D-300 MK2 User Manual Firmware V-6.3

D-300 MK2

ADVANCED

GENSET

CONTROLLER

The D-300-MK2 is a next generation genset control unit

combining multi-functionality and wide communication

possibilities together with a reliable and low cost design.

The same controller provides AMF, ATS, Remote Start

and Engine Control functionalities.

The module comes ready for remote monitoring over

GSM or Ethernet with plug-in communication modules.

Various plug-in modules provide unlimited expansion

capabilities allowing to meet any special requirement.

The unit complies and mostly exceeds world’s tightest

safety, EMC, vibration and environmental standards for

the industrial category.

Software features are complete with easy firmware

upgrade process through USB port.

The Windows based PC software allows monitoring and

programming through USB, serial and GPRS.

The Rainbow Scada central monitoring service allows

monitoring and control of an unlimited number of

gensets from a single central location.

AMF unit

ATS unit

Remote start controller

Manual start controller

Engine controller

Waveform display of V & I

Harmonic analysis of V & I

CTs at genset or load side

• GSM Modem (2G-3G-4G) *

• Ethernet 100Mbps *

• Wi-Fi *

• RS-485 isolated (2400-57600baud) *

• RS-232 isolated (2400-57600baud) *

• USB Device

• J1939 CANBUS

• Web monitoring *

• Web programming *

• Central Monitoring through internet *

• SMS message sending *

• E-mail sending *

• PC software: Rainbow Plus

• Central monitoring *

• Modbus RTU through RS-485 *

• Modbus TCP/IP *

*Optional with plug-in module

3 phases 4 wires, star & delta

3 phases 3 wires, 3 CTs

3 phases 3 wires, 2 CTs

2 phases 3 wires

1 phase 2 wires

FUNCTIONALITIES

COMMUNICATIONS

TOPOLOGIES

DESCRIPTION

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 2 -

Any unauthorized use or copying of the contents or any part of this document is prohibited.

This applies in particular to trademarks, model denominations, part numbers and drawings.

This document describes minimum requirements and necessary steps for the successful installation of

the D-300 family units.

Follow carefully advices given in the document. These are often good practices for the installation of

genset control units which reduce future issues.

For all technical queries please contact Datakom at below e-mail address:

technical.support@datakom.com.tr

If additional information to this manual is required, please contact the manufacturer directly at below email address:

technical.support@datakom.com.tr

Please provide following information in order to get answers to any question:

- Device model name (see the back panel of the unit),

- Complete serial number (see the back panel of the unit),

- Firmware version (read from the display screen),

- Measuring-circuit voltage and power supply voltage,

- Precise description of the query.

FILENAME

DESCRIPTION

500-Rainbow Installation

Rainbow Plus Installation Guide

500-Rainbow Usage

Rainbow Plus Usage Guide

500-GSM Configuration

GSM Configuration Guide for D-series

300-Firmware Update

Firmware Update Guide for D-200 D-300 and D-500-LITE

500-MODBUS

Modbus Application Manual for D-series

500-Rainbow Scada Usage

Rainbow Scada Usage Guide

QUERRIES

RELATED DOCUMENTS

ABOUT THIS DOCUMENT

COPYRIGHT NOTICE

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 3 -

REVISION

DATE

AUTHOR

DESCRIPTION

01

30.07.2018

MH

First edition, firmware version 6.0

02

19.08.2019

MH

Firmware version 6.3

-Below features have been added:

Ethernet communication

Wi-Fi communication

RS-485 modbus communication

-J1939 ECU List has been revised

CAUTION: Potential risk of injury or death.

WARNING: Potential risk of malfunction or material damage.

ATTENTION: Useful hints for the understanding of device operation.

REVISION HISTORY

TERMINOLOGY

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 4 -

The D-xxx family units are available in various options and peripheral features. Please use below

information for ordering the correct version:

D300

-M2

-G

-T

-00

Screw type bracket

Stock Code=J10P01 (per unit)

Self Retaining type bracket

Stock Code=K16P01 (per unit)

Sealing Gasket

SPARE PARTS

ORDERING CODES

Family Code

PLUG-IN MODULE

M2: 2G-GSM Modem

M3: 3G-GSM Modem

M4: 4G-GSM Modem

W: WiFi module

E: Ethernet module

R4: RS-485 module

R2: RS-232 module

With Conformal

Coating

Variant

00: standard unit

01...99: customer

specific products

With Sealing

Gasket

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 5 -

▪ Electrical equipment should be installed only by qualified

specialist. No responsibility is assured by the manufacturer or

any of its subsidiaries for any consequences resulting from the

non-compliance to these instructions.

▪ Check the unit for cracks and damages due to transportation. Do

not install damaged equipment.

▪ Do not open the unit. There are no serviceable parts inside.

▪ Fuses must be connected to the power supply and phase voltage

inputs, in close proximity of the unit.

▪ Fuses must be of fast type (FF) with a maximum rating of 6A.

▪ Disconnect all power before working on equipment.

▪ When the unit is connected to the network do not touch

terminals.

▪ Short circuit terminals of unused current transformers.

▪ Any electrical parameter applied to the device must be in the

range specified in the user manual. Although the unit is designed

with a wide safety margin, over-range parameters may reduce

lifetime, alter operational precision or even damage the unit.

▪ Do not try to clean the device with solvent or the like. Only clean

with a dump cloth.

▪ Verify correct terminal connections before applying power.

▪ Only for front panel mounting.

SAFETY NOTICE

Failure to follow below instructions

Current Transformers must be used for current measurement.

No direct connection allowed.

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 6 -

1. INSTALLATION INSTRUCTIONS

2. MOUNTING

2.1 DIMENSIONS

2.2 SEALING, GASKET

2.3 ELECTRICAL INSTALLATION

3. TERMINAL DESCRIPTIONS

3.1. BATTERY VOLTAGE INPUT

3.2. AC VOLTAGE INPUTS

3.3. AC CURRENT INPUTS

3.4. DIGITAL INPUTS

3.5. ANALOG SENDER INPUTS AND SENDER GROUND

3.6. CHARGE INPUT TERMINAL

3.7. MAGNETIC PICKUP INPUT

3.8. MAINS CONTACTOR OUTPUT

3.9. GENERATOR CONTACTOR OUTPUT

3.10. DIGITAL OUTPUTS

3.11. INPUT/OUTPUT EXTENSION

3.12. RS-485 PORT (PLUG-IN MODULE)

3.13. J1939-CANBUS PORT

3.14. USB DEVICE PORT

3.15. GSM MODEM (PLUG-IN MODULE)

3.16. ETHERNET PORT (PLUG-IN MODULE)

3.17. WI-FI (PLUG-IN MODULE)

4. TOPOLOGIES

4.1. SELECTING THE TOPOLOGY

4.2. 3 PHASE, 4 WIRE, STAR

4.3. 3 PHASE, 3 WIRE, DELTA

4.4. 3 PHASE, 4 WIRE, DELTA

4.5. 3 PHASE, 3 WIRE, DELTA, 2 CT (L1-L2)

4.6. 3 PHASE, 3 WIRE, DELTA, 2 CT (L1-L3)

4.7. 2 PHASE, 3 WIRE, DELTA, 2 CTs (L1-L2)

4.8. 2 PHASE, 3 WIRE, DELTA, 2 CTs (L1-L3)

4.9. 1 PHASE, 2 WIRE

TABLE OF CONTENTS

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 7 -

5. FUNCTIONALITIES

5.1. CT LOCATION SELECTION

5.2. AMF FUNCTIONALITY

5.3. ATS FUNCTIONALITY

5.4. REMOTE START FUNCTIONALITY

5.5. ENGINE CONTROLLER FUNCTIONALITY

5.6. -

5.7. 400HZ OPERATION

6. CONNECTION DIAGRAMS

6.1. AMF FUNCTIONALITY, CTs AT LOAD SIDE

6.2. AMF FUNCTIONALITY, CTs AT ALTERNATOR SIDE

6.3. ATS FUNCTIONALITY

6.4. REMOTE START FUNCTIONALITY

6.5. ENGINE CONTROL FUNCTIONALITY

6.6. -

7. TERMINAL DESCRIPTION

8. TECHNICAL SPECIFICATIONS

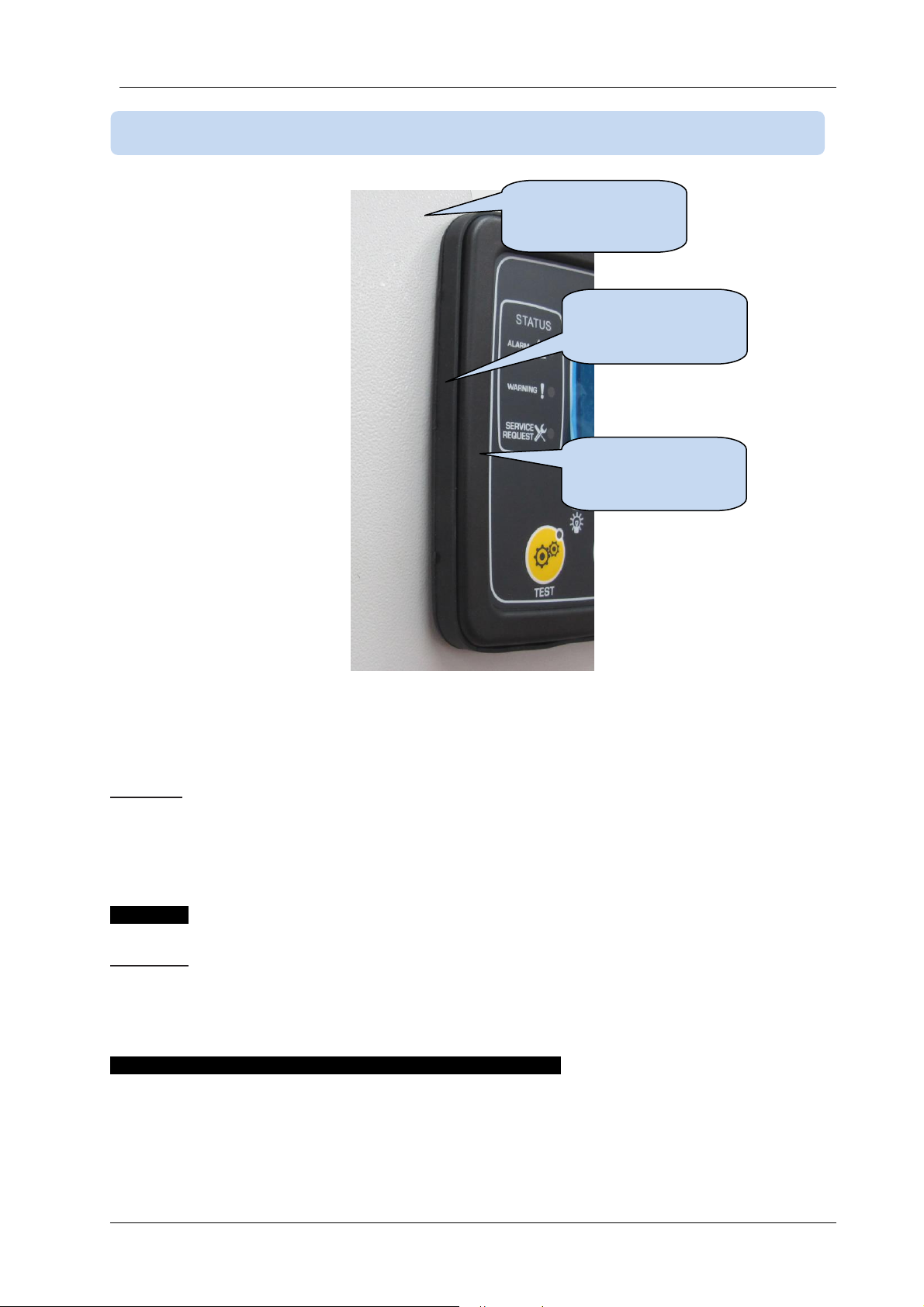

9. DESCRIPTION OF CONTROLS

9.1. FRONT PANEL FUNCTIONALITY

9.2. PUSHBUTTON FUNCTIONS

9.3. DISPLAY SCREEN ORGANIZATION

9.4. AUTOMATIC DISPLAY SCROLL

9.5. MEASURED PARAMETERS

9.6. LED LAMPS

10. WAVEFORM DISPLAY & HARMONIC ANALYSIS

11. DISPLAYING EVENT LOGS

12. STATISTICAL COUNTERS

12.1. FUEL FILLING COUNTER

12.2. FUEL CONSUMPTION MONITORING

13. OPERATION OF THE UNIT

13.1. QUICK START GUIDE

13.2. STOP MODE

13.3. AUTO MODE

13.4. RUN MODE, MANUAL CONTROL

13.5. TEST MODE

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 8 -

14. PROTECTIONS AND ALARMS

14.1. DISABLING ALL PROTECTIONS

14.2. SERVICE REQUEST ALARM

14.3. SHUTDOWN ALARMS

14.4. LOADDUMP ALARMS

14.5. WARNINGS

14.6. NON-VISUAL WARNINGS

15. PROGRAMMING

15.1. RESETTING TO FACTORY DEFAULTS

15.2. ENTERING THE PROGRAMMING MODE

15.3. NAVIGATING BETWEEN MENUS

15.4. MODIFYING PARAMETER VALUE

15.5. PROGRAMMING MODE EXIT

16. PROGRAM PARAMETER LIST

16.1. CONTROLLER CONFIGURATION GROUP

16.2. ELECTRICAL PARAMETERS GROUP

16.3. ENGINE PARAMETERS GROUP

16.4. ADJUST DATE AND TIME

16.5. WEEKLY OPERATION SCHEDULE

16.6. EXERCISER SCHEDULE

16.7. SENDER CONFIGURATION

16.8. DIGITAL INPUT CONFIGURATION

16.9. OUTPUT CONFIGURATION

16.10. SITE ID STRING

16.11. ENGINE SERIAL NUMBER

16.12. MODEM1-2/SMS1-2-3-4 TELEPHONE NUMBERS

16.13. GSM MODEM PARAMETERS

16.14. TCP/IP PARAMETERS

16.15. Wi-Fi PARAMETERS

17. ETHERNET CONFIGURATION

18. Wi-Fi CONFIGURATION

19. GSM CONFIGURATION

20. CRANK CUTTING

21. OVERCURRENT PROTECTION (IDMT)

22. MOTORIZED CIRCUIT BREAKER CONTROL

23. J1939 CANBUS ENGINE SUPPORT

24. SMS COMMANDS

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 9 -

25. SOFTWARE FEATURES

25.1. LOAD SHEDDING / DUMMY LOAD

25.2. LOAD ADD / SUBSTRACT

25.3. FIVE STEP LOAD MANAGEMENT

25.4. REMOTE START OPERATION

25.5. DISABLE AUTO START, SIMULATE MAINS

25.6. BATTERY CHARGING OPERATION, DELAYED SIMULATE MAINS

25.7. DUAL GENSET MUTUAL STANDBY OPERATION

25.8. MULTIPLE VOLTAGE AND FREQUENCY

25.9. SINGLE PHASE OPERATION

25.10. EXTERNAL CONTROL OF THE UNIT

25.11. AUTOMATIC EXERCISER

25.12. WEEKLY OPERATION SCHEDULER

25.13. ENGINE HEATING OPERATION

25.14. ENGİNE IDLE SPEED OPERATİON

25.15. ENGINE BLOCK HEATER

25.16. FUEL PUMP CONTROL

25.17. GAS ENGINE FUEL SOLENOID CONTROL

25.18. PRE-TRANSFER SIGNAL

25.19. CHARGING THE ENGINE BATTERY

25.20. EXTERNALLY CONTROLLED DIGITAL OUTPUTS

25.21. COMBAT MODE

25.22. RESETTING THE CONTROLLER

25.23. -

25.24. ZERO POWER AT REST

26. MODBUS COMMUNICATIONS

27.1. PARAMETERS REQUIRED FOR RS-485 MODBUS OPERATION

27.2. DATA FORMATS

27. DECLARATION OF CONFORMITY

28. MAINTENANCE

29. DISPOSAL OF THE UNIT

30. ROHS COMPLIANCE

31. TROUBLESHOOTING GUIDE

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 10 -

Before installation:

▪ Read the user manual carefully, determine the correct connection diagram.

▪ Remove all connectors and mounting brackets from the unit, then pass the unit through the

mounting opening.

▪ Put mounting brackets and tighten. Do not tighten too much, this can brake the enclosure.

▪ Make electrical connections with plugs removed from sockets, then place plugs to their sockets.

▪ Be sure that adequate cooling is provided.

▪ Be sure that the temperature of the environment will not exceed the maximum operating

temperature in any case.

Below conditions may damage the device:

▪ Incorrect connections.

▪ Incorrect power supply voltage.

▪ Voltage at measuring terminals beyond specified range.

▪ Voltage applied to digital inputs over specified range.

▪ Current at measuring terminals beyond specified range.

▪ Overload or short circuit at relay outputs

▪ Connecting or removing data terminals when the unit is powered-up.

▪ High voltage applied to communication ports.

▪ Ground potential differences at non-isolated communication ports.

▪ Excessive vibration, direct installation on vibrating parts.

Below conditions may cause abnormal operation:

▪ Power supply voltage below minimum acceptable level.

▪ Power supply frequency out of specified limits

▪ Phase order of voltage inputs not correct.

▪ Current transformers not matching related phases.

▪ Current transformer polarity incorrect.

▪ Missing grounding.

Current Transformers must be used for current

measurement.

No direct connection allowed.

1. INSTALLATION INSTRUCTIONS

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 11 -

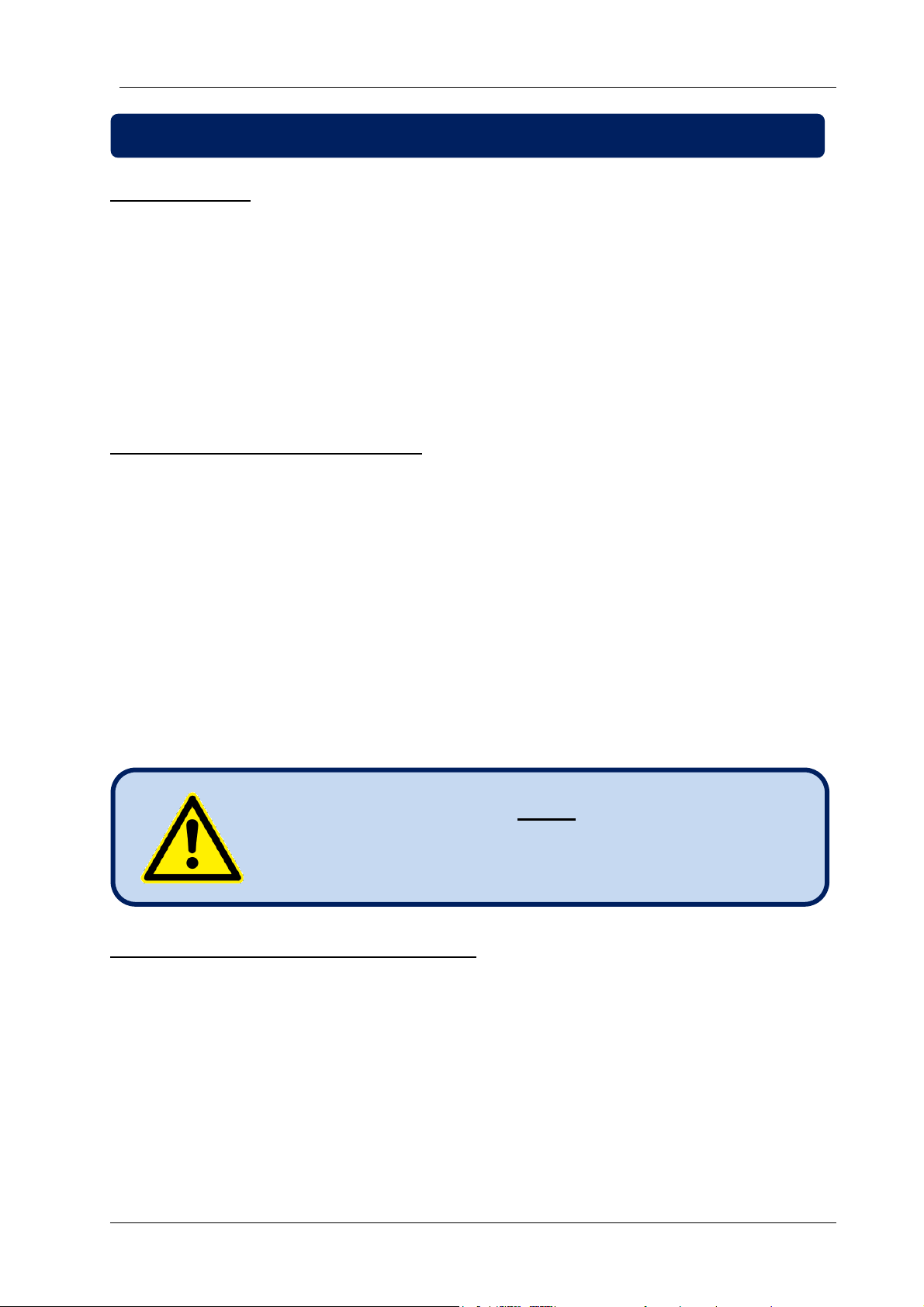

Dimensions: 180x140x46mm (7”x5.5”x1.9”)

Panel Cutout: 151x111mm minimum (6.0”x4.4”)

Weight: 300g (0.7 lb)

Mount the unit on a flat, vertical surface. Before mounting, remove the mounting brackets and connectors

from the unit, then pass the unit through the mounting opening.

The unit is designed for panel mounting. The user

should not be able to access parts of the unit other

than the front panel.

2.1. DIMENSIONS

2. MOUNTING

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 12 -

Place and tighten mounting brackets.

111mm

151mm

Panel Cutout

Required Panel Depth

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 13 -

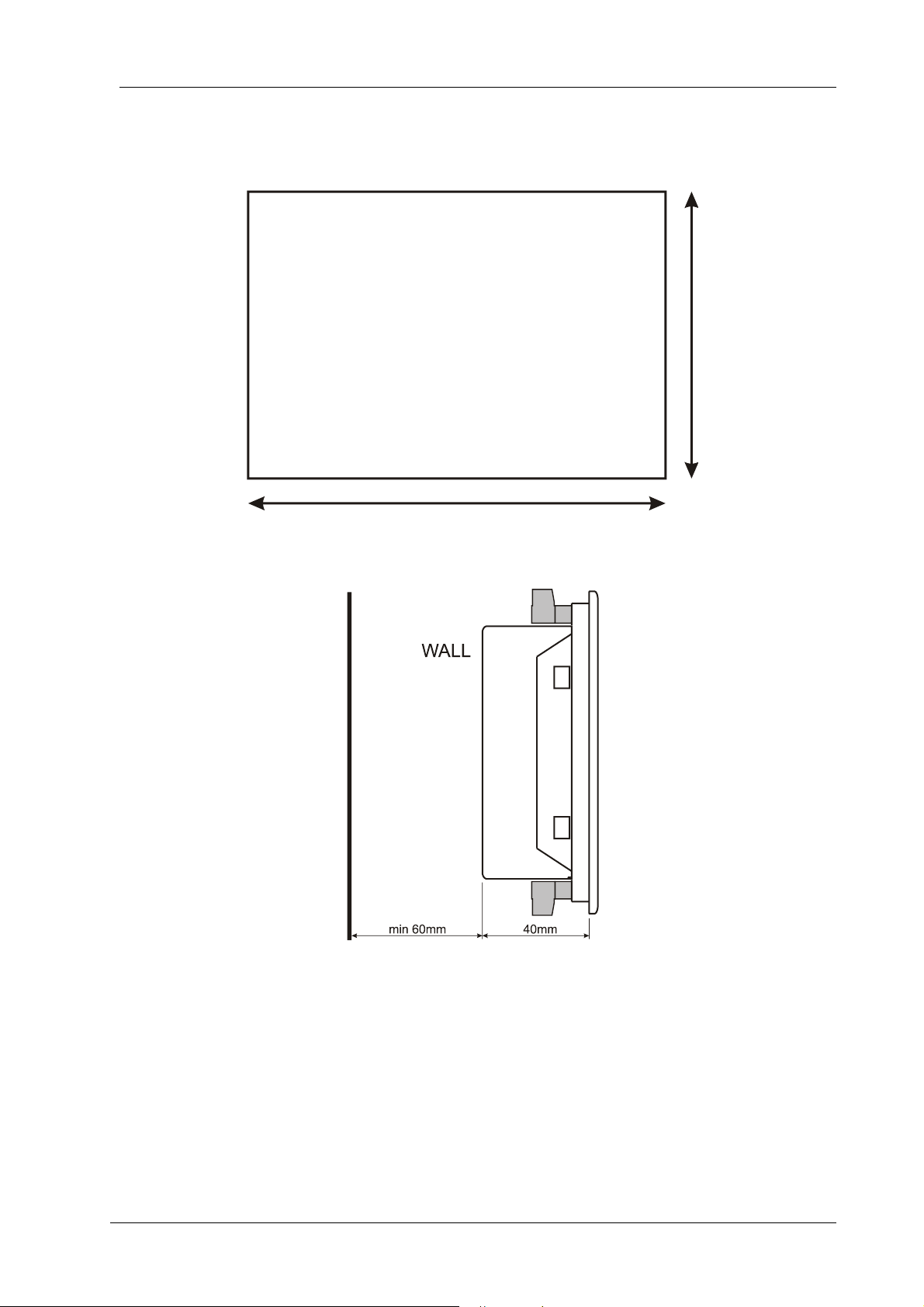

Two different types of brackets are provided:

Screw type bracket

Self retaining type bracket

Installation of screw type bracket

Installation of self retaining type bracket

Do not tighten too much, this may break the unit.

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 14 -

The rubber gasket provides a watertight means of mounting the module to the genset panel. Together

with the gasket, IEC 60529-IP65 protection can be reached from the front panel. A short definition of IP

protection levels is given below.

1st Digit Description of Protection Level

0 Not protected

1 Protected against solid foreign objects of 50 mm diameter and greater

2 Protected against solid foreign objects of 12,5 mm diameter and greater

3 Protected against solid foreign objects of 2,5 mm diameter and greater

4 Protected against solid foreign objects of 1,0 mm diameter and greater

5 Protected from the amount of dust that would interfere with normal operation

6 Dust tight

2nd Digit Description of Protection Level

0 Not protected

1 Protected against vertically falling water drops

2 Protected against vertically falling water drops when enclosure is tilted up to 15 °

3 Protected against water sprayed at an angle up to 60 ° on either side of the vertical

4 Protected against water splashed against the component from any direction

5 Protected against water projected in jets from any direction

6 Protected against water projected in powerful jets from any direction

7 Protected against temporary immersion in water

8 Protected against continuous immersion in water, or as specified by the user

2.2. SEALING, GASKET

Gasket

Panel

Module

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 15 -

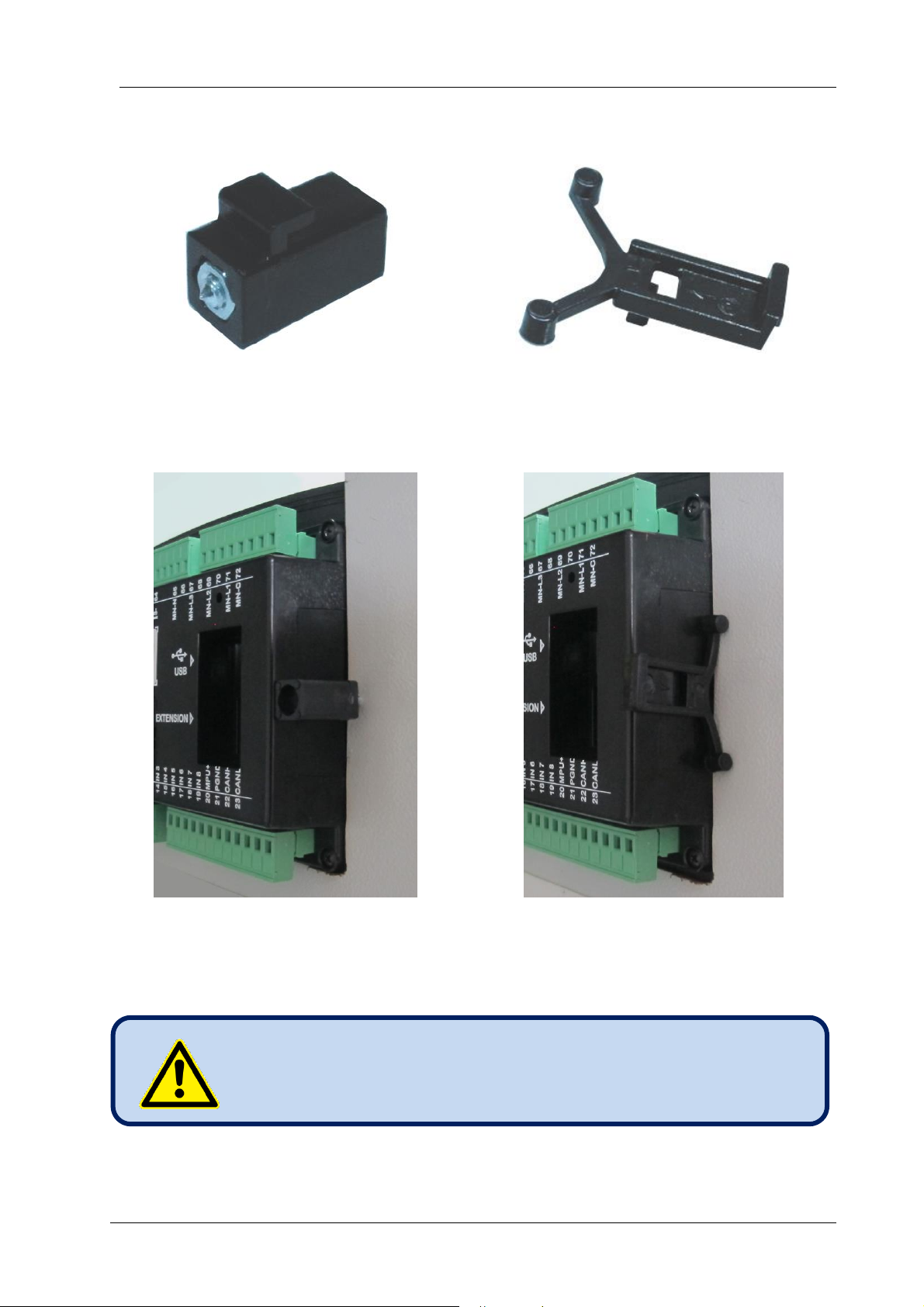

Although the unit is protected against electromagnetic disturbance, excessive

disturbance can affect the operation, measurement precision and data communication

quality.

▪ ALWAYS remove plug connectors when inserting wires with a screwdriver.

▪ Fuses must be connected to the power supply and phase voltage inputs, in

close proximity of the unit.

▪ Fuses must be of fast type (FF) with a maximum rating of 6A.

▪ Use cables of appropriate temperature range.

▪ Use adequate cable section, at least 0.75mm2 (AWG18).

▪ Follow national rules for electrical installation.

▪ Current transformers must have 1A or 5A output.

▪ For current transformer inputs, use at least 1.5mm2 section (AWG15) cable.

▪ The current transformer cable length should not exceed 1.5 meters. If

longer cable is used, increase the cable section proportionally.

For the correct operation of the exerciser and

weekly schedule programs, adjust the real time

clock of the unit through programming menu.

The engine body must be grounded. Otherwise faulty

voltage and frequency measurements may occur.

Current Transformers must be used for current

measurement.

No direct connection allowed.

Do not install the unit close to high electromagnetic

noise emitting devices like contactors, high current

busbars, switchmode power supplies and the like.

2.3. ELECTRICAL INSTALLATION

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 16 -

Supply voltage:

8 to 36VDC

Cranking dropouts:

Survives 0VDC during 100ms. The voltage before surge should be

8VDC minimum

Overvoltage protection:

Withstands 150VDC continuously.

Reverse voltage:

-150VDC continuous

Maximum operating

current:

500mA @ 12VDC. (All options included, digital outputs open.)

250mA @ 24VDC. (All options included, digital outputs open.)

Typical operating current:

250mA @ 12VDC. (all options passive, digital outputs open)

125mA @ 24VDC. (all options passive, digital outputs open)

Measurement range:

0 to 36VDC

Display resolution:

0.1VDC

Accuracy:

0.5% + 1 digit @ 24VDC

3.1. BATTERY VOLTAGE INPUT

3. TERMINAL DESCRIPTIONS

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 17 -

Measurement method:

True RMS

Sampling rate:

8000 Hz

Harmonic analysis:

up to 31th harmonic

Input voltage range:

14 to 300 VAC

Minimum voltage for

frequency detection:

15 VAC (Ph-N)

Supported topologies:

3 ph 4 wires star

3 ph 3 wires delta

3ph 4 wires delta

2ph 3 wires L1-L2

2ph 3 wires L1-L3

1 ph 2 wires

Measurement range:

0 to 330VAC ph-N (0 to 570VAC ph-ph)

Common mode offset:

max 100V between neutral and BAT-

Input impedance:

4.5M-ohms

Display resolution:

1VDC

Accuracy:

0.5% + 1 digit @ 230VAC ph-N (±2VAC ph-N)

0.5% + 1 digit @ 400VAC ph-ph (±3VAC ph-ph)

Frequency range:

DC to 650Hz

Frequency display

resolution:

0.1 Hz

Frequency accuracy:

0.2% + 1 digit (±0.1 Hz @ 50Hz)

3.2. AC VOLTAGE INPUTS

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 18 -

Measurement method:

True RMS

Sampling rate:

8000 Hz

Harmonic analysis:

up to 31th harmonic

Supported topologies:

3 ph 3 CTs

3 ph 2 CTs L1-L2

3 ph 2 CTs L1-L3

2 ph 2 CTs L1-L2

2 ph 2 CTs L1-L3

1 ph 1 CT

CT secondary rating:

5A or 1A

Measurement range:

5/5 to 5000/5A minimum

Input impedance:

15 mili-ohms

Burden:

0.375W

Maximum continuous

current:

6A

Measurement range:

0.1 to 7.5A

Common mode offset:

Max 30VAC between BAT- and any CT terminal.

Display resolution:

1A

Accuracy:

0.5% + 1 digit @ 5A (± 4.5A @ 5/500A full range)

SELECTING THE CT RATING AND CABLE SECTION:

The load on a CT should be kept

minimum in order to minimize phase shift

effect of the current transformer. Phase

shift in a CT will cause erroneous power

and power factor readings, although amp

readings are correct.

Datakom advises CT rating to be selected

following this table for the best

measurement accuracy.

SELECTING THE CT ACCURACY CLASS:

The CT accuracy class should be selected in accordance with the required measurement precision. The

accuracy class of the Datakom controller is 0.5%. Thus 0.5% class CTs are advised for the best result.

3.3. AC CURRENT INPUTS

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 19 -

CONNECTING CTs:

Be sure of connecting each CT to the related phase input with the correct polarity. Mixing CTs between

phases will cause faulty power and pf readings.

Many combinations of incorrect CTs connections are possible, so check both order of CTs and their

polarity. Reactive power measurement is affected by incorrect CTs connection in similar way as active

power measurement.

CORRECT CT CONNECTIONS

Let’s suppose that the genset is loaded with 100 kW on each phase. The load Power Factor (PF) is 1.

Measured values are as follows:

kW

kVAr

kVA

pf

Phase L1

100.0

0.0

100

1.00

Phase L2

100.0

0.0

100

1.00

Phase L3

100.0

0.0

100

1.00

Total

300.0

0.0

300

1.00

▪ Current Transformers must be used for current

measurement. No direct connection allowed.

▪ No common terminals or grounding allowed.

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 20 -

EFFECT OF POLARITY REVERSAL

The generator is still loaded with 100 kW On each phase. The load Power Factor (PF) is 1.

PF in phase L2 will show -1,00 due to reverse CT polarity. The result is that total generator power

displayed by the controller is 100 kW.

Measured values are as follows:

kW

kVAr

kVA

pf

Phase L1

100.0

0.0

100

1.00

Phase L2

-100.0

0.0

100

-1.00

Phase L3

100.0

0.0

100

1.00

Total

100.0

0.0

300

0.33

EFFECT OF PHASE SWAPPING

The generator is still loaded with 100 kW on each phase. The load Power Factor (PF) is 1.

PF in phases L2 and L3 will show -0,50 due to phase shift between voltages and currents which is

caused by CT swapping. The result is that total generator power displayed by controller is 0 kW.

Measured values are as follows:

kW

kVAr

kVA

pf

Phase L1

100.0

0.0

100

1.00

Phase L2

-50.0

86.6

100

-0.50

Phase L3

-50.0

-86.6

100

-0.50

Total

0.0

0.0

300

0.0

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 21 -

Type of inputs:

all configurable

Function selection:

from list

Contact type:

Normally open or normally closed (programmable)

Switching:

Battery negative or battery positive (programmable)

Structure:

47 k-ohms resistor to battery positive, 110k-ohms to battery negative.

Measurement:

Analog voltage measurement.

Open circuit voltage:

70% of battery voltage

Low level threshold:

35% of battery voltage

High level threshold:

85% of battery voltage

Maximum input voltage:

+100VDC with respect to battery negative

Minimum input voltage:

-70VDC with respect to battery negative

Noise filtering:

yes

Type of inputs:

all configurable, additional sender ground input

Function selection:

from list

Structure:

667 ohms resistor polarizing to +3.3VDC

Measurement:

Analog resistor measurement.

Open circuit voltage:

+3.3VDC

Short circuit current:

5mA

Measurement range:

0 to 5000 ohms.

Open circuit threshold:

5000 ohms.

Resolution:

1 ohms @ 300 ohms or lower

Accuracy:

2 %+1 ohm (±7 ohms @300 ohms)

Common mode voltage

range:

± 3VDC

Noise filtering:

yes

3.5. ANALOG SENDER INPUTS AND SENDER GROUND

3.4. DIGITAL INPUTS

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 22 -

The Charge terminal is both an input and output.

When the engine is ready to run, this terminal supplies the excitation current to the charge alternator.

The excitation circuit is equivalent to a 2W lamp.

The threshold voltages for warning and shutdown alarm are adjustable through program parameter.

Structure:

• battery voltage output through 100 ohm resistor

• voltage measurement input

Output current:

100mA @12VDC

200mA @24VDC

Voltage measurement

resolution:

0.1VDC

Voltage measurement

accuracy:

2% + 0.1V (0.9V @30VDC)

Charge Fail Warning

Threshold:

adjustable

Charge Fail Shutdown

Alarm Threshold:

adjustable

Open circuit voltage:

battery positive

Overvoltage protection:

> 500VDC continuous, with respect to battery negative

Reverse voltage

protection:

-30VDC with respect to battery negative

Structure:

Differential frequency measurement input

Input impedance:

50 k-ohms

Input voltage:

0.5VAC-RMS to 50VAC-RMS

Frequency range:

10Hz to 10 kHz

Resolution:

1 rpm

Accuracy:

0.2% + 1 rpm (±3rpm @1500 rpm)

Flywheel teeth range:

1 to 500

Do not share MPU with other devices.

3.6. CHARGE INPUT TERMINAL

3.7. MAGNETIC PICKUP INPUT

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 23 -

Structure:

Relay output, normally closed contact. One terminal is internally

connected to mains phase L1 input.

Max switching current:

16A @250VAC

Max switching voltage:

440VAC

Max switching power:

3000VA

Structure:

Relay output, normally open contact. One terminal is internally

connected to genset phase L1 input.

Max switching current:

16A @250VAC

Max switching voltage:

440VAC

Max switching power:

4000VA

Structure:

Negative pulling protected semiconductor output. One terminal is

connected to battery negative.

Function

programmable, selectable from list.

Max continuous current:

1.0 ADC

Max switching voltage:

33 VDC

Overvoltage protection:

40 VDC

Short circuit protection:

> 1.7 ADC

Reverse voltage

protection:

500 VDC

3.9. GENERATOR CONTACTOR OUTPUT

3.10. DIGITAL OUTPUTS

3.8. MAINS CONTACTOR OUTPUT

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 24 -

The module provides resources for 32 additional digital inputs

and 32 additional digital outputs.

Digital inputs can be extended using DKG-188 Digital Input

Extension modules, each one providing 8 inputs. Digital

inputs are programmable through the main controller. The

switching characteristic is not programmable and must be

battery negative. Any function can be assigned to digital

inputs.

Digital outputs can be extended using DKG-186 Fet

Extension modules, each one providing 8 outputs. Digital

outputs have the same electrical characteristics as on board

outputs. They have programmable functions through the

main controller. Any function can be assigned to any output.

Input and output extension modules are connected to the

main controller in a cascade structure, in any order. The

connection cable is provided with each extension module.

3.11. INPUT/OUTPUT EXTENSION

I/O Extension

Connector

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 25 -

Structure:

RS-485, isolated.

Connection:

3 wires (A-B-GND). Half duplex.

Baud rate:

2400-115200 bauds, selectable

Data type:

8 bit data, no parity, 1 bit stop

Termination:

External 120 ohms required

Isolation:

250VAC, 1 minute

Common mode voltage:

-0.5 VDC to +7VDC, internally clamped by transient suppressors.

Max distance:

1200m @ 9600 bauds (with 120 ohms balanced cable)

The RS-485 port features MODBUS-RTU protocol. Multiple modules (up to 128) can be paralleled on the

same RS-485 bus for data transfer to automation or building management systems.

The RS-485 port provides also a good solution for distant PC connection where RainbowPlus program

will enable programming, control and monitoring.

For more details about programming, control and

monitoring through RS-485 port please refer to

RainbowPlus user manual.

The Modbus register list is available at Datakom

technical support.

3.12. RS-485 PORT (PLUG-IN MODULE)

RS-485 Slot

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 26 -

Structure:

CANBUS, non isolated.

Connection:

3 wires (CANH-CANL-GND).

Data rate:

250 kbps

Termination:

Internal 120 ohms provided

Common mode voltage:

-0.5 VDC to +15 VDC, internally clamped by transient suppressors.

Max distance:

200m with 120 ohm balanced cable

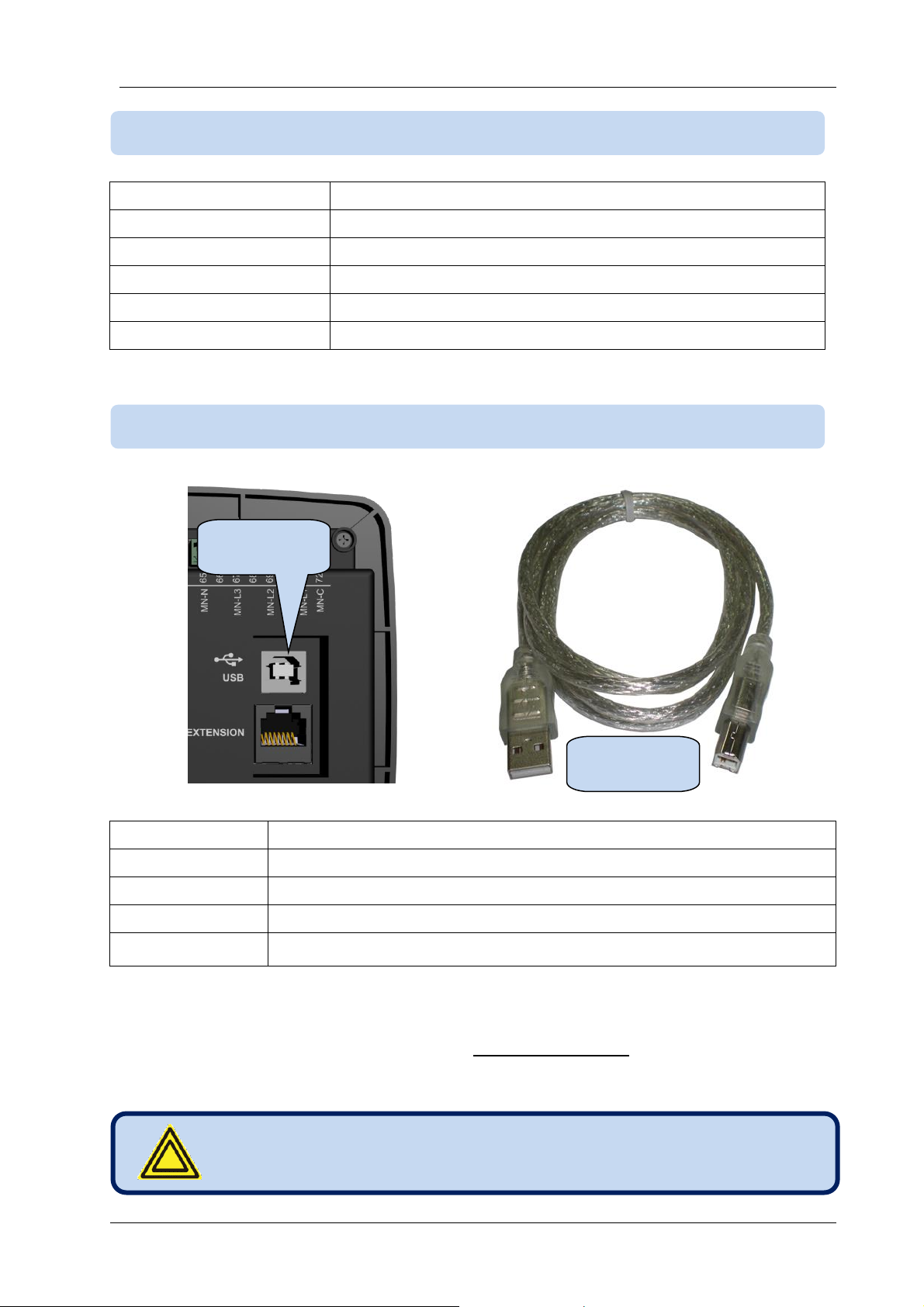

Description:

USB 2.0, not isolated, HID mode

Data rate:

Full Speed 1.5/12 Mbits/s, auto detecting

Connector:

USB-B (printer connector)

Cable length:

Max 6m

Functionality:

Modbus, FAT32 for firmware upgrade (boot loader mode only)

The USB-Device port is designed to connect the module to a PC. Using the RainbowPlus software,

programming, control of the genset and monitoring of measured parameters are achieved.

The RainbowPlus software can be downloaded from www.datakom.com.tr website.

The connector on the module is of USB-B type. Thus A to B type USB cable should be used. This is the

same cable used for USB printers.

The battery voltage must be connected.

3.14. USB DEVICE PORT

3.13. J1939-CANBUS PORT

USB A to B

Cable

USB Device

Connector

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 27 -

The optional GSM modem offers the advantage of being internally powered and is fully compatible with

the unit. It does not require any special setup.

The 1800/1900 MHz magnetic antenna together with its 2 meter cable is supplied with the internal

modem option. The antenna is intended to be placed outside of the genset panel for the best signal

reception.

The module requires a GPRS enabled SIM card for full functionality. Voice-only type SIM cards will

usually not function properly.

Please refer to GSM Modem Configuration Guide for more details.

LOCATION DETERMINATION VIA GSM

The unit determines automatically the geographical position through the GSM network. No settings are

necessary for this.

This feature is especially useful for the remote monitoring where the controller will appear automatically at

its geo-position or for mobile gensets.

Although the controller supports also GPS location determination for more precise positioning, the GSM

based location is free of charge, available everywhere, even where GPS signal is not available.

The location precision will depend of the GSM

system. In highly populated areas, the precision is

good (a few hundred meters), but rural areas may

lead to errors of a many kilometers.

3.15. GSM MODEM (PLUG-IN MODULE)

GSM Modem Slot

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 28 -

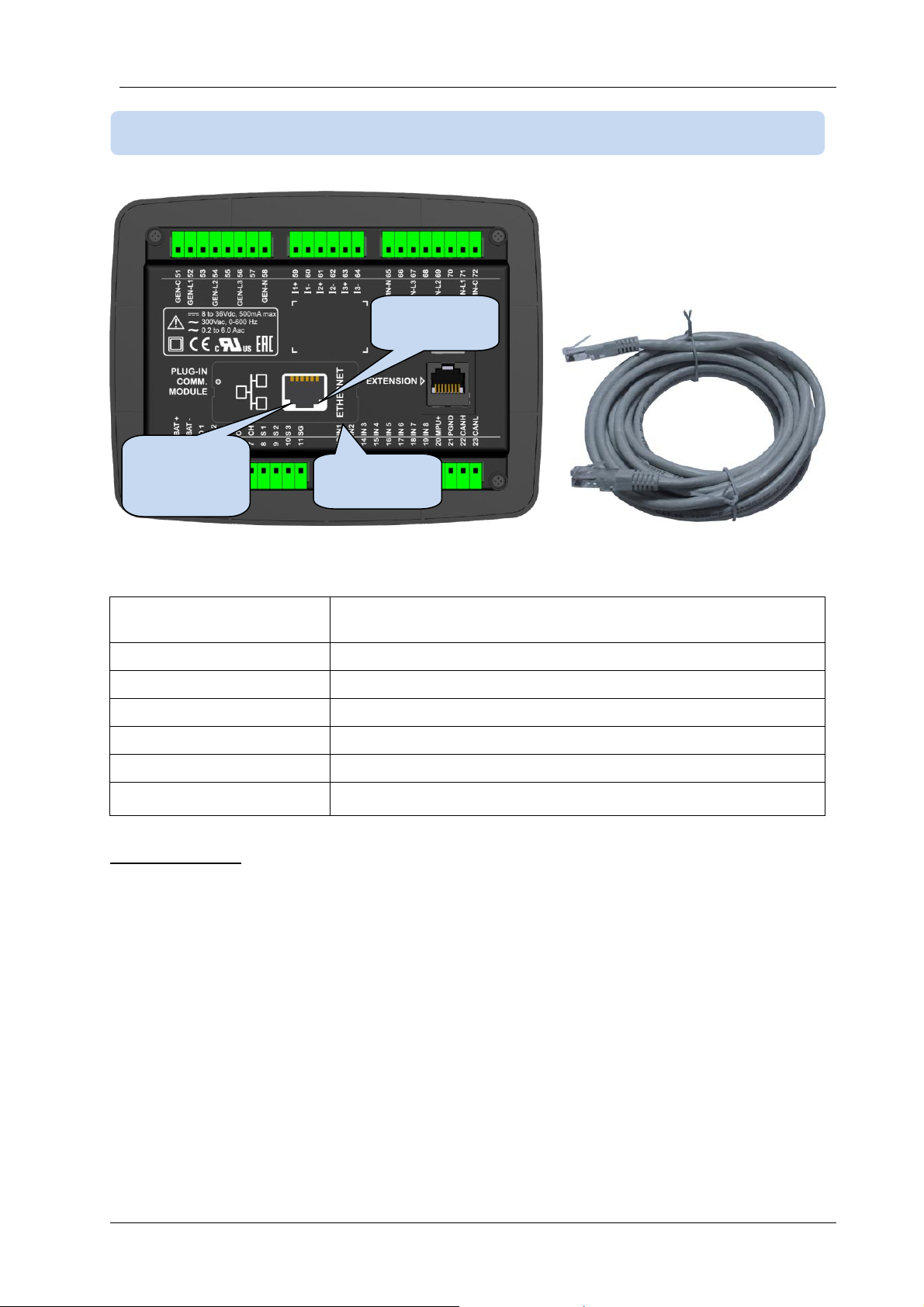

STANDARD ETHERNET CABLE

Description:

IEEE802.3 compliant, 100 Base-TX RJ45 ethernet port with

indicating leds

Data rate:

100 Mbps, auto detecting

Connector:

RJ45

Cable type:

CAT5 or CAT6

Isolation:

1500 VAC, 1 minute

Max distance:

100m with CAT5 or CAT6 cable

Functionality:

Web Client, E-mail, Modbus TCP_IP

LED FUNCTIONS:

GREEN: This led turns on when the ethernet link is established (connector inserted)

YELLOW: This led blinks when data transfer occurs inwards or outwards. Periodic blinking will witness

data flow.

3.16. ETHERNET PORT (PLUG-IN MODULE)

Ethernet

Slot

Link

Established

led

Data Flow

led

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 29 -

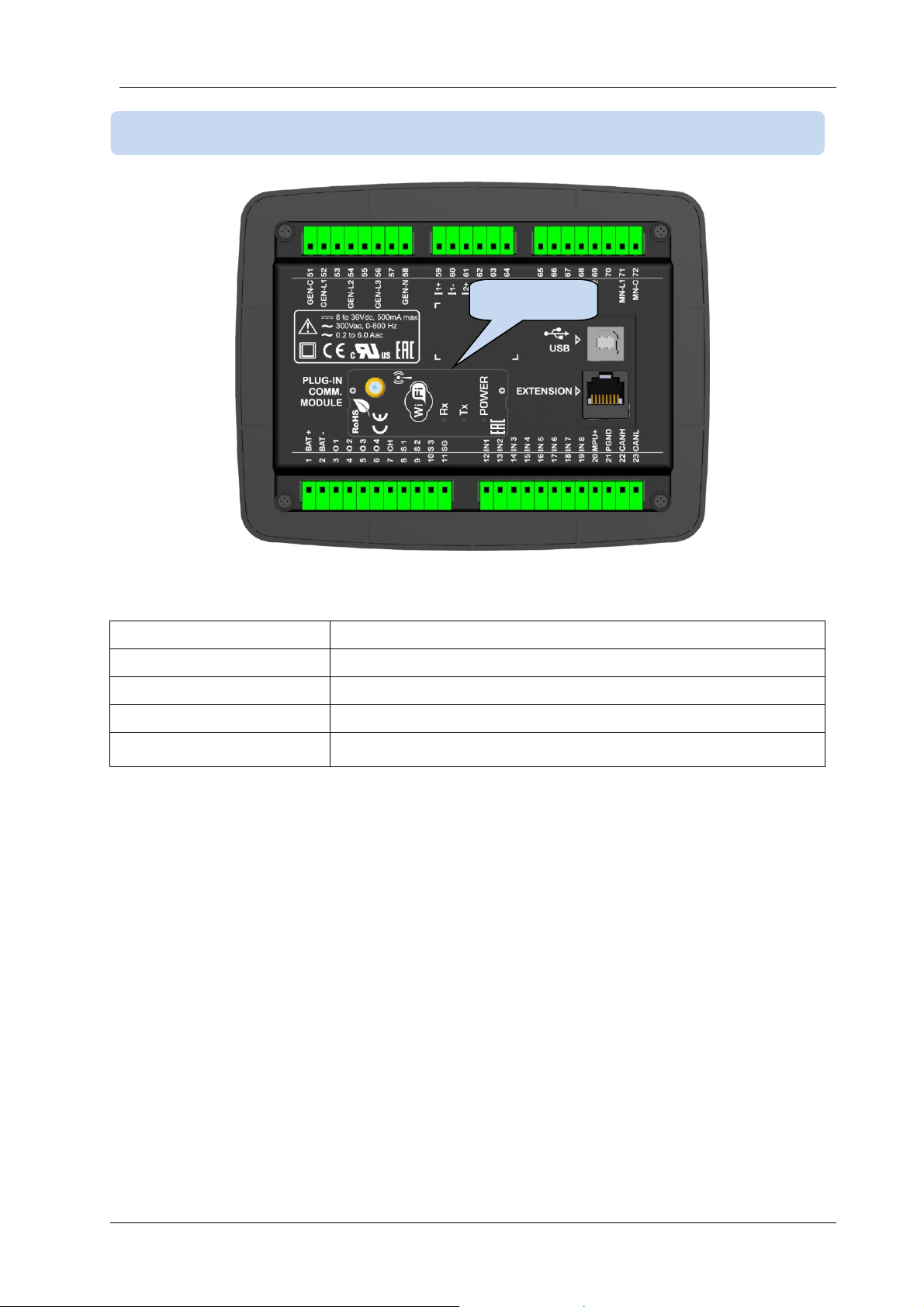

Wi-Fi protocols:

802.11 b/g/n

Frequency range:

2.4 GHz ~ 2.5 GHz (2400M ~ 2483.5M)

Network Protocols:

IPv4, TCP/UDP

Security:

WPA/WPA2

Functionality:

Web Client, E-mail, Modbus TCP_IP

3.17. Wi-Fi (PLUG-IN MODULE)

Wi-Fi Slot

D-300 MK2 User Manual Firmware V-6.3

L052D01-EN - 30 -

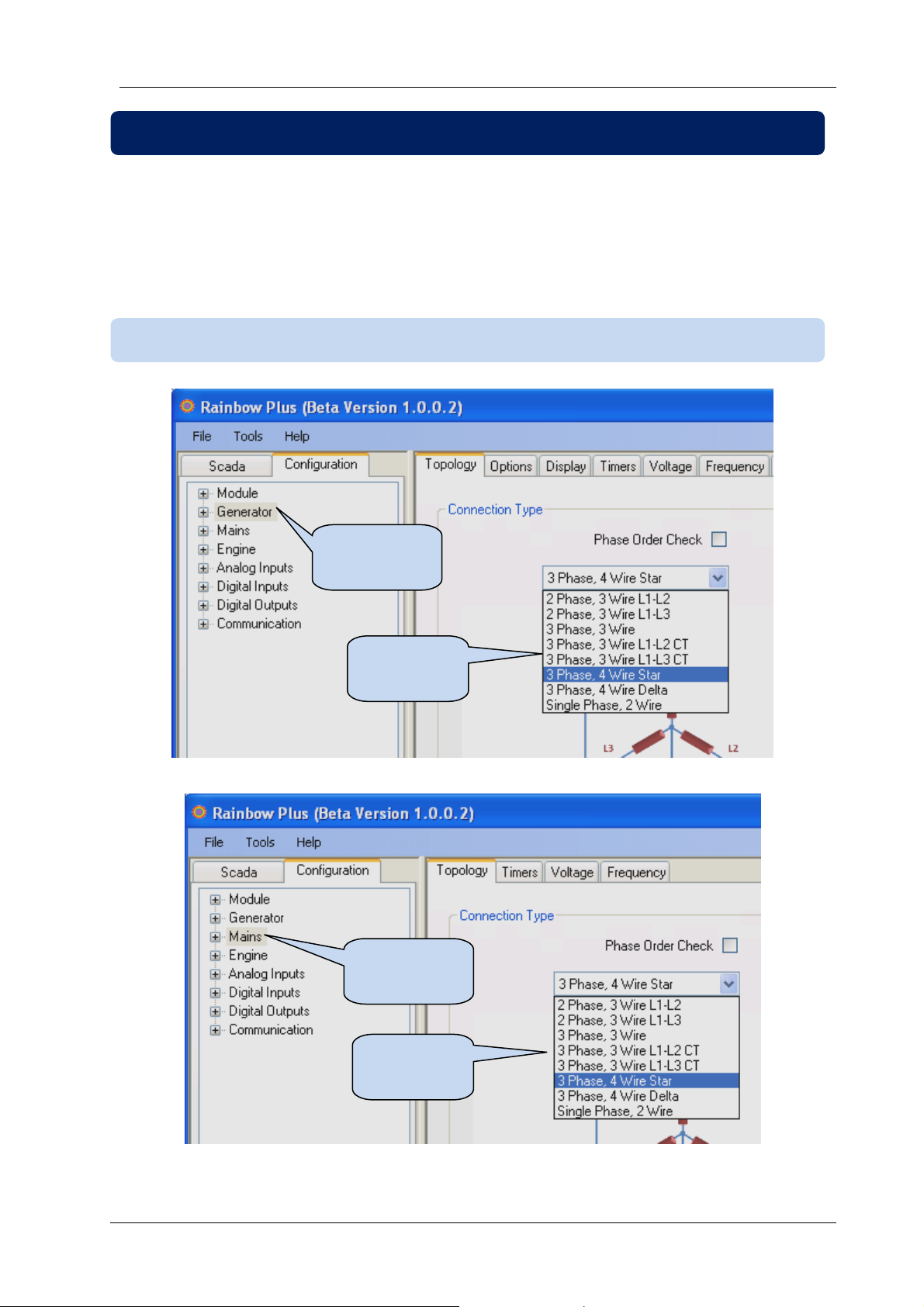

Various topologies are selectable through program parameter.

The topology is independently selectable for both genset and mains sections.

In following drawings the connections are shown for the alternator. Current transformers are supposed

connected to the alternator side.

Similar topologies re available for the mains side as well.

4.1. SELECTING THE TOPOLOGY

4. TOPOLOGIES

Generator

Parameters

Topology

Selection

Topology

Selection

Mains

Parameters

Loading...

Loading...