Page 1

Matrix 450™ + LT-03X

QUICK REFERENCE GUIDE

NOTE

This manual illustrates a Stand Alone application. For other types of

installations, such as ID-NET™, and for a complete reader configuration using

the VisiSet™ configuration program, refer to the Matrix 450™ Reference

Manual available on the mini-DVD and also downloadable from the Web at

www.automation.datalogic.com.

821000250

Page 2

MATRIX 450™ QUICK REFERENCE GUIDE

2

UPDATES AVAILABILITY

UK/US

The latest drivers and documentation updates for this product are available on Internet.

Log on to: www.automation.datalogic.com

I

Su Internet sono disponibili le versioni aggiornate di driver e documentazione di questo

prodotto. Collegarsi a: www.automation.datalogic.com

F

Les versions mises à jour de drivers et documentation de ce produit sont disponibles sur

Internet. Cliquez sur : www.automation.datalogic.com

D

Im Internet finden Sie die aktuellsten Versionen der Treiber und Dokumentation von

diesem Produkt. Adresse : www.automation.datalogic.com

E

En Internet están disponibles las versiones actualizadas de los drivers y documentación

de este producto. Dirección Internet : www.automation.datalogic.com

SERVICES AND SUPPORT

Datalogic provides several services as well as technical support through its website. Log on to

www.automation.datalogic.com and click on the links indicated for further information:

PRODUCTS

Search through the links to arrive at your product page which describes specific Info, Features,

Applications, Models, Accessories, and specific Downloads.

DOWNLOAD > PRODUCT LITERATURE > SW&UTILITIES

The VisiSet™

utility program, which allows device configuration using a PC can be downloaded

from this page. It provides RS232 and Ethernet interface configuration.

SERVICE

- Overview

- Technical Support, Maintenance Agreements and Warranty Extensions

- Repair Centers

- Helpdesk

- Material Return Authorization

LEGAL NOTICES

© 2012 Datalogic Automation S.r.l. ALL RIGHTS RESERVED. Protected to the fullest extent under

U.S. and international laws. Copying, or altering of this document is prohibited without express written

consent from Datalogic Automation S.r.l.

Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in many countries,

including the U.S.A. and the E.U.

Matrix 450, ID-NET, VisiSet and X-PRESS are trademarks of Datalogic Automation S.r.l. All other

brand and product names mentioned herein are for identification purposes only and may be

trademarks or registered trademarks of their respective owners.

Datalogic shall not be liable for technical or editorial errors or omissions contained herein, nor for

incidental or consequential damages resulting from the use of this material.

Page 3

MATRIX 450™ QUICK REFERENCE GUIDE

3

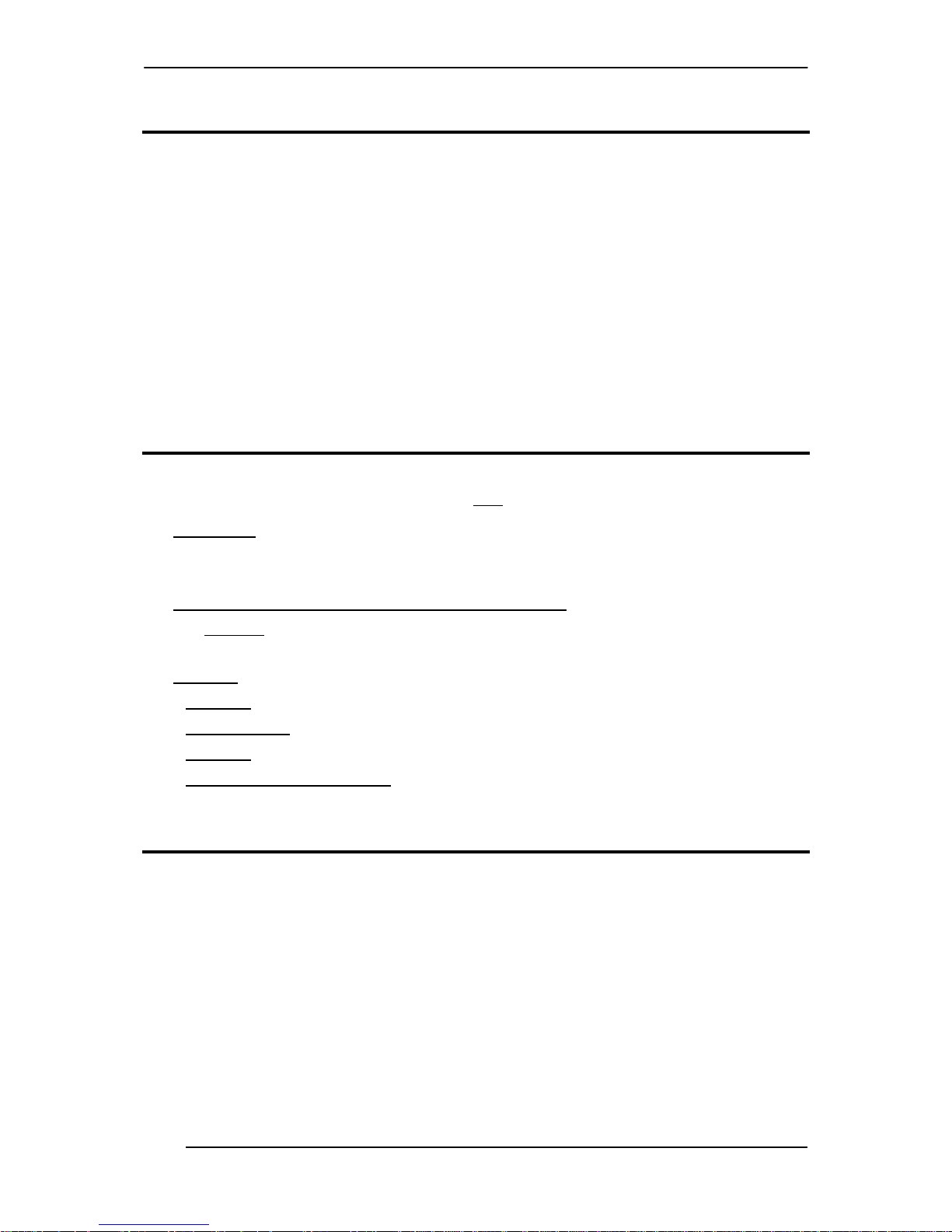

STEP 1 – ASSEMBLE THE READER

The first step to perform is to assemble the accessories that make up the Matrix 450™

reader. The lens and lighting system or external illuminator must be used. This procedure

shows an LT-03x lighting system.

CAUTION

Matrix 450™ must be disconnected from the power supply during this

procedure.

1. In a dust-free environment, remove the Matrix 450™ Lens Cover by unscrewing it.

CAUTION

Do not touch the sensor aperture, lens glass or lens cover glass. These

areas must be kept clean. Avoid any abrasive substances that might

damage these surfaces during cleaning.

2. Remove the sensor protection label by pulling it off of the base.

3. Mount the LNS-12xx lens by slowly screwing it onto the base until it arrives at the

mechanical stop.

NOTE

The lens mount is equipped with a special slip mechanism and together

with the LT-03x design facilitates the focusing procedure during installation,

for example if the locking knobs on the lens are obstructed by the body of

the illuminator. See note in Step 4 "Focusing the Reader" or Step 8.

Figure 1 – Assembling Matrix 450™ and LNS-12xx Lens

NOTE

The anti-vibration components are already mounted to all Datalogic

LNS-12xx Lenses.

4. To keep dust and dirt off of the lens during mounting, temporarily replace the lens cover.

Locking Knobs Lens Cover

anti-vibration components

(see note below)

Protective Film

(remove before calibration)

Matrix 450™ Base

Page 4

MATRIX 450™ QUICK REFERENCE GUIDE

4

Figure 2 – Assembling Matrix 450™ to LT-03x

NOTE

The mating bracket can be mounted in the reverse direction to create a

compact version of the Matrix 450™ + LT-03x assembly. The compact

assembly however will reduce access to the lens for the focusing procedure.

REQUIRED ACCESSORIES

The following table shows the correct lens/illuminator combinations to be used for Matrix

450™ imager assembly.

Lenses Illuminators

93ACC0041 LNS-1216

16 mm C-Mount Lens 5MP

with anti-vibration components

93A400034 LT-032 ULTRA POWER LT NARROW BLUE 40°

93A400032 LT-030

ULTRA POWER LT SUPERNARROW

BLUE 20°

93A400033 LT-031

ULTRA POWER LT SUPERNARROW

WHITE 20°

93ACC0034 LNS-1225

25 mm C-Mount Lens 5MP

with anti-vibration components

93A400034 LT-032 ULTRA POWER LT NARROW BLUE 40°

93A400032 LT-030 ULTRA POWER LT SUPERNARROW

BLUE 20°

93ACC0035 LNS-1235

35 mm C-Mount Lens 5MP

with anti-vibration components

93A400033 LT-031 ULTRA POWER LT SUPERNARROW

WHITE 20°

93A400032 LT-030 ULTRA POWER LT SUPERNARROW

BLUE 20°

93ACC0036 LNS-1250

50 mm C-Mount Lens 5MP

with anti-vibration components

93A400033 LT-031 ULTRA POWER LT SUPERNARROW

WHITE 20°

Page 5

MATRIX 450™ QUICK REFERENCE GUIDE

5

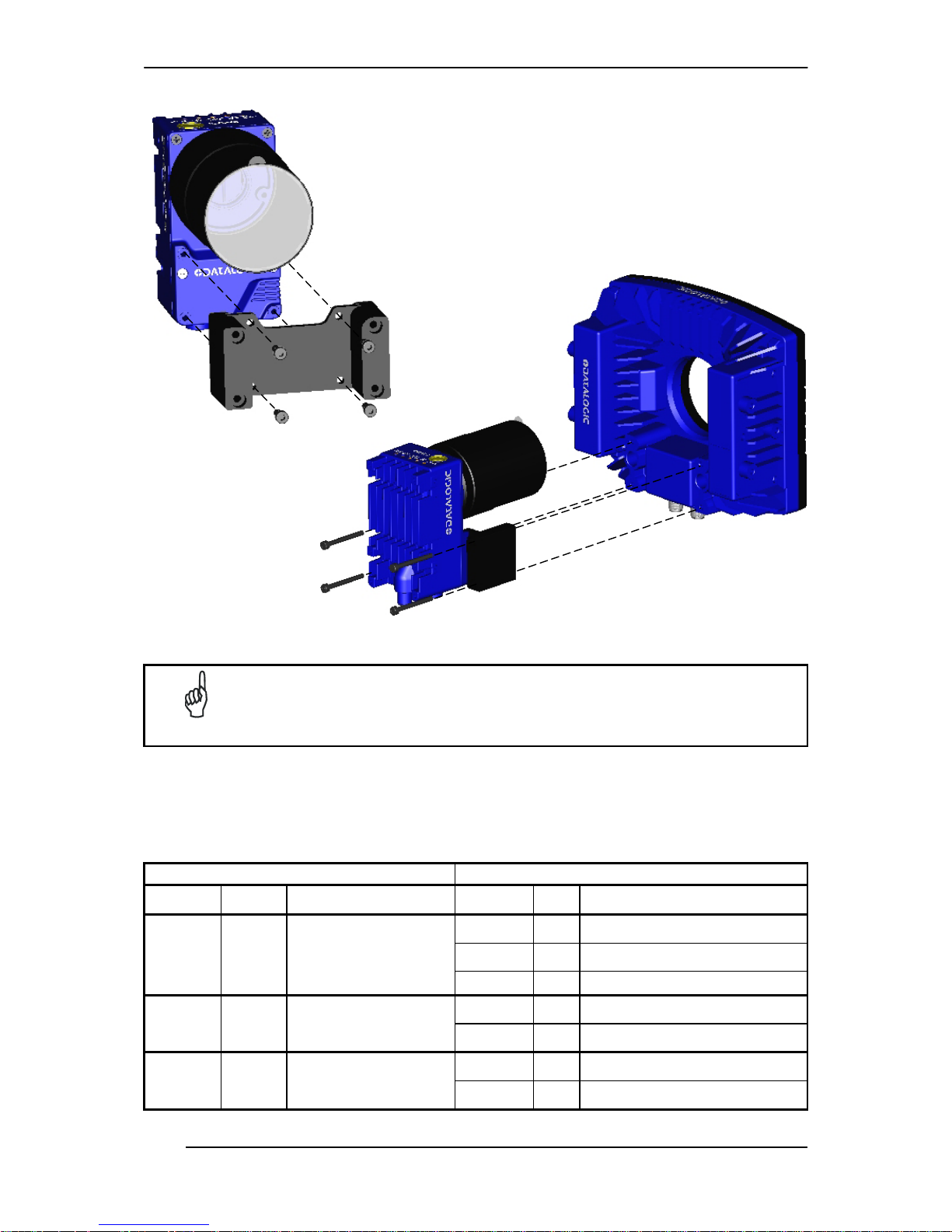

STEP 2 – CONNECT THE SYSTEM

In the typical standalone layout shown in the figure below a serial host is connected to the

Matrix 450™ + LT-03x. The reader operates in One Shot or Phase Mode and can use an

external trigger to signal image acquisition.

The CBX is used to facilitate the connection between the Matrix 450™ + LT-03x assembly

and the serial host interface, external trigger, serial aux configuration, and optional input and

output devices.

Matrix 450™ Standalone Layout to Serial Host

Power Supply Connection

Use the PG-120 power Kit (3 versions for European, UK or US plug) and CAB-PG-0002

+ BA400 connector to connect the PG-120 to the CBX. An alternative power supply to the

PG-120 is the PWR-120.

CBX Connection

Use CAB-LP-0x to supply power from the CBX to the LT-03x. Connect Brown/White

wires to Vdc and Black/Blue wires to GND. Connect the cable shield to Earth ground.

Use CAB-MS0x between Matrix 450™ and the CBX for: power, serial host, external

trigger device (photocell), serial aux, additional I/O connections.

Optionally: use the CAB-GE0x for the Gigabit Ethernet connection towards a remote host

or Datalogic WebSentinel™ monitoring station.

Matrix 450™ LT-03x Connection

Use the CAB-LD-102 (no power) cable (provided with the LT-03x), to connect the

communication signals between the Matrix 450™ and the LT-03x while isolating the

power. Through the CBX internal power switch you can control power to the Matrix 450™

independently from the LT-03x.

NOTE

Matrix 450™ does not support sourcing power towards the CBX in order to

power I/O devices. These devices must be powered through the CBX or

from an external source.

CAB-GE0x (to Remote Host or

Datalogic WebSentinel™ Monitor)

CAB-PG-0002

+ BA400

CAB-MS0x

CAB-LP-0x

CAB-LD-102

(no power)

Serial Host

PG-120

Ext. Trigger

CBX500

AUX (Matrix 450™

configuration)

I/O

Page 6

MATRIX 450™ QUICK REFERENCE GUIDE

6

Alternatively, Matrix 450™ + LT-03x can be connected directly to an Ethernet host through

the Gigabit Ethernet connection (CAB-GE0x). If an external trigger is not necessary, the

layout is simplified. The LT-03x is powered directly from the PG-120 through the CAB-PG0105 cable. The CAB-LD-002 (with power) cable (provided with the LT-03x), is used to

supply power to the Matrix 450™ from the LT-03x.

Matrix 450™ Standalone Layout to Ethernet Host

Matrix 450™ + LT-03x can also be used in an ID-NET™ Master/Slave configuration. See the

Matrix 450™ Reference Manual for details, including power supply recommendations.

NOTE

If using separate power sources for LT-03x and Matrix 450™, make sure

that LT-03x is powered up before Matrix 450™ in order to be correctly

recognized.

CAB-GE0x

CAB-PG-0105

CAB-LD-002

(with power)

PG-120

Ethernet Host

(Data collection +

Matrix 450™ configuration)

Page 7

MATRIX 450™ QUICK REFERENCE GUIDE

7

CBX100/CBX500 Pinout for Matrix 450™

The table below gives the pinout of the CBX100/CBX500 terminal block connectors. Use this

pinout when the Matrix 450™ reader is connected by means of the CBX100/CBX500:

CBX100/500 Terminal Block Connectors

Input Power Outputs

Vdc Power Supply Input Voltage + +V Power Source - Outputs

GND Power Supply Input Voltage - -V Power Reference - Outputs

Earth Protection Earth Ground O1+ Output 1 +

O1- Output 1 -

Inputs

O2+ Output 2 +

+V Power Source – External Trigger O2- Output 2 -

I1A External Trigger A (polarity insensitive)

Auxiliary Interface

I1B External Trigger B (polarity insensitive) TX Auxiliary Interface TX

-V Power Reference – External Trigger RX Auxiliary Interface RX

+V Power Source – Inputs SGND Auxiliary Interface Reference

I2A Input 2 A (polarity insensitive)

ID-NET™

I2B Input 2 B (polarity insensitive) REF Network Reference

-V Power Reference – Inputs ID+ ID-NET™ network +

Shield

ID- ID-NET™ network -

Shield Network Cable Shield

Main Interface

RS232 RS485 Full-Duplex RS485 Half-Duplex

TX TX+ RTX+

RTS TX- RTX RX *RX+

CTS *RX-

SGND SGND SGND

* Do not leave floating, see Reference Manual for connection details.

CAUTION

Do not connect GND, SGND and REF to different (external) ground

references. GND, SGND and REF are internally connected through filtering

circuitry which can be permanently damaged if subjected to voltage drops

over 0.8 Vdc.

Page 8

MATRIX 450™ QUICK REFERENCE GUIDE

8

STEP 3 – MOUNT AND POSITION THE READER

1. To mount the Matrix 450™ + LT-03x assembly, use the L-shaped mounting bracket to

obtain the most suitable position for the reader. The most common mounting

configurations are shown in the figure below. Other mounting solutions are provided in

the Matrix 450™ Reference Manual.

Figure 3 –Positioning with LT-03x L-shaped Mounting Bracket

CAUTION

Do not mount the Matrix 450™ + LT-03x assembly with the Matrix 450™

body mounting bracket accessory. The body mounting bracket is not

designed to support the LT-03x.

2. When mounting the Matrix 450™ + LT-03x assembly, take into consideration these three

ideal label position angles: Pitch or Skew 10° to 20° and Tilt 0°, although the reader can

read a code at any tilt angle. Assure at least 10° Pitch or Skew to avoid direct illuminator

light reflection which will reduce performance.

3. Refer to the Reading Diagrams to determine the correct reading distance according to

your application requirements.

NOTE

Rapid Configuration of the Matrix 450™ reader can be made either through

the X-PRESS™ interface (steps 4-6) which requires no PC connection, or

by using the VisiSet™ Setup Wizard (steps 7-8). Select the procedure

according to your needs.

Both the X-PRESS™ interface and the VisiSet™ Setup Wizard are easy setup methods valid

for single code applications with uniform labels that do not require reading at the extreme

ends of the reading ranges shown in the diagrams.

For advanced applications including those that operate at the extreme ends of the reading

ranges, use the VisiSet™ Calibration Tool. See the Help On Line for more details.

Pitch

Tilt

Pitch

Tilt

Page 9

MATRIX 450™ QUICK REFERENCE GUIDE

9

STEP 4 – FOCUS THE READER

Matrix 450™ provides a built-in tool called Blue Diamonds™ to aid focusing the reader. The

Blue Diamonds™ are accessed through the X-PRESS™ Interface.

1. Remove the lens cover in order to focus the reader.

2. Prepare the correct accessory lens for your application:

NOTE

Once the lens is fully tightened to the mechanical stop (Step 1), it can be

rotated counterclockwise (up to one full turn without loosening the lens), so

that the diaphragm scale and locking knobs can be easily accessed from

behind the LT-03x.

a. Remove the anti-vibration o-ring from the two Locking Knobs on the lens and loosen

them.

b. Adjust the Focus ring to the "Far position" and the Diaphragm ring to the "F2.8"

number setting which is the preferred setting for installation using the X-PRESS™

interface.

3. Power the reader on. During the reader startup (reset or restart phase), all the LEDs

blink for one second. On the connector side of the reader near the cable, the “POWER

ON” LED (blue) indicates the reader is correctly powered.

4. Enter the Focus function by pressing and holding the X-PRESS™ push button until the

Focus LED is on.

Figure 4 – X-PRESS™ Interface: Focus Function

5. Release the button to enter the Focus function. The Blue Diamonds™ and laser pointers

turn on.

NOTE

If the reading surface is too dark, in order to increase the contrast, it may be

helpful to place a piece of white paper at the Blue Diamonds™ positions to

see them better.

The procedure is as follows:

a. At the correct reading distance

(see the Reading Diagrams in this Quick Reference

Guide), adjust the Focus ring towards the "Near position" until the Blue Diamonds™

are perfectly in focus, see Figure 5.

b. At long focal distances a "skew" angle may cause a noticeable difference in focus

between the two diamonds, in this case select the best possible focus (both diamonds

slightly out of focus). Tighten the Focus Locking Knob.

c. Set the Diaphragm to the aperture stop (F-number) stated in the conditions relative to

the selected reading diagram and then tighten the Diaphragm Locking Knob.

d. Replace the anti-vibration o-ring onto the two Locking Knobs.

NOTE

If necessary you can use the Fine Focusing Tool in the VisiSet™ Setup

Wizard for fine focusing. See Step 8.

READY

SETUP

FOCUS

TEST LEARN

GOODTRIGGERCOM STATUS

red yellow yellow green green

Page 10

MATRIX 450™ QUICK REFERENCE GUIDE

10

Figure 5 – Focus Function Using Blue Diamonds™

6. Exit the Focus function by pressing the X-PRESS™ push button once. The Blue

Diamonds™ turn off.

7. Replace the lens cover, screwing it tightly to the base.

STEP 5 – CALIBRATE IMAGE DENSITY

In order to function correctly to the fullest extent of its capabilities, Matrix 450™ must acquire

information regarding image density or PPI (pixels per inch). This calibration takes place

through the X-PRESS™ Interface and the Focusing and PPI Setup Chart included in the

package. This procedure is necessary for the first time installation, if the lens type is changed

or if the focal distance is changed.

Locate

1. Enter the Focus function by pressing and holding the X-PRESS™ push button until the

Focus LED is on.

2. Release the button to enter the Focus function. The Blue Diamonds™ and laser pointers

turn on.

Figure 6 – X-PRESS™ Interface: Locate Function

3. From the Focusing and PPI Setup Chart, position the 1 mm code at the center of the

Horizontal FOV (aligned with the laser pointers).

Figure 7 –Aligning the Focusing and PPI Setup Chart Using Laser Pointers as Reference

4. Exit the Focus function by pressing the X-PRESS™ push button once. The Blue

Diamonds™ and laser pointers turn off.

Your reader can have one of the

above types of Blue Diamonds™.

Blue Diamond™

in focus

FOV

READY

SETUP

FOCUS

TEST LEARN

GOODTRIGGERCOM STATUS

red yellow yellow green green

Page 11

MATRIX 450™ QUICK REFERENCE GUIDE

11

Setup

5. Enter the Setup function by pressing and holding the X-PRESS™ push button until the

Setup LED is on.

Figure 8 – X-PRESS™ Interface: Setup Function

6. Release the button to enter the Setup function. The Setup LED will blink until the

procedure is completed.

The Setup procedure ends when the Image Acquisition parameters are successfully saved

in the reader memory, the Setup LED will remain on continuously and Matrix 450™ emits

3 high pitched beeps.

If the calibration cannot be reached after a timeout of about 5 (five) seconds Matrix 450™

will exit without saving the parameters to memory, the Setup LED will not

remain on

continuously but it will just stop blinking. In this case Matrix 450™ emits a long low pitched

beep.

7. Exit the Setup function by pressing the X-PRESS™ push button once.

Learn

8. Enter the Learn function by pressing and holding the X-PRESS™ push button until the

Learn LED is on.

Figure 9 – X-PRESS™ Interface: Learn Function

9. Release the button to enter the Learn function. The Learn LED will blink until the

procedure is completed.

The Learn procedure ends when the Image Density value is successfully saved in the

reader memory, the Learn LED will remain on continuously, the Green Spot is activated

and Matrix 450™ emits 3 high pitched beeps.

If the calibration cannot be reached after a timeout of about 3 (three) minutes Matrix 450™

will exit without saving the parameters to memory, the Learn LED will not

remain on

continuously but it will just stop blinking. In this case Matrix 450™ emits a long low pitched

beep.

10. Exit the Learn function by pressing the X-PRESS™ push button once.

READY

SETUP

FOCUS

TEST LEARN

GOODTRIGGERCOM STATUS

red yellow yellow green green

READY

SETUP

FOCUS

TEST LEARN

GOOD TRIGGERCOM STATUS

red yellow yellow green green

Page 12

MATRIX 450™ QUICK REFERENCE GUIDE

12

STEP 6 – X-PRESS™ CONFIGURATION

Once Matrix 450™ has calibrated image density, you can configure it for optimal code

reading relative to your application.

Locate

1. Enter the Focus function by pressing and holding the X-PRESS™ push button until the

Focus LED is on.

Figure 10 – X-PRESS™ Interface: Locate Function

2. Release the button to enter the Focus function. The Blue Diamonds™ and laser pointers

turn on.

3. Select a code from your application. Position the code at the center of the Horizontal

FOV (aligned with the laser pointers).

4. Exit the Focus function by pressing the X-PRESS™ push button once. The Blue

Diamonds™ and laser pointers turn off.

Setup

5. Enter the Setup function by pressing and holding the X-PRESS™ push button until the

Setup LED is on.

Figure 11 – X-PRESS™ Interface: Setup Function

6. Release the button to enter the Setup function. The Setup LED will blink until the

procedure is completed.

The Setup procedure ends when the Image Acquisition parameters are successfully saved

in the reader memory, the Setup LED will remain on continuously and Matrix 450™ emits

3 high pitched beeps.

If the calibration cannot be reached after a timeout of about 5 (five) seconds Matrix 450™

will exit without saving the parameters to memory, the Setup LED will not

remain on

continuously but it will just stop blinking. In this case Matrix 450™ emits a long low pitched

beep.

7. Exit the Setup function by pressing the X-PRESS™ push button once.

READY

SETUP

FOCUS

TEST LEARN

GOODTRIGGERCOM STATUS

red yellow yellow green green

READY

SETUP

FOCUS

TEST LEARN

GOOD TRIGGERCOM STATUS

red yellow yellow green green

Page 13

MATRIX 450™ QUICK REFERENCE GUIDE

13

Learn

8. Enter the Learn function by pressing and holding the X-PRESS™ push button until the

Learn LED is on.

Figure 12 – X-PRESS™ Interface: Learn Function

9. Release the button to enter the Learn function. The Learn LED will blink until the

procedure is completed.

The Learn procedure ends when the Image Processing and Decoding parameters are

successfully saved in the reader memory, the Learn LED will remain on continuously, the

Green Spot is activated and Matrix 450™ emits 3 high pitched beeps

1

.

If the autolearning cannot be reached after a timeout of about 3 (three) minutes Matrix

450™ will exit without saving the parameters to memory, the Learn LED will not

remain on

continuously but it will just stop blinking. In this case Matrix 450™ emits a long low pitched

beep.

10. Exit the Learn function by pressing the X-PRESS™ push button once.

NOTE

If you have used this procedure to configure Matrix 450™ go to step 9.

RESET READER TO FACTORY DEFAULT (OPTIONAL)

If it ever becomes necessary to reset the reader to the factory default values, you can

perform this procedure by holding the X-PRESS™ push button pressed while powering up

the reader. You must keep the X-PRESS™ push button pressed until the power up

sequence is completed (several seconds) and all LEDs blink simultaneously 3 times.

All LEDs remain on for about one second, then off for one second, the Configuration and

Environmental parameters are reset, and the status LED remains on. If connected through a

CBX500 with display module, the message "Default Set" is shown on the display.

1

The Learn procedure will not recognize Pharmacode symbologies.

READY

SETUP

FOCUS

TEST LEARN

GOODTRIGGERCOM STATUS

red yellow yellow green green

Page 14

MATRIX 450™ QUICK REFERENCE GUIDE

14

STEP 7 – INSTALLING VISISET™ CONFIGURATION PROGRAM

VisiSet

™

is a Datalogic reader configuration tool providing several important advantages:

Setup Wizard for rapid configuration and new users;

Defined configuration directly stored in the reader;

Communication protocol independent from the physical interface allowing the reader to

be considered as a remote object to be configured and monitored.

To install VisiSet™, turn on the PC that will be used for the configuration, running

Windows: 98/2000, NT 4.0+SP4 or later, XP, Vista or 7, then insert the VisiSet™ MiniDVD, wait for the CD to autorun and follow the installation procedure.

This configuration procedure assumes a laptop computer, running VisiSet™, connected to

either the reader's auxiliary serial port (through the CBX) or to the reader's on-board Ethernet

port (previously configured using the programming barcode procedure).

After installing and running the VisiSet™ software program the following window appears:

Figure 13 - VisiSet™ Opening Window

Set the communication parameters from the "Options" menu. Then select "Connect", the

following window appears:

Figure 14 - VisiSet™ Main Window After Connection

Page 15

MATRIX 450™ QUICK REFERENCE GUIDE

15

STEP 8 – CONFIGURATION USING SETUP WIZARD

The Setup Wizard option is advised for rapid configuration or for new users. It allows reader

configuration in a few easy steps.

1. Select the Setup Wizard button from the Main menu.

2. Remove the lens cover and prepare the correct accessory lens for your application:

NOTE

Once the lens is fully tightened to the mechanical stop (Step 1), it can be

rotated counterclockwise (up to one full turn without loosening the lens), so

that the diaphragm scale and locking knobs can be easily accessed from

behind the LT-03x.

a. Remove the anti-vibration o-ring from the two Locking Knobs on the lens and loosen

them.

b. Adjust the Focus ring to the "Far position" and the Diaphragm ring to the "F4"

number setting which is the preferred setting for installation using the VisSet™ Setup

Wizard.

c. Place the Focusing and PPI Setup Chart in front of the reader at the correct reading

distance (see the Reading Diagrams in this Quick Reference Guide).

Page 16

MATRIX 450™ QUICK REFERENCE GUIDE

16

3. Press the "Positioning" button. The reader continuously acquires images and gives

visual feedback in the view image window. Move the Focusing Pattern to center it on the

X-axis reference line at the center of the FOV and on the four delimiters (red points) in

the acquired images which indicate the region in which the calibration algorithm is active.

See figure below.

Press the Positioning button again to stop positioning.

4. Select a Calibration Mode choice and press the "Calibrate" button. The reader flashes

once acquiring the image and auto determines the best exposure and gain settings. If

the code symbology is enabled by default, the code will also be decoded.

3

4

5

Page 17

MATRIX 450™ QUICK REFERENCE GUIDE

17

5. Press the "Fine Focusing" button to activate the Fine Focusing Tool.

The reader continuously acquires images and gives visual feedback on the focusing

quality in the Focusing Tool window.

NOTE

In the Focusing Tool window, use the Zoom feature to make Fine Tuning

easier.

a. Rotate the Focusing ring on the lens. The

Current Focus Quality Bar (green)

together with the vertical optimal focus

line (green) increase together until the

optimal focus is reached; the vertical

optimal focus line stops.

b. Continue rotating the Focusing ring on

the lens a little farther; the Current

Focus Quality Bar decreases (red) see

middle figure.

c. Rotate the Focusing ring in the opposite

direction. The Current Focus Quality Bar

(green) increases towards the vertical

optimal focus line (green) until the

optimal focus is reached; the Current

Focus Quality Bar touches the

vertical optimal focus line (indicating

the best focus) see bottom figure.

d. Tighten the Focus Locking Knob on the

lens.

e. Set the Diaphragm to the aperture stop

(F-number) stated in the conditions

relative to the selected reading diagram

and then tighten the Diaphragm Locking

Knob.

f. Replace the anti-vibration o-ring onto the

two Locking Knobs.

g. Replace the lens cover, screwing it

tightly to the base.

h. Press the "Close" button to return to the

Setup Wizard.

Page 18

MATRIX 450™ QUICK REFERENCE GUIDE

18

6. From the Focusing and PPI Setup Chart, select the 1 mm code and position it at the

center of the Horizontal FOV (aligned with the laser pointers).

a. Select a Calibration Mode choice and press the "Calibrate" button.

b. Select a Code Setting Mode choice and press the "Code Setting" button.

This step performs image density calibration in order for Matrix 450™ to function correctly

and to the fullest extent of its capabilities. The Setup Result section of the Setup Wizard

window shows the code type results and the image density calibration settings.

6

Page 19

MATRIX 450™ QUICK REFERENCE GUIDE

19

7. Substitute the Focusing and PPI Setup Chart with the application specific code,

placing it in front of the reader at the same reading distance, then repeat step 6a and 6b.

8. Select a Saving Options choice and press the

"Save" button.

9. Close the Setup Wizard.

NOTE

If your application has been configured using the VisiSet™ Setup Wizard,

your reader is ready. If necessary you can use VisiSet™ for advanced

reader configuration.

Setup Result

6

Page 20

MATRIX 450™ QUICK REFERENCE GUIDE

20

STEP 9 – TEST MODE

Use a code suitable to your application to test the reading performance of the system.

1. Enter the Test function by pressing and holding the X-PRESS™ push button until the

Test LED is on.

2. Release the button to enter the Test function.

Once entered, the Bar Graph on the five LEDs is activated and when codes are placed

in the reading area (FOV), the Bar-Graph shows the Good Read Rate. In case of no

read condition, only the STATUS LED is on and blinks.

Figure 15 – X-PRESS™ Interface: Test Function

3. To exit the Test, press the X-PRESS™ push button once.

NOTE

By default, the Test exits automatically after three minutes.

The Bar Graph has the following meaning:

READY

SETUP

FOCUS

TEST LEARN

GOOD TRIGGERCOM STATUS

red yellow yellow green green

READY

SETUPFOCUSTEST LEARN

GOOD TRIGGER COM STATUS

20% 40% 60% 75% 95%

Page 21

MATRIX 450™ QUICK REFERENCE GUIDE

21

ADVANCED READER CONFIGURATION

For further details on advanced product configuration, refer to the complete Reference

Manual and the Matrix 450™ Help On Line on the installation Mini-DVD.

The following are alternative or advanced reader configuration methods:

Advanced Configuration Using VisiSet™

Advanced configuration can be performed through the VisiSet™ program by selecting

Device>Get Configuration From Temporary Memory to open the Parameter Setup window in

off-line mode. Advanced configuration is addressed to expert users being able to complete a

detailed reader configuration. The desired parameters can be defined in the various folders

of the Parameter Setup window and then sent to the reader memory (either Temporary or

Permanent):

Figure 16 - VisiSet™ Parameter Setup Window

Host Mode Programming

The reader can also be configured from a host computer using the Host Mode programming

procedure, by commands via the serial interface. See the Host Mode Programming file on

the Mini-DVD.

Alternative Layouts

If you need to install an Ethernet network, ID-NET™ network, Fieldbus network, etc., refer to

the Matrix 450™ Reference Manual.

The reader can also be setup for alternative layouts by reading programming barcodes. See

the "Setup Procedure Using Programming Barcodes" printable from the Mini-DVD.

Page 22

MATRIX 450™ QUICK REFERENCE GUIDE

22

APPENDIX

X-PRESS™ is the intuitive Human Machine Interface designed to improve ease of

installation and maintenance.

Status information is clearly presented by means of the five colored LEDs, whereas the

single push button gives immediate access to the following relevant functions:

Learn to self-detect and auto-configure for

reading unknown codes.

Setup to perform Exposure Time and Gain

calibration.

Focus/Locate to turn on the Blue Diamonds™

to aid focusing and the laser pointer LEDs to

aid positioning.

Test with bar graph visualization to check

static reading performance.

In normal operating mode the colors and meaning of the five LEDs are illustrated in the

following table:

READY

green LED indicates the device is ready to operate

GOOD

green LED confirms successful reading

TRIGGER

yellow LED indicates the status of the reading phase

COM

yellow LED indicates active communication on the main serial port*

STATUS

red LED indicates a NO READ result

* When connected to a Fieldbus network through the CBX500, the COM LED is always active, even in

the absence of data transmission, because of polling activity on the Fieldbus network.

During the reader startup (reset or restart phase), all the LEDs blink for one second.

Reader power is indicated by the blue Power LED (located near the Power connector).

Power can be applied to the reader either through the 19-pin male Power connector or the

M12 8-pin male LT-03x Lighting System connector.

The yellow Ethernet Network Presence LED (near the Ethernet connector), indicates

connection to the on-board Ethernet network.

Figure 17 – Power and On-Board Ethernet Network LEDs

On-board Ethernet

Network Presence LED

Power LED

Ethernet MAC Address

Label

Lighting System Signal,

Power Connector

On-board Ethernet

Connector

Power, Serial Host,

I/O Connector

Page 23

MATRIX 450™ QUICK REFERENCE GUIDE

23

REFERENCE READING DIAGRAMS

The following reading diagrams are to be considered as references and are given for

typical performance at 25°C using high quality grade A symbols: Code 128 (1D code) and

Data Matrix ECC 200 (2D code) from the Test Charts provided with the reader.

Testing should be performed with the actual Matrix 450™ + LT-03x assembly using

application codes in order to evaluate whether maximizing application performance

requires adjustments to the HW/SW configuration with respect to the Reference

Conditions given under each diagram.

The ratio of the Vertical FOV width with respect to the Horizontal FOV width in the

diagrams is about equal to 0.84; specifically 2050/2448. (i.e. FOV

V.

FOVH x 0.84).

The focus distance and reading distance ranges are measured from the Lens Cover

window surface.

When using a 25 mm focal length lens (LNS-1225), it is possible to use Super Narrow

Angle Lighting Systems (LT-030 or LT-031) as well as the Narrow Angle Lighting System

LT-032. It is suggested to use the LT-032 in applications with very low contrast codes

and in all cases where the higher lighting power of the LT-030 isn't necessary. LT-030

and LT-031 Lighting Systems are especially effective in high speed code movement

applications.

When defining a HW/SW configuration for the Matrix 450™ + LT-03x assembly for

conditions different from those of the reference diagrams, it is suggested to keep in mind

the following rules:

Changes in the diaphragm aperture influence the depth of field (reading distance

range) and the luminosity of the image. Increasing the the diaphragm aperture by

one stop (i.e. from F/8 to F/5.6 or from F/11 to F/8) doubles the luminosity of the

image, but can cause significant reduction in the reading distance range.

Changes in Exposure Time act directly proportional to the luminosity of the image

and inversely proportional to the maximum code reading movement speed.

Consequently, reducing the Exposure Time by half, reduces the luminosity of the

image by half but doubles the theoretical code reading movement speed.

Changes in Gain act directly proportional to the luminosity of the image.

Increasing the Gain value however, can reduce the quality of the acquired image.

The LT-030 lighting power (at the center of the field of view) is about equal to

twice that of the LT-031 and 3.5 times that of the LT-032.

For example, for the purpose of only changing the luminosity of the image, the

following three adjustments are equivalent:

increase the the diaphragm aperture by one stop;

double the Exposure Time;

double the Gain.

Page 24

MATRIX 450™ QUICK REFERENCE GUIDE

24

Matrix 450™ + LNS-1216

CONDITIONS:

Hardware Settings

Code Symbology Code 128

Code Resolution 0.38 mm (15 mils) 0.50 mm (20 mils)

Focal Length 16 mm

Aperture Stop F/8

Focus Distance 1.200 mm (47.2 inches) 1.400 mm (55.1 inches)

PPI 94 84

Tilt Angle 45°

Skew Angle 15°

Lighting System LT-032 LT-032

Software Parameters

Exposure Time (×10µs) 19 25

Max code moving speed 1.8 m/s 1.8 m/s

Gain 13 14

LT-03x Lighting Mode Very High Power Strobed or Continuous High Power

Minimum Code Height (mm) 5

Code 128 Narrow Margins Enabled

Image Processing Mode Advanced Code Setting

Reading Distance

Horizontal Reading Width

Code 1D 0.38 mm (15 mils) Code 1D 0.50 mm (20 mils)

(in)

(cm)

30

20

0

10

50

40

-30

-20

-10

-50

-40

12

8

0

4

16

-12

-8

-4

-16

80 100 120 140 150 200190 180 170 16013011090 70

28 40 60 8044 48 52 56 64 68 72 7632 36

Page 25

MATRIX 450™ QUICK REFERENCE GUIDE

25

Matrix 450™ + LNS-1225

CONDITIONS:

Hardware Settings

Code Symbology Code 128

Code Resolution 0.33 mm (13 mils) 0.38 mm (15 mils)

Focal Length 25 mm

Aperture Stop F/5.6

Focus Distance 1.700 mm (66.9 inches) 1.900 mm (74.8 inches)

PPI 100 90

Tilt Angle 45°

Skew Angle 15°

Lighting System LT-030 LT-031 LT-032 LT-030 LT-031 LT-032

Software Parameters

Exposure Time (×10µs) 15 16 20 12 12 19

Max code moving speed 1.8 m/s 1.8 m/s 1.5 m/s 2.8 m/s 2.8 m/s 1.8 m/s

Gain 7 13 16 8 16 15

LT-03x Lighting Mode Very High Power Strobed or Continuous High Power

Minimum Code Height (mm) 5

Code 128 Narrow Margins Enabled

Image Processing Mode Advanced Code Setting

Reading Distance

Horizontal Reading Width

Code 1D 0.33 mm (13 mils) Code 1D 0.38 mm (15 mils)

(in)

(cm)

15

10

0

5

25

20

-15

-10

-5

-25

-20

-30

-35

30

35

6

4

0

2

8

-6

-4

-2

-8

10

12

14

-10

-12

-14

145 155 165 175 180 205 200 195 190185170160150 140

210 215

56 62 72 82 64 66 68 70 74 76 78 80

60 58 84

Page 26

MATRIX 450™ QUICK REFERENCE GUIDE

26

Matrix 450™ + LNS-1225

CONDITIONS:

Hardware Settings

Code Symbology Code 128 Data Matrix ECC 200

Code Resolution 0.30 mm (12 mils) 0.61 mm (24 mils)

Focal Length 25 mm

Aperture Stop F/5.6

Focus Distance 1.600 mm (63.0 inches) 1.700 mm (66.9 inches)

PPI 106 100

Tilt Angle 45°

Skew Angle 15°

Lighting System LT-030 LT-031 LT-032 LT-030 LT-031 LT-032

Software Parameters

Exposure Time (×10µs) 12 12 18 16 16 22

Max code moving speed 2.3 m/s 2.3 m/s 1.5 m/s 3.2 m/s 3.2 m/s 2.5 m/s

Gain 7 14 16 6 12 16

LT-03x Lighting Mode Very High Power Strobed or Continuous High Power

Minimum Code Height (mm) 5

Code 128 Narrow Margins Enabled

Module Size (mils) 24

Image Processing Mode Advanced Code Setting

Reading Distance

Horizontal Reading Width

Code 1D 0.30 mm (12 mils) Code 2D 0.61 mm (24 mils)

(in)

(cm)

15

10

0

5

25

20

-15

-10

-5

-25

-20

-30

-35

30

35

6

4

0

2

8

-6

-4

-2

-8

10

12

14

-10

-12

-14

130 140 150 160 165 190 185 180 175170155145135 125

195

50 56 66 76 58 60 62 64 68 70 72 74

54 52 78

Page 27

MATRIX 450™ QUICK REFERENCE GUIDE

27

Matrix 450™ + LNS-1235

CONDITIONS:

Hardware Settings

Code Symbology Code 128

Code Resolution 0.25 mm (10 mils) 0.30 mm (12 mils)

Focal Length 35 mm

Aperture Stop F/11 F/8

Focus Distance 1.800 mm (70.9 inches) 2.300 mm (90.5 inches)

PPI 140 110

Tilt Angle 45°

Skew Angle 15°

Lighting System LT-030 LT-031 LT-030 LT-031

Software Parameters

Exposure Time (×10µs) 20 40 15 27

Max code moving speed 1.0 m/s 0.5 m/s 1.8 m/s 1.0 m/s

Gain 22 22 18 22

LT-03x Lighting Mode Very High Power Strobed or Continuous High Power

Minimum Code Height (mm) 5

Code 128 Narrow Margins Enabled

Image Processing Mode Advanced Code Setting

Reading Distance

Horizontal Reading Width

Code 1D 0.25 mm (10 mils) Code 1D 0.30 mm (12 mils)

(in)

(cm)

30

20

0

10

40

-30

-20

-10

-40

12

8

0

4

16

-12

-8

-4

-16

150 170 190 210 220 260250240 230 200180160 140

56 68 8872 76 80 84 92 96 100

6460

Page 28

MATRIX 450™ QUICK REFERENCE GUIDE

28

MECHANICAL DIMENSIONS

M 5 x 8 n°3

150

[5.91]

213

[8.39]

202

[7.95]

5

[0.20]

130

[5.12]

200

[7.87]

179

[7.05]

90

[3.54]

9

[0.35]

65

[2.56]

30

[1.18]

62

[2.44]

5

0

°

2

5

°

27.5

[1.08]

34.5

[1.36]

55

[2.17]

45

[1.77]

9

[0.35]

22.5

[0.89]

42.5

[1.67]

20

[0.79]

20

[0.79]

60

[2.36]

Figure 18 – Matrix 450™ + LT-03x + L-Bracket Overall Dimensions

compact assembly

standard assembly

mm

in

202

[7.95]

130

[5.12]

5

[0.20]

125

[4.92]

143

[5.61]

62.5

[2.46]

Ø

213

[8.39]

Page 29

MATRIX 450™ QUICK REFERENCE GUIDE

29

TECHNICAL FEATURES

ELECTRICAL FEATURES

Power

Supply Voltage 24 Vdc ± 20%

Consumption (max) 2.5 A ( 0.5A Matrix 450™; 2A LT-03x )

Communication Interfaces

Main

- RS232

- RS485 full-duplex

- RS485 half-duplex

2400 to 115200 bit/s

2400 to 115200 bit/s

2400 to 115200 bit/s

Auxiliary - RS232 2400 to 115200 bit/s

ID-NET™ Up to 1MBaud

Ethernet 1000 Mbit/s, Gigabit Ethernet

Inputs

Input 1(External Trigger) and Input 2 Opto-coupled and polarity insensitive

Max. Voltage 30 Vdc

Max. Input Current 10 mA

Outputs

Output 1 and Output 2 Opto-coupled

V

Out

(I

Load

= 0 mA) Max.

24 Vdc

V

Out

(I

Load

= 10 mA) Max.

1.8 Vdc

PD = V

Out

x I

Load

Max.

170 mW

OPTICAL FEATURES

Image Sensor CCD

Image Format 2448 x 2050

Frame Rate 15 frames/sec.

Pitch

35°

Tilt 0° - 360°

Lighting System

(LT-03x Family Illuminators)

Risk 2 Group LED product to EN62471

Class 2 LED product to IEC60825-1

Laser Safety Class (pointers) Class 2 Laser Light to IEC60825-1

ENVIRONMENTAL FEATURES

Operating Temperature2

0 to 50 C (32 to 122 °F)

Storage Temperature

-20 to 70 C (-4 to 158 °F)

Max. Humidity 90% non condensing

Vibration Resistance3

1.5 mm @ 5 to 9 Hz; 0.5 g @ 9 to 150 Hz 2 hours on each axis

EN 60068-2-6 2 g @ 70 to 200 Hz; 2 hours on each axis

Shock Resistance 30g; 11 ms;

EN 60068-2-27 3 shocks on each axis

Protection Class4

EN 60529

IP65

2

High ambient temperature applications should use metal mounting bracket for heat dissipation.

3

When operating in high vibration environments use two L-shaped mounting brackets and mount the anti-vibration kit for

C-mount lenses, see "Accessories" in the Matrix 450™ Reference Manual.

4

Requires correct connection to IP67 cables with seals and Lens Cover mounting.

Page 30

MATRIX 450™ QUICK REFERENCE GUIDE

30

PHYSICAL FEATURES

Dimensions

Matrix 450™

Matrix 450™ + LT-03x

123 x 64 x 143 mm (4.8 x 2.5 x 5.6 in)

202 x 213 x 179 mm (8.0 x 8.4 x 7.1 in)

Weight (with lens and LT-03x) 3000 g. (6.6 lbs.)

Material Aluminium

SOFTWARE FEATURES

Readable Code Symbologies

1-D and stacked 2-D POSTAL

PDF417 (Standard and

Micro PDF417)

Code 128 (GS1-128)

Code 39 (Standard and

Full ASCII)

Code 32

MSI

Standard 2 of 5

Matrix 2 of 5

Interleaved 2 of 5

Codabar

Code 93

Pharmacode

EAN-8/13 - UPC-A/E

(including Addon 2 and

Addon 5)

GS1 DataBar Family

Composite Symbologies

Data Matrix ECC 200 (Standard,

GS1 and Direct Marking)

QR Code (Standard and

Direct Marking)

MicroQR Code

MAXICODE

Aztec Code

Australia Post

Royal Mail 4 State

Customer

Kix Code

Japan Post

PLANET

POSTNET

POSTNET (+BB)

Intelligent Mail

Swedish Post

Operating Mode

O

NE SHOT, CONTINUOUS, PHASE MODE

Configuration Methods

X-PRESS™ Human Machine Interface

Windows-based SW (VisiSet™) via serial or Ethernet link

Serial Host Mode Programming via serial or Ethernet link

Parameter Storage

Permanent memory (Flash)

USER INTERFACE

LED Indicators Power, Ready, Good; Trigger; Com, Status, (Ethernet

Network); (Green Spot); (Red Spot); Laser Pointers

Keypad Button Configurable via VisiSet™

PATENTS

This product is covered by one or more of the following patents:

Design patents: EP 1,950,486.

Utility patents: US6,512,218 B1; US6,616,039 B1; US6,808,114 B1; US6,997,385 B2;

US7,053,954 B1; US7,102,116 B2; US7,282,688 B2; US7,387,246 B2; US7,433,590 B2;

US7,468,499 B2; US8,058,600 B2; US8,113,430 B2; EP996,284 B1; EP999,514 B1;

EP1,014,292 B1; EP1,128,315 B1; EP1,396,811 B1; EP1,413,971 B1; EP1,804,089 B1;

JP4,435,343 B2; CN ZL200680050007,8.

Additional patents pending.

Page 31

MATRIX 450™ QUICK REFERENCE GUIDE

31

COMPLIANCE

See the Matrix 450™ Reference Manual for the Declaration of Conformity.

Only connect Ethernet and dataport connections to a network which has routing only within the plant

or building and no routing outside the plant or building.

EMC COMPLIANCE

In order to meet the EMC requirements:

connect reader chassis to the plant earth ground by means of a flat copper braid shorter than

100 mm;

connect pin "Earth" of the CBX connection box to a good Earth Ground;

POWER SUPPLY

This product is intended to be installed by Qualified Personnel only.

This product is intended to be connected to a UL Listed Computer which supplies power directly to the

reader or a UL Listed Direct Plug-in Power Unit marked LPS or “Class 2”.

CE COMPLIANCE

Warning: This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

FCC COMPLIANCE

Modifications or changes to this equipment without the expressed written approval of Datalogic could

void the authority to use the equipment.

This device complies with PART 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference which may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

LT-03X LASER SAFETY

The LT-03x Series Lighting Systems contain two

aiming Laser LEDs used to position the reader.

Therefore the product is classified as a Class 2 laser

product according to IEC 60825-1 regulations and

as a Class II laser product according to CDRH

regulations. Disconnect the power supply when

opening the device during maintenance or

installation to avoid exposure to hazardous laser

light. The laser beam can be switched on or

off through a software command.

CRUS

This product is covered by one or more of following patents:

U.S. Pat.: 6,808,114 B1; 6,997,385 B2; 7,387,246 B2.

See product manual and package for entire patent listing.

DATALOGIC AUTOMATION S.r.l.

Page 32

MATRIX 450™ QUICK REFERENCE GUIDE

32

SERIAL NUMBER REFERENCES

Place the replicate, lens, and illuminator serial number labels here for reference. Some of

this information can also be written in the Reader Information configuration parameters in the

Miscellaneous folder in VisiSet™.

Serial Numbers

Matrix 450™

Lens

Illuminator

Loading...

Loading...