Page 1

INSTRUCTION MANUAL

> DataVS2 - VSM

Page 2

Datalogic S.r.l.

Via S. Vitalino 13

40012 Calderara di Reno

Bologna - Italy

DataVS2 - VSM Instruction Manual

Ed.: 12/2017

© 2011 - 2017 Datalogic S.p.A. and/or its affiliates ALL RIGHTS RESERVED. Without limiting the

rights under copyright, no part of this documentation may be reproduced, stored in or introduced into a

retrieval system, or transmitted in any form or by any means, or for any purpose, without the express

written permission of Datalogic S.p.A. and/or its affiliates.

Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in many countries,

including the U.S.A. and the E.U.

All other trademarks and brands are property of their respective owners. Datalogic reserves the right

to make modifications and improvements without prior notification.

18/12/17

Page 3

iii

CONTENTS

COMPLIANCE .............................................................................................................. v

CE Compliance ............................................................................................................. v

FCC Compliance .......................................................................................................... v

GENERAL VIEW ......................................................................................................... vi

1 GENERAL INFORMATION .......................................................................................... 1

1.1 Conventions Used in the Manual .................................................................................. 1

1.2 General Description ...................................................................................................... 1

2 INSTALLATION ........................................................................................................... 2

2.1 Safety Recommendations ............................................................................................. 2

2.2 DataVS2 VSM DIN Rail Mounting ................................................................................ 2

2.3 DataVS2 VSM Panel Mounting ..................................................................................... 4

3 ELECTRICAL CONNECTIONS ................................................................................... 6

3.1 Pinouts .......................................................................................................................... 6

3.1.1 DataVS2 OBJ/AOR Sensor .......................................................................................... 6

3.1.2 DataVS2 ID/PRO Sensor .............................................................................................. 6

3.1.3 VSM Monitor ................................................................................................................. 7

3.2 Point-to-Point Connection ............................................................................................. 7

3.3 LAN Connection ............................................................................................................ 7

3.4 Ground Connection ....................................................................................................... 8

3.5 DataVS2 Power Connection ......................................................................................... 8

4 FIRST APPROACH TO VSM ....................................................................................... 9

4.1 Introduction ................................................................................................................... 9

4.2 VSM User Interface ...................................................................................................... 9

4.3 Connection to DataVS2 .............................................................................................. 10

5 MONITORING AN INSPECTION ............................................................................... 12

6 INSPECTION CHANGE ............................................................................................. 13

7 INSPECTION PARAMETER CHANGE ..................................................................... 14

7.1 Current Inspection Change ......................................................................................... 14

7.2 Camera Parameter Change ........................................................................................ 15

7.3 Tool Parameters Change ............................................................................................ 17

7.3.1 Tool Selection ............................................................................................................. 17

7.3.2 ROI Change ................................................................................................................ 18

7.3.3 Other Parameter Changes of the Selected Tool ......................................................... 20

7.4 Reference Image Change ........................................................................................... 21

7.5 Trigger Mode Change ................................................................................................. 22

8 ADVANCED FUNCTIONS ......................................................................................... 23

8.1 Monitor Settings .......................................................................................................... 23

8.2 Sensor Settings .......................................................................................................... 24

8.3 Memory Management ................................................................................................. 25

8.3.1 Slot Selection (VSM) ................................................................................................... 25

8.3.2 Slot Selection (DataVS2) ............................................................................................ 26

8.3.3 Transfer from VSM to DataVS2 .................................................................................. 26

8.3.4 Transfer from DataVS2 to VSM .................................................................................. 27

Page 4

iv

8.3.5 Cancellation of a VSM Slot ......................................................................................... 27

8.3.6 Cancellation of a DataVS2 Slot .................................................................................. 28

8.3.7 Cancellation of all the VSM Slots ................................................................................ 28

8.3.8 Cancellation of all the DataVS2 Slots ......................................................................... 29

8.4 Factory Reset ............................................................................................................. 29

8.5 Sensor List .................................................................................................................. 31

8.6 Users .......................................................................................................................... 31

8.6.1 Removal of the Password ........................................................................................... 35

8.7 Language .................................................................................................................... 36

8.8 Disconnect .................................................................................................................. 36

9 DATAVS2 GUI CONNECTION .................................................................................. 37

9.1 VSM General Information ........................................................................................... 38

9.2 VSM Memory Settings ................................................................................................ 39

9.3 Firmware Update ........................................................................................................ 40

10 RECOVERY MODE .................................................................................................... 42

10.1 Recovery Procedure ................................................................................................... 42

11 CHECKS AND PERIODIC MAINTENANCE .............................................................. 44

12 WARRANTY ............................................................................................................... 45

13 SPECIFICATIONS ...................................................................................................... 46

14 OVERALL DIMENSIONS ........................................................................................... 47

Page 5

v

COMPLIANCE

For installation, use and maintenance it is not necessary to open the reader.

Only connect Ethernet and dataport connections to a network which has routing only within

the plant or building and no routing outside the plant or building.

CE COMPLIANCE

CE marking states the compliance of the product with essential requirements listed in the

applicable European directive. Since the directives and applicable standards are subject to

continuous updates, and since Datalogic promptly adopts these updates, therefore the EU

declaration of conformity is a living document. The EU declaration of conformity is available for

competent authorities and customers through Datalogic commercial reference contacts. Since

April 20th, 2016 the main European directives applicable to Datalogic products require inclusion

of an adequate analysis and assessment of the risk(s). This evaluation was carried out in relation

to the applicable points of the standards listed in the Declaration of Conformity. Datalogic

products are mainly designed for integration purposes into more complex systems. For this

reason it is under the responsibility of the system integrator to do a new risk assessment

regarding the final installation.

Warning: This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

FCC COMPLIANCE

Modifications or changes to this equipment without the expressed written approval of

Datalogic could void the authority to use the equipment.

This device complies with PART 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference which may cause undesired

operation.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

Page 6

vi

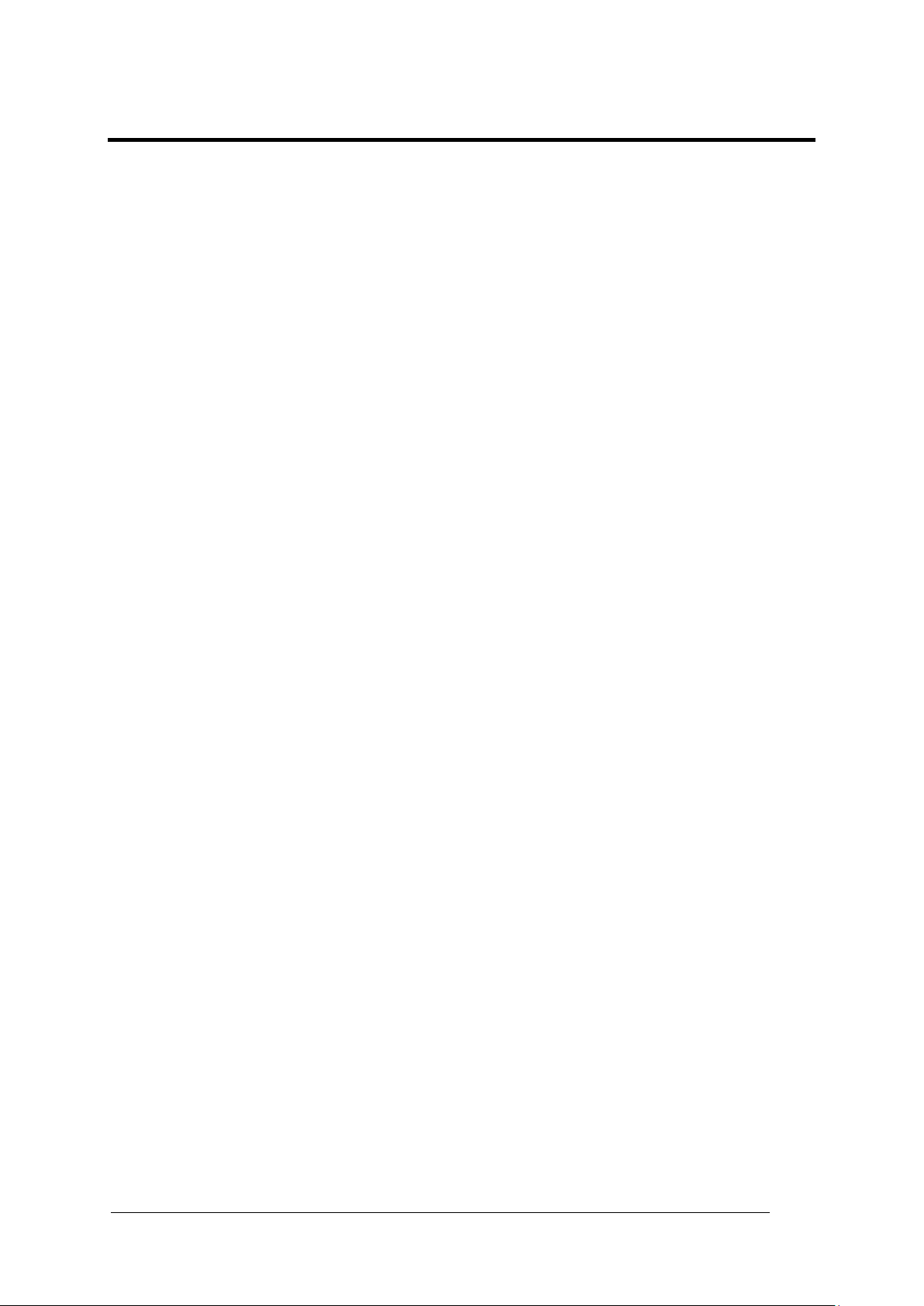

Monitor (color 3.5" LCD 320x240 pixel)

1

TEACH Button

4

Status LEDs

2

Power Supply Connector

5

ARROW Buttons

6

Ethernet Network Connector

7

STATUS Button

3

ESC Button

8

SET Button

9

Power, OUT, ETH Link LEDs

10

1 2 3

4 5 6 7 8

9

10

GENERAL VIEW

DataVS2-VSM

Figure A

Page 7

GENERAL INFORMATION

1

1

NOTE

This refers to information of particular interest.

NOTE

The Datalogic DataVS2 vision sensor (machine vision) is easy to use and

has advanced inspection functions which makes it very suitable to many

different fields (quality control on production lines or automatic material

handling are just a few examples).

1 GENERAL INFORMATION

1.1 CONVENTIONS USED IN THE MANUAL

This manual was developed to provide clear and precise information on how to use the

DataVS2 VSM system.

1.2 GENERAL DESCRIPTION

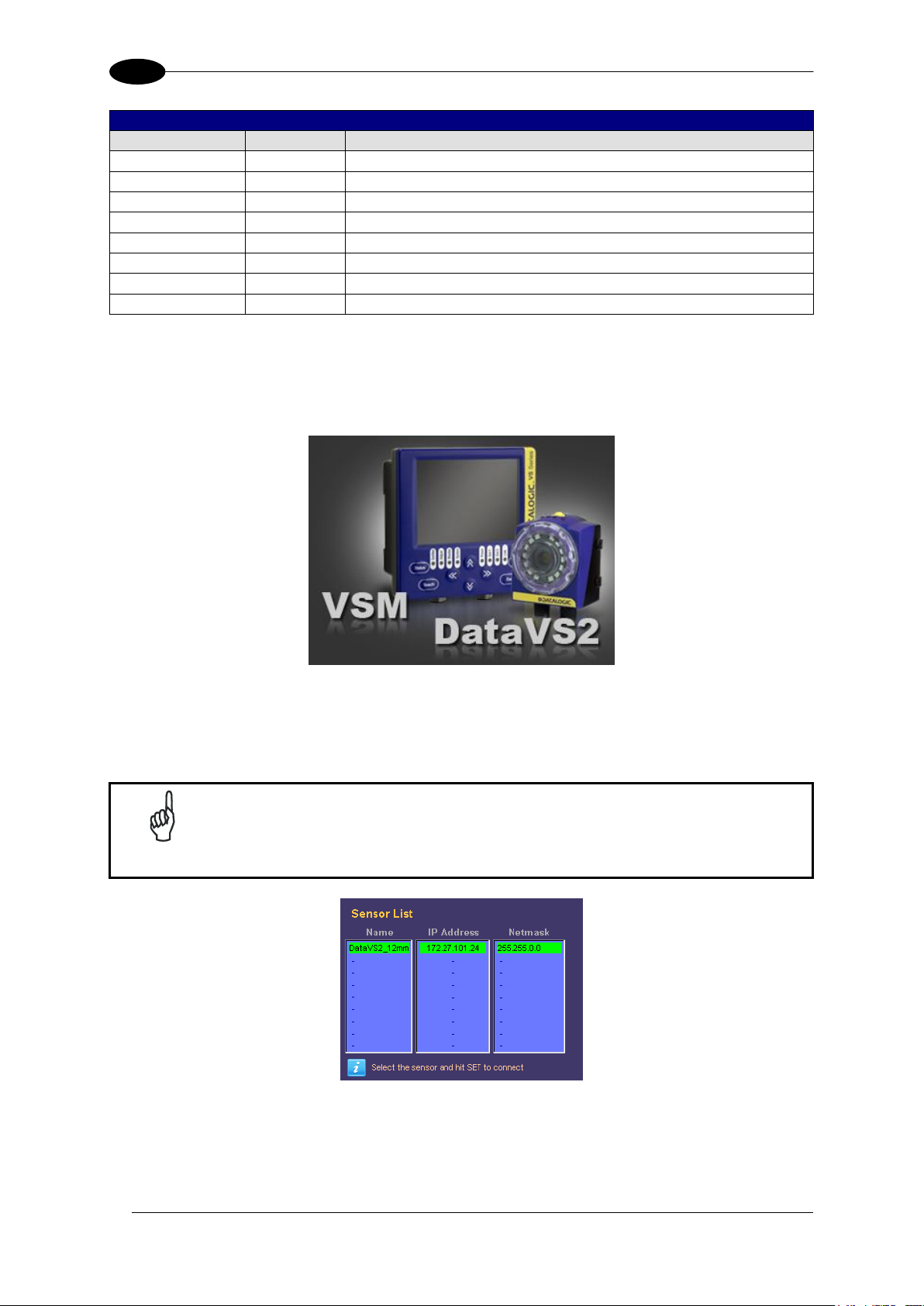

The VSM is a visualisation and control device compatible will all the vision sensors of the

DataVS2 series. The monitor can be connected directly to one sensor or installed on a

network.

Once connected, the VSM monitor displays the processed images together with the results

of the analysis tools as well as a few statistics relative to control results. The device controls

the functioning of the vision sensors as well as changing the parameters in order to adapt

and vary the DataVS2 configuration without using a PC.

VSM allows simple and rapid sensor setting. The user can immediately access all the

functions: change an inspection, modify in real time the inspection in execution, view results

and statistics.

Once the DataVS2 settings have been completed, the VSM can be used to view the results

of the current inspection, or it can be disconnected and the sensor will continue to function in

stand-alone mode.

Thanks to the wide range of functions, the VSM represents an excellent and complete HMI

interface, ideal for automatic production lines controlled by operators.

Page 8

DATAVS2-VSM INSTRUCTION MANUAL

2

2

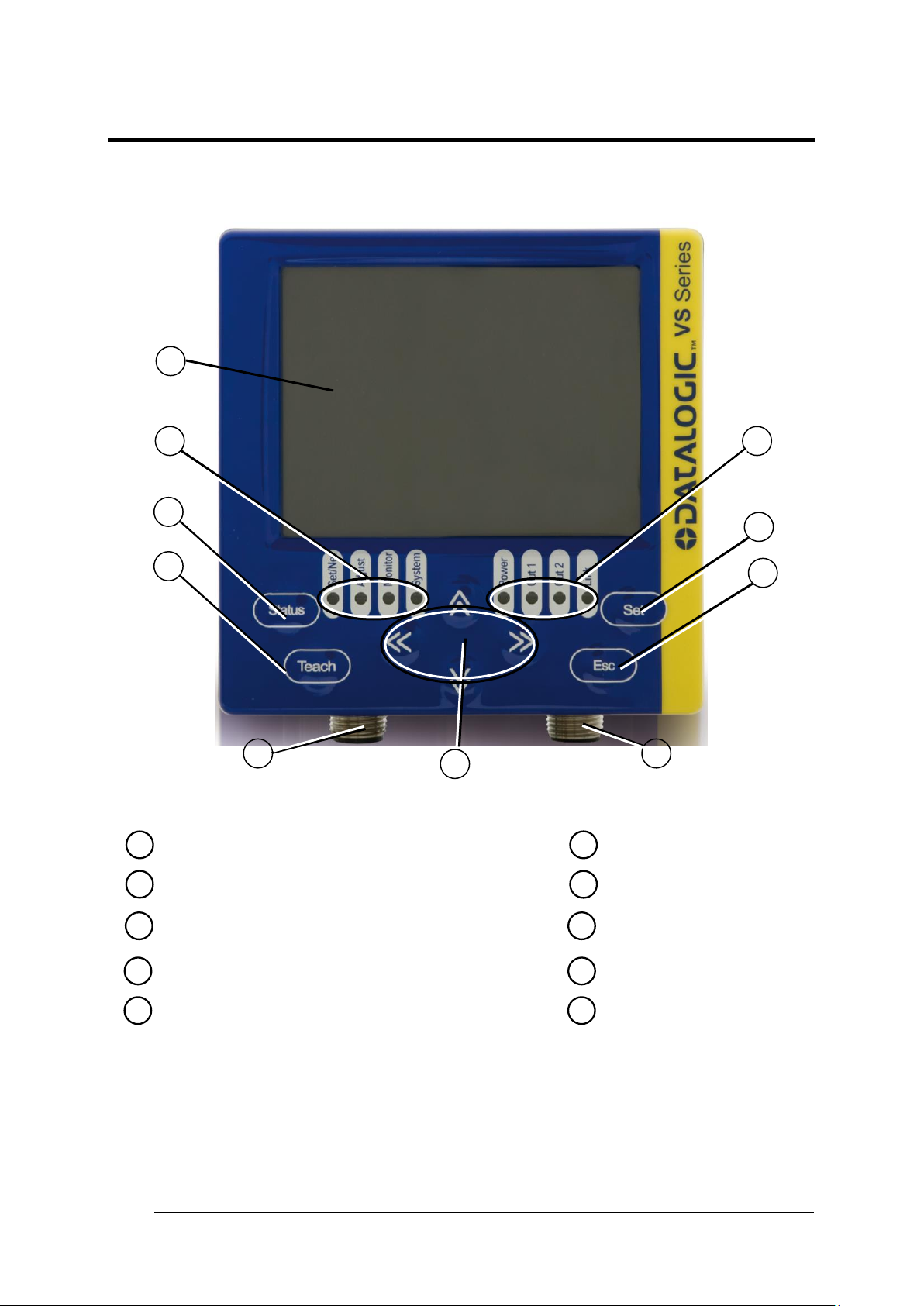

Locking clips

Slot for the

DIN guide

2 INSTALLATION

2.1 SAFETY RECOMMENDATIONS

Read the instruction manual carefully before installing the sensor and VSM.

Make sure that the product is suitable for the system that you intend to set up.

Connect the cables to the devices with the poles in the right direction.

Power up the devices following the instructions contained in the Manual.

Protect all devices against dust, dirt and humidity.

Never spill liquids on the devices

It is strictly prohibited to use DataVS2 in applications where the safety of persons

and/or things is guaranteed by the correct functioning of the device.

Always comply with all safety rules and regulations.

Never use the devices in environments where there is a risk of explosion.

Do not subject the devices to strong and continuous vibration.

2.2 DATAVS2 VSM DIN RAIL MOUNTING

There is a slot on the rear of the VSM which allows the user to connect the device to a DIN

guide.

Page 9

INSTALLATION

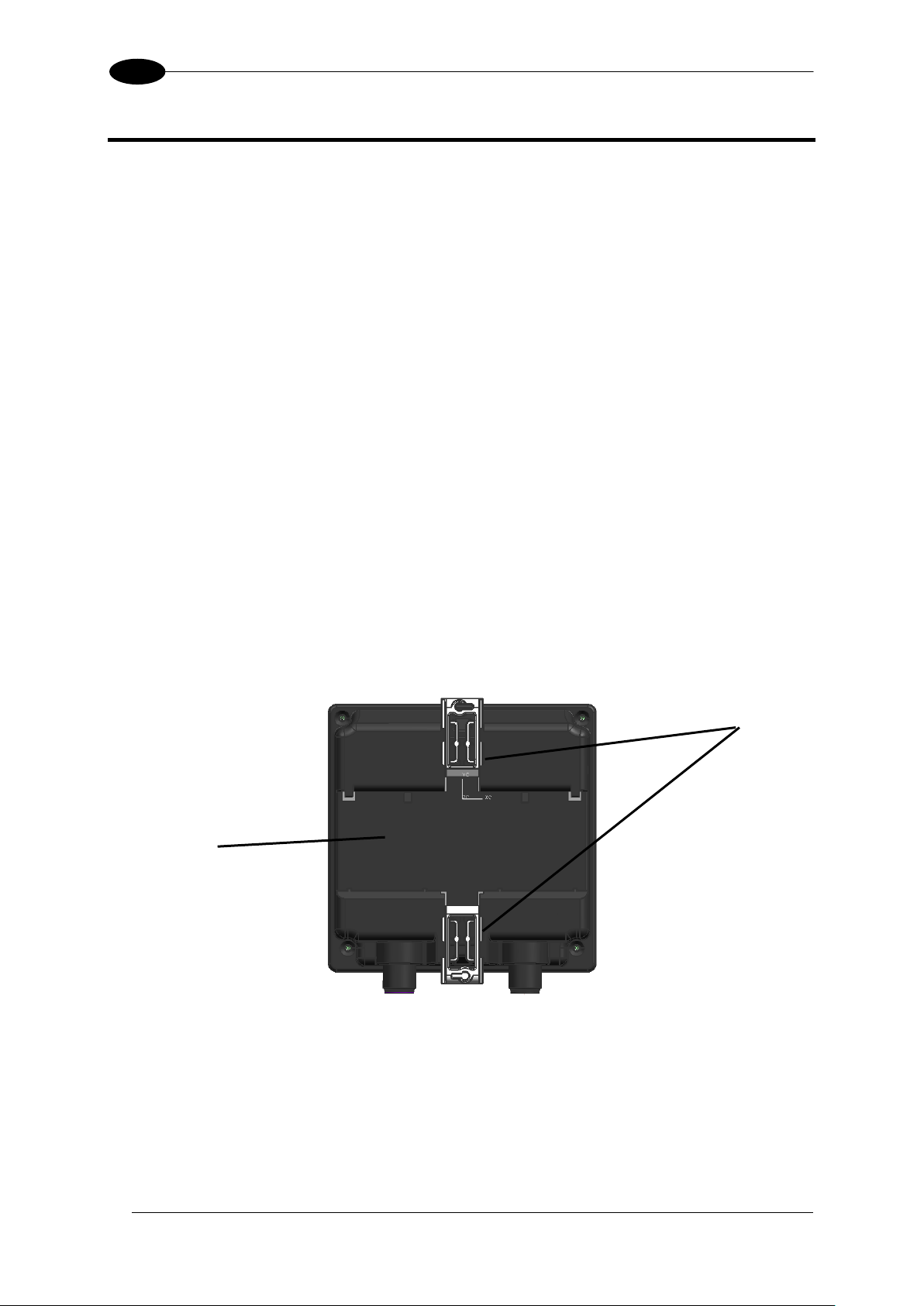

3

2

DIN Guide

Wedge the VSM unit in the DIN rail. First set the upper part of the monitor and then press

down the lower part.

Once inserted, block the VSM monitor using the two white side locking clips.

Page 10

DATAVS2-VSM INSTRUCTION MANUAL

4

2

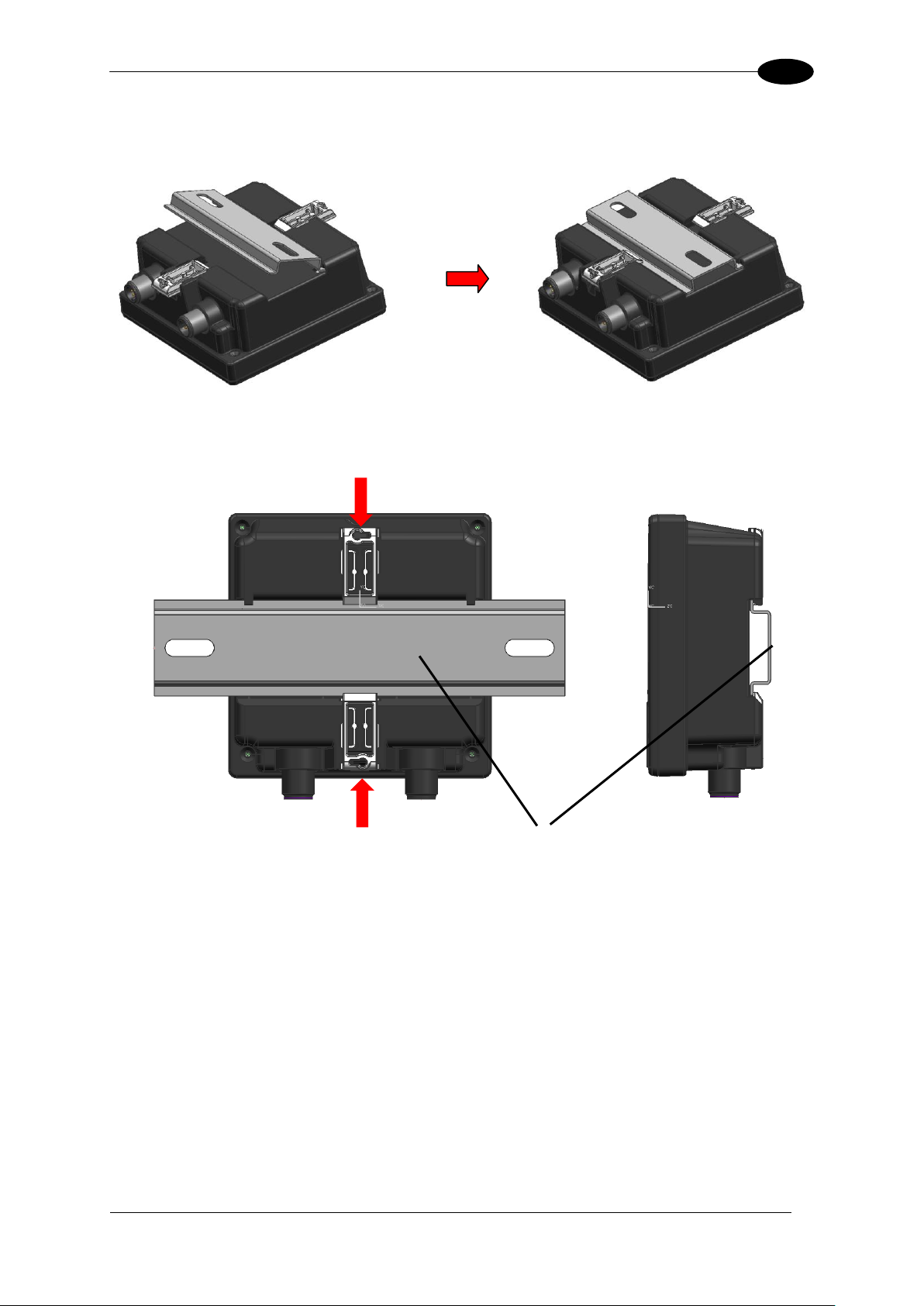

Rubber seal

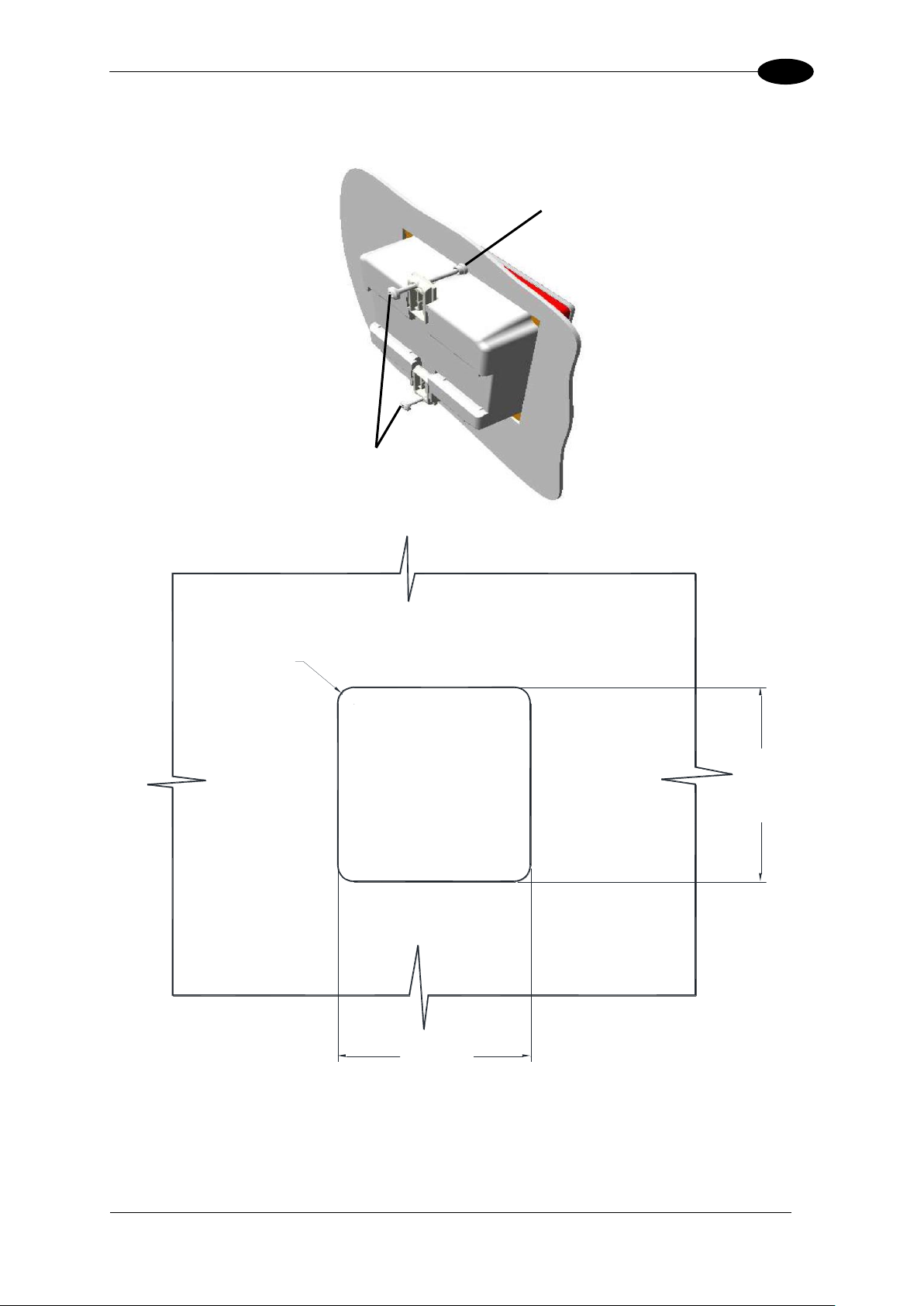

2.3 DATAVS2 VSM PANEL MOUNTING

The VSM can also be installed on a panel. All the accessories for this mounting are included

in the package.

First, carefully place the rubber seal around the VSM unit.

Page 11

INSTALLATION

5

2

92

±0.2

[3.62

±0.01

]

92

±0.2

[3.62

±0.01

]

R7.5

[R0.30]

Locking screw

Cap

Then fix the VSM on the panel using the two locking screws and the two rubber caps.

Page 12

6

3

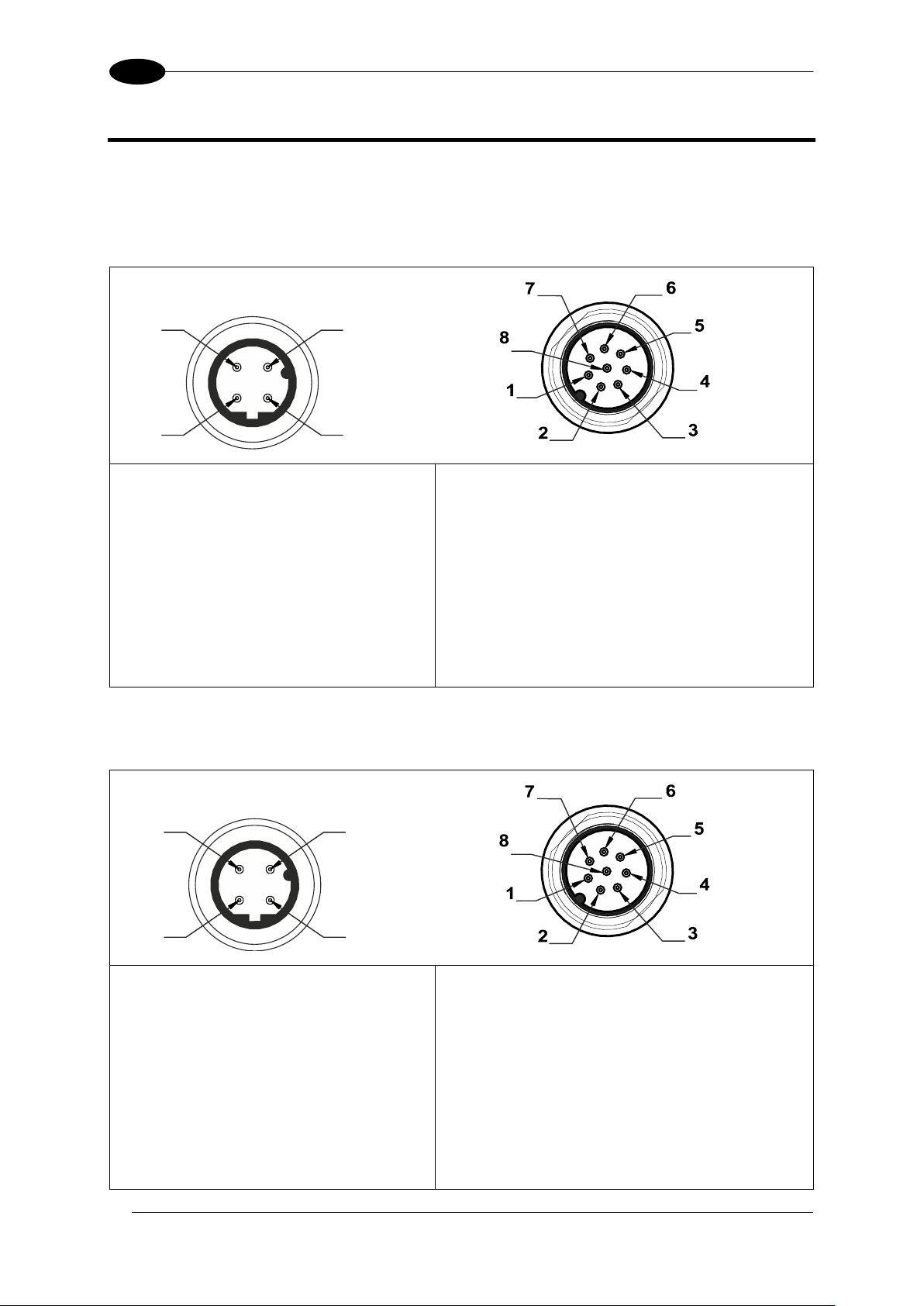

3 ELECTRICAL CONNECTIONS

3

1

2

4

M12 Reverse Keyed 4-Pin Male

(Ethernet connection)

pin 1: Ethernet RX+

pin 2: Ethernet TX+

pin 3: Ethernet RX-

pin 4: Ethernet TX-

M12 8-Pin Male

(power supply and I/O)

pin 1: white : Digital Input 1

pin 2: brown: +24 Vdc

pin 3: green : Output 4 /

Strobe for external illuminator

pin 4: yellow: Output 1

pin 5: grey: Output 2

pin 6: pink: Output 3

pin 7: blue: Ground

pin 8: red: External Trigger

3

1

2

4

M12 Reverse Keyed 4-Pin Male

(Ethernet connection)

pin 1: Ethernet RX+

pin 2: Ethernet TX+

pin 3: Ethernet RX-

pin 4: Ethernet TX-

M12 8-Pin Male

(power supply and I/O)

pin 1: white : RS-232 Rx

pin 2: brown: +24 Vdc

pin 3: green : Output 4 /

Strobe for External Illuminator

pin 4: yellow: Output 1

pin 5: grey: Output 2

pin 6: pink : RS-232 Tx

pin 7: blue: Ground

pin 8: red: External Trigger

3.1 PINOUTS

3.1.1 DataVS2 OBJ/AOR Sensor

DATAVS2-VSM INSTRUCTION MANUAL

3.1.2 DataVS2 ID/PRO Sensor

Page 13

ELECTRICAL CONNECTIONS

7

3

3

1

2

4

3

1

2

4

M12 4-Pin Male

(Power supply)

pin 1: +24 Vdc

pin 2: Reserved

pin 3: GROUND

pin 4: Reserved

M12 Reverse Keyed 4-Pin Male

(Ethernet connection)

pin 1: Ethernet RX+

pin 2: Ethernet TX+

pin 3: Ethernet RX-

pin 4: Ethernet TX-

Power

DATAVS-CV-VSM-xx

Power

LAN

Power

Power

DATAVS-CV-RJ45D-03

Power

Power

3.1.3 VSM Monitor

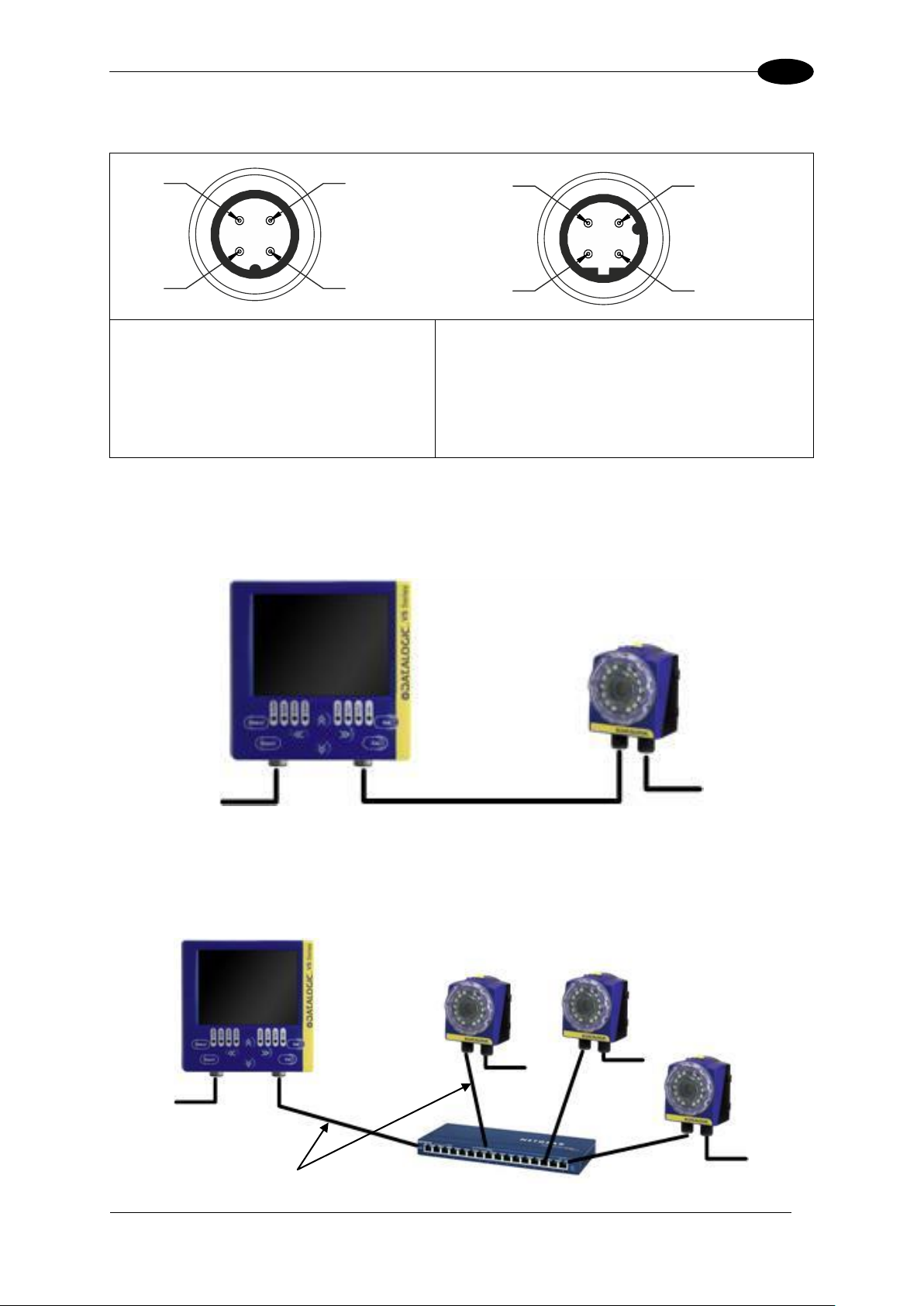

3.2 POINT-TO-POINT CONNECTION

Connect DataVS2 to VSM using the specific connection cable (DataVS-CV-VSM-xx).

3.3 LAN CONNECTION

Connect DataVS2 and VSM to LAN using the specific connection cable (DataVS-CV-RJ45D-

03).

Page 14

DATAVS2-VSM INSTRUCTION MANUAL

8

3

Washer M12

Ring Nut

PWR-I/O

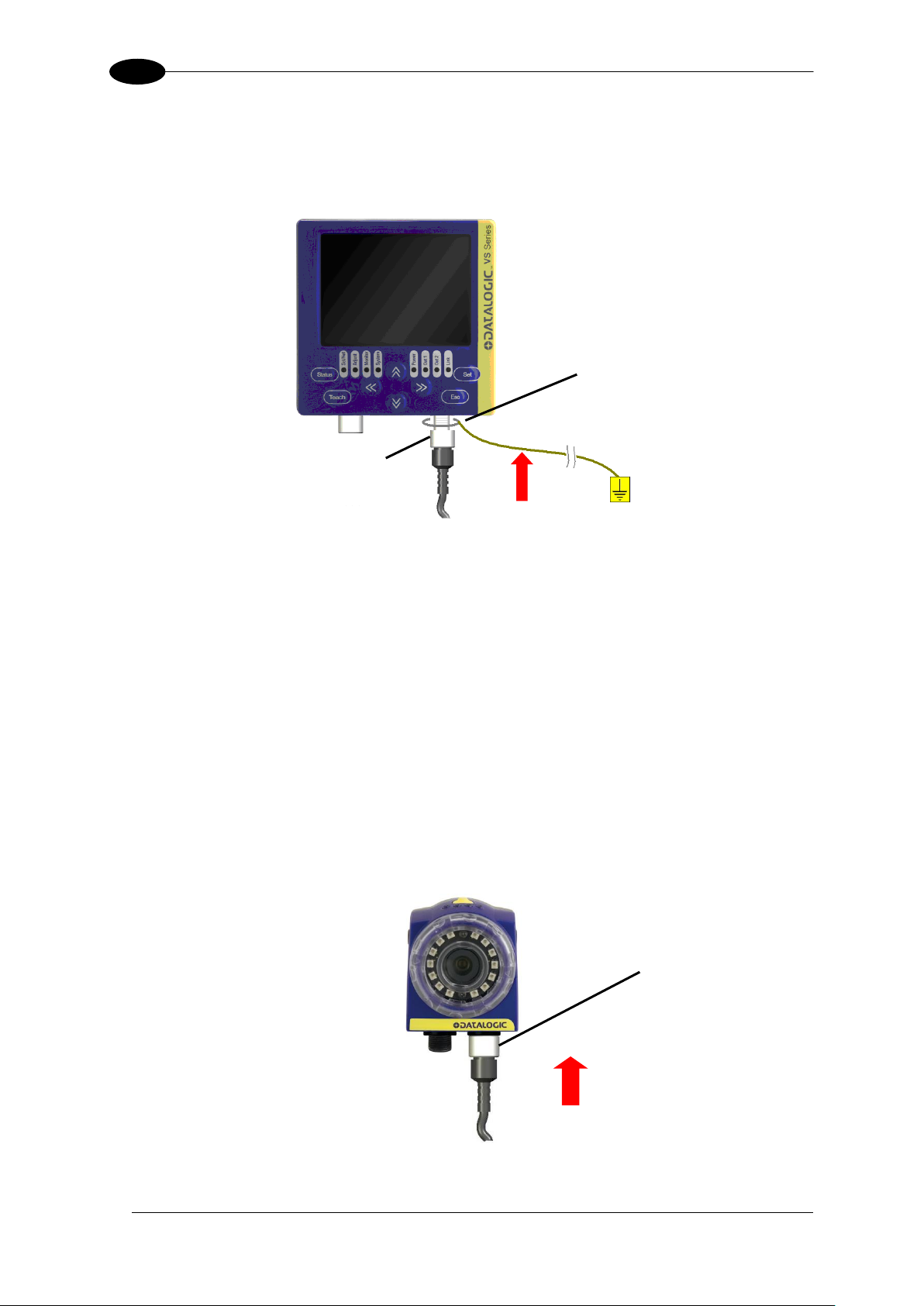

3.4 GROUND CONNECTION

To comply with the EMC requirements, the Ethernet cable shield has to be grounded. (Use

the yellow/green cable supplied with the VSM).

Insert the washer M12 on the yellow/green cable in the VSM connector and then screw the

Ethernet cable until the ring nut reaches the washer.

Warnings

Insert the cable into the correct connector following the key indications inside the

body

After inserting the cable, turn the ring nut anticlockwise to ensure connection

Never force the cable inside the connectors.

Make sure that every cable is connected to the right connector

Before disconnecting the cable, completely turn the ring nut anticlockwise

3.5 DATAVS2 POWER CONNECTION

Connect the power and I/O cable (CV-A1-36-B-xx) inserting it into the connector identified by the icon

(PWR-I/O).

Page 15

FIRST APPROACH TO VSM

9

4

BUTTON

Button ID

Main Functions

Status

Go to main menu (“System”)

Teach

Go to “Adjust” status

Set

Confirms selected option

Confirms setting value

Esc

Exit without saving

Back to previous screen

Arrows

Changes selected option

Movement/resizing of the ROI

Changes the parameters

4 FIRST APPROACH TO VSM

4.1 INTRODUCTION

The configuration of the DataVS2 vision sensor has to be made only through DataVS2 GUI.

To simplify the instructions described in this manual, the pressing of the buttons on the VSM

user interface will be indicated as follows:

4.2 VSM USER INTERFACE

The chart shown below provides a general overview of the user interface on the VSM user

interface. Please note however that the functions of the buttons vary according to the

operating mode selected by the user. Please consult the next chapters for further details on

how the system reacts to the pressing of such buttons.

Page 16

DATAVS2-VSM INSTRUCTION MANUAL

10

4

LED

LED ID

Colour

Meaning

Power

Green

VSM correctly powered

Out 1

Orange

Digital output 1 active

Out 2

Orange

Digital output 2 active

Link

Green

VSM correctly connected to LAN

Set/Net

Green

Current status: Setup

Adjust

Green

Current status: Adjust

Monitor

Green

Current status: Monitor

System

Green

Current status: System

NOTE

The VSM suggests to connect the last sensor used selecting it from the list

of DataVS2 (shown in green).

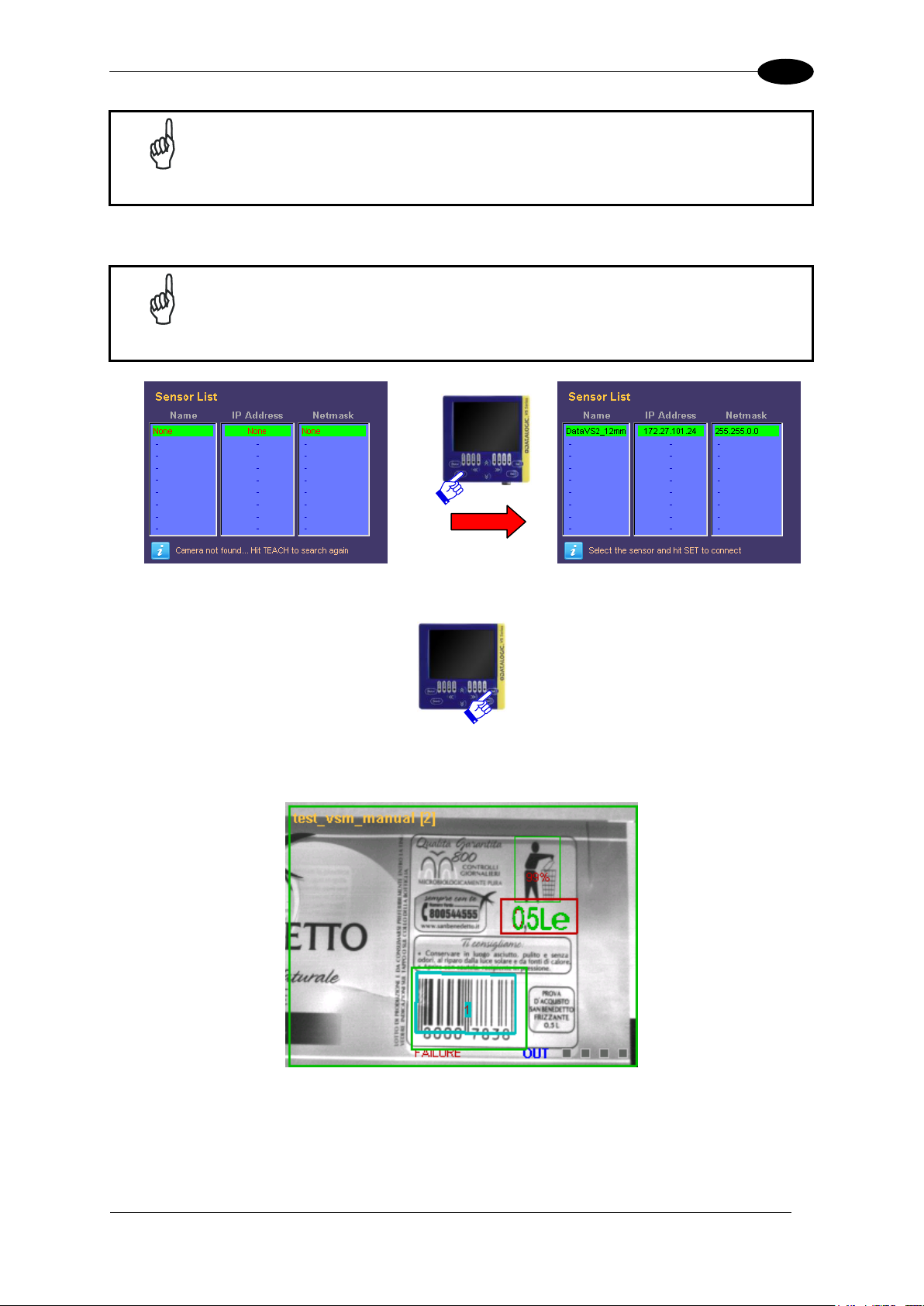

4.3 CONNECTION TO DATAVS2

When the VSM is powered, the welcome screen will be displayed on the monitor.

After a few seconds, a “Net Discovery” is automatically carried/out in order to find how many

DataVS2 are present in the LAN network.

At the end of the discovery, a panel will be displayed listing all the DataVS2s found.

Page 17

FIRST APPROACH TO VSM

11

4

NOTE

The maximum number of DataVS2 displayed in the list is 32.

NOTE

If no devices have been found in the first discovery, a new search can be

carried-out by pressing TEACH.

To connect a sensor, just select it from the list and press SET.

Once connected, the VSM enters in the monitor status displaying the inspection currently

being carried/out by the DataVS2.

If the field is out of focus, the user can adjust it by regulating directly the focus ring on the

sensor.

Page 18

DATAVS2-VSM INSTRUCTION MANUAL

12

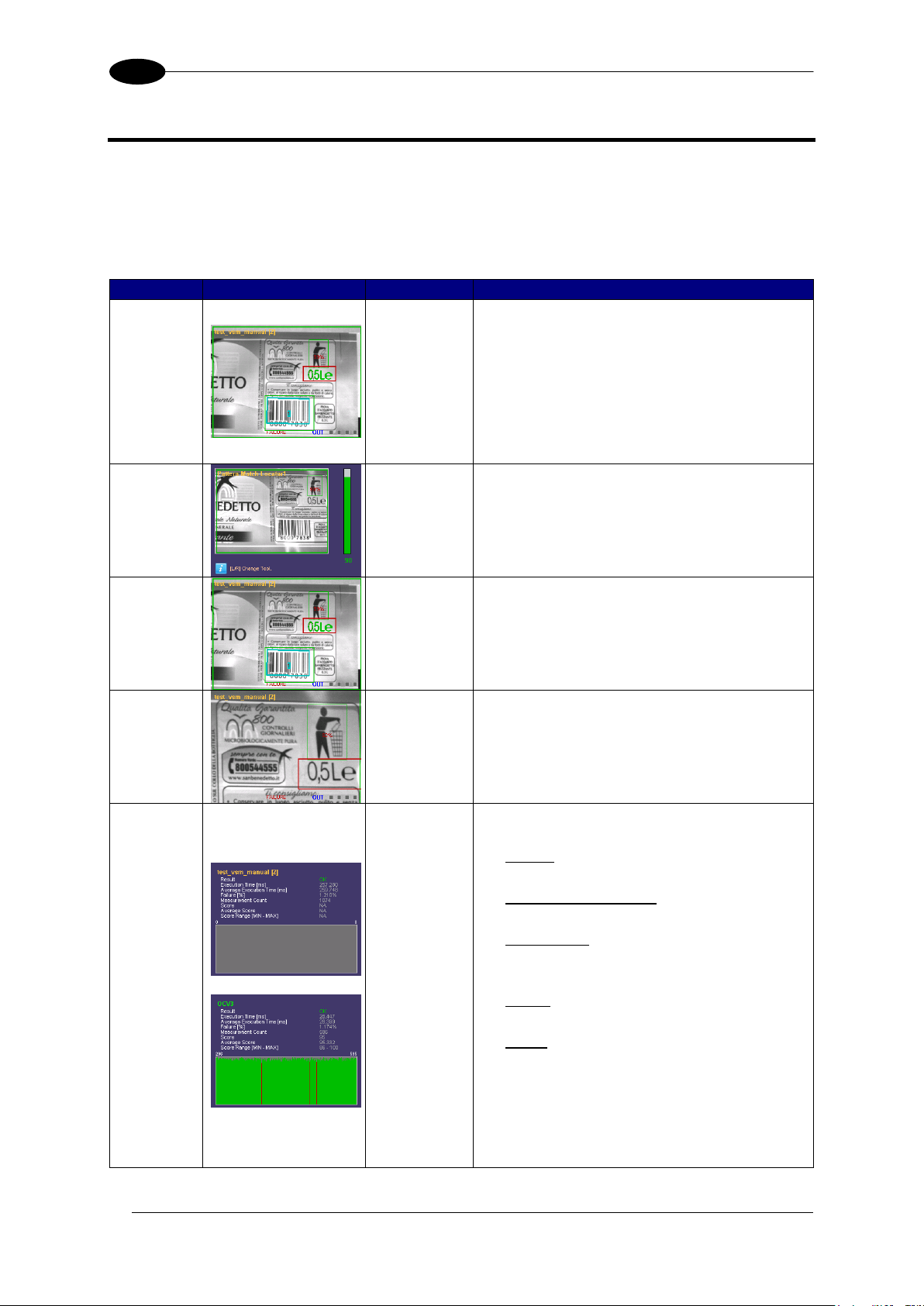

5

Mode

Example

Enable

Description

Standard

The monitor displays the sensor field focus

in full screen mode. The following

information is also displayed:

Inspection name and relative memory

slot

ROI

Inspection result

Logic value of the outputs

Tool

Result

DOWN

ARROW

This screen shows the tool result of the

current inspection.

The results of all the inspection tools can

be displayed using the RIGHT/LEFT

ARROWS.

Display

On

Condition

ESC

BUTTON

This mode displays only the images that

comply with the condition specified during

inspection configuration using the

DataVS2 GUI.

Zoom

Mode

UP

ARROW

An image of the sensor field focus is

displayed on the monitor with 200% zoom.

To move the zoom area, use the ARROW

buttons. Press ESC to exit zoom mode.

Statistics

SET

BUTTON

Statistics on the inspection results are

displayed on the monitor, including:

Result

Current inspection outcome

Execution time (ms)

Total inspection execution time

Failure (%)

% of failed inspections of the total

number executed

Score

Current inspection result

Etc…

The statistics of the single tools can be

displayed by pressing STATUS. Use

UP/DOWN ARROWS to scroll the tool

panels.

Use RIGHT/LEFT ARROWS to change

the scale of the graphics.

5 MONITORING AN INSPECTION

The “Monitor” mode allows the user to check the correct functioning of the inspection defined

previously.

The chart shown below provides a description of the main modes available and shows how

to enable viewing.

Page 19

INSPECTION CHANGE

13

6

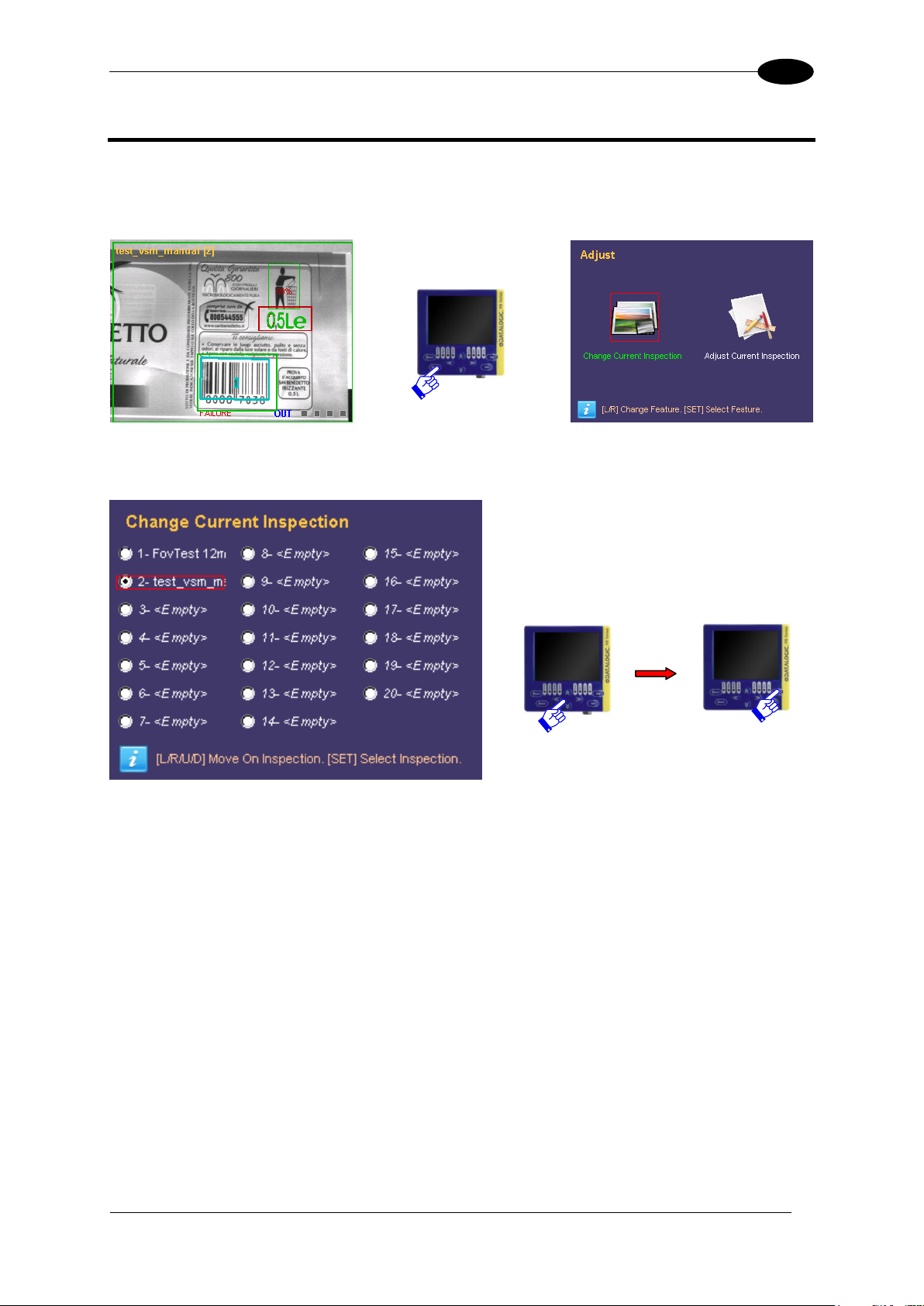

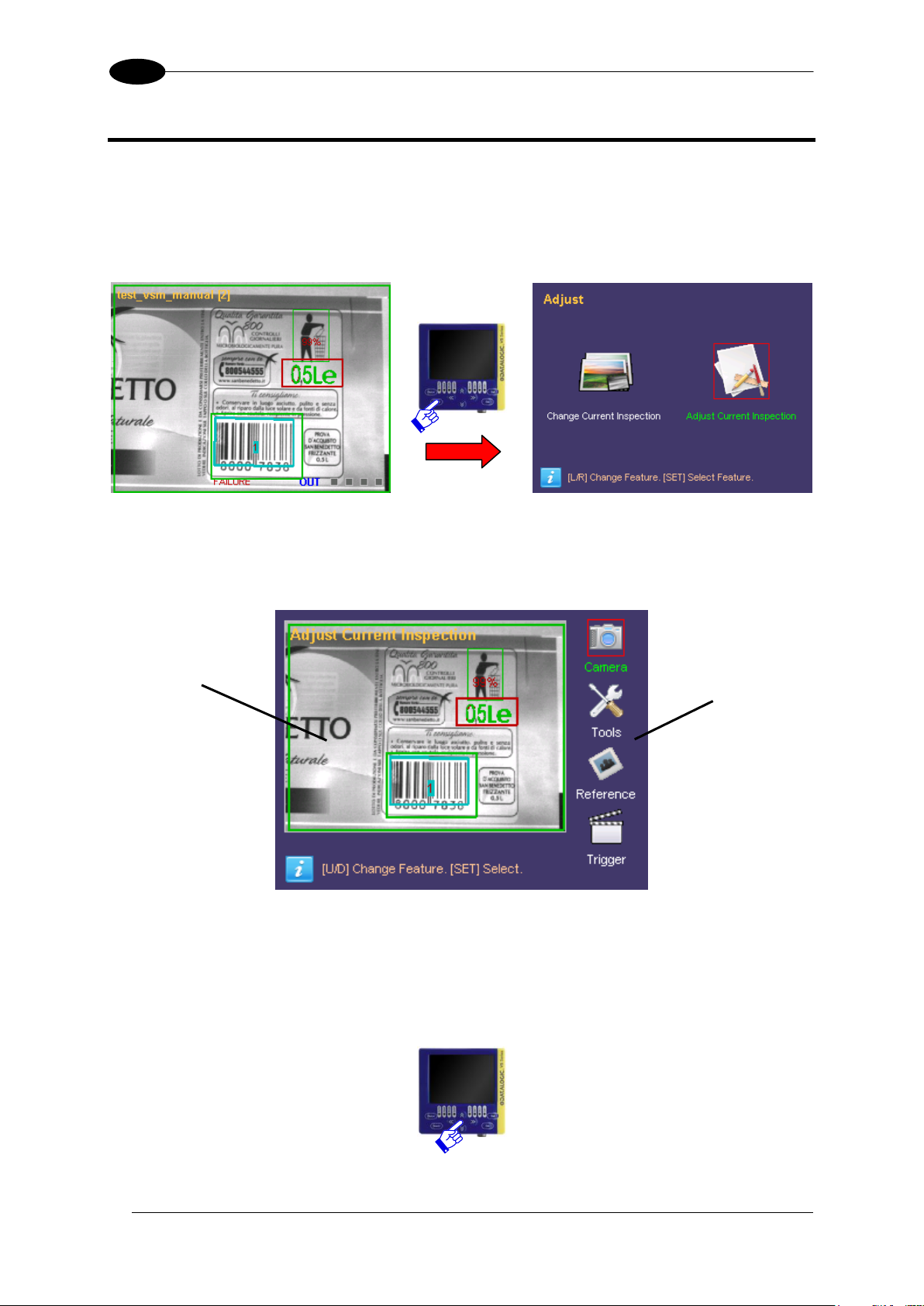

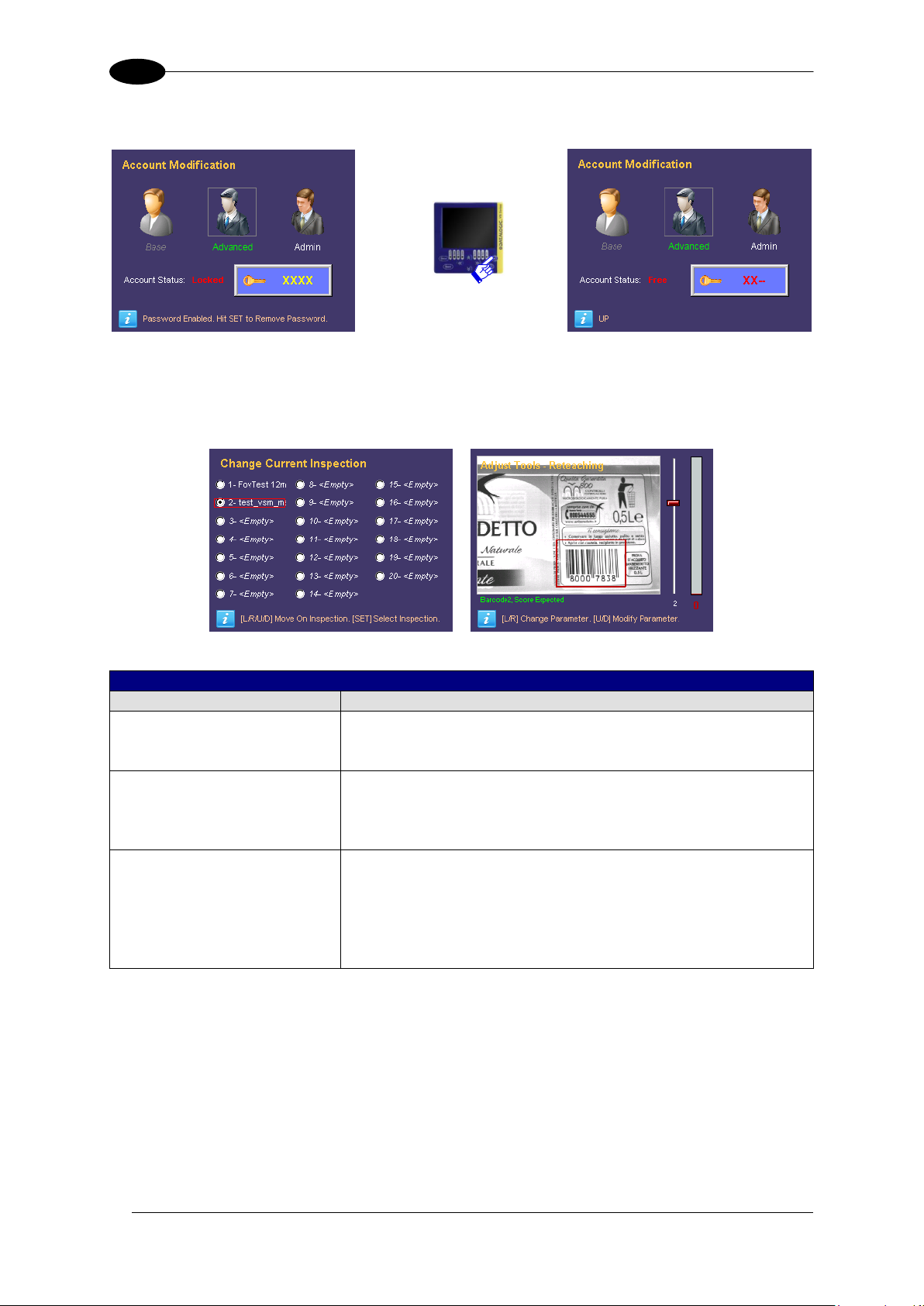

6 INSPECTION CHANGE

To change the inspection currently in execution on the DataVS2, the user must start from the

monitor screen and press TEACH. The selection panel will be displayed:

Press SET on “Change Current Inspection” to access another panel where the user can

select the inspection to carry-out.

Use the ARROWS to move the focus on the desired inspection and press SET to start the

inspection.

At this point DataVS2 carries-out the new inspection and the monitor status is restored.

Page 20

DATAVS2-VSM INSTRUCTION MANUAL

14

7

Configuration

Options

Field Range

7 INSPECTION PARAMETER CHANGE

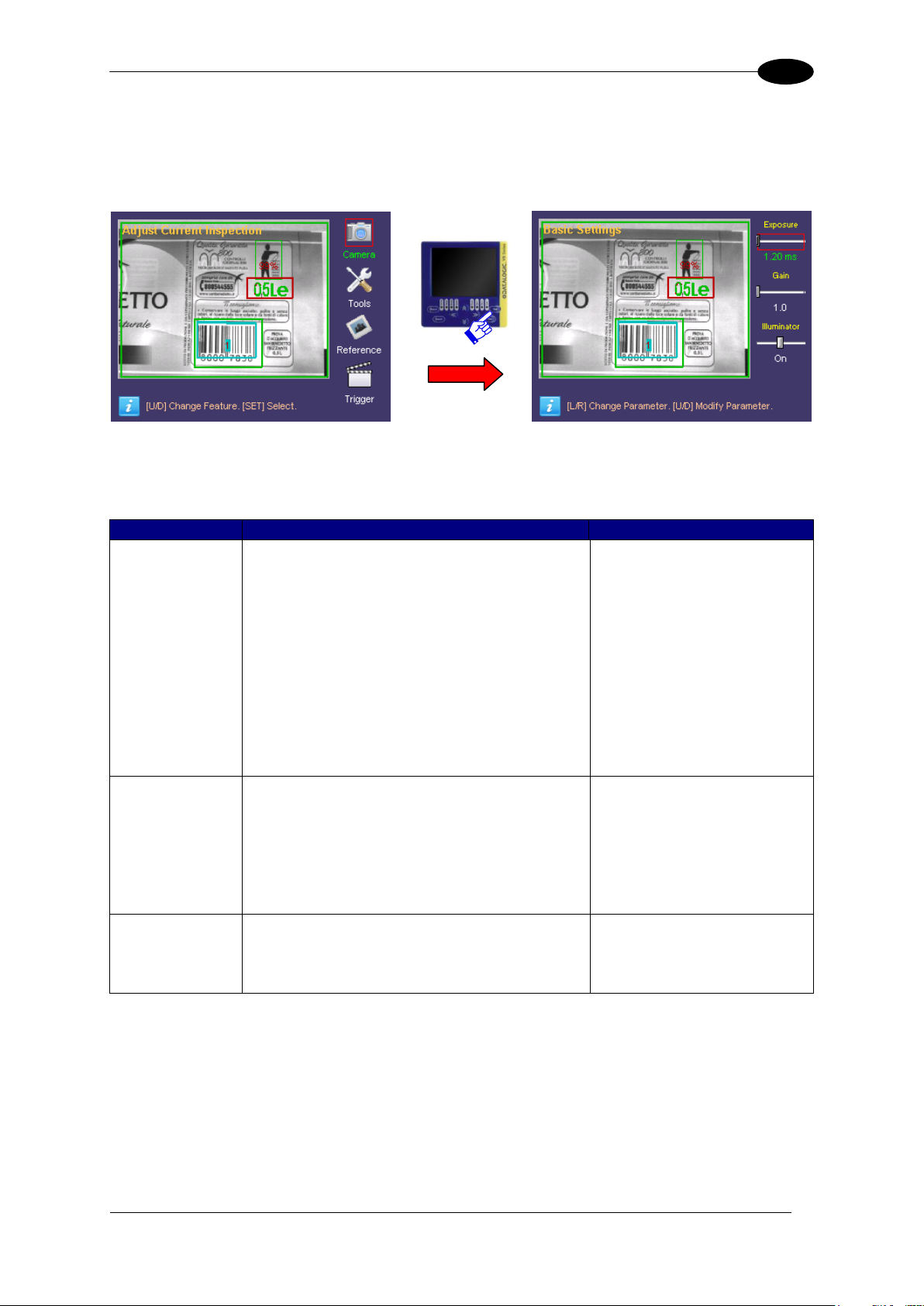

7.1 CURRENT INSPECTION CHANGE

To change the sensor parameters, press TEACH in the monitor mode. The following panel is

displayed:

At this point the user can choose to change the current inspection or modify the parameters.

Selecting “Adjust Current Inspection” the user accesses the main panel of the Adjust

status:

As you can see in the image, the VSM is split into two main areas: the field range of the

camera and the configuration options available.

The image acquired by the sensor is displayed in the first area. The configuration options are

displayed on the right side of the monitor, where the user can scroll through the options using

the UP/DOWN ARROWS.

Page 21

INSPECTION PARAMETER CHANGE

15

7

Parameter

Description

Change

Exposure time

The exposure time identifies the period that

the lens remains open and allows light to

reach the CMOS mounted on the sensor.

Therefore, the longer the exposure time,

the brighter the image will be. On the other

hand, increasing the exposure times

increases the risk of acquiring blurred

images where the detail being monitored

moves at a certain speed. If the images of

objects that move quickly are not very

bright, it is recommended to adjust the gain

settings.

To adjust the exposure

time, move to the option

and use the RIGHT/LEFT

ARROW buttons.

Press STATUS to change

the scale of the slider

values.

(At each pressing the scale

is increased of one order

of magnitude).

Gain

The gain setting allows you to adjust the

brightness of the image acquired by the

sensor by amplifying the signal transmitted

by the CMOS to the processing unit.

Increasing the gain setting, however, also

increases the disturbance on the image

which decreases its quality.

To adjust the gain setting,

move to the option and use

the RIGHT/LEFT ARROW

buttons.

Illuminator

This parameter is referred to the illuminator

inside the sensor and only one of the three

options can be selected: OFF, ON and

POWER.

To adjust the gain setting,

move to the option and use

the RIGHT/LEFT ARROW

buttons.

7.2 CAMERA PARAMETER CHANGE

Selecting the “Camera” option and pressing SET, the user accesses some DataVS2

parameters such as: exposure time, gain and illuminator operating mode.

The user can change the focus between the objects on the panel by using the UP/DOWN

ARROWS. To change the parameter value, once selected the focus, the user has to use the

RIGHT/LEFT ARROWS.

Once the camera settings have been completed, it is possible to return to the Setup menu by

pressing ESC.

Page 22

DATAVS2-VSM INSTRUCTION MANUAL

16

7

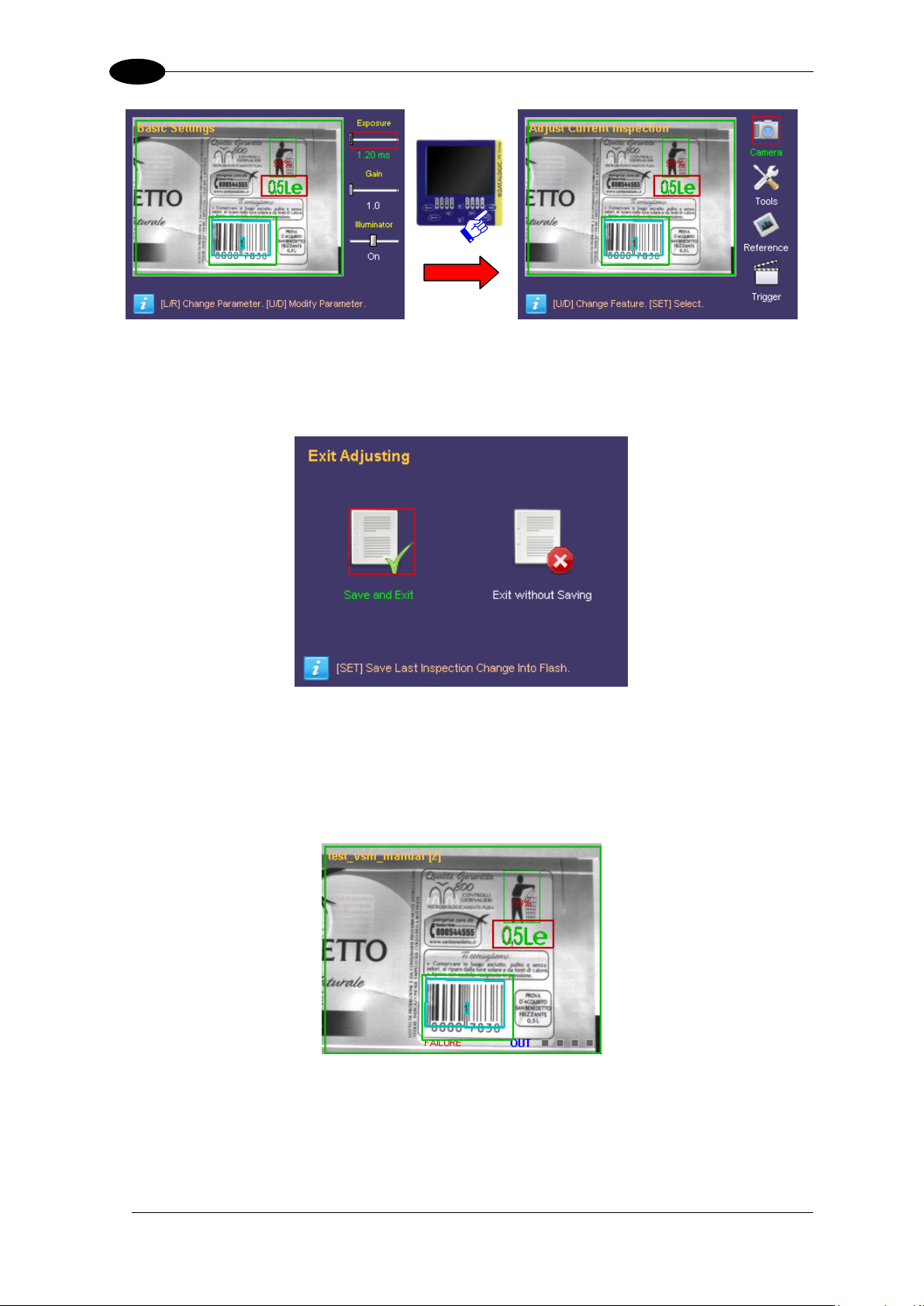

If no other change has to be made, press ESC to return to the “Monitor” status.

If inspection parameters have been changed, another panel will be displayed requesting the

saving of the changes:

To save the new data in the memory select “Save and Exit” using the SET button.

If the changes must have to be cancelled, select “Exit without Saving” using the SET

button.

At this point the system returns to the monitor status.

Page 23

INSPECTION PARAMETER CHANGE

17

7

NOTE

All the inspection parameters can be modified only if previously enabled

through the DataVS2 GUI panel. For further information, please refer to the

DataVS2 Instruction Manual.

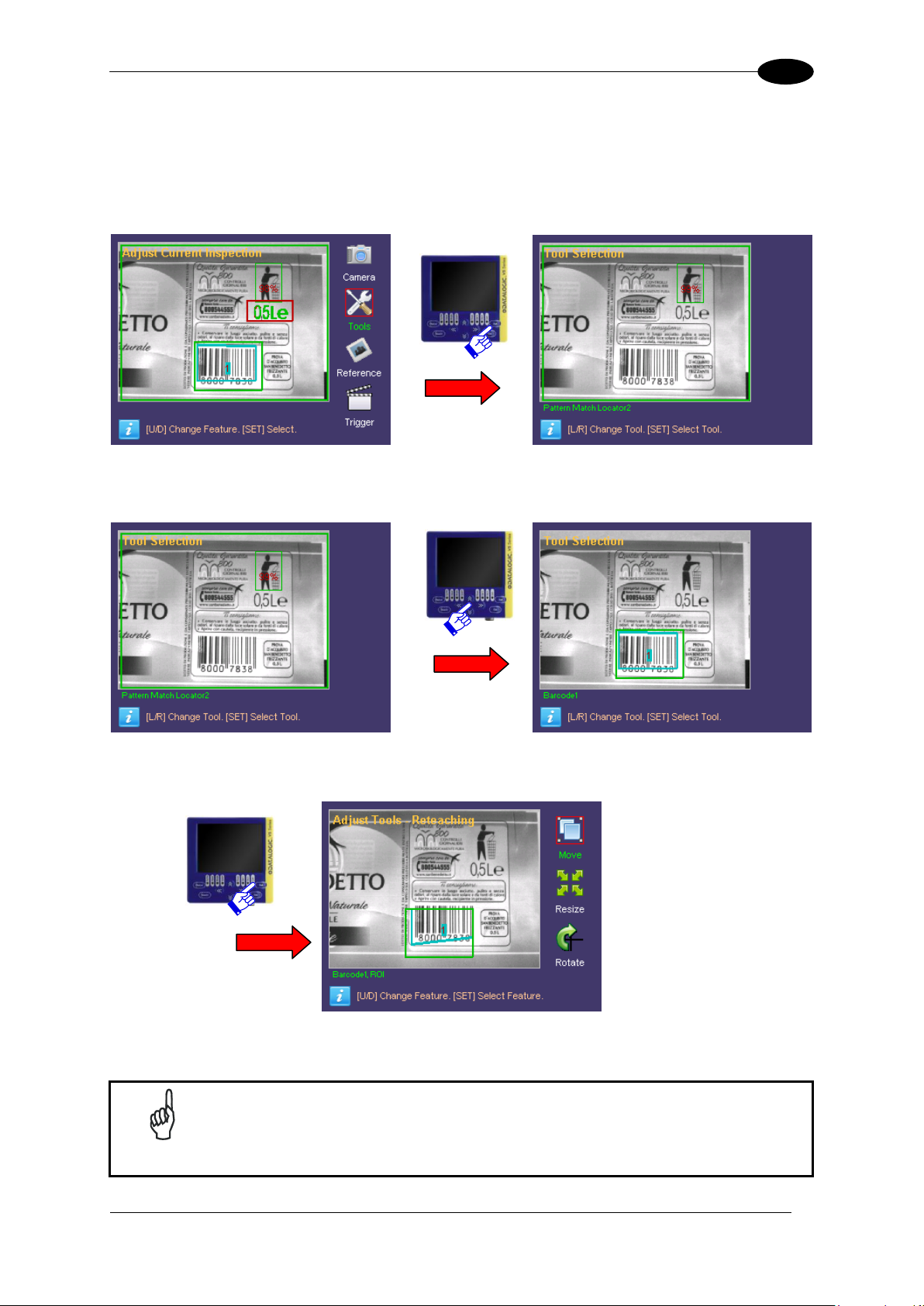

7.3 TOOL PARAMETERS CHANGE

7.3.1 Tool Selection

Press SET on the “Tools” icon in the “Adjust Current Inspection” panel.

The “Tool Selection” panel is displayed and the user can choose the tools to use.

All the inspection tools will be displayed one at time according to the creation order.

The user can scroll through the different tools using the RIGHT/LEFT ARROWS. Press SET

to confirm.

All the parameter change panels can be accessed from here on starting from the ROI panel

up to the last one with the parameters that can be changed using the selected tool.

Page 24

DATAVS2-VSM INSTRUCTION MANUAL

18

7

NOTE

For the tools characterized by two ROIs, such as the Pattern Match or 360°

Pattern Match, the VSM allows editing only the ROI research.

NOTE

Press TEACH to confirm. When exiting the change mode, the user is

requested to discard changes or save them definitively in the flash memory.

All changes will be cancelled by selecting “Exit without saving”.

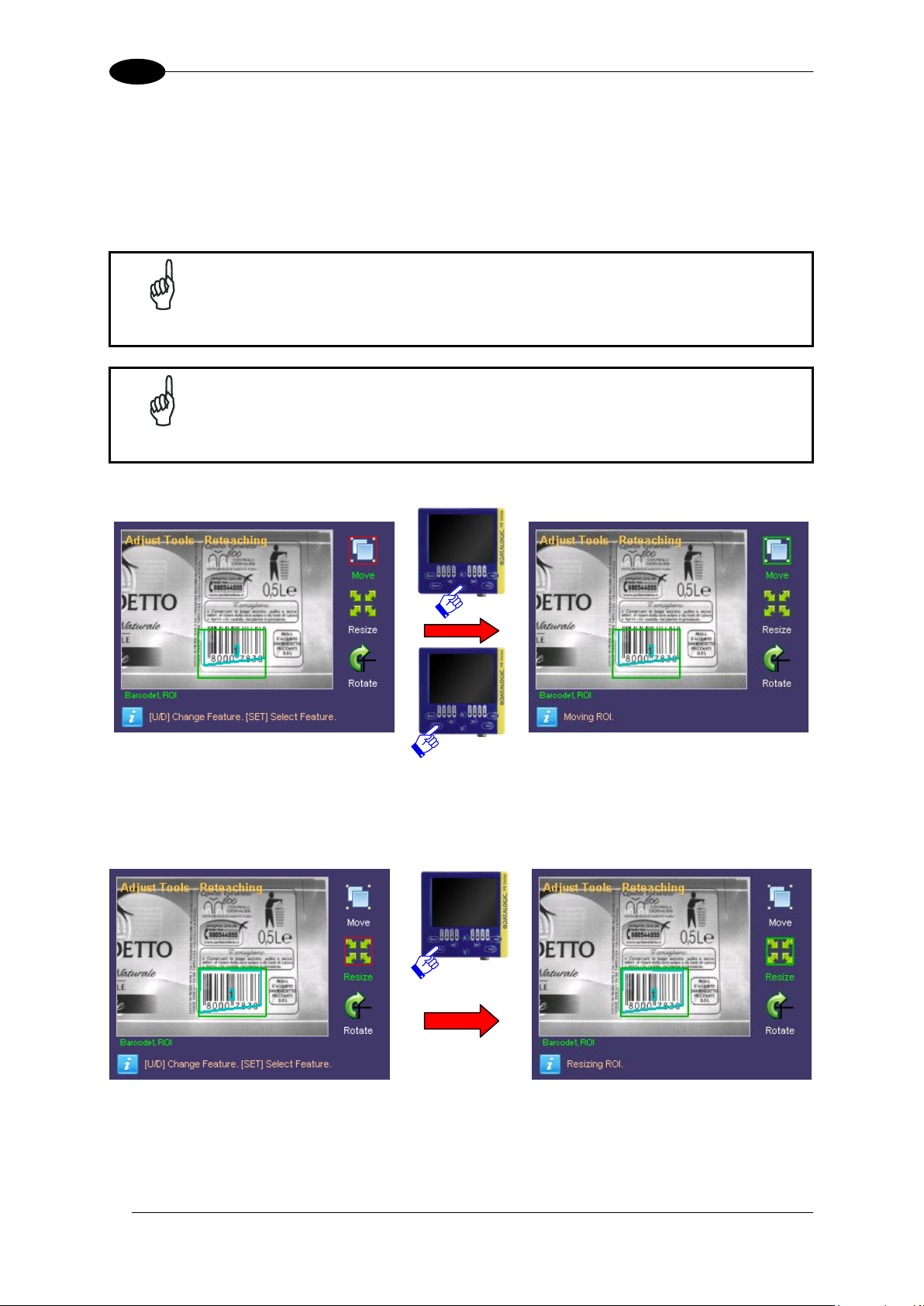

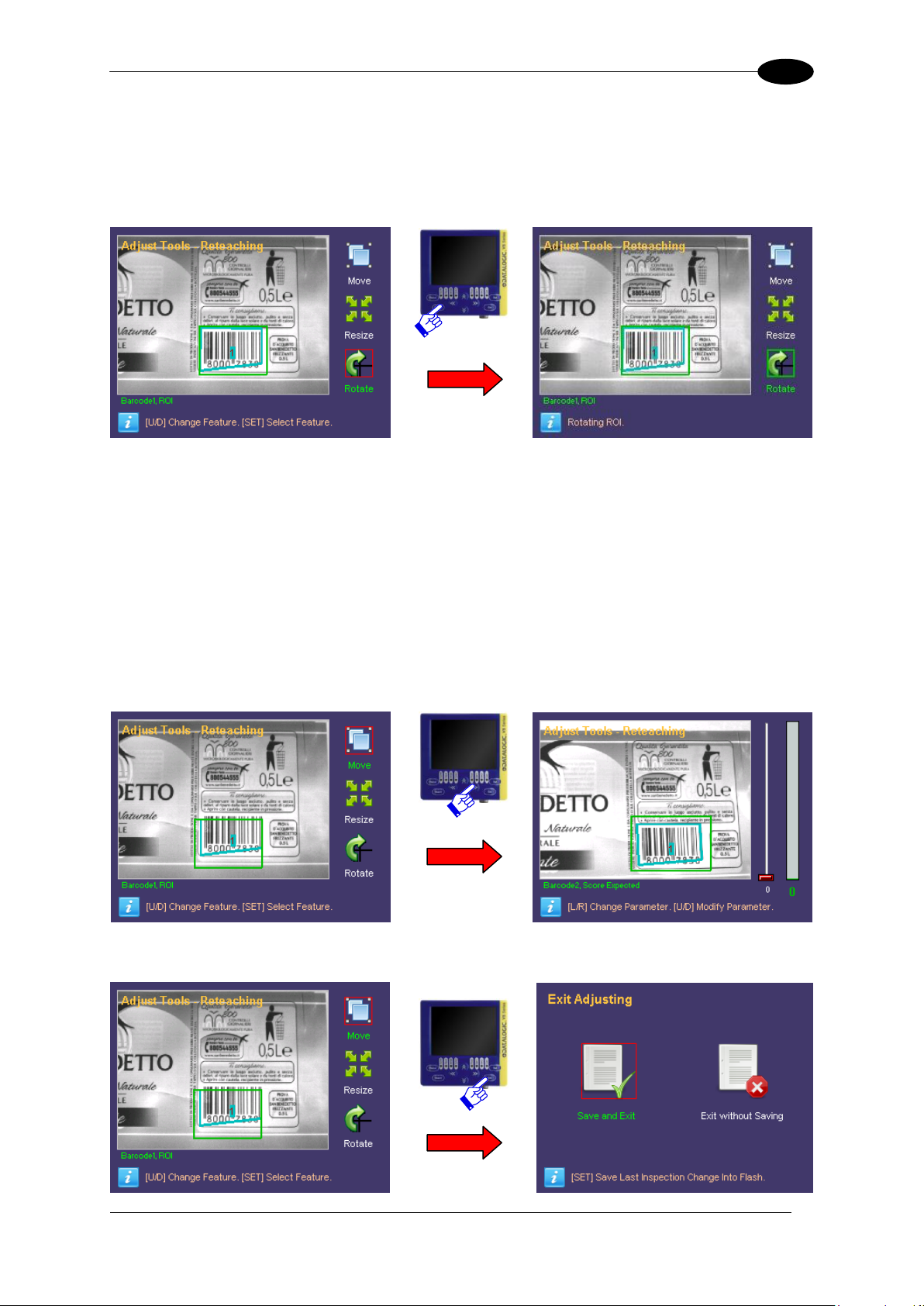

7.3.2 ROI Change

To modify a ROI, the tool must have been selected previously and the “Adjust Tools” panel

opened.

The following operations are possible: Move, Resize and Rotate.

MOVE:

Once selected “Move”, the focus is transferred in the field range and the ROI can be moved

using the ARROWS.Once you have achieved the desired position, press TEACH to save

changes. Press ESC to return to the Setup menu ignoring the changes made.

RESIZE:

If you wish to modify the ROI size, select the “Resize” option from the Setup menu (using

the SET button again). It is now possible to increase or decrease the ROI size using the

ARROW buttons.

Page 25

INSPECTION PARAMETER CHANGE

19

7

Once you have achieved the desired size, press the TEACH button to save the settings and

return to the Setup menu. Press the ESC button to return to the Setup menu without saving

the modifications (the system will request confirmation on the saving option).

ROTATE:

To rotate the ROI, select the “Rotate” option from the Setup menu (using the SET button

again). The ROI will rotate in a clockwise/anticlockwise directly depending of the

RIGHT/LEFT ARROW button pressed.

Once you have achieved the desired rotation angle, press TEACH to save the settings and

return to the Setup menu. Press ESC to return to the Setup menu ignoring the changes

made.

Once the changes on the ROI are completed, the user can exit from the “Adjust” mode or

proceed with the configuration of the single parameters of the selected tool.

All the parameters that can be changed by the DataVS2 GUI can be scrolled by pressing the

RIGHT/LEFT ARROWS.

To return to the “Monitor” mode the user must return to the higher level panels by pressing

ESC. If changes have been made, the user is requested to save or ignore them definitively.

Page 26

DATAVS2-VSM INSTRUCTION MANUAL

20

7

NOTE

The parameters that can be modified vary according to the tool and the

inspection selected.

Field size

Calculated

value

Current

setting

value

Setting name

7.3.3 Other Parameter Changes of the Selected Tool

This paragraph explains how to change the parameters that adjust the functioning of a tool.

The VSM monitor is divided as follows: the parameters that the user can change are

displayed on the right side, while the image captured by the sensor is displayed on the

remaining area. The name of the parameter currently in use is shown on the bottom of the

monitor.

The parameters are displayed one at a time, and so the RIGHT/LEFT ARROWS must be

used to pass from parameter to the another.

To change the current value, use the UP/DOWN ARROW. Each time the button is pressed,

the value associated to the slider, is increased or decreased of one unit (to change the value

faster keep the corresponding button pressed).

Page 27

INSPECTION PARAMETER CHANGE

21

7

7.4 REFERENCE IMAGE CHANGE

Select "Reference" and press SET to access the management screen of the reference

image.

The screen shows the current image, pressing TEACH you can activate the reference image

change procedure. After the press of TEACH button the first acquired image will be set as

new reference image of the current inspection.

Pressing STATUS you can see the current reference image. Pressing STATUS again

returns to the Reference image management screen.

Once you set the reference image, press the ESC key to return to the "Adjust current

inspection" menu.

Page 28

DATAVS2-VSM INSTRUCTION MANUAL

22

7

7.5 TRIGGER MODE CHANGE

Select "Trigger" and press SET to access the management screen of the trigger mode.

As you can see in the image, the VSM is split into two main areas: the parameters that the

user can change are displayed on the right side of the monitor, while the remaining area

displays the image acquired by the sensor.

At the bottom of the monitor also is shown the name of the selected trigger parameter;

Parameters that can be modified are “Trigger Mode” and “Trigger Delay”.

The user can scroll through the parameter using the UP/DOWN ARROWS.

To change the current value, use the UP/DOWN ARROW. Each time the button is pressed,

the value associated to the slider, is increased or decreased of one unit (to change the value

faster keep the corresponding button pressed).

Page 29

ADVANCED FUNCTIONS

23

8

NOTE

The “Disconnect” icon is displayed only when a DataVS2 is connected as it

indicates the active status of the sensor connection.

Indication of connected sensor

Network

Parameters

Data of DataVS2

connected

Product info

8 ADVANCED FUNCTIONS

The previous chapter described the procedure used to modify an inspection for DataVS2.

Further to the functions above-described, there are other user settings on the VSM monitor

which can be accessed from the System menu.

“System” menu is accesed from “Monitor” pressing STATUS.

8.1 MONITOR SETTINGS

This panel provides access to VSM information such as name, serial number, model, etc…

Moreover the IP and NetMask network parameters can be modified and the data of the last

DataVS2 connected can be displayed.

To change the network parameters, the user has to simply move the focus on the desired

value and use the UP/DOWN ARROWS to increase or decrease the current value.

To save the changes press SET.

Page 30

DATAVS2-VSM INSTRUCTION MANUAL

24

8

NOTE

Restart the device to apply correctly the changes.

NOTE

Restart DataVS2 to apply correctly the changes.

DataVS2 Info

unchangeable

Parameters

changeable

To return to main panel without saving, press ESC.

8.2 SENSOR SETTINGS

This panel, when a DataVS2 is connected, can display information such as name, firmware,

Hardware revision, MAC and modify the sensor network parameters: IP, Netmask and

DHCP...

To change the network parameters of DataVS2, the user has to simply move the focus on

the desired value and use the UP/DOWN ARROWS to increase or decrease the current

value.

To save the changes press SET.

To return to main panel without saving, press ESC.

Page 31

ADVANCED FUNCTIONS

25

8

NOTE

If panel is accessed without DataVS2 connection, the sensor area cannot be

accessed and the user can operate only on the VSM memory (only

cancellations).

Memories of

DataVS2

Memories of VSM

Controls for VSM

Transfer

DataVS2 – VSM

Transfer

VSM– DataVS2

Controls for

DataVS2

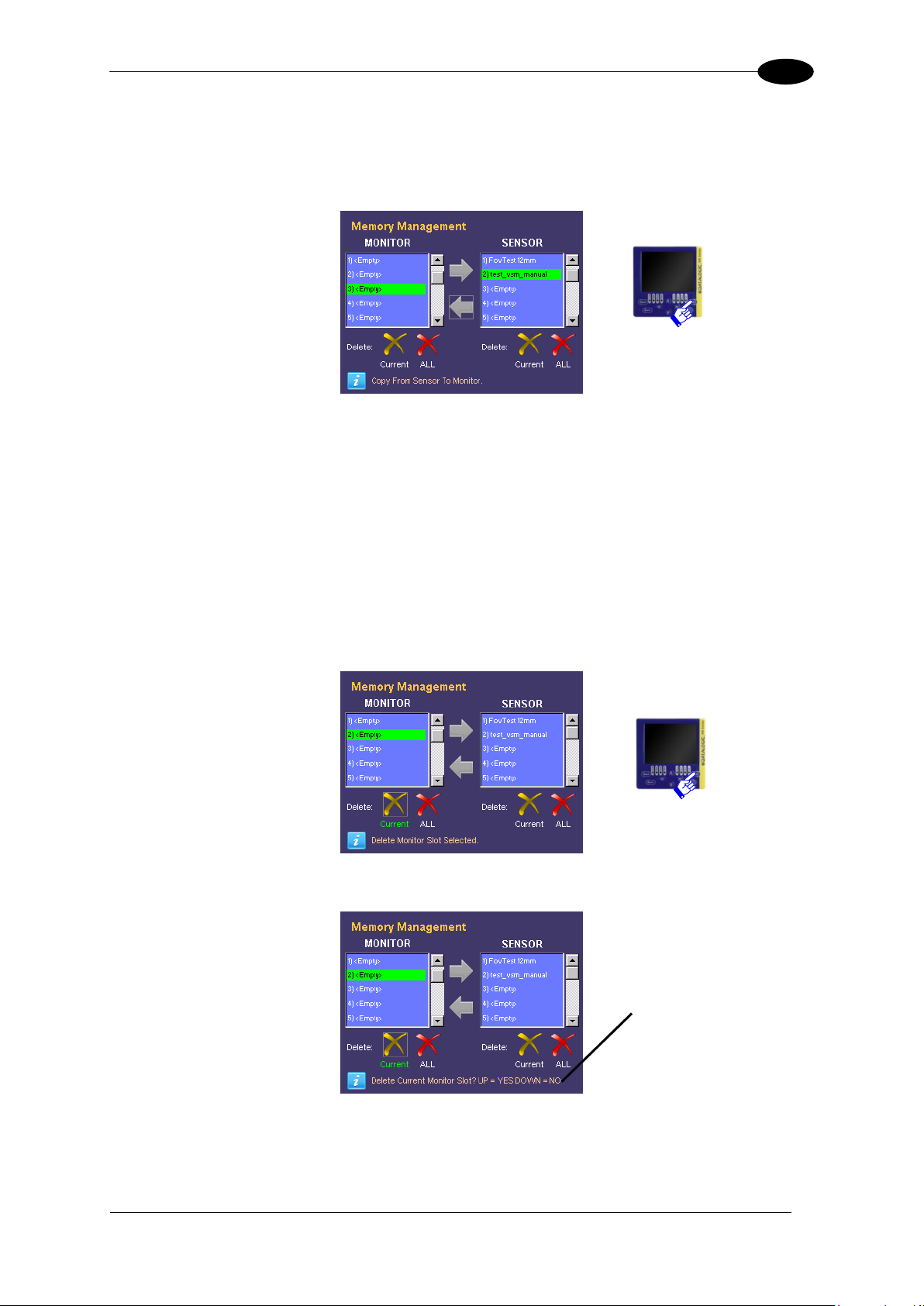

8.3 MEMORY MANAGEMENT

This paragraph explains how to transfer or cancel a memory slot between VSM and

DataVS2.

At this point the user can select the “Memory Management” icon and press SET. The

following panel is displayed:

As shown in the figure, the panel is divided in two: a VSM area (concerning the local

memory) and a DataVS2 area (remote device memory).

8.3.1 Slot Selection (VSM)

To select a memory slot to use, the focus must be moved on the “MONITOR” label using the

ARROWS and SET must be pressed.

Once done, the focus is moved in the list of slots where the user can scroll through the

memories only using the UP/DOWN ARROWS

Press SET to confirm the slot currently selected.

At this point, the focus returns outside the memory area and allows navigation between the

other buttons.

Page 32

DATAVS2-VSM INSTRUCTION MANUAL

26

8

8.3.2 Slot Selection (DataVS2)

The slot selection is similar to the VSM one: the focus must be moved using the ARROWS

on the “SENSOR” label and SET must be pressed. The focus will be moved inside the

memory list and once chosen the desired one press SET to confirm.

Once selected both memory slots, the transfer operations can be made.

8.3.3 Transfer from VSM to DataVS2

To transfer the memory slot from VSM to DataVS2 (after selecting both the source as well as

the destination) move the focus on the “Arrow on Right” button and press SET.

At this point the information label will request another operation confirmation, to proceed

press ARROW UP, otherwise press ARROW DOWN to abandon.

If confermed, the data will be transferred between VSM and DataVS2. As soon as the

operation has finished, an information label will display the result and a refresh of the panel

names will be made.

Page 33

ADVANCED FUNCTIONS

27

8

Confirm

8.3.4 Transfer from DataVS2 to VSM

To transfer the memory slot from DataVS2 to VSM (after selecting both the source as well as

the destination) move the focus on the “Arrow on Left” button and press SET.

At this point the information label will request another operation confirmation, to proceed

press ARROW UP, otherwise press ARROW DOWN to abandon.

If confermed,the data will be transferred between VSM and DataVS2. As soon as the

operation has finished, an information label will display the result and a refresh of the panel

names will be made.

8.3.5 Cancellation of a VSM Slot

First select the desired slot (refer to previous paragraph “Selection of slot (VSM)”).

Then move the focus on “Delete Current” button (on the bottom left side of the screen) and

press SET to confirm:

At this point the information label will request another operation confirmation:

To proceed press ARROW UP otherwise, press ARROW DOWN to abandon. In both cases,

the information label will display the operation result and a refresh of the panel names will be

made.

Page 34

DATAVS2-VSM INSTRUCTION MANUAL

28

8

NOTA

It is not possibile to delete actual running inspection.

Confirm

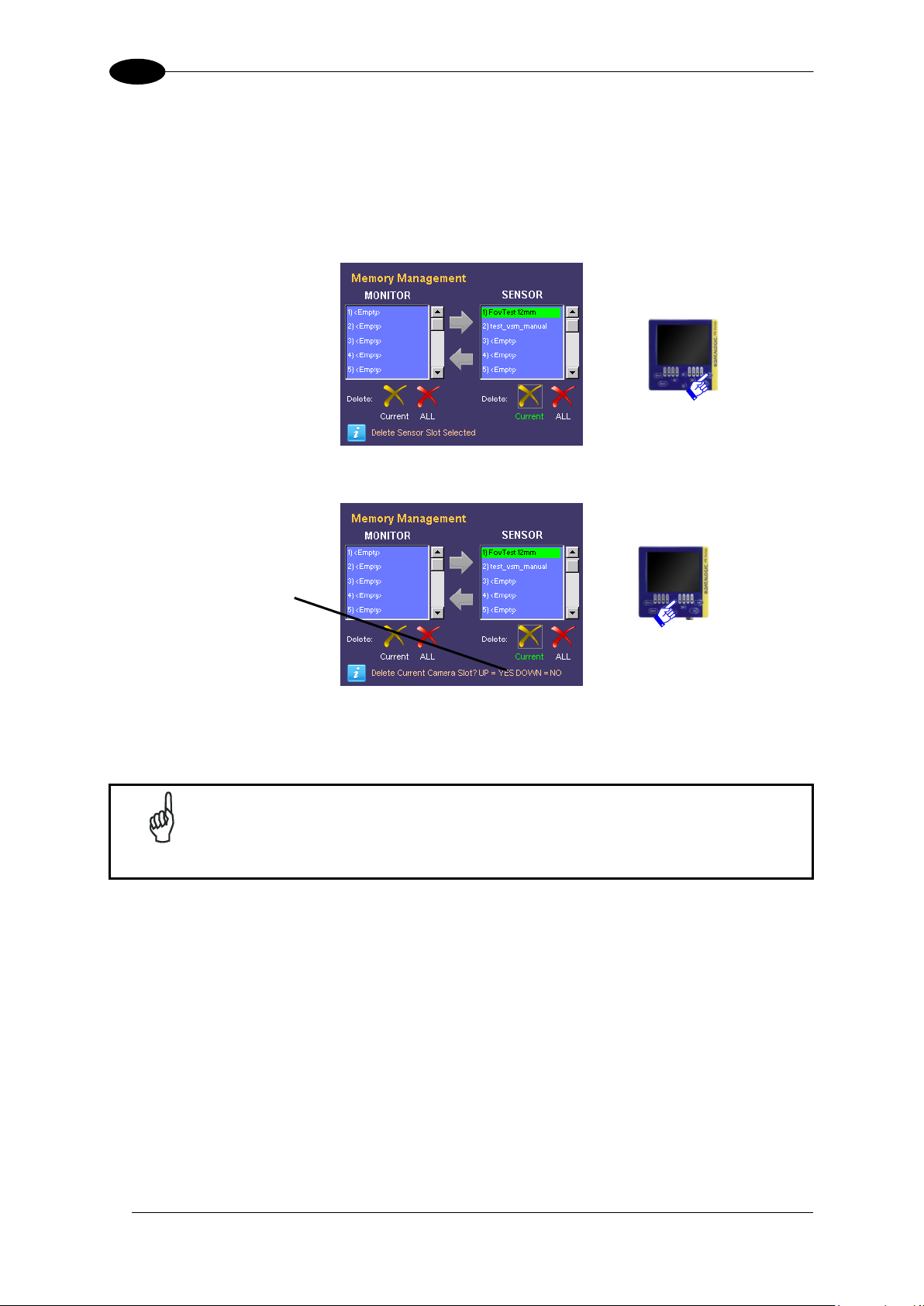

8.3.6 Cancellation of a DataVS2 Slot

Just like the VSM slots, the desired slot has to be selected (refer to previous paragraph

“Selection of slot (DataVS2)”). Obviously the monitor must be connected to a sensor to

access its memory.

Then move the focus on “Delete Current” button (on the bottom right side of the screen)

and press SET to confirm:

Another operation confirmation is requested also for the DataVS2 slots:

To proceed press ARROW UP otherwise, press ARROW DOWN to abandon. In both cases,

the information label will display the operation result and a refresh of the panel names will be

made.

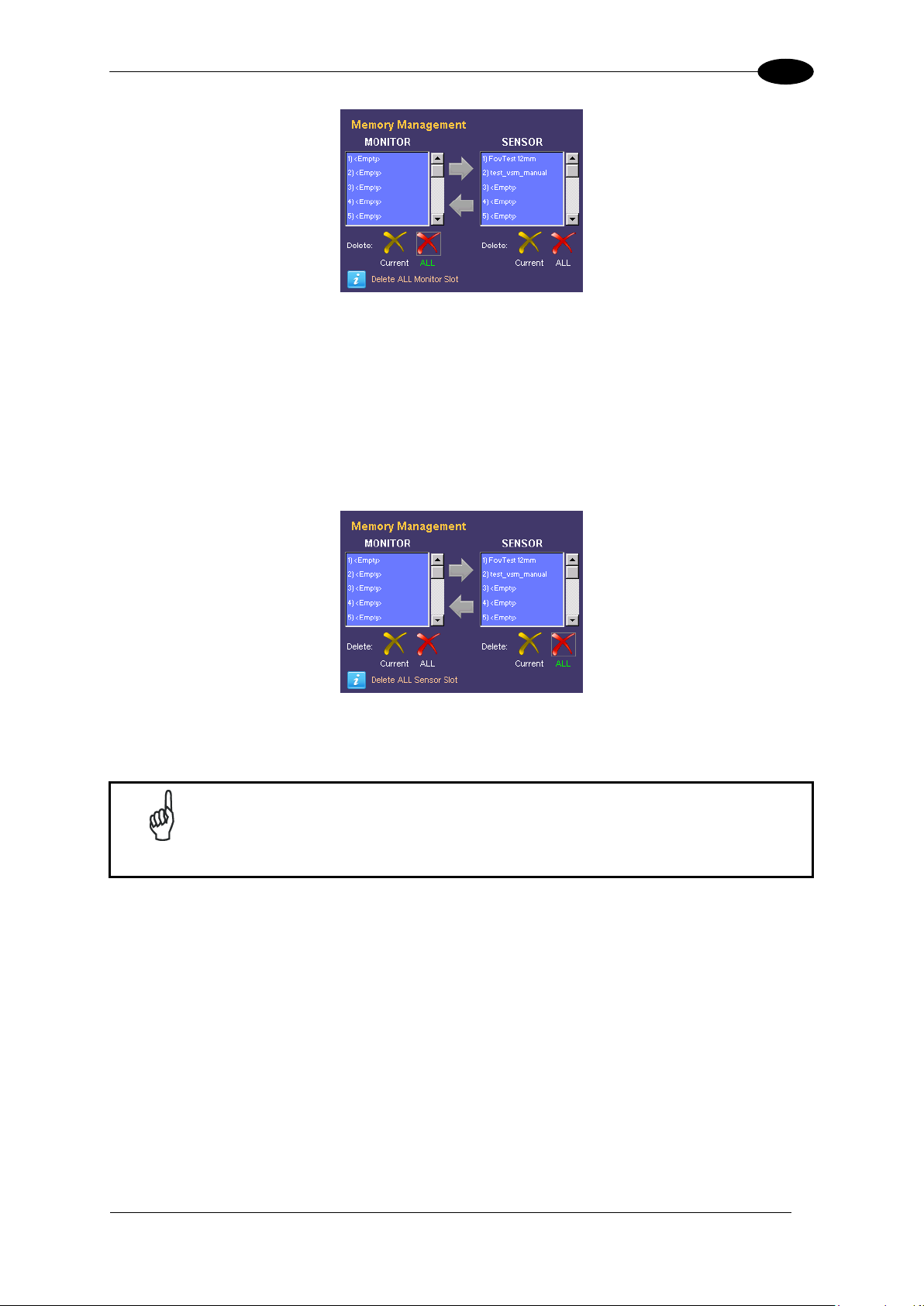

8.3.7 Cancellation of all the VSM Slots

To cancel all the VSM memory slots no specific slot has to be selected but the user must

only move the focus on the “Delete ALL” icon on the bottom left side of the screen and

press SET.

Page 35

ADVANCED FUNCTIONS

29

8

NOTA

With this command all the inspections, with the exception of the actual

running one, will be deleted..

Another confirmation will be requested. To proceed press ARROW UP otherwise, press

ARROW DOWN to abandon. In both cases, the information label will display the operation

result and a refresh of the panel names will be made.

8.3.8 Cancellation of all the DataVS2 Slots

To cancel all the DataVS2 memory slots no specific slot has to be selected but the user must

only move the focus on the “Delete ALL” icon on the bottom right side of the screen and

press SET.

Another confirmation will be requested. To proceed press ARROW UP otherwise, press

ARROW DOWN to abandon. In both cases, the information label will display the operation

result and a refresh of the panel names will be made.

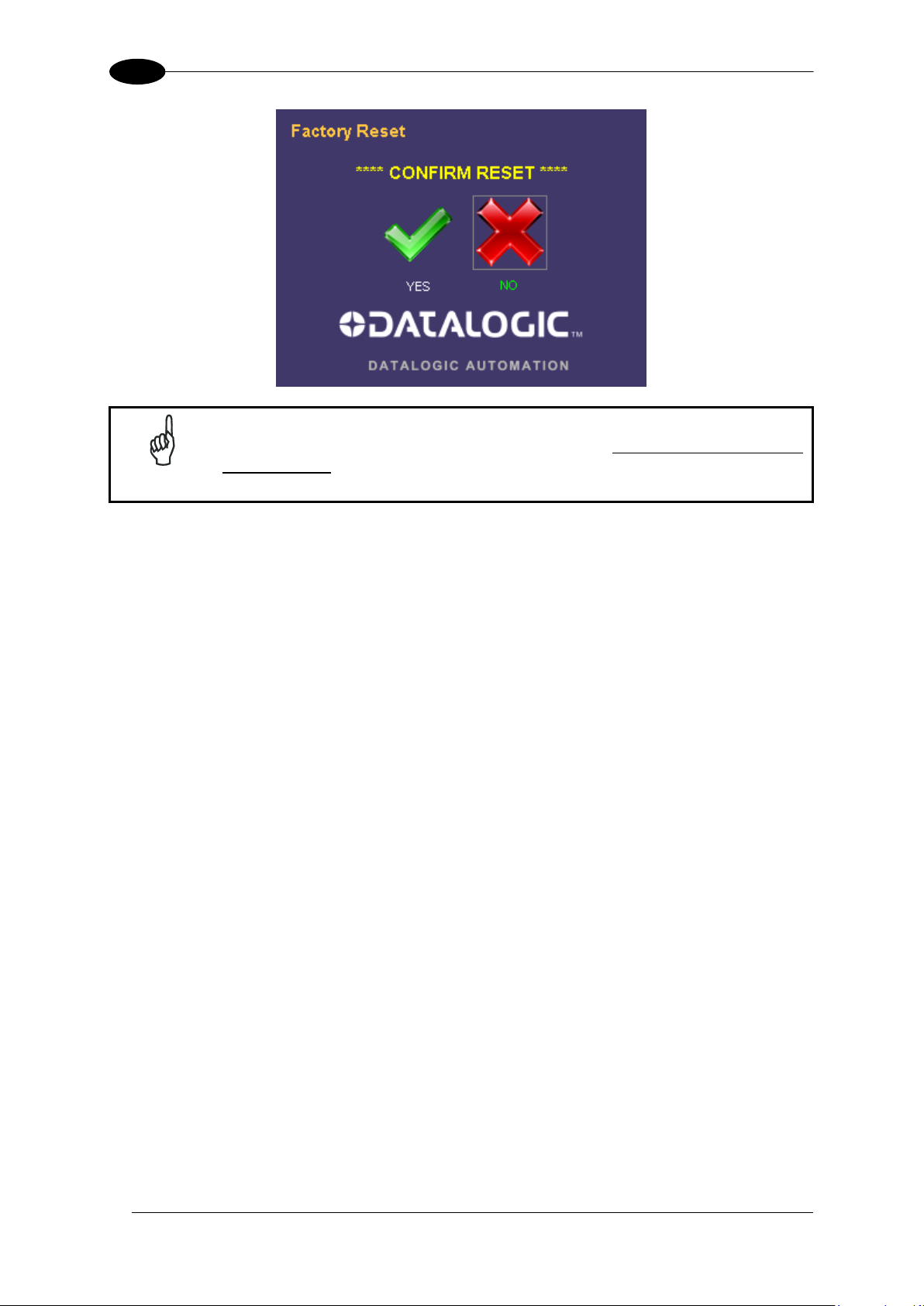

8.4 FACTORY RESET

This panel can be accessed only when no DataVS2 are connected and when the factory

reset of the VSM has to be restored.

All the memory slots are going to be cancelled, the network parameters changed and

passwords cancelled.

Page 36

DATAVS2-VSM INSTRUCTION MANUAL

30

8

NOTE

The system reset requires the VSM restart and the loss of all the data stored

in the memory.

Page 37

ADVANCED FUNCTIONS

31

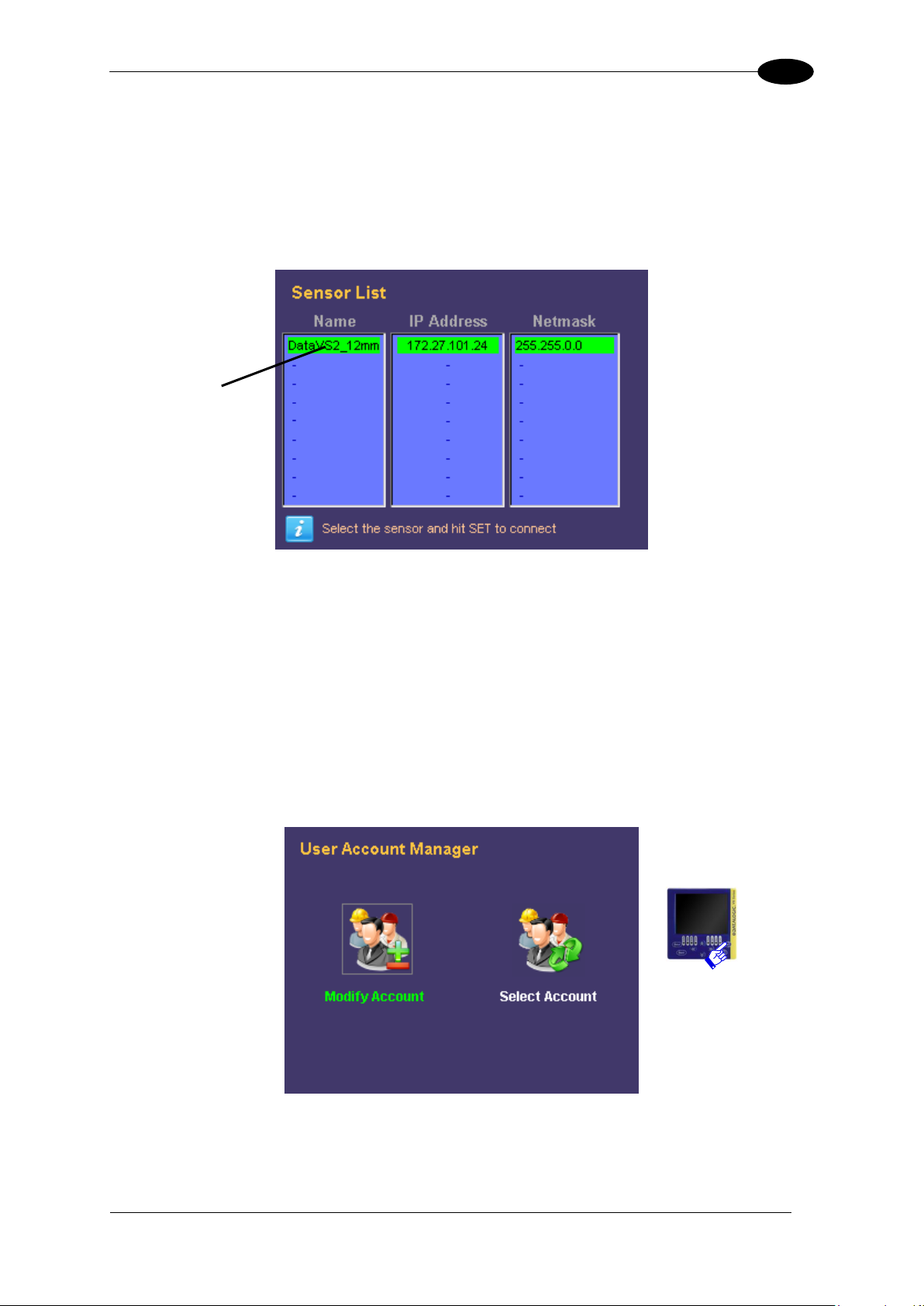

8

Selected sensor

8.5 SENSOR LIST

The “Sensor List” panel, after having made a discovery, lists the DataVS2 present in the

subnet.

To connect a sensor the user just has to select it from the list with the UP/DOWN ARROWS

and press SET.

Once the connection has been established, the VSM returns immediately to the monitor

mode.

8.6 USERS

This panel allows the user to set a password to protect the system. This protects the sensor

against accidental or unauthorised modifications. In the factory setting the password is

disabled for all accounts.

Firstly, the operation to effect on the profiles must be selected: “Selection” or “Modify” and

then press SET.

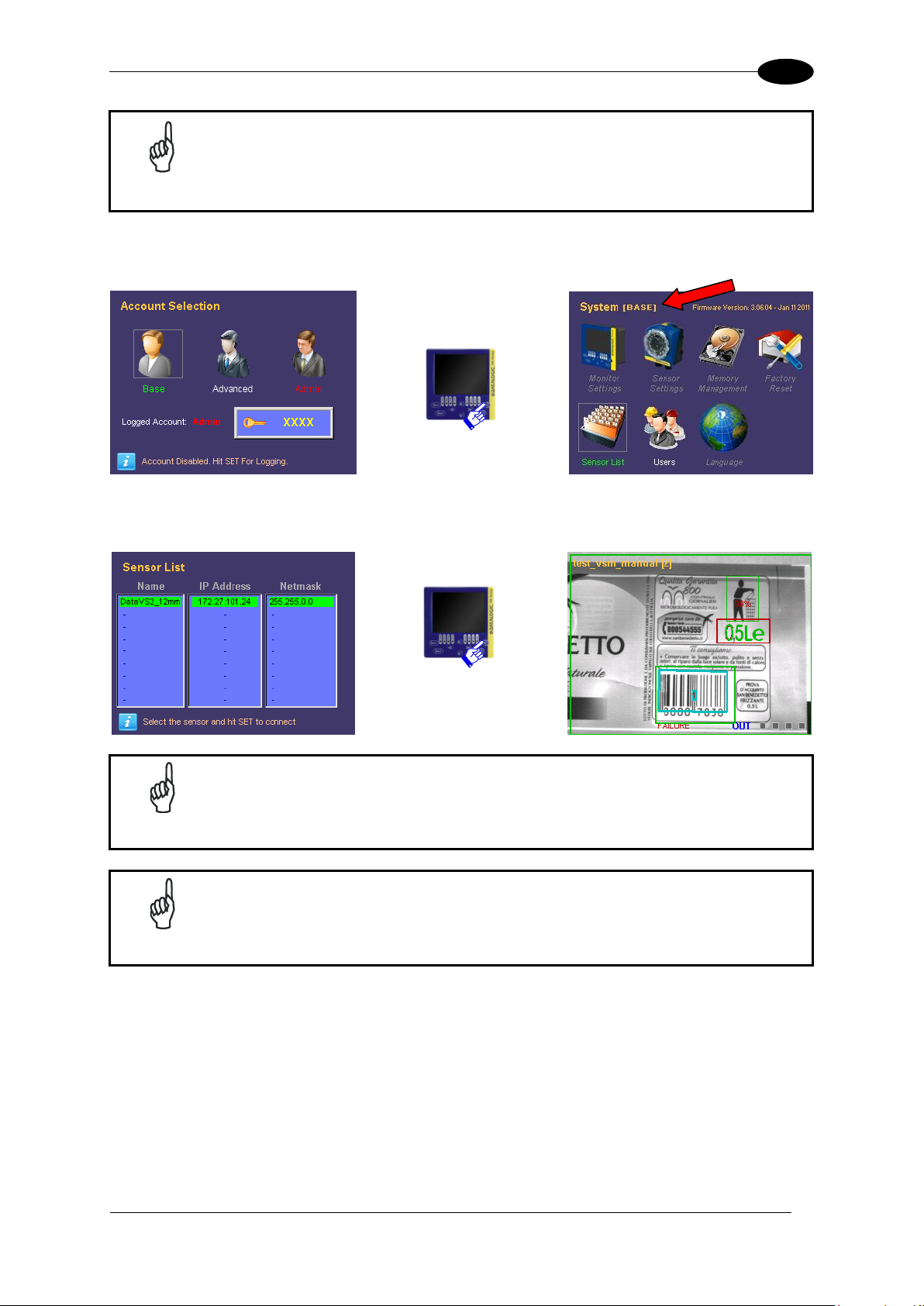

Page 38

32

8

The account selection panel is displayed as follows:

NOTE

Each user logins in using the administrator account until a new password is

memorised.

User typology

Password field

Info on account

Information Label

DATAVS2-VSM INSTRUCTION MANUAL

To enable the administrator password, the user must access “Modify Account”, select

“Admin” and press SET.

The user can now digit a new password made up of a sequence of four keyboard buttons

(ARROW UP/DOWN/RIGHT/LEFT).

Once the password has been entered, press SET to confirm. The password will be saved

and each time the user wants to login as administrator, the “Admin” account must be

selected and the password entered.

Page 39

ADVANCED FUNCTIONS

33

8

NOTE

When the administrator password has been forgotten, the VSM can be

unblocked with the recovery password ARROW UP, ARROW LEFT,

ARROW RIGHT, ARROW RIGHT. At the end of the procedure remember

to cancel the old password and set a new one in the “Modify Account”

panel.

NOTE

After a “Factory Reset”, all the passwords are cancelled and the

administrator account is restored as default.

NOTE

The “Advanced” account can be activated only after activating the

“Admin” account.

By selecting the “Base” user, the majority of the advanced functions of the VSM cannot be

accessed.

Only the “Sensor List” panel can be displayed, as well as the sensor to select for

connection and the visualisation in “Monitor” during inspection execution.

To select the “Advanced” user, the administrator account has to be first activated.

Page 40

DATAVS2-VSM INSTRUCTION MANUAL

34

8

USER RIGHTS

Account

Main Functions

Base

This user can only view the current status of the inspection

(“Monitor” mode) and cannot access any of the advanced

functions panels.

Advanced

This user can be selected only after the administrator

account has enabled the profile.

Has limited rights and can monitor the status of the current

inspection, change it and modify tool parameters.

Admin

(User enabled by default when no password is set and after

every “Factory Reset”.)

This user controls completely the device, can manage all

controls, scroll through all the panels and can create and/or

cancel other users.

In “Modify Account” mode the user has to select “Advanced” and then save a password.

After this, the account will be active and only a part of the advanced functions enabled.

Besides the basic rights, the inspection can be changed and the parameters of the relative

tools modified.

Page 41

ADVANCED FUNCTIONS

35

8

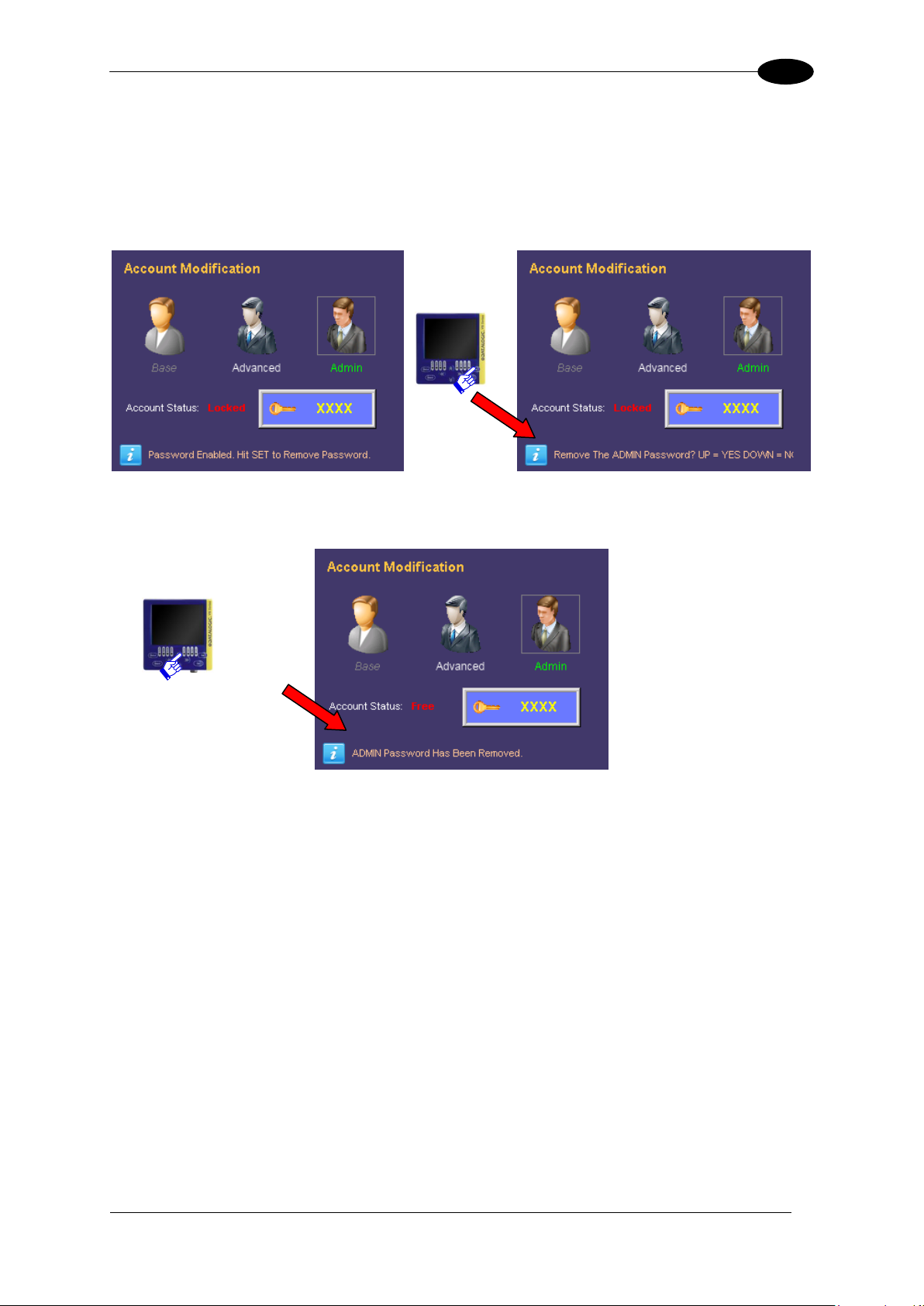

8.6.1 Removal of the Password

To disable all the accounts and remove the administrator password, the user must log in as

“Admin”.

Access “Modify Account”, select “Admin” user and press SET.

At this point the system requests the user to confirm the cancellation of the password. To

confirm press ARROW UP.

Page 42

DATAVS2-VSM INSTRUCTION MANUAL

36

8

NOTE

If the sensor is connected the “Sensor List” and “Factory Reset” panels

cannot be accessed.

8.7 LANGUAGE

Through this panel you can change the language of the VSM, current language is written in

the upper right side of screen. To set up a new language, choose the one you want with the

RIGHT/LEFT ARROW and press SET.

8.8 DISCONNECT

The “Disconnect” icon is displayed on the “System” panel only when connected to a

DataVs2. This indicates that the sensor is still connected and allows the user to disconnect

from the device.

If disconnected, to reconnect a DataVS2 or another device, the user must access the

“Sensor List” panel and select it from the list.

Page 43

DATAVS2 GUI CONNECTION

37

9

Parameters:

Description

Find sensor

DataVS2 GUI searches for all the connected

sensors/monitors and lists them in the CONTROL PANEL

Connect to …

DataVS2 GUI will connect the sensor/monitor whose

address corresponds to the IP address displayed

9 DATAVS2 GUI CONNECTION

To connect the VSM to DataVS2 GUI the “On Line“ mode must be selected from the specific

interface.

After having selected the relative radio button, the following screen will appear:

If “Find sensor” has been selected, the software will initially show a window with a progress

bar and, if any devices are connected, it will show this screen in the Control Panel present on

the right side of the main window:

Page 44

DATAVS2-VSM INSTRUCTION MANUAL

38

9

NOTE

If the line relevant to the desired device is highlighted in red, the connection

cannot be established. In this case we suggest to check the IP address and

Subnet Mask

The control panel will display a list of all the DataVS2/VSMs found by the “Find sensor”

function. The following information will be shown for each device:

The IP address;

The name;

An indication on the possibility of creating a connection (line highlighted in green) or

not (line highlighted in red);

A check box to select the DataVS2/VSM to reach.

To connect, check the box relative to the VSM and click on Connect. If connection is

successful the DataVS2 GUI will display the “VSM setting” panel.

9.1 VSM GENERAL INFORMATION

This window displays general information on VSM to which you are connected. Of the

parameters displayed, you can change:

the name of the VSM

IP address

Subnet Mask

After defining the new values, if you want to confirm those changes, you must click the Apply

button.

Page 45

DATAVS2 GUI CONNECTION

39

9

9.2 VSM MEMORY SETTINGS

This window shows the memory status of the VSM to which you are connected.

It also allows you to save on VSM PC inspections by pressing the button "Save On VSM”;

To save on PC the inspections saved on the memory of VSM by pressing the button "Save

On PC";

To cancel inspections of VSM by pressing the button"Delete".

Page 46

DATAVS2-VSM INSTRUCTION MANUAL

40

9

9.3 FIRMWARE UPDATE

The “VSM firmware updating” section can be accessed from the “VSM setting” panel and is

displayed as follows:

Page 47

DATAVS2 GUI CONNECTION

41

9

Parameters:

Description

Current Firmware

Version of Firmware currently executed on the connected

VSM.

Choose File

Press this button to select the Firmware file to be loaded on

the sensor. A dialogue window will then allow the user to

choose the “Desired Firmware” file saved in the PC.

After selecting the desired firmware and pressing “OK” in the

dialogue window, the firmware version selected will be

displayed in the “Desired Firmware” field.

Update Firmware

Press this button to update firmware in execution on the

connected VSM.

Two types of firmware updates are possible:

firmware upgrade: more recent firmware version, with

respect to the one currently in execution, is loaded on

the VSM;

firmware downgrade: a less recent firmware version,

with respect to the one currently in execution, is loaded

on the VSM.

Note: if this button is disabled, the selected firmware cannot

be loaded on the connected VSM due to Hardware version

incompatibility. In this case please select a different

firmware.

Note: after having updated the VSM firmware, the DataVS2

GUI will disconnect from the device and the VSM has to be

restarted.

Warning !! never power Down the VSM during Firmware

update procedure. The Monitor will restart by self at the end

of the update sequence.

Page 48

DATAVS2-VSM INSTRUCTION MANUAL

42

10

NOTE

Please enter Recovery Mode only if the sensor is not working and you are

not able to establish a communication with the sensor via the DataVS2

Graphic User Interface.

NOTE

The Recovery Mode is only intended for troubleshooting. The sensor in

Recovery Mode cannot be used for machine control.

10 RECOVERY MODE

In case of software crash, it is possible to run a recovery firmware on the device with a basic

communication service to restore the working environment.

In order to launch the recovery mode, power up the VSM, wait until the four status LEDs

(Set/Net, Adjust, Monitor e System) turn on in sequence, then press the STATUS button and

then the ESC button. The two Output LEDs start blinking, signalling that the recovery

firmware is running.

The VSM can be connected to the DataVS2 GUI in the recovery condition and perform the

following operations:

Update monitor firmware

Change VSM memory settings

Change monitor general information

10.1 RECOVERY PROCEDURE

In this paragraph you will find a simple recovery procedure to follow in case of monitor

malfunctioning.

Please follow the steps listed below whenever your VSM is not working properly:

1. Power on the monitor in Recovery Mode.

2. Open the DataVS2 GUI

3. From the STEP 1 select Online and connect to the monitor

4. Select “VSM Firmware Update” tab, choose the firmware file by clicking on “Choose

File” button and lastly click on “Update Firmware”.

5. Wait until the end of the update procedure. The interface gets automatically

disconnected from the monitor.

6. VSM restarts automatically. Verify that now it is working properly (i.e. it displays the

available sensor list panel).

Page 49

RECOVERY MODE

43

10

NOTE

If you are not able to connect to the VSM through the DataVS2 GUI, please

contact Sales Service.

Page 50

DATAVS2-VSM INSTRUCTION MANUAL

44

11

11 CHECKS AND PERIODIC MAINTENANCE

Correct system maintenance is necessary to remove dust or foreign objects from the VSM

display.

Remove dust using a soft cloth, if necessary dampened with a neutral detergent solution.

Avoid using:

detergents which contain alcohol or solvents

wool or synthetic cloths

Refer to the Datalogic website (www. datalogic.com) to verify the availability of new firmware

updates. To check the firmware version and date on your system, please refer to the System

Monitor Settings menu.

Page 51

WARRANTY

45

12

12 WARRANTY

The product you purchased is warranted to be free from manufacturing defects for a period

of 24 (twenty-four) months from date of manufacture.

Warranty does not cover damage and defects resulting from improper use of the sensor or

accidental damage due to shock or in the event the product is dropped.

The sensor contains cutting-edge electronic components that cannot be repaired or replaced

by the final user. Do not dismantle the device or make any changes to its components or the

warranty will become null and void.

DATALOGIC will not be liable for any damages to persons and things caused by the nonobservance of the correct installation modes and device use.

In presence of a non-functioning device, always return the emitting and receiving units for

repair or replacement

In case of problems, contact Datalogic Technical Service.

Page 52

46

13

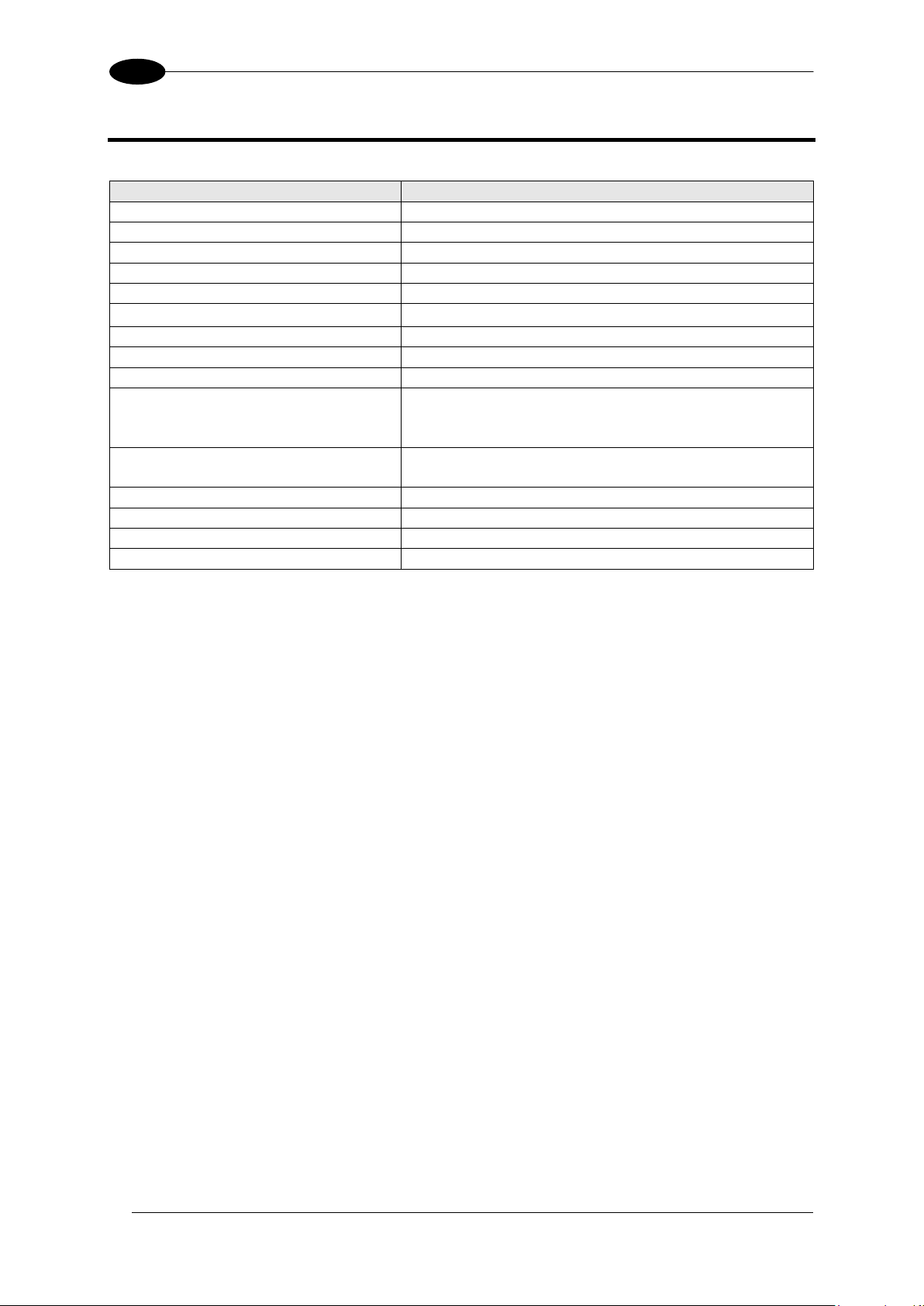

13 SPECIFICATIONS

Item

Description

Supply voltage:

24 Vdc ± 10%

Ripple voltage:

2.4 Vpp max.

Current draw:

Max 150 mA @ 24Vdc max

Dimensions:

96 x 96 x 39 mm

Indicators:

8 LEDs + 3.5'' colour LCD monitor

Setup:

DataVS2 GUI

Data retention:

Non volatile FLASH memory

Operating temperature:

-10 °C ... +55 °C

Storage temperature:

-20 °C ... +70 °C

Vibrations:

(EN60068-2-6)

14 mm @ 2 to 10 Hz;

1.5 mm @ 13 to 55 Hz;

2 g @ 70 to 200 Hz; 2 hours on each axis

Shock resistance:

(EN60068-2-27)

11 ms (30 G) 6 shocks on each axis

Housing material:

ABS

Mechanical protection:

IP20 (IP40 when panel mounted)

Connections:

2 x M12 4 poles

Weight:

180 g

DATAVS2-VSM INSTRUCTION MANUAL

Page 53

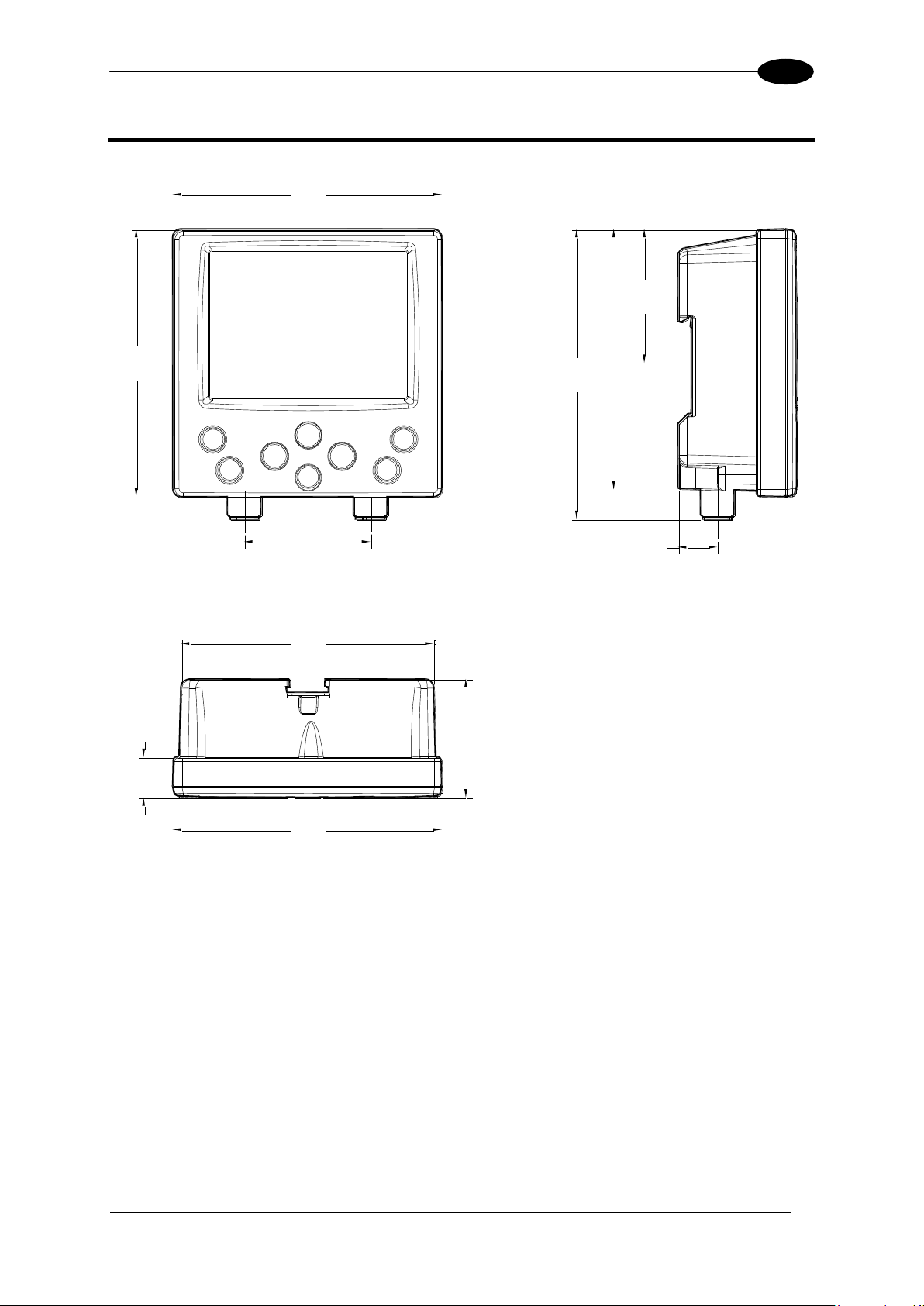

OVERALL DIMENSIONS

47

14

96

[3.78]

96

[3.78]

48.0

[1.89]

93.4

[3.68]

104

[4.09]

45.0

[1.77]

90.2

[3.55]

14.5

[0.57]

96

[3.78]

42.5

[1.67]

14.0

[0.55]

14 OVERALL DIMENSIONS

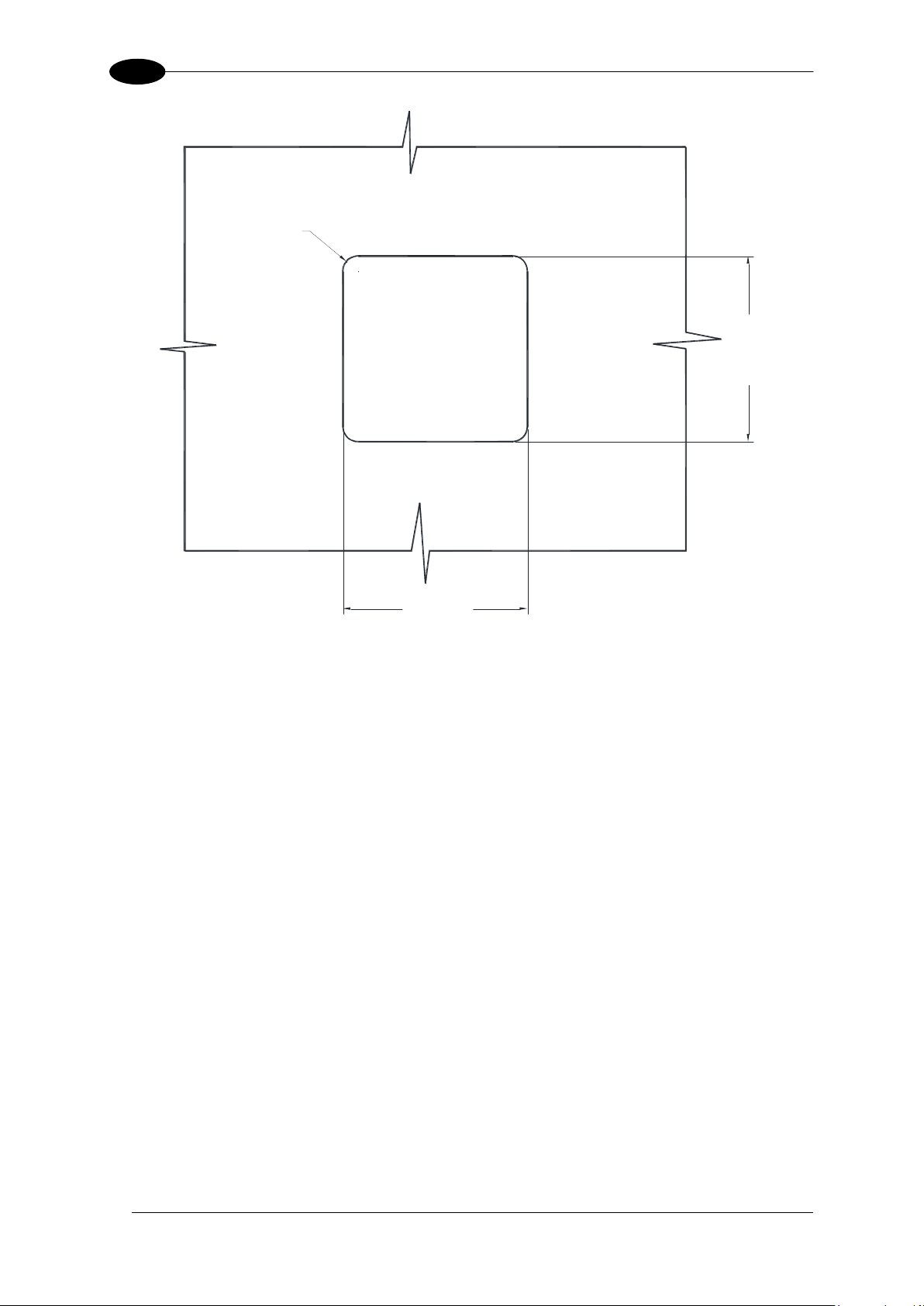

Page 54

DATAVS2-VSM INSTRUCTION MANUAL

48

14

92

±0.2

[3.62

±0.01

]

92

±0.2

[3.62

±0.01

]

R7.5

[R0.30]

Page 55

Loading...

Loading...