Page 1

Clarity Controls

Agilent 7890

GC ENG

Code/Rev.: M144/70B

Date: 1/10/2017

Phone: +420 251 013 400 DataApex Ltd.

Fax: +420 251 013 401 Petrzilkova 2583/13

clarity@dataapex.com 158 00 Prague 5

www.dataapex.com The Czech Republic

Page 2

Clarity®, DataApex®and

®

are trademarks of DataApex Ltd. Microsoft®and Windows

TM

are

trademarks of Microsoft Corporation.

DataApex reserves the right to make changes to manuals without prior notice. Updated manuals can be

downloaded from www.dataapex.com.

Author: MP

Page 3

Agilent 7890 Table of Contents

Contents

1 Agilent 7890 Control module 1

1.1 General Conditions of Agilent Autosampler Control 1

2 Requirements 3

3 Installation Procedure 4

3.1 Agilent 7890 Setup - Communication 4

3.2 Clarity Configuration 5

4 Using the control module 8

4.1 Hardware Configuration 8

4.2 Method Setup - Autosampler 9

4.3 Method Setup - GC 11

4.3.1 Oven/Zones 11

4.3.2 Front (Back) Inlet 13

4.3.3 Column # 15

4.3.4 Front (Back) Detector 17

4.3.5 Time Table 19

4.3.6 PCM 20

4.3.7 Gradients 22

4.4 Method Setup - Acquisition 23

4.5 Method Setup - Valves 25

4.6 Using Dual Injector 26

4.7 Device Monitor 27

4.8 Agilent 7890 Setup 28

4.8.1 Connection tab 28

4.8.2 GC tab 29

4.8.3 Signals tab 30

4.8.4 Sampler tab 31

4.8.5 Valves tab 32

4.8.6 Aux tab 32

4.8.7 PCM tab 33

5 Report Setup 34

6 Troubleshooting 35

- i -

Page 4

Table of Contents Clarity Controls

To facilitate the orientation in the Agilent 7890 manual and Clarity chromatography station,

different fonts are used throughout the manual. Meanings of these fonts are:

Instrument (blue text) marks the name of the window to which the text refers.

Open File(italics) describes the commands and names of fields in Clarity, parameters that can

be entered into them or a window or dialog name (when you already are in the topic describing

the window).

WORK1 (capitals) indicates the name of the file and/or directory.

ACTIVE (capital italics) marks the state of the station or its part.

The bold text is sometimes also used for important parts of the text and the name of the Clarity

station. Moreover, some sections are written in format other than normal text. These sections are

formatted as follows:

Note: Notifies the reader of relevant information.

Caution: Warns the user of possibly dangerous or very important

information.

▌ Marks the problem statement or trouble question.

Description: Presents more detailed information on the problem, describes its causes,

etc.

Solution: Marks the response to the question, presents a procedure how to remove it.

- ii -

Page 5

Agilent 7890 1 Agilent 7890 Control module

1 Agilent 7890 Control module

This manual describes the setting of the Agilent 7890 chromatograph

control module. Supported versions of the chromatograph are 7890A and

7890B. The control module enables direct control of the instrument over

Local Area Network (LAN).

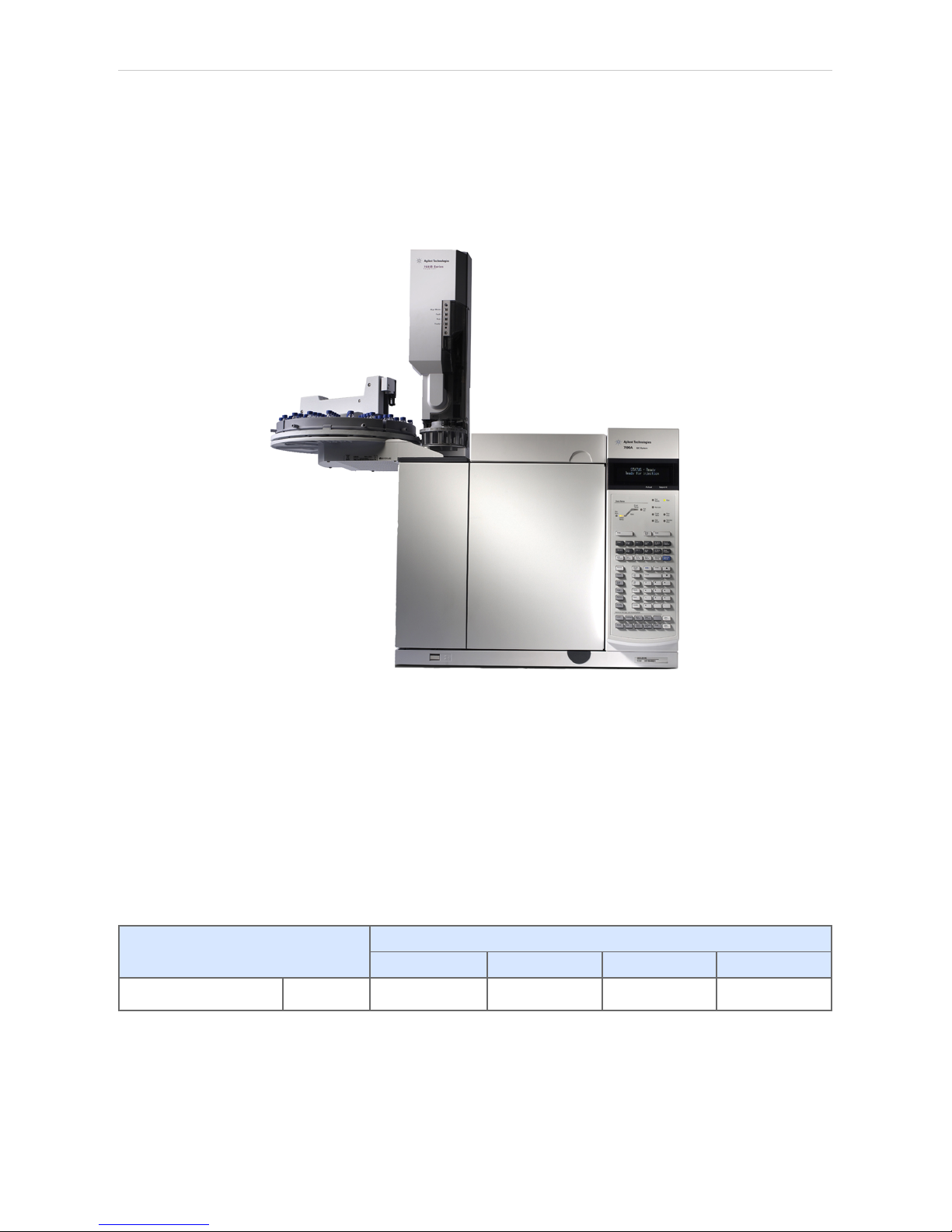

Fig 1: Agilent 7890A Gas Chromatograph (with 7683 autosampler)

1.1 General Conditions of Agilent Autosampler Control

Clarity allows controlling all Agilent GC autosamplers and for their control

is always required to purchase AS Control Module (p/n A26) license. Not

all combinations of autosamplers and 7890 GCs are possible. To find out

if desired combination of autosampler and 7890 GC is available refer to

following table.

Tab 1: Possible combinations of Agilent autosamplers and Agilent gas chromatographs:

Autosamplers

7673 (A, B, II) 7683 7693 6850

Chromatograph 7890

û ü ü û

The autosampler 7683 (or 7693) is connected to GC via Agilent

proprietary connection and its hardware configuration is described in the

section Sampler tab on pg 31 because the autosampler control is

implemented through DataApex 7980 Control Module.

- 1 -

Page 6

1 Agilent 7890 Control module Clarity Controls

There is a Dual Injection mode support implemented for 7890 GCs. In

case of 7890 CGs Dual Injection hardware configuration is described in

the section Sampler tab on pg 31 because the autosampler control is

implemented through DataApex 7890 Control Module.

- 2 -

Page 7

Agilent 7890 2 Requirements

2 Requirements

l Clarity Installation CD ROM with GC Control module (p/n A23).

Caution: Minimal firmware version required for 7890A and 7890B is A.01.10.0.

l LAN card in the PC.

l Cross LAN cable (p/n SK08).

Note: Cables are not part of Clarity Control Module. It is strongly

recommended to order required cables together with the Control Module.

- 3 -

Page 8

Agilent 7890 3 Installation Procedure

3 Installation Procedure

3.1 Agilent 7890 Setup - Communication

The GC must be fully configured prior to connecting to Clarity. No special

settings have to be made on the Agilent 7890 chromatograph, only the

correct IP address of the instrument (set on the OPTIONS key screen by

using COMMUNICATION - IP item). A default IP address of most Agilent

GC's is 10.1.1.101 which is suitable only in case the GC is connected

directly to computer using separate network.

Caution: Do not use the Agilent 7890 DHCP server feature.

When using the LAN communication it is recommended to attach the GC

chromatograph directly to the PC avoiding hubs, switches etc. Contact

your local LAN administrator who can make the appropriate settings.

In case your network uses firewall for protection, make sure that

connection is not blocked in both directions. (chromatograph uses

separate connection for control communication and for data sending).

Caution: Cross LAN cable is primarily used for the direct connection of the

chromatograph and the PC. This cable can also be used for the

connection of the device to the switch or network socket, but with older

switches, the straight LAN cable might be necessary.

- 4 -

Page 9

3 Installation Procedure Clarity Controls

3.2 Clarity Configuration

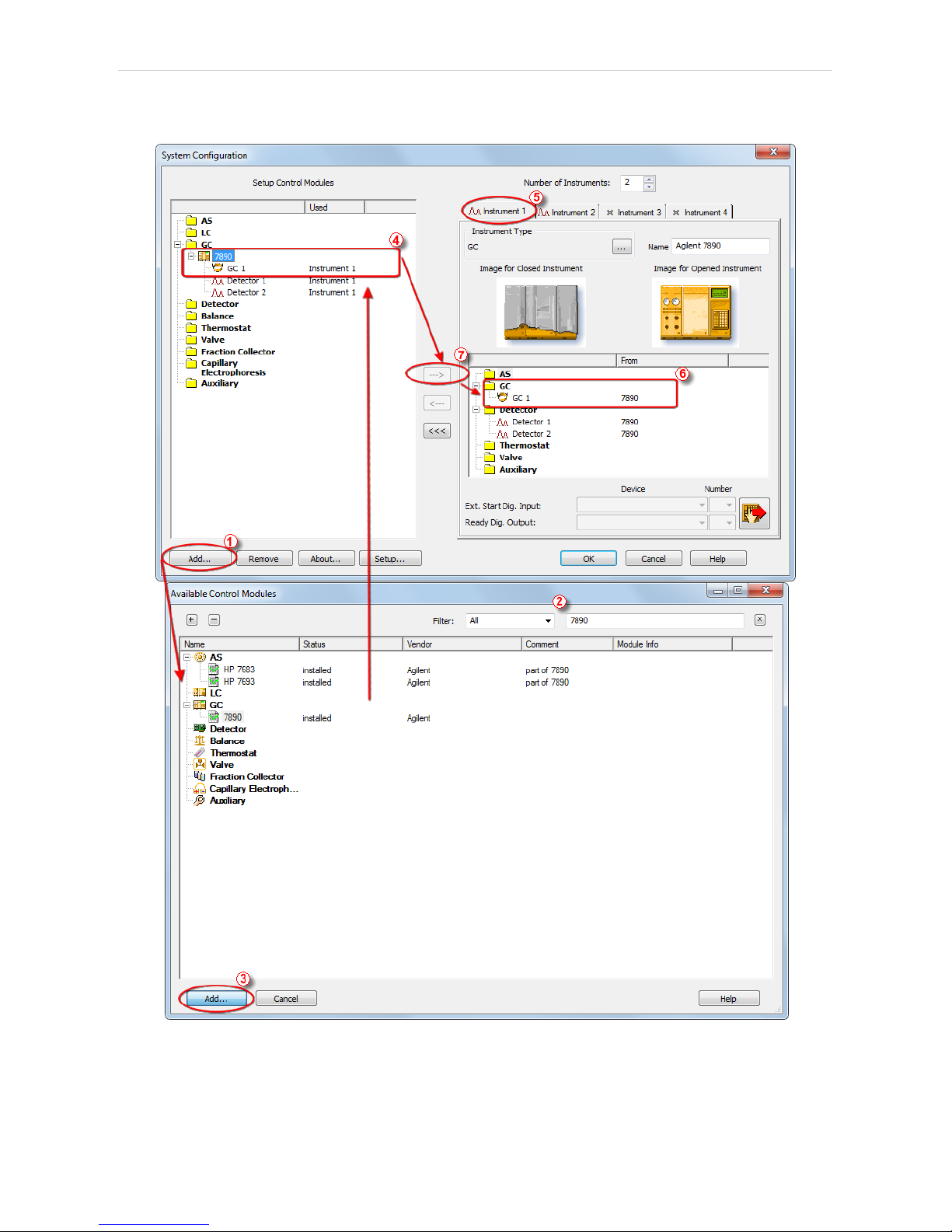

Fig 2: System Configuration

- 5 -

Page 10

Agilent 7890 3 Installation Procedure

l In the System Configuration dialog press the Add button ① to invoke the

Available Control Modules dialog.

l Type "7890" into the searching field on the top of the dialog ② for quick

filtering out the desired instrument.

l Select the Agilent 7890 in the GC section and press the Add button.③

l The Agilent 7890 Setup dialog will appear.

Fig 3: Agilent 7890 Setup

l Fill in the IP address of the 7890 and IP address for receiving data (i.e. IP

address of computer with installed Clarity datastation). Ask your

company's IT person if you don't know them. A default IP address of most

Agilent GC's is 10.1.1.101 which is suitable only in case the GC is

connected directly to computer using separate network.

l Press the Autodetect button to read all settings from the instrument. Upon

successful detection the serial number of the GC will be displayed.

Note: In most cases it is recommended not to change the settings obtained

through the Autodetect function. However some modules (e.g. PCM,

valves or Aux Pressure modules) are not autodetected correctly and in

certain systems it is necessary to set them manually.

l Check the Keyboard Lock checkbox for ensuring the exclusive access to the

chromatograph. Apart from locking the keyboard of the device, this will also

prevent other users connected to the same network from connecting to the

chromatograph.

l Switch to the GC tab to verify the correct detection of injectors, inlets, detectors

and columns. Do not change the autodetected values.

l Switch to the Signals tab (for more details see the Agilent 7890 Setup

dialog section later in the manual ), select the correct number of signals

- 6 -

Page 11

3 Installation Procedure Clarity Controls

you want to acquire, name them and possibly check This Device Starts the

Run in Clarity / Clarity Starts This Device radiobutton. The Clarity Starts

This Device option should be checked only when the GC will not start the

acquisition (that means it will not be triggered by the GC Start button,

external start contact or autosampler). Press the OK button.

l On the Sampler tab verify the auto detected sampler version and

components, set the Syringe Size and Solvent Wash Mode.

l On Valves tab verify the identified valves, on the Aux tab verify the

detected auxiliaries.

l Press OK. The Agilent 7890 item ④ will appear in the Setup Control

Modules list of the System Configuration dialog.

l Drag the GC icon from the Setup Control Modules list on the left side to

the desired Instrument tab ⑤ on the right side ⑥ , or use the button ⑦

to do so.

Note: In case there is no detector used with 7890 it is necessary to add other

detector to the same Instrument (e.g. DEMO detector available on each

station), otherwise it would be not possible to send the method and start

the GC by Clarity.

- 7 -

Page 12

Agilent 7890 4 Using the control module

4 Using the control module

New GC tab appears in the Method Setup dialog, enabling the setting of

the GC control method. With an automatic sampler configured, AS tab also

appears, allowing the setting of the autosampler method.

4.1 Hardware Configuration

Fig 4: Hardware Configuration

This dialog is invoked by pressing the GC Status button in the Method

Setup - GC dialog. Hardware Configuration dialog displays the type of the

chromatograph, it's serial number and the IP address and port to which it

is connected.

- 8 -

Page 13

4 Using the control module Clarity Controls

4.2 Method Setup - Autosampler

Fig 5: Method Setup - AS - Mode

Use Injector

Selects the injector which will be used.

Use Tray

Checks if Tray will have to be used.

Vial No. Shift

Sets the shift between numbers of vials injected by both injectors. Active

with both injectors and tray used.

- 9 -

Page 14

Agilent 7890 4 Using the control module

Fig 6: Method Setup - AS - Injector

Number of Injections

Sets the number of injections performed with every sample.

Multiple Injection Delay

Sets the delay between individual injections in case of multiple injections.

Pre Injection Dwell Time

Sets the time the needle remains in the inlet before the injection.

Post Injection Dwell Time

Sets the time the needle remains in the inlet after the injection.

Pre Washes

Sets how many times the syringe will be washed by a particular solvent or

sample before the injection.

Post Washes

Sets how many times the syringe will be washed by a particular solvent

after the injection.

Volume

Sets the percentage of the syringe volume washed.

Sample Pumps

Sets how many times the syringe plunger is moved up and down with the

needle in the sample.

Draw Speed

Sets the speed of drawing the sample.

Dispense Speed

Sets the speed of injecting the sample.

- 10 -

Page 15

4 Using the control module Clarity Controls

Viscosity Delay

Sets how many seconds the plunger pauses at the top of the pump and

injection strokes.

Depth offset

Sets the depth offset of the syringe needle.

4.3 Method Setup - GC

4.3.1 Oven/Zones

Fig 7: Method Setup - GC - Oven/Zones

This tab allows to set the parameters for oven and temperature zones.

Particular fields may vary, according to the configuration.

Oven : Max

Sets the maximal allowed temperature for the column oven.

Note: Please note that the maximum value may differ for certain GC models.

Equilibration

Sets the time of oven temperature equilibration.

Gradient Table

Sets the Heat Rate, desired temperature (Final Temp ) and time to hold

this temperature (Hold Time). The Total Time column will be calculated

automatically. In other words, for isothermal part of the temperature

gradient, the temperature set in Final Temp will be kept for the interval set

- 11 -

Page 16

Agilent 7890 4 Using the control module

in Hold Time. To delete a row, simply delete the value in the Heat Rate

column on that row.

Temperature Zones

Sets the temperature of particular zones.

Cryo Temp

Sets the temperature setpoint for the cryogenic cooling.

Quick Cool

Turns on/off the Quick Cool feature.

Fault

When checked, GC shuts the oven down if it does not reach setpoint

temperature after 16 minutes of continuous Cryo operation.

Timeout

Turns on/off and setting the setpoint for Cryo Timeout.

Post Run (Time and Temp)

Sets the time and temperature of the Post Run period.

- 12 -

Page 17

4 Using the control module Clarity Controls

4.3.2 Front (Back) Inlet

Fig 8: Method Setup - GC - Inlet

This tab governs the settings concerning the inlets of the Agilent 7890

chromatograph. According to configuration of particular chromatograph,

there can be Front Inlet or Back Inlet tabs, both with the same appearance.

Particular fields may vary, according to the type of the inlet set.

Temperature Mode

Defines the temperature mode for the inlet. Available for COC and PTV

inlets.

Carrier Gas

Sets the type of carrier gas used on this GC.

Temperature Gradient Table

Allows to edit temperature ramp for the inlet (up to three rates and

plateaus). Available for COC and PTV inlets.

Injection Pulse (Press + Time)

Sets the pressure and duration of pressure pulse during injection of the

sample. Available for PTV and Split/Splitless inlets.

Pneumatic Mode

Defines the operation mode for the injector port. Available for PTV and

Split/Splitless inlets.

Total Flow

Turns on/off and sets the flow rate for carrier gas. The value entered here

is used only when there are no columns defined on the GC, however the

- 13 -

Page 18

Agilent 7890 4 Using the control module

checkbox have to be checked in order to the inlet work properly. Available

for PTV, Purged Packed and Split/Splitless inlets.

Split Ratio

The ratio of split vent flow to column flow. This line appears only if the

columns in the flow path are defined. Available for PTV and Split/Splitless

inlets.

Purge Flow

Sets the flow rate from the purge vent. Available for PTV and Split/Splitless

inlets.

Purge Time

Sets the time, after the beginning of the run, when you want the purge

valve to open. Available for PTV and Split/Splitless inlets.

Saver (Flow +Time)

Turns on/off and setting the flow and time for the Gas Saver. Available for

PTV and Split/Splitless inlets.

Cryo Temp

Sets the temperature setpoint for the cryogenic cooling.

Quick Cool

Turns on/off the Quick Cool feature.

Fault

When checked, GC shuts the oven down if it does not reach the setpoint

temperature after 16 minutes of continuous Cryo operation.

Timeout

Turns on/off and setting the setpoint for Cryo Timeout.

Vent Flow

Sets the flow rate for venting. Available for PTV inlet.

Vent Press

Sets the pressure of gas used for venting. Available for PTV inlet.

Vent Time

Sets the time of venting. Available for PTV inlet.

Septum Purge

Turns on/off the Septum Purge function.

Septum Purge Flow

Sets the flow rate for Septum Purge.

Septum Purge Switching

Turns on/off the Septum Purge Switching function. Available for splitless

pneumatic mode.

Switch Time [min]

Sets the time of Septum Purge Switching function.

- 14 -

Page 19

4 Using the control module Clarity Controls

4.3.3 Column #

Fig 9: Method Setup - GC - Column

This tab allows to set the parameters for a column configured in the

Agilent 7890 Setup dialog. Particular fields may vary, according to the

column mode selected.

Length

Sets the length of the column.

Ins.Diameter

Sets the internal diameter of the column.

Film

Sets the thickness of coating of the column.

Inlet

Sets to which inlet is the particular column connected.

Detector

Sets to which detector is the particular column connected.

Mode

Sets the temperature mode of the column.

Pressure/Flow Gradient Table

Allows to edit the pressure or flow ramp for the column (up to three rates

and plateaus). Active in Pressure Ramp or Flow Ramp mode only.

Pressure

Sets the pressure of a carrier gas in the column. Active in Constant

Pressure mode only.

- 15 -

Page 20

Agilent 7890 4 Using the control module

Flow

Sets the flow rate of a carrier gas in the column. Active in Constant Flow

mode only.

Post Run (Flow or Pressure)

Sets the flow or pressure rate of a carrier gas after finishing the gradient.

Active in Pressure Ramp or Flow Ramp mode only.

- 16 -

Page 21

4 Using the control module Clarity Controls

4.3.4 Front (Back) Detector

Fig 10: Method Setup - GC - Detector

This tab allows to set the parameters for the detector configured in the

Agilent 7890 Setup dialog. Particular fields may vary, according to the

type of the detector set.

Makeup Flow

Turns the makeup gas flow on and off, eventually sets the flow. Available

for most detectors.

Makeup Gas

Sets the type of makeup gas used for detector. Available for most

detectors.

Constant Makeup Flow

Sets the constant makeup flow into the detector. In this mode, GC will

keep the actual makeup flow regardless of changes in the total flow during

the GC run. Available for most detectors.

Constant Column + Makeup Flow

Sets the constant combined flow into the detector. In this mode, GC will be

adjusting the actual makeup flow in order to keep the total flow constant.

Available for most detectors.

Flame

Turns the detector flame on and off. After turning on turns on the air and

hydrogen and initiates the ignition sequence.The temperature of the

detector must be greater than 150 °C for the flame to light. Available for

FID and FPD detectors.

- 17 -

Page 22

Agilent 7890 4 Using the control module

H2 Flow

Sets the hydrogen flow into the detector. The flow of hydrogen will be

turned off automatically after turning off the flame. Available for FID, FPD

and NPD detectors.

Air Flow

Sets the air flow into the detector. The flow of air will be turned off

automatically after turning off the flame. Available for FID, FPD and NPD

detectors.

Negative Polarity

Reverses the polarity of detector signal. Available for TCD detector.

Reference Flow

Sets the flow of reference gas for the detector. Available for TCD detector.

Dual

Turns on/off the Dual mode. Available for FPD detector.

Electronics

Turns on/off the detector electronics. Available for ECD detector.

Auto Adjust

Turns on/off the automatic bead voltage adjusting. When checked, Offset

field becomes active, allowing to set the desired current offset value.

When unchecked, Bead Voltage field becomes active, allowing to set the

voltage manually. Available for NPD detector.

Lit Offset

Sets the lit offset value. Available for FID, NPD and FPD detectors.

Bead Voltage

Sets the bead voltage. Field is active only with Auto Adjust checkbox

unchecked. Available for NPD detector. It is important to set the proper

voltage for actually installed bead because setting the voltage too high

can destroy the bead irreversibly.

Dry Bead during Warm-up

Turns on/off the Dry Bead function. This causes the detector to wait 5

minutes at 150°C during warming up. Available for NPD detector.

Bead Type

Sets the type of bead installed. It is important to set the proper type of

bead because improper setting can destroy the bead irreversibly.

Available for NPD detector.

- 18 -

Page 23

4 Using the control module Clarity Controls

4.3.5 Time Table

Fig 11: Method Setup - GC - Time Table

This tab allows to set the events that will be triggered during the run based

on the analysis time. This includes events like switching the detector

polarity, range or signal source (where applicable), setting temperatures

to detector / injector / auxiliary zones, controlling the valves etc. To delete

a row, simply delete the value in the Time column on that row.

- 19 -

Page 24

Agilent 7890 4 Using the control module

4.3.6 PCM

Fig 12: Method Setup - GC - Inlet

This tab governs the settings concerning the Pressure Control Modules

installed in the Agilent 7890 chromatograph. According to configuration of

particular chromatograph, there can be several tabs, both with the similar

appearance.

Pneumatics

Turns on/off the pneumatic control of a particular channel.

Mode

Sets the working mode of PCM Channel A.

Pressure

Sets the initial pressure (available only in Pressure mode).

Total Flow

Sets the initial Flow (available only in Flow mode).

Postrun Pressure

Sets the postrun pressure (available only in Pressure mode).

Postrun Flow

Sets the postrun Flow (available only in Flow mode).

- 20 -

Page 25

4 Using the control module Clarity Controls

Gradient Table

Sets the Pressure/Flow/Temperature rate, desired value and time to hold

this value (Hold Time). To delete a row, simply delete the value in the

Rate column on that row.

Heater

Turns on/off the heater.

Postrun Temperature

Sets the postrun temperature.

- 21 -

Page 26

Agilent 7890 4 Using the control module

4.3.7 Gradients

Fig 13: Method Setup - GC - Gradients

This tab displays the temperature gradient as set on the Method Setup -

GC - Oven/Zones tab.

- 22 -

Page 27

4 Using the control module Clarity Controls

4.4 Method Setup - Acquisition

Fig 14: Method Setup - Acquisition

Each detector allows to set the source of signal on the appropriate tab. To

switch to another detector, use the Select Detector field in the upper left

corner of the Method Setup - Acquisition dialog.

Signal Source

Selects the source of the signal (signal from a particular detector or

various internal and auxiliary signals, used for monitoring the state of the

device).

Signal Type

Selects the type of signal from the particular Signal Source.

Note: In case your GC has some non- standard detector installed (so called

Channel Partner detectors), it would be not possible to configure it in

Agilent 7890 Setup window, however its signal would be available for

acquisition. In such a case you have to select the signal according to

position of the detector.

Specific Signal

Selects the specific signal available for selected Signal Type.

Channel #

Selects the channel of the signal. Available for some signals only.

Sample Rate

Sets the frequency of the data sent from the Agilent 7890 detector to

Clarity , it has nothing to do with the frequency of the actual data

- 23 -

Page 28

Agilent 7890 4 Using the control module

acquisition in the instrument. The sample rate is common to all signals of

the same instrument.

Note: Onlyfor detector signal it is possible to change the sample rate, all auxiliary

signals are collected at 50 Hz sample rate. In case some of the collected

signals are auxiliary (e.g. oven temperature or column gas flow), all

signals will be sampled at 50 Hz.

Signal Range

Sets the range for the output signal. As the range is increasing, sensitivity

is decreasing, so the overall resolution is still the same (24 bit).

- 24 -

Page 29

4 Using the control module Clarity Controls

4.5 Method Setup - Valves

Fig 15: Method Setup - Valves

Each valve allows to set its parameters on the appropriate tab. To switch

to another valve, use the Select Valve field in the upper left corner of the

Method Setup - Valves dialog. Each type of valve has different parameters

available, thus the appearance of Valves panel depends on the type of

selected valve.

Initially On

Selects the initial state of the valve. Available for Switch and Other valves

only.

BCD Inverted

Available for Multiposition valves only.

Step Time [s]

Sets the Step Time. Available for Multiposition valves only.

Position

Sets the position. Available for Multiposition valves only.

Loop Volume [cm3]

Sets the Loop Volume. Available for Gas Sampling valves only.

Load Time [min]

Sets the Load Time. Available for Gas Sampling valves only.

Inject Time [min]

Sets the Inject Time. Available for Gas Sampling valves only.

- 25 -

Page 30

Agilent 7890 4 Using the control module

4.6 Using Dual Injector

In case your GC is equipped with two injectors, it is possible to use them

simultaneously. For this purpose it is necessary to have two unused

Instrument available.

l At first, ensure the GC has two injectors and tray correctly detected. See

also 7890 Setup - Sampler.

l Configure the GC, Sampler and Detector 1 on the first Instrument. See

also Clarity Configuration.

l Configure the Detector 2 on the second Instrument.

l First instrument serves as a master, all GC and AS method parameters will

be set here. In the method setup, AS tab, select the option Use Both

Injector and fill in the Vial No. Shift.

l On the second instrument, the AS and GC tabs are not available in

method setup. Only the Acquisition tab is available to set the configured

detector Range and Sample rate.

The sequence on first Instrument defines the vial numbers for first injector

and injection volume for both. The injection vial and injection volume in

the second instrument sequence are just informative, injection volume is

equal to that on first instrument, the vial number is equal to the vial

number in first instrument and the specified vial shift. To run the system,

prepare methods and sequences for both instruments, start the sequence

on second instrument and then the sequence on first instrument.

Sequence on the master Instrument (controlling the GC) needs to have

Active Sequence checkbox checked, the sequence on the second

Instrument needs to have it unchecked (passive sequence). Checkbox is

available on the Sequence Options dialog.

- 26 -

Page 31

4 Using the control module Clarity Controls

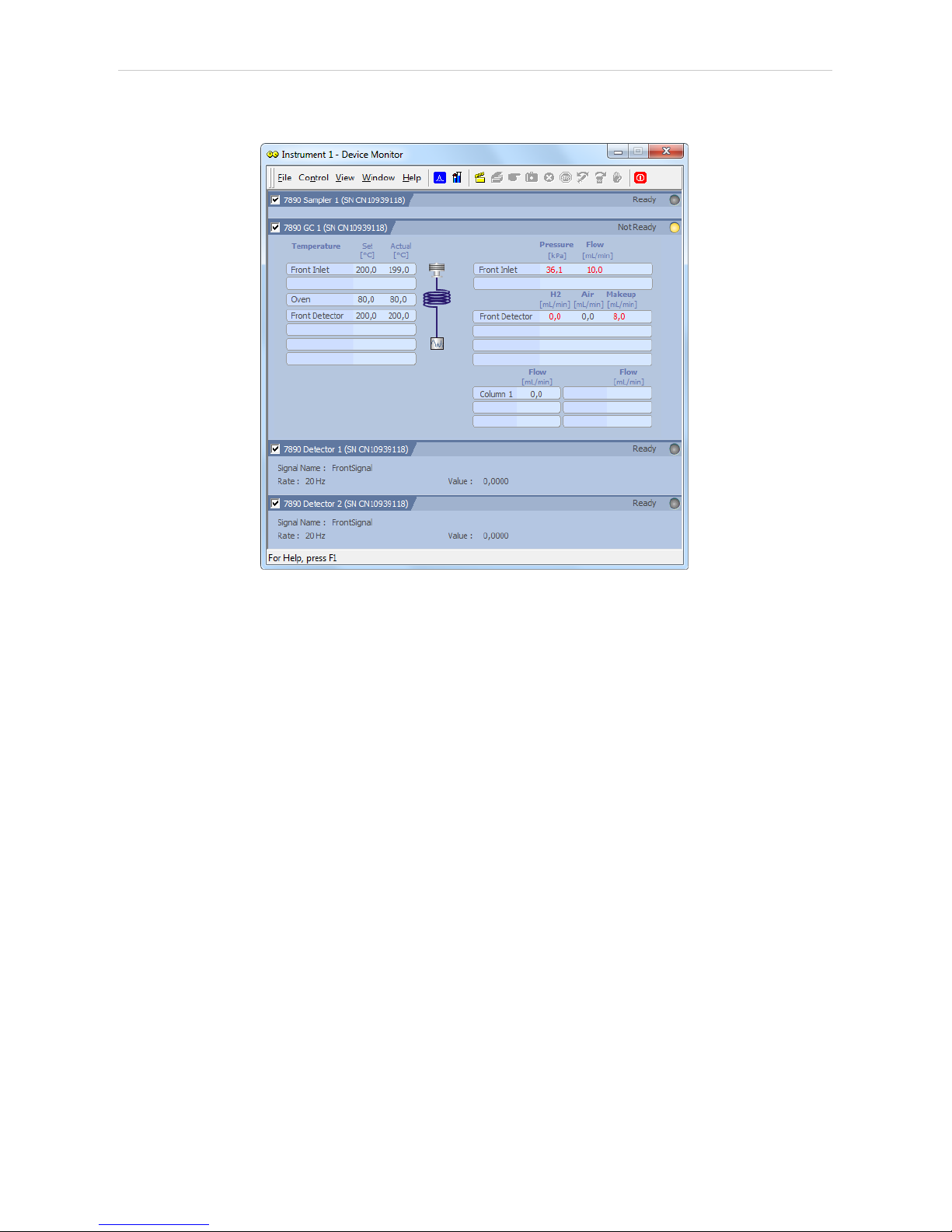

4.7 Device Monitor

Fig 16: Agilent 7890 Device Monitor

The Monitor window for the Agilent 7890 chromatograph displays all set

and actual temperatures in each temperature zone and the column oven.

It also displays gas flows and pressures for all important parts of the GC.

An unequilibrated values are displayed in red letters. Besides that, there

are sections for each detector and autosampler present. Detector section

shows names of the signals, its sampling rates and the actual value of a

particular signal.

- 27 -

Page 32

Agilent 7890 4 Using the control module

4.8 Agilent 7890 Setup

Agilent 7890 Setup dialog (accessible through the System Configuration

dialog) allows to view and manually set the hardware configuration of the

chromatograph. Most fields (with the exception of IP addresses ) can be

read from the chromatograph by using the Autodetect button, however it is

recommended to check the settings after autodetection. In case some part

of the GC cannot be autodetected, user has to set it manually.

4.8.1 Connection tab

Fig 17: Agilent 7890 Setup - Connection

IP address of 7890

Fill in the IP address of the Agilent 7890 chromatograph.

IP Address of This Computer

The IP address of the computer with installed Clarity datastation. In case

the computer is connected to more than one network, select the IP

address corresponding to the network with Agilent 7890 connected.

Autodetect

Read all settings from the instrument. Upon successful detection the serial

number of the GC will be displayed.

Please note that some modules (e.g. PCM, valves or Aux Pressure

modules) are not autodetected correctly and in certain systems it is

necessary to set them manually.

Keyboard Lock

Use this checkbox to ensure the exclusive access to the chromatograph.

Apart from locking the keyboard of the device, this will also prevent other

users connected to the same network from connecting to the

chromatograph.

- 28 -

Page 33

4 Using the control module Clarity Controls

4.8.2 GC tab

Fig 18: Agilent 7890 Setup - GC

After successful autodetection of GC parameters it is advisable to verify

them manually.

Front (Back) Inlet

Sets the type of inlet installed in the GC.

Front (Back, etc.) Detector

Sets the type of detector installed in the GC.

Column #

Check the presence of the columns installed in the GC.

Pressure Units

Sets the pressure units used for setting the pressure of a carrier gas. After

changing the units the values in the methods will be converted

automatically.

- 29 -

Page 34

Agilent 7890 4 Using the control module

4.8.3 Signals tab

Fig 19: Agilent 7890 Setup - Signals

This tab defines the number of signals that will be processed by Clarity.

Count

Defines the number of signals received by Clarity . These signals

correspond to Clarity detectors and will have their own sub-tabs in the

Method Setup - Acquisition dialog, if configured on the given Clarity

Instrument.

Signal 1 (..4)

Sets the name of the particular signal.

This Device Starts the Run in Clarity / Clarity Starts This Device

This radiobutton enables to start the analysis run from the Clarity. With

This Device Starts the Run in Clarity checked, the device is started prior to

Clarity by its front button or autosampler connected to this device and

passes the start to Clarity. When Clarity Starts This Device is checked,

Clarity is started prior to this device by separately wired autosampler,

Start button in Single Run or different device and then starts this device.

Note: The This Device Starts the Run in Clarity option is checked by default.

- 30 -

Page 35

4 Using the control module Clarity Controls

4.8.4 Sampler tab

Fig 20: Agilent 7890 Setup - Sampler

This tab displays the settings of the automatic liquid sampler

(autosampler) connected directly to GC. Settings on this tab may be read

from the chromatograph using the Autodetect button, however it is

advisable to verify them manually.

Use Sampler

Enables the autosampler for use with Agilent 7890 chromatograph.

Needs to be unchecked if you want to start the acquisition from the

Clarity.

Name

Allows to set the arbitrary name for the autosampler.

Type

Sets the type of the autosampler installed.

Front (Back) Injector

Enables the use of the particular injector.

Syringe Size

Sets the size of the syringe installed.

Solvent Wash Mode

Sets the solvent wash mode for the autosampler.

Tray

Sets the presence of an autosampler tray.

- 31 -

Page 36

Agilent 7890 4 Using the control module

4.8.5 Valves tab

Fig 21: Agilent 7890 Setup - Valves

This tab displays the settings of valves in the GC. Settings on this tab may

be read from the chromatograph using the Autodetect button, however it is

advisable to verify them manually.

4.8.6 Aux tab

Fig 22: Agilent 7890 Setup - Aux

This tab displays the settings of auxiliary devices in the GC. Settings on

this tab may be read from the chromatograph using the Autodetect button,

however it is advisable to verify them manually.

- 32 -

Page 37

4 Using the control module Clarity Controls

4.8.7 PCM tab

Fig 23: Agilent 7890 Setup - PCM

This tab displays the settings of Pneumatic Control Modules in the GC.

Settings on this tab may be read from the chromatograph using the

Autodetect button, however it is advisable to verify them manually.

- 33 -

Page 38

Agilent 7890 5 Report Setup

5 Report Setup

Fig 24: Agilent 7890 - report preview

All chromatograph- specific settings (e.g. temperatures set to particular

temperature zones) are reported as a part of the data displayed by the use

of Instrument Control checkbox of the Report Setup - Method dialog.

- 34 -

Page 39

Agilent 7890 6 Troubleshooting

6 Troubleshooting

When the remedy for some problem cannot be discovered easily, the

recording of communication between Clarity and the chromatograph can

significantly help the DataApex support to discover the cause of the

problem.

The recording can be enabled by adding or amending the COMMDRV.INI

file in the Clarity installation directory (C:\CLARITY\CFG by default). The

file can be edited in any text editor (e.g. Notepad). Following section

should be edited or added:

[TCP_IP 192.168.0.100:9110]

echo=on

textmode=on

filename=Agilent7890_%D.txt

reset=off

Note: Instead of 192.168.0.100:9110 type correct IP address and port used to

communicate with the Agilent 7890 chromatograph. This port number is

displayed when the GC Status button in the Method Setup - GC dialog is

invoked or in the Agilent 7890 Setup dialog.

Note: %D (or %d) in the filename parameter means that the log will be created

separately for each day. The reset=off parameter disables deleting the

content of the log each time the station is started during the same day.

The created *.TXT files will greatly help in diagnosis of unrecognised

errors and problems in communication.

- 35 -

Loading...

Loading...