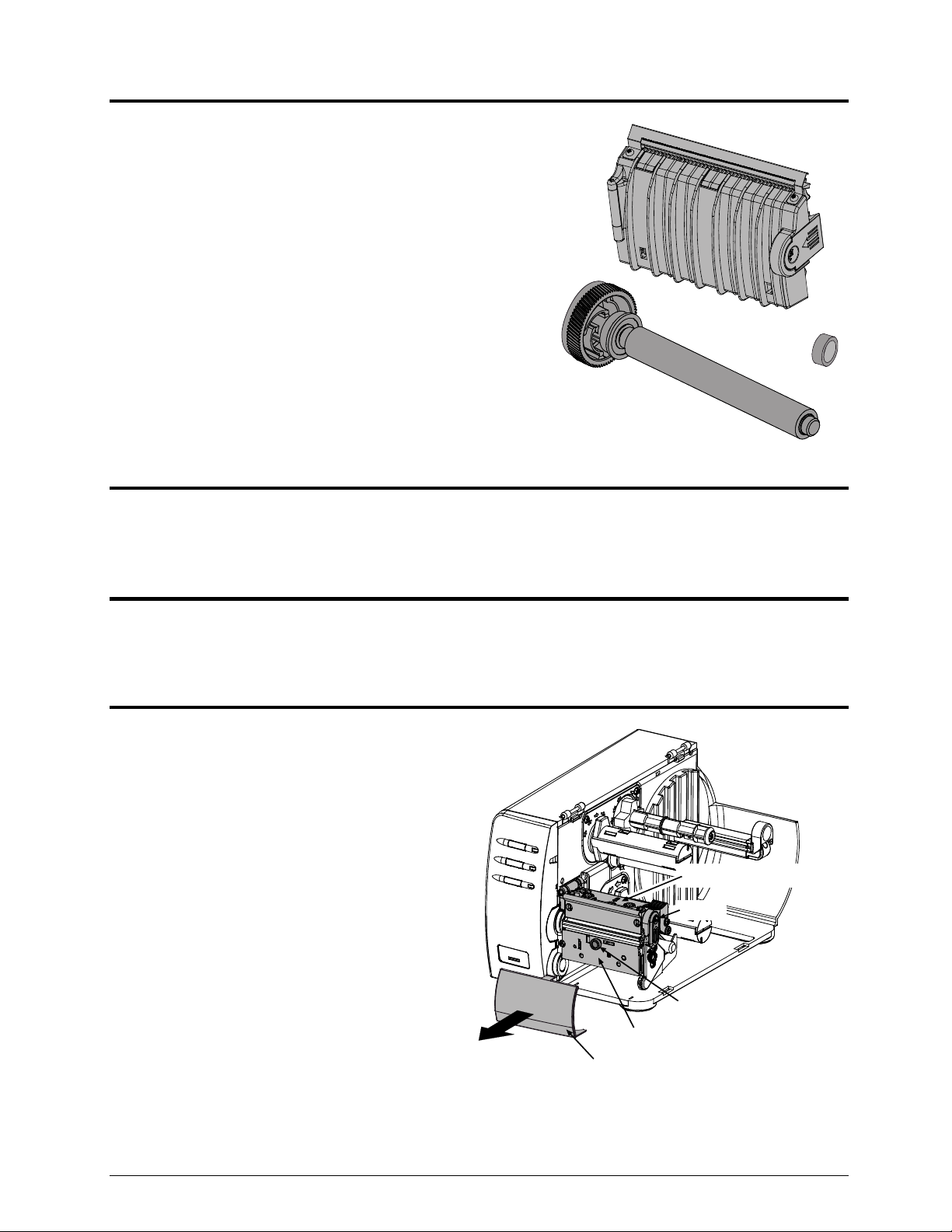

Step 1: Preparing the Printer

Turn ‘Off’ the power switch and unplug the

printer.

Open the cover. Press in Latch and raise the

Printhead Mechanism.

Remove any media from the printer.

Remove the Fascia by gently pulling it

forward.

Loosen and remove the Thumbscrew, then

remove the Tear Plate.

Tear Plate

Fascia

Printhead Mechanism

Latch

Thumbscrew

1

Page 4

Using a #2 Philips head screwdriver, remove

the Screw that secures the Side Plate to the

printer.

Remove the Side Plate.

Side Plate

Screw

Using a #2 Philips head screwdriver, remove

the Screw that secures the Bearing Cap to the

printer.

Remove the Bearing Cap and the Hole Plug.

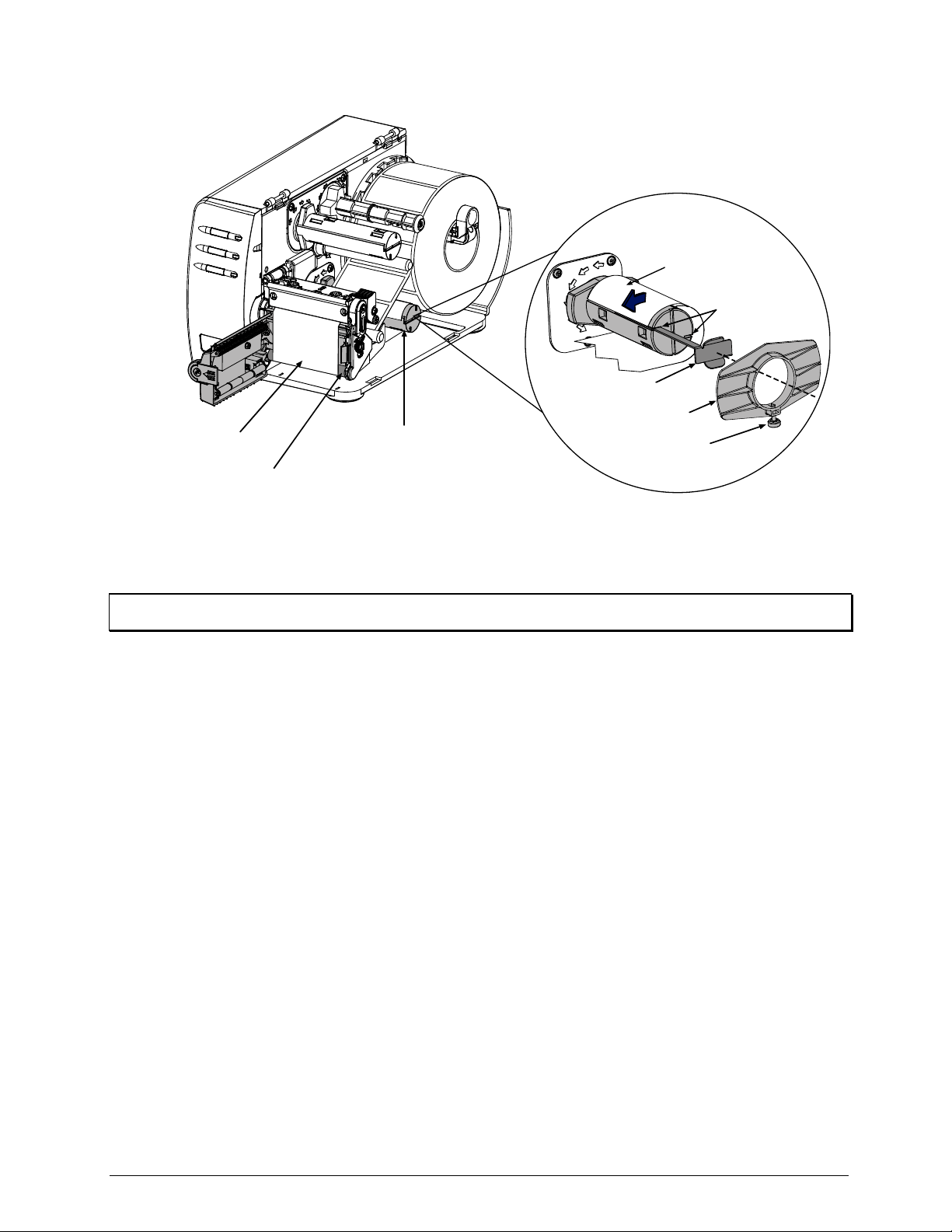

Step 2: Installing the Assist Roller

Insert the Assist Roller, as shown, gears first

into the printer.

Pivot the other end of the roller into the

Bearing Block.

Screw

Hole Plug

Bearing Cap

Assist Roller

2

Bearing Block

Page 5

Insert the Bushing completely into

the Bearing Block.

While holding the Assist Roller

Bearing against the Centerplate,

replace the Bearing Cap.

Hold the Bearing Cap in place and

secure it with the Screw.

Replace the Side Plate and start, but

tighten the Screw.

do not

Assist Roller

Bearing Cap

Screw

Centerplate

Assist Roller Bearing

Bushing

Bearing Block

Side Plate

Screw

3

Page 6

Ensure that the Leveling Cam is

loose, and then close and latch the

Printhead Assembly.

Printhead Assembly

While pushing down on the

Printhead Assembly, as shown, pull

Leveling Cam

down on the Side Plate and tighten

the Screw.

Screw

Side Plate

Verify Latch Operation:

- Open and close the printhead assembly, verify that the latch is fully engaged. If you are unable to get

the printhead to latch, the side plate is too low.

- Pressing down on the printhead assembly should not cause the latch to loosen or reveal any gap at the

latch point. If there is a gap or movement in the latch then the side plate is too high.

- Print some sample labels. If degraded print quality or ribbon tracking problems are observed then the

side plate is not positioned correctly.

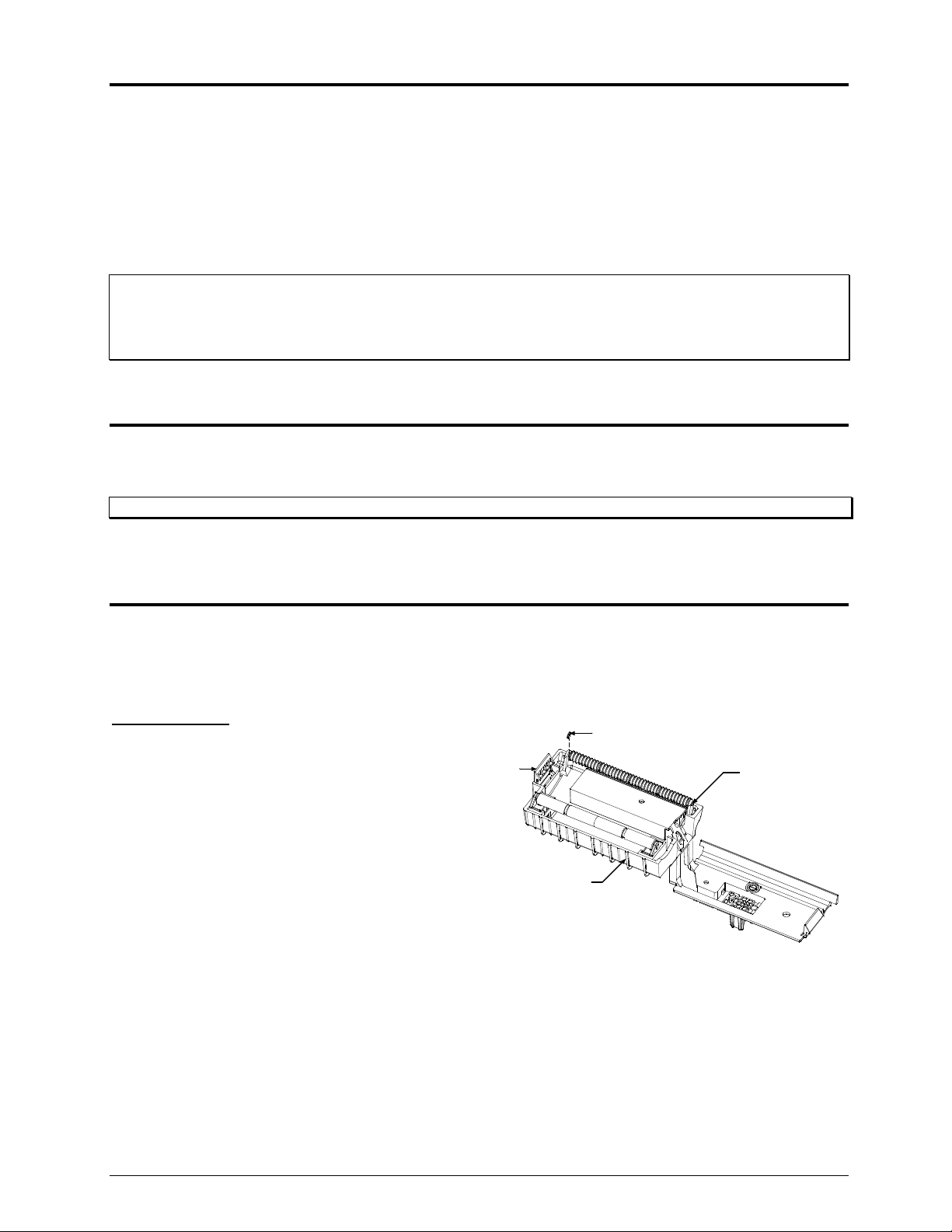

Step 3: Installing the Peel & Present Mechanism

Position the Peel and Present Mechanism

for mounting on the front of the printer.

Tighten the Mounting Screw to secure

the mechanism to the printer.

This completes the installation process.

Proceed to Loading Media to begin use.

Mounting Screw

Peel and Present Mechanism

4

Page 7

Loading Media

With the Peel and Present option, labels printed in a batch will be automatically be separated from the

backing material and dispensed “on-demand”– that is, printing will occur only after a previously printed

label has been removed from the printer.

Press in the Latch to open the mechanism.

Swing the mechanism open.

Load the printer with media (see the

Operator’s Manual for detailed instructions).

Load media into the printer as you normally

would for tear-off operation (see the

Operator’s Manual for details), however,

extend an additional 12 inches (30 cm) of

media out the front of the printer.

From this 12 inches (30 cm) of media, remove

all of the labels, so that only the Backing

Material remains.

Latch

Backing Material only

5

Page 8

Route the Backing Material under the Assist Roller and around the Internal Rewinder, as shown

below.

Backing Material

Slots

Media Clip

Retainer

Backing Material

Assist Roller

Internal Rewinder

Thumbscrew

Note: The Media Retainer can be used in place of the Media Clip for a more consistent rewound roll. The Media

Clip and Media Retainer cannot be used together.

Put the leading edge of the Media into a Slot on the Internal Rewinder and insert the Media Clip. Be

sure the leading edge of the Media is cut square and that is inserted evenly into the slot.

Manually rotate the Internal Rewinder to remove slack from the Media.

Plug in and turn ‘On” the printer. After initialization, press the FEED Button to align the next label to

the top of form position. (If a peeled label is presented, remove it to proceed.) The printer is now ready

for on-demand use.

6

Page 9

Setup, Configuration, and Operation

The Peel and Present option is plug and play; no setup or configuration is required. As soon as power is

applied, the printer senses and enables the Present Sensor for operation.

During operation, when a label is present (blocking the sensor), the yellow Stop Light on the front panel of

the printer will flash to prompt you that a label awaits removal.

With printers equipped with an LCD display, the display will read “REMOVE LABEL”

Notes: (1) The operation of the Present Sensor can also be controlled via software commands from the host. Be

sure that your software program is properly configured for use with this option. (2) If the Present Sensor is

disconnected without first powering off the printer, the printer will behave as if there is a label blocking the

sensor. Turn the printer off and then back on. The printer will reconfigure itself to operate without the

Present Option

Unloading the Internal Rewinder

When the Internal Rewinder becomes full remove the Media Clip. Grasp the used backing material and

pull it from the Internal Rewinder.

Note: Never allow the outer diameter of backing material to exceed 4 inches (102 mm) on the Internal Rewinder.

Periodic Maintenance

The Peel Mechanism Rollers will need to be disassembled and cleaned approximately every 100,000

inches to ensure trouble free operation. This cleaning interval may be more or less depending on the type

of adhesive on the back of your media. Heavy or “gummy” adhesive will require more frequent cleaning.

Upper Rollers:

Remove the Peel Mechanism from the printer.

Press in on the Latch and allow the Front Cover

to swing open.

Remove the small C-Clip from the Upper

Roller Shaft.

C-Clip

Latch

Front Cover

Upper Roller

Shaft

7

Page 10

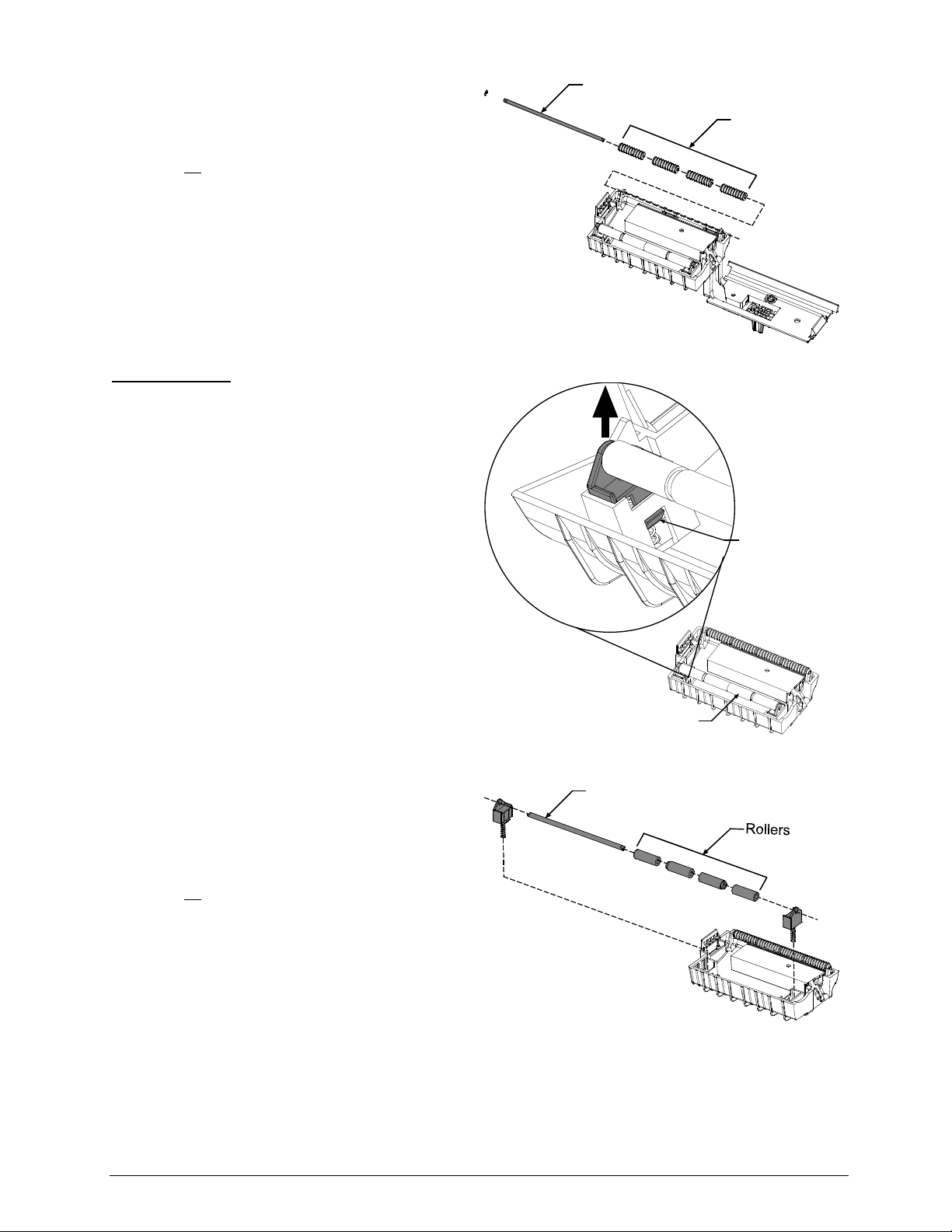

Remove Upper Roller Shaft and associated

Rollers.

Clean all

surfaces of the Rollers and the Upper

Roller Shaft. Isopropyl Alcohol can be used,

for heavy or stubborn deposits WD-40

or an

adhesive remover can be used. Be sure all the

ridges on the rollers are free of debris.

Re-assemble the Upper Roller Shaft, Rollers,

and C-Clip into the Peel Mechanism Assembly.

Lower Rollers:

Remove the Peel Mechanism from the printer.

Press in on the Latch and allow the Front Cover

to swing open.

Push in on the Tab as shown, repeat for the

other side and then remove the entire Lower

Roller Assembly.

Upper Roller

Shaft

Rollers

Push in on Tab

Remove Lower Roller Shaft and associated

Rollers. Note the order of the Rollers as they

are removed, they must be re-installed in the

same order.

Clean all

surfaces of the Rollers and the Lower

Roller Shaft. Isopropyl Alcohol can be used,

for heavy or stubborn deposits WD-40

or an

adhesive remover can be used. Be sure all the

ridges on the rollers are free of debris.

Re-assemble the Lower Roller Shaft and

Rollers. Reinstall the assembly into the Peel

Mechanism Assembly

Lower Roller

Assembly

Lower Roller

Shaft

8

Loading...

Loading...