Page 1

Datacom Systems Inc

Access Your Network

FVS-1044 Data Access Switch

TM

FVS-1080 Data Access Switch

May 2010

USER

© 2010 Datacom Systems Inc

guide

541-0114-U-B.00

Page 2

This page intentionally left blank

Page 3

Product Description

Datacom Systems Inc. Filtered VERSAstream™ Data Access Switches are

made to be adaptable. The Filtered Data Access Switch introduces line-rate

filtering that provides you with the ability to eliminate unwanted traffic from your

analysis tools or security sensors. With less data to work with through filtering,

network devices can run faster and more efficiently, which can reduce or

eliminate the possiblity of port oversubscription.

The Filtered VERSAstream™ product provides you with unprecedented

flexibility and filtering capability for your network monitoring needs offering a

complete view of the traffic and easily lets security and analysis tools collect all

the data they need, expanding network visibility.

Page 4

VERSAstream™

© 2010 Datacom Systems Inc

All rights reserved. No parts of this work may be reproduced in any form or by any means - graphic, electronic, or

mechanical, including photocopying, recording, taping, or information storage and retrieval systems - without the written

permission of the publisher.

Products that are referred to in this document may be either trademarks and/or registered trademarks of the respective

owners. The publisher and the author make no claim to these trademarks.

While every precaution has been taken in the preparation of this document, the publisher and the author assume no

responsibility for errors or omissions, or for damages resulting from the use of information contained in this document or

from the use of programs and source code that may accompany it. In no event shall the publisher and the author be liable

for any loss of profit or any other commercial damage caused or alleged to have been caused directly or indirectly by this

document.

Printed: June 2010 in East Syracuse, New York

Printed: June 2010 in East Syracuse, New York

Page 5

Table of Contents

5Table of Contents

Section 1 Terms of Use

Section 2 Overview

Section 3 Hardware

.................................................................................................... 9

........................................................................................ 91 Copyright

........................................................................................ 92 License Agreement

........................................................................................ 93 Trademark Attribution

........................................................................................ 94 Proprietary Notice

........................................................................................ 105 Certifications and Marks

........................................................................................ 106 Safety Notices and Warnings

.................................................................................................... 11

........................................................................................ 111 Shipped Contents

........................................................................................ 122 FVS Features and Benefits

........................................................................................ 133 FVS-1044 Specifications

........................................................................................ 144 FVS-1080 Specifications

.................................................................................................... 15

........................................................................................ 151 Power

........................................................................................ 152 Any-to-Any Ports

........................................................................................ 163 Management Port

........................................................................................ 164 Serial USB

........................................................................................ 165 Rear Panel

Section 4 Initial Configuration

Section 5 Hardware Installation

Section 6 FVS Application

Section 7 FLOWcontrol™

.................................................................................................... 17

........................................................................................ 171 SERIAL Port Configuration

........................................................................................ 172 IP Address

........................................................................................ 193 Small Form-Factor Plug Module

1 Installation Prerequisites

2 Safety Guidelines

3 Installing the SFP Module

4 Removing the SFP Module

...................................................................................................... 19

...................................................................................................... 19

...................................................................................................... 20

...................................................................................................... 20

.................................................................................................... 21

........................................................................................ 211 Power

........................................................................................ 212 Management Connection

........................................................................................ 223 Any-to-Any Connection

.................................................................................................... 23

.................................................................................................... 24

........................................................................................ 241 Introduction

© 2010 Datacom Systems Inc

VERSA™stream

Page 6

Table of Contents6

1 Supported Products

2 PC Requirements

3 Installation

...................................................................................................... 25

...................................................................................................... 26

...................................................................................................... 26

........................................................................................ 272 FLOWcontrol™ User Interface

1 FLOWcontrol Main Screen

1 Pull Down Menu Bar

...................................................................................................... 27

..................................................................................................... 27

........................................................................................................................................ 28

1 File

........................................................................................................................................ 29

2 Agent

.................................................................................................................................. 29

1 Connect

.................................................................................................................................. 30

2 Disconnect

.................................................................................................................................. 30

3 Communications Console

.................................................................................................................................. 30

4 Add

.................................................................................................................................. 31

5 Delete

.................................................................................................................................. 31

6 Modify

.................................................................................................................................. 31

7 Refresh

.................................................................................................................................. 31

8 Restart

.................................................................................................................................. 31

9 Agent > Add, Modify Properties Form

........................................................................................................................................ 32

3 Utilities

........................................................................................................................................ 34

4 Tabs

........................................................................................................................................ 34

5 Help

.................................................................................................................................. 34

1 About

.................................................................................................................................. 34

2 FLOWcontrol Help

.................................................................................................................................. 35

3 Web Site

.................................................................................................................................. 35

4 Tutorials

2 Agent List

2 Filter Management

1 Saved Filters Panel

2 Filter Specifics Panel

..................................................................................................... 35

...................................................................................................... 36

..................................................................................................... 37

..................................................................................................... 38

........................................................................................................................................ 39

1 Include/Exclude Definition

........................................................................................................................................ 39

2 Include VLAN Tunneling Frames

........................................................................................................................................ 40

3 Rule Definition

........................................................................................................................................ 41

4 Combinatorial Logic

........................................................................................................................................ 44

5 MAC Address Filter

........................................................................................................................................ 44

6 VLAN ID Filter

........................................................................................................................................ 44

7 IPv4 IP Address Filter

........................................................................................................................................ 45

8 IPv4 PORT Number Filter

........................................................................................................................................ 45

9 IPv6 IP Address Filter

........................................................................................................................................ 46

10 Advanced Filter

........................................................................................................................................ 47

11 Context Menus

VERSA™stream

© 2010 Datacom Systems Inc

Page 7

7Table of Contents

........................................................................................................................................ 47

12 Value Specifications

3 Advanced Filter Wizard

3 Communications Console

1 Pull Down Menus

2 Console Main Screen

4 Product Control

1 Product Control Tabs

..................................................................................................... 48

........................................................................................................................................ 51

1 MAC Address Wizard

........................................................................................................................................ 53

2 VLAN ID Wizard

........................................................................................................................................ 54

3 ETHERtype Wizard

........................................................................................................................................ 55

4 IPv4 IP Address Wizard

........................................................................................................................................ 56

5 IPv4 Protocol Wizard

........................................................................................................................................ 57

6 IPv4 PORT Number Wizard

...................................................................................................... 59

..................................................................................................... 59

..................................................................................................... 60

...................................................................................................... 60

..................................................................................................... 61

........................................................................................................................................ 61

1 Configuration Summary

.................................................................................................................................. 62

1 Filtered SINGLEstream Summary

.................................................................................................................................. 62

2 Filtered VERSAstream Summary

........................................................................................................................................ 62

2 Counter Resets

........................................................................................................................................ 63

3 Summary Expanded

........................................................................................................................................ 64

4 Port Configuration

........................................................................................................................................ 66

5 Aggregation Configuration

.................................................................................................................................. 67

1 Example Filtered SINGLEstream

.................................................................................................................................. 69

2 Example Filtered VERSAstream

5 Filter Configuration

6 Event Log

Section 8 Appendix 1 - Command Line Interface (CLI)

.................................................................................................... 73

...................................................................................................... 71

...................................................................................................... 72

........................................................................................ 731 Basic Functionality

........................................................................................ 732 Basic Command Set

1 HELP (?)

2 CLEAR LOG (CL LOG)

3 PASSWORD

4 SHOW (SH)

5 SHOW DAEMON (SH DN)

6 SHOW MANAGEMENT (SH MA)

7 SHOW NTP (SH NTP)

8 SHOW TIME (SH TI)

9 SHOW PORT STATS (SH PO ST)

10 SHOW PRODUCT (SH PR)

11 SET BAUD (SE BD)

12 SET FTP (SE FP)

...................................................................................................... 73

...................................................................................................... 74

...................................................................................................... 74

...................................................................................................... 75

...................................................................................................... 75

...................................................................................................... 76

...................................................................................................... 76

...................................................................................................... 76

...................................................................................................... 76

...................................................................................................... 77

...................................................................................................... 77

...................................................................................................... 77

© 2010 Datacom Systems Inc

VERSA™stream

Page 8

Table of Contents8

13 SET DEFAULT IP (SE DEF IP)

14 SET IP (SE IP)

15 SET SUBNET (SE SU)

16 SET GATEWAY (SE GA)

17 SET PORT (SE PO)

18 SET NTP (SE NTP)

19 SET PING (SE PG)

20 SET SSH (SE SH)

21 SET SYSLOG (SE SY)

22 SET TELNET (SE TT)

23 SET TFTP (SE TP)

24 SET TIME (SE TI)

25 REBOOT

26 REBOOT -management

27 EXIT

Section 9 Appendix 2 - Sample Filter Setup

Section 10 Customer Service

.................................................................................................... 84

.................................................................................................... 88

...................................................................................................... 78

...................................................................................................... 78

...................................................................................................... 79

...................................................................................................... 79

...................................................................................................... 80

...................................................................................................... 80

...................................................................................................... 81

...................................................................................................... 81

...................................................................................................... 81

...................................................................................................... 81

...................................................................................................... 82

...................................................................................................... 82

...................................................................................................... 82

...................................................................................................... 83

...................................................................................................... 83

........................................................................................ 881 World Wide Web

........................................................................................ 882 Warranty

........................................................................................ 893 Limits of Liability

........................................................................................ 894 Force Majeure

VERSA™stream

© 2010 Datacom Systems Inc

Page 9

Terms of Use

9

1 Terms of Use

The following terms and conditions relate to the use of this document. Please note that Datacom Systems Inc.

reserves the right, at its entire discretion, to change, modify, add, or remove portions of these Terms of Use at

any time. Please read the Terms of Use carefully as your use of this document is subject to the Terms of Use

stipulated herein.

1.1 Copyright

Copyright© 2007-2010 by Datacom Systems, Inc. All rights reserved. Printed in the United States of America.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by

any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission

of Datacom Systems, Inc. To obtain this permission, write to the attention of the Datacom Systems legal

department at 9 Adler Drive, East Syracuse, New York 13057-1290, or call 315-463-9541.

1.2 License Agreement

Notice To All Users: By using Datacom Systems, Inc. products, you agree to the terms set forth. No licenses,

express or implied, are granted with respect to the technology described and Datacom Systems, Inc. retains all

rights with respect to the technology described herein. If applicable, you may return the product to the place of

purchase for a full refund.

1.3 Trademark Attribution

Access Your Network , DS3 ACTIVEtap , DS3switch , DURAstream , ETHERNETtap , Empowering

Network Professionals , FDDIswitch , FIBERsplitter , FIBERswitch , FIBERSWITCHsystem , FLOW

control , GIGABITswitch , INSERTswitch , INSERTunit , LANswitch , MANAgents ,

MULTINETswitch , NETspan , PERMAlink , PROline , RMON SWITCHINGanalyzer , SINGLE

stream , UNIVERSALswitch , VERSAstream , and WANswitch are trademarks of Datacom Systems,

Inc. 1ST in Switching Solutions®, DATACOMsystems®, LANclipper®, MANAgents®, and MULTIview® are

registered trademarks of Datacom Systems, Inc. All other registered and unregistered trademarks are the sole

property of their respective owners. All specifications may be changed without notice.

1.4 Proprietary Notice

This document contains proprietary information about the filtered product family of products and is not to be

disclosed or used except as authorized by written contract with Datacom Systems, Inc.

© 2010 Datacom Systems Inc

VERSA™stream

Page 10

1.5 Certifications and Marks

CAUTION: Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

The CE logo indicates that this equipment was tested and found to meet radiated and

conducted emission to the European Community EMC Directive 89/336/EEC requirements as

per EN 61000-6-3:2001, the generic emissions standard for residential, commercial and light

industrial devices, the limits are those for an EN 55022 Class A product.

This equipment also has been tested and found to meet the immunity levels for residential, commercial and

light industrial devices according to EN 61000-6-1:2001, the interference severity levels to the standards

and requirements of EN 61000-3-2 Harmonic Current, EN 61000-3-3 Voltage Fluctuations and Flicker,

EN 61000-4-2 Electrostatic Discharge, EN 610004-3 Radiated Susceptibility, EN 61000-4-4 Electrical

Fast Transient/Burst, EN 61000-4-5 Surge and EN 61000-4-6 Conducted Susceptibility.

This equipment completed the Product Safety Review and meets the Low Voltage Directive 98/68/EEC

requirements to the standards of EN 60950 Safety of Information Technology Equipment.

The RoHS compliant logo indicates that this electronic product does not exceed the limit

requirements of toxic, hazardous substances or elements as set forth in Directive 2002/95/EC

of the European Parliament and of the Council of 27 January 2003 on the restriction of the use

of certain hazardous substances in electrical and electronic equipment.

The crossed out wheelie bin logo signifies that the product can be recycled after being

discarded, and should not be casually discarded as set forth in Directive 2002/96/EC of the

European Parliament and of the Council of 27 January 2003 on waste electrical and electronic

equipment (WEEE).

These explanatory labels are included in this information for the user in accordance

with the requirements of IEC 60825.1.

WARNING: Class 1 laser and LED product. A class 1 laser is safe under all

conditions of normal use. Invisible laser radiation may be emitted from optical

port openings when no fiber cable is connected, avoid exposure to laser

radiation and do not stare into open optical ports.

Terms of Use10

1.6 Safety Notices and Warnings

VERSA™stream

© 2010 Datacom Systems Inc

Page 11

Overview

11

2 Overview

The Filtered VERSAstream™ (FVS) product line increases network visibility and leverages your investment in

network analyzers, probes, and security equipment by allowing you to simultaneously monitor as many

supported ports as you may need to fit your peripheral network tools. Greater visibility accelerates problem

resolution, reduces downtime and increases enterprise productivity.

Like all Datacom Systems filtered products, the FVS-1044 and FVS-1080 filtered products are compatible

with all vendor hardware and can be controlled by our FLOWcontrol software, which will allow you to

control your filtered product line through a single interface regardless of what network appliances you choose to

deploy.

The Filtered VERSAstream™ product line gives you access to your network without creating bottlenecks by

providing the capability to monitor, aggregate and filter network traffic to an analysis device or sensor.

Aggregation combines two or more streams of network traffic into one link. Aggregated network traffic may

overload or oversubscribe an analysis device. Filtering unwanted network traffic reduces the potential for

oversubscribing. The Filtered VERSAstream™ product line features hardware based, line-rate filtering. This

allows you to eliminate unwanted network traffic from analysis tools or sensors. Filtering also gives you the

ability to deploy lower speed tools on higher speed networks.

2.1 Shipped Contents

FVS-1044 filtered product

1 — Model: FVS-1044

2 — AC Line Cords

1 — FLOWcontrol™ software

1 — DRL434-6-R cable, USB type A to DB9 F

1 — DRL366-3-R cable, RJ45 to RJ45

FVS-1080 filtered product

1 — Model: FVS-1080

2 — AC Line Cords

1 — FLOWcontrol™ software

1 — DRL434-6-R cable, USB type A to DB9 F

1 — DRL366-3-R cable, RJ45 to RJ45

© 2010 Datacom Systems Inc

VERSA™stream

Page 12

2.2 FVS Features and Benefits

Apply port level packet filtering to SPAN monitoring solutions.

Line-rate filtering eliminates unwanted traffic from analysis tools or security sensors.

Load balancing eliminates bottlenecks and port over subscription.

Filter network traffic to any monitoring port based upon IP address, port number, MAC address,

VLAN, protocol type or customizable offsets in the IP header.

"Any-to-Any" architecture can send traffic from any input ports to any monitoring ports.

"Many-to-Any" architecture combines traffic from up to four of the input ports, providing visibility into

multiple network segments with one monitoring tool.

"One-to-Many" architecture allows sending multiple copies of data from the input port to multiple

monitoring devices.

Aggregate and reassembly full duplex conversations from multiple trunk links, redundant networks,

Ether Channel, load balanced servers and asymmetrically routed traffic.

Overview12

Simultaneously monitor data at multiple points on the network with the same set of devices.

Datacom Customer Service Support is available via:

Phone: (315) 463-9541

Fax: (315 ) 463-9557

E-mail: support@datacomsystems.com

Website: www.datacomsystems.com

VERSA™stream

© 2010 Datacom Systems Inc

Page 13

Overview

2.3 FVS-1044 Specifications

Network Ports (front):

4 - 10/100/1000BaseT (RJ45 Connectors) or SFP*

*SFP = Small Form Pluggable can be LX or SX

Monitor Ports (front):

4 - 10/100/1000BaseT (RJ45 Connectors) or SFP*

*SFP = Small Form Pluggable can be LX or SX

Management Port (front):

RJ45 @ 10/100 Mbs Full-Duplex

Serial Port (front):

USB-type A style

Power:

Input: 120-240VAC 50-60Hz, 0.6A-0.3A

13

Dimensions (H x W x D): includes mount bracket

1.75 x 19.00 x 12.00 inch

4.44 x 48.26 x 30.48 cm

Weight:

7.0 lbs; shipping: 14.0 lbs

3.175 kg; shipping; 6.3 kg

Operating Temperature:

32º to 104° F

0º to 40° C

Storage Temperature:

-22º to 149° F

-30º to 65° C

Humidity:

Less than 95° C non-condensing

Warranty:

One (1) year - see 'Warranty' section for details.

88

© 2010 Datacom Systems Inc

VERSA™stream

Page 14

2.4 FVS-1080 Specifications

Network or Monitor Ports (front):

8 - 10/100/1000BaseT (RJ45 Connectors) or SFP*

*SFP = Small Form Pluggable can be LX or SX

Management Port (front):

RJ45 @ 10/100 Mbs Full-Duplex

Serial Port (front):

USB-type A style

Power:

Input: 120-240VAC 50-60Hz, 0.6A-0.3A

Dimensions (H x W x D): includes mount bracket

1.75 x 19.00 x 12.00 inch

4.44 x 48.26 x 30.48 cm

Weight:

7.0 lbs; shipping: 14.0 lbs

3.175 kg; shipping; 6.3 kg

Overview14

Operating Temperature:

32º to 104° F

0º to 40° C

Storage Temperature:

-22º to 149° F

-30º to 65° C

Humidity:

Less than 95° C non-condensing

Warranty:

One (1) year - see 'Warranty' section for details.

88

VERSA™stream

© 2010 Datacom Systems Inc

Page 15

Hardware

15

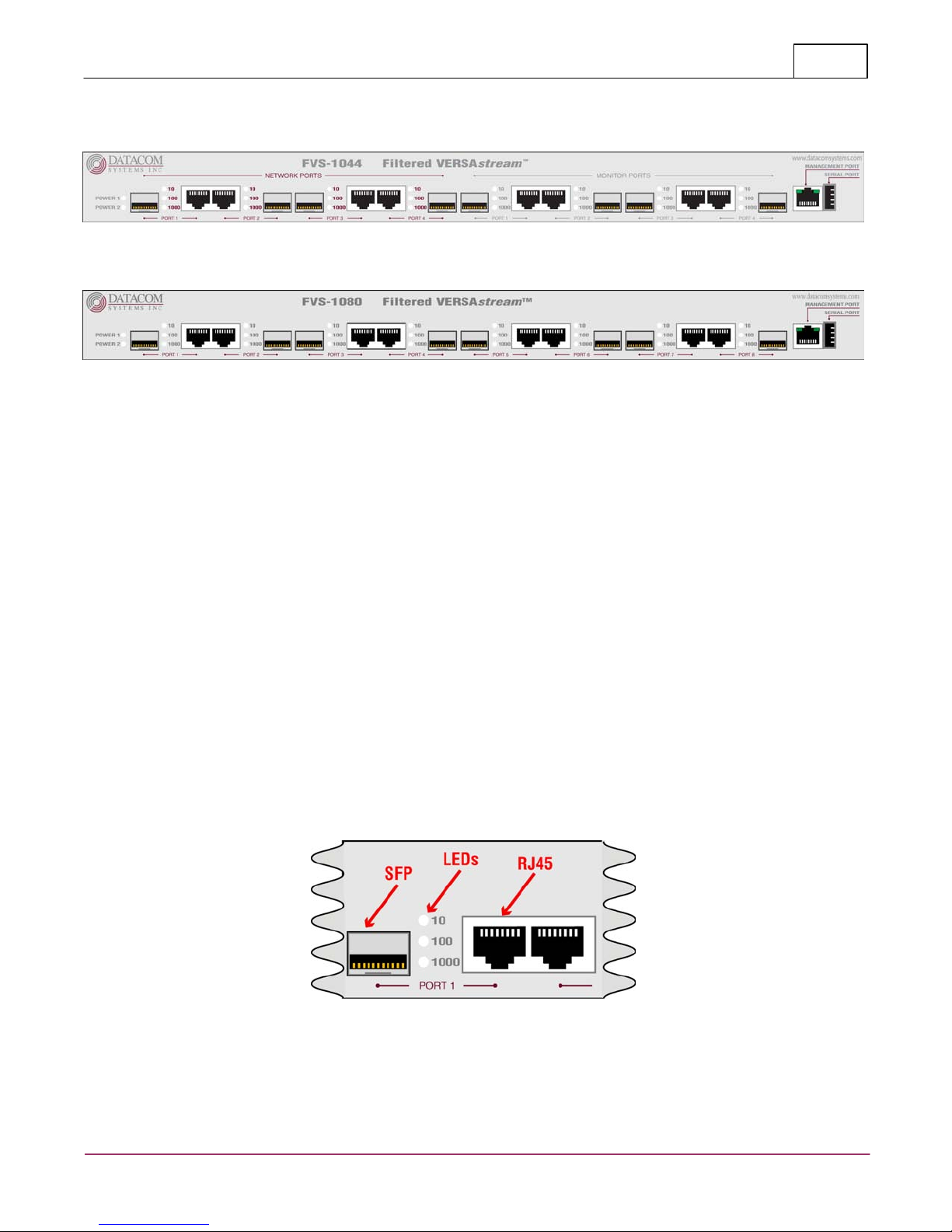

3 Hardware

This section provides an illustration and description of the FVS series product:

FVS-1044

FVS-1080

An explanation of each front panel legend follows:

3.1 Power

Two AC power sources are provided for the filtered product unit. Although only one power source is required

to power the module, use of a second independent power source is strongly recommended to assure

uninterrupted monitoring. Furthermore, connecting the second AC input power socket to a different external

power source circuit than the first AC input power source eliminates power as a single point of failure. The

power sockets are located on the rear.

The POWER 1 and 2 front panel LEDs illuminate green when power is available at both of the two rear power

sockets indicating power 1 and 2, respectively, are on. Either LED not illuminated indicates immediate

investigation is recommended if both power sources are being used and a power led is not illuminated to insure

redundant power integrity.

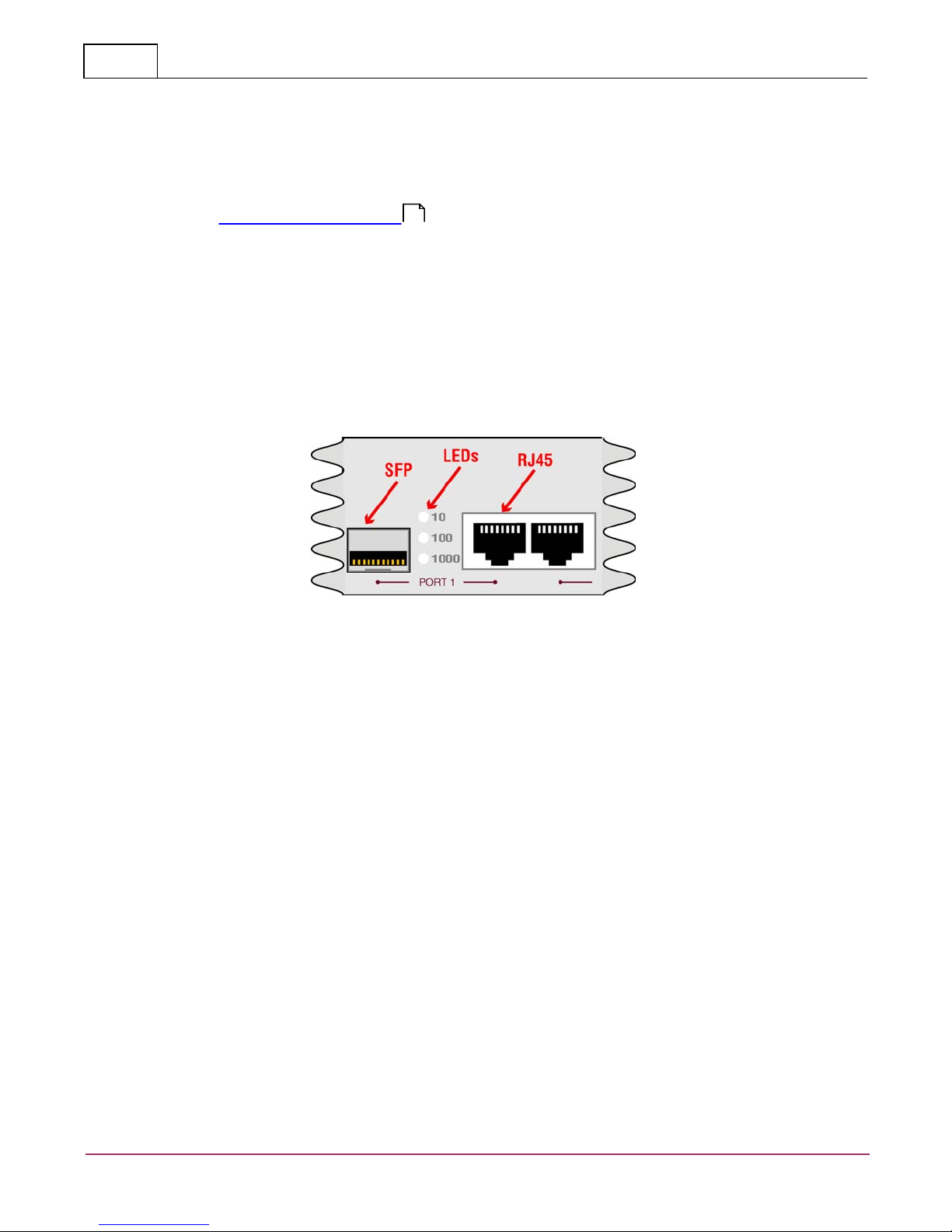

3.2 Any-to-Any Ports

SFP or RJ45 — SFPare Small Form Pluggable (can be LX or SX) or RJ45 are RJ45 connectors used for

connection to network segments or analysis tools. Between the connectors are LEDs that display line status and

line speed of each port. A solid light indicates the Fiber SFP or RJ45 10/100/1000BaseT port is connected. A

blinking light indicates the presence of traffic.

© 2010 Datacom Systems Inc

VERSA™stream

Page 16

Hardware16

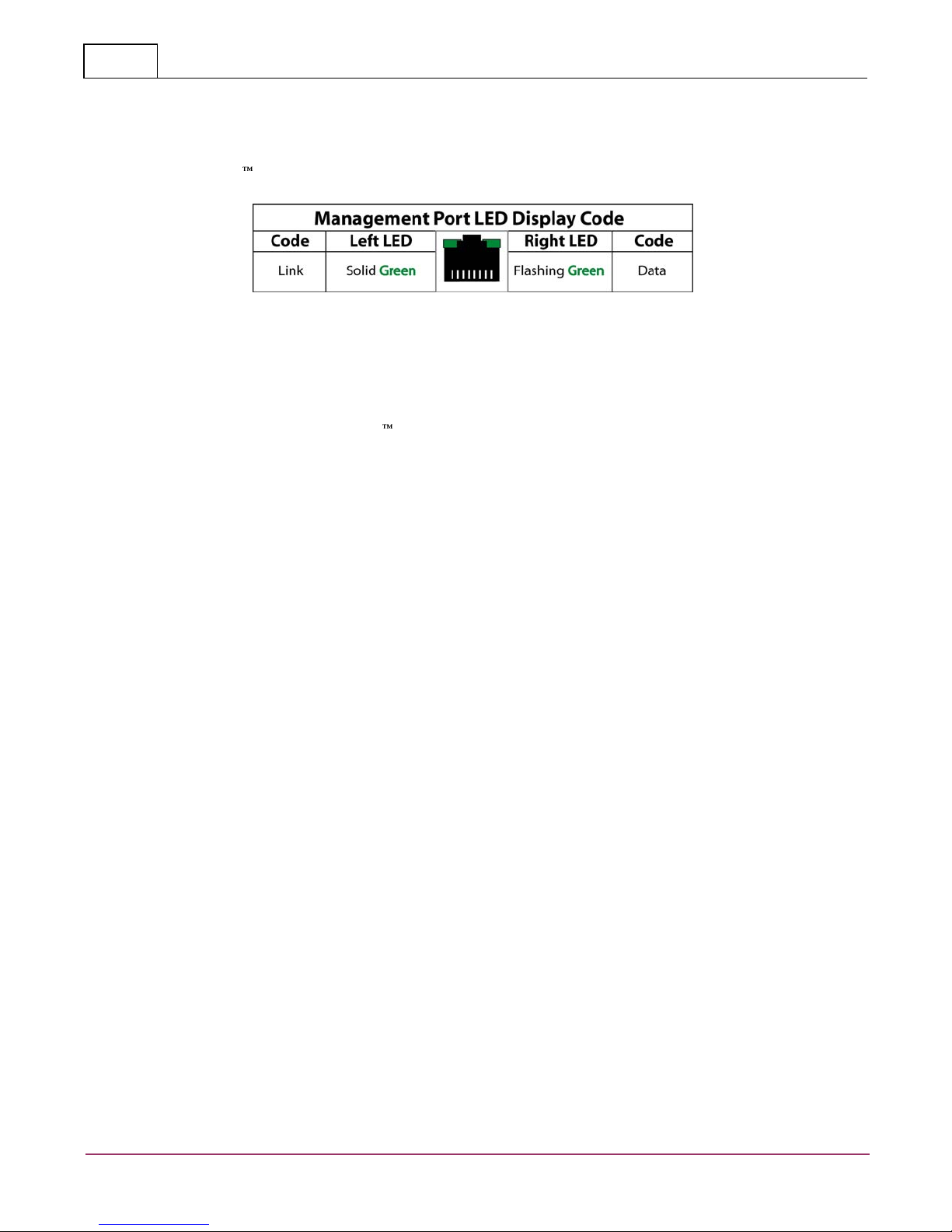

3.3 Management Port

The MANAGEMENT PORT is an RJ45 socket used for 10/100 Mbs fixed full-duplex connection with a straightthrough LAN cable via your management LAN to a Remote Management Console which is a standard PC

running FLOWcontrol .

Link indicates connection. The LED Display Code table deciphers the RJ45 jacks with integrated LEDs that

display line status of the MANAGEMENT PORT.

3.4 Serial USB

The SERIAL connector port is a shielded USB type A Female and is cabled to the COM port of any compatible

network tool or PC where FLOWcontrol Software resides. It is the only port that can easily connect the

Management PC to set the IP address for the first time.

3.5 Rear Panel

Two AC input power sockets are provided on the rear panel.The POWER 1 and 2 front panel LEDs illuminate

green when power is available at both of the two rear power sockets indicating power 1 and 2, respectively,

are on. Either front panel LED not illuminated indicates immediate investigation is recommended if both power

sources are being used and a power led is not illuminated to insure redundant power integrity.

Although only one AC power source is required to power the filtered product unit, use of a second independent

power source is strongly recommended to assure uninterrupted monitoring. Furthermore, connecting the second

AC input power socket to a different external power source circuit than the first AC input power source

eliminates power as a single point of failure.

VERSA™stream

© 2010 Datacom Systems Inc

Page 17

Initial Configuration

FVS-1044

FVS-1080

2400 bits per second

9600 bits per second

8 data bits

8 data bits

Parity none

Parity none

1 stop bit

1 stop bit

Flow control none

Flow control none

17

4 Initial Configuration

IMPORTANT: Review the following section prior to initial configuration of the hardware.

IMPORTANT: Detailed Command Line Interface (CLI) syntax information is found in the 'Appendix

1 - Command Line Interface (CLI) ' section.

Initial configuration is performed directly with a terminal emulation application on a management PC connected

to the FVS through the SERIAL USB-style type A port. After initial configuration, the FVS can be remotely

operated though the MANAGEMENT RJ45 port. Only one configuration session can be open at a time.

4.1 SERIAL Port Configuration

Once the FVS SERIAL port hardware connection is made, open the terminal emulator application on the

management PC and create a connection with the settings that fit your needs:

73

4.2 IP Address

All FVS filtered products are assigned an IP address (192.168.1.1) by default. You must change the IP

address to match your network.

NOTE: If your FVS already has an IP address for your network, you may proceed to the 'Small Form-Factor

Plug Module ' section.

Step 1. First, connect your terminal emulator application PC and FVS using the provided Datacom Systems

DRL434-6-R cable. Connect the DB9 Female pin end to the serial port on your PC and connect the USBstyle Type A end to the SERIAL port on the unit.

Step 2. Open the terminal emulator application on your PC.

Step 3. Create a serial link by selecting the COM port assigned to the serial port on your PC.

Step 4. Next, configure the COM Properties. The initial correct setting to communicate with the FVS series

product (9600, 8, None, 1, None) are shown below. Once all settings are configured correctly, you can

connect to your Filtered VERSAstream™ product.

19

NOTE: For PCs without 9-pin serial ports, check with you product representative for available sources

of a USB to RS-232 Plug-in Adapter.

Step 5. Next, plug the FVS into the external power source using the supplied AC line cord. Note that either

POWER 1 or 2 LED is illuminate green indicating power is available at the rear AC power socket to which the

AC Line Cord is connected. The other POWER LED is not illuminated, indicating a lack of power to the

unconnected AC power socket.

© 2010 Datacom Systems Inc

VERSA™stream

Page 18

Initial Configuration18

Prior to proceeding any command line entry, observe the following serial startup screen activity that will last for

approximately one and a half to two minutes:

DipSwitch Status = 0xFF

Enabling Datacom RS232 serial port.

Datacom Systems, Inc. FVS-1080

Starting Self Tests.....

Memory Tests Pass!

Located Datacom 512MB DDR

*

*

*

Booting Operating System.....please wait.....

VERSAstream Initialization In Process....

Restoring Settings...

VERSAstream Active...

The FVS is now ready to accept command line entry commands.

Step 6. Hit the Enter key twice in succession (i.e., Enter, Enter) to display the username: prompt. The CLI

username and password are case-sensitive. The default values are:

username: Administrator

password: admin

> ? and press the Enter key to see available commands list, details in 'Basic Command Set ' section.

73

Step 7. Separate IP, Subnet or Gateway CLI entries ARE NOT ALLOWED for the FVS-1080. 'Set IP

Address ' by typing SET IP ppp.ppp.ppp.ppp sss.sss.sss.sss ggg.ggg.ggg.ggg where ppp.ppp.ppp.ppp

78

corresponds to a valid IP address, where sss.sss.sss.sss corresponds to a valid SUBNET for your network and

where ggg.ggg.ggg.ggg corresponds to a valid GATEWAY for your network. Press the Enter key to continue.

Step 8. Review and verify the network address settings are correct and enter (y) to confirm changes (updating

elapsed time approximately 15 seconds) otherwise enter (n) to cancel and repeat Step 7.

Step 9. Follow the screen prompts and at the command prompt, type 'REBOOT -management ' to allow the

83

new network setting to take effect.

Step 10. Follow the screen prompts and after the screen response VERSAstream Active . . . (elapsed time

approximately 35 seconds) type 'SH MA ' to review the network address settings. Verify settings are correct.

76

Step 11. Type 'EXIT ' and press the Enter key to end the connection session indicated by 'Closing

83

Connection . . . ' response, then close the terminal emulation application.

Step 12. Disconnect the DRL512-2M-R serial cable from your FVS series product and proceed to install the

FVS series product in your chosen network location.

VERSA™stream

© 2010 Datacom Systems Inc

Page 19

Initial Configuration

19

4.3 Small Form-Factor Plug Module

This section provides information about small form-factor plug (SFP) modules. The SFP modules are input/

output devices that plug into a Gigabit Ethernet (GE) small form-factor (SFF) port, linking the port with a

1000Base-X fiber.

The fiber SFP module have a receiver port (Rx) and a transmitter port (Tx) that make up one optical interface.

The 1000Base-SX (short wavelength) SFP module operates on standard multimode fiber networks compliant

with the 1000Base SX standard. The 1000Base-LX (long wavelength) SFP module operates on standard

single-mode fiber networks compliant with the 1000Base LX standard. The fiber SFP module is a 1000 Mbps

optical interface in the form of an LC-type duplex port that supports interfaces compliant with the 1000Base-X

standard.

4.3.1 Installation Prerequisites

This section describes safety and compliance guidelines you should observe before you install an SFP module in

your FVS unit.

NOTE: You can install and remove SFP modules with power on to the system; however, it is strongly

recommended that you do not install or remove the SFP module with fiber or copper cables attached to it.

Disconnect all cables before removing or installing a SFP module.

CAUTION: Prevent system problems, use only Datacom Systems Inc. supplied SFP modules.

4.3.2 Safety Guidelines

Before handling a SFP module, observe the following guidelines:

Copper and fiber SFP modules are static-sensitive. To prevent electrostatic discharge (ESD) damage, follow

your normal ESD handling procedures.

Fiber SFP modules are dust-sensitive. When storing a SFP module or when a fiber cable is not plugged in,

always keep plugs in the SFP module optical hole.

The most common source of contaminants in the fiber SFP optical aperture is debris picked up on the

terminations of the optical connectors. Use an alcohol swab or lint-free absorbent wipes to clean the

terminations of the optical connector.

WARNING: Fiber SFP modules are class 1 laser and LED products. Invisible laser radiation may be

emitted from the port opening when no fiber cable is connected, avoid exposure to laser radiation and

do not stare in open optical ports.

© 2010 Datacom Systems Inc

VERSA™stream

Page 20

Initial Configuration20

4.3.3 Installing the SFP Module

SFP modules might ship already installed in your FVS or they might arrive packaged separately. This section

describes how to install the SFP module.

NOTE: You can install SFP modules with power on to the system; however, it is strongly recommended that

you do not install the SFP module with fiber or copper cables attached to it. Disconnect all cables before

installing a SFP module.

CAUTION: Prevent system problems, use only Datacom Systems Inc. supplied SFP modules.

Step 1. Turn the SFP module so the latch is towards the center of the Gigabit Ethernet Interface sockets. The

SFP module is keyed so that it cannot be inserted incorrectly.

Step 2. Insert the SFP module into the SFF port and repeat Step 1 and Step 2 inserting other SFP modules

until completed.

Step 3. Attach the appropriate network cable to the LC-type or RJ45-type connector on the SFP module. For

fiber optic SFP modules you can use either simplex or duplex connectors. For simplex connectors, two cables

are required, one cable for transmit (Rx) and a second cable for receive (Rx). For duplex connectors, only one

cable that has both Tx and Rx connectors is required.

4.3.4 Removing the SFP Module

SFP modules might ship already installed in your FVS or they might arrive packaged separately. This section

describes how to remove the SFP module.

NOTE: You can remove SFP modules with power on to the system; however, it is strongly recommended that

you do not remove the SFP module with fiber or copper cables attached to it. Disconnect all cables before

removing a SFP module.

Step 1. Disconnect the network cable from the SFP module LC-type or RJ45-type connector.

Step 2. Release the SFP module from the GE SFF port by moving the swing latch away from the body of the

unit.

Step 3. Slide the SFP module out of the GE SFF port.

VERSA™stream

© 2010 Datacom Systems Inc

Page 21

Hardware Installation

21

5 Hardware Installation

This section specifically describes the FVS-1080 hardware installation at the network site of your choice. The

FVS-1044 is similar in functionality and the same basic installation procedure may be used as a guide during

FVS-1004 installation.

5.1 Power

This section describes the installation site power connection of the FVS-1080 at the network site.

Two AC input power sockets are provided on the rear panel. The front panel POWER 1 and 2 LEDs are

illuminated green, respectively when AC power is available at both the two rear AC power sockets.

Either POWER 1 or 2 LED not illuminated when powered, indicates a defective power source and immediate

investigation as to the cause is required to insure redundant power integrity.

Step 1. Using the supplied AC Line Cords, plug the FVS-1080 series product into different circuit external

power sources. Although only one external power source is required to power the unit, use of a second

independent external power source is strongly recommended to assure uninterrupted monitoring. Furthermore,

connecting to a second different external power source circuit than the first AC power source eliminates power

as a single point of failure.

5.2 Management Connection

This section shows the MANAGEMENT port 100 Mbs fixed full-duplex connection of the typical FVS-1080

hardware installation.

Step 1. Connect a network cable to the MANAGEMENT port RJ45 socket. The MANAGEMENT port RJ45 left

LED illuminates green when link has been established with the network. The MANAGEMENT port right LED

illuminates green when passing data.

Step 2. Refer to the FLOWcontrol help file for detail operation of the FVS-1080 filtered product.

The MANAGEMENT PORT is an RJ45 socket used for 100 Mbs fixed full-duplex connection with a straightthrough LAN cable via your management LAN to a Remote Management Console which is a standard PC

running FLOWcontrol .

Link indicates connection. The LED Display Code table deciphers the RJ45 jacks with integrated LEDs that

display line status of the MANAGEMENT PORT.

© 2010 Datacom Systems Inc

VERSA™stream

Page 22

Hardware Installation22

5.3 Any-to-Any Connection

This section will focus on the Any-to-Any port connection of the typical FVS-1080 hardware installation.

NOTE: For FVS-1080 with the Gigabit Ethernet (GE) small form-factor (SFF) ports, the SFP modules might

ship already installed in your unit, or they might arrive packaged separately. See the 'Small Form-Factor

Pluggable' section, 'Installing the SFP Module ,' on how to install the SFP module.

Step 1. Connect a network or monitoring cable to an Any-to-Any port socket and the other side of this cable to

the network or monitoring tool NIC port as appropriate..

Step 2. Continue repeating Step 1. for any remaining Any-to-Any port socket you want connected from the

FVS-1080.

Between the connectors are LEDs that display line status and line speed of each port. A solid light indicates the

Fiber SFP or RJ45 10/100/1000BaseT port is connected. A blinking light indicates the presence of traffic.

20

VERSA™stream

© 2010 Datacom Systems Inc

Page 23

FVS Application

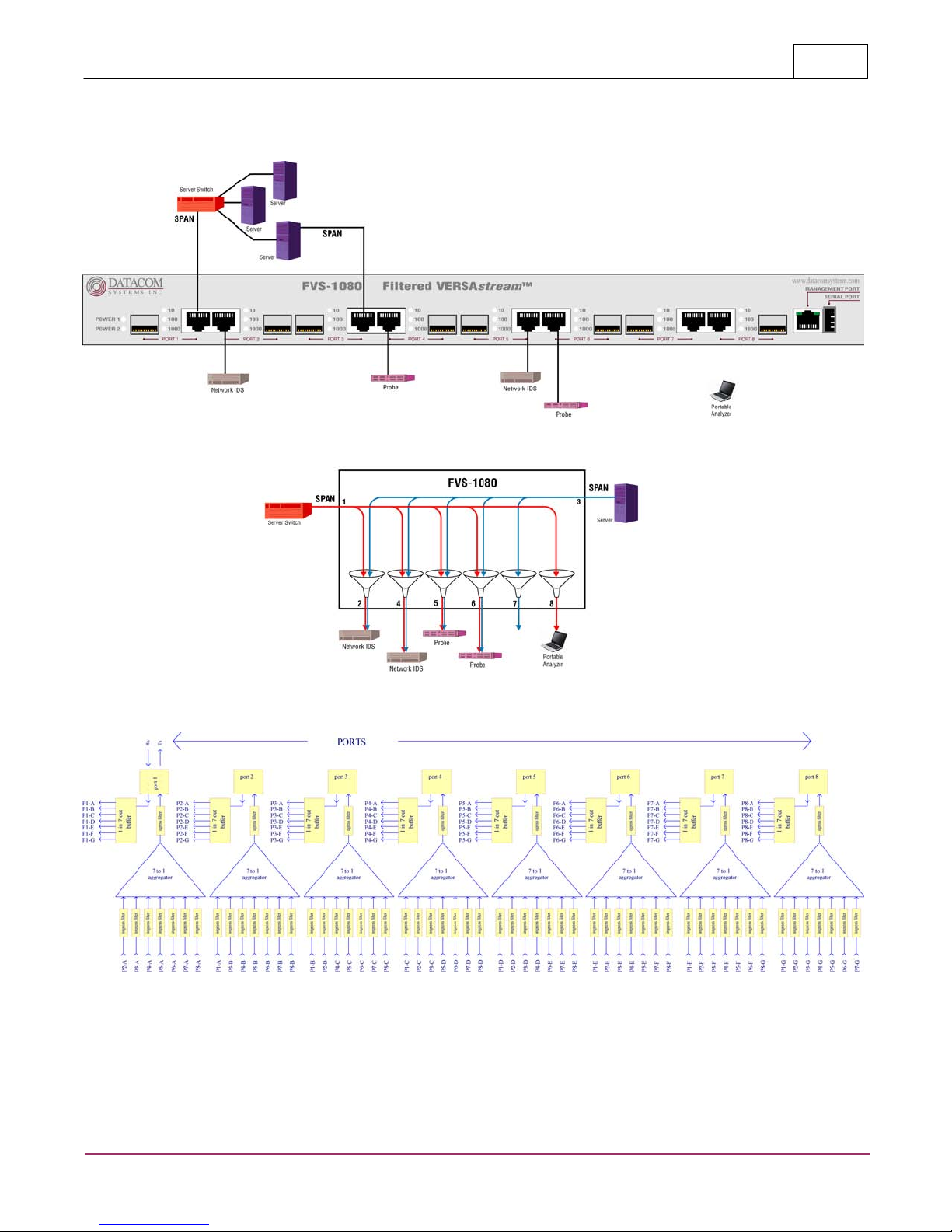

6 FVS Application

This section depicts a simple application using the Filtered VERSAstream™ FVS-1080 solution.

23

FVS-1080 Functional

© 2010 Datacom Systems Inc

VERSA™stream

Page 24

FLOWcontrol™24

7 FLOWcontrol™

FLOWcontrol™ is specifically designed for control of Filtered Products

manufactured by Datacom Systems Inc. Specific elements of the Graphical User

Interface (GUI) provide guidance in the management, configuration and

troubleshooting of Datacom Systems Inc based products.

7.1 Introduction

The Filtered Product Aggregation Tap gives you in-line access, without creating a

network bottleneck, since the tap allows all network traffic through to the far

end, but provides the ability to aggregate, regenerate and filter copies of

network traffic to specific monitoring ports.

The Filtered Product Data Access Switch allows aggregation, regeneration and

filtering with inputs from Switch Probe Analyzer (SPAN) or Port Mirror ports.

Line-rate filtering provides you the ability to eliminate unwanted traffic from

your analysis tools or security sensors. With less data to work with, network

devices run faster and more effectively, and through filtering, you can reduce or

eliminate the possibility of port oversubscribing.

Using the built-in technologies of link aggregation, regeneration, and filtering,

you can quickly and easily load balance both your network and your network

tools and eliminate bottlenecks.

Aggregation lets you load balance your network with confidence. The Filtered

Product will combine one or more full duplex streams of data from one or more

network segments, reassemble the conversation, and send an exact copy to your

connected monitoring device.

Regeneration allows you to attach more than one device to a single network

segment. Connect an analyzer and a security sensor to the same link, and you

can troubleshoot your network without having to disconnect your IDS. Add

filtering, and you can send only the data you want to each tool, improving

monitoring efficiency, speed, and network uptime.

Regeneration also allows you to connect two or more identical devices to the

same link, so you can load balance your tools. Extending the power of

regeneration with filtering, you can filter and send data to each tool based on

whatever parameter you choose (e.g. IP range). Distributing processes over

multiple tools allows them to work faster and reduces or eliminates network

bottlenecks that can be caused by slow processing of data.

VERSA™stream

© 2010 Datacom Systems Inc

Page 25

FLOWcontrol™

SS-1204LR-10G

VS-1204-10G

SS-1204SR-10G

VS-1206LR-10G

SS-1206LR-10G

VS-1206SR-10G

SS-1206SR-10G

VS-1214-10G

SS-1214LX-10G

SS-1214SR-10G

SS-1214SX-10G

FSS-1000BT

FVS-1044

SS-1204LR-10G-F

VS-1204-10G-F

FSS-1000LX

FVS-1080

SS-1204SR-10G-F

VS-1206LR-10G-F

FSS-1000SX

SS-1206LR-10G-F

VS-1206SR-10G-F

FSS-2000BT

SS-1206SR-10G-F

VS-1214-10G-F

FSS-2000LX

SS-1214LX-10G-F

FSS-2000SX

SS-1214SR-10G-F

FSS-2000BT/LX

SS-1214SX-10G-F

FSS-2000BT/SX

FTAP-1000BT

FTAP-2000BT

FASTAP-1044BT

FTAP-1000LX

FTAP-2000LX

FTAP-1000SX

FTAP-2000SX

FTAP-2000BT/LX

FTAP-2000BT/SX

7.1.1 Supported Products

FLOWcontrol™ supports these Datacom Systems Inc Products:

FLOWcontrol™ supports these Datacom Systems Inc Filter Products:

25

Also, FLOWcontrol™ supports these Fluke Networks Filtered Products:

© 2010 Datacom Systems Inc

VERSA™stream

Page 26

FLOWcontrol™26

7.1.2 PC Requirements

IMPORTANT: Update to the current Microsoft® .NET Framework before

installing FLOWcontrol™ software.

The FLOWcontrol™ software is compatible with any Windows Operating System

that supports Microsoft® .NET Framework.

7.1.3 Installation

This section installs FLOWcontrol™ software and is used to configure the Filtered

Products listed in Supported Products . You must run the setup program which

25

takes you through the installation with instructions on every screen. Copying

files directly from the distribution CD to your hard disk will result in a failed

installation. When the setup program is finished, put the CD in a safe place.

Before installing FLOWcontrol™:

Log into your Windows operating systems computer with administrator

privileges

Close all other applications before beginning the installation.

Make sure you have at least 100 MB of available disk space.

NOTE: Some computers have security protections associated with the

installation of new applications. If presented with a Security Warning, click

through to continue the installation process.

To install the FLOWcontrol™ software on your computer:

Insert the FLOWcontrol™ CD into your computer's CD-ROM drive. The

1.

installation InstallShield Wizard program should start automatically. If it

does not start, locate your CD-ROM drive in Windows Explorer and doubleclick the setup.exe program.

Follow the specific instructions on each screen to run the setup program.

2.

Read and accept the terms of the Software License Agreement.

3.

Choose either the default or an appropriate Destination Folder and click

4.

Next to begin the installation. All files needed are copied during

installation.

When InstallShield is done, before clicking the Finish button, you may

5.

optionally check the Launch FLOWcontrol box to immediately use

FLOWcontrol™ after clicking the Finish button.

NOTE: It may be necessary to open TCP Port 2370 on local Firewall settings

in the Windows 2000 / Windows XP environments in order for the

FLOWcontrol™ software to function properly. the software uses this port to

communicate with connected devices.

You are now ready to begin using FLOWcontrol™!

VERSA™stream

© 2010 Datacom Systems Inc

Page 27

FLOWcontrol™

FLOWcontrol™ Main Screen

Communications Console

Filter Management

Product Control Screen

The FLOWcontrol

Main Screen

contains three

elements. The first

is the Pull Down

Menu Bar, the

second is the

Agent List and the

third is the Filter

Management.

File

Tabs

Agent

Help

Utilities

27

7.2 FLOWcontrol™ User Interface

In order to start the FLOWcontrol™ application, use the Windows Menu

Selections by selecting: Start > Programs > Datacom Systems >

FLOWcontrol_V2

The Graphical User Interface (GUI) for FLOWcontrol™ consists of multiple

elements which will be described in the sections that follow. These include:

27 59

36 60

You may need to configure your Filtered Product with an IP address that is

appropriate for your local network before making use of the FLOWcontrol

software. Details for setting the IP address can be found in the Filtered Product

Hardware USERguide. A connection can also be established using the factory

default (192.168.1.1) IP address.

7.2.1 FLOWcontrol Main Screen

The Main Screen is shown here when FLOWcontrol™ is run the first time. From

the Main screen the user is able to connect to a Filtered Product to create a new

Agent, use an existing Agent or modify the properties of an existing Agent. After

subsequent runs of FLOWcontrol™, a short delay may be experienced while

FLOWcontrol™ loads existing Agent elements. FLOWcontrol™ supports off-line

filter management.

7.2.1.1 Pull Down Menu Bar

The FLOWcontrol™ Main Screen Pull Down Menu Bar includes a number of

sections. These include:

28 34

29 34

32

Each of these menu options may also have sub menu items. Each of the pull

down menu options are discussed in later sections.

© 2010 Datacom Systems Inc

VERSA™stream

Page 28

7.2.1.1.1 File

Selection of this sub menu will operate in one of two

ways. If no Agent connection exists, the FLOWcontrol

program exits. If a connection exists, a LOGOUT is

performed and the tab page which contains the product specific controls is

removed. All other tabs, including Filter Management, other connected

Agents, and any Communications Consoles will remain. Multiple connected

agents can be maintained within FLOWcontrol™. If the Filter Management tab

is selected when File > Exit is executed, a sequence of dialog boxes will

appear asking for confirmation to close any other Agents that may be

connected.

This first figure

represents the

unconnected

Main Screen

This second figure

represents the

Main Screen with

a single Agent

connected to a

Filtered product

(specifically an

FVS-1080).

And this third

figure represents

a Main Screen

with multiple

agents

connected.

File > Exit — The File menu option provides only an Exit option.

FLOWcontrol™28

Selection of the in the upper right of the window in either case performs the

exact same functionality as the File > Exit menu option.

VERSA™stream

© 2010 Datacom Systems Inc

Page 29

FLOWcontrol™

Connect

Disconnect

Communications Console

Add

Modify

Delete

Refresh

Restart

Agent > Connect — menu selection will

attempt to authenticate to the selected

agent. If no agent is selected, a message

box will be presented indicating that an

agent must be selected.

If the agent is a normal FLOWcontrol™ agent, a dialog box

will appear requesting authentication information for the

selected agent. The Username field of the dialog box will be

loaded with the last known User to login.

7.2.1.1.2 Agent

The Agent menu provides for context sensitive options. These include:

7.2.1.1.2.1 Connect

29

If the agent is a telnet Agent, a TELNET Communications Console will

automatically open.

© 2010 Datacom Systems Inc

VERSA™stream

Page 30

FLOWcontrol™30

Entry of a valid Username and Password will authenticate and subsequently

connect to the filtered product for which the agent was selected. During the

connection phase, the authentication of the entered Username and Password is

completed. If the authentication is valid, FLOWcontrol™ requests information

from the filtered product regarding its product properties (i.e., supported media

types, tap ports, etc.). Based upon the properties, various FLOWcontrol

elements are loaded. These elements may vary from product to product. Once

the product elements are loaded, another tab page is added which corresponds

to the product selected. A front panel graphic is presented and a series of

subordinate tab pages are populated, also based on the product properties.

In FLOWcontrol™, it is possible to connect to multiple agents simultaneously.

However, when a connection has been established, the newly connected agent's

product tab is selected.

7.2.1.1.2.2 Disconnect

Agent > Disconnect — menu selection will perform the same functionality as

the File > Exit menu option. Please refer to that section to determine the

28

functionality.

7.2.1.1.2.3 Communications Console

Agent > Communications Console — will Open or Close a specified

Communications Console. A newly created Communications Console can be used

for either Telnet or Serial communications.

Additional information regarding the Communications Console can be found in

59

the section that follows.

7.2.1.1.2.4 Add

Agent > Add — menu selection will invoke the Agent Properties form as noted in

the Agent > Add, Modify Properties Form section of this document. A new

31

Agent can be added to the Agent List using this function.

VERSA™stream

© 2010 Datacom Systems Inc

Page 31

FLOWcontrol™

Agent > Delete — menu selection will remove

an agent from the Agent List and from the

registry, where the definition for said agent

resides. A confirmation screen is presented

prior to allowing deletion to occur..

Agent > Add, Modify — is handled using an

Agent Properties form into which specific

information can be designated. The Agent

Properties form appears when Add or Modify

is selected from the Agent menu.

From this form the Agent, Location and

Connection can be managed. In addition, the

filtered product found at a specified

Connection can be determined. Selection of

the button on the form attempts to

communicate and determine what filtered

product responds. Although this capability is

provided, an agent may be specified without

determining the product. Whenever an actual

7.2.1.1.2.5 Delete

31

Selecting the button will accomplish the deletion, while selection of the

button will cancel the deletion.

7.2.1.1.2.6 Modify

Agent > Modify — menu selection will invoke the Agent Properties form as

noted in the Agent > Add, Modify Properties Form section of this document.

31

The Agent properties unique to the selected Agent will be populated into the

Agent Properties form for modification by the user.

7.2.1.1.2.7 Refresh

Agent > Refresh — clears the agent list and reloads it from the registry.

7.2.1.1.2.8 Restart

Agent > Restart — performs a warm boot and causes the agent to disconnect.

7.2.1.1.2.9 Agent > Add, Modify Properties Form

connection is made to a specified agent, the product type and properties are

retrieved from the hardware and appropriate adjustments are made to the Agent

definition in the computer registry and on the Agent List. Each Agent defined is

stored in the local computer's registry.

All controls on the form are editable. As a result, if a new Agent is required,

enter the new agent name into the drop down box. Subsequent Agent additions

will build a list of agents found so that selection of a given Agent can be made

through the drop-down box. The same is true of the Location. The Agent and

Location Descriptions are free text used to specify unique characteristics for the

given Agent or Location. The Connection Type drop-down box is populated with

any local unused COM ports as well as populating the entry of "Network

Connectivity". Whenever Network Connectivity is selected, the IP Address and IP

© 2010 Datacom Systems Inc

VERSA™stream

Page 32

FLOWcontrol™32

Upgrade

Memory

Options

Reset to Factory Defaults

User Accounts

The Utilities > Upgrade performs different

actions depending upon the product that is

connected. For example, a PDF with instructions

for upgrading a FVS-1080 file will open. Check for

specific instructions on performing this function.

The Utilities > Options is context sensitive and

will present a form with the available options

under user control.

This form also provides the ability to set:

Filter File Location

Filtered Product IP Address

Real Time Clock

SYSLOG parameters

The Filter File Location option is used to

share a filter file on a network location or

the default installed directory can be

used.

The Product IP Address may be modified

by checking to enable

the Product IP Configuration.

Port fields become enabled and appropriate text can be entered. When all

information is entered on the form as desired, selection of the button will

update all entered information into the registry appropriate for FLOWcontrol™.

Selection of the button will not save any of the information entered.

7.2.1.1.3 Utilities

The selected Agent determines the menu items provided and could include:

32 33

32 34

The Real Time Clock can be set by checking to enable the

System Time Configuration. In addition, to use the current time from the PC on

which FLOWcontrol™ is installed, check the . This will fill in the

System Date and System Time from the PC Clock. Otherwise, the Date and Time

can be set by the user.

The SYSLOG option allows the user to enable the SYSLOG capability by checking

VERSA™stream

© 2010 Datacom Systems Inc

Page 33

FLOWcontrol™

The Utilities > User

Accounts menu item

allows for product

specific User Accounts

management.

The User Account Management Screen is

depicted. Specifically, the Username field is a

text box into which the new Username should

be entered. In the case of a Modify or Delete of

a User Account, the text box will appear as a

combo box from which to select the user to be

operated upon. this combo box is depicted as

. The individual tabs within the User

Management form allow for customizing the

security rights for the selected user. The major

groupings for the rights are:

User Rights

Aggregation Rights

Port Rights

Options Rights

Filter Rights

Agent Rights

Memory Rights

Within each of these groupings specific rights are enabled or disabled

depending on the requirements for a given user.

The Utilities > Memory menu item provides the means for a user to do the

following actions:

Determine the Status of the

installed Memory

Enable the Oversubscription

Memory

Disable the Oversubscription

Memory

33

to enable the SYSLOG configuration. The SYSLOG Server IP

Address will become enabled and the SYSLOG server IP must be entered. If

is not checked, the SYSLOG capability will be disabled.

Pressing saves all the values and sets them on the connected Filtered

Product. Pressing closes the form and does not save any of the options.

PLEASE NOTE: Only the Filter File Location option will be available if FLOW

control™ does not have an established connection to a filtered product. All other

options become available when a valid connection is made.

© 2010 Datacom Systems Inc

VERSA™stream

Page 34

The Utilities > Reset resets all parameters back to factory defaults:

Port Names

Memory Oversubscription

Port Media Settings

Filter Configuration (PASS-ALL)

Port Assignments

Clear the Event Log

Aggregation Settings

The Tabs menu is dynamically built providing

the ability to select an agent, communications

console or the Filter Management tab,

depending upon those tabs being available.

The Help menu provides information regarding

FLOWcontrol™:

unconnected

The Help > About

menu option will

present a dialog box

containing information

about FLOWcontrol™,

its element dynamic

data libraries (DLLs)

and any connected

product firmware and

configuration

information. Both a

unconnected and

connected Help About

screen are depicted:

connected

The Help > FLOWcontrol menu

option presents this help file.

7.2.1.1.4 Tabs

7.2.1.1.5 Help

7.2.1.1.5.1 About

FLOWcontrol™34

7.2.1.1.5.2 FLOWcontrol Help

VERSA™stream

© 2010 Datacom Systems Inc

Page 35

FLOWcontrol™

The Help > Web Site menu option launches the Datacom

Systems Inc company web site for the FLOWcontrol

application.

The Help > Tutorials provides a list

of tutorial files that may aid in

understanding the FLOWcontrol

product and its application.These

may be Windows Media Player files,

Acrobat Reader files or other media

files. The appropriate application

will launch the selected file.

The agent tree view shows the list of Agents defined

by a user of FLOWcontrol™. The list is divided into

Agent Groupings. Within the Agent Groupings, specific

Locations are specified. Please note that the list is

alphabetically sorted. Within the Locations, specific

Agents are designated as either a local COM port or

as a network agent with an IP address specified. The

specific Agents are sorted showing the COM ports

first, then the IP Addresses are sorted by IP address.

From the Agent List, connectivity can be established

between FLOWcontrol™ and the Supported Products

. Agents can be added, deleted or modified by using

either the context sensitive menus for the Agent List

or by using the pull down menus on the Main Screen.

The context sensitive menu is depicted.

As can be seen, Agents can be Added, deleted or

modified. In addition, connection can be made or

a Telnet or Serial Console may be launched

directly. The Telnet Console menu item is

enabled when an IP address is selected on the

Agent List. The Serial Console menu item is

enabled when a COM port is selected on the

Agent List.

7.2.1.1.5.3 Web Site

7.2.1.1.5.4 Tutorials

7.2.1.2 Agent List

35

The Agent List is a element of the Main Screen and displays as a treeview,

similar to Windows Explorer. From this treeview, the user is able to create a new

Agent, use an existing Agent or modify the properties of an existing Agent.

31

© 2010 Datacom Systems Inc

25

VERSA™stream

Page 36

FLOWcontrol™36

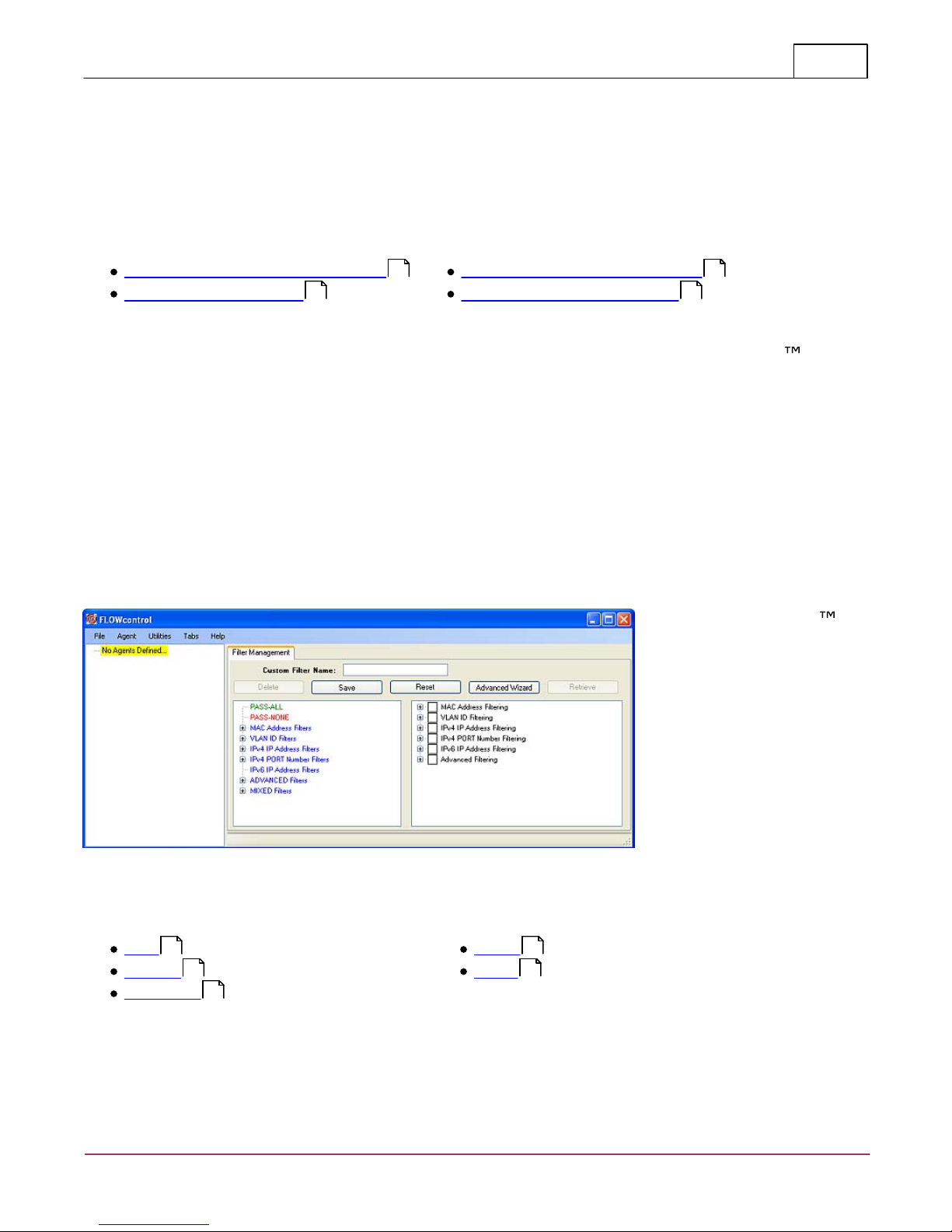

7.2.2 Filter Management

FLOWcontrol™ provides the capability to manage filters off-line. Upon starting

FLOWcontrol™, not only does the Agent List appear, but a tab control appears

in the left hand pane of the FLOWcontrol™ Main Screen. From the "Filter

Management" tab, filters can be added, deleted or modified. An Advanced

Wizard is provided to ease filter creation. The Advanced Wizard provides a

methodology for creation of complex filters. Each of the filters created, both with

and without the wizard, are grouped into the following major sections.

MAC Address Filters

VLAN ID Filters

IPv4 IP Address Filters

IPv4 PORT Number Filters

IPv6 IP Address Filters

ADVANCED Filters

MIXED Filters

Frame Type and Protocol Filters built in the Advanced Wizard are considered

ADVANCED Filters and will appear under this major section.

The Filter Management capability provides the user with off-line filter

management. Filters can be created, deleted, and modified without being

attached to a specific filtered product. In addition, a wizard is provided to

facilitate easy filter creation. The Filter Management screen is depicted next.

Filter Management is divided into two major areas, the first is Saved Filters (left

hand panel), which sorts the saved filters into major groups and the second is

Filter Specifics (right hand panel) which is used to define a filter with various

parts. The button is used to delete a currently defined filter. This is

done by selecting a filter which is a subordinate node in the Saved Filters panel.

VERSA™stream

© 2010 Datacom Systems Inc

Page 37

FLOWcontrol™

The Saved Filters Panel consists of a tree view

that has a total of nine groupings as depicted.

PASS-ALL and PASS-NONE are fixed entries. The

next seven groupings contain filters that are

specific to a given filter type. The last grouping

(MIXED Filters) contains filters that are made up of

multiple elements of any of the previous six

groupings. The six individual groupings are:

MAC Address Filters

VLAN ID Filters

IPv4 IP Address Filters

IPv4 PORT Number Filters

IPv6 IP Address Filters

ADVANCED Filters

Expanding a Filter type will give a list of filters within that group. Doubleclicking on a filter will populate the Filter Specifics panel with the filter

definition. No changes can be made to a given filter within this area of the Filter

Management control. Changes are made in the Filter Specifics panel.

37

The top level nodes of the Saved Filters panel cannot be deleted. A confirmation

for deletion of a filter is required. Once a filter definition has been specified in

the Filter Specifics panel, the filter can be saved using the button. In

order for the save to be completed, a filter name must be entered. If a filter

already exists by that name, a confirmation dialog box is presented asking if the

current filter definition is to be overwritten. The button is used to

clear out any current definitions in the Filter Specifics panel so that a new filter

definition can be created. The button presents a wizard to the user

that allows a guided approach to filter creation. More information on this wizard

is found elsewhere in this document. The button allows for retrieval of

a filter definition currently assigned to a given port filter. The is only

enabled when attached to a Filtered product.

Since FLOWcontrol™ supports multiple connections to Filtered products,

selection of the button presents a list of connected filter products

from which to choose. If only one connected Filtered product is populated, a list

will not be shown. Selection of a filtered product from the dialog box combo box

then determines the number and names of the ports on the filtered product and

presents another dialog box with the list of ports from which to select. Selection

of a port from this list then proceeds to another dialog box asking which filter to

retrieve. Depending upon the product, the list of filters available may vary.

Specifically for the Filtered SINGLEstream™, only an Ingress and Egress filter

will be available for retrieval. For the Filtered VERSAstream, multiple ingress and

a single egress filter may be retrieved.

7.2.2.1 Saved Filters Panel

© 2010 Datacom Systems Inc

VERSA™stream

Page 38

FLOWcontrol™38

The Filter Specifics Panel consists of a tree view

that has a total of six groupings as depicted.

MAC Address Filtering

VLAN ID Filtering

IPv4 IP Address

Filtering

IPv4 PORT Number Filtering

IPv6 IP Address Filtering

Advanced Filtering

7.2.2.2 Filter Specifics Panel

The six individual filter groupings consist of a unique blend of elements with

specific differences based upon the filter type. The individual group definitions

are represented in the following six figures:

VERSA™stream

© 2010 Datacom Systems Inc

Page 39

FLOWcontrol™

A filter can consist of multiple filter types. For

example, a filter can be created which is looking

for a source MAC Address of 00-14-E2-00-F9-34

and a VLAN Tag range of 10-25. This filter

definition is represented in the following Filter

Specifics Panel. With a filter of multiple filter

types, the saved filter will appear in the MIXED

filters tree. Otherwise, the specific Filter type

will be populated in the saved filter tree.

7.2.2.2.1 Include/Exclude Definition

39

Within a Filter Type, the filter can be defined as either an Include or an Exclude

Filter. These are mutually exclusive. Each Filter Type has a unique Include/

Exclude flag. For instance, the MAC Address Filter definition may be an Include

Filter, while a VLAN ID Filter may be an Exclude Filter. The Include Filter and

Exclude Filter check boxes apply to all of the Filter Types.

7.2.2.2.2 Include VLAN Tunneling Frames

The Include VLAN Tunneling Frames check box is found in the following Filter

Types:

VLAN ID Filter

IPv4 Address Filter

IPv4 PORT Filter

IPv6 Address Filter

This flag, if checked, forces the filter engine to examine an Ethernet frame to

determine if the frame is a VLAN tagged frame. If so, the specified filter will

accommodate an offset to correspondingly examine the packet structure for a

match whether the frame is VLAN tagged or not.

For example, if a filter is defined to match an IPv4 Source Address of

12.45.76.98, the filter engine examines the frame to determine if the source

address found at offsets 26,27,28,29 (zero based) are equal to 12,45,76,98. In

addition, if the VLAN Tunneling Frames checkbox is checked, the filter engine

will also check offsets 12,13,30,31,32,33 (zero based) for values equal to

81,00,12,45,76,98. If an incoming frame matches either of these definitions, the

frame will be passed by the filter engine.

© 2010 Datacom Systems Inc

VERSA™stream

Page 40

FLOWcontrol™40

7.2.2.2.3 Rule Definition

A Rule Definition can vary between Filter Types. The Filter Engine allows for a

total of 16 rules for each of:

MAC Address Filter

VLAN ID Filter

IPv4 Address Filter

IPv4 PORT Number Filter

IPv6 Address Filter

In this context, the following applies:

Range Definitions: If any range of values is defined, the number of rules that

are able to be managed by the user drops from 16 to 8. The reason for this is

that a range consumes two rules. If Rule 1 is defined as a Destination Address

value and Rule 2 is a range of Source Addresses, a total of 4 rules are

consumed. This is handled within the Filter Engine as Rule 1 equals a

Destination Address range with the lower and upper values of the range equal to

one another. If there are no ranges defined, then a total of 16 rules are still

available.

Directional Selections: are applicable for the following Filter Types only:

MAC Address Filter

IPv4 Address Filter

IPv4 PORT Number Filter

IPv6 Address Filter

The Directional Selections include:

Source --> Destination

Destination --> Source