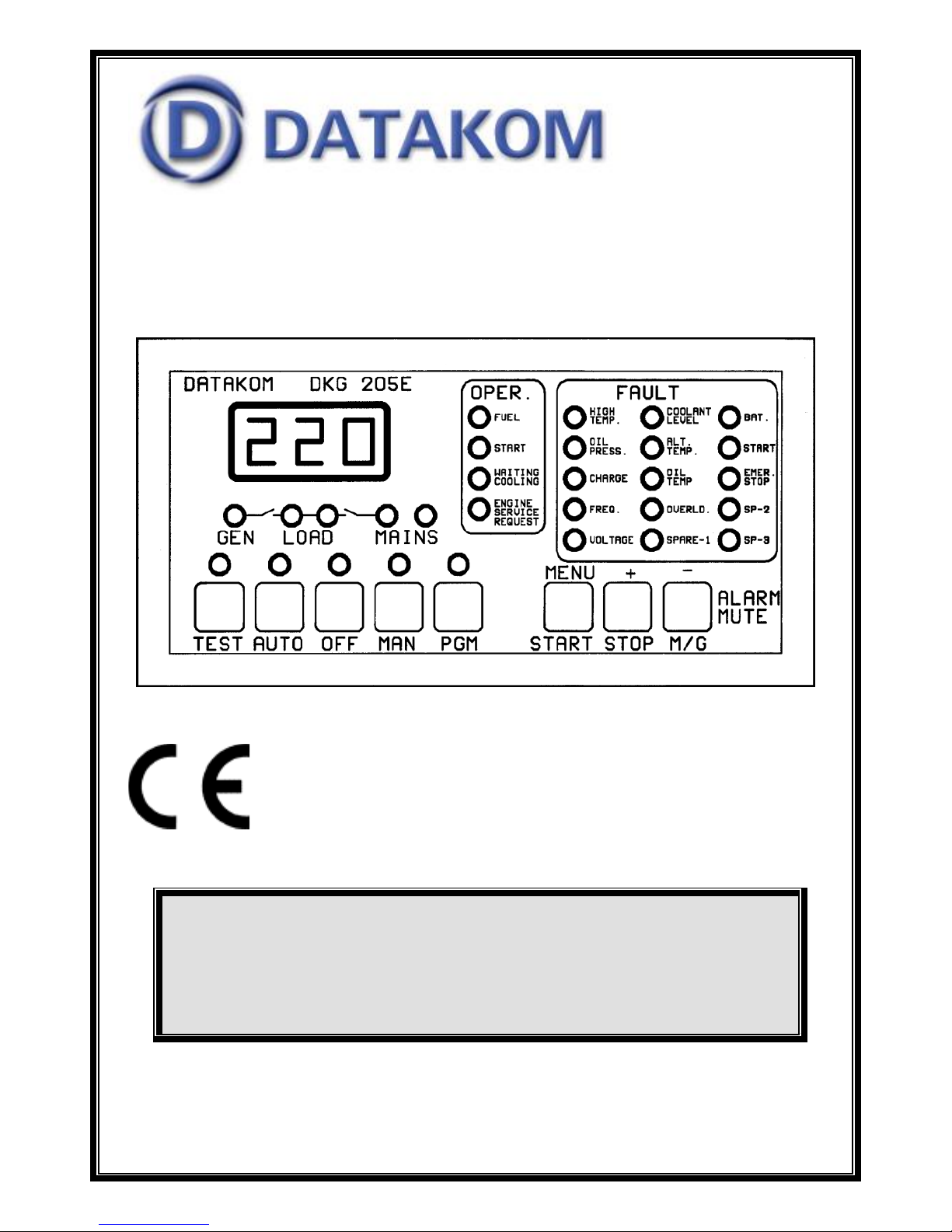

DKG-205 AUTOMATIC

MAINS FAILURE UNIT

TABLE OF CONTENTS

Section

1. PROGRAMMING SUMMARY

2. INSTALLATION

2.1. Introduction to the Control Panel

2.2. Mounting the Unit

2.3. Wiring the Unit

2.4. Inputs and Outputs

2.5. Digital display

2.6. Led displays

2.7. Periodic maintenance request display

2.8. Alarms

2.9. Modes of Operation

3. MAINTENANCE

4. TROUBLESHOOTING

5. PROGRAMMING

6. CALIBRATION

7. TECHNICAL SPECIFICATIONS

8. DECLARATION OF CONFORMITY

9. CONNECTION DIAGRAM

- 3 -

1. PROGRAMMING SUMMARY

To enter the program mode, press the PGM button. The display shows (Pr)

when program mode is selected.

PGM

NUMBER

PROGRAM OPTION

UNIT

FACT

SET

MIN.

VAL.

MAX.

VAL.

P01

Mains Voltage Lower Limit

Volt

170

30

250

P02

Mains Voltage Upper Limit

Volt

270

100

400

P03

Generator Voltage Lower Limit

Volt

180

30

250

P04

Generator Voltage Upper Limit

Volt

270

100

400

P05

Frequency Lower Limit

Hz.

45

10

60

P06

Frequency Upper Limit

Hz.

57

50

100

P07

Frequency Delay Timer

Sec.

3 0 15

P08

DC Supply Upper Limit

Volts

33.0

12.0

33.0

P09

Number of Start Attempts

- 3 1 6 P10

Wait before Start Timer

Sec.

3 0 240

P11

Wait between Starts Timer

Sec.

10 1 30

P12

Start Timer

Sec.

10 2 15

P13

Stop Timer

Sec.

0 0 60

P14

Mains Waiting Timer

Min.

0.5

0

15

P15

Cooling Timer

Min.

1.0

0

15

P16

Mains Contactor Timer

Sec.

1 0 15

P17

Generator Contactor Timer

Sec.

4 0 15

P18

Relay Configuration

- 0 0

7

P19

Maintenance Period (engine

hours)

hours

0 0 750

P20

Maintenance Period (duration)

months

0 0 15

- 4 -

2. INSTALLATION

2.1 Introduction to the Control Panel

The control panel is designed to provide user friendliness for both the installer

and the user. Programming is usually unnecessary, as the factory settings

have been carefully selected to fit most applications. However programmable

parameters allow the complete control over the generating set. Programmed

parameters are stored in a Non Volatile Memory and thus all information is

retained even in the event of complete loss of power.

2.2 Mounting the Unit

The unit is designed for panel mounting. The user should not be able to

access parts of the unit other than the front panel.

Mount the unit on a flat, vertical surface. The unit fits into a standard panel

meter opening of 140x68 millimeters. Before mounting, remove the steel

spring from the unit, and then pass the unit through the mounting opening.

The unit will be maintained in its position by the steel spring.

2.3 Wiring the Unit

WARNING: THE UNIT IS NOT FUSED.

Use external fuses for

Mains phases: R-S-T

Generator phase: L1-L2-L3

Battery positive: BAT(+).

Install the fuses as nearly as possible to

the unit in a place easily accessible for the user.

The fuse rating should be 6 Amps.

WARNING: ELECTRICITY CAN KILL

ALWAYS disconnect the power BEFORE

connecting the unit.

- 5 -

1) ALWAYS remove the plug connectors when inserting

wires with a screwdriver.

2) ALWAYS refer to the National Wiring Regulations

when conducting installation.

3) An appropriate and readily accessible set of

disconnection devices (e.g. automatic fuses) MUST be

provided as part of the installation.

4) The disconnection device must NOT be fitted in a

flexible cord.

5) The building mains supply MUST incorporate

appropriate short-circuit backup protection (e.g. a fuse

or circuit breaker) of High Breaking Capacity (HBC, at

least 1500A).

6) Use cables of adequate current carrying capacity (at

least 0.75mm2) and temperature range.

2.4 Inputs and Outputs

SERIAL DATA CONNECTION: This connection is used to transfer data to the

PC via the serial adapter.

1- GENERATOR CONTACTOR: This output provides energy to the generator

contactor. If the generator phase voltage is outside of the programmed limits,

the generator contactor will be de-energized. In order to provide extra security,

normally closed contact of the mains contactor should be serially connected to

this output. Relay contact rating is 16A/250V-AC

2/3/4- L1/L2/L3: Connect the generator phases to these inputs. The generator

phase voltage upper and lower limits are programmable.

5- GENERATOR NEUTRAL: Neutral terminal for the generator phases.

6- MAINS NEUTRAL: Neutral terminal for the mains phases.

7/8/9- T-S-R: Connect the mains phases to these inputs. The mains voltages

upper and lower limits are programmable.

10- MAINS CONTACTOR: This output provides energy to the mains

contactor. If the voltage of at least one of the mains voltages is outside of the

programmed limits, the mains contactor will be de-energized. In order to

provide extra security, normally closed contact of the generator contactor

should be serially connected to this output. Relay contact rating is 16A/250VAC

11- AUXILIARY RELAY OUTPUT: This relay fulfills 4 different functions

following programming. Relay contact rating is 10A/28V-DC.

1) ALARM RELAY: If an alarm occurs, the relay will be activated. It will be

deactivated when the ALARM MUTE key is pressed.

- 6 -

2) STOP RELAY: The relay will operate during programmed period in order to

stop the engine (Activate to Stop)

3) PREHEAT RELAY: The relay will operate the programmed delay before the

cranking of the engine. It will be deactivated during cranking and reactivated

during the rest period between cranks. It will be deactivated when the engine

runs.

4) CHOKE RELAY: The relay will operate the programmed delay before the

cranking of the engine. It will be deactivated when the engine runs.

12- CRANK OUTPUT: Engine crank output. Relay automatically turns off

when the alternator voltage reaches 100 volts or the alternator frequency

reaches 10Hz.

Relay contact rating is 10A/28V-DC.

13- FUEL OUTPUT: This output is used on engines equipped with a fuel

solenoid. The unit activates this output before starting the engine and

deactivates it to stop it. By programming, this relay can also control 'Activate

to Stop’ type of engines.

Relay contact rating is 10A/28V-DC.

14- CHARGE INPUT: Connect the charging alternator’s lamp output to this

terminal. If the charging alternator fails when the engine is running, the related

alarm indicator will turn on and the alarm output will be activated. This alarm

will not prevent the normal operation of the generating set.

15/16- BAT(+) / BAT(-): The positive (+) and negative (-) terminals of the DC

Supply shall be connected to these terminals. Be careful for the polarization, in

case of polarity error the unit will not operate. The unit operates on both 12V

and 24V battery systems.

17- PROGRAM LOCK INPUT: This input is used to prevent unwanted

modification to programmed values. If this input is left open, program values

can be modified via the front panel buttons, but if this input is connected to DC

Supply (-) it will not possible to change the program values.

18- LOW COOLANT LEVEL SWITCH: Connect the cooling radiator liquid

level switch to this input. This switch shall be negative closing in case of low

liquid level. This input has delayed sampling feature to prevent false detection.

19- SPARE-3 ALARM INPUT: Connect the spare alarm switch to this input.

The switch shall be negative closing type.

20- SPARE-2 ALARM INPUT: Connect the spare alarm switch to this input.

The switch shall be negative closing type.

21- SPARE-1 ALARM INPUT: Connect the spare alarm switch to this input.

The switch shall be negative closing type.

22- HIGH TEMPERATURE SWITCH: Connect the high temperature switch to

this input. This switch shall be negative closing switch type.

23- LOW OIL PRESSURE SWITCH: Connect the low oil pressure switch to

this input. The switch should be negative closing in case of loss of oil

Loading...

Loading...