Page 1

Customer Documentation

Installing and Operating the

Cartridge Tape Drive:

Models 6675, 6676, 6677, and 6756

Copyright Data General Corporation, 1992

All Rights Reserved

Printed in the United States of America

Rev. 02, May 1992

Ordering No. 014–001953

014–001953–02

Page 2

Notice

DATA GENERAL CORPORATION (DGC) HAS PREPARED THIS DOCUMENT FOR USE BY DGC PERSONNEL,

CUSTOMERS, AND PROSPECTIVE CUSTOMERS. THE INFORMATION CONTAINED HEREIN SHALL NOT BE

REPRODUCED IN WHOLE OR IN PART WITHOUT DGC’S PRIOR WRITTEN APPROVAL.

DGC reserves the right to make changes in specifications and other information contained in this document without prior

notice, and the reader should in all cases consult DGC to determine whether any such changes have been made.

THE TERMS AND CONDITIONS GOVERNING THE SALE OF DGC HARDWARE PRODUCTS AND THE

LICENSING OF DGC SOFTWARE CONSIST SOLELY OF THOSE SET FORTH IN THE WRITTEN CONTRACTS

BETWEEN DGC AND ITS CUSTOMERS. NO REPRESENTATION OR OTHER AFFIRMATION OF FACT

CONTAINED IN THIS DOCUMENT INCLUDING BUT NOT LIMITED TO ST ATEMENTS REGARDING CAP ACITY ,

RESPONSE–TIME PERFORMANCE, SUITABILITY FOR USE OR PERFORMANCE OF PRODUCTS DESCRIBED

HEREIN SHALL BE DEEMED TO BE A WARRANTY BY DGC FOR ANY PURPOSE, OR GIVE RISE TO ANY

LIABILITY OF DGC WHATSOEVER.

IN NO EVENT SHALL DGC BE LIABLE FOR ANY INCIDENTAL, INDIRECT, SPECIAL OR CONSEQUENTIAL

DAMAGES WHATSOEVER (INCLUDING BUT NOT LIMITED TO LOST PROFITS) ARISING OUT OF OR RELA TED

TO THIS DOCUMENT OR THE INFORMATION CONT AINED IN IT, EVEN IF DGC HAS BEEN ADVISED, KNEW OR

SHOULD HAVE KNOWN OF THE POSSIBILITY OF SUCH DAMAGES.

AV cold, AV Object Office, AV Office, AViiON, CEO, CLARiiON, DASHER, DATAPREP,

DESKTOP GENERA TION, DG/UX, ECLIPSE, ECLIPSE MV/4000 , ECLIPSE MV/6000, ECLIPSE MV/8000,

GENAP, INFOS, microNOVA, NOVA, OpenMAC, PRESENT, PROXI, SWAT , TRENDVIEW, and WALKABOUT

are U.S. registered trademarks of Data General Corporation; and AOSMAGIC, AOS/VSMAGIC, AROSE/PC,

ArrayGUIde, ArrayPlus, AV Image, AV Imagizer Toolkit, AV SysScope, BaseLink, BusiGEN, BusiPEN,

BusiTEXT , CEO Connection, CEO Connection/LAN, CEO Drawing Board, CEO DXA, CEO Light,

CEO MAILI, CEO Object Office, CEO PXA, CEO Wordview, CEOwrite, COBOL/SMART, COMPUCALC,

CSMAGIC, DATA GENERAL/One, DESKTOP/UX, DG/500, DG/AROSE, DGConnect, DG/DBUS,

DG/Fontstyles, DG/GATE, DG/GEO, DG/HEO, DG/L, DG/LIBRARY, DG/UX CLARiiON Manager,

DG/UX Cluster Manager, DG/UX Manager, DG/ViiSION, DG/XAP, DSO, ECLIPSE MV/1000,

ECLIPSE MV/1400, ECLIPSE MV/2000, ECLIPSE MV/2500, ECLIPSE MV/3200, ECLIPSE MV/3500,

ECLIPSE MV/3600, ECLIPSE MV/5000, ECLIPSE MV/5500, ECLIPSE MV/5600, ECLIPSE MV/7800,

ECLIPSE MV/9300, ECLIPSE MV/9500, ECLIPSE MV/9600, ECLIPSE MV/9800, ECLIPSE MV/10000,

ECLIPSE MV/15000, ECLIPSE MV/18000, ECLIPSE MV/20000, ECLIPSE MV/25000, ECLIPSE MV/30000,

ECLIPSE MV/35000, ECLIPSE MV/40000, ECLIPSE MV/60000, FORMA–TEXT, GATEKEEPER, GDC/1000,

GDC/2400, GuardWare, Intellibook, microECLIPSE, microMV , MV/UX, OpStar , PC Liaison, RASS, REV–UP ,

RomMaker, SLATE, SPARE MAIL, SUPPORT MANAGER, TEO, TEO/3D, TEO/Electronics, TURBO/4,

UNITE, and XODIAC are trademarks of Data General Corporation. AV/Alert and Common Sense Connection

are service marks of Data General Corporation.

Installing and Operating the Cartridge Tape Drive:

Models 6675, 6676, 6677, and 6756

014–001953–02

Revision History:

Original Release – March 1990

First Revision – August 1990

Second Revision – May 1992

This manual is an extensive revision of the original manual. Therefore, we have not used

change indicators.

Page 3

NOTE

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

WARNING

Changes or modifications to this unit not expressly approved by the party responsible for complicance could void the

user’s authority to operate the equipment.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation. T esting was done with shielded cables. Therefore, in order to comply

with the FCC regulations, you must use shielded cables with your installation.

This digital apparatus does not exceed the Class B limits for radio noise emissions from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’ émet pas de bruits radioélectriques dépassant les limites applicables aux appareils

numériques de la classe B prescrites dans le Règlement sur le brouillage radioélectrique édicté par le ministère des

Communications du Canada.

Dieses Gerät ist funkentstört nach VDE 0871 Grenzwertklasse B und entspricht den technischen Vorschriften der

DBP–V erfügung 1046/1984.

Page 4

Page 5

About This Document

This document explains how to install and operate the Models

drives. Before you begin, find the setting up, expanding, or

maintaining manual for the computer in which you will install the drive. If you are

installing the drive in a mass–storage subsystem, you need the computer manual

and also a copy of the mass–storage subsystem’s installation and maintaining

manual. During the installation procedure, you must refer to the drive–jumpering

rules and drive–mounting instructions contained in one or both of these manuals.

Occasionally, you may need to refer to the operating instructions for the Model

drive. We suggest that you place this drive

manual in the back of the binder that contains the manual for your computer.

Telephone Assistance

If you are unable to solve a problem using any manual you received with your

system, telephone support is available with your hardware warranty and with

Support Plus and Hotline Software Support service contracts. If you are within the

United States or Canada, contact the Data General Customer Support Center (CSC)

by calling 1–800–DG–HELPS. Lines are open from 8:00 a.m. to 5:00 p.m., your time,

Monday through Friday. The center will put you in touch with a member of

Data General’s telephone assistance staff who can answer your questions.

For telephone assistance outside the United States or Canada, ask your Data

General sales representative for the appropriate telephone number .

Avoiding Electrostatic Discharge (ESD)

Damage

The cover(s) and filler panel(s) installed on your equipment protect the electronic

circuits inside the equipment from electrostatic discharge (ESD) damage. However ,

when you remove these covers and filler panels to replace or install subassemblies,

you can inadvertently damage the sensitive electronic circuits in the equipment by

simply touching them. Electrostatic charge that has accumulated on your body

discharges through the circuits. If the air in the work area is very dry, running a

humidifier in the work area will help decrease the risk of ESD damage. You must

follow the procedures below to prevent damage to the equipment.

CAUTION: Read and understand the following instructions before you remove the

cover(s) or panel(s) from the equipment.

• Provide enough room to work on the equipment. Clear the work site of any

unnecessary materials or materials that naturally build up electrostatic charge,

such as foam packaging, foam cups, cellophane wrappers, and similar materials.

014–001953

v

Page 6

About This Document

• Do not remove replacement or upgrade subassemblies from their antistatic

packaging until the exact moment that you are ready to install them.

• Gather the tools, manuals, an ESD kit, and all other materials you will need

before you remove covers and panels from the equipment. Procedures for

removing subassemblies usually list required materials at the beginning. After

you remove a cover or panel, you should avoid moving away from the work site;

otherwise, you may build up an electrostatic charge.

• Use an ESD kit when handling circuit boards or when touching the electronic

circuits inside the equipment. If you don’t have an ESD kit, you can order one

from Data General. If an emergency arises and an ESD kit is not available,

follow the procedures in the “Emergency Procedures (without an ESD kit)”

section.

• Replace the cover(s) or panel(s) on the equipment as soon as possible so that the

electronic circuits are protected.

• If the equipment has an opening for an optional device (such as a mass–storage

drive), and the device is not installed, make sure a filler panel is installed in the

opening before connecting the equipment to the ac power outlet.

Emergency Procedures (without an ESD kit)

In an emergency when an ESD kit is not available, use the following procedures to

reduce the possibility of an electrostatic discharge by ensuring that your body and

the subassembly are at the same electrostatic potential.

CAUTION: These procedures are not a substitute for the use of an ESD kit. Follow

them only in the event of an emergency.

• Before touching any electronic circuits or boards inside the equipment, firmly

touch a bare (unpainted) surface of the equipment.

• Before removing any replacement or upgrade subassembly from its antistatic

bag, place one hand firmly on an unpainted surface of the chassis, and at the

same time, pick up the replacement or upgrade subassembly while it is still

sealed in the antistatic bag. Once you have done this, do not move around the

room or contact other furnishings, personnel, or surfaces until you have

installed and secured the subassembly in the equipment.

• Remove the subassembly from the antistatic bag, handling printed–circuit

boards by the edges. Avoid touching components and circuits on a

printed– circuit board.

• If you must move around the room or touch other surfaces before securing the

subassembly in the equipment, first place the subassembly back in the antistatic

bag. When you are ready again to install the subassembly repeat these

procedures.

• Order an ESD kit from Data General for the next time you need to add or

remove a cover or panel.

vi

014–001953

Page 7

Installing the Drive

This section explains how to install the Models 6675, 6676, 6677, and 6756

half–height 1/4–inch cartridge tape drives in a Data General computer or

mass–storage subsystem that uses the small computer system interface (SCSI).

Table 1 highlights the specifications for the cartridge tape drive and removable tape

cartridge. Refer to the information in this table as needed.

Table 1 Specifications for the Cartridge Tape Drive and Removable Tape

Cartridges

Cartridge Tape Drive

Interface SCSI-1

± 12Vdc(±5%) .50 A (maximum)

+5Vdc(±12%) .90 A (maximum)

Power Dissipation

± 12 V dc 15.0 W

+5Vdc 3.1W

Weight 1.36 kg (3 lbs)

Removable Tape Cartridge

Format

QIC-24

1

2

Capacity Tape Speed

60 Mbytes 90 ips

QIC-120 125 Mbytes 90 ips

QIC-150 150 Mbytes 90 ips

QIC-320 320 Mbytes 120 ips

QIC-525 525 Mbytes 120 ips

1

The actual format imposed on a blank tape depends on which size cartridge tape you use. When

you write to QIC–24 or QIC–150 tapes, a QIC–150 format is imposed. When you write to

QIC–320 or QIC–525 tapes, a QIC–525 format is imposed. If you want to use a QIC–320 tape to

transfer data from this stand–alone cartridge tape drive to a 150–Mbyte tape drive, you must

first write to the QIC–320 tape from the 150–Mbyte tape drive to impose the correct format.

2

Read only.

NOTE: The environmental specifications for the cartridge tape drive meet or exceed those of the

Data General computer or mass–storage subsystem in which you install this cartridge tape

drive. Refer to your Data General computer or mass–storage subsystem installation manual

for the environmental specifications.

Prerequisites

Make sure that the system in which you will install the drive meets the following

hardware and software requirements.

014–001953

1

Page 8

Installing the Drive

For AViiON Computer Systems

• DG/UX operating system, revision 4.30 or higher

• Data General preformatted, certified tape cartridges or other hardware

(low–level) preformatted brands whose reliability, certification, and quality equal

Data General’s. For the specifications of the tape cartridges, refer to Table 1.

NOTE: AViiON systems can boot only from media formatted with a fixed

length record size of 512 bytes. Data General preformatted tape

cartridges are formatted with a fixed record size of 512 bytes.

AViiON systems will not boot from QIC–320 or QIC–525 media

written to in either 1024 bytes (1 Kbyte) block size or in variable

block size media.

For ECLIPSE Computer Systems

• AOS/VS operating system, revision 7.67 or higher

or

AOS/VS II operating system, revision 2.0 or higher

• Revision 19 of the Peripheral Microcode Installer (PMI), which includes

diagnostic firmware revision 076–0667–0008

• Data General preformatted, certified tape cartridges or other hardware

(low–level) preformatted brands whose reliability, certification, and quality equal

Data General’s. For the specifications of the tape cartridges, refer to Table 1.

Once you determine that your system meets these requirements, go to the next

section to unpack and inspect your drive and cables, and when included, SCSI host

adapter PCB. If you have any questions about these requirements or restrictions,

contact Data General as described in the section “About This Document.”

Unpacking and Inspecting the Drive

Follow the next steps to make sure your drive arrived undamaged and without

missing parts.

1. Read the “A voiding Electrostatic Discharge (ESD) Damage” section in the front

of this document.

CAUTION: You can cause electrostatic discharge (ESD) damage to electronic

equipment by improper handling.

2. Remove and set aside the packing slip from the outside of the shipping carton.

CAUTION: Handle your drive gently; do not drop or jar it. Make sure you

have a firm grip on it before you lift it, and lift it with both hands.

3. Open the cartons one by one and remove the drive. As you do, carefully

inspect the drive or mass storage subsystem for any visible damage. If the

drive or mass storage subsystem is damaged, contact Data General as

described in the “Telephone Assistance” section in the front of this document.

2

014–001953

Page 9

Installing the Drive

CAUTION: Handle your drive or mass storage subsystem gently; do not drop

or jar it. Make sure you have a firm grip on it before you lift it,

and lift it with both hands.

4. Make sure that the model and part numbers on the packing slip match those

on your drive and cables. If you think you received the wrong drive or cables,

contact Data General as described in the “Telephone Assistance” section in the

front of this document.

5. Make sure that you have all necessary mounting brackets for the computer or

mass–storage subsystem in which you intend to install the drive. Refer to the

expanding or maintaining manual that came with your computer or

mass–storage subsystem. It contains information that you will need to install

the drive.

The drive has several features that you may need to select using jumpers. The next

section explains how to install or remove these jumpers.

Installing or Removing the Cartridge Tape

Drive’s Jumpers

This section explains how to select the SCSI ID number and other drive features by

installing or removing jumpers. Figure 1 shows the location and name of the five

jumpers on the cartridge tape drive. You may need to install or remove some of

these jumpers. Read the next sections to find out.

014–001953

3

Page 10

Installing the Drive

Parity

Select

012

TPWR

DC power

connector

SCSI

connector

TPWR Off Disable TPWR. Host supplys terminator power.

On Enable TPWR. Drive supplys terminator power.

Parity Off Disable parity checking

On Enable parity checking.

SEL0 Off On Off On Off On Off

SEL1 Off Off On On Off Off On

SEL2 Off Off Off Off On On On

Factory default jumper positions. Always read your computer setup,

installation, or maintenance manual. This manual will tell you what SCSI ID

number you need to set and it may require you to change one or more of the

other jumpers.

Figure 1 Factory Default Jumper Settings for the Multicapacity 1/4–Inch Cartridge Tape

Drive

Jumpers SEL0, SEL1, and SEL2

Jumpers SEL0, SEL1, and SEL2 in Figure 1 select the SCSI ID number for the

drive. SCSI ID 6 (jumper SEL 0 is off; SEL1 and SEL2 are on) is the factory default

setting. Each SCSI device connected to your computer must have a unique SCSI ID

number.

Refer to the installation or setup manual for your computer. This manual lists the

SCSI IDs for each category of drive that your computer supports (for example, disk,

diskette, or tape) and also provides you with the general rules for choosing a SCSI

ID number. Next, find the SCSI number in Figure 1 that you have chosen. Then, if

necessary, install or remove jumpers to select that SCSI ID.

4

014–001953

Page 11

Installing the Drive

Termpower (TPWR) and Parity Checking Jumpers

Refer to your installation or setup manual for your computer. If this manual

specifies a jumper setting different than the factory default setting shown in

Figure 1, use needlenose pliers to install or remove the jumper accordingly. If there

is no mention of the jumper’s function in these manuals, leave the jumper in the

factory default position.

Installing or Removing the Drive Terminator

Resistors

Figure 2 shows the three removable SCSI–bus terminator resistor packs on the

cartridge tape drive. You may need to remove these three terminator resistor packs.

Refer to the installation or setup manual for your AViiON or ECLIPSE computer

system or mass–storage subsystem. In most cases, you must remove these three

terminator resistor packs because AViiON and ECLIPSE computer systems and

mass–storage subsystems use an external SCSI bus terminator plug. If you need to

remove the resistor packs, use needlenose pliers, as shown in Figure 2. Save the

terminator resistor packs for possible future use. For easy storage, tape the

terminator resistor packs to the drive enclosure.

Viewed from top

and front of the

drive

Pin

identifying

mark

Figure 2 Installing or Removing a Terminator Resistor Pack from the Drive Board

014–001953

5

Page 12

Installing the Drive

Installing the Tape Drive and Connecting the

Cables

After you set the drive’s jumpers, install and cable the drive in your computer or

mass–storage subsystem. You can position the drive vertically with the load/eject

button at the top. If you mount the drive horizontally, always position the drive

with the eject button in the upper right corner, never with the eject button in the

lower left corner .

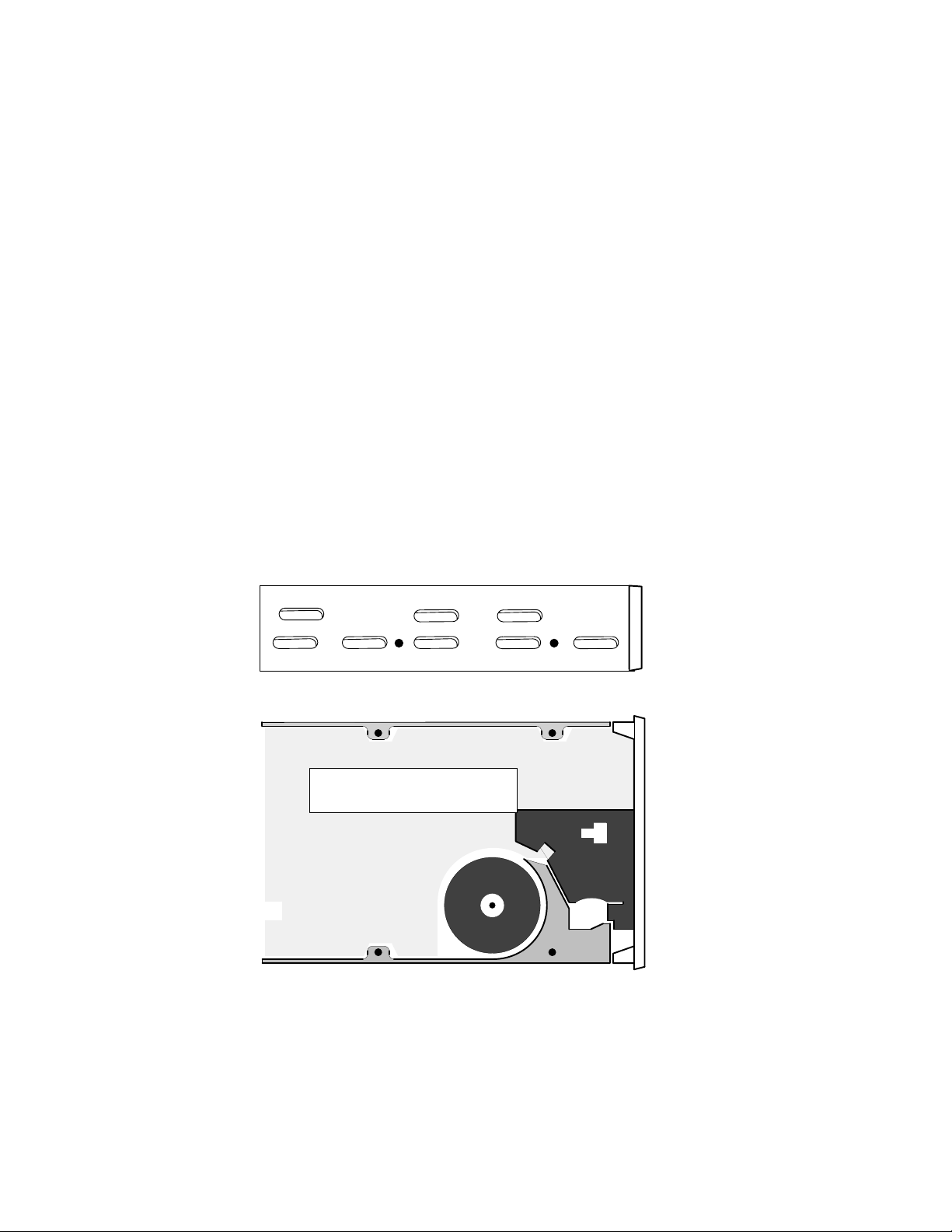

Figure 3 shows the four mounting–screw holes on the side and the bottom of the

drive. The mounting holes you use (side or bottom) and the orientation of the drive

(horizontal or vertical) depend on the computer or mass–storage subsystem in which

you will install the drive. Read the installing, maintaining, or expanding manual

for your computer or mass–storage subsystem. It shows you where to install a

half–height drive, and how to orient and attach it. Carefully follow all procedures

for installing a drive, and make sure you have turned off the computer or

mass–storage subsystem and unplugged its power cord before removing any covers.

Four mounting–screw holes

(two on each side)

Four mounting–screw holes

(on bottom)

Figure 3 Mounting–Screw Holes for Attaching the Tape Drive Inside the Computer or

Mass–Storage Subsystem

Once you have installed the drive, connect the power cable and SCSI bus cable to

the connectors shown in Figure 4. Make sure that you plug the SCSI bus cable into

the drive so that the red stripe on the cable lines up with Pin 1 on the connector.

(Most cables are keyed so that you cannot install them improperly.) You will find the

power cable and SCSI bus cable inside your computer or mass–storage subsystem.

6

014–001953

Page 13

Power cable

(provided by the computer

or mass–storage subsystem)

Installing the Drive

SCSI–bus cable

(provided by the computer

or mass–storage subsystem)

Red stripe = pin 1

Figure 4 Connecting the Cables

DG/UX Operating System Requirements

Once you have installed and cabled your cartridge tape drive and have closed the

computer or mass–storage subsystem chassis, refer to your operating system

manual. You will need to rebuild and reboot your DG/UX operating system.

014–001953

7

Page 14

Operating the Drive

This section describes how to write–protect and insert or remove a tape cartridge. It

also provides information on resolving simple problems that may occur during

operation.

Using and Write–Protecting a Cartridge Tape

The cartridge is available from Data General in four tape capacities: 60 Mbytes,

125 Mbytes, 150 Mbytes, and 320/525 Mbytes. Each cartridge tape comes in a

protective plastic case. Keep the cartridge in the case when it is not in use.

When storing cartridges, make sure the storage area is clean, dry and away from

direct sunlight, high humidity, and extreme temperatures– not below 5° C (41° F)

and not above 45° C (113° F). Do not place or store cartridges near magnets or

equipment that generate magnetic fields, such as telephones, power supplies,

printers, or display monitors. Before using a cartridge tape that was moved from a

warmer or colder location, for example a car , allow the cartridge to acclimate for

approximately the same amount of time that it was exposed to the warmer or colder

location. It is not necessary to acclimate the cartridge for more than 24 hours.

When handling cartridge tapes, never expose or touch the magnetic tape. Dirt or oil

from your fingers can make data on the tape unreadable by the drive. Never drop,

toss, or handle a cartridge carelessly. Operate a cartridge tape in the drive only

within the following ambient temperature and relative humidity ranges:

Temperature 5° C – 45° C

Relative Humidity 20%–80% (noncondensing) maximum

Do not read or write a cartridge tape when the ambient temperature is changing at

the rate of 6° C (108° F) /hour.

Your cartridge tape has a write–protect indicator. When you rotate the indicator

clockwise so that it points to the word SAFE (Figure 5), the system can read data

from the cartridge tape, but cannot write data or alter data on the cartridge tape.

When you rotate the write–protect indicator counterclockwise so that it points away

from the word SAFE, the system can read, write and alter cartridge tape data.

8

014–001953

Page 15

Coin or

similar tool

Write protect indicator

Operating the Drive

Write–enabled Write–protected

Figure 5 Write–Protecting 1/4–inch Cartridge Tape

Loading a Cartridge Tape

1. Turn on the power to the computer system or mass–storage subsystem, as

described in your computer or mass–storage subsystem installation or

expanding manual.

2. Remove the tape from its plastic protective case.

3. Rotate the protect switch on the tape cartridge (Figure 5) to the position that

you want.

4. Press the eject button shown in Figure 6 to open the drive door.

Multicapacity cartridge

tape drive, horizontally

mounted

Eject button

Eject button

Multicapacity cartridge

tape drive, vertically

mounted

014–001953

Drive Busy

LED

Drive Busy

LED

Figure 6 Eject Button and Tape Busy LED

9

Page 16

Operating the Drive

5. Hold the cartridge tape with the metal plate oriented as shown in Figure 7.

Gently push the cartridge tape into the drive opening; then push firmly all the

way into the drive. Close the drive door.

Cartridge tape drive,

vertically mounted

1/4–inch cartridge tape

Metal plate

Cartridge tape drive,

horizontally mounted

1/4–inch cartridge tape

Metal plate

Figure 7 Inserting a Cartridge Tape into the Tape Drive

As you push the cartridge into the drive’s cartridge–insertion slot, the drive

pulls in the cartridge and automatically positions it. The green drive–busy LED

(Figure 6) lights to indicate that the drive is checking the format of the

cartridge tape and is positioning the tape at the “Logical Beginning of Tape”

position. This check takes about 10 –12 seconds. If the drive and its LED do

not behave in this manner , refer to the section “Solving Operating Problems.”

NOTE: If the tape is blank, the drive automatically initializes (formats)

the tape during the first write operation. This procedure takes

about 30 additional seconds. When the drive finishes initializing

the tape, the green LED goes out. If you eject the tape before it is

10

014–001953

Page 17

Operating the Drive

initialized, the drive aborts this procedure, making it necessary to

initialize the tape again from the beginning the next time the

drive writes to this tape.

The green drive–busy LED lights when the drive reads or writes to the

cartridge tape. Never eject the cartridge tape when the drive–busy indicator is

lit. Once you have loaded the cartridge tape into the drive, refer to your

operating system manual for the commands that allow you to read or write the

cartridge tape.

Removing a Cartridge Tape

If you are using the AOS/VS or AOS/VS II operating system, follow the steps in the

next section to remove the cartridge tape. If you are using the DG/UX operating

system, follow the steps in the section “For DG/UX Operating System Users.”

For AOS/VS or AOS/VS II Operating System Users

1. If you have initialized the cartridge tape in your drive using the CLI command

INITIALIZE, release the logical disk using the CLI command RELEASE. The

manual Using the CLI (AOS/VS and AOS/VS II) and the installing manual

for your AOS/VS or AOS/VS II operating system describe these commands.

2. Press the cartridge eject button (Figure 6). When you do, the cartridge tape

will eject part way out of the opening of the drive.

3. Grasp the cartridge at the center, and pull it out of the drive.

4. Store the cartridge tape in its protective plastic case when you are not using it.

For DG/UX Operating System Users

1. Press the cartridge eject button shown in Figure 6. When you do, the tape

cartridge will slide part way out of the opening of the drive.

2. Grasp the cartridge at the center, and pull it out of the drive.

3. Store the cartridge tape in its protective packaging in a safe place.

Cleaning the Tape Drive Head

Dirt and dust can collect on the tape drive head and interfere with the transfer of

information or even destroy it. You must clean the tape path and heads routinely

after about 8 hours of operation or at least once a month, whichever occurs first.

Also, clean the tape path and head if a tested–and–checked tape cartridge

experiences slow read/write performance or read/write errors.

To clean the drive you must have the Data General Model 18933 Tape Cleaning Kit.

The kit contains a special cleaning cartridge, cleaning fluid, 25 sponge pads for the

cleaning cartridge, and a pair of tweezers. The following steps explain how to install

a cleaning cartridge and clean the drive. The section “Removing a Cleaning Pad

from the Cleaning Cartridge” describes how to remove the cleaning cartridge pad.

014–001953

11

Page 18

Operating the Drive

ÄÄÄ

ÄÄÄ

1. Power up the cartridge tape drive.

If there is a cleaning pad already installed in the cleaning cartridge ensure that

a clean surface of the pad faces out from the cartridge. If the side facing out is

dirty remove the pad following the steps in the section “Removing a Cleaning

Pad from the Cleaning Cartridge.”

CAUTION: Each cleaning pad can be used only once on each side. The special

cleaning tape picks up dirt and oxide particles as it cleans.

Running a dirty pad through the tape path will not clean it

effectively and may actually expose the rotary heads and path to

more dirt and wear.

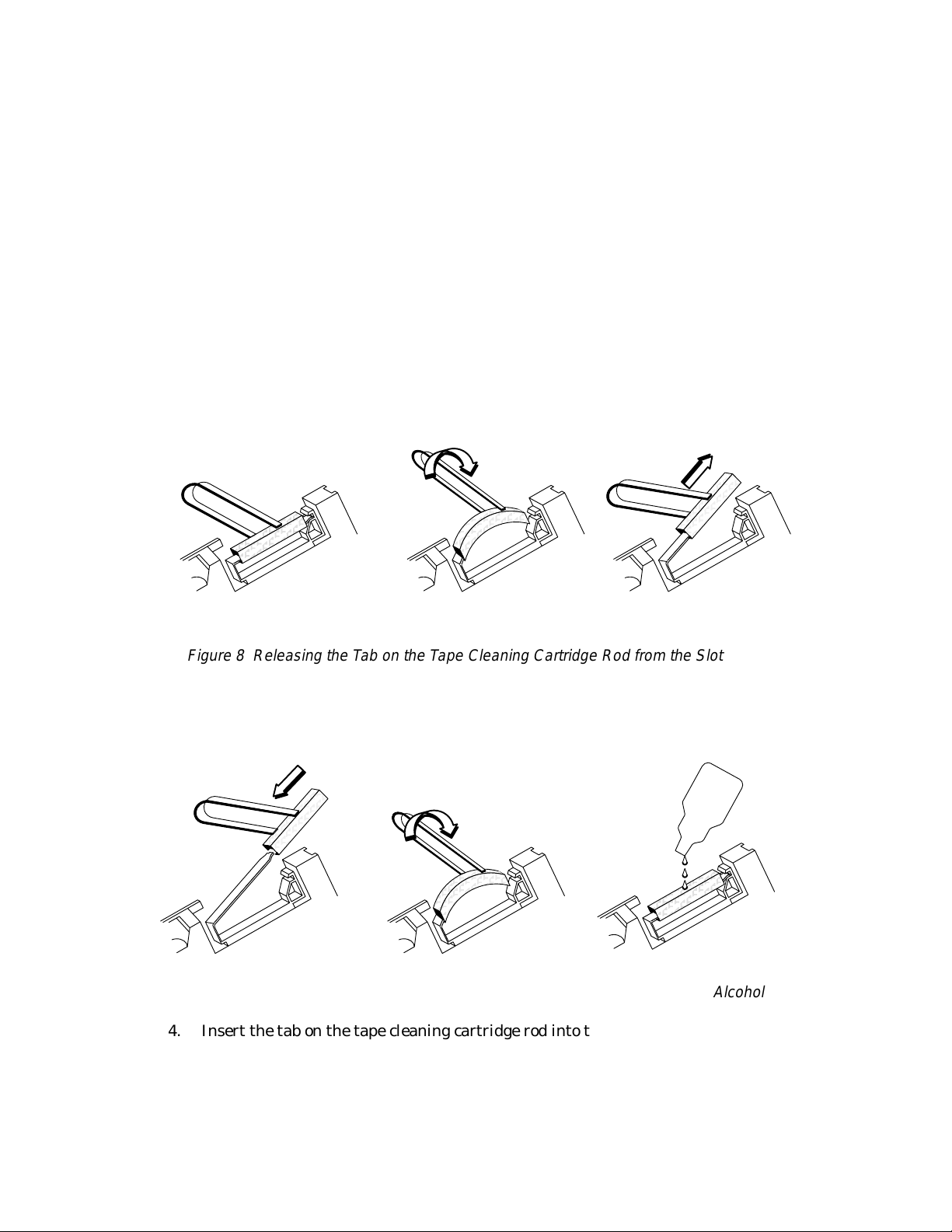

2. Release the tab on the tape cleaning cartridge rod from the slot in the tape

cleaning cartridge as shown in Figure 8.

Figure 8 Releasing the Tab on the Tape Cleaning Cartridge Rod from the Slot in the

Tape Cleaning Cartridge

3. Insert a pad with a clean surface facing away from the tape cleaning cartridge

as shown in Figure 9.

Figure 9 Inserting the Pad to the Cleaning Cartridge and Applying Isopropyl Alcohol

4. Insert the tab on the tape cleaning cartridge rod into the slot in the tape

cleaning cartridge as shown in Figure 9.

5. Moisten one side of the cleaning cartridge sponge pad with 12 drops of the

isopropyl alcohol as shown in Figure 9.

NOTE: Use only 91% isopropyl alcohol. Do not use rubbing alcohol.

12

014–001953

Page 19

Operating the Drive

6. Insert the cleaning cartridge in the drive as described in the section “Loading a

Cartridge T ape.” The cartridge tape drive senses the presence of the special

cleaning cartridge and begins the process of cleaning the tape path and rotary

heads. The cleaning process takes about 20 seconds.

7. Remove the cleaning cartridge from the drive as described in the section

“Removing a Cartridge Tape.”

8. Record the present date. By referring to this recorded date you will know when

the next monthly cleaning is required. A Data General cleaning cartridge

provides about 40 uses. Always have a new cleaning cartridge on hand.

9. Store the cleaning cartridge in its protective case in a convenient place for

future use. After you have used up the cleaning cartridge, discard it and

replace it with a new one.

Removing a Cleaning Pad from the Cleaning

Cartridge

1. Release the tab on the tape cleaning cartridge rod from the slot in the tape

cleaning cartridge as shown in Figure 10.

Figure 10 Removing the Pad from the Cleaning Cartridge

2. Remove the pad from the rod as shown in Figure 10. If the pad is used up on both

sides, discard it.

3. Install a new pad as described in the section “Installing a Cleaning Pad in the

Cleaning Cartridge.”

Solving Operating Problems

This section provides suggestions for solving common problems that you may

encounter. If you cannot resolve the problem yourself, contact Data General as

described in the section “About This Document.”

If the cartridge tape drive LED indicator blinks it does not indicate an operating

problem. The cartridge tape drive LED indicator should briefly blink as the

computer runs its self–test.

014–001953

13

Page 20

Operating the Drive

Cannot insert cartridge

• Make sure a tape cartridge is not already installed in the drive.

• You may have a tape drive failure. Contact Data General.

Cannot eject cartridge

• Make sure the computer or mass–storage subsystem’s power is on.

• If you initialized the tape cartridge, make sure you have released the tape

cartridge before attempting to eject the cartridge.

• You may have a tape drive failure. Contact Data General.

“Physical–unit failure” message

• You may have ejected the cartridge before releasing it. Reinsert the cartridge and

refer to the AOS/VS or AOS/VS II operating system manual for the procedure to

correct this condition.

• You may have a tape drive failure. Contact Data General.

“Hard write–protected” message

• You may have tried to write to a write–protected cartridge. Release or unmount

the cartridge, eject the tape cartridge, change the write–protection switch, and

reinsert the cartridge.

• You may have a tape drive failure. Contact Data General.

End of Document

14

014–001953

Page 21

Index

Within the index, a range of page numbers indicates the reference spans those

pages.

avoiding electrostatic discharge (ESD)

damage, v

cables, connecting, 6–7

cartridge tape drive

cleaning, 11–13

installation requirements, 1–2

installing, 6–7

setting jumpers, 3–5

specifications, 1

unpacking, 2–3

cartridge tapes

ejecting, 11

inserting, 9

specifications, 1

storing, 8

write–protecting, 8–9

connecting cables, 6–7

inserting cartridge tape, 9–11

inspecting the drive, 2–3

installing

cleaning pad in the cleaning

cartridge, 11–13

drive terminator resistors, 5

jumpers, 3–5

tape drive, 6–7

jumpers, installing and removing, 3–5

loading, cartridge tapes, 9–11

operating system requirements, 7

drive specifications, 1

drive terminator resistors, installing or

removing, 5

ejecting, cartridge tape, 11

electrostatic discharge (ESD) damage,

avoiding, v

hardware requirements

for AViiON computer systems, 2

for ECLIPSE computer systems, 2

014–001953

removing

cleaning pad from the cleaning

cartridge, 13

drive terminator resistors, 5

jumpers, 3–5

requirements

for installing, 1–2

operating system, 7

software requirements

for AViiON computer systems, 2

for ECLIPSE computer systems, 2

solving problems, telephone assistance,

v

specifications, 1

Index-1

Page 22

tape specifications, 1

troubleshooting

operation problems, 13–14

telephone assistance, v

unpacking the drive, 2–3

write–protecting, 8–9

Index-2

014–001953

Loading...

Loading...