Impact Drill

Trapano a percussione

L220114

Read through carefully and understand these instructions before use.

Prima dell’uso leggere attentamente e comprendere queste istruzioni.

Handling instructions

Istruzioni per l’uso

1

5

6

2

6

4

5

3

4

8

3

@

0

9

4

8

!

56

#

4

$

5

3

^%

4 3

7

8

q

&

*

)

(

9

2

9

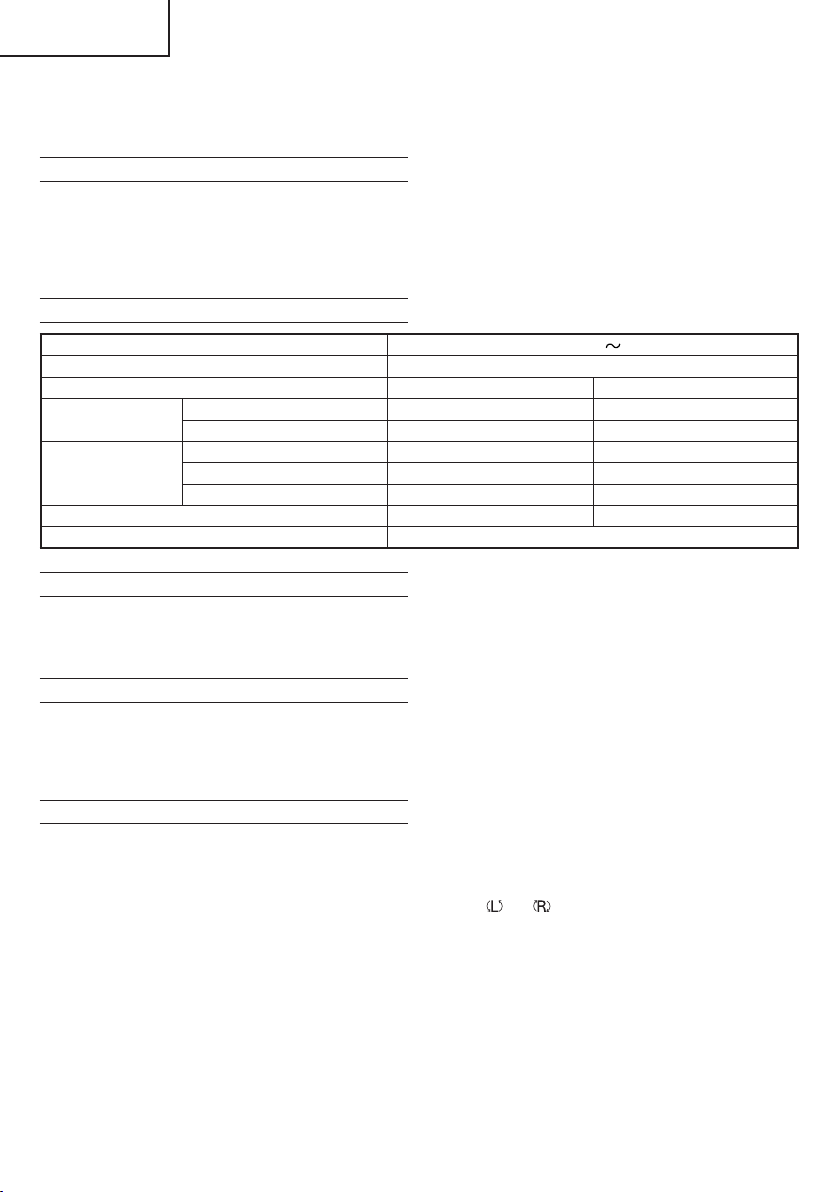

English Italiano

Drill chuck

1

Chuck wrench

2

Tighten

3

Loosen

4

Sleeve

5

Ring

6

Lock collar

7

Side handle

8

Switch trigger

9

Push button

0

mark

!

mark

@

Depth gauge

#

Change lever

$

Impact

%

Rotation

^

Gear shift dial

&

Speed control dial

*

High speed

(

Low speed

)

Stopper Fermo

q

Mandrino trapano

Chiave mandrino

Stringere

Allentare

Collare

Anello

Collare di blocco

Maniglia laterale

Grilletto interruttore

Pulsante

Segno

Segno

Calibro di profondità

Leva di cambiamento

Impatto

Rotazione

Regolazione di velocità

Comando di velocità

Alta velocità

Bassa velocità

3

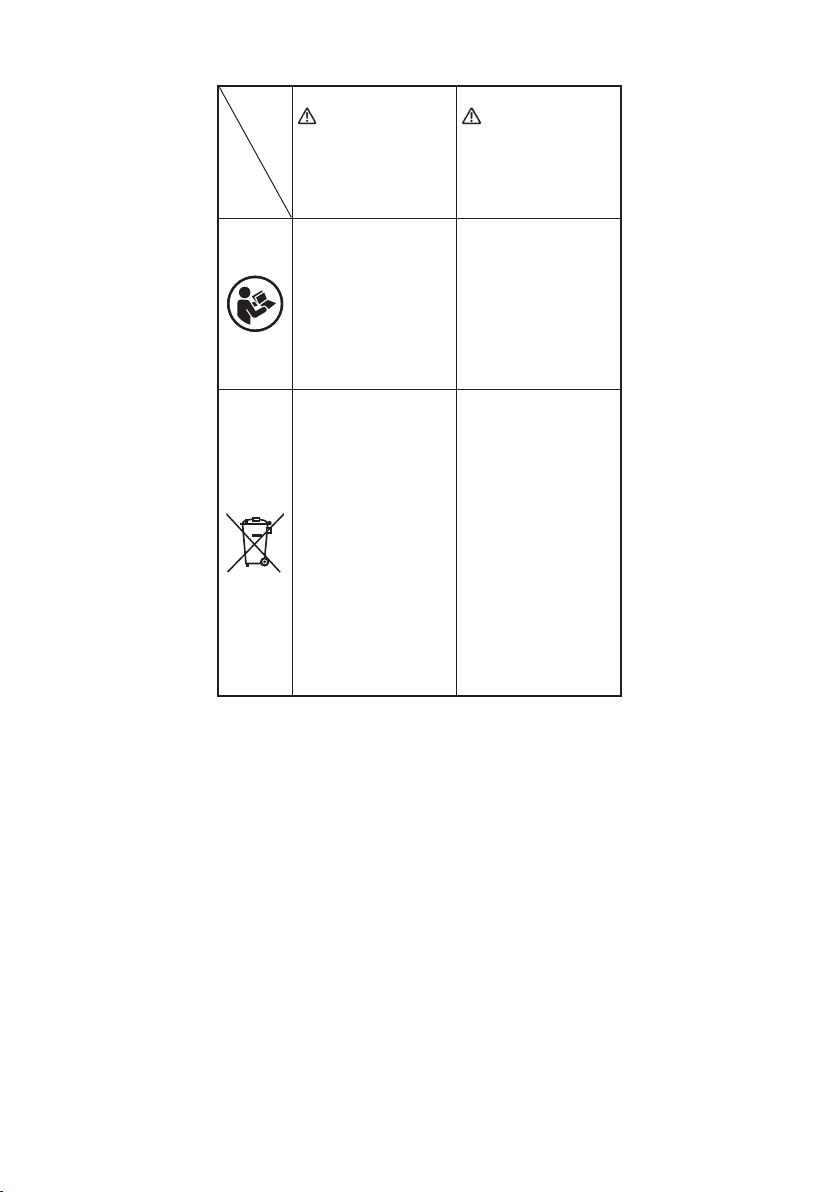

Symbols

WARNING

The following show

symbols used for the

machine. Be sure that

you understand their

meaning before use.

To reduce the risk of

injury, user must read

instruction manual.

Failure to follow

the warnings and

instructions may result

in electric shock, fi re

and/or serious injury.

Only for EU countries

Do not dispose of

electric tools together

with household waste

material!

In observance of

European Directive

2002/96/EC on

waste electrical and

electronic equipment

and its implementation

in accordance with

national law, electric

tools that have reached

the end of their life

must be collected

separately and returned

to an environmentally

compatible recycling

facility.

Simboli

AVV ER TENZ A

Di seguito mostriamo

i simboli usati per la

macchina. Assicurarsi

di comprenderne

il signifi cato prima

dell’uso.

Per ridurre il rischio

di lesioni, l’utente

deve leggere il

manuale delle

istruzioni.

La mancata osservanza

degli avvertimenti e

delle istruzioni potrebbe

essere causa di scosse

elettriche, incendi e/o

gravi lesioni.

Solo per Paesi UE

Non gettare le

apparecchiature

elettriche tra i rifi uti

domestici.

Secondo la Direttiva

Europea 2002/96/

CE sui rifi uti di

apparecchiature

elettriche ed

elettroniche e la

sua attuazione in

conformità alle

norme nazionali,

le apparecchiature

elettriche esauste

devono essere raccolte

separatamente, al fi ne

di essere reimpiegate in

modo eco-compatibile.

4

English

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safet y warnings and all instructions.

Failure to follow the warnings and instructions may result in

electric shock, fi re and/or serious injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

power tool.

1) Work ar e a s a fet y

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

fl ammable liquids, gases or dust.

Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while

operating a power tool.

Distractions can cause you to lose control.

2) Electrica l safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way.

Do not use any adapter plugs with earthed

(grounded) power tools.

Unmodifi ed plugs and matching outlets will reduce

risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions.

Water entering a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an

extension cord suit able for outdoor use.

Use of a cord suitable for outdoor use reduces the

risk of electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply.

Use of an RCD reduces the risk of electric shock.

3) Personal safet y

a) Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired

or under the infl uence of drugs, alcohol or

medication.

A moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection.

Protective equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal

injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off position before connecting

to power source and/or battery pack, picking

up or carrying the tool.

Carrying power tools with your fi nger on the switch

or energising power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on.

A wrench or a key left attached to a rotating part of

the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times.

This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts.

Loose clothes, jewellery or long hair can be caught

in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application.

The correct power tool will do the job better and

safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not

turn it on and off .

Any power tool that cannot be controlled with the

switch is dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or the bat tery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool.

Power to ols are dangero us in the hands of untrain ed

users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may aff ect the

power toolʼs operation.

If damaged, have the power tool repaired

before use.

Many accidents are caused by poorly maintained

power tools.

f) Keep cut ting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions and

the work to be per formed.

Use of the power tool for operations diff erent from

those i ntended coul d result in a haza rdous situati on.

5) Service

a) Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts.

This will ensure that the safety of the power tool is

maintained.

5

English

PRECAUTION

Keep children and infi rm persons away.

When not in use, tools should be stored out of reach

of children and infi rm persons.

IMPACT DRILL SAFETY WARNINGS

1. Wear ear protectors when impact drilling.

Exposure to noise can cause hearing loss.

2. Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

3. Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may cont act hidden wiring or its own

cord.

Cutting accessory contacting a “live” wire may make

exposed metal parts of the power tool “live” and could

give the operator an electric shock.

4. Before drilling into walls, ceilings or fl oors, ensure that

there are no concealed power cables inside.

5. Always use side handle and hold the tool fi rmly with

both hands.

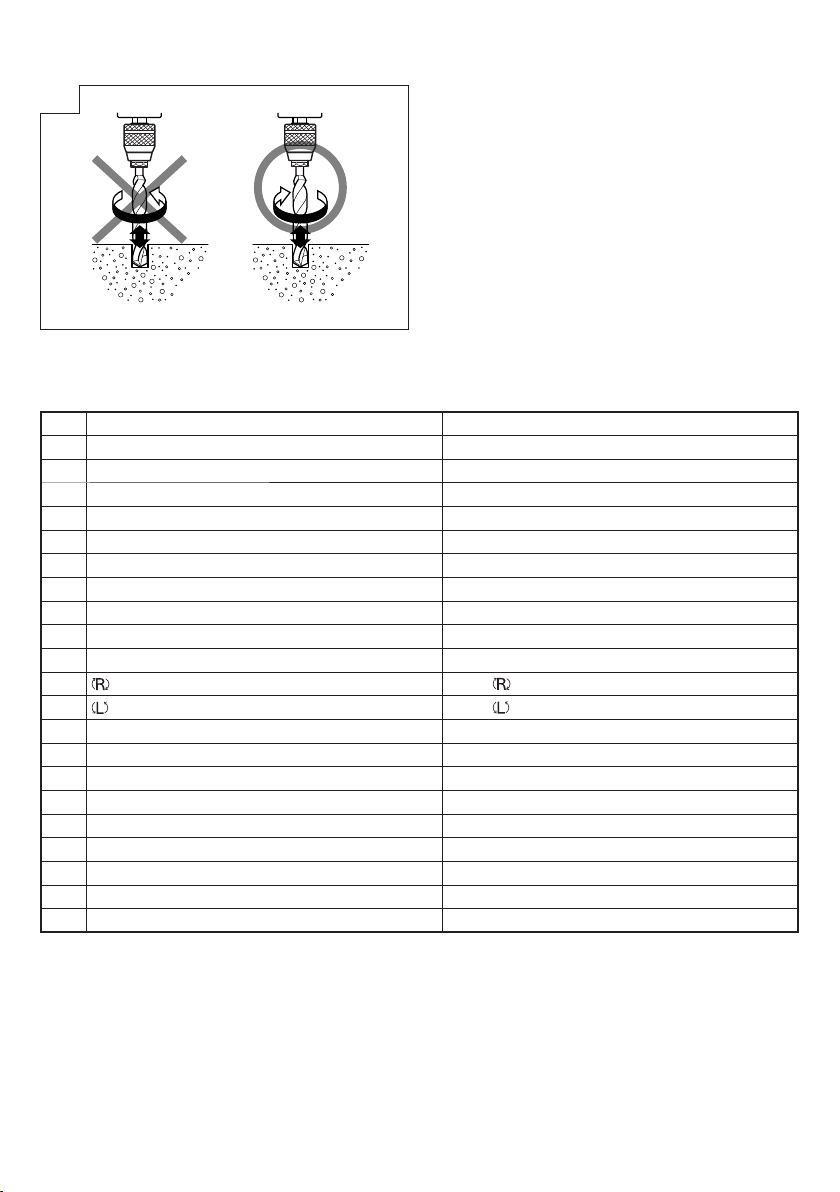

6. Always use the impact drill with clock wise rotation,

when using it as an impact drill. (Fig . 9)

SPECIFICATIONS

Voltage 230 V

Power input 790 W

Speed change 1 2

No load speed

Forward rotation 0 – 1000 min

Reverse rotation 0 – 600 min

Steel 13 mm 8 mm

Capacity

Concrete 20 mm 13 mm

Wood 40 mm 25 mm

Full load impact rate 8000 min

Weight (without cord) 2.2 kg

STANDARD ACCESSORIES

(1) Plastic Case .................................................................1

(2) Side Handle ..................................................................1

(3) Depth Gauge ................................................................1

Stand ard accessor ies are subjec t to change wit hout notice.

APPLICATIONS

○ By combined actions of ROTATION and IMPACT:

Boring holes in hard materials (concrete, marble,

granite, tiles, etc.)

○ By ROTATIONAL action:

Boring holes in metal, wood and plastic.

PRIOR TO OPERATION

1. Power sour ce

Ensure that the power source to be utilized conforms

to the power requirements specifi ed on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position. If

the plug is connected to a receptacle while the power

switch is in the ON position, the power tool will start

operating immediately, inviting serious accident.

3. Extension cord

When the work area is removed from the power source,

use an extension cord of suffi cient thickness and rated

capaci ty. The extension c ord should be kept a s short as

practicable.

4. Selec ting the appropriate drill bit

○ When boring concrete or stone

Use the drill bits specifi ed in the Optional Accessories.

○ When boring metal or plastic

Use an ordinary metalworking drill bit.

○ When boring wood

Use an ordinary woodworking drill bit.

However, when drilling 6.5 mm or smaller holes, use a

metalworking drill bit.

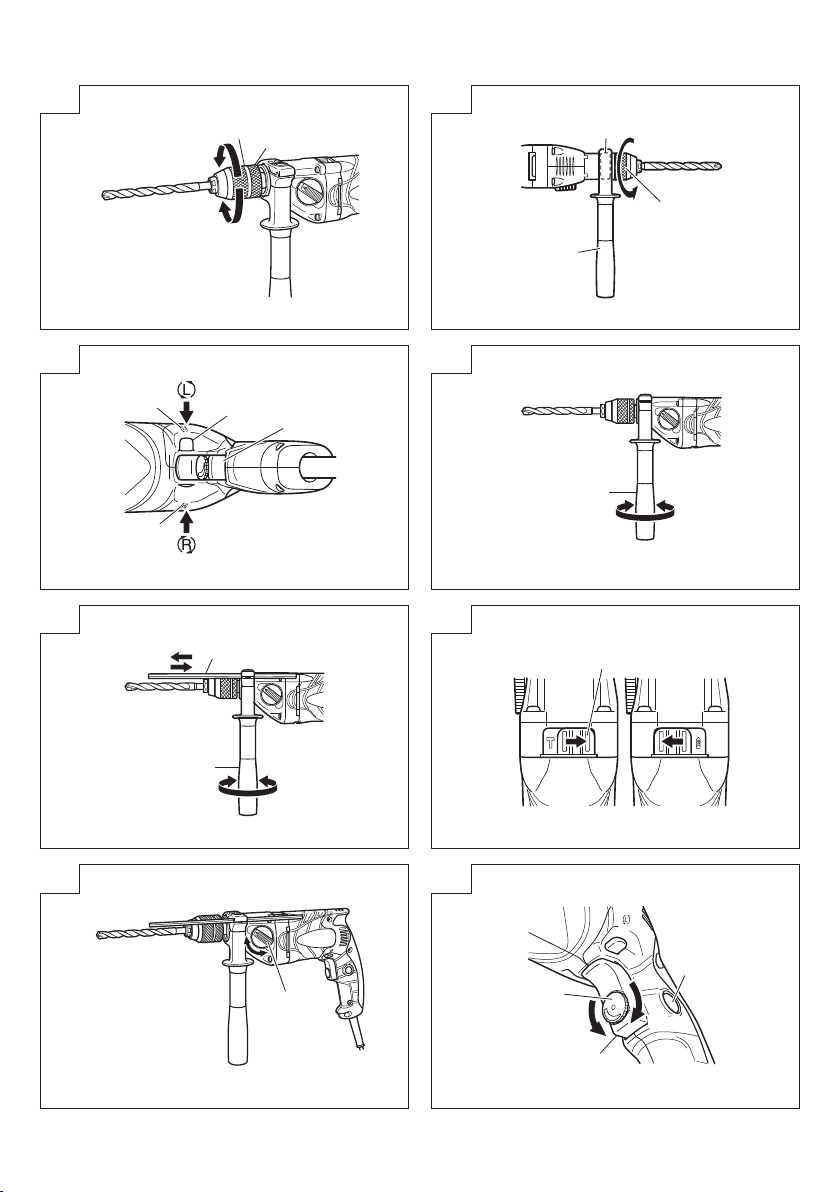

5. Mounting and dismounting of the bit.

(1) Mounting the bit

Turn the sleeve counterclockwise and open the chuck.

After inserting the drill bit into the chuck as far it will go,

grip the ring and close the chuck by turning the sleeve

clock wise as viewed from the front. (Fig. 1)

(2) Dismounting the bit

Grip the ring and open the chuck by turning the sleeve

counterclockwise. (Fig. 1)

NOTE

When the sleeve does not become loose any further, fi x

the side handle to ring, hold side handle fi rmly, then turn

the sleeve to loosen by hand. (Fig. 2)

6. Check the rotational direction (Fig. 3)

The bit rotates clockwise (viewed from the rear side) by

pushing the R-side of the push button.

The L-side of the push button is pushed to turn the bit

counterclockwise.

(The

CAUTION

Always use the impact drill with clockwise rotation,

when using it as an impact drill.

7. Fixing the side handle (Fig. 4)

Attach the side handle to the mounting part.

Rotate the side handle grip in a clockwise direction to

secure it.

Set the side handle to a position that is suited to the

operation and then securely tighten the side handle

grip.

To attach a depth gauge on the side handle, insert the

gauge into the U-shaped groove on the side handle,

adjust the position of the depth gauge in accordance

with the desired depth of the hole, and fi rmly tighten the

side handle grip. (Fig. 5)

6

-1

-1

-1

0 – 3000 min

0 – 1800 min

26000 min

and marks are provided on the body.)

-1

-1

-1

English

8. IMPACT to ROTATION changeover (Fig. 6)

Shift the change lever between the right and left

posit ions to switch e asily bet ween IMPACT (rotation an d

impact) and ROTATION (rotation only), respectively.

To bore holes in hard materials such as concrete,

stone and tiles, shift the change lever to the right-hand

position (as indicated by the

The drill bit operates by the combined actions of impact

and rotation.

To bore holes in metal, wood and plastic, shift the

change lever to the left-hand position (as indicated by

the

mark). The drill bit operates by rotational action

only, as in the case of a conventional electric drill.

CAUTION

○ Do not use the Impact Drill in the IMPACT function

if the material can be bored by rotation only. Such

action will not only reduce drill effi ciency, but may

also damage the drill tip.

○ Operating the Impact Drill with the change lever

in mid-position may result in damage. When

switching, make sure that you shift the change lever

to the correct position.

9. High-speed/Low-speed changeover:

Prior to changing speed, ensure that the switch is in the

OFF position, and the drill has come to a complete stop.

To change speed, rotate the gear shift dial as indicated

by the arrow in Fig. 7. The numeral “1” engraved on the

drill body denotes low speed, the numeral “2” denotes

high speed.

If it is hard to turn the gear shif t dial, turn the chuck

slightly in either direction and then turn the gear shift

dial again.

mark).

HOW TO USE

1. Switch operation

○ When the trigger is depressed, the tool rotates. When

the trigger is released, the tool stops.

○ The rotational speed of the drill can be controlled by

varying the amount that the trigger switch is pulled.

Speed is low when the trigger switch is pulled slightly

and increases as the trigger switch is pulled more.

○ The desired rotation speed can be pre-selected with

the speed control dial.

Turn the speed control dial clockwise for higher speed

and counterclockwise for lower speed. (Fig. 8)

○ Pulling the trigger and pushing the stopper, it keeps

the switched- on condition which is convenient for

continuous running. When switching off , the stopper

can be disconnected by pulling the trigger again.

CAUTION

If the L-side of push button is pressed for reverse bit

rotation, the stopper cannot be used.

2. Drilling

○ When drilling, start the drill slowly, and gradually

increasing speed as you drill.

○ Always apply pressure in a straight line with the bit. Use

enough pressure to keep drilling, but do not push hard

enough to stall the motor or defl ect the bit.

○ To minimize stalling or breaking through the material,

reduce pressure on drill and ease the bit through the

last par t of the hole.

○ I f the drill stalls, rele ase the trigge r immediately, remove

the bit from the work and start again. Do not click the

trigger on and off in an attempt to start a stalled drill.

This can damage the drill.

○ The larger the drill bit diameter, the larger the reactive

force on your arm.

Be careful not to lose control of the drill because of this

reactive force.

To maintain fi rm control, establish a good foothold,

use side handle, hold the drill tightly with both hands,

and ensure that the drill is vertical to the material being

drilled.

MAINTENANCE AND INSPECTION

1. Inspecting the drill bits

Since use of an abraded drill bits will cause motor

malfunctioning and degraded effi ciency, replace the

drill bits with a new one or resharpening without delay

when abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws

be loose, retighten them immediately. Failure to do so

could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the power

tool. Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Inspecting the carbon brushes

For your continued safety and electrical shock

protection, carbon brush inspection and replacement

on this tool should ONLY be performed by an Authorized

Service Center.

5. Replacing supply cord

If the supply cord of Tool is damaged, the Tool must be

returned to Authorized Service Center for the cord to be

replaced.

6. Service parts list

CAUTION:

Repair, modifi cation and inspection of Power Tools

must be carried out by an Authorized Ser vice Center.

This Parts List will be helpful if presented with th e tool to

the Authorized Service Center when requesting repair

or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

countr y must be observed.

MODIFICATION:

Power Tools are constantly being improved and

modifi ed to incorporate the latest technological

advancements.

Accordingly, some parts may be changed without prior

notice.

GUARANTEE

We guarantee DATACOL Power Tools in accordance with

statutory/country specifi c regulation. This guarantee does

not cover defects or damage due to misuse, abuse, or

normal wear and tear. In case of complaint, please send

the Power Tool, undismantled, with the GUARANTEE

CERTIFICATE found at the end of this Handling instruction,

to an Authorized Service Center.

NOTE

Due to DATACOL’s continuing program of research and

development, the specifi cations herein are subject to

change without prior notice.

7

English

IMPORTANT

Correct connection of the plug

The wires of the mains lead are coloured in accordance

with the following code:

Blue:- Neutral

Brown:- Live

As the colours of the wires in the mains lead of this

tool may not correspond with the coloured mark ings

identifying the terminals in your plug proceed as follows:

The wire c oloured blu e must be connec ted to the termin al

marked with the letter N or coloured black.

The wire coloured brown must be connected to the

terminal marked with the letter L or coloured red.

Neither core must be connected to the earth terminal.

NOTE

This requirement is provided according to BRITISH

STANDARD 2769: 1984.

Therefore, the letter code and colour code may not be

applicable to other markets except United Kingdom.

Information concerning airborne noise and vibration

The measured values were determined according to

EN60745 and declared in accordance with ISO 4871.

Measured A-weighted sound power level: 109 dB (A)

Measured A-weighted sound pressure level: 98 dB (A)

Uncer tainty K: 3 dB (A).

Wear ear protection.

The typical weighted root mean square acceleration value:

2

12.9 m/s

.

8

Italiano

AVVERTENZE GENERALI DI SICUREZZA

SUGLI UTENSILI ELETTRICI

ATT E NZI ONE

Leggere tutti gli av vertimenti di sicurezza e tutte le

istruzioni.

La mancata osservanza degli avvertimenti e delle istruzioni

potrebbe essere causa di scosse elettriche, incendi e/o

gravi lesioni.

Salvare tutti gli avvertimenti e le istruzioni per

riferimenti futuri.

Il termine “utensile elettrico” riportato nelle avvertenze si

riferisce al proprio utensile elettrico alimentato dalla rete

(via cavo) o all’utensile alimentato a batterie (senza cavo).

1) Sicurezza dell’area operativa

a) Mantenere l’area operativa pulit a e ordinata.

Aree operative sporche o disordinate possono

favorire gli infortuni.

b) Non utilizzare gli elettroutensili in atmosfere

esplosive, ad es. in presenza di liquidi, gas o

polveri infi ammabili.

Gli elettroutensili generano delle scintille che

potrebbero accendere la polvere o i fumi.

c) Tenere lontani bambini e astanti durante

l’utilizzo degli elettroutensili.

Qualsiasi distrazione può essere causa di perdita di

controllo.

2) Sicurezza elettrica

a) Le spine degli elettroutensili devono essere

idonee alle prese disponibili.

Non modifi care mai le prese.

Con gli elettroutensili a massa (messi a terra),

non utilizzare alcun adattatore.

L’utilizzo di spine intatte e corrispondenti alle prese

disponibili ridurrà il rischio di scosse elettriche.

b) Evitare qualsiasi contat to con le superfi ci a

massa o a terra, quali tubi, radiatori, fornelli e

frigoriferi.

In caso di messa a terra o massa del corpo, s ussiste

un maggior rischio di scosse elettriche.

c) Non esporre gli elettroutensili alla pioggia o

all’umidità.

La penetrazione di acqua negli elettroutensili

aumenterà il rischio di scosse elettriche.

d) No n tirare il cavo . Non utiliz zarlo per i l traspor to,

o per tirare o scollegare l’elettroutensile.

Tenere il cavo lontano da fonti di calore, oli,

bordi appuntiti o parti in movimento.

Cavi danneggiati o attorcigliati possono aumentare

il rischio di scosse elettriche.

e) Durante l’uso degli elet troutensili all’esterno,

utilizzare una prolunga idonea per usi esterni.

L’utilizzo di cavi per esterno riduce il rischio di

scosse elettriche.

f) Se è impossibile evitare l’impiego di un

elettroutensile in un luogo umido, utilizzare

l’alimentazione protetta da un dispositivo a

corrente residua (RCD).

L’uso di un RCD ridu ce il rischio di scoss e elettriche.

3) Sicurezza personale

a) Durante l’uso degli elet troutensili, state

all’erta, verifi cate ciò che state eseguendo e

adottate sempre il buon senso.

Non utilizzate gli elettroutensili qualora siate

stanchi, sotto l’infl uenza di farmaci, alcol o

cure mediche.

Anche un attimo di disattenzione durante l’uso

degli elettroutensili potrebbe essere causa di gravi

lesioni personali.

b) Indossate l’attrezzatura di protezione

personale. Indossate sempre le protezioni

oculari.

L’attrezzatura protettiva, quali maschera facciale,

calzature antiscivolo, caschi o protezioni oculari

ridurrà il rischio di lesioni personali.

c) Impedite le accensioni involontarie. Prima del

collegamento a una sorgente di alimentazione

e/o pacco batteria e prima di raccogliere

o trasportare l’utensile, verifi cate che

l’interruttore sia posizionato su OFF.

Il trasporto degli utensili elettrici tenendo le proprie

dita sull’interruttore o l’attivazione elettrica degli

utensili che hanno l’interruttore acceso, favorisce

gli incidenti.

d) Prima di attivare l’elettroutensile, rimuovete

qualsiasi chiave di regolazione.

Lasciando la chiave in un componente in rotazione

dell’elettroutensile, sussiste il rischio di lesioni

personali.

e) Mantenersi in equilibrio. Mantenersi sempre su

due piedi, in equilibrio stabile.

Ciò consente di controllare al meglio l'elettroutensile

in caso di situazioni impreviste.

f) Vestirsi in modo adeguato. Non indossare abiti

larghi o gioielli. Tenere i capelli, gli abiti e i

guanti lontano dalle parti in movimento.

Abiti allentati, gioielli e capelli lunghi potrebbero

impigliarsi nelle parti in movimento.

g) In caso di dispositivi provvisti di collegamento

ad apparecchiature di rimozione e raccolta

polveri, verifi care che queste siano collegate e

utilizzate in modo adeguato.

L’utilizzo della raccolta della polvere può ridurre i

rischi connessi alle polveri.

4) Utilizzo e manutenzione degli elettroutensili

a) Non utilizzare elettroutensili non idonei.

Utilizzare l’elettroutensile idoneo alla propria

applicazione.

Utilizzando l’elettroutensile corretto, si garantirà

un’esecuzione migliore e più sicura del lavoro, alla

velocità di progetto.

b) Non utilizzare l’elettroutensile qualora non

sia possibile accenderlo/spegnerlo tramite

l’interruttore.

É pericoloso utilizzare elettroutensili che non

possano essere azionati dall’interruttore.

Provvedere alla relativa riparazione.

c) Prima di eff ettuare qualsiasi regolazione,

sostituire gli accessori o depositare gli

elettroutensili, scollegare la spina dalla presa

elettrica e/o il pacco batteria dall’utensile

elettrico.

Queste misure di sicurezza preventive riducono il

rischio di avvio involontario dell’elettroutensile.

d) Depositare gli elettroutensili non utilizzati

lontano dalla portata dei bambini ed evitare

che persone non esperte di elettroutensili o

non a conoscenza di quanto riportato sulle

presenti istruzioni azionino l’elettroutensile.

É pericoloso consentire che utenti non esperti

utilizzino gli elettroutensili.

e) Manutenzione degli elettroutensili. Verifi care

che non vi siano componenti in movimento

disallineati o bloccati, componenti

rotti o altre condizioni che potrebbero

infl uenzare negativamente il funzionamento

dell’elettroutensile.

9

Italiano

In caso di guasti, provvedere alla riparazione

dell’elettroutensile prima di riutilizzarlo.

Molti incidenti sono causati da una scarsa

manutenzione.

f) Mantenere gli strumenti di taglio affi lati e puliti.

Gli strumenti di taglio in condizioni di manutenzione

adeguata, con bordi affi lati, sono meno soggetti al

bloccaggio e sono più facilmente controllabili.

g) Utilizzare l’elettroutensile, gli accessori, le

punte, ecc. in conformità a quanto riportato

nelle presenti istruzioni, tenendo in debita

considerazione le condizioni operative e il tipo

di lavoro da eseguire.

L’uso dell’utensile elettrico per operazioni diverse

da quelle previste potrebbe causare una situazione

pericolosa.

5) Assistenza

a) Affi date le riparazioni dell'elettroutensile a

persone qualifi cate che utilizzino solamente

parti di ricambio identiche.

Ciò garantirà il mantenimento della sicurezza

dell’elettroutensile.

PRECAUZIONI

Tenere lont ano dalla portata di bambini e invalidi.

Quando non utilizzati, gli strumenti dovranno essere

deposti lontano dalla portat a di bambini e invalidi.

AVVISI DI SICUREZZA RELATIVI AL TRAPANO

A PERCUSSIONE

1. Indossare protezioni per le orecchie con le sonde

a percussione.

L’esposizione al rumore può causare la perdita

dell’udito.

2. Utilizzare le leve ausiliarie se fornite con l’utensile.

La perdita di controllo può causare lesioni alla persona.

3. Aff errare l'elettroutensile dalle superfi ci isolate

quando si eseguono operazioni in cui l'attrezzo di

taglio potrebbe venire a contatto con fi li elettrici

nascosti o con il proprio fi lo.

Il contatto dell’accessorio da taglio con un fi lo in

tensione potrebbe mettere in tensione le parti

metalliche esposte dell’utensile elettrico e dare una

scossa elettrica all’operatore.

4. Prima di praticare fori nei muri, soffi tti o pavimenti,

assicurarsi che non ci siano, nacostiall’interno, cavi

elettrici.

5. Utilizzae sempre la manopola laterale e aff errare

saldamente lo strumento con entrambe le mani.

6. Usando il trapano nel modo a impatto, inserire sempre

la direzione di rotazione in senso orario. (Fig. 9)

CARATTERISTICHE

Voltagio 230 V

Potenza assorbita 790 W

Cambio di velocità 1 2

Velocità senza cario

Capacitá mandrino

Frequenza d’impatto a pieno carico 8000 min

Peso (senza il cavo) 2,2 kg

ACCESSORI STANDARD

(1) Custodia di plastica ......................................................1

(2) Impugnatura laterale ....................................................1

(3) Calibro di profondità .....................................................1

Gli accessori standard possono essere cambiamn to

senza preavviso.

IMPIEGHI

○ Azione combinata di ROTAZIONE e BATTITO:

Per l’esecuzione di fori in superfi ci dure (cemento,

marmo, granito, ecc.).

○ Funzionamento solo a ROTAZIONE:

Per l’esecuzione di fori nel metallo, legno e plastica.

PRIMA DELL’USO

1. Alimenta zi on e

Assicurarsi che la rete di alimentazione che si vuole

usare sia compatibile con le caratteristiche relative

all’alimentazione di corrente specifi cate nella piastrina

dell’apparecchio.

10

Rotazione in avanti 0 – 1000 min

Rotazione indietro 0 – 600 min

Acciao 13 mm 8 mm

Cemento 20 mm 13 mm

Legno 40 mm 25 mm

2. Interruttore di dorrente

Met tere l’interruttore in posizione OFF. Se la spina è

infi lata in una presa mentre l’interrut tore è accesso,

l’utinsile elettrico si mette immediatamente in moto,

facilitando il verifi carsi di incidenti gravi.

3. Prolunga del cavo

Quando l’ambiente di lavoro è lontano da una presa

di corrente, usare una prolunga del cavo di suffi ciente

spessore e di prestazione adeguata. La prolunga deve

essere piú corta possibile.

4. Scelta della punta appropriata

○ Quando si fora cemento o pietra

Usare la punta indicata engli accessori disponibili a

richiesta.

○ Quando si fora metallo o plastica

Usare una punta normale de metallo.

○ Quando si fora il legno

Usare una punta normale da legno. Tuttavia, quando

si fanno fori da 6,5 mm o inferiori, usare una punta da

metallo.

-1

-1

-1

0 – 3000 min

0 – 1800 min

26000 min

-1

-1

-1

Italiano

5. Installazione e rimozione delle punte.

(1) Montaggio della punta

Girare il manicotto in senso antiorario e aprire il

mandrino. Dopo aver inserito la punta trapano nel

mandrino il più possibile, aff errare l’anello e chiudere il

mandrino girando il manicot to in senso orario visto dal

davanti. (Fig. 1)

(2) Smontaggio della punta

Aff errare l’anello e chiudere il mandrino girando il

manicotto in senso antiorario. (Fig. 1)

NOTA

Quando il manicotto non si allenta ulteriormente,

fi ssare la maniglia laterale all’anello, tenere saldamente

la maniglia laterale e quindi girare il manicotto per

allentarlo a mano (Fig. 2).

6. Controllo della direzione di rotazione (Fig. 3)

Il trapano ruota in senso orario (visto dal retro) quando

si preme il lato R del pulsante. Premere il lato L del

pulsante per far girare il trapano in senso antiorario.

(I segni

ATT ENZ ION E

Usando il trapano nel modo a impatto, inserire sempre

la direzione di rotazione in senso orario.

7. Fissaggio dell’impugnatura laterale (Fig. 4)

Attaccare l’impugnatura laterale alla sezione di

montaggio.

Ruotare il gancio dell’impugnatura laterale in senso

orario per fi ssarla.

Regolare l’impugnatura laterale in una posizione

che sia comoda per l’operazione e quindi stringerne

fermamente il gancio. Per fi ssare un calibro di

profondità all'impugnatura laterale, infi lare il calibro

nella scanalatura a forma di U sull'im pugnatura late rale,

regolare la posizione del calibro secondo la profondità

desiderata per il foro e serrare saldamente la presa

dell'impugnatura laterale. (Fig. 5)

8. Cambio da IMPATTO a ROTAZIONE (Fig. 6)

Spostare la leva del cambio tra le posizioni destra

e sinistra per alternare facilmente rispet tivamente

tra IMPACT (rotazione e impatto) e ROTATION (solo

rotazione).

Per trapanare fori in materiali duri come cemento, pietra

e piastrelle, spostare la leva del cambio alla posizione

destra (come indicato dal segno

trapano agisce con una combinazione di impatto e

rotazione.

Per trapanare fori in metallo, legno e plastica, spostare

la leva del cambio sulla posizione di sinistra (come

indicato dal segno

in rotazione, come per un trapano elettrico normale.

ATT ENZ ION E

○ Non usare il trapano variabile bat tente e av vitatore

○ Se si usa il trapano a percussione con la leva del

9. Cambio di velocità:

Pr ima di cambiar e velocità, as sicurarsi c he l’interrut tore

sia spento (posizione OFF) e che il trapano si sia

arrestato del tutto.

Per cambiare velocità, ruotare la manòpola di

regola zione della velocità come indicato dalla freccia

nella Fig. 7. Il numero “1” inciso sul corpo del trapano

indica la velocità bassa ed il numero “2” indica la

velocità alta.

e sono marcati sul corpo.)

). La punta del

). La punta del trapano agisce solo

nella posizione IMPACT se il materiale puó essere

forato dalla sola rotazione. Un tale fatto non solo

diminuirá l’effi cacia del trapano ma danneggerá

anche la punta.

cambio in posizione intermedia ne possono risultare

danni. Quando si cambia posizione, assicurarsi di

spostare la leva del cambio sull a posizione cor retta.

Qualora risulti diffi cile ruotare la regolazione di

velocità, ruotare leggermente il mandrino in entrambe

le direzioni, quindi ruotare ancora la regolazione di

velocità.

MODO DI IMPIEGO

1. Uso dell’interruttore

○ Qu ando il grilletto è premu to, l’utensil e ruota. Qua ndo il

grilletto viene rilasciato, l’utensile si ferma.

○ La velocità di rotazione del trapano può essere

contro llata variando la pressione esercitata sul grill etto.

La velocità è bassa quando il grilletto interruttore è

premuto leggermente e aumenta quando si preme

maggiormente.

○ La velocità di rotazione desiderata può essere

impostata con il comando di velocità.

Girare il comando di velocità in senso orario per

velocità maggiori o in senso antiorario per velocità

inferiori. (Fig. 8)

○ Se si preme il grilletto e si spinge il fermo, si può

mantenere la condizione attivata, comodo per il

funzionamento continuo. Per spegnere, il fermo può

essere sbloccata premendo di nuovo il grilletto.

ATT E NZI ONE

Premendo il lato sinistro del pulsante per avviare la

rotazione indietro, il fermo non potrà essere utilizzato.

2. Trapanatura

○ Quando si trapana, avviare il trapano lentamente e

aumentare gradualmente la velocità mentre si procede.

○ Applicare sempre pressione in linea retta con la

punta. Usare una pressione suffi ciente a continuare la

trapanatura ma non spingere con forza tale da bloccare

il motore o deviare la punta.

○ Per ridurre il minimo l’arresto del motore o il

trapassamento del materiale, ridurre la pressione sul

trapano e lasciare entrare la punta nella parte fi nale del

foro.

○ Se il trapano si blocca, rilasciare immediatamente il

grilletto, estrarre la punta dal lavoro e ricominciare. Non

premere e rilasciare il grilletto per riavviare il trapano

bloccato. Questo potrebbe danneggiare il trapano.

○ Quando più grande è il diametro della punta del

trapano, tanto maggiore sarà la forza esercitata sul

braccio dell’operatore.

Fare attenzione a non perdere controllo del trapano a

causa di questa forza di reazione.

Per ma ntenere un controllo sa ldo, piazzare bene i pi edi,

usare la maniglia laterale, tenere saldamente il trapano

con entrambe le mani e assicurarsi che il trapano sia

verticale rispetto al materiale da trapanare.

MANUTENZIONE E CONTROLLI

1. Ispezione delle punte trapano

Poiché l’uso di punte trapano usurate causa problemi

di funzionamento del motore e una minore effi cienza,

sostituire le punte trapano con altre nuove o riaffi larle

subito quando si nota usura.

2. Controllo delle punte perforanti e dei maschi

Poiché l’uso continuativo di una punta perforante o

di um maschio logorati può diminuire la capacità di

funzionamento e provocare eventuali sovracarichi al

motore, sostituire o affi lare la punta perforante od il

maschio, senza indugio, quando si nota una eccessiva

usura.

3. Manutenzione del motore

L’avvolgimento del motore è il vero e proprio “cuore”

dell’utensili elettrici. Fare attenzione a non danneggiare

l’avvolgimento e/o a non bagnarlo con olio o acqua.

11

Italiano

4. Ispezione delle spazzole di carbone

Per Per mantenere la vostra sicurezza e la protezione

da scosse elettriche, l’ispezione delle spa zzole di

carbone e la loro sostituzione su questo utensile

deve essere eseguita SOLO da un centro assistenza

autorizzato.

5. Sostituzione del cavo di alimentazione

Se il cavo di alimentazione dell’attrezzo è danneggiato,

l’attrezzo deve essere rinviato ad un centro assistenza

autorizzato per la sostituzione del cavo.

6. Lista dei pezzi di ricambio

CAUTELA:

Riparazioni, modifi che e ispezioni di utensili elettrici

devono essere eseguite da un centro assistenza

autorizzato.

Questa lista dei pezzi torna utile se viene presentata

con l’utensile al centro assistenza autorizzato quando si

richi edono ripara zioni o altri interv enti di manuten zione.

Nell’uso e nella manutenzione degli utensili elettrici

devono essere osservate le normative di sicurezza e i

criteri prescritti in ciascun paese.

MODIFICHE:

Gli utensili elettrici vengono continuamente migliorati

e modifi cati per includere le più recenti innovazioni

tecnologiche.

Di conseguenza, alcuni pezzi possono essere

modifi cati senza preavviso.

GARANZIA

Garantiamo gli Utensili Elet trici DATACOL in conformità

alle specifi che normative imposte dalla legge e dai paesi.

Questa garanzia non copre difetti o danni dovuti a uso

erroneo, abuso o normale usura. In caso di lamentele, si

prega di inviare l’Utensile Elettrico, non smontato, insieme

al CERTIFICATO DI GARANZIA che si trova al termine

di queste Istruzioni per l’uso, ad un Centro di Assistenza

Autorizzato.

NOTA

A causa del continuo programma di ricerca e sviluppo

della DATACOL, le carat teristiche riportate in questo

foglio sono soggette a cambiamenti senza preventiva

comunicazione.

Informazioni riguardanti i rumori trasmessi dall’aria

e le vibrazioni

I valori misurati sono stati determinati in conformitá a

EN60745 e descritti in conformità alla normativa ISO 4871.

Livello misurato di potenza sonora pesato A: 109 dB (A)

Livello misurato di pressione sonora pesato A: 98 dB (A)

K incer tezza: 3 dB (A)

Indossare protezioni per le orecchie.

Il valore effi cace pesato tipico dell’accelerazione è di

2

12,9 m/s

12

.

Part Name

TAPPING SCREW

(W/FLANGE) D4×20

TAPPING SCREW

(W/FLANGE) D4×16

31 BALL BE ARING 608DDC 2PS2L

32 RETAINI NG RING FOR D22 HOLE

33 ARMATURE

No.

Item

Part Name

FLAT HD. SCREW (A)

(LEFT HA ND) M6×25

1

3 DRILL CHUCK 13VLRE-N

No.

Item

4SPINDLE

37 BALL BEARIN G 608V VC2PS2L

36 STATOR

6DUST SEAL

38 HOUSING

7 BALL BE ARING 6 202DDC MPS2

8RATCHET (A)

35 HEX . HD. TAPPI NG SCREW D4×50

34 FAN GUID E

5 RETAINING RING FOR D 35 HOLE

39 NAME PLATE

9 SPRING (A)

41 H ANDLE COVE R

42 PUSHING BUTTON

40

10 STEEL BALL D6.35

43 SWITCH

11 RATCHET (B)

14 SECOND P INION AN D GEAR SET

12 TAPPING SCREW (W/FLANGE)

13 WA SH ER (B)

47 BR USH HOLD ER

46 CARBON BRUSH

45 CHOKE COIL (BROWN)

44 INTERNAL WIRE (BROWN) 100L

17 CHANGE SHAFT

15 C HANGE LE VER

18 INNER COVER

16 CHAN GE COVE R

51 INTERNAL WIRE (BLUE) 55L

52 CHOK E COIL (BLUE)

49 NOISE SUPPRESSOR

50 EARTH TERMINAL

48 LABEL

19 SHIF T LEVER ASS’Y

21 SHIF T PIN

20 SHIF T LEVER

53

24 STEEL BALL D3.5

23 SPRING (H)

25 GEA R COVER (A) ASS’Y

22 O-RING (S-22)

54 CORD CLIP

RETAINING RING (E-TYPE)

26

55 CORD ARMOR

FOR D15 SHAFT

57 RUBBER BUSHING

56 CORD

27 SHIF T ARM

28 PIN D5

501 CASE

502 SIDE HANDLE

503 DEPTH GAUGE

29 GEAR SET

30 LA BEL (FOR SL IP CLUTCH)

13

14

English Italiano

GUARANTEE CERTIFICATE

1 Model No.

2 Serial No.

3 Date of Purchase

4 Customer Name and Address

5 Dealer Name and Address

(Please stamp dealer name and address)

1 Modello

2 N° di serie

3 Data di acquisto

4 Nome e indirizzo dell'acquirente

5 Nome e indirizzo del rivenditore

(Si prega di apporre il timbro con questi dati)

CERTIFICATO DI GARANZIA

15

1

2

3

4

5

16

171819

Datacol S.r.L.

Strada Statale 11, Z.A.I.

37047 San Bonifacio (VR), Italy

806

Code No. C99144144 F

Printed in China

Loading...

Loading...