Page 1

GWY-01-PBS-01

Reference Manual

Page 2

Datalogic Automation Srl

Via S. Vitalino, 13

40012 - Lippo di Calderara di Reno

Bologna - Italy

GWY-01-PBS-01 Reference Manual

Ed.: 02/2010

© 2010 Datalogic Automation S.r.l. ALL RIGHTS RESERVED. Protected to the fullest extent under

U.S. and international laws. Copying, or altering of this document is prohibited without express written

consent from Datalogic Automation S.r.l.

Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in many countries,

including the U.S.A. and the E.U.

Subnet16 and Cobalt Dashboard are trademarks of Datalogic Automation S.r.l. All other brand and

product names mentioned herein are for identification purposes only and may be trademarks or

registered trademarks of their respective owners.

Datalogic shall not be liable for technical or editorial errors or omissions contained herein, nor for

incidental or consequential damages resulting from the use of this material.

26/02/10

Page 3

iii

CONTENTS

REFERENCES ............................................................................................................vi

Conventions................................................................................................................. vi

Reference Documentation........................................................................................... vi

Services and Support .................................................................................................. vi

SAFETY AND COMPLIANCE NOTICES................................................................... vii

FCC Compliance .........................................................................................................vii

Power Supply...............................................................................................................vii

CE Compliance............................................................................................................vii

GENERAL VIEW.......................................................................................................viii

1 GETTING STARTED....................................................................................................1

1.1 Introduction...................................................................................................................1

1.1.1 The Subnet16™ Gateway ............................................................................................1

1.2 Subnet16 Profibus Gateway Features..........................................................................1

1.3 About this Manual.........................................................................................................2

1.3.1 Who Should Read This Manual?..................................................................................2

1.3.2 HEX Notation................................................................................................................2

1.4 Gateway Dimensions....................................................................................................3

1.5 Installation Guidelines...................................................................................................4

1.5.1 Hardware Requirements...............................................................................................4

1.5.2 Installation Precautions.................................................................................................4

1.5.3 Network & Power Considerations.................................................................................4

1.5.4 Maximum Supported Trunk and Drop Cable Lengths ..................................................5

1.6 Installing the Gateway ..................................................................................................5

1.7 Additional Application Specific Configuration ...............................................................6

1.8 USB Driver Installation..................................................................................................7

1.9 Gateway Profibus Configuration using Cobalt Dashboard™......................................11

2 GATEWAY OVERVIEW ............................................................................................. 13

2.1 Operating Modes ........................................................................................................13

2.1.1 Subnet16™.................................................................................................................13

2.2 LED Indicators ............................................................................................................14

2.2.1 Front Panel LEDs .......................................................................................................14

2.3 External Connectors ...................................................................................................14

2.3.1 Profibus.......................................................................................................................15

2.3.2 USB ............................................................................................................................15

2.3.3 Subnet16™ RS485.....................................................................................................16

2.4 Power & Wiring...........................................................................................................16

2.4.1 Power Requirements ..................................................................................................16

2.4.2 Total System Current Consumption............................................................................ 17

2.4.3 Cable Voltage Drop ....................................................................................................17

2.4.4 Current Rating for Cables...........................................................................................18

2.5 Node ID Configuration & Management.......................................................................18

2.6 Gateway and Subnet Node Naming ...........................................................................19

2.7 Configuration Tools.....................................................................................................20

2.7.1 Cobalt Dashboard™ ...................................................................................................20

2.7.2 C-Macro Builder™ ......................................................................................................21

3 RFID COMMAND MACROS ......................................................................................22

Page 4

iv

3.1 What are RFID Command Macros? ...........................................................................22

3.2 Why use macros?.......................................................................................................22

3.3 What can macros do?.................................................................................................22

3.4 What is a macro trigger?.............................................................................................22

3.5 How are macros created?...........................................................................................23

3.6 Which communication interfaces support the use of macros? ...................................23

3.7 What happens to existing Macros if a controller must be replaced? ..........................23

3.8 How can I learn more about the Dashboard and C-Macro Builder? ........................... 23

4 COMMAND PROTOCOL ...........................................................................................24

4.1 CBx Command Protocol Overview .............................................................................24

4.2 CBx - Command Packet Structure.............................................................................. 25

4.3 CBx - Response Packet Structure..............................................................................26

4.3.1 Instance Counter ........................................................................................................26

4.4 CBx Commands Table................................................................................................27

4.5 CBx Command Protocol Examples ............................................................................29

4.5.1 CBx - Controller Command Example.......................................................................... 29

4.5.2 CBx - Controller Response Example .......................................................................... 30

4.5.3 CBx - Gateway Command Example ........................................................................... 30

4.5.4 CBx - Gateway Response Example ...........................................................................31

4.6 Node Status Byte Definition Table..............................................................................32

4.7 CBx Error Response Packet Structure .......................................................................33

4.8 CBx Error Code Table ................................................................................................34

4.9 CBx - Error Response Example..................................................................................35

4.10 Notification Messages.................................................................................................36

4.10.1 Notification Message Table ........................................................................................ 37

4.10.2 Notification Mask Example .........................................................................................37

4.10.3 Notification Message Packet Structure.......................................................................38

5 PROFIBUS INTERFACE............................................................................................ 39

5.1 Profibus Overview.......................................................................................................39

5.2 Profibus-DP ................................................................................................................39

5.3 Data Exchange ...........................................................................................................40

5.4 Protocol Implementation.............................................................................................41

5.4.1 Definitions...................................................................................................................41

5.4.2 Control Field ...............................................................................................................42

5.4.3 SAP Field....................................................................................................................45

5.4.4 Length Field................................................................................................................45

5.4.5 Application Data Buffer...............................................................................................46

5.5 Examples of Profibus Command/Response Mechanism............................................ 46

5.5.1 Example 1: Normal Command/Response Sequence .................................................48

5.5.2 Example 2: Unsolicited Responses (Continuous Read Mode) ...................................58

5.5.3 Example 3: Fragmentation of Responses................................................................... 62

5.5.4 Example 4: Fragmentation of Commands ..................................................................71

5.5.5 Example 5: Resynchronization ...................................................................................82

6 TECHNICAL FEATURES........................................................................................... 87

A MODELS AND ACCESSORIES ................................................................................88

Datalogic Automation RFID Tags ...............................................................................89

B EXAMPLE NETWORK LAYOUTS............................................................................. 90

Subnet16™ Gateway –ThickNet Network Layout ......................................................90

Subnet16™ Gateway –ThinNet Network Layout ........................................................ 91

Page 5

v

C

ASCII CHART.............................................................................................................92

Page 6

vi

REFERENCES

CONVENTIONS

This manual uses the following conventions:

“User” or “Operator” refers to anyone using a GWY-01-PBS-01.

“Device” refers to the GWY-01-PBS-01.

“You” refers to the System Administrator or Technical Support person using this manual to

install, mount, operate, maintain or troubleshoot a GWY-01-PBS-01.

Throughout this manual, the GWY-01-PBS-01 is referred to as the “Subnet16 Gateway” or

simply “the Gateway”.

Cobalt C-Series, HF-Series and UHF-Series RFID Controllers are referred to as Cobalt

Controllers, or just “the Controller”.

In addition, the terms “Subnet Node Number”, “Node ID” and “Controller ID” are used

interchangeably.

REFERENCE DOCUMENTATION

The documentation related to the GWY-01-PBS-01 management is available at the website:

www.automation.datalogic.com

SERVICES AND SUPPORT

Datalogic provides several services as well as technical support through its website. Log on

to www.automation.datalogic.com and click on the

UlinksU indicated for further information

including:

PRODUCTS

Search through the links to arrive at your product page where you can download specific

Manuals

and Software & Utilities including:

- Cobalt Dashboard™ a Windows-based application that provides users with complete

control over their Datalogic Automation RFID hardware. Users can monitor their entire

RFID infrastructure - from the tag level, to the RFID controller, to the Gateway and to

the Host. It provides device configuration through serial and TCP/IP interfaces

depending on the device type.

- C-Macro Builder™ is an easy to use GUI-driven utility for Windows. This software tool

allows users with minimal programming experience to “build” their own macro programs

(which are stored internally on and executed directly by Cobalt RFID Controllers).

SERVICES & SUPPORT

- Datalogic Services

- Warranty Extensions and Maintenance Agreements

- Authorised Repair Centres

CONTACT US

E-mail form and listing of Datalogic Subsidiaries

Page 7

vii

SAFETY AND COMPLIANCE NOTICES

FCC COMPLIANCE

Modifications or changes to this equipment without the expressed written approval of

Datalogic could void the authority to use the equipment.

This device complies with PART 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference which may cause undesired

operation.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

POWER SUPPLY

This product is intended to be installed by Qualified Personnel only.

This device is intended to be supplied by a UL Listed or CSA Certified Power Unit with

«Class 2» or LPS power source.

CE COMPLIANCE

Warning:

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Page 8

viii

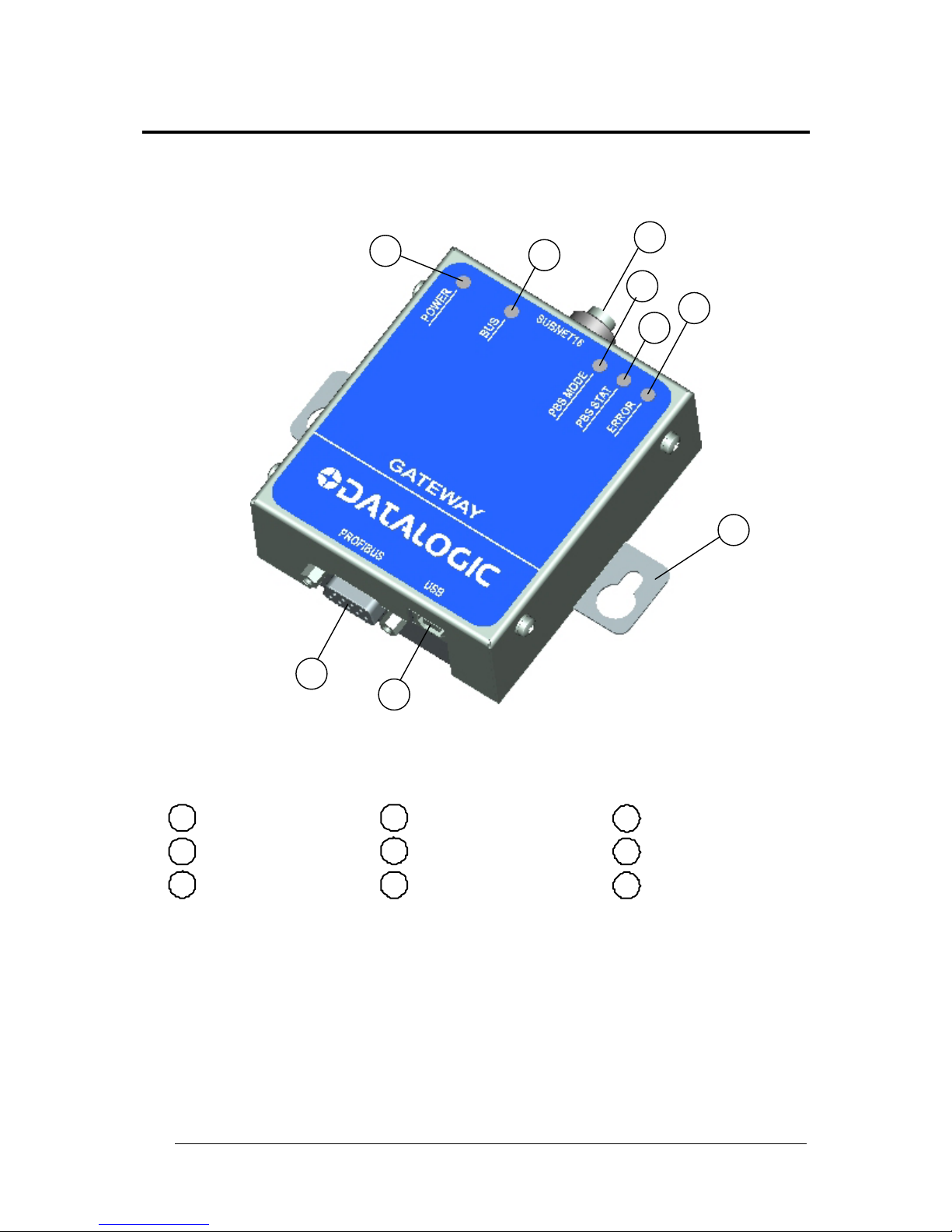

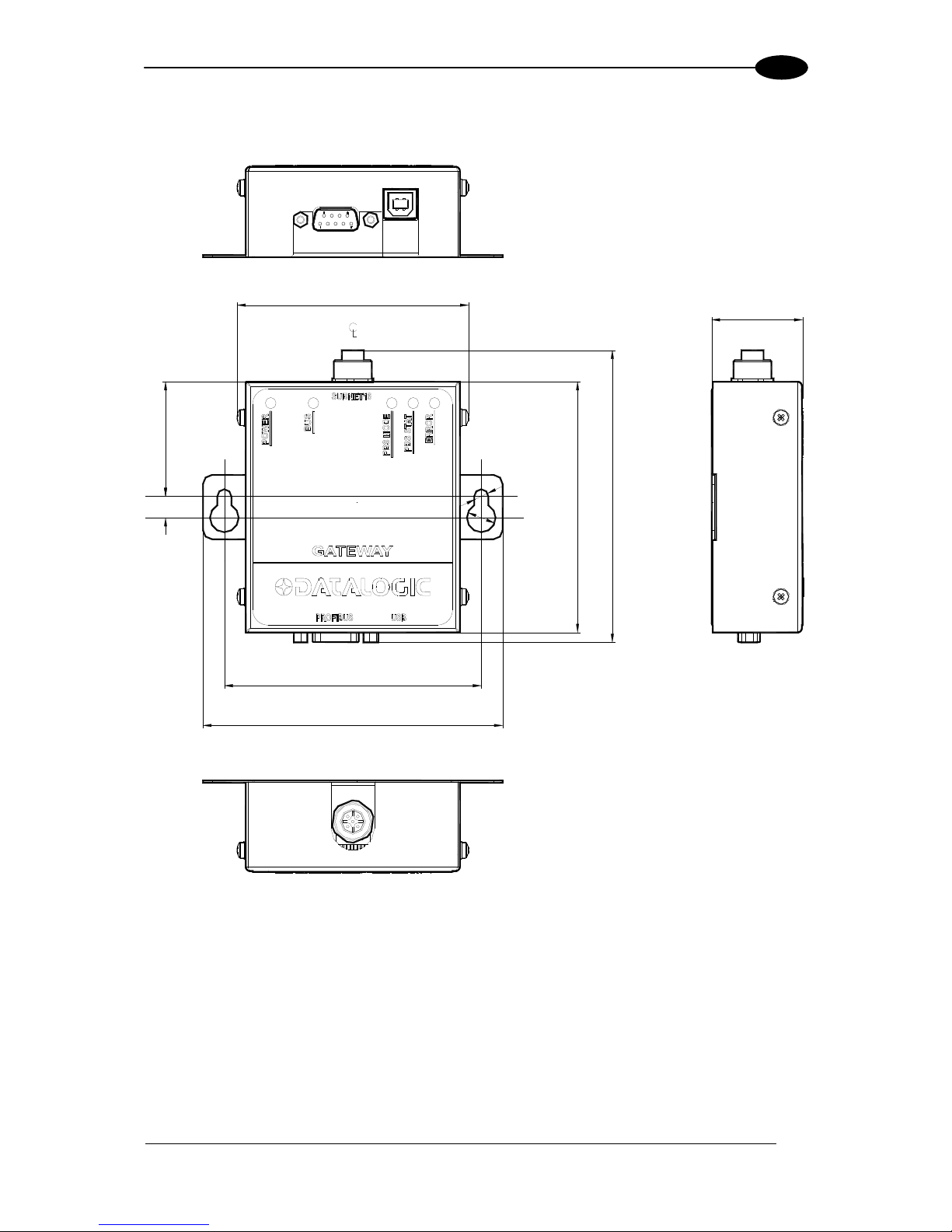

GENERAL VIEW

GWY-01-PBS-01

Figure A

1

2

3

6

5

Power On LED

Subnet 16 Co nnecto

r

Profibus Status LED

Configuration Error LED

4

Profibus Mode LED

Subnet 16 BUS LED

9

8

US B Con nector

Profibus Conn ector

7

Mounting Bracket

3

1

4

7

8

2

5

6

9

Page 9

GETTING STARTED

1

1

1 GETTING STARTED

1.1 INTRODUCTION

Welcome to the GWY-01-PBS-01 Reference Manual. This manual will assist you in the

installation, configuration and operation of Datalogic Automation Subnet16™ Profibus

Gateway Interface Module.

The Profibus Gateway can control up to 16 passive ultra-high or high frequency read/write

Radio-Frequency Identification (RFID) controllers. In order to meet and exceed the

requirements of the industrial automation industry, the Profibus Gateway and Datalogic

Automation RFID controllers are designed to be compact, reliable and rugged.

1.1.1 The Subnet16™ Gateway

Subnet16™ is a 16-Node Multidrop bus architecture and protocol that provides connectivity

for up to 16 RFID controllers through a single Gateway device.

The Profibus Gateway supports Profibus -DP communications and can be connected to a

Programmable Logic Controller (PLC) via Profibus compatible cabling. It’s compatible with

Datalogic Automation Cobalt UHF-Series, HF-Series and C-Series RFID controllers, reading

LRP, HMS and T-Series RFID tags.

1.2 SUBNET16 PROFIBUS GATEWAY FEATURES

Multi-Drop capable; controls up to 16 RFID reader/writers, each functioning

independently and simultaneously.

Operational power is supplied directly from the Subnet 16™ network

Small footprint provides ease of mounting (104 x 107 x 32 mm).

Galvanically isolated Profibus interface with auto baud rate detection 9.6 kbit/s - 12

Mbit/s

Selectable Profibus node addressing (0 to 128), default is 63

LED status indicators for Power/Ready, Subnet16 bus activity, Profibus mode,

Profibus network status, Configuration error indication

Supports controller macro functionality

Flash memory for software updates

Real-time Calendar/Date functions

Auto configuration of RFID controllers, automatic Node ID number assignment

Node Fault Detection

Isolated bus interfaces

Page 10

GWY-01-PBS-01

2

1

1.3 ABOUT THIS MANUAL

This manual provides guidelines and instructions for installing, configuring and operating

Datalogic Automation's Subnet16 Profibus Gateway Interface Module (GWY-01-PBS-01).

This document does NOT include explicit details regarding each of the Gateway’s RFID

commands. Specific RFID command related information is available in the CBx Command

Protocol – Reference Manual, which is available at www.automation.datalogic.com.

However, this manual does explain the process of issuing commands from a host PC or

Programmable Logic Controller (PLC) to a Subnet16 Gateway, Subnet network and attached

RFID controllers.

1.3.1 Who Should Read This Manual?

This manual should be read by those who will be installing, configuring and operating the

Gateway. This may include the following people:

Hardware Installers

System Integrators

Project Managers

IT Personnel

System and Database Administrators

Software Application Engineers

Service and Maintenance Engineers

1.3.2 HEX Notation

Throughout this manual, numbers expressed in Hexadecimal notation are prefaced with “0x”.

For example, the number "10" in decimal is expressed as "0x0A" in hexadecimal. See

Appendix C for a chart containing Hex values, ASCII characters and their corresponding

decimal integers.

Page 11

GETTING STARTED

3

1

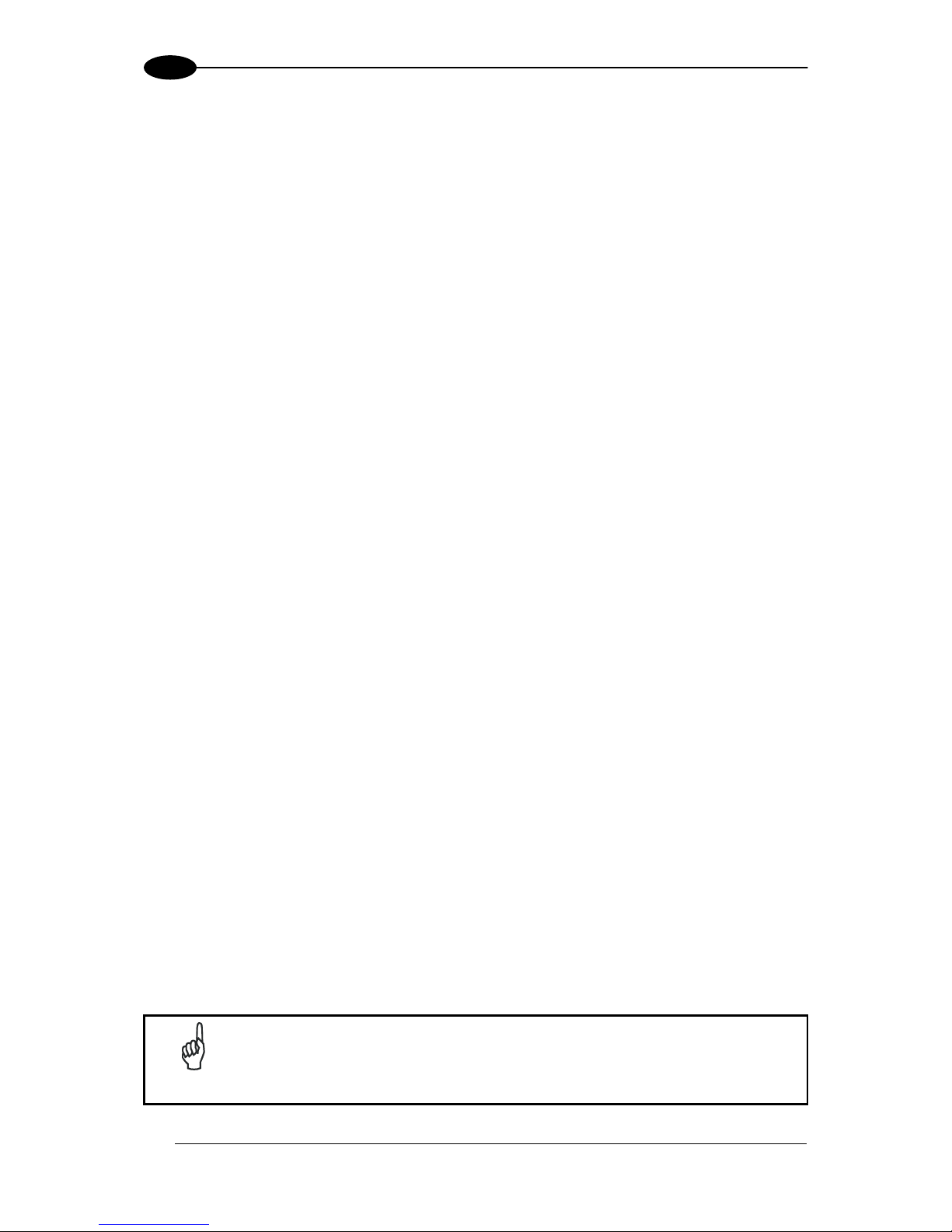

1.4 GATEWAY DIMENSIONS

82

[3.24]

104

[4.08]

89

[3.50]

40.7

[1.60]

7.6

[0.30]

91.4

[3.60]

107

[4.20]

32

[1.27]

Ø5.0

[Ø0.20]

Ø10.2

[Ø0.40]

N° 2

N° 2

Figure 1: GWY-01-PBS-01 Dimensions

Page 12

GWY-01-PBS-01

4

1

1.5 INSTALLATION GUIDELINES

1.5.1 Hardware Requirements

The following components are required for a complete Subnet16 RFID system:

One Subnet16 Profibus Gateway Interface Module

One Profibus-capable host; Programmable Logic Controller (PLC) or PC

One to 16 RFID controllers (Cobalt C-Series, HF-Series or UHF-Series Controllers -

RS485 models)

Adequate length cabling, connectors and terminators

Sufficient power, supplied via Subnet16 network cabling, capable of powering the

Gateway and its RFID controllers

Datalogic Automation RFID series tags: HMS, LRP, T/Gamma, I, or UHF-G2-525

1.5.2 Installation Precautions

Do not route cables near unshielded cables or near wiring carrying high voltage or

high current. Cross cables at perpendicular intersections and avoid routing cables

near motors and solenoids.

Review the power requirements of your RFID network and provide a suitable power

supply.

Avoid mounting the controller near sources of EMI (electro-magnetic interference) or

near devices that generate high ESD (electro-static discharge) levels. Always use

adequate ESD prevention measures to dissipate potentially high voltages.

If electrical interference is encountered (as indicated by a significant reduction in

read/write performance), relocate the controller to an area free from potential sources

of interference.

Perform a test phase by constructing a small scale, independent network that

includes only the essential devices required to test your RFID application (use

Datalogic Automation approved Subnet16™ cables and accessories).

1.5.3 Network & Power Considerations

Refer to the network diagrams in Appendix B. Choose the network architecture

(ThickNet vs. ThinNet) that best suits your RFID requirements.

Construct your chosen network using only Datalogic Automation approved

Subnet16™ cables, Drop-T connectors, Terminating Resistors and accessories.

Review the power requirements of your RFID network and provide a suitable power

supply. (See Appendix A for power supplies offered by Datalogic Automation).

NOTE

It is recommended that power be applied directly to the Subnet16™ Network

trunk and distributed through drop cables to the Gateway and RFID

controllers. By positioning the power supply near the middle of the network

(see examples), you can limit voltage drop at the ends.

Page 13

GETTING STARTED

5

1

1.5.4 Maximum Supported Trunk and Drop Cable Lengths

ThickNet trunk length up to 300 m.

ThinNet trunk length up to 20 m.

ThinNet drop cable length up to 2 m.

1.6 INSTALLING THE GATEWAY

The numbered steps in the following procedure are also indicated in the SubNet16 networks

example layouts shown in Appendix B.

1. Preliminary Notes: Read the Installation Guidelines in par. 1.5.

2. Mounting: Mount the Gateway to your chosen location using two M5 (#10) screws,

lock washers and nuts. The Gateway may be mounted in any orientation, but should

be aligned in such a manner that the LED indicators can be seen during operation.

3. Gateway Connection: Attach one end of a 5-pin, male-to-male, M12, ThinNet drop

cable (P/N: CBL-1481-XX) to the 5-pin, female, M12 connector on the Gateway.

Connect the other end of this 5-pin, male-to-male, M12, ThinNet drop cable to the 5pin, female, M12 connector on EITHER a ThickNet to ThinNet Drop-T Connector

OR a ThinNet to ThinNet Drop-T Connector (as per your network and RFID

application requirements).

4. Trunk Wiring: Attach one end of a male-to-female trunk cable to each mating

connector on the Drop-T Connector. Continue connecting trunk cables and Drop-T

connectors as needed.

Note: trunk length should not exceed 300 m for ThickNet and 20 m for ThinNet.

5. RFID Controller Connection: Connect the male end of a 5-pin, male-to-female,

ThinNet drop cable to the female end on your Drop-T connector(s). Attach the

remaining female end of the ThinNet drop cable to the 5-pin, male, M12 connector on

a Cobalt UHF, Cobalt HF or C-Series Controller (RS485 models). Repeat Step 5

for each RFID controller you plan to install.

Note: maximum drop cable length is 2 m.

6. Termination Resistors: For ThickNet Networks: Connect a Terminating Resistor

(P/N: CBL-1489, male) or (P/N: CBL-1497, female) to the first and last Drop-T

Connector on the trunk line.

For ThinNet Networks: Connect a Terminating Resistor (P/N: CBL-1490, male) or

(P/N: CBL-1496, female) to the first and last Drop-T Connector on the trunk line.

7. Power Supply Wiring: For ThickNet Networks: Using a 5-pin, female, 7/8 - 16,

ThickNet to Bare Wire Leads cable (P/N: CBL-1495-XX), connect the bare wires to

your power supply (SHIELD wire connected to Earth). Attach the female, ThickNet

end to the 5-pin, male, ThickNet end on a Drop-T connector (P/N: CBL-1526).

For ThinNet Networks: Using a 5-pin, female, M12, ThinNet to Bare Wire Leads cable

(P/N: CBL-1494-XX), connect the bare wires to your power supply (SHIELD wire

connected to Earth). Attach the female, ThinNet end to the 5-pin, male, ThinNet end

on a Drop-T connector (P/N: CBL-1486).

Page 14

GWY-01-PBS-01

6

1

8. Host Connection: Connect the Gateway to the Profibus network via a Profibus-

compatible interface cable. Turn the power supply ON.

The POWER LED on the Gateway will remain lit while power is applied to the unit.

After the boot process is complete, the PBS Mode LED will also light up to indicate

the Gateway Profibus mode. It may appear green or red (solid or flashing) depending

on the status of the connection with your Profibus network (see par. 2.2 for the

behavior of the Gateway’s Profibus Mode LED).

9. Automatically Configure Subset16™ Node IDs: At this point all controllers are

powered and should have Node IDs set to 00, (all controller Node LEDs

= OFF), and

Subnet16™ baudrate = 9600 (factory defaults).

a. Place the RFID Controller Configuration Tag in front of an RFID Controller (the

controller's red RF Activity LED blinks once indicating the tag has been read), and

wait for the Gateway to assign a valid Node ID to it. The controller's Node LEDs

now indicate a valid Node ID. Remove the Configuration Tag from the controller.

b. Repeat this step for each node in the Subnet16™ network (one controller at a

time). The first is Node ID 1, then 2 and so on up to 16 (binary).

The Subnet16™ network is now configured with the default values and can communicate

with the Gateway Profibus which in turn communicates with the Master Profibus.

GWY-01-PBS-01 PROFIBUS FACTORY DEFAULTS

Node Address: 63

Input and Output Buffer size: 64 bytes

1.7 ADDITIONAL APPLICATION SPECIFIC CONFIGURATION

To modify the Gateway’s internal configuration for application specific requirements:

1. Install the USB Driver onto the configuration PC, see par. 1.8.

2. Download the Cobalt Dashboard™ utility from www.automation.datalogic.com and

install the software on your configuration computer. Use the Dashboard utility to

connect, via USB, to the Gateway. You will then be able to use the Cobalt Dashboard

Utility to configure the Gateway and send RFID commands for testing purposes. See

par. 1.9.

Page 15

GETTING STARTED

7

1

1.8 USB DRIVER INSTALLATION

This paragraph contains instructions for installing the Windows 2000/XP USB driver for

Datalogic Automation RFID devices. Complete the following steps before installing the RFID

USB driver.

1. Download the RFID USB driver package from www.automation.datalogic.com.

2. Extract the driver files to a separate folder on your host computers’ Desktop.

3. Connect the USB interface cable (and power supply, if applicable) as described in the

Installation Guide included with your RFID product.

4. Apply power to your RFID device. Windows should detect the new hardware and start

the Found New Hardware Wizard. If it does not, run the Add Hardware applet in

Windows’ Control Panel.

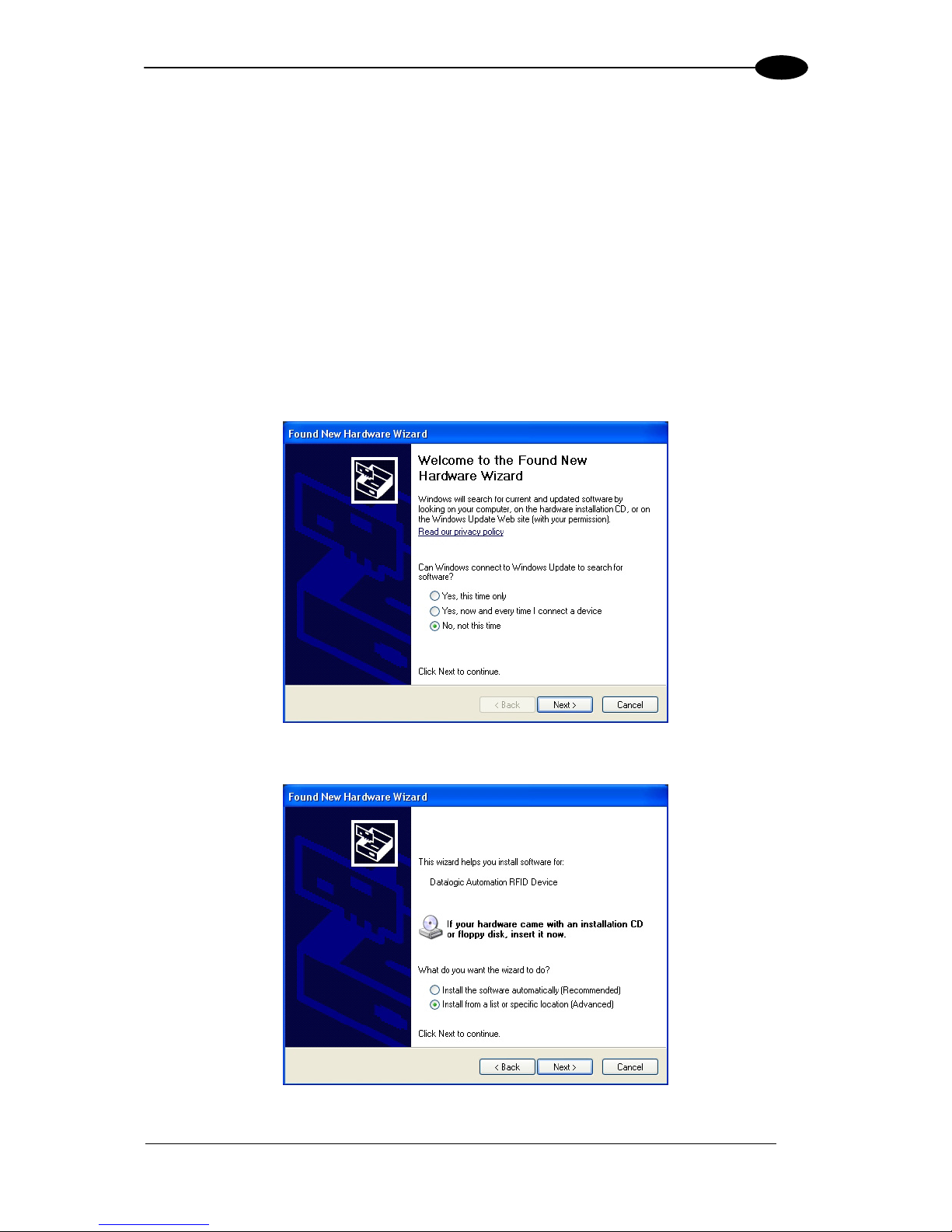

Figure 2: Found New Hardware Wizard – Do Not Connect to Windows Update

Figure 3: Found New Hardware Wizard – Install From List

Page 16

GWY-01-PBS-01

8

1

5. Select “Install from a list or specific location” and then click Next.

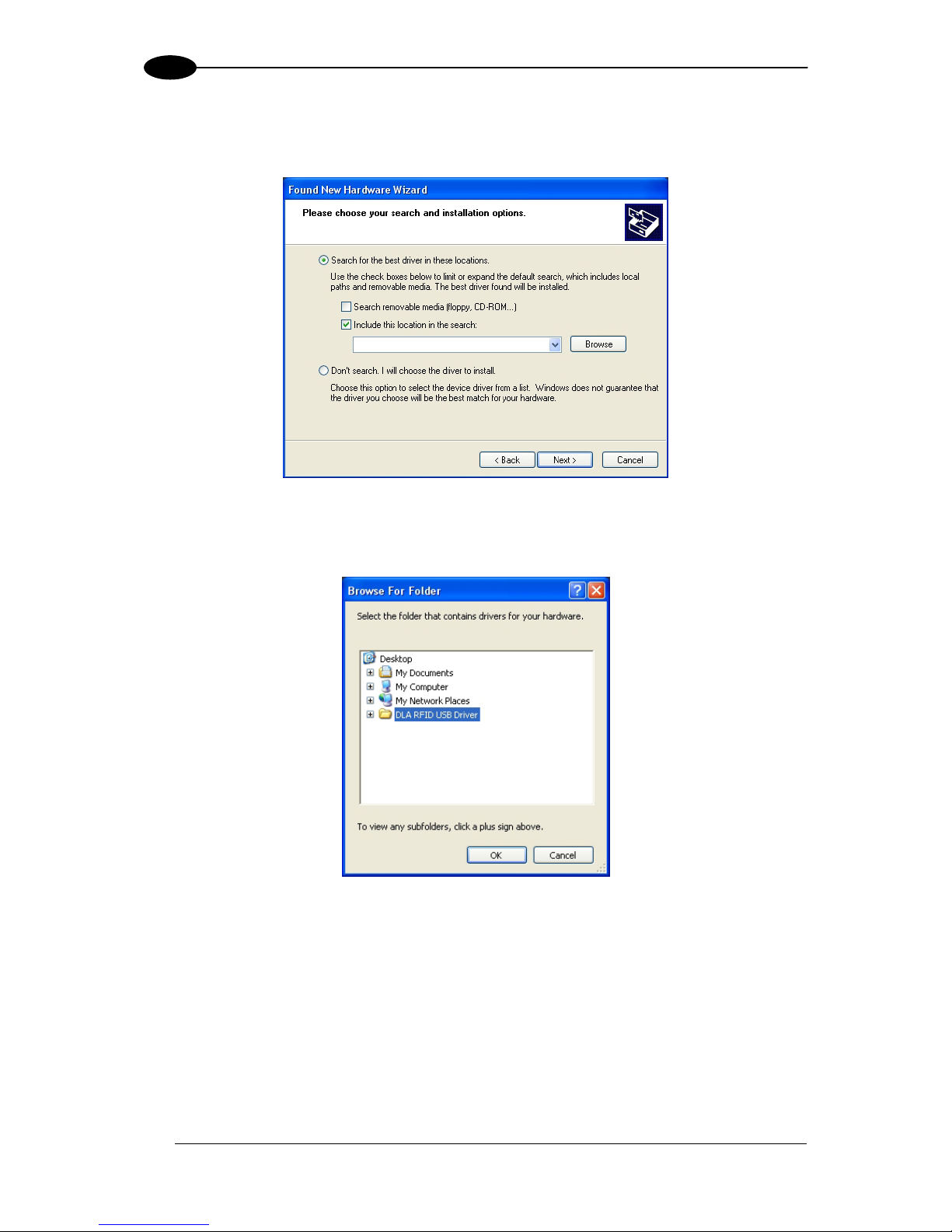

6. Check the box labeled: “Include this location in the search” and then click the Browse

button.

Figure 4: Found New Hardware Wizard – Include this Location

7. Browse to the folder containing the extracted RFID USB driver files and then click OK.

Figure 5: Found New Hardware Wizard - Browse for Folder

Page 17

GETTING STARTED

9

1

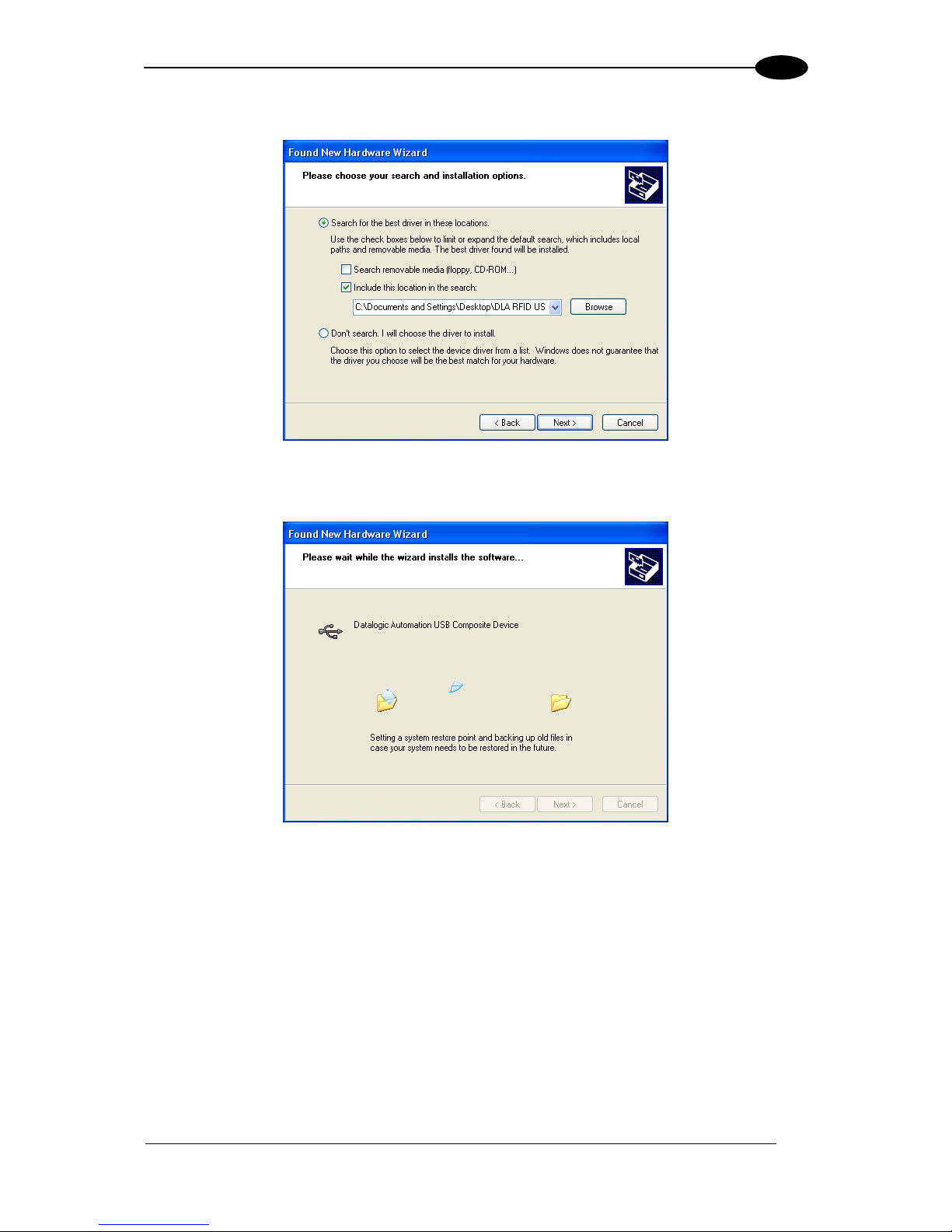

8. Click Next to install the USB driver.

Figure 6: Found New Hardware Wizard – Ready to Install

Please wait while the Found New Hardware Wizard installs the USB driver.

Figure 7: Installing the USB Driver

Page 18

GWY-01-PBS-01

10

1

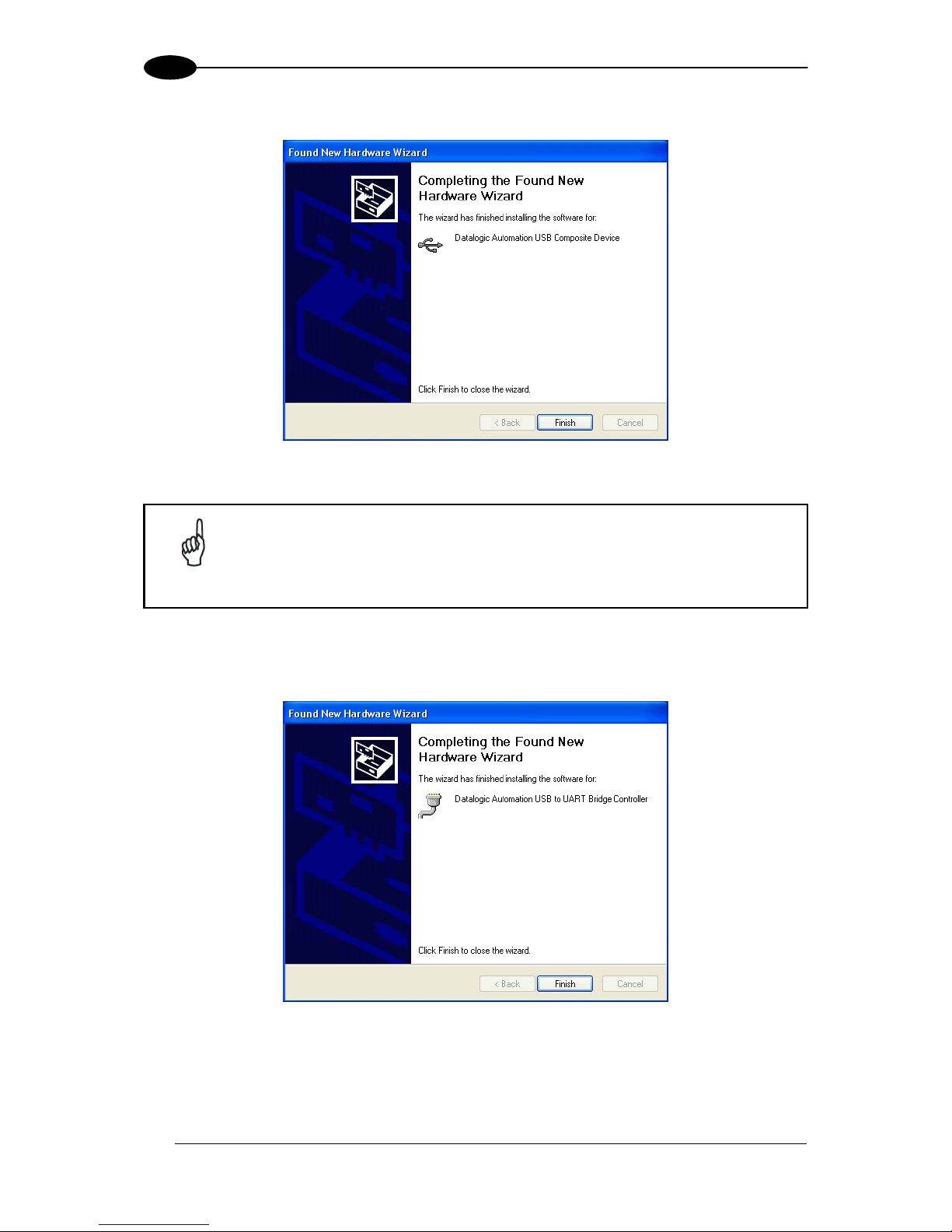

9. After the USB driver has been installed, click Finish.

Figure 8: USB Driver Installation Complete

NOTE

Immediately after you click Finish, the Found New Hardware Wizard will

close and then automatically restart, prompting you to repeat the USB driver

installation. This occurs because Windows requires a second trip through

the installation routine to install and configure a virtual COM port for use by

the RFID USB device.

10. Repeat Steps 5-9 to install the virtual COM port and complete the installation of the

RFID USB driver.

Figure 9: Virtual COM Port USB Driver Installation Complete

Page 19

GETTING STARTED

11

1

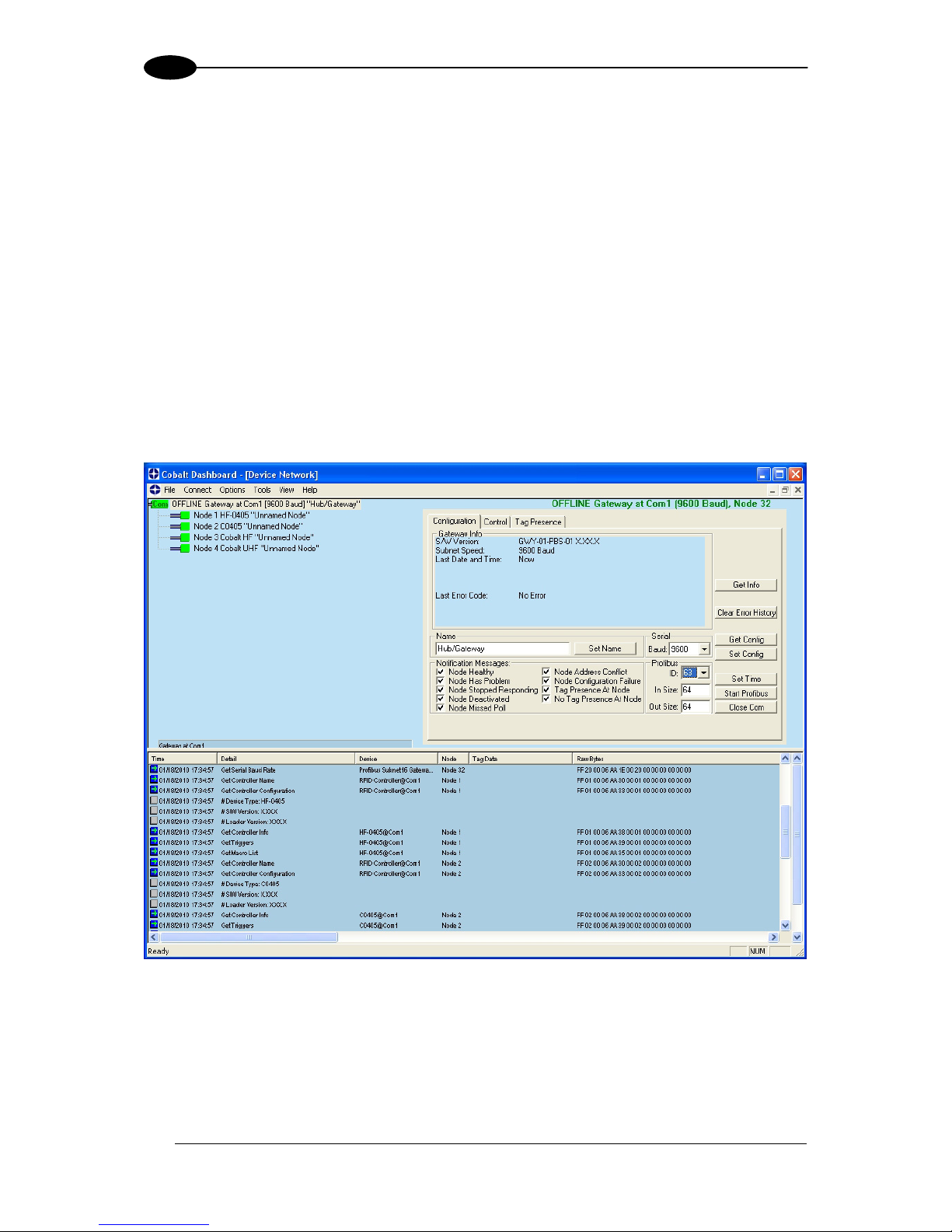

1.9 GATEWAY PROFIBUS CONFIGURATION USING COBALT

DASHBOARD™

The Cobalt Dashboard™ Utility is a software application that allows users to view, modify,

save and update the configuration settings of their Cobalt controllers. Follow the instructions

below to operate the Cobalt Dashboard Utility and to set the Cobalt device’s configuration.

1. Install the Gateway as described in par. 1.6.

2. Install the Cobalt USB driver to your PC as described in par. 1.8.

3. Connect the Gateway to your PC through the USB interface, power the network and

wait for the boot procedure to finish.

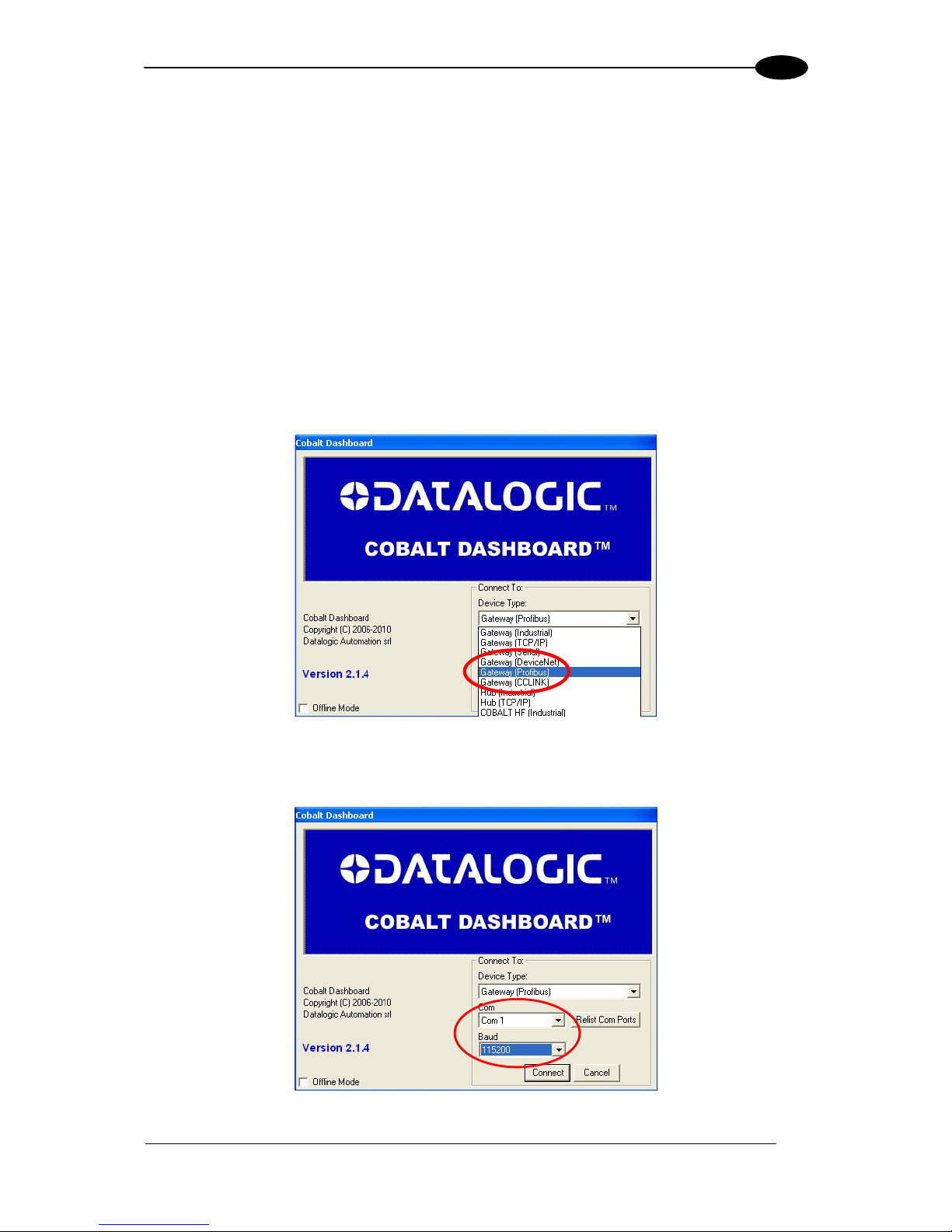

4. Run the Cobalt Dashboard™.

5. From the Connection screen, choose “Gateway Profibus”.

Figure 10: Cobalt Dashboard™ Gateway Profibus Selection

6. Choose the appropriate COM port and select 115200 Baud (this is the default serial

baud rate for USB connection); click “Connect”.

Figure 11: Cobalt Dashboard™ COM and Baudrate Selection

Page 20

GWY-01-PBS-01

12

1

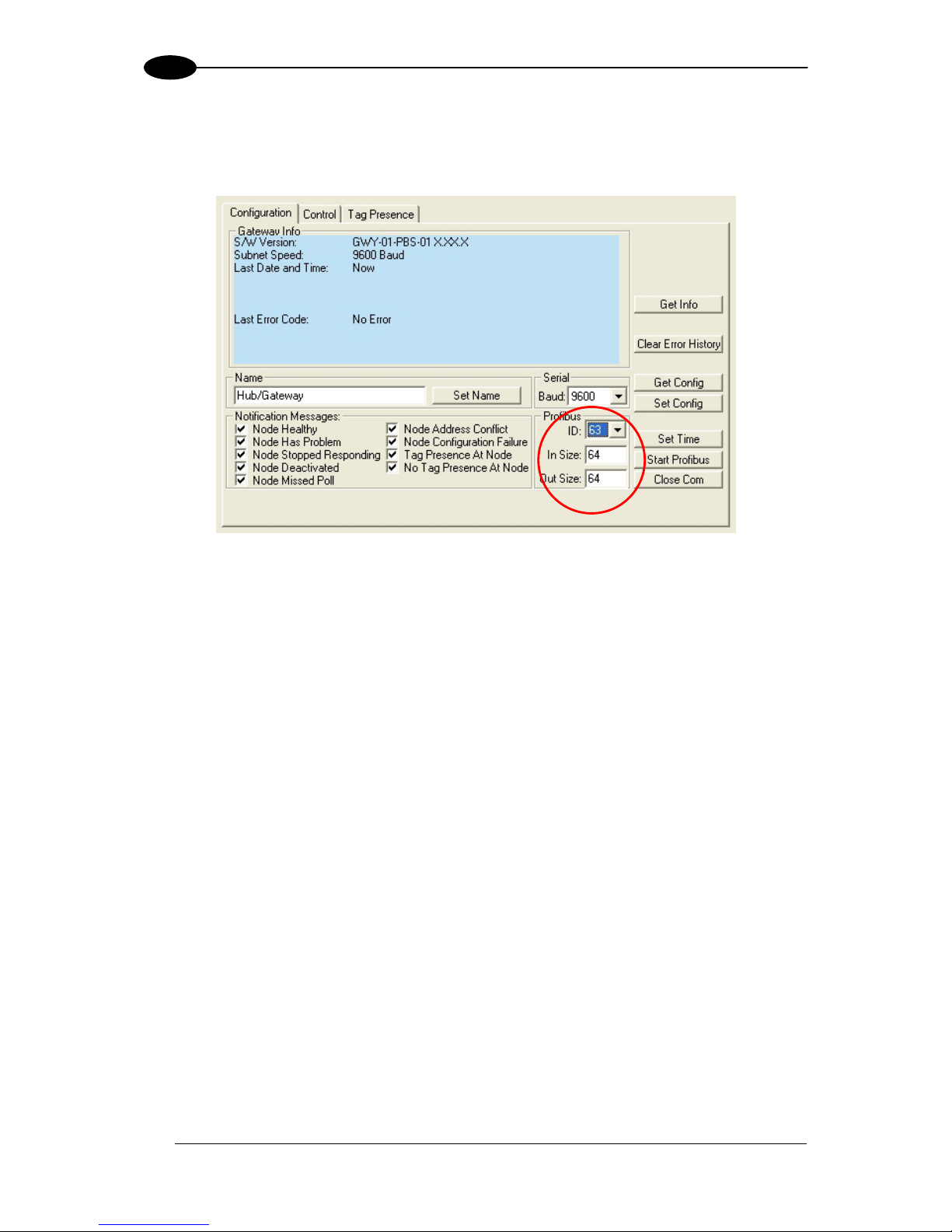

The Dashboard should send some commands to retrieve device and configuration

information from the device. If serial communications are set up correctly, the device

configuration area within the Cobalt Dashboard should now look like this:

Figure 12: Cobalt Dashboard™ Gateway Profibus Device Configuration Area

The default Profibus ID is 63, and the default Input and Output Buffer sizes are 64 bytes

each.

To change the Profibus ID of the device, and/or the Input Buffer/Output Buffer sizes, enter

the desired values in the appropriate boxes in the configuration tab, and click “Set Config”.

For Profibus, the new ID and buffer sizes will not take effect until the device is reset one

more time, or the power is cycled. Turn the unit off and back on to use the new ID and buffer

size settings. For other settings (such as Tag Type, continuous read parameters, etc), the

unit does not need to be reset again or have the power cycled.

See the Cobalt Dashboard™ User's Manual for more configuration details.

Page 21

GATEWAY OVERVIEW

13

2

2 GATEWAY OVERVIEW

2.1 OPERATING MODES

2.1.1 Subnet16™

Subnet16™ is an advanced feature-rich network protocol that supports a subset of the

Datalogic Automation MUX32 legacy protocol. The advanced features implemented in the

Subnet16 protocol allow the Gateway to assign individual Node ID values automatically to

each RFID controller connected on the Subnet bus. Subnet16 also allows the Gateway to

detect when a new controller is connected to the Subnet or when a controller “falls off the

bus” (stops responding).

Through the Subnet16 protocol, the Gateway is able to store a backup copy of each RFID

controller’s custom configuration settings. In the event that an RFID controller fails, the

stored configuration settings can be automatically reassigned to a replacement RFID

controller.

Real-time clock functionality is supported in Subnet16 mode. Host-bound data packets are

automatically Time/Date stamped as they pass through the Gateway and on to the host.

NOTE

The Gateway communicates over the RS485 physical layer using Subnet16,

but it is not a generic RS485 device. RS485 cabling requirements are

however the same.

Page 22

GWY-01-PBS-01

14

2

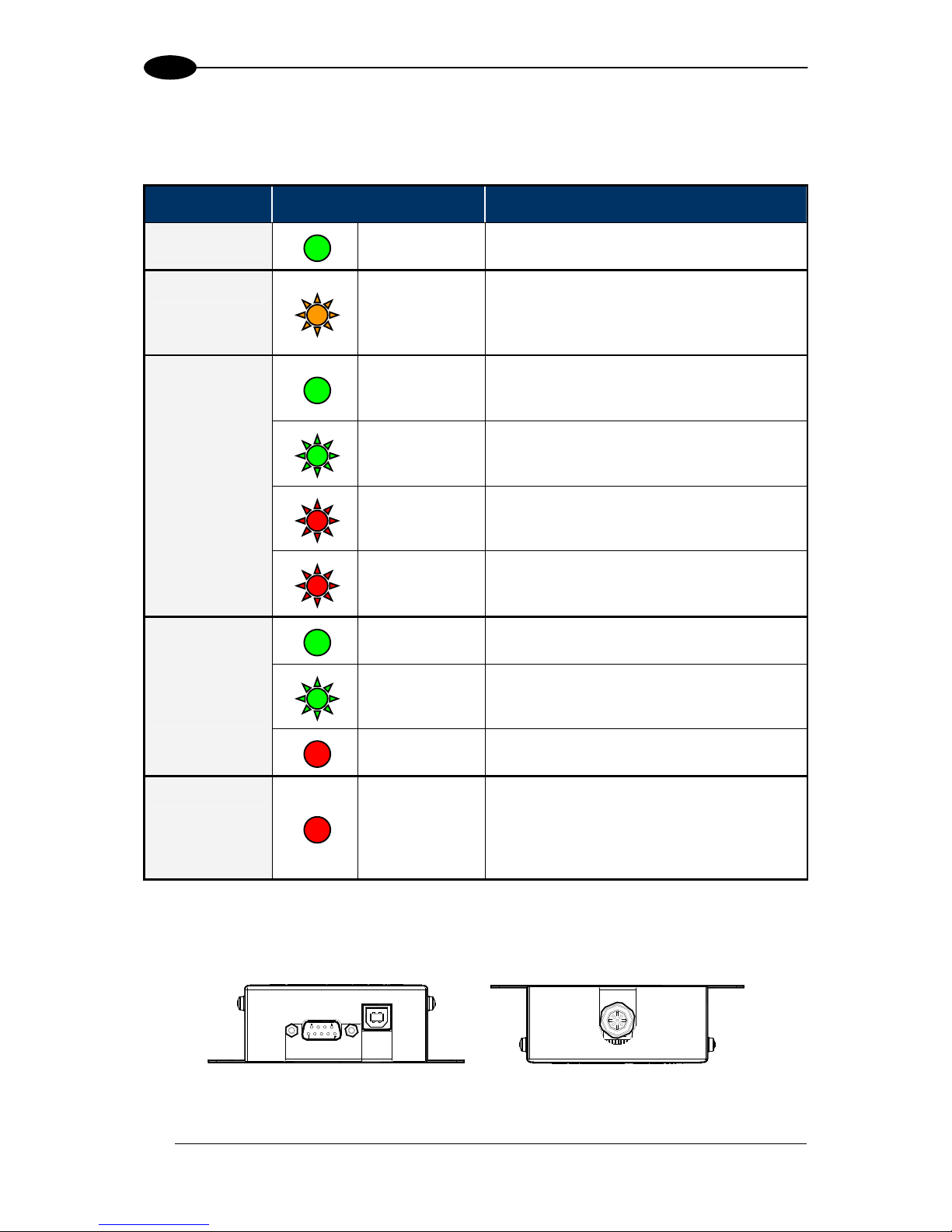

2.2 LED INDICATORS

2.2.1 Front Panel LEDs

LED Name LED Color LED Description

POWER

GREEN

The POWER LED is ON whenever power

is applied to the Gateway.

BUS

AMBER

The BUS LED will flash ON and OFF to

indicate that data is being transmitted

between the Gateway and one or more

RFID controllers on the Subnet16 network.

SOLID GREEN

The Profibus Mode LED is solid green

when the Gateway Profibus interface is

operational, online and exchanging data.

FLASHING

GREEN

The Profibus Mode LED is flashing green

when the Gateway Profibus interface is

operational and on-line, but idle.

FLASHING RED

(1 FLASH)

The Profibus Mode LED is flashing red

and blinks once when a Profibus

parameterization error has occurred.

PBS MODE

Profibus Mode

FLASHING RED

(2 FLASHES)

The Profibus Mode LED is flashing red

and blinks twice when a Profibus

configuration error has occurred.

SOLID GREEN

The Status LED is solid green when the

Profibus communication is initialized.

FLASHING

GREEN

The Status LED is flashing green when the

Profibus communication is initialized, but a

diagnostic event(s) is present.

PBS STAT

Profibus Status

SOLID RED

The Status LED is solid red when a

Profibus exception error has occurred.

ERROR

SOLID RED

The Error LED is solid red when a

Gateway configuration error has occurred,

i.e. an invalid or unrecognized command.

This LED will be cleared when a valid

command is sent.

Table 1: Front Panel LEDs

2.3 EXTERNAL CONNECTORS

Figure 13: External Connectors

Page 23

GATEWAY OVERVIEW

15

2

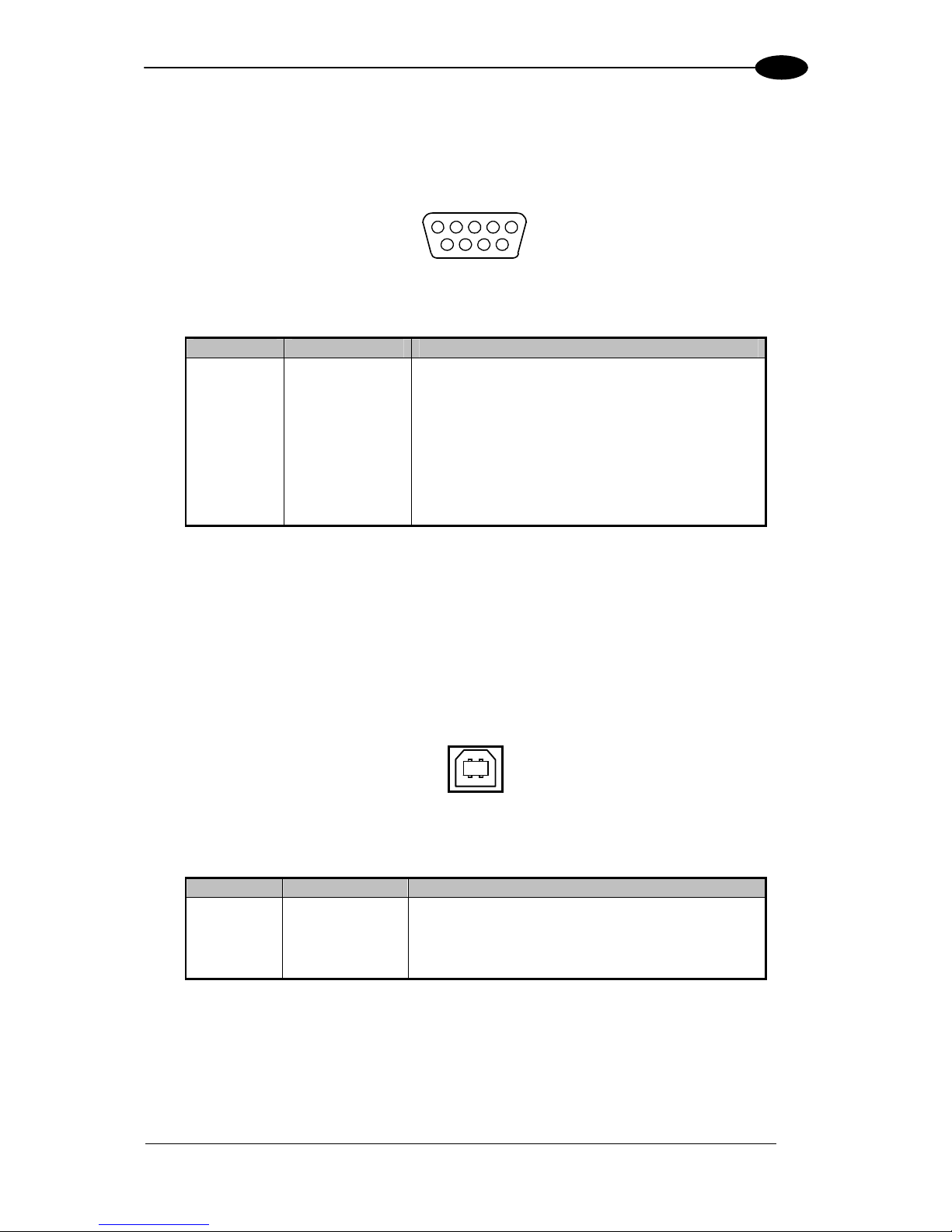

2.3.1 Profibus

The Gateway Profibus Connector is used for Profibus Slave Node connection to the Profibus

network.

5 1

69

Figure 14: Profibus DB9F Interface Connector

Pin Name Function

1 nc

2 nc

3 B Line (+) Positive RxD/TxD (RS485 level)

4 RTS Request To Send

5 GND Bus Ground (isolated)

6 +5 Vdc Bus Power

7 nc

8 A Line (-) Negative RxD/TxD (RS485 level)

9 nc

See par. 2.4 for more information regarding power and wiring for the Gateway.

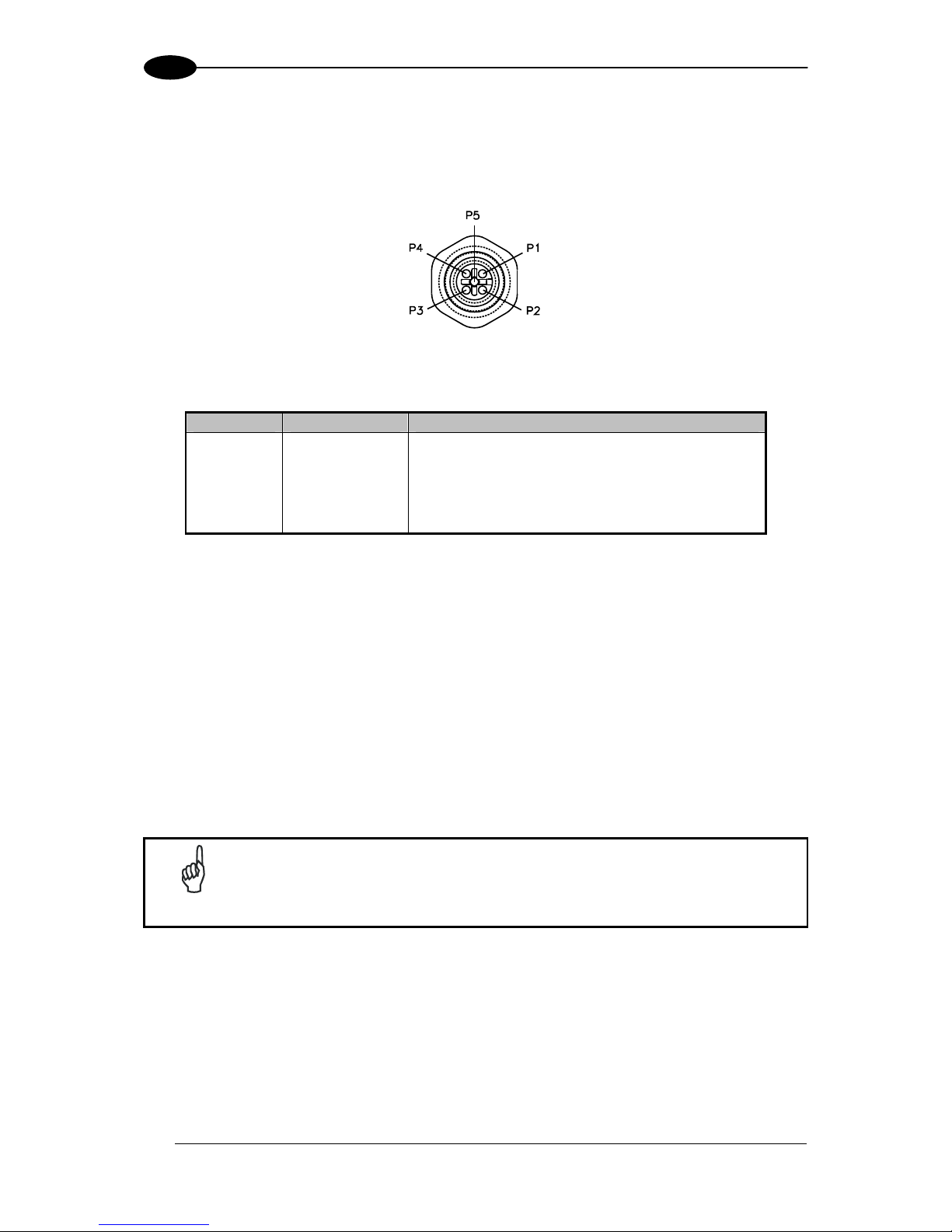

2.3.2 USB

The Gateway USB Connector (type B, female) is used for establishing a direct serial

connection with a host computer for the purpose of configuring the Gateway.

12

34

Figure 15: USB Type B Female Interface Connector

Pin Name Function

1

Vdc 5 + Vdc USB power source

2

D- Data -

3

D+ Data +

4

GND USB power source Ground

Page 24

GWY-01-PBS-01

16

2

2.3.3 Subnet16™ RS485

The Gateway Subnet16™ RS485 Connector (M12 5PF) is used for connecting to the

Subnet16 network and RFID controllers.

Figure 16: M12 5PF Subnet16™ RS485 Interface Connector

Pin Name Function

1

Shield Cable shield

2

Vdc Power supply input voltage +

3

GND Power supply input voltage -

4

RTX+ RS485 Receive/Transmit Data +

5

RTX- RS485 Receive/Transmit Data -

2.4 POWER & WIRING

The information presented below is provided to assist the installer in determining the amount

of power that will be required by the Gateway and its Subnet network.

2.4.1 Power Requirements

The Gateway requires an electrical supply voltage of 12 to 30 Vdc. In addition, each RFID

controller connected to the Gateway via the Subnet16™ network will also require power. Use

a regulated power supply that is capable of delivering the requirements listed in the

Technical Features.

NOTE

Power is applied directly to the Subnet16™ Network trunk and distributed

through drop cables to the Gateway and RFID controllers. By positioning the

power supply near the middle of the network, you can limit voltage drop at

the ends, (see Appendix B for network layout diagrams).

The following information is provided to assist you in determining the power requirements of

your RFID application.

Page 25

GATEWAY OVERVIEW

17

2

2.4.2 Total System Current Consumption

NOTE

The current consumption values of each product are given in the Technical

Features paragraph of the relative Installation manual and refer to the min

and max input voltage range. These values already include an adequate

safety margin. The consumption values given in the following examples have

been interpolated for an input voltage of 24 Vdc.

Max Gateway Current: 200 mA @ 12 Vdc (133 mA @ 24 Vdc).

Max Controller Current: 366 mA @ 24 Vdc for Cobalt HF-Series, 87 mA @ 24 Vdc for

C0405-Series, etc. (refer to controller’s spec).

Calculating Total System Current Consumption:

Total System Current Consumption = [Max Gateway Current + (Max Controller Current x

Number of Controllers)]

Example

A Subnet16™ network powered at 24 Vdc is composed of a GWY-01-PBS-01 connecting

eight C0405-485 RFID Controllers.

Total System Current Consumption = [0.133 A + (0.087 A X 8)] = 0.829 A

2.4.3 Cable Voltage Drop

In addition, each RFID controller on the Subnet will experience a certain amount of voltage

drop depending on the length of the cable.

Cable Resistance per Meter

ThinNet = 0.058 ohms per meter per wire

ThickNet = 0.0105 ohms per meter per wire

Calculating Voltage Drop

Voltage Drop = (Max Controller Current x Number of Controllers) x (Cable Resistance per

Meter per Wire

1

x Cable length in Meters)

Example

A Subnet16™ network is composed of a GWY-01-PBS-01 connecting eight C0405-485 RFID

Controllers (87 mA each @ 24 Vdc). A total of 20 meters of ThinNet cables are used to

connect the devices, which have Cable Resistance = 0.058 Ohms per meter per wire. The

network power is 24 Vdc.

2

Voltage Drop = [0.133 A GWY + (0.087 A x 8 controllers)] x [(0.058 x 2) x 20 meters] =

1.92 Vdc

24 Vdc - 1.92 = 22.08 Vdc at controller number 8

1

The resistance calculation must include both wires (Vdc and GND).

2

This example assumes the power supply is placed at the end of the network, therefore controller #8 is the worst case. By

placing the power supply in the middle of the network the voltage drop at the ends is reduced.

Page 26

GWY-01-PBS-01

18

2

It is recommended that the voltage drop calculation be conducted on the RFID controller that

is farthest from the Gateway, as it will experience the greatest voltage drop.

2.4.4 Current Rating for Cables

The maximum current rating for the Subnet16™ network using Datalogic Automation's

cables and accessories (CBL-xxxx), is 4.0 A.

2.5 NODE ID CONFIGURATION & MANAGEMENT

Only RS485-based RFID controllers can be connected to a Gateway’s Subnet network and

each must be assigned a unique Node ID value between 1 and 16.

When an RFID controller is connected to the Gateway’s Subnet network, the Gateway will

query the new controller to obtain certain configuration values (specifically the Node ID

number). If the Gateway does not detect a Node ID conflict, it will “allow” the RFID controller

onto the Subnet network.

By using the Cobalt HF Configuration Tag that is included with each RS485-based Cobalt

and HF-Series RFID Controller, or the Cobalt UHF Configuration Tag that is included with

each RS485-based Cobalt UHF-Series RFID Controller, the Node ID value can be

dynamically assigned by the Gateway or can be manually assigned by the user.

For the Gateway to dynamically assign a Node ID value to a controller, the controller must

first be initialized with the Node ID value of zero. This is the equivalent of having no Node ID

assigned.

NOTE

All Datalogic Automation RS485-based controllers ship with their Node ID

value set to 0.

When a powered controller (that is set to Node ID 0) is connected to the Subnet, it will not

initially be recognized by the Gateway until the Configuration Tag is placed in the antenna’s

RF field. After a few seconds the controller will display its new assigned Node ID value in

binary code from right to left or (top to bottom) using the five amber Node LEDs on the

controller.

When dynamically assigning a Node ID value for a new controller, the Gateway will either

assign the next available Node ID value or the value that the Gateway recognizes as offline

or “missing” – that is, a Node ID value that previously existed, but has since disappeared

from the network.

Because the Gateway stores a backup of each Subnet Node’s configuration, should an RFID

controller ever fail, a replacement controller can be installed quickly and easily. The new

controller will be automatically assigned the same Node ID value and configuration as the

replaced controller, provided the Configuration Tag is introduced to the antenna field after

startup and then removed.

Page 27

GATEWAY OVERVIEW

19

2

NOTE

Avoid that the configuration tag is simultaneously read by more than one

controller, especially for UHF controllers.

2.6 GATEWAY AND SUBNET NODE NAMING

The Gateway can store a 64-byte ASCII string for each of the 16 Subnet Nodes and one 64byte ASCII string for the Gateway itself. These text strings can be used to assign logical or

“user friendly” names to the Gateway and its Subnet Nodes.

For example, you could assign the Gateway a logical name such as “PRODUCTION LINE 1”

and then name the controller connected to Subnet Node 01 “PRODUCTION STATION 1”.

The controller at Subnet Node 02 could then be named “PRODUCTION STATION 2” (and so

forth).

Gateway and Node names can be retrieved and edited by issuing specific commands to the

Gateway (which are covered later in this manual). See the table below for specific CBx

protocol command ID numbers.

Gateway and Node Naming – CBx Command IDs

Gateway Node

Get Name

Command 0x11 Command 0x30

Set Name

Command 0x21 Command 0x40

Table 2: Gateway and Node Naming – CBx Command IDs

Gateway and Node naming can also be accomplished through the Cobalt Dashboard™

software utility, see the Cobalt Dashboard™ User's Manual for more details.

Page 28

GWY-01-PBS-01

20

2

2.7 CONFIGURATION TOOLS

Datalogic Automation offers the following powerful RFID configuration utilities for Microsoft

Windows XP and Windows 2000 based systems:

Cobalt Dashboard™

C-Macro Builder™

These configuration tools can be downloaded from the Datalogic Automation website:

www.automation.datalogic.com

2.7.1 Cobalt Dashboard™

The Cobalt Dashboard™ is a Windows-based software application that provides users with

complete control over their Datalogic Automation RFID Solution. Users can monitor their

entire RFID system, from the tag level, to the RFID controller, to the Gateway, and to the

host.

Figure 17: Cobalt Dashboard™

Cobalt Dashboard Features:

Complete Subnet16™ Node configuration

Data packet inspection and Subnet network health monitoring

Gateway and Subnet Node “Friendly” Name Assignment (users can quickly and

easily assign logical “friendly” names to the Gateway and its Subnet Nodes).

Page 29

GATEWAY OVERVIEW

21

2

Supports Ethernet, Profibus, DeviceNet, RS232, and USB models

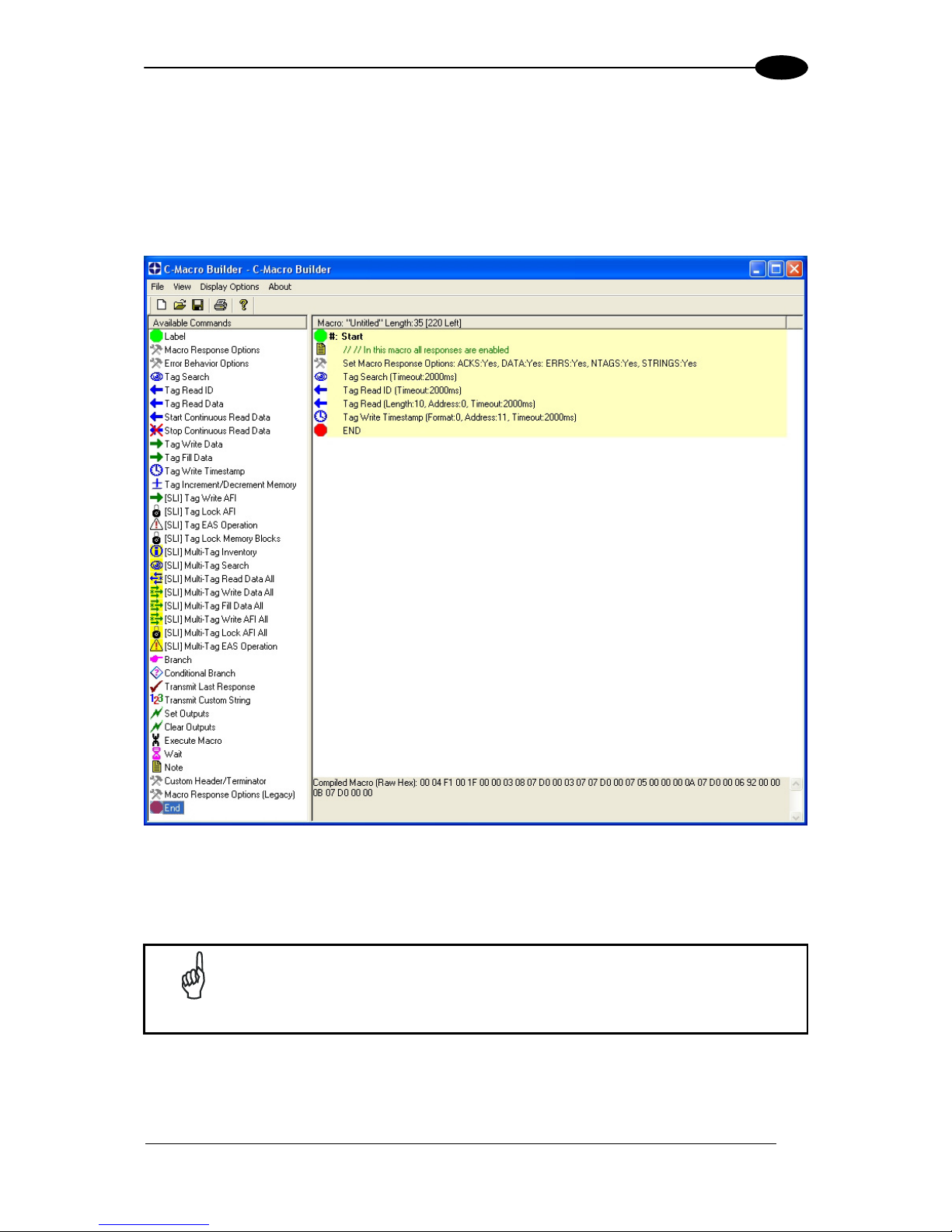

2.7.2 C-Macro Builder™

C-Macro Builder™ is an easy to use GUI-driven utility for Windows that allows users to

create powerful RFID command macro programs.

Figure 18: C-Macro Builder™

When used in conjunction with the Cobalt Dashboard™, users can easily download, erase,

backup and manage multiple RFID command macros and macro triggers for each Subnet

Node. See Chapter 3 for more on macros.

NOTE

For specific information regarding the configuration and use of either of

these utilities, please see the accompanying documentation included when

downloading each software application.

Page 30

GWY-01-PBS-01

22

3

3 RFID COMMAND MACROS

3.1 WHAT ARE RFID COMMAND MACROS?

RFID Command Macros are a powerful feature of Datalogic Automation Cobalt Controllers.

Macros are simple programs that direct a controller to execute multiple pre-programmed

instructions.

Because macros reside within the controller’s internal memory, they can be programmed to

instruct the controller to automatically read and/or write a specified set of data to an RFID tag

without the controller ever having to receive a command from the host. In fact, the controllers

do not even require a connection to a host in order to execute macros.

Each macro can contain up to 255 bytes of data and each supported controller can store up

to eight macros at a time. Though they are stored locally on the controller, macros are also

backed up in the Gateway’s flash memory as well.

3.2 WHY USE MACROS?

The power of macros is in distributed intelligence, the reduction in network bus traffic and the

ability to accelerate routine decision making at the point of data collection.

3.3 WHAT CAN MACROS DO?

In addition to the automated reading and writing of data, macro capabilities include:

The ability to write time stamps to RFID tags

The ability to filter command responses to only those of interest to the host (such as

when an error occurs or when a tag has arrived in the RF field)

The ability to harness powerful logic and triggering capabilities such as; read, write,

start/stop continuous read, data compare, branch, transmit custom string, and set

outputs.

3.4 WHAT IS A MACRO TRIGGER?

Macros are initiated by “triggers.” Triggers can be configured in numerous ways. A simple

command from the host, such as “execute macro number three” can be considered a trigger.

Triggers can be configured, for example, to activate a macro when a tag enters or leaves a

controller’s RF field.

Datalogic Automation RFID controllers can store up to eight separate triggers in addition to

the eight macros they can also house. Any trigger can activate any of the eight stored

macros.

Page 31

RFID COMMAND MACROS

23

3

3.5 HOW ARE MACROS CREATED?

Macros are created using the powerful, yet simple, C-Macro Builder™

utility from Datalogic

Automation. The easy to use GUI allows the user to create powerful RFID macro programs

quickly and easily.

When used with Datalogic Automation Cobalt Dashboard™

utility, users can effortlessly

download, erase, and manage their macros and triggers, as well as set the operational

configurations of their RFID controllers and Subnet16™ Gateways.

3.6 WHICH COMMUNICATION INTERFACES SUPPORT THE USE OF

MACROS?

Macros are supported on the following Cobalt Controllers: Ethernet, Profibus, DeviceNet,

RS232 and USB interfaces.

3.7 WHAT HAPPENS TO EXISTING MACROS IF A CONTROLLER MUST

BE REPLACED?

When using a Subnet16™ Gateway, users do not need to worry. Macros and triggers

normally residing in an RFID controller’s flash memory are always backed up in the

Gateway’s flash memory as well. Therefore, if a controller should ever require replacement,

all existing macro and trigger settings are automatically exported from the Gateway to the

new RFID controller.

In short, when an RFID controller is initially connected to the Gateway, macro and trigger

data from the controller’s flash memory is compared to the macro and trigger data backed up

in the Gateway from the previous RFID controller. If the data does not match that which is

stored on the Gateway, the controller’s flash memory will be overwritten with the backed up

data stored in the Gateway’s flash memory.

3.8 HOW CAN I LEARN MORE ABOUT THE DASHBOARD AND C-

MACRO BUILDER?

More information regarding macros, triggers, uploading, downloading, configuring and

monitoring Datalogic Automation RFID equipment is available in the respective User’s

Manuals for these products, which are available on the Datalogic Automation website at:

www.automation.datalogic.com

Page 32

GWY-01-PBS-01

24

4

4 COMMAND PROTOCOL

A command is initiated by a host PC or Programmable Logic Controller (PLC) and is

distributed to the Gateway over a network connection. Once issued, the command is then

executed directly by the Gateway or is otherwise routed to the appropriate RFID controller

(specified by its numerical “Node ID” value, for which there are 16).

In general, there are two types of commands that can be issued:

Controller Commands - commands intended for one of the attached RFID

controllers. “Read Data” and “Write Data” are two common controller commands.

Gateway Commands - commands intended for the Gateway itself. Gateway

commands are those commands that query the Gateway for information or instruct

the Gateway to perform a task. The commands “Get Node Status List” and “Set

Notification Mask” are examples of Gateway commands.

4.1 CBX COMMAND PROTOCOL OVERVIEW

In order to execute RFID commands properly, the RFID device and host computer must be

able to communicate using the same language. The language that is used to communicate is

referred to as the Command Protocol. The command protocol used by GWY-01-PBS-01 is

called "CBx".

The CBx Command Protocol is an advanced protocol that supports Multidrop Subnet16

networking with TCP/IP, Profibus and Industrial Ethernet applications. It is based on a

double-byte oriented packet structure where commands always contain a minimum of six

data “words” (12 bytes) - even when one or more packet elements are not applicable to the

command.

The CBx packet structures described herein are protocol independent and therefore can be

implemented the same for all protocols (Ethernet/IP, Modbus TCP, Profibus, etc.).

NOTE

For complete command and response packet structures and examples of

each RFID command, refer to the CBx Command Protocol Reference

Manual available at: www.automation.datalogic.com.

Page 33

COMMAND PROTOCOL

25

4

4.2 CBX - COMMAND PACKET STRUCTURE

Below is the packet structure of a standard CBx command.

Word # Command Packet Element MSB LSB

01

Overall Length: 2-byte value indicating

the number of “words” in the command

packet. This value will always be at least 6

words.

0x00 0x06 + (number

of any additional

words)

02

Command ID: 0xAA + 1-byte value

indicating command to perform.

0xAA <Command ID>

03

0x00 in MSB, Node ID in LSB 0x00 <Node ID>

04

Timeout Value: 2-byte integer for the

length of time allowed for the completion of

the command, measured in 1 millisecond

units, where 0x07D0 = 2000 x .001 = 2

seconds.

0x07 0xD0

05

Start Address: 2-byte integer indicating

the location of tag memory where a

Read/Write operation will begin (when

applicable).

<Start MSB> <Start LSB>

06

Block Size: 2-byte integer indicating the

number of bytes that are to be read from or

written to a tag beginning at the specified

Start Address (when applicable).

<Length

MSB>

<Length LSB>

07

Additional Data Byte Values 1 & 2: holds

2 bytes of data used for fills, writes, etc.

(when applicable)

<D1> <D2>

08

Additional Data Byte Values 3 & 4:

(when applicable)

<D3> <D4>

Table 3: CBx Command Packet Structure

Page 34

GWY-01-PBS-01

26

4

4.3 CBX - RESPONSE PACKET STRUCTURE

After performing a command, the Gateway or RFID controller will issue a host-bound

response packet. Below is the packet structure of a standard CBx response message.

Word # Response Packet Element MSB LSB

01

Overall Length: 2-byte integer indicating

the number of “words” in the response

packet. This value will always be at least 6

(+ number of any data words retrieved).

0x00 0x06 + (number

of any retrieved

words)

02

0xAA in MSB

Command Echo in LSB

0xAA <Command

Echo>

03

Instance Counter: 1-byte value indicating

the number of responses generated by the

Node ID identified in the LSB (see details

below).

Node ID Echo: 1-byte value indicating the

Node ID of the controller that performed

the command.

<IC> <Node ID

Echo>

04 Month and Day Timestamp

<Month> <Day>

05 Hour and Minute Timestamp

<Hour> <Minute>

06

Second Timestamp in MSB

Additional Data Length in LSB: 1-byte

value indicates number of additional bytes

retrieved.

<Second> <N-bytes>

07

Retrieved Data Bytes 1 and 2: holds 2

bytes of retrieved data from tag reads,

serial numbers, etc. (when applicable)

<D1> <D2>

Table 4: CBx - Response Packet Structure

4.3.1 Instance Counter

The Instance Counter is a one-byte value used by the Subnet16 Gateway to track the

number of responses generated by the controller at a given Node ID. The Gateway tallies, in

its internal RAM, separate Instance Counter values for each Node ID.

A Node ID’s Instance Counter will be incremented by one following each response. If, for

example, the controller at Node 01 has generated 10 responses, its Instance Counter value

will read 0x0A. However, when the Gateway is rebooted or power-cycled, the Instance

Counter values for all Node IDs will be reset to zero (0x00).

Page 35

COMMAND PROTOCOL

27

4

4.4 CBX COMMANDS TABLE

The table below lists the CBx protocol RFID commands supported by the Gateway and RFID

Controllers.

Command ID Command Name Description

RFID Tag Commands

0x02

Lock Memory Block Write protects a block of tag memory

0x04

Fill Tag

Writes a specified data byte value to all

defined tag addresses

0x05

Read Data

Reads a specified length of data from a

contiguous (sequential) area of tag

memory

0x06

Write Data

Writes a specified number of bytes to a

contiguous area of tag memory

0x07

Read Tag ID Reads a tag’s unique tag ID number

0x08

Tag Search

Instructs the controller to search for a tag

in its RF field

0x0C

Execute Macro

Instructs the controller to execute one of

its eight possible macros

0x0D

Start Continuous Read

Instructs the controller to start or stop

Continuous Read mode.

0x0E

Read Tag ID and Data

Reads a tag’s ID and the requested

number of bytes from tag memory

0x0F

Start Continuous Read Tag ID

and Data

Places the controller into (or out of)

Continuous Read mode and (when

evoked) will retrieve a tag’s ID.

Gateway Information Commands

0x10

Get Gateway Software Version

Retrieves the version number of the

firmware code installed on the Gateway

0x11

Get Gateway Name

Retrieves the Gateway’s user-defined

ASCII name

0x12

Get DIP-switch Settings

Retrieves the status of the Gateway

configuration DIP switches

0x13

Get Node Status List

Retrieves the operational status of the

Gateway Subnet Nodes

0x14

Get Notification Mask

Retrieves the user-defined 16-bit

“Notification Mask” that determines for

which events the Gateway notifies the

host PC

0x15

Get Last Gateway Error

Retrieves information from the Gateway

regarding the last or most recent error

that was experienced

0x16

Get Gateway Time

Retrieves the current date and time as

set internally on the Gateway

Page 36

GWY-01-PBS-01

28

4

Command ID Command Name Description

0x1C

Get Subnet Baud Rate

Retrieves the baud rate of the Subnet

network

0x21

Set Gateway Name

Writes to flash memory, a user-defined

“friendly” name for the Gateway

0x24

Set Notification Mask

Used to customize or modify the

Gateway’s 16-bit Notification Mask

0x26

Set Gateway Time

Used to set the Gateway’s internal clock

and calendar

0x2C

Set Subnet Baud Rate

Used to modify and store changes to the

Subnet network baud rate

RFID Controller Commands

0x30

Get Controller Name

Retrieves the controller’s user-defined

name

0x33

Get Controller Configuration

Retrieves the controller’s configuration

settings

0x38

Get Controller Info

Retrieves hardware, firmware and serial

number information from the controller

0x40

Set Controller Name

Used to set (create or modify) the userdefined name for the controller

0x43

Set Controller Configuration

Used to set (configure or modify) the

controller’s configuration parameters and

settings

0x4E

Set Controller Time Used to set the time for the controller

0x53

Initialize Controller

Removes all configuration settings stored

for the controller

0x54

Reset Controller Resets power to the controller

Gateway Subnet Commands

0x60

Initialize Gateway

Clears all Subnet Node configuration

information stored in the Gateway’s flash

memory

0x61

Reset Gateway

Performs an electrical reset of the

Gateway

0x62

Initialize All Nodes

Removes all stored configuration

information for all nodes and reconfigures

them to factory defaults

0x63

Initialize All Node Macros

Removes all stored macros from all

nodes

0x70

Start Subnet

Instructs the Gateway to begin “polling”

the Subnet network

0x71

Move Controller

Used to move all stored configuration

data for a particular Node ID to another

specified Node ID

Page 37

COMMAND PROTOCOL

29

4

Command ID Command Name Description

0x79

Clear Pending Response

Deletes all pending or buffered

responses in the Gateway and resets all

Instance Counters to zero

Multi-Tag RFID Commands

0x92

Multi-Tag Read ID and Data All

Retrieves the tag ID number and a

contiguous segment of data from all

RFID tags in range

0x95

Multi-Tag Block Read All

Retrieves a contiguous segment of data

from all RFID tags in range

0x96

Multi-Tag Block Write All

Writes a contiguous segment of data to

all RFID tags in range

0x97

Multi-Tag Get Inventory

Retrieves the tag ID number from all

RFID tags found in range

0x98

Multi-Tag Search All

Checks for the presence of RFID tags in

RF range and returns only the number of

tags found

0xA5

Multi-Tag Block Read by ID

Reads a contiguous segment of data

from a specific RFID tag identified by its

tag ID

0xA6

Multi-Tag Block Write by ID

Writes a contiguous segment of data to a

specific RFID tag identified by its tag ID

Table 5: CBx Commands

4.5 CBX COMMAND PROTOCOL EXAMPLES

4.5.1 CBx - Controller Command Example

In the example below, Command 0x05 (Read Data) is issued to the RFID controller at Node

01. The controller is instructed to read four bytes of data from a tag beginning at tag address

0x0020. The Timeout Value, measured in milliseconds, is set for two seconds for the

completion of this command (0x07D0 = 2000 x .001 = 2 seconds).

Word # Packet Element MSB LSB

01

Overall Length of Command (in "words") 0x00 0x06

02

0xAA in MSB

Command ID in LSB: (0x05 - Read Data)

0xAA 0x05

03

0x00 in MSB

Node ID in LSB: (0x01)

0x00 0x01

04

Timeout Value: (2 seconds) 0x07 0xD0

05

Start Address: (0x0020) 0x00 0x20

06

Read Length: (4 bytes) 0x00 0x04

Table 6: Controller Command Example

Page 38

GWY-01-PBS-01

30

4

4.5.2 CBx - Controller Response Example

Below is a controller’s response after successfully completing the Read Data command (as

issued in the previous example).

Word # Packet Element MSB LSB

01

Overall Length of Response (in "words") 0x00 0x08

02

0xAA in MSB

Command Echo in LSB: (0x05 - Read

Data)

0xAA 0x05

03

Instance Counter in MSB

Node ID Echo in LSB

<IC> 0x01

04

Month and Day Timestamp (March 19

th

) 0x03 0x13

05

Hour and Minute Timestamp (10:11: AM) 0x0A 0x0B

06

Seconds Timestamp in MSB: (36

seconds)

Additional Data Length in LSB (4 bytes)

0x24 0x04

07

Retrieved Data (bytes 1 and 2) 0x01 0x02

08

Retrieved Data (bytes 3 and 4) 0x03 0x04

Table 7: Controller Response Example

4.5.3 CBx - Gateway Command Example

In this example, the host issues Command 0x13 (Get Node Status List), which retrieves from

the Gateway, a list that indicates the operating status of the 16 Nodes.

Word # Packet Element MSB LSB

01

Overall Length of Command (in “words”) 0x00 0x06

02

0xAA in MSB

Command ID in LSB: (0x13 - Get Node

Status List)

0xAA 0x13

03

0x00 in MSB

Node ID in LSB: (0x20 = Gateway Node

32)

0x00 0x20

04

Not Used: 0x00, 0x00 (default) 0x00 0x00

05

Not Used: 0x00, 0x00 (default) 0x00 0x00

06

Not Used: 0x00, 0x00 (default) 0x00 0x00

Table 8: Gateway Command Example

Note that even though the last three words (6 bytes) of this command are not used, these

parameters still require zero’s (0x00, 0x00) and are to be included when calculating Overall

Length.

Page 39

COMMAND PROTOCOL

31

4

4.5.4 CBx - Gateway Response Example

Below is the Gateway response to the command “Get Node Status List” (as issued in the

previous example).

Word # Packet Element MSB LSB

01

Overall Length of Response (in “words,”

not including the previous 2-bytes – CBx

Header and Node ID Echo)

0x00 0x0E

02

0xAA in MSB

Command Echo in LSB: (0x13)

0xAA 0x13

03

Instance Counter in MSB

Node ID Echo in LSB (0x20 = Gateway

Node 32)

<IC> 0x20

04

Month and Day Timestamp (March 19th) 0x03 0x13

05

Hour and Minute Timestamp (10:11: AM) 0x0A 0x0B

06

Seconds Timestamp in MSB: (36

seconds)

Additional Data Length in LSB: (16 bytes)

0x24 0x10

07 Status of Node ID 1 and 2

0x00 0x00

08 Status of Node ID 3 and 4

0x04 0x00

09 Status of Node ID 5 and 6

0x00 0x04

0A Status of Node ID 7 and 8

0x00 0x00

0B Status of Node ID 9 and 10

0x00 0x00

0C Status of Node ID 11 and 12

0x00 0x00

0D Status of Node ID 13 and 14

0x00 0x00

0E Status of Node ID 15 and 16

0x00 0x00

Table 9: Gateway Response Example

In the above example, the Node Status Byte “0x04” (meaning “Controller Healthy”) was

reported for Nodes 03 and 06, indicating that the Gateway recognizes functioning RFID

controllers at Node 03 and Node 06. (See the Node Status Byte Definition Table below for

more information).

Page 40

GWY-01-PBS-01

32

4

4.6 NODE STATUS BYTE DEFINITION TABLE

Node Status

Byte

Node Status Status Description

0

CONTROLLER

INACTIVE

The controller at this node has not responded to a

poll for at least 40 seconds.

If a controller does eventually respond at this Node

ID, its status will be changed to “0x04 CONTROLLER HEALTHY”.

1

CONTROLLER

STOPPED

RESPONDING

The controller at this node has not responded to a

poll in over 10 seconds.

If the controller does not respond to a poll within

another 30 seconds, its status will be changed to

“0x00 - CONTROLLER INACTIVE”.

If the controller does eventually respond to a poll,

its status will be changed back to “0x04 CONTROLLER HEALTHY”.

2

CONTROLLER HAS

PROBLEM

The controller at this node has missed at least 3

consecutive polls.

If the controller does not respond to a poll within

another 10 seconds, its status will be changed to

“0x01 - CONTROLLER STOPPED RESPONDING.”

If the controller does eventually respond to a poll,

its status will be changed back to “0x04 CONTROLLER HEALTHY”.

3

CONTROLLER

EXPECTED SOON

This Node Status indicates that a controller is

temporarily disconnected or that it is being moved

to another Node ID.

Because a controller is “expected” to appear soon,

the Gateway will poll this node more frequently than

other ‘inactive’ nodes.

4

CONTROLLER

HEALTHY

The controller at this node is healthy and

responding to polls.

However, if the controller misses 3 consecutive

polls, its status will be changed to “0x02 CONTROLLER HAS PROBLEM”.

5

CONTROLLER

DOWNLOADING

This status is only applied to a controller that is

currently downloading and installing new firmware

to its flash memory.

To optimize polling and allow for the fastest

possible firmware installation, the Gateway will

temporarily halt the polling of this node until the

controller has finished its installation.

Table 10: Node Status Byte Definition

Page 41

COMMAND PROTOCOL

33

4

4.7 CBX ERROR RESPONSE PACKET STRUCTURE

Below is the packet structure of a CBx error response. Note that the one-byte Error Code

value is returned in the MSB of the seventh data word.

Error Response Element MSB LSB

Overall Length: 2-byte value indicating the number

of “words” in the Response Packet. This value will

always be at least 7 words (6 + 1 for the error

code).

0x00 0x07

Error Flag: 0xFF in the MSB indicates that an error

occurred.

Error Information Byte: 0xFF in the LSB indicates

that a controller-based error occurred. Any value

other than 0xFF indicates that a Gateway-based

error occurred (and indicates the command that

was attempted when the error occurred).

0xFF 0xFF

Instance Counter: This 1-byte value tallies the

number of responses from a given Node ID.

Node ID Echo: The 1-byte LSB value indicates the

Node ID of the controller for which the command

was intended.

<IC> 0x01

Month and Day Timestamp <Month> <Day>

Hour and Minute Timestamp <Hour> <Minute>

Seconds Timestamp in MSB

Number of Additional Bytes Retrieved in LSB (0x01

for error responses)

<Seconds> 0x01

Error Code: 1-byte Error Code in MSB

0x00 in LSB

<Error Code> 0x00

Table 11: CBx Error Response Packet Structure

Page 42

GWY-01-PBS-01

34

4

4.8 CBX ERROR CODE TABLE

Error Code Error Description

0x04

FILL TAG FAILED Fill Tag Command Failed

0x05

READ DATA FAILED Read Data Command Failed

0x06

WRITE DATA FAILED Write Data Command Failed

0x07

READ TAG ID FAILED /

TAG SEARCH FAILED

Read Tag ID Command Failed,

Tag Search Command Failed

and/or No Tag Found

0x21

INVALID SYNTAX Command Contained a Syntax

Error

0x23

INVALID TAG TYPE Invalid Tag Type Specified

0x30

INTERNAL

CONTROLLER ERROR

Generic Internal Controller Error

0x31

INVALID CONTROLLER

TYPE

Invalid Controller Type (when

Setting Configuration)

0x34

INVALID VERSION Invalid Software Version

Specified (when Setting

Configuration)

0x35

INVALID RESET Invalid Hardware Reset

0x36

WRITE

CONFIGURATION

FAILED

Set Configuration Command

Failed

0x37

READ CONFIGURATION

FAILED

Get Configuration Command

Failed

0x80

UNKNOWN GATEWAY

ERROR

Generic Gateway Error – an

undetermined error occurred.

0x81

COMMAND

MALFORMED

Generic Command Syntax Error

0x82

COMMAND PROTOCOL

MISMATCH

An invalid protocol value was

specified in the command

0x83

COMMAND INVALID

OPCODE

An invalid Opcode (Command ID

number) was specified in the

command

0x84

COMMAND INVALID

PARAMETER

A parameter specified in the

command was invalid

0x85

COMMAND INVALID

CONTROLLER ID

A Controller ID (Node ID)

specified in the command was

invalid, or no controller

detected/present at the specified

node

0x86

COMMAND INACTIVE

CONTROLLER ID

A Controller ID (Node ID)

specified in the command is

currently inactive.

0x87

SUBNET DEVICE

SELECT FAILED

Internal Subnet Error – the

specified Subnet device failed.

0x88

SUBNET DEVICE

FAILED TO

ACKNOWLEDGE

Internal Subnet Error - the

specified Subnet device failed to

respond to the Gateway’s polling.

0x89

SUBNET RESPONSE

MALFORMED

Internal Subnet Error – a

controller returned a malformed

response.

Page 43

COMMAND PROTOCOL

35

4

Error Code Error Description

0x8A

SUBNET RESPONSE

TIMEOUT

Internal Subnet Error – a

controller was unable to generate

a response before timeout was

reached.

0x8B

SUBNET RESPONSE

INVALID CHECKSUM

Internal Subnet Error – a

controller generated a response

that has an invalid checksum.

0x8C

SUBNET DEVICE

CONFLICT DETECTED

Internal Subnet Error – a Node

ID conflict has been detected

0x8D

BUFFER OVERFLOW Internal Gateway Error –

Gateway buffer limit was

exceeded

0x8E

FLASH FAILURE Internal Gateway Error –

Gateway flash memory failure

0x92

SUBNET16 ONLY

COMMAND

A Subnet16-only command was

issued when in MUX32 mode.

0x93

NODE MISMATCH

ERROR

The Node ID specified in the

command did not match the

Node to which the command was

sent.

0x94

CRC ERROR Cyclic Redundancy Check Error

0x95

PROTOCOL ERROR Internal Communications Error

Table 12: CBx Error Codes

4.9 CBX - ERROR RESPONSE EXAMPLE

Below is an example of a typical controller generated error response following a failed Read

Data Command. For this example, a “Tag not Found” error was generated.

Error Response Parameter MSB LSB

0x00 in MSB

Overall Length of Response in LSB (in words)

0x00

0x07

Error Flag in MSB

Error Information Byte in LSB

0xFF

0xFF

0x00 in MSB

Node ID Echo in LSB

0x00

0x01

Month and Day Timestamp: (March 19th) 0x03

0x13

Hour and Minute Timestamp: (9:30: AM) 0x09

0x1E

Seconds Timestamp in MSB (:03 seconds)

Number of Additional Bytes Retrieved in LSB

(0x01 for error responses)

0x03

0x01

Error Code in MSB: (0x07 = "Tag not Found")

0x00 in LSB

0x07 0x00

Table 13: CBx Error Response Example

Page 44

GWY-01-PBS-01

36

4

4.10 NOTIFICATION MESSAGES

Notification Messages are small host-bound informational packets of data that are issued

by the Gateway when a specified Notification Event (or series of events) occurs within the

Gateway or on the Subnet network. For example, the Gateway can be configured to send the

host a Notification Message when a controller is attached, or removed, or experiences a

problem.

The Gateway stores nine different Notification Messages internally (all of which are enabled

by default). A 16-bit value, called the Notification Mask, controls which Notification Events

trigger Notification Messages to the host. Bits 00 through 08 in the 16-bit Notification Mask

correspond to the nine possible Notification Messages. The remaining 7 bits (bits 09-15) are

not implemented at this time (default value is zero for each bit).

Notification Messages are enabled by changing the associated bit from zero to one within the

Notification Mask. A bit is either set to “0” (OFF – disabled) or “1” (ON – enabled). When a bit

is turned ON, the related Notification Message will be enabled. The next time the enabled

Notification Event occurs, the corresponding Notification Message will be generated and

immediately delivered to the host.

When a Notification Event occurs it generates a Notification Message which is written to the

Host. Notification Messages include a one-byte value indicating which of the nine possible

Notification Events occurred. Notification Messages also contain a one-byte value that

identifies the affected Node ID.

For Notification Messages, a handshaking scheme of enabling and clearing a specific bit in

the Notification Mask is implemented (as previously explained).

To enable all nine Notification Messages, the 2-byte Notification Mask would read:

0x01FF.

16-BIT NOTIFICATION MASK

Bits

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Value

[0] [0] [0] [0] [0] [0] [0]

[1] [1] [1] [1] [1] [1] [1] [1] [1]

Page 45

COMMAND PROTOCOL

37

4

4.10.1 Notification Message Table

The following table contains a listing of the nine possible Notification Messages.

Bit Notification Message Event Description

0

CONTROLLER IS HEALTHY Sent whenever the status of a controller changes

to ‘Healthy’

1

CONTROLLER HAS

PROBLEM

Sent whenever a controller is marked ‘Has

Problem’

2

CONTROLLER STOPPED

RESPONDING

Sent whenever a controller is marked ‘Stopped

Responding’

3

CONTROLLER DEACTIVATED Sent whenever a controller is deactivated (is

marked ‘Inactive’)

4

CONTROLLER MISSED POLL Sent whenever a controller misses a poll

5

CONTROLLER ADDRESS

CONFLICT