CONTROLS

Instruction Manual

Signal Conditioner/Generator

P.O. Box 10

5000 W. 106th Street

DP10 CONTROL SERIES

LT168 (0318)

Zionsville, Indiana 46077

Phone (317) 873-5211

Fax (317) 873-1105

www.dartcontrols.com

A-5-4023E

Table of Contents

Introduction ....................................................................................................................................... 2

General Features .............................................................................................................................. 2

Models & Options ............................................................................................................................. 2

Specifications ................................................................................................................................... 3

DP10 Electrical ............................................................................................................................. 3

DP10 Mechanical ......................................................................................................................... 3

Environmental ............................................................................................................................... 3

Mechanical Installation .................................................................................................................... 4

Exploded Panel View .................................................................................................................... 4

Cut-out and Mounting Dimensions ............................................................................................... 4

Installation & Diagrams .................................................................................................................... 5

P3 Terminal Block Hook-Up Diagram ........................................................................................... 5

P3 Terminal Block Descriptions .................................................................................................... 5

Basic Operating Information ........................................................................................................... 6

Visual Reference .......................................................................................................................... 6

How to Change a Parameter's Value (The Short Story) ............................................................. 7

Operating the User Interface (The Long Story) .......................................................................... 7

Device Configuration .................................................................................................................... 8

Mode of Operation ........................................................................................................................ 8

Software Parameters ................................................................................................................... 9

Parameter Descriptions ............................................................................................................ 10

Troubleshooting .............................................................................................................................. 14

Technical Support Options ............................................................................................................... 14

What's Special About www.dartcontrols.com? ................................................................................. 14

1

Introduction

The DP10 is a panel mounted, multi-purpose signal conditioner that allows the operator easy access

to make adjustments to system operations. The DP10 may be used in OEM equipment designs, plant

operation or laboratory applications. Most other signal conditioners are DIN rail mounted inside a panel

and designed to be set up once - many applications require frequent adjustments to meet application

needs. The DP10's unique front-panel design addresses this by making output adjustment easily

accessible via convenient up and down pushbuttons with a large, easy to read LED display.

General Features

- Microprocessor design digital accuracy and repeatability

- Digital design offers long-term stability in a variety of environments

- Dual-Mode operation: Signal Scaling, or Signal Generation

- Works in either voltage or Current output modes - PWM voltage (1kHz - 100kHz) Optional

- Universal power supply accepts supply voltages of 85-265VAC @ 50-60Hz without switches or

jumper settings.

- Transient voltage protection protects device in harsh industrial environments

- 1/8 DIN panel mount is rated up to NEMA 4X in similarly rated panel

- Large 4 digit, 1/2” LED display is easy to read in indoor or outdoor applications

- Euro style terminal strip standard - pluggable terminal strip optional

- Wide operating temperature -10C to +45C (14F to 113F)

- Jumper selectable signal type - Voltage or Current (mA) signal

- Configurable input to lock out operator changes once set

Models & Options

Models & Options

Model

DP10 Voltage or Current (mA) signal conditioner with terminal strip

Description

2

Specifications

DP10 Electrical

Line Input Voltage ..................................................................................................... Any Voltage from 85-265 VAC

Line Input Frequency .................................................................................................... Any Freq. from 48-62 Hertz

Voltage Signal Input ....................................................................................................... 0-5 VDC (Optional Higher)

Voltage Signal Output ..................................................................... 0.1-5VDC MIN; 0.1-20 VDC MAX; 10mA MAX

mA Signal Input ........................................................................................................................................... 4-20mA

mA Signal Output ........................................................................................................................................ 4-20mA

Display Range ........................................................................................................................... Default: 0 – 100.0%

................................................................................................................................ Maximum: ‘-9999’ – ‘9999’

Units of Operation ............................................................................................................................. programmable

Onboard Power Supply (Externally Accessible) .................................................................................... 5V @ 500Ma

Voltage Regulated Supply Output Range ............................................................... Default: 24VDC +/-5%; 200mA

Customer Specific Option Available (Regulated) .............................................. 5VDC/50mA – 20VDC/200mA

DP10 Mechanical

Display Type .................................................................................................................LED, Red, 4 Digit, ½” Height

Housing Type (with supplied gasket in NEMA 4X panel) ............................................................... 1/8 DIN NEMA 4X

Connector Style .........................................................................................................3.5mm & 5mm European Style

Terminal Block Torque Setting ................................................................................................ 4.4 in. lb. Max or .5Nm

Faceplate Material ............................................................................................... Polycarbonate with Lexan Overlay

Housing Material ........................................................................................................................................Aluminum

Length (Required Panel Depth) .................................................................................................... 4.625”, 117.48mm

Faceplate Width ........................................................................................................................... 4.539”, 115.29mm

Weight DP10 .................................................................................................................... 0.900 lb, 14.4 oz, 408.22g

Environmental

Operating Temperature Range ........................................................................................ -10C to 45C (14F to 113F)

Operating Humidity Range ..................................................................................................... 95%, non-condensin

g

3

Mechanical Installation

5.000"

4.625"

2.289"

1.656"

Tach

Item

ValuPage

Tach

Item

ValuPage

3.622"

HOUSING DEPTH

4.625"

PANEL CUT-OUT

1.770"

DP10

MICRO-DRIVE

SIGNAL CONDITIONER

ENTER

CONTROLS

4.000"

4.000"

.140" x 2

0.885"

GEN

SCL

SPL

PANEL MOUNTING GASKET

(WITH THE ADHESIVE SIDE OF

GASKET FACING THE CUSTOMER

MOUNTING PANEL)

CUSTOMER

MOUNTING PANEL

(HOLE CUT-OUT FOR CONTROL

HOUSING APPROXIMATELY

3.622" WIDE BY 1.770" HIGH)

DP10

CONTROL

SUPPLIED WITH EACH CONTROL:

1) GASKET

2) (2) 6-32 X 3/4 PANHEAD BLACK OXIDE STAINLESS SCREWS

3) (2) #6 NUT WITH LOCKWASHER

Exploded Panel View

Cut-out and Mounting Dimensions

Figure 1

Figure 2

4

Installation & Diagrams

AC INPUT

AC INPUT

P3-1

P3-2

P3-3

P3-4

P3-5

P3-6

P3-7

P3-8

DP10

2 AMP

P3-9

P3-10

P3-11

P3-12

}

85-265VAC

N

L

+5V

COM

IN2

IN1

4-20 OUT (+)

4-20 OUT (-)

V-OUT (+)

V-OUT (-)

SIGNAL IN (+)

SIGNAL IN (-)

+V_USER

-V_USER

+24VDC SUPPLY -24VDC SUPPLY

}

OUTPUT TO USER DEVICE

JP5

JP4

JP3

JP1

P3 Terminal Block Hook-Up Diagram

Figure 3

P3 Terminal Block Descriptions

P3-1 (AC / N) – For single phase AC lines connect the Neutral side of your AC line to this terminal.

For systems with two hot AC lines, connect either of the Hot AC lines to this terminal.

P3-2 (AC / L) – For single phase AC lines connect the Hot side of your AC line to this terminal. For

systems with two hot AC lines, connect either of the Hot AC lines to this terminal.

P3-3 (-SIGNAL IN) – In Scaled Mode, connects to Negative or Common of voltage or current signal

to be attenuated.

P3-4 (+SIGNAL IN) – In Scaled Mode, connects to Positive of voltage or current signal to be attenuated.

P3-5 (-24VDC SUPPLY) – A 24VDC* supply output is provided to the user for sensor or other device.

P3-6 (+24VDC SUPPLY) – A 24VDC* supply output is provided to the user for sensor or other device.

P3-7 (-mA OUTPUT) – The negative connection for either Scaled or Generated mA current output

signal.

P3-8 (+mA OUTPUT) – The Positive connection for either Scaled or Generated mA current output

signal.

P3-9 IN1 - Contact input for user configurable actions such as specified output, and set point lock.

P3-10 IN2 - Contact input for user configurable actions such as specified output, and set point lock.

P3-11 COM

P3-12 +5V

* Note: An optional Voltage Regulator for 5-20V is available for customer use. Current capability depends on voltage required; e.g.

5V/50mA to 20V/200mA; thermally current limited.

5

Basic Operating Information

Tach

Item

ValuPage

Tach

Item

ValuPage

MICRO-DRIVE

SIGNAL CONDITIONER

ENTER

CONTROLS

Display Window

Up & Down Buttons

ENTER (Select) Button

GEN

SCL

SPL

The DP10 Signal Conditioner is a panel-mounted multiple function device used to either attenuate

(scale or reduce), convert, or generate control signals typically used in laboratory/R&D or plant/industrial

applications. The input signals are analog in nature and specifically in the 0-5VDC or 4-20mA range.

The output signal can be either 4-20mA or from 0.1Vdc to the Vset voltage (5-20VDC).

Visual Reference

The Up/Down buttons are used to Scale or Set the output level, in percent (default). The Minimum

Scaling/Generator output is 0.0%. The Maximum Scaling/Generator output is 100.0%. On power up,

the factory default setting is "Last Value".

When lit, the annunciator LED’s across the top of the DP10 indicate the following:

SCL: Scaling mode is active and depending on jumper configuration, either a current or voltage will be

output. In current output mode the Display setting and the input Current or Voltage effects the 4-20mA

output. In Voltage output mode the Display setting, the maximum level set by the potentiometer R9

adjustment and the input Current or Voltage effects the output Voltage level; see appropriate sections

for proper hardware and software setup.

Gen: Generate mode is active and depending on jumper configuration, either a current or voltage will

be output. In Current output mode only the Display setting effects the 4-20mA current output. In Voltage

output mode, the Display setting and the maximum level set by the potentiometer R9 adjustment

determine the output level; see appropriate sections for proper hardware and software setup.

SPL: The DP10 is in Set Point Lock; this effectively disables any changes until IN1/IN2 input levels

change according to the functional configurations. Various modes are available with SPL, please see

appropriate sections for proper setup.

Figure 4

6

How to Change a Parameter's Value (The Short Story)

1. Hold down the Enter button until Parameter-Selection Mode is entered (Parameter 'P 0'

Displayed)

2. Using the Up and Down buttons, select the desired parameter number to view or edit

3. Press the Enter button to change the value of the parameter

4. Using the Up and Down buttons, change the parameter's value as desired

5. Press the Enter button to permanently save the changes (Return to Parameter-Selection Mode)

6. Select parameter zero and press the Enter button to return to Running Mode

Operating the User Interface (The Long Story)

The LED display has three basic operating modes: Running Mode, Parameter-Selection Mode,

and Value Mode. Each of the three modes have specific visual indicators that allow the user to

immediately determine the current state or mode of the user interface. Parameter-Selection Mode

and Value Mode can only be entered if the Program Enable jumper is in the 'P/EN' position.

Running Mode is the default display of the unit when power is applied. The display shows the

target value in the appropriate user-defined format. The Up and Down buttons increase or decrease

the displayed target value until either the display minimum or display maximum limit is reached.

Parameter-Selection Mode can be entered by simply pressing and holding the Enter button down

for three seconds. Once in Parameter-Selection Mode, the far left of the display will be a ‘P’. The

right side of the display will indicate the currently selected parameter number for editing purposes.

Pressing the Up or Down button will increase or decrease the selected parameter number on the

display. Although the parameter numbers are in numerical order, some numbers are skipped.

These skipped numbers represent reserved parameters that are not yet implemented and are

not displayed. Once the desired parameter number is displayed, a press of the Enter button will

change the display to the Value Mode.

Value Mode is used to modify the value of the selected parameter. When in Value Mode, the

two dots which form the colon between digits two and three, will alternately flash (one, then the

other.) Pressing the Up or Down button increases or decreases the selected parameter’s value.

See the Software Parameters for a list of allowable values and ranges. Value changes take effect

immediately. Once the desired value is showing in the display window, pressing the Enter button

again will return to Parameter-Selection Mode. The new value is not saved in permanent memory

until the Enter button is pressed. Removing power from the unit while in Value Mode may result

in the specified new value being lost.

The front panel Annunciators will be perform as follows:

Parameter 10 = 1; ‘Gen’ annunciator lit

Parameter 10 = 2; ‘SCL’ annunciator lit

Parameter 30 = 7, IN1 = Low; ‘SCL’ annunciator lit

Parameter 35 = 7, IN2 = High; ‘SCL’ annunciator lit

7

Device Configuration

Configuration is accomplished via jumper settings and (for Voltage Outputs only) a trimpot adjustment.

Location is as follows:

P3

P6

Program Enable

(JP5)

I_IN V_IN

/4-20mA

V

OUT

Jumper 4 (JP4)

COM P/EN

Trimpot

(R9)

/4-20mA

V

OUT

Jumper 3 (JP3)

Figure 5

JP1

V_OUT

I_OUT

V_OUT

I_OUT

P5

With the display set to 100.0 and no user device connected to ‘V-OUT’, P3-5 (-) and P3-6(+), adjust

R9 for the desired maximum V-OUT. Finally, connect the user device and carefully re-adjust R9 to

trim the output to desired maximum V-OUT. This will prevent the output from exceeding the limits of

the user device if done properly. The user should evaluate what their system will be doing during this

adjustment to prevent any harmful results.

Mode of Operation

There are three Modes of Operation for the DP10, established by the JP1, JP3, and JP4 jumper settings:

1. JP1 - If the DP10 is receiving a signal to be Scaled or Converted, this setting defines the

input signal type (0-5Vdc or 4-20mA Current) (Optional high input voltage or PWM).

2. JP3 - Determines the Output Signal type - Vdc or mA Current. MUST be same type as JP4

3. JP4 - Determines the Output Signal type - Vdc or mA Current. MUST be same type as JP3

The four jumper settings allow the DP10 to operate as:

• 4-20mA Input/Scaled 4-20mA or 0.1-20Vdc Output

• 0-5Vdc Input/Scaled 4-20mA or 0.1-20Vdc Output

• No Input/Generator 4-20mA or 0.1-20Vdc Output

Note: Both JP3 and JP4 must be set correctly.

DP10Current/VoltageI/OJumpers&Parameter10Settings

Input Output Parameter10 JP1 JP3 JP4 JP5

Scale/Generate V/IIN V/IOutReference V/IOUTPowerSupply ApplicationConfiguration

PintoPinJumperConfiguration

Current Voltage Scale Ii Vo Vo

Current Current Scale Ii Io Io

Voltage Voltage Scale Vi Vo Vo

Voltage Current Scale Vi Io Io

Generate Voltage Gen N/A Vo Vo

Generate Current Gen N/A Io Io

Scale=2 AllowChange=P/ENposition

Gen=1 InhibitChange='COM'position

8

Software Parameters

Value Range

Factory

User

Parameter

0 Selecting this item exits to Running Mode n/a n/a

1 Model Number 90 – DP10 Unit 90

2 Software Build 1 – 9999 n/a

3 Hardware Version 1 – 9999 n/a

4 Serial Number – Major (reserved) n/a n/a

5 Serial Number – Minor (reserved) n/a n/a

10 Generate / Scale 1 – Generate

11 Display Intensity 0 – 31 (Dim – Bright) 26

12 Display Zero Blanking 1 – ___X Show at least 1 Digit

13 Decimal Point Position 0 – DP Disabled (XXXX)

15 Keypad Mode 1 – Linear, Constant Rate

16 Keypad Scroll Delay 0 – 30 (Fast – Slow) 10

18 Power-up Mode 1 – Default to Zero Display

19 Power-up Value 0 – 9999 (Display Units) 0

20 Display Value at Minimum Output -9999 – 9999 (Display Units) 0

21 Display Value at Maximum Output -9999 – 9999 (Display Units) 1000

25 Output % - Minimum 0 – 1000 (1/10th Percent Units) 0

26 Output % - Maximum 0 – 1000 (1/10th Percent Units) 1000

30 IN1 Input Configuration 1 – Output 0% When IN1 Low

31 IN1 Setpoint -9999 – 9999 (Display Units) 0

Input #2 (IN2) Setup

35 IN2 Input Configuration 1 – Output 0% When IN2 Low

36 IN2 Setpoint -9999 – 9999 (Display Units) 0

95 Restore Settings to Factory Default 0 – Do Nothing & Exit

98 Save to User Default Area 0 – Do Nothing & Exit

99 Restore from User Default Area 0 – Do Nothing & Exit

Read-Only Parameters

General Setup

Display & Output Setup

Input #1 (IN1) Setup

Parameter Memory Commands

Description

2 - Scale

2 – __XX Show at least 2 Digits

3 – _XXX Show at least 3 Digits

4 – XXXX Show all 4 Digits

1 – X.XXX

2 – XX.XX

3 – XXX.X

4 – XXXX.

2 – Non-linear, Accelerating Rate

2 – Default to Power-up Value

3 – Default to Previous Running Val.

2 – Output 0% When IN1 High

3 – Output Setpoint When IN1 Low

4 – Output Setpoint When IN1 High

5 – Output 100% When IN1 Low

6 – Output 100% When IN1 High

7 – Lock Set Point when IN1 is Low

(See: Parameter Description for details)

2 – Output 0% When IN2 High

3 – Output Setpoint When IN2 Low

4 – Output Setpoint When IN2 High

5 – Output 100% When IN2 Low

6 – Output 100% When IN2 High

7 – Lock Set Point when IN2 is High

(See: Parameter Description for details)

5 – Restore Factory Defaults

1 – Save Setting

1 – Restore Settings

(units)

Default

1

2

3

2

3

1

1

0

0

0

Settings

9

Parameter Descriptions

Parameter 0 – Exit to Running Mode

When parameter 0 is selected in Parameter-Selection Mode, the unit will return to Running

Mode and display the running value. This should be selected once the changes to the

parameters are completed.

Parameter 1 – Model Number (Read Only)

This is a number which represents the base model number for the product. The model

code for the DP10 is 90.

Parameter 2 – Software Build (Read Only)

The software build is a code which identifies the software version of the unit.

Parameter 3 – Hardware Version (Read Only)

The hardware version is a code which identifies which hardware was used to build the unit.

Parameter 4 & 5 – Serial Number, Major & Minor (Read Only)

These parameters are reserved for future use as an electronic serial number and are unique

to each manufactured unit.

Parameter 10 – Generate / Scale

Mode 1: Generate

Generate Output Signal

Mode 2: Scale

Scale Input Signal

Parameter 11 – Display Intensity

This parameter adjusts the intensity of the LED display digits in the front panel of the unit.

The values of 0 – 31 correspond to a gradual change from very dim to very bright.

Parameter 12 – Display Zero Blanking

This selects the number of display digits that are required to be displayed regardless of

the display value. For example, with a Display Zero Blanking setting of 3 and a displayed

value of 6, the display would show "_006".

Mode 1: ___X Always show at least 1 digit

Mode 2: __XX Always show at least 2 digits

Mode 3: _XXX Always show at least 3 digits

Mode 4: XXXX Always show all 4 digits

Parameter 13 – Decimal Point (DP) Position

This selects the format of the display with respect to the decimal point’s position. This

parameter does not affect the value entry for other parameters. For example, if the user

desires to display numbers such as 12.34 or 1.05, then parameter 13 should be set to 2.

Mode 0: Fixed XXXX (DP disabled)

Mode 1: Fixed X.XXX

Mode 2: Fixed XX.XX

Mode 3: Fixed XXX.X

Mode 4: Fixed XXXX.

Parameter 15 – Keypad Mode

This parameter selects the operating mode of the front-panel push buttons. In some

applications, increasing or decreasing the scroll rate provides the user more controllability

when entering settings. Parameters 14 and 15 affect only the Up and Down buttons when

the user interface is in Running Mode.

Mode 1: Linear, Constant Rate

In linear mode, pressing and holding the Up or Down buttons will cause the display to

continuously change value in the requested direction until either the Display Minimum

or Display Maximum is reached. The displayed value will scroll at a constant rate

which is specified using parameter 16.

10

Mode 2: Non-linear, Accelerating Rate

In non-linear mode, pressing and holding the Up or Down buttons will cause the

display to continuously change value in the requested direction until either the Display

Minimum or Display Maximum is reached. The displayed value will initially scroll at a

slow rate and increase in speed until the maximum scroll rate is achieved. The initial

scroll rate is specified using parameter 16.

Parameter 16 – Keypad Scroll Mode

This parameter sets the scroll speed for the front-panel push buttons. The function of this

parameter varies slightly depending on the Keypad Mode. See parameter 15 for more details.

Parameter 18 – Power-Up Mode

This parameter defines the mode which determines the default Running Value when power

is initially applied to the DP10.

Mode 1: Default to Zero

When in this mode, the unit will default to zero (display units).

Mode 2: Default to Power-Up Value

When in this mode, the unit will default to the Power-up Value, parameter 19.

Mode 3: Default to Previously Running Value

When in this mode, the unit will default to the previous running value before power

was removed. A previous running value must have been active for at least 3 seconds

to be recalled after power has been disconnected and reapplied.

Parameter 19 – Power-Up Value

When Power-up Mode is set to 2, this parameter will designate the default display value

at power-up in display units.

Parameter 20 – Display Value at Minimum Output

This parameter defines the lower end of the display range. This is the value which limits

how low the user is able to scroll the displayed value in Running Mode. This parameter

is set without consideration for the decimal point's position. For example, setting this

parameter to 125 would set the lower display limit at 12.5, 0.125, or 125 according to the

other configuration parameters.

Parameter 21 – Display Value at Maximum Output

This parameter defines the upper end of the display range. This is the value which limits

how high the user is able to scroll the displayed value in Running Mode. This parameter

is set without consideration for the decimal point's position. For example, setting this

parameter to 1000 would set the upper display limit at 100.0, 1.000, or 1000 according to

the other configuration parameters.

Parameter 25 – Minimum Output % (in 1/10 percent units)

This parameter sets the output percentage which corresponds to the minimum display

value, parameter 20. This parameter has a range of 0 to 1000 which represents 0.0 to +100.0

percent of output. When the user is adjusting the display value towards the programmed

minimum display, the output will linearly approach the value of this parameter. For example,

setting this parameter to 25 will configure the DP10 to output 2.5% when the user adjusts

the display value to equal the display minimum, parameter 20. See parameters 20 - 22

and the application examples for additional information.

Parameter 26 – Maximum Output % (in 1/10 percent units)

This parameter sets the output percentage which corresponds to the maximum display

value, parameter 21. This parameter has a range of 0 to 1000 which represents 0.0 to +100.0

percent of output. When the user is adjusting the display value towards the programmed

maximum display, the output will linearly approach the value of this parameter. For example,

setting this parameter to 850 will configure the DP10 to output 85.0% when the user adjusts

the display value to equal the display maximum, parameter 21. See parameters 20 - 21and

the application examples for additional information.

11

Parameter 30 – Input 1 (IN1) Conguration

This parameter determines the operating mode of input 1 (IN1).

Mode 1: Output 0% When IN1 Low

When the IN1 input is at an electrically low state or wired to the unit's common, the

DP10 will force its output to 0%. Once the IN1 input returns to an electrically high

(+5V) state or allowed to float disconnected, the output will once again correspond

to the display value.

Mode 2: Output 0% When IN1 High

When the IN1 input is at an electrically high (+5V) state or allowed to float disconnected,

the DP10 will force its output to 0%. Once the IN1 input returns to an electrically low

state or wired to the unit's common, the output will once again correspond to the

display value.

Mode 3: Output Setpoint When IN1 Low

When the IN1 input is at an electrically low state or wired to the unit's common, the

DP10 will force its output to a percentage which corresponds to the programmed

jog setpoint, parameter 31. Once the IN1 input returns to an electrically high (+5V)

state or allowed to float disconnected, the output will once again correspond to the

display value.

Mode 4: Output Setpoint When IN1 High

When the IN1 input is at an electrically high (+5V) state or allowed to float disconnected,

the DP10 will force its output to a percentage which corresponds to the programmed

jog setpoint, parameter 31. Once the IN1 input returns to an electrically low state or

wired to the unit's common, the output will once again correspond to the display value.

Mode 5: Output 100% When IN1 Low

When the IN1 input is at an electrically low state or wired to the unit's common, the

DP10 will force its output to 100%. Once the IN1 input returns to an electrically high

(+5V) state or allowed to float disconnected, the output will once again correspond

to the display value.

Mode 6: Output 100% When IN1 High

When the IN1 input is at an electrically high (+5V) state or allowed to float disconnected,

the DP10 will force its output to 100%. Once the IN1 input returns to an electrically

low state or wired to the unit's common, the output will once again correspond to

the display value.

Mode 7: Lock Set Point when IN1 is Low

“LOC” is displayed when one of the front panel buttons is pressed with IN1 in an

electrically Low State. Program by bringing IN1 terminal P3-9 to electrically High state

or allow IN1 to float when disconnected from Common terminal P3-11. Enter Program

Mode, Select Parameter 30, Press Enter, select value item 7, Press Enter again.

Note: (Select a value 1-6 to Exit the LOCK Set Point than press enter) Select Parameter

0 and press enter to Exit Program Mode. Activate for the new changes to take effect

by cycling AC power Off/On.

Parameter 31 – Input 1 (IN1) Jog Setpoint

When the S1 configuration, parameter 30, is set to one of the setpoint (jog) modes(modes

3 or 4), this parameter defines the jog setpoint in display units. This parameter is always

set in display units.

Parameter 35 – Input 2 (IN2) Conguration

This parameter determines the operating mode of input 2 (IN2).

Mode 1: Output 0% When IN2 Low

When the IN2 input is at an electrically low state or wired to the unit's common, the

DP10 will force its output to 0%. Once the IN2 input returns to an electrically high

(+5V) state or allowed to float disconnected, the output will once again correspond

to the display value.

12

Mode 2: Output 0% When IN2 High

When the IN2 input is at an electrically high (+5V) state or allowed to float disconnected,

the DP10 will force its output to 0%. Once the IN2 input returns to an electrically low

state or wired to the unit's common, the output will once again correspond to the

display value.

Mode 3: Ouput Setpoint When IN2 Low

When the IN2 input is at an electrically low state or wired to the unit's common, the

DP10 will force its output to a percentage which corresponds to the programmed

jog setpoint, parameter 36. Once the IN2 input returns to an electrically high (+5V)

state or allowed to float disconnected, the output will once again correspond to the

display value.

Mode 4: Output Setpoint When IN2 High

When the IN2 input is at an electrically high (+5V) state or allowed to float disconnected,

the DP10 will force its output to a percentage which corresponds to the programmed

jog setpoint, parameter 36. Once the IN2 input returns to an electrically low state or

wired to the unit's common, the output will once again correspond to the display value.

Mode 5: Output 100% When IN2 Low

When the IN2 input is at an electrically low state or wired to the unit's common, the

DP10 will force its output to 100%. Once the IN2 input returns to an electrically high

(+5V) state or allowed to float disconnected, the output will once again correspond

to the display value.

Mode 6: Output 100% When IN2 High

When the IN2 input is at an electrically high (+5V) state or allowed to float disconnected,

the DP10 will force its output to 100%. Once the IN2 input returns to an electrically

low state or wired to the unit's common, the output will once again correspond to

the display value.

Mode 7: Lock Set Point when IN2 is High

“LOC” is displayed when one of the front panel buttons is pressed with IN2 in an

electrically High State. Program by bringing IN2 terminal P3-10 to electrically Low

state or wire to unit’s Common terminal P3-11. Enter Program Mode, Select Parameter

35, Press Enter, select value item 7, Press Enter again.

Note: (Select a value 1-6 to Exit the LOCK Set Point than press enter) Select Parameter

0 and press enter to Exit Program Mode. Activate for the new changes to take effect

by cycling AC power Off/On.

Parameter 36 – Input 2 (IN2) Jog Setpoint

When the IN2 configuration, parameter 35, is set to one of the setpoint (jog) modes(modes

3 or 4), this parameter defines the jog setpoint in display units. This parameter is always

set in display units.

Parameter 95 – Factory Default Command

When set to a value of 5, the unit will be reset to factory default settings. This can also be

achieved by applying power to the unit with both the Enter and Down buttons depressed.

The programming jumper must be in the "On" position for this method to function.

Parameter 98 – Save to User Default Area Command

When set to a value of 1, the unit will store all adjustable parameters to the user default

area. The user default area is intended to be a location where an OEM or integrator can

store settings specific to their application. Using this, an OEM can easily refresh their

custom settings in the field if an end-user accidentally reconfigures the unit unsuccessfully.

Another common use for this area is testing and initial setup. The user can store knowngood settings here and easily experiment without the fear of losing the optimal configuration.

Parameter 99 – Restore from User Default Area Command

When set to a value of 1, the unit will restore all adjustable parameters from the user default

area. See parameter 98 for additional information.

13

Troubleshooting

Problem Possible Case Solution

Display is blank Power not applied

Defective unit

Using a volt meter, verify that a voltage between 85 and 265VAC is measured between

the L and N terminal block positions.

Contact technical support for additional help and instructions.

Display is dim Display intensity

parameter is too low

Editing and increasing the display intensity parameter should cause the display digits

to become brighter.

“-S1-” or “-S2-”

displayed

Switch S1 or S2 is

active

Remove S1 or S2 input. Refer to Parameter 30 and 35 for information on settings.

“LOC” displayed Parameter 30 or 35 is

set to 7

Change input state of S1 or S2; or reprogram Parameter 30 or 35.

Does not provide

proper output.

Jumpers in wrong

position

Verify jumpers are properly set for desired operation (see table page 7)

No output if either JP3 or JP4 in wrong location.

JP1 in wrong location:

For Scaled Mode, neither current nor voltage output will be properly scaled with the

intended input.

For Generate Mode, it will have no effect. Check all connects to make sure they are

secure and not reversed.

For Voltage Output Mode, check that R9 was properly set for the Maximum output

desired; therefore it was adjusted at 100% of display with the user hardware

connected correctly to the V-out terminals.

If Parameter 10 Value = 1, then the DP10 is in Generate Mode and there will be no

output change for a change in Signal Input only for Keypad entry.

If Parameter 10 Value = 2, then the DP10 is in Scale Mode and the output will change

for both a change in Signal Input and Keypad entry.

If JP1, JP3 or JP4 are missing or on one pin, then it will have either minimal value

output or none at all depending on output type configuration.

Please recheck all settings and jumper configurations.

Technical Support Options

• Visit the Dart Controls Web Site at: www.dartcontrols.com

• Email technical support at: sales@dartcontrols.com

• Telephone technical support at 317-873-5211

What's Special About www.dartcontrols.com?

• Changes to printed material and product offerings first appear online

• Product manuals and other literature are easily accessible

• All information can be easily displayed or printed as needed

14

REPAIR PROCEDURE

In the event that a Product manufactured by Dart Controls Incorporated (DCI) is in need of

repair service, it should be shipped, freight paid, to: Dart Controls, Inc., 5000 W. 106th Street,

Zionsville, IN. 46077, ATTN: Repair Department. Please include Name, Shipping Address (no

P.O. Box), Phone Number and if possible, e-mail address.

Those orders received from anyone without an existing account with DCI must specify if they

will be paying COD or Credit Card (Master Card/Visa/American Express). This information is

required before work will begin. If you have an account with Dart your order will be processed

according to the terms listed on your account. Products with Serial Number date codes over

5 years old will automatically be deemed Beyond Economical Repair (BER). A new, equivalent

device will be offered at a substantial discount.

Completed repairs are returned with a Repair Report that states the problem with the control

and the possible cause. Repair orders are returned via UPS Ground unless other arrangements

are made. If you have further questions regarding repair procedures, contact Dart Controls,

Inc. at 317-873-5211.

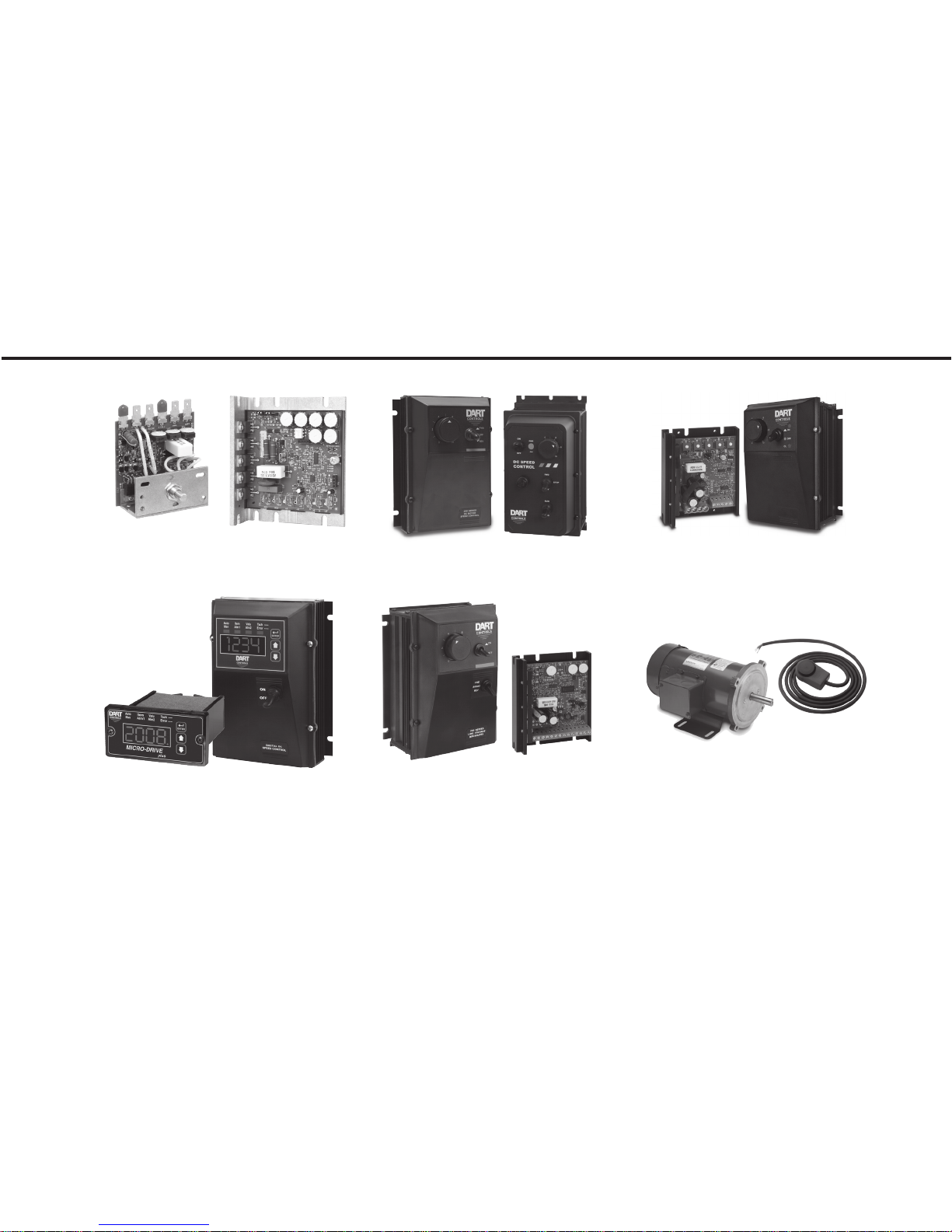

YOUR MOTOR SPEED CONTROL SOLUTION PROVIDER

OEM Chassis SCR Drives

Dual Input voltage, adjustable HP

range, isolated signal follower and

Closed loop accuracy, 4-20mA and

Dart Controls, Inc. is a

designer, manufacturer, and

marketer of analog and

digital electronic variable

speed drives, controls, and

accessories for AC, DC,

and DC brushless motor

applications.

reversing options

Digital SCR Drives

serial communications, integral

programmable display

Shown above is just a

sampling of the expanded

line of Dart controls that

feature the latest in electronic

technology and engineering.

Products are manufactured

in the U.S.A. at our Zionsville

(Indianapolis, Indiana)

NEMA 4/4X SCR Drives

Dual Input voltage, adjustable HP

range, isolated signal follower and

reversing options

Brushless DC Drives

Closed loop accuracy, line and low

voltage versions through 1 HP

production and headquarters

facility - with over 2,000,000

variable speed units in the

field.

In addition to the standard

off-the-shelf products, you

can select from a wide variety

of options to customize

controls for your specific

application. For further

information and application

assistance, contact your local

Dart sales representative,

stocking distributor, or Dart

Controls, Inc.

Low Voltage/Battery

PWM Drives

Chassis and NEMA 4X versions,

speed pot and signal follower

operation

Digital Accessory &

Resale Items

Motors to 700 HP, VFD's to 200

HP, NEMA rated encoder, digital

programmable potentiometers and

tachometers

Dart Controls, Inc.

Manufacturer of high quality

DC and AC motor speed

controls and accessories

since 1963.

P.O. Box 10

5000 W. 106th Street

Zionsville, Indiana 46077

Phone: (317) 873-5211

Fax: (317) 873-1105

www.dartcontrols.com

ISO9001 REGISTERED

MADE IN USA

Loading...

Loading...